Making better products...to make other products better

NORTON COMPANY, Worcester 6, Mass., U.S.A.

Behr-Manning Corp., Troy, New York (Division of Norton Company)

Norton Pike Company: Littleton, New Hampshire (Division of Norton Company)

Alundum and Crystolon Abrasive Plants: Chippawa, Ontario, Canada and Cap-de-la-Madeleine, Quebec

Bauxite Plant: Bauxite, Arkansas

DISTRICT OFFICES AND WAREHOUSES AT:

Chicago 32: 4737 So. Christiana Avenue Cleveland 3: 1306 East 55th Street Detroit 8: 58

iana Avenue Philadelphia 44: 4732 Stenton Avenue a Street Pittsburgh 23: Butler Road Detroit 8: 5805 Lincoln Avenue

DISTRICT SALES OFFICES AT:

West Hartford 7: 1007 Farmington Ave. Los Angeles 11: 4890 So. Alameda St. New York Area: Green and North Sts., Teterboro, N. J.

EXPORT:

NORTON BEHR-MANNING OVERSEAS INC.

CABLE ADDRESS: NORBEMO WORCESTER 6, MASS., U.S.A.

Norton Company of Canada, Ltd. Norton Grinding Wheel Co. Ltd. Compagnie des Meules Norton Deutsche Norton Gesellschaft m.b.h. Mole Norton S. p. A. Australian Abrasives Pty. Ltd. Norton Abrasives S.A. (Pty.) Ltd. Norton-Behr-Manning, S.A. de C.V. Behr-Manning (Canada) Ltd. Behr-Manning De France Behr-Manning (Australia) Pty. Ltd. Behr-Manning Limited

Hamilton, Ontario, Canada Welwyn Garden City, England La Courneuve, France Wesseling bez Cologne, Germany Corsico (Milano), Italy Auburn, New South Wales, Australia Isando, Transvaal, Union of South Africa Mexico, D.F. Brantford, Ontario Conflans-Ste.-Honorine, France Lidcombe, N.S.W., Australia Belfast, Northern Ireland

*Trade Mark Reg. U. S. Pat. Off.

Form 835-21PBXM-10-54

Printed in United States of America

NORTON ABRASIVES

Introduction

Successful sharpening of cutting tools depends mostly upon the use of the correct grinding wheel, tool set-up and method of grinding for each kind of tool. This handbook has been prepared to guide the tool room operator or the apprentice in the proper selection and use of grinding wheels, and to familiarize him with the principles and methods of grinding various types of tools and cutters.

For a complete treatise on wheel markings, selection and use of grinding wheels in general, the reader is referred to a separate handbook, "Abrasives and Grinding Wheels," Form 1508, which may be obtained by writing to the Norton Company.

Acknowledgment is made to the several tool and grinding machine manufacturers who generously assisted in the preparation of this book with photographs, drawings or tables.

•

ALUNDUM and CRYSTOLON are registered trade marks of Norton Company for aluminum oxide and silicon carbide respectively.

Table of Contents

Chapter

тт

| I | age |

|---|---|

| Wheels for Tool Room Grinding | |

| The Abrasives | 6 |

| The Bonds | 7 |

| Grinding Wheel Specifications | 10 |

| Grain Size | 10 |

| Grade | 11 |

| Structure | 11 |

| Norton Method of Marking Grinding Wheels | 12 |

| Factors Affecting the Selection of a Grinding | |

| Wheel | 15 |

| Standard Types of Grinding Wheels | 17 |

| Standard Shapes of Grinding Wheel Faces | 20 |

| Grinding Wheel Speeds | 21 |

| Truing and Dressing the Grinding Wheel | 21 |

| Use of the Diamond for Truing and Dressing | 23 |

| Care and Safe Use of Grinding Wheels | 25 |

| Sharpening Milling Cutters and Reamer | s |

| Grinding Wheels Recommended | 31 |

| Direction of Wheel Rotation | 32 |

| Clearance | 33 |

| Width of Land | 34 |

| Producing the Clearance Angle | 35 |

| Setting the Tooth Rest, Using a Straight Wheel | 36 |

| Setting the Tooth Rest, Using a Cup Wheel | 37 |

| Typical Set-ups for Sharpening Cutters | 37 |

| Plain Milling Cutters | 39 |

| Staggered Tooth Milling Cutters | 41 |

| Side Milling Cutters | 42 |

| Face Milling Cutters | 42 |

| Angular Cutters | 45 |

| Chapter | Page | |

|---|---|---|

| End Mills | 46 | |

| Formed Cutters | 47 | |

| Fellows Gear Shaper Cutters | 49 | |

| Hobs | 49 | |

| Metal Cutting Saws | 51 | |

| Chucking Reamers | 53 | |

| Hand Reamers | 55 | |

| Taper Reamers | 55 | |

| III. | Sharpening Miscellaneous Tools | |

| Drills | 57 | |

| Taps | 62 | |

| Broaches | 64 | |

| Thread Chasers | 67 | |

| Milled Chasers | 68 | |

| Tapped Chasers | 69 | |

| Collapsing Tap Chasers | 73 | |

| Tangent Chasers | 73 | |

| Circular Chasers | 82 | |

| Dies | 85 | |

| Surface Grinding | 86 | |

| Cylindrical Grinding | 86 | |

| Internal Grinding | 87 | |

| Offhand Grinding | 87 | |

| 137 | ||

| 1. | Sharpening Lathe and Planer Tools | |

| Offhand Grinding | 91 | |

| Machine Grinding | 92 | |

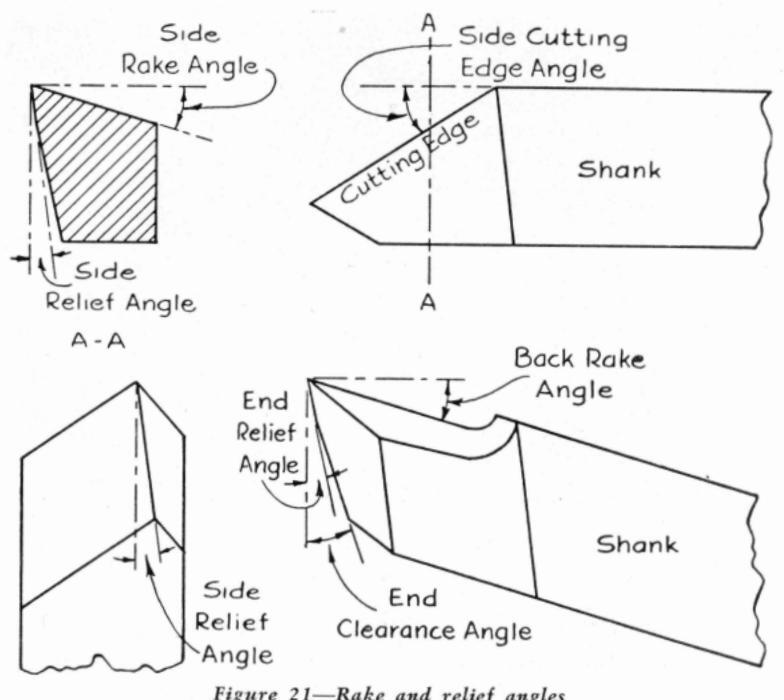

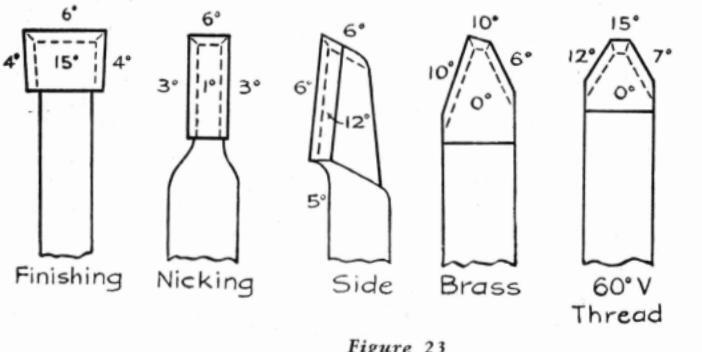

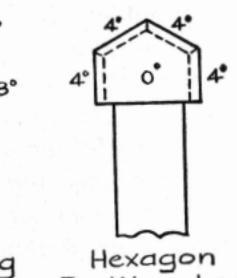

| Tool Angles | 93 | |

| Tool Shapes | 93 | |

| High Speed Steel Tools | 100 | |

| Cast Alloy Tools | 102 | |

| Cemented Carbide Tools | 104 | |

| [4] |

NORTON ABRASIVES

| ahter | P | age | |

|---|---|---|---|

| V. | Other Types of Tool Room Grinding | ||

| Cylindrical Grinding 1 | .08 | ||

| Surface Grinding | .11 | ||

| Internal Grinding | 18 | ||

| Cutting-Off 1 | 19 | ||

| VI. | Miscellaneous Abrasive Products | ||

| for the Tool Room | |||

| Lightning Metalite Cloth | 123 | ||

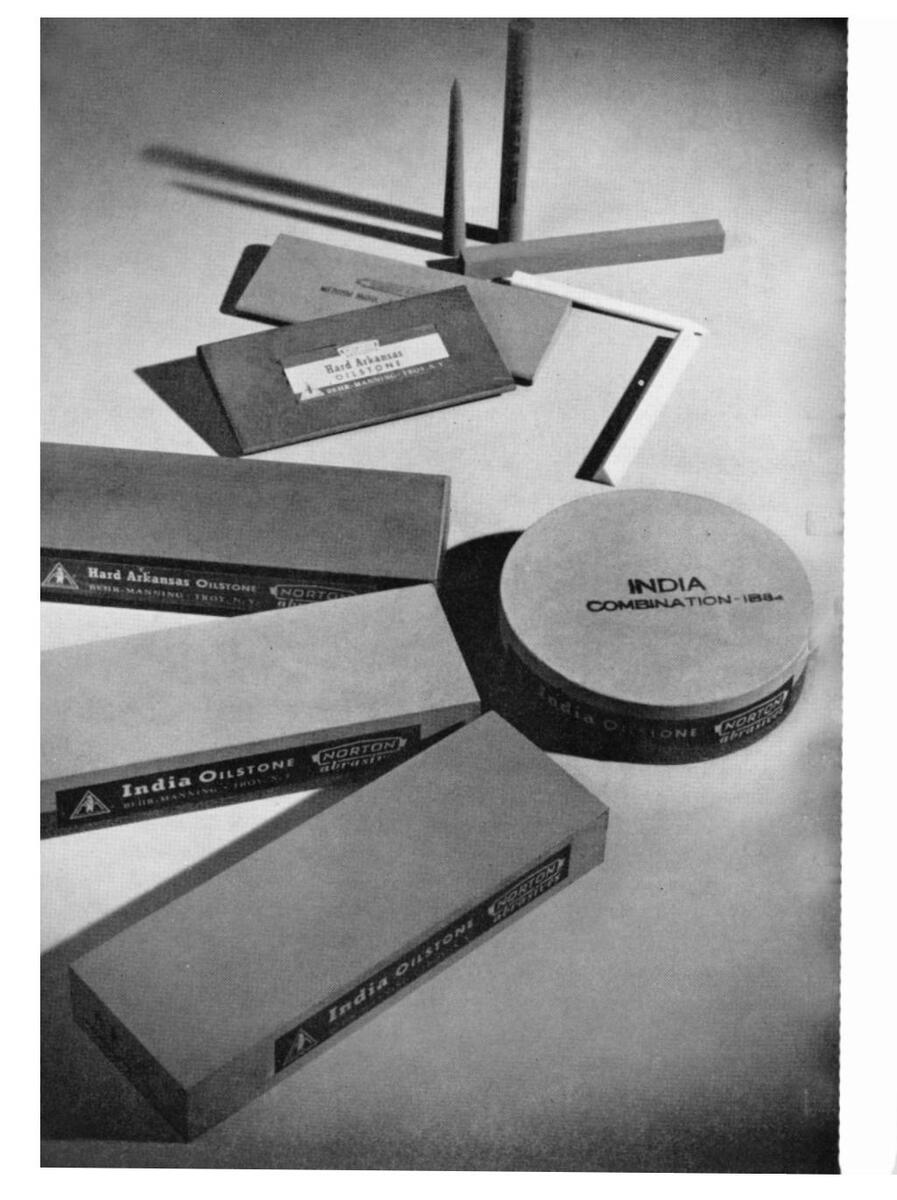

| India Oilstones | 124 | ||

| VII. | Norton Grinding Machines | ||

| for the Tool Room | |||

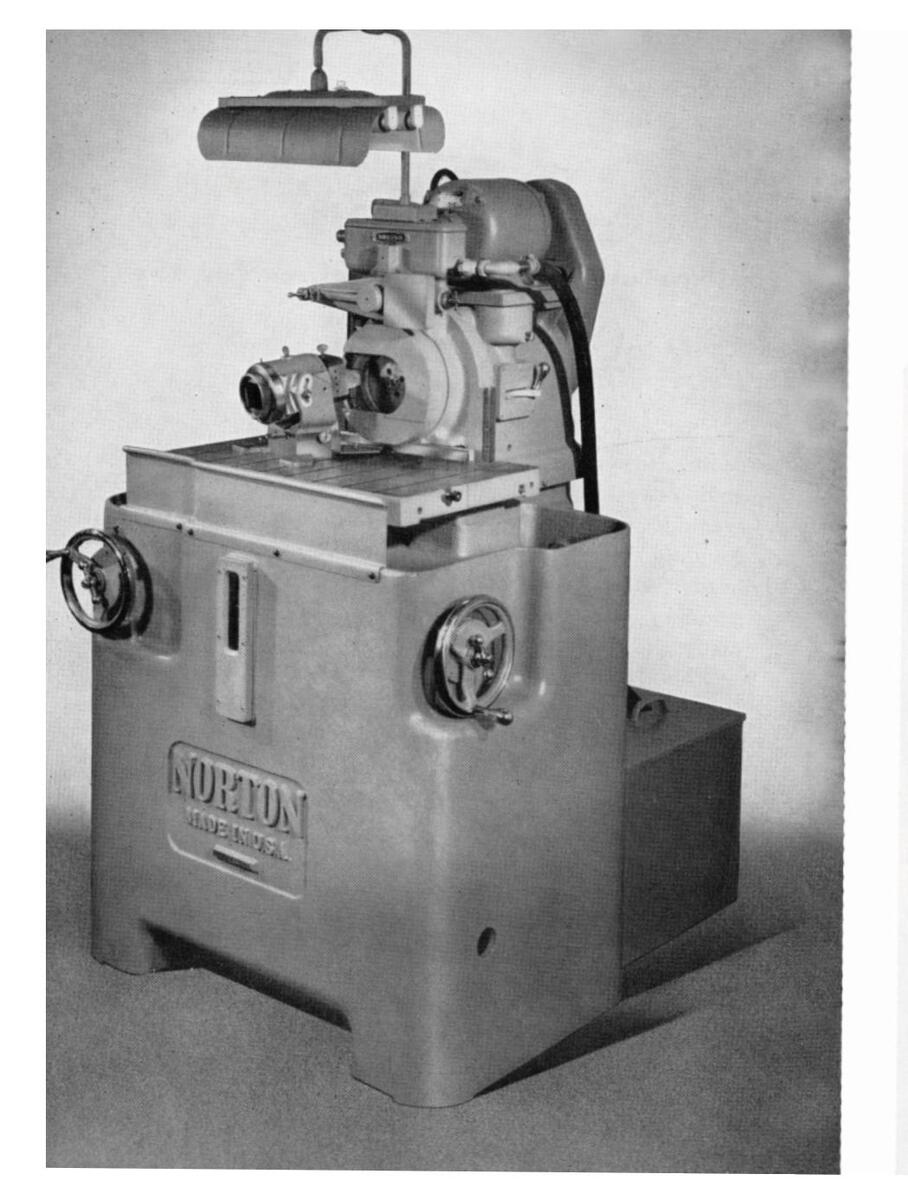

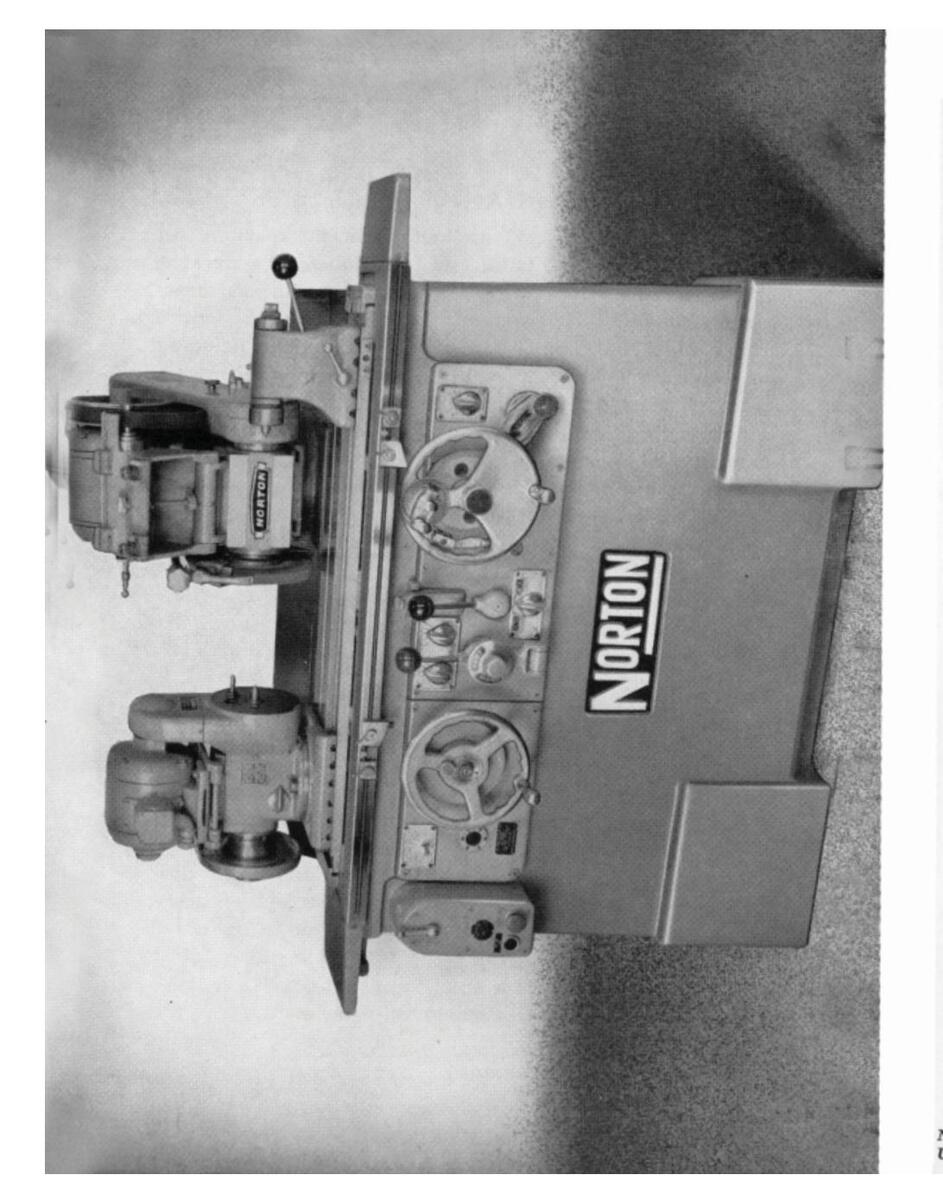

| Universal Tool and Cutter Grinders | 127 | ||

| Bura-Way Grinder | 129 | ||

| 10", 12", 14" and 16" Universal Grinders | 131 | ||

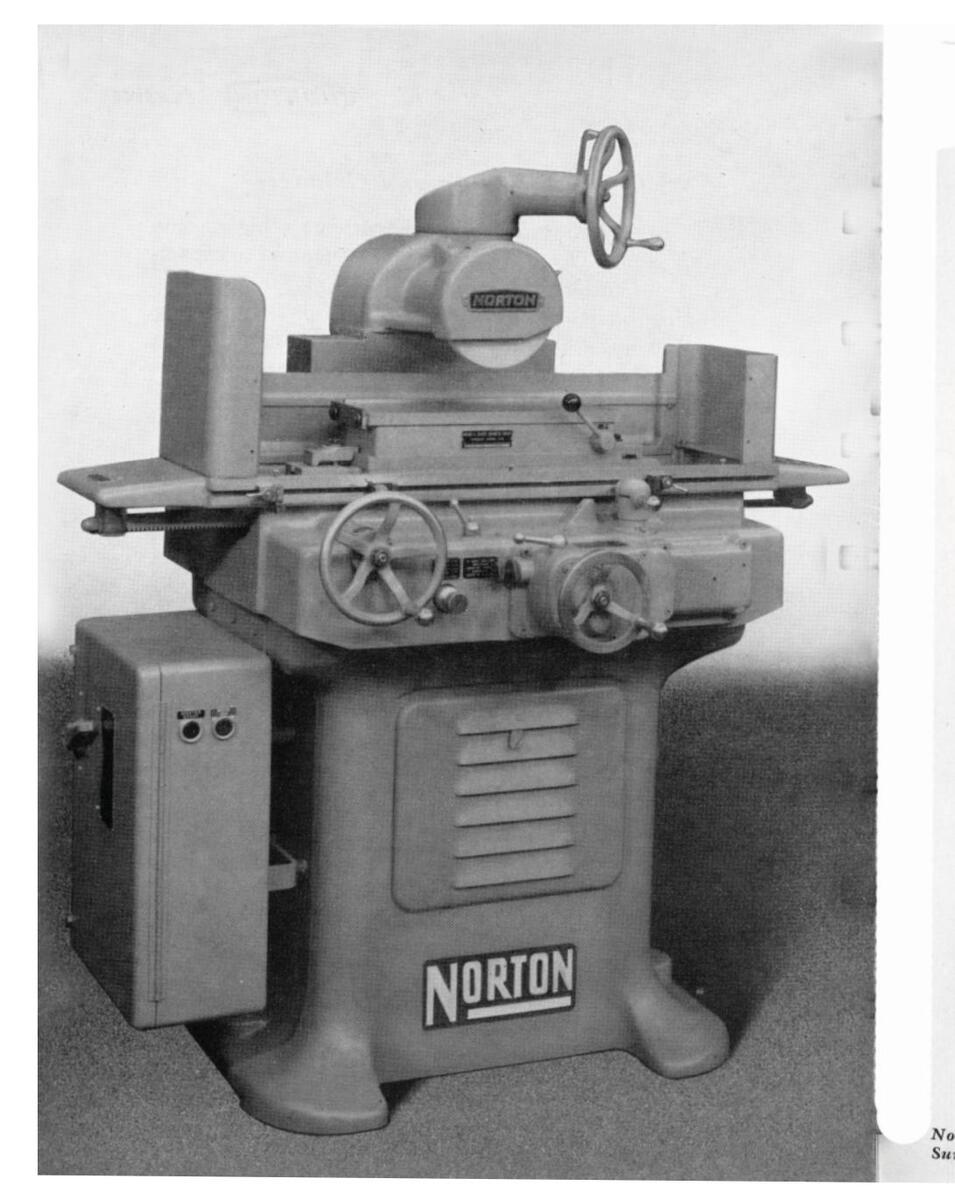

| 6" x 18" and 8" x 24" Hydraulic Surface | |||

| Grinders | 133 | ||

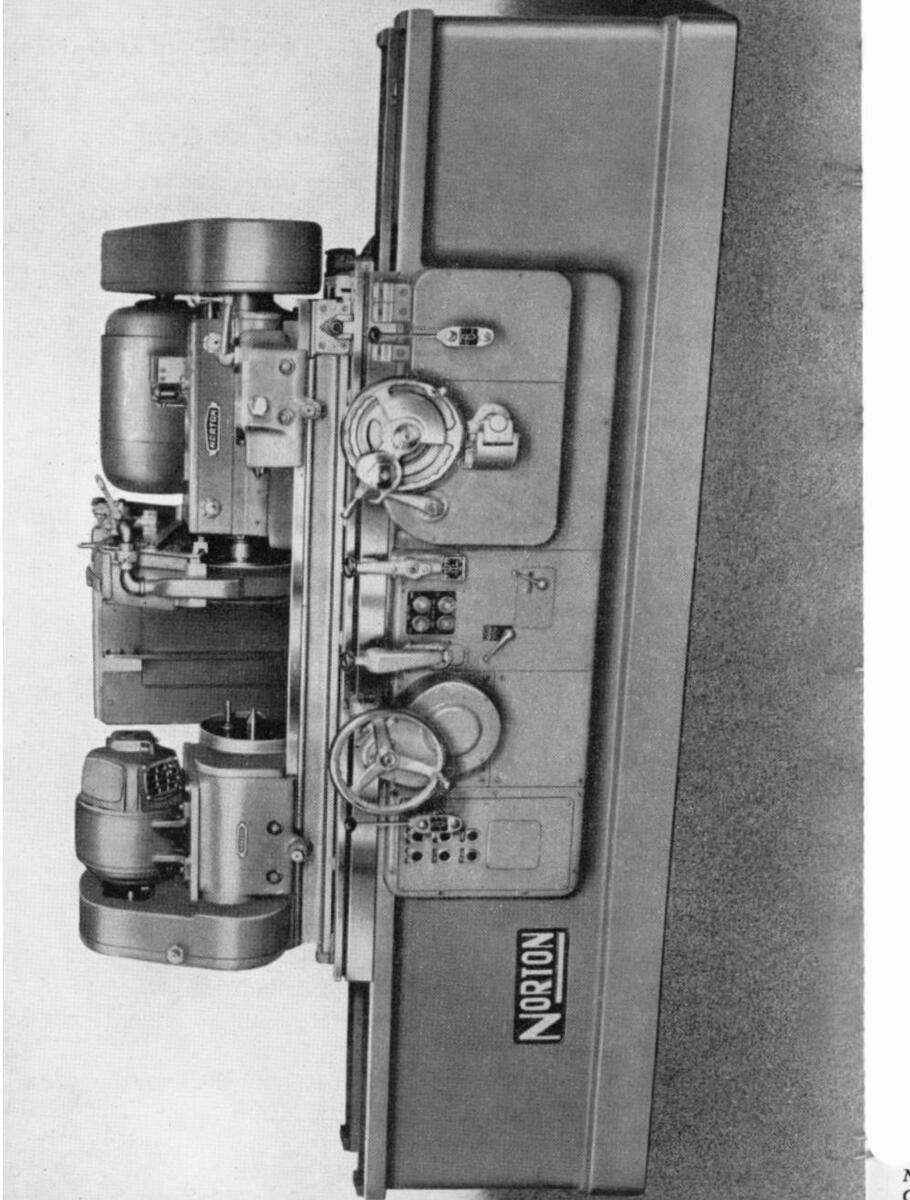

| 6" and 10" Type CTU Plain Cylindrical | |||

| Grinders | 133 | ||

| III. | Tables of Useful Information | ||

| Summary of Grinding Wheel Recommendations | 136 | ||

| Clearance Tables | 141 | ||

| Recommended Thread Chaser Grinds | 143 | ||

| Types of Cutting Face Grinds on Thread | |||

| Chasers | 144 | ||

| Grinding Wheel Speeds | 152 | ||

| Metric and Decimal Equivalents of Fractions | 153 | ||

| Comparative Rockwell, Scleroscope and Bri- | |||

| nell Hardness Table | 154 | ||

| S.A.E. Steel Specifications | 157 |

Ck

CHAPTER I

Wheels for Tool Room Grinding

The Abrasives

The abrasives used in Norton grinding wheels may be classified into two general groups—the aluminum oxide abrasives, designated by the trade-mark ALUNDUM , and the silicon carbide abrasives, designated by the trade-mark CRYSTOLON . Both are products of the electric furnace, but differ materially from each other. Silicon carbide abrasive grains are intrinsically harder but are also more brittle. Aluminous abrasive grains, while not so hard, are tougher and do not fracture so easily and are thus able to withstand a greater stress.

As a result of this difference in physical characteristics, Alundum abrasive wheels are used for grinding carbon steel, alloy steel, high speed steel, annealed malleable iron, wrought iron, tough bronzes and other materials that are hard, yet tough and strong; Crystolon abrasive wheels for grinding gray iron, chilled iron, 18-8 stainless steel, brass, soft bronze, copper, aluminum, stone, marble, rubber, hard facing alloys, and cemented carbides.

Norton Company manufactures several types of Alundum abrasives which have the trade-marks "Alundum" (commonly referred to as "regular"), "32 Alundum," "38 Alundum," and "19 Alundum." They possess individual characteristics, principally with respect to friability and resistance to point dulling which make each abrasive adaptable to different classes of work. For example, "38 Alundum" because of its porous nature, is more friable than regular Alundum, which is tough and capable of heavy duty grinding. As a result, "38 Alundum" has a cool cutting

and almost self-dressing action. It has long been a popular type of abrasive for tool room wheels.

"19 Alundum" abrasive may be described as having a grinding action intermediate between "Alundum" and "38 Alundum" abrasives and as such is sometimes used for such tool grinding and other operations where the regular Alundum abrasive is too tough.

The basic requirements of the ideal abrasive are resistance to point dulling and ability of the grain to fracture under normal grinding pressures before serious dulling occurs. Norton "32 Alundum." the latest development in aluminum oxide abrasives. fulfills both of these requirements to an exceptional degree. In the available grit range namely 16 to 220. "32 Alundum" wheels are ideally suited to grinding tool steels. On such tool room operations as cutter sharpening, surface grinding, and internal grinding "32 Alundum" wheels of proper specifications will grind faster and cooler, last longer and require fewer dressings than other abrasive wheels. Throughout this handbook "32 Alundum" wheels have been recommended for the majority of precision tool grinding operations. When converting to "32 Alundum" wheels specify the same grit size and grade as white or red tool grinding wheels now in use.

There are two types of silicon carbide abrasive produced by Norton Company under the trade-mark Crystolon. In addition to the familiar gray—almost black-colored 37C Crystolon, there is a green-colored variety, 39C, which is widely used for grinding cemented carbide tools.

The Bonds

There are five popular processes of bonding grinding wheels, namely, vitrified, silicate, resinoid, rubber and shellac. Each type of bond imparts distinct characteristics to

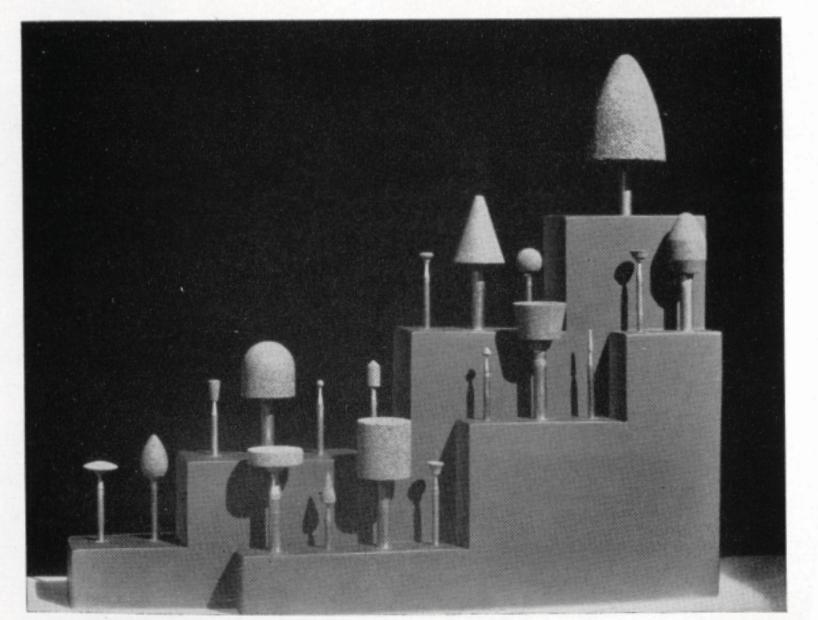

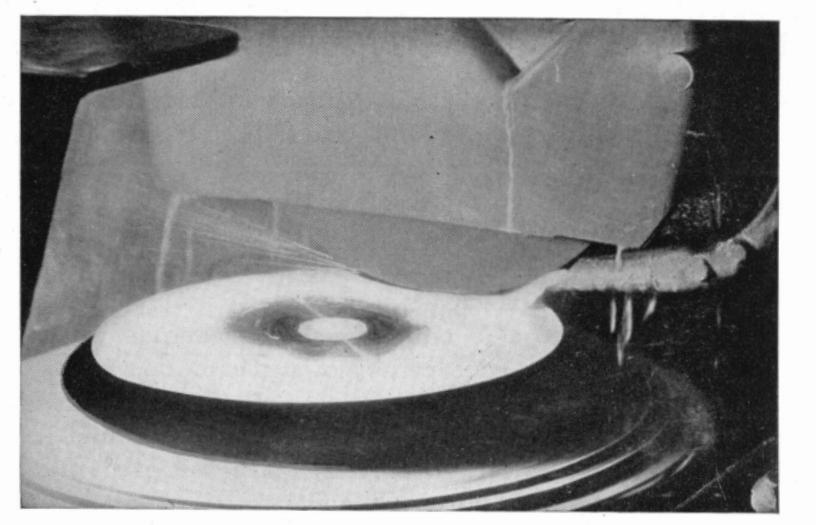

Commonly used types of tool grinding wheels

the grinding action of the wheel. With this variety of bonds, therefore, Norton Company is in a position to provide wheels that will most effectively meet specific grinding requirements.

Vitrified Bond—Most grinding wheels are made with a vitrified bond, which consists of a mixture of carefully selected clays. At the high temperatures produced in the burning kilns, the clays mixed with the abrasive grain fuse into a molten glass condition. On cooling, a span of this glass attaches each abrasive grain to its neighbors and supports them while they grind.

To provide a still closer fitting of the wheel to the work, Norton Company offers three different types of vitrified bonds, namely, "G" bond, "BE" bond and regular vitrified

bond. While all three types may be used in wheels for tool room grinding, "G" bond wheels in particular are recommended.

"G" bond was introduced early in 1953 as a distinctly new and superior bond for precision and semiprecision grinding. It possesses the unique ability of breaking down at just the right time in the grinding cycle to give the wheel, in the right grade, practically a self-dressing action. Its built-in free and cool cutting action makes it an ideal bond, in combination with one of the Alundum abrasives, for cutter sharpening.

Silicate (silicate of soda) bonded wheels have a milder cutting action than vitrified wheels and are still used to a limited extent for grinding edge tools. In the tool room they are found on some of the large wet tool grinders.

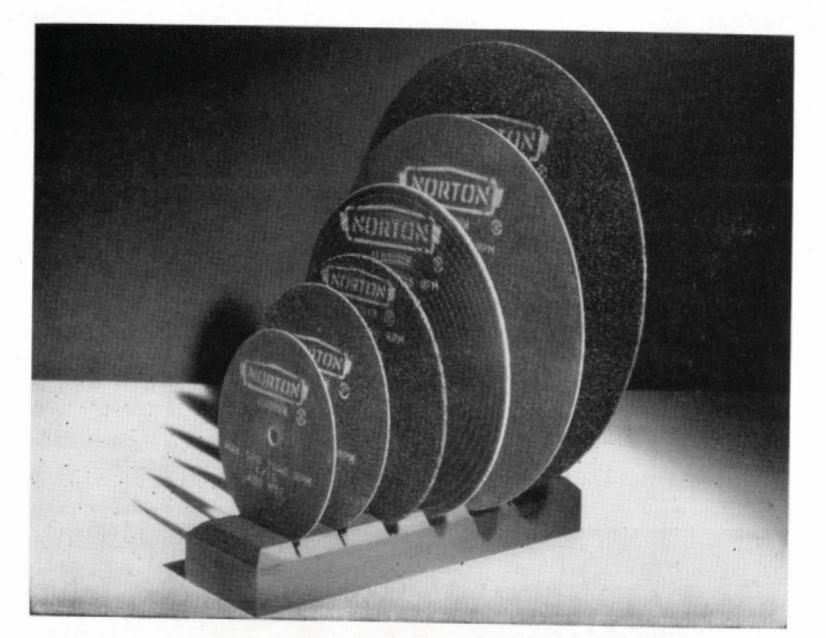

Resinoid bonded wheels are designed to operate at 9000 to 9500 surface feet per minute. Because of their fast cutting ability at these higher speeds, they are particularly suited for snagging castings and for other heavy duty operations. Resinoid bonded cut-off wheels are popular for cutting all kinds of materials. On proper equipment, such wheels can be safely operated at speeds as high as 16,000 s.f.p.m.

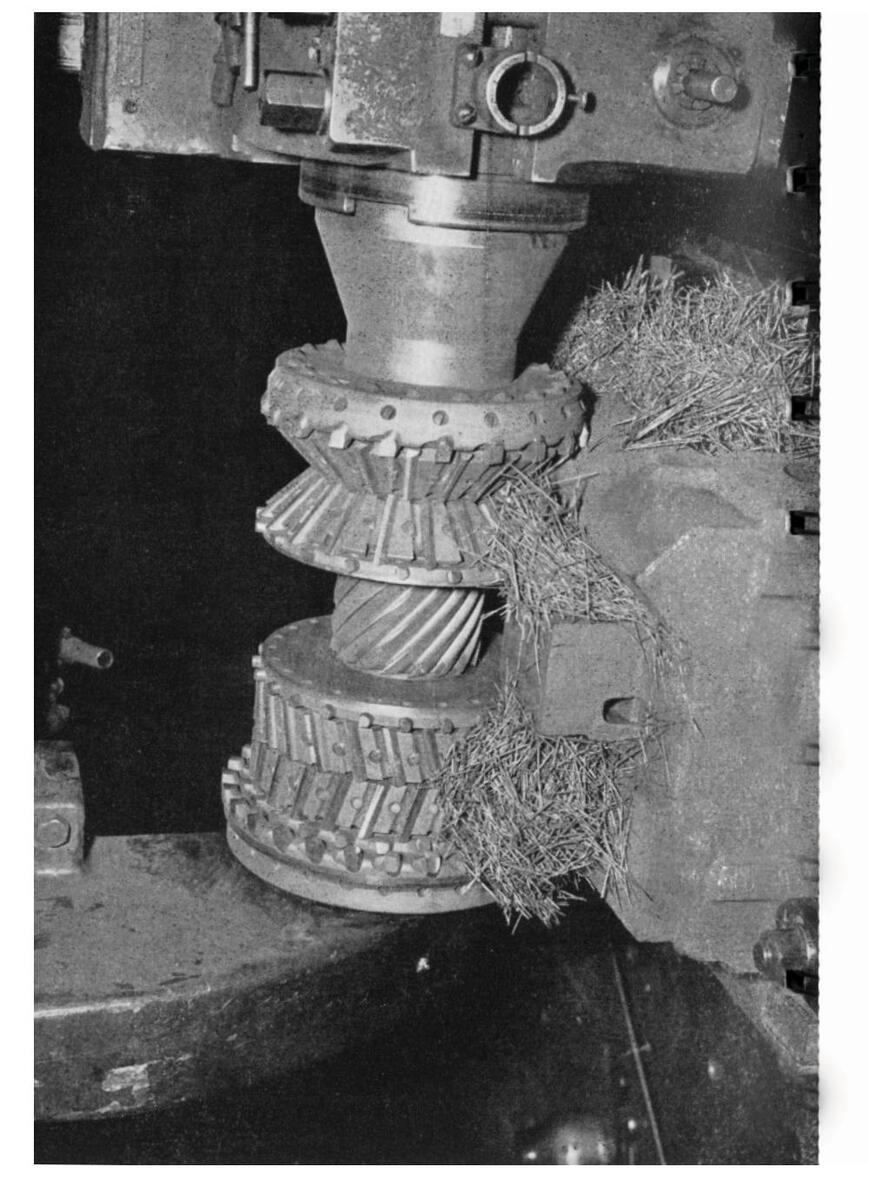

More recently, resinoid bonded wheels have been successfully applied to the grinding of large milling cutters. For this work they are operated at normal machine speeds.

Rubber bonded wheels also are capable of rapid stock removal when operated at high speed. Their grinding action is characterized by a certain smoothness and as a result, they are used to a large extent on work where a high quality of finish is required, as on ball and roller bearing races. In the tool room, they are used principally for fluting taps and for wet cutting-off operations.

Shellac bonded wheels grind with a burnishing or buffing

action as a result of the bond softening under the heat of grinding. They are therefore capable of producing bright finishes such as are required on cold mill rolls and the sides of certain slitting saws. They are also used for grinding cutlery and for "gumming" saws in lumber mills.

Grinding Wheel Specifications

All grinding wheels are made up of three elements abrasive grain, bonding material, and pores.

The first is the working element, the second determines the grade, and the third represents the voids between the grain required for chip clearance on most operations.

By the term "specifications" is meant the choice of these three elements which are described more fully in the following paragraphs.

Grain Size (Grit)

A number is used to designate the size of individual abrasive grains in the wheel. This number corresponds to the meshes per linear inch in the screen employed in sizing the abrasive particles. For example, a grinding wheel of 30 grit contains abrasive grains that will just pass through a screen having 24 openings to the linear inch, but are retained on the next finer size screen.

Grain Sizes of Norton Abrasives

| Coarse | Medium | Fine | Very Fine |

|---|---|---|---|

| 10 | 30 | 70 | 220 |

| 12 | 36 | 80 | 240 |

| 14 | 90 | 280 | |

| 16 | 46 | 100 | 320 |

| 20 | 54 | 120 | 400 |

| 24 | 60 | 150 | 500 |

| and the first second | 180 | 600 |

The very fine sizes are classified by hydraulic separation. Combinations of various grain sizes are often used to produce a desired refinement in grinding action.

Grade (Hardness)

The abrasive grains in a grinding wheel are held in place by posts of bond. If these bond posts are very strong and are capable of retaining the grains against the grinding forces tending to pry them loose, the wheel is said to be of a hard grade. On the other hand, if only a small force is needed to release the grains, the wheel is said to be of a soft grade. Thus, with a given type of bond, it is the relative amount of bond in the wheel which determines its grade or hardness.

In the Norton method of marking wheels, which conforms to the system now standard throughout the industry, the grade letters for all types of wheels range from A to Z in the order of increasing hardness.

| Soft | 1 | to | 1 | Hard | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AB | C | D | F | F | G | н | т | т | ĸ | т | м | N | 0 | D | 0 | P | S | т | TT | v | XX/ | 7 |

It should be understood that grade is not an exact value. Actually, it is a range between narrow limits, and all wheels that come within the range designated by any particular letter are considered to be of one grade and carry the same grade letter.

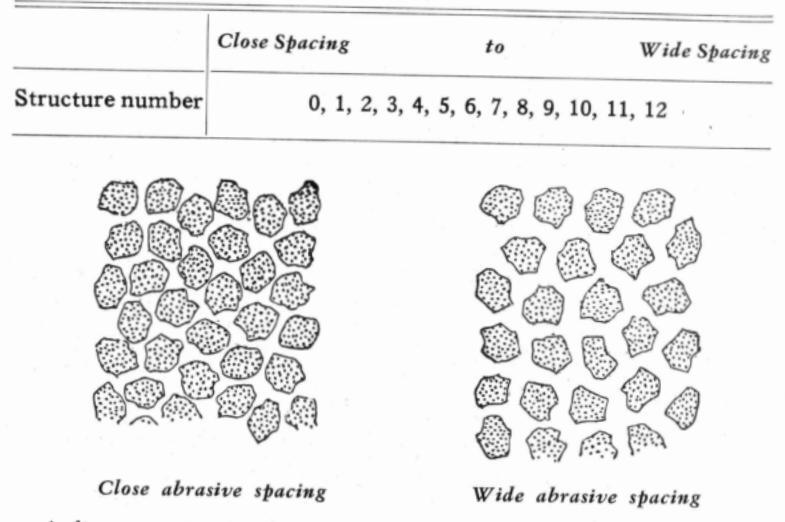

Structure (Grain Spacing)

Two wheels of the same grain and grade, but differing in the quantity or spacing of the abrasive grains, obviously will not grind alike. "Controlled structure" is a term used to indicate accurate control over the grain spacing in Norton

wheels and offers the user an additional standard by which to fit grinding wheels to his particular work.

It is possible by the use of "controlled structure" to provide for each tool grinding operation the precise spacing of the cutting particles that is most effective for that particular operation. The spacing of the grains—each structure —is designated by a numerical symbol and can be exactly specified just as the grain and grade are specified. The structure number is omitted in some types of products even though the spacing is controlled.

A diagrammatic sketch to show how two wheels may be identical in grain size and grade (strength of bonding) but differ in grain spacing or STRUCTURE—and thereby differ in grinding action

Norton Method of Marking Grinding Wheels

Norton wheel markings, based on the system now standard throughout the industry, are composed of six so-

called "positions," each position clearly designating a characteristic of the grinding wheel. These six positions are:

1. Kind of Abrasive (i.e., Alundum, 32 Alundum, Crystolon, etc.)—The letter "A" alone, signifies Alundum abrasive; "C" denotes Crystolon abrasive. "A" or "C" may be combined with a special trade-mark numeral as "32A" denoting 32 Alundum abrasive or "39C" designating 39 Crystolon abrasive.

2. Grain (size of abrasive particles)—Consists of numerals from 10 to 600 for the standard grit sizes. Special grain combinations are designated by an additional number immediately following the grain size.

3. Grade (strength of bonding)—Designated by a letter of the alphabet ranging from "A" (soft) to "Z" (hard).

4. Structure (grain spacing)—The structure of a wheel refers to the relative spacing of the grains of abrasive. It is designated by a number; the larger the number, the wider the grain spacing.

5. Kind of Bond (i.e., Vitrified, Resinoid, Rubber, etc.) —To designate bond a letter is used, V, Vitrified; S, Silicate; R, Rubber; B, Resinoid; E, Shellac or O, Magnesite.

6. A Norton Company symbol designating a particular characteristic of the grinding wheel itself, due to special bonds or other variations, that distinguishes it as a variation from a basic wheel. This position may be omitted or shown according to the characteristics of the wheel specified. When omitted in any type of bond, a "regular" wheel of that bond is indicated. When used, it may be one or more letters or numbers or a combination of both. The chart on the next page shows the more commonly used symbols for position number six.

Factors Affecting the Selection of a Grinding Wheel

The following is an outline of the factors which govern the selection of the various elements of a grinding wheel, namely, the abrasive, grain size, grade and type of bond. It should be understood, however, that the rules and conditions set down are quite flexible and that occasionally exceptions will occur.

NORTON ABRASIVES

1. Factors Affecting the Selection of Abrasive

| Carbon steels | ||

|---|---|---|

| High speed steels | ||

| Use aluminous | Alloy steels | |

| abrasive (Alundum) | Cast alloys | |

| Physical | wheels for | Malleable iron |

| properties of | Hard bronzes, etc. | |

| material to be | ||

| ground | Gray iron | |

| 김희감 같은 모두 | Use silicon carbide | Chilled iron |

| abrasive (Crystolon) | Brass and soft | |

| wheels for | bronze | |

| a statege to te | Aluminum | |

| Cemented carbides | ||

2. Factors Affecting the Selection of Grain Size

A. Physical properties of material to be ground

Δ

B. Amount of stock to be removed

The softer and more ductile the material, the coarser the grain size.

The larger the amount of stock removal, the coarser the grain size.*

*Exception-Very hard materials where depth of grain penetration is necesarily small.

[15]

NORTON ABRASIVES

| C. Finish required |

The better the finish required,

the finer the grain size.** |

A. Dimensions of wheels |

Thin cut-off wheels and

others subjected to bending strains require resinoid, shel- lac, or rubber bonds. Solid |

|---|---|---|---|

|

A. Physical properties of

material to be ground |

The harder the material, the softer the grade should be. |

wheels of very large diam-

eters require silicate bond. |

|

|

B. Area of contact between

wheel and work |

The smaller the area of con-

tact, the harder the grade should be. |

B. Wheel speed |

Vitrified wheels are usually

best for speeds up to 6500 s.f.p.m.; resinoid, shellac and |

| C. Wheel speed and work speed |

The higher the work speed

with relation to wheel speed, the softer the resulting grind- ing action and the harder the grade should be. |

C. Finish required |

rubber wheels for speeds

above 6500 s.f.p.m. Resinoid, shellac or rubber bonds are generally best for high finishes |

|

D. Condition of the grind-

machine |

The presence of vibration and

worn master parts usually calls for a harder grade of wheel than would be required on a machine in grade condition |

Standard Types of Grin | nding Wheels |

| E. Coolants |

With the proper coolant, a

harder grade of wheel can usually be used. |

On the following pages

standard types of grinding of the various shapes that a room grinding. The six typ each dimension designated |

are shown cross sections of six

wheels which are representative re most commonly used for tool pes of wheels are numbered and by a letter. The key to the di- |

4. Factors Affecting the Selection of Bond

The vitrified types of bond are most generally used. However, in some instances, operating and performance requirements make the selection of other types of bonds advantageous or essential.

**Exception—In machine grinding, reasonably fine finishes are obtainable with medium or even relatively coarse grit wheels by dressing the wheel fine with a diamond and properly adjusting the wheel and work speeds.

This classification of grinding wheels greatly simplifies the stocking of wheels wherever a quantity is kept on hand.

It also enables the user to accurately order a grinding wheel

by giving the type number and dimensions as designated by

mension letters is shown on the next page.

the cross section of that type.

Kev to Letter Dimensions

- A = Flat Spot of Beveled Wall

- D = Diameter (Over All).

- E = Center or Back Thickness.

-

F = Depth of Recess

- (See Type 5.)

- G = Depth of Recess

- H = Arbor Hole

- I = Diameter of Flat or Small Diameter 0

- K = Diameter of Flat Inside M = Large Diameter of Beyel

- P = Diameter of Recess.

-

P = Diamete R = Radius.

- W = Thickness of Wall

Tabe No 6

NORTON ABRASIVES

Standard Shapes of Grinding Wheel Faces

When no face is specified a straight "A" face wheel is furnished. The different faces which are regularly supplied are designated by letters as shown below:

۲ 20 T

Grinding Wheel Speeds

It is good practice to operate a grinding wheel as near to the speed recommended by the maker as possible. In general, for cylindrical grinding, wheels should be run from 5500 to 6500 surface feet per minute, for surface grinding from 4000 to 5000 s.f.p.m., for cutter grinding from 4500 to 6000 s.f.p.m. and for wet tool grinding from 5000 to 6000 s.f.p.m.

The grain, grade and structure usually recommended for any certain operation are based on the assumption that approximately the recommended speed will be employed. If for some reason this is not possible, then the grade at least should be changed to conform to the different speed. Too slow speed means wastage 'of abrasive without too much useful work in return, whereas an excessive speed may result in hard grinding action and may introduce the danger of the wheel breaking or burning the work.

Recommended Wheel Speeds in Surface Feet Per Minute

| Tool and cutter grinding | 4.500- 6.000 |

|---|---|

| Calle dates 1 and a line | r,000 0,000 |

| Cylindrical grinding | 5,500- 6,500 |

| Internal grinding | 2,000- 6,000 |

| Snagging, offhand grinding (vitrified wheels) | 5,000- 6,000 |

| Snagging (rubber and resinoid wheels) | 7,000- 9,500 |

| Surface grinding | 4,000- 5,000 |

| Knife grinding | 3,500- 4,500 |

| Hemming cylinders | 2,100- 5,500* |

| Wet tool grinding | 5,000- 6,000 |

| Cutting-off wheels (rubber, resinoid and shellac) . | 9,000-16,000* |

Truing and Dressing the Grinding Wheel

These two terms are sometimes confused in the minds of grinding operators. Truing means removal of material

*This higher speed is recommended only where bearings, protection devices and machine rigidity are adequate.

[21]

from the cutting face of a wheel so that the resultant surface runs absolutely true. Dressing is the operation of cleaning or restoring the sharpness of the wheel face that has become dulled or loaded with the material being ground.

Truing can best be accomplished by the use of a diamond tool rigidly supported in a fixed tool post. For certain classes of work, mechanical or abrasive wheel truing devices have been found to be more economical and effective substitutes for the diamond. Obviously, the accuracy of such rotary truing devices is affected by the condition of their bearings and the technique employed.

Wheels used on tool and cutter grinding machines are preferably trued and dressed with a diamond. The hard diamond point in the dressing tool fractures the abrasive grains on the face of the wheel, or removes the dull grains entirely and thus allows new, sharp cutting points to be presented to the work.

For dressing large tool sharpening wheels, the Huntington or the Norton type of dresser, rigidly supported on the work rest, is recommended. Smaller tool room wheels, including cutter grinding wheels, are commonly dressed and rough formed with a suitable Crystolon abrasive stick applied by hand.

For dressing tool and cutter wheels 10" and smaller, especially cup and saucer shapes, Norbide dressing sticks are highly effective. Because they are the hardest of all dressing sticks, they dress tool wheels quickly, efficiently, and have extremely long service life. They are small (3/16" x 1/2" x 3"), lightweight and easy to use. (See illustration on next page.)

Use of the Diamond for Truing and Dressing

The diamond tool should always be canted or set at an angle to the wheel face with the diamond pointing in the direction of wheel rotation to prevent gouging the wheel face. This is sometimes referred to as the "drag angle." As the diamond wears, the nib in the holder should be turned to insure a sharp cutting point at all times. Dull diamonds tend to glaze the wheel face, dulling the cutting points and causing the wheel to act harder than normally.

The grinding wheel face usually wears more on the edges, leaving a high spot in the center. It is good practice to contact the diamond at the highest point before traversing, thus preventing excessive penetration with possible damage to the diamond. For high finish grinding, however, it is not advisable to make this preliminary contact without traverse, as the diamond may leave a mark on the wheel

which may be transferred to the work. In this class of grinding it is best to bring the diamond almost in contact with the high spot on the wheel face, start traversing and feed in .001" to .002" at the end of each pass until contact is made, and then proceed in the following manner.

Traverse the diamond back and forth across the wheel face, using a light feed (not over 0.001" for finishing; roughing cuts may be slightly heavier) until the sound of the diamond on the wheel indicates that the wheel is perfectly round, or flat in the case of cup wheels. The rapidity with which the diamond is traversed across the wheel face depends upon the grain and grade of the wheel and the finish desired.

A slow traverse gives a high finish, but if too slow, will glaze the wheel. A fast traverse produces a free cutting wheel but if too fast, may leave "diamond marks" on the wheel

[24]

Wheels may be trued or dressed either wet or dry but the operation should always be carried on under the same conditions as when grinding. If grinding wet—dress wet.

Care and Safe Use of Grinding Wheels

The following operating rules and general data have been reprinted from the "Safety Code for the Use, Care and Protection of Abrasive Wheels." A copy of the complete code should be available in every tool room for reference at all times. Copies will gladly be furnished by Norton Company upon request.

"Responsibility"

Competent operators shall be assigned to the mounting, care and inspection of grinding wheels and machines.

"Inspection after Breakage"

Whenever a wheel breaks, a careful inspection shall be made to make sure that the hood has not been damaged, nor the flanges bent or sprung out of true or out of balance. The spindle and nuts shall also be carefully inspected.

"Replacing Hood"

After mounting a new wheel, care should be taken to see that the hood is properly replaced.

NORTON ABRASIVES

"Starting New Wheels"

All new wheels shall be run at full operating speed for at least one minute before applying work, during which time the operator shall stand at one side.

"Applying Work"

Work should not be forced against a cold wheel, but applied gradually, giving the wheel an opportunity to warm and thereby minimize the chance of breakage. This applies to starting work in the morning in cold rooms, and to new wheels which have been stored in a cold place.

"Test for Balance"

Wheels should be occasionally tested for balance, and rebalanced if necessary.

"Truing"

Wheels worn out-of-round shall be trued by a competent operator. Wheels out of balance through wear, which cannot be balanced by truing or dressing, shall be removed from the machine.

"Wet Grinding Wheels"

Wheels used in wet grinding should not be allowed to stand partly immersed in the water; the water-soaked portion may throw the wheel dangerously out of balance.

All wet tool grinders which are not so designed as to provide a constant supply of fresh water shall be thoroughly drained at the end of each day's work and a fresh supply provided just before starting.

"Side Grinding"

Grinding on the flat sides of straight wheels is often hazardous and should not be allowed on such operations when the sides of the wheel are appreciably worn thereby or when any considerable or sudden pressure is brought to bear against the sides.

"Dresser Guards"

Wheel dressers, excepting the diamond type, shall be equipped with guards over the tops of the cutters to protect the operator from flying pieces of broken cutters or wheel particles.

"Grinding Room"

The space about the machine should be kept light, dry and as free as possible from obstructions.

"Lubrication"

Care should be exercised so that the spindle will not become sufficiently heated to damage the wheel.

"Check for Wear"

All arbors, adaptors, or other machine parts on which wheels fit, should be periodically inspected and maintained to size.

"Work Rests"

Work rests (or plain tables) shall be kept adjusted close to the wheel with a maximum distance of 1/8" to prevent the work from being caught between the wheel and the rest. The work rest shall be securely clamped after each adjustment. The adjustment shall not be made while the wheel is in motion.

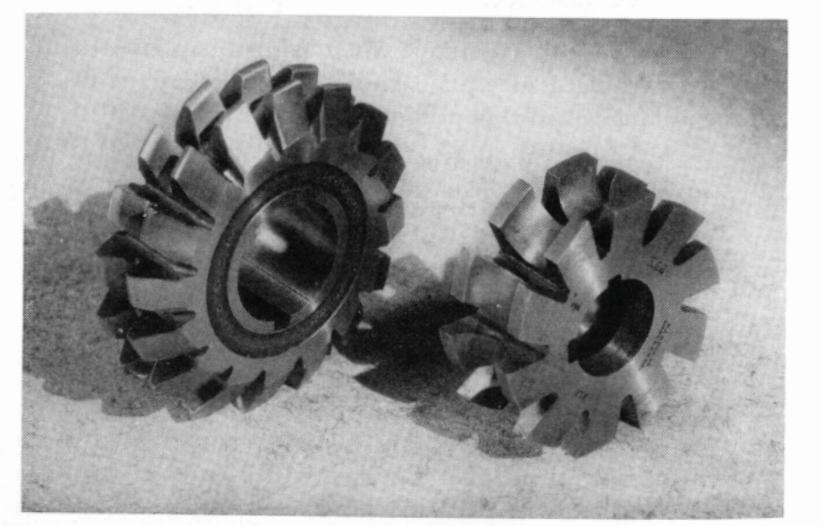

CHAPTER II harpening Milling Cutters and Reamers

In general, it may be said that the working efficiency of a cutter is largely determined by the keenness of its cutting edges. Consequently, it is important to sharpen a cutter at the first signs of dullness. A dull cutter not only leaves a poorly finished surface, but the continued use of such a cutter leaves it in a condition where it becomes necessary to grind away a considerable portion of the teeth to restore the cutting edges. When the cutter is maintained in good working condition by frequent sharpening, it is certain to be cutting rapidly and effectively at all times. Furthermore, when such a cutter does need resharpening, it is necessary to grind the teeth only a very small amount to restore its keen cutting edges.

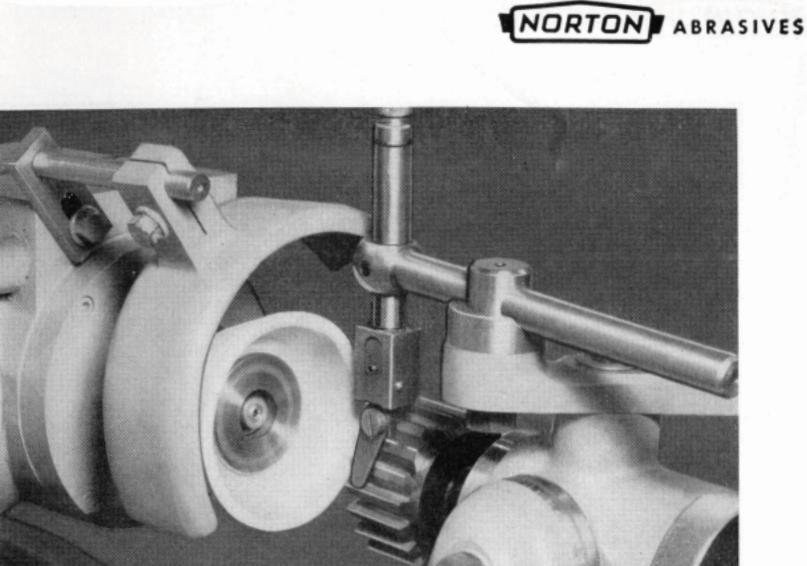

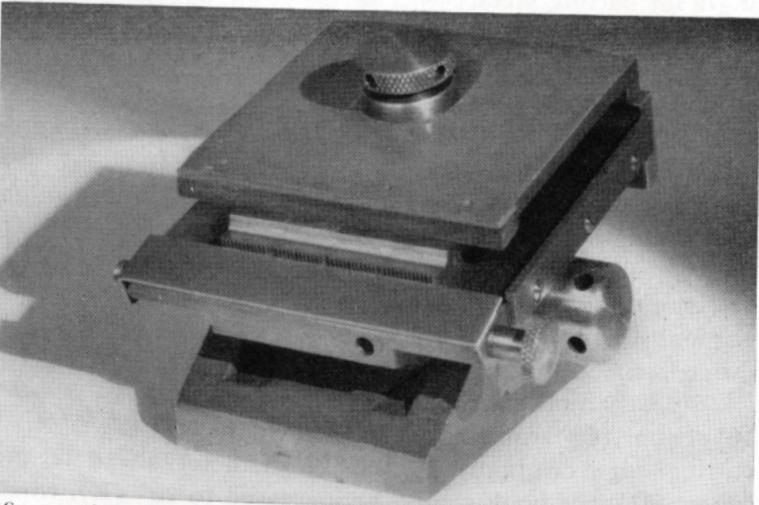

Cutters and reamers are usually ground on tool and cutter grinding machines. The universal type of cutter grinder, as the name implies, can be set up for a variety of grinding operations, including light cylindrical, surfacing and internal, as well as for sharpening cutters of all kinds, reamers, etc.

The grinding machine for sharpening cutters should be kept in good repair. The wheel spindle must be free running, but the bearings should be snug so that there is no tendency to chatter, nor must there be any end play. Table ways must be kept straight and true if accurate work is to be obtained. The tooth rest should be substantial enough to avoid springing and the tip shaped so as to provide a smooth and solid contact under each tooth being sharpened.

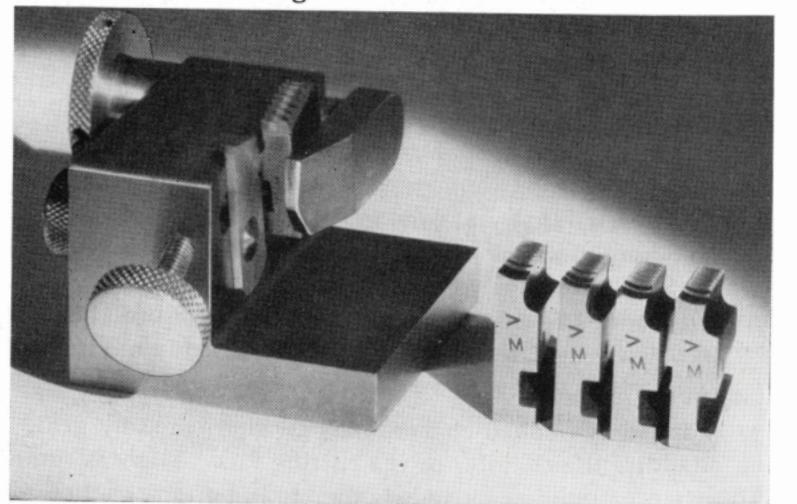

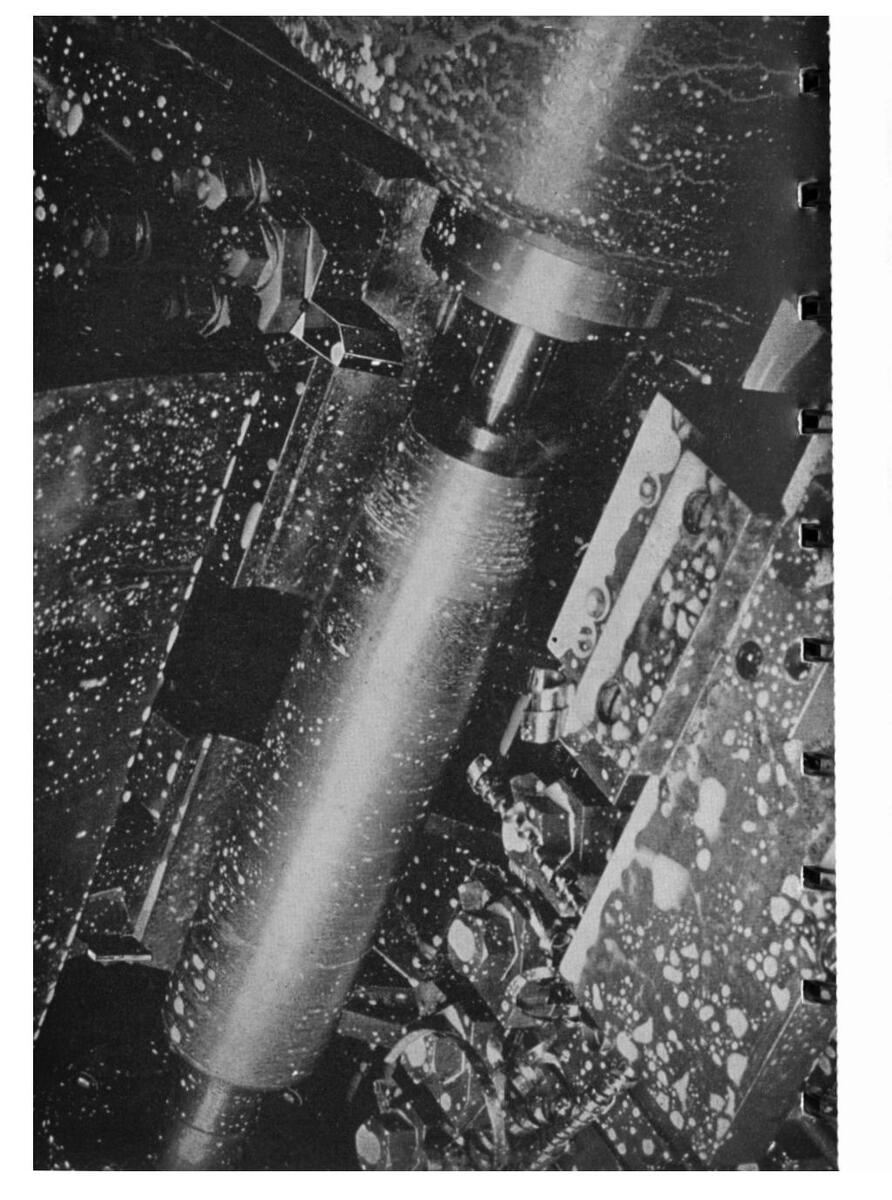

Gang set-up of milling cutters on planer type machine

Grinding Wheels Recommended

The grade of the grinding wheel used for sharpening cutters must be in the soft range to insure a free cutting action and to avoid drawing the temper of the cutting edge. At the same time, if the wheel is too soft, its rapid wear makes it difficult to keep the cutter a true cylinder or to produce a keep edge.

32A46-K8VG, 32A60-J8VG and 32A46-J8VG Alundum vitrified, in the order named, are the most preferred specifications of small straight cup and tapered cup wheels for sharpening carbon steel, high speed steel and cast nonferrous alloy cutters of the profile type, which are ground on the back of the cutting edge. Included in this class of cutters are plain and side milling cutters, end mills, reamers, etc. When the machine set-up calls for a straight wheel, 38A46-K8VG is most commonly used.

Formed cutters, including rotary gear cutters, are generally ground with dish shaped wheels, 38A46-J8VG or 38A60-J8VG Alundum vitrified. For sharpening Fellows Gear Shaper cutters, slightly finer grit wheels, 32A80-I8VG, should be used. A complete list of wheels to use for sharpening various types of cutters is included in the table of grinding wheel recommendations, beginning on page 136.

Dry grinding is generally recommended for most high speed steel cutter sharpening operations because experience has shown that satisfactory results are obtained in this way and the operations are such that wet grinding causes inconvenience to the operator. However, where machines expressly provide for wet grinding, they should continue to be so used.

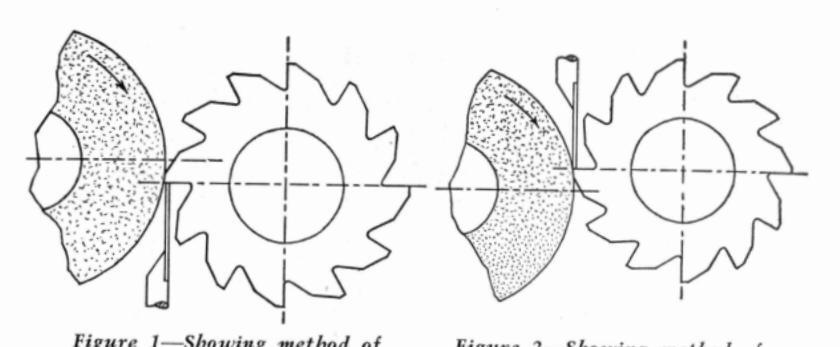

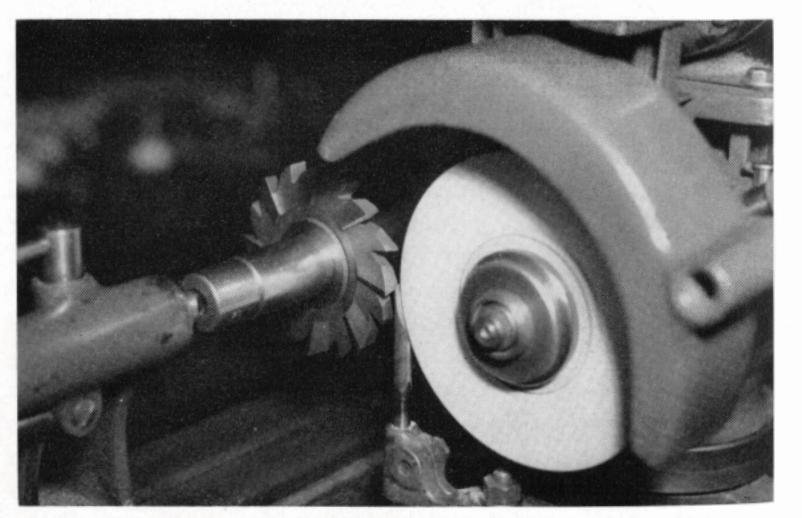

Figure 1—Showing method of grinding with wheel rotating off the cutting edge

Figure 2—Showing method of grinding with wheel rotating on to the cutting day

Direction of Wheel Rotation

Cutters and reamers may be ground with the grinding wheel rotation either off or toward the cutting edge as shown above:

If the wheel is run off or away from the cutting edge as shown in figure 1, the wheel holds the cutter against the tooth rest. As this is the safer method it is more commonly used. However, it has the objection of throwing up a burr on the cutting edge of the tooth which should be oilstoned off. Furthermore, there is some danger of burning the tooth at the cutting edge.

If the cutter is ground by rotating the wheel on to the cutting edge as shown in figure 2, there is less tendency to burn the tooth and a keener cutting edge, free from burr, is possible. However, care must be taken to hold the cutter firmly against the tooth rest as otherwise the rotation of the wheel will carry the tooth into the wheel and cause it to be ground away.

While straight wheels are shown in the above illustrations, the same comments regarding direction of grinding wheel rotation apply to the use of cup wheels.

Clearance

Clearance or relief may be defined as the amount of stock removed from the teeth behind the cutting edge to permit the teeth to cut freely and to clear the material after the cutting edge has done its work.

NORTON ABRASIVES

It is important that the clearance be correct. If it is insufficient, the teeth will have a dragging cut, while if it is too great, the teeth will wear rapidly and the cutter is likely to chatter. Too much clearance, however, is less objectionable than too little.

The proper angle of clearance depends upon a number of factors, principally the type and diameter of the cutter and hardness of the material to be machined. For example, cutters employed on soft materials like brass can stand more clearance than those employed on steel or cast iron. Likewise, the clearance must be greater for small cutters than for large ones. For these reasons, it is generally agreed that the correct clearance angle for a given cutter must be determined by experience. Once the clearance angle (as well as cutting speed and feed) that gives the best results on a certain operation has been determined, it should be recorded for future reference.

As a general rule, the clearance angle should be from 6° to 7° for cutters up to 3" in diameter and from 4° to 5° for cutters larger than 3". The following table may also be used as a guide in selecting the proper clearance angle according to the material to be cut:

| Low Carbon Steels | 5° | to | 7° |

| High Carbon and Alloy Steels | 3° | to | 5° |

| Steel Castings | 5° | to | 7° |

| Cast Iron | 4 ° | to | 7° |

| Brass and Soft Bronze | 10° | to | 12° |

| Medium and Hard Bronze | 4° | to | 7° |

| Aluminum | 10° | to | 12° |

F 33 1

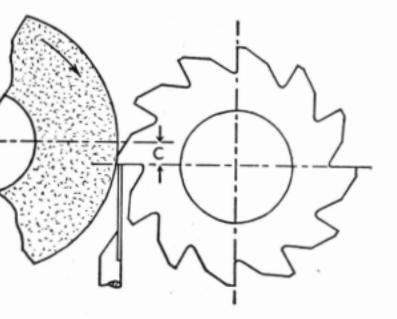

Due to repeated grindings the width of land is increased, causing interference at A. Grind secondary clearance as shown by dotted line.

Figure 3—Showing reason for secondary clearance

Width of Land

The land, which is the narrow surface immediately behind the cutting edge that is ground to the clearance angle, should be about 1/32" to 1/16" wide, depending upon the type and size of the cutter. As a result of repeated grinding, the land may become so wide as to cause the heel of the tooth

to drag on the work. To control the width of the land, a secondary clearance, usually double the original clearance, is ground as shown in figure 3.

The clearance of the end teeth of end mills should be about 3° to 5°. On formed milling cutters or involute gear cutters, clearance does not have to be considered in resharpening, because the teeth are so formed that when ground radially on the face, the clearance remains the same.

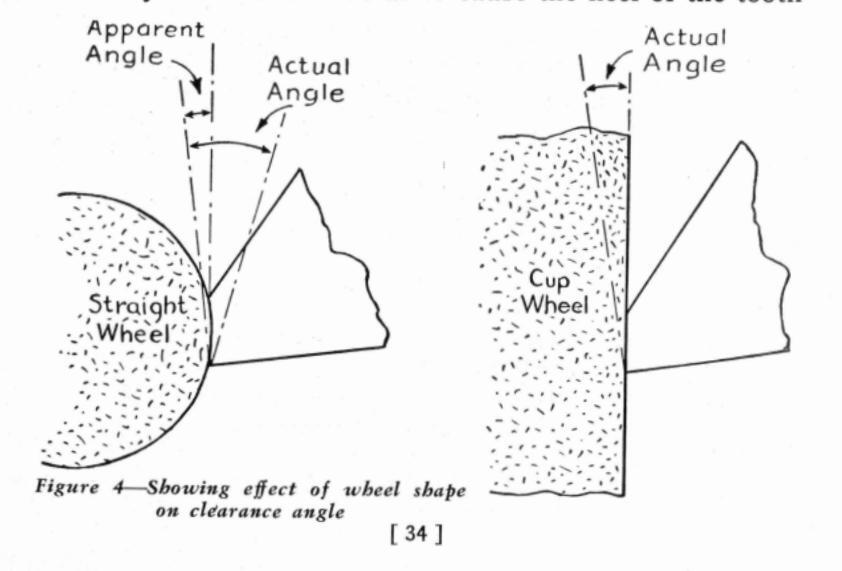

Producing the Clearance Angle

The clearance angle is determined by the setting of the grinding wheel, the cutter and the tooth rest. Either a straight wheel or a cup wheel may be used. If the lands on the cutter teeth are narrow, a straight wheel is frequently used. If the lands are wide, a cup wheel should be used. It is possible to use a straight wheel on wide lands by swivelling the wheel head about 1° from the zero line so that the cut approaches a straight line.

The general procedure in obtaining the setting for the clearance angle is to bring the center of the wheel and the work as well as the tooth rest all in the same plane and then raise or lower the wheel head (or the table) the proper distance to give the desired clearance angle. When using a straight wheel, this distance varies with the diameter of the wheel; when using a cup wheel, the distance varies with the diameter of the cutter.

On some of the cutter grinding machines, the work head unit is provided with a dial graduated in degrees for quickly setting the cutter to the exact clearance angle desired. If this attachment is not available, the tooth rest setting for the clearance angle must be obtained either from clearance tables (see pages 141 and 142) or by the following methods and calculations:

Setting the Tooth Rest, Using a Straight Wheel

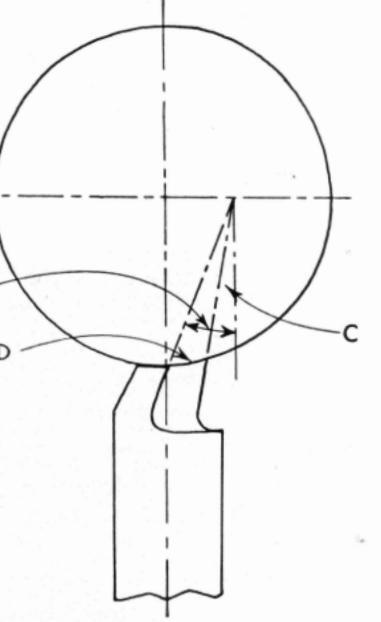

Figure 5 illustrates a milling cutter being ground with a straight wheel. The distance C between the center lines of the wheel and cutter varies with the clearance angle. The method of producing the desired clearance angle, when using a straight wheel, is as follows:

- 1. Bring the center of the wheel and the work into the same plane.

- Fasten the tooth rest to the table of the machine and adjust the tooth rest to the same height as the center of the work, using a height gauge. Raise (or lower

depending upon the

Figure 5—Developing the clearance angle when using a straight wheel

direction of wheel rotation) the wheel head the proper distance by means of the graduated hand wheel (on Norton tool and cutter grinding machines). On some machines, where the wheel head is stationary and the table moves, the same effect is obtained by lowering the table.

The distance to raise or lower the wheel head when using a straight wheel may be calculated as follows: Multiply the clearance angle in degrees by the diameter of the wheel in inches, and this product by the constant .0087.

Example: To determine the distance to raise or lower the wheel head for a 7° clearance angle, using a straight wheel 6" diameter. Solution: C = 7° x 6" x .0087 = .365".

Setting the Tooth Rest, Using a Cup Wheel

Figure 6 shows the use of a cup wheel for grinding a cutter. The setting for producing the desired clearance angle, of a spiral milling cutter, for example, is obtained as follows:

Fasten the toothrest to the wheel head and line up the tooth rest and center of the cutter in the same plane, using a height gauge. Raise or lower the wheel head with the tooth rest the required distance.

Figure 6—Developing the clearance angle when using a cup wheel

To calculate this distance when using a cup wheel, multiply the required clearance angle by the diameter of the cutter in inches and this product by the constant .0087.

Example: To determine the distance to raise or lower the wheel head beyond the center of a cutter 3" in diameter in order to produce a clearance angle of 5°, using a cup wheel 4" in diameter. Solution: C = 5° x 3" x .0087 = .130".

Typical Set-Ups for Sharpening Cutters

To give the reader a general idea of the methods commonly employed in the setting-up and sharpening of cutters, reamers and similar tools, the following pages illustrate a number of typical set-ups, together with a brief description of the set-up and the grinding procedure employed in each case.

Spiral milling cutter, side milling cutter and end mill

Formed cutters [ 38 ]

From the standpoint of design and method of sharpening, cutters may be classified into two general groups:

- 1. Cutters which are sharpened on the periphery, or sides, by grinding the clearance angle behind the cutting edge of the tooth. Included in this group are plain milling cutters (straight and spiral teeth), side milling cutters, face milling cutters, end mills, slitting saws, reamers, etc.

- 2. Cutters which are sharpened by grinding the front, radial cutting faces of the teeth so as not to alter their profile. This group includes formed cutters, involute gear cutters, taps, forming tools, etc.

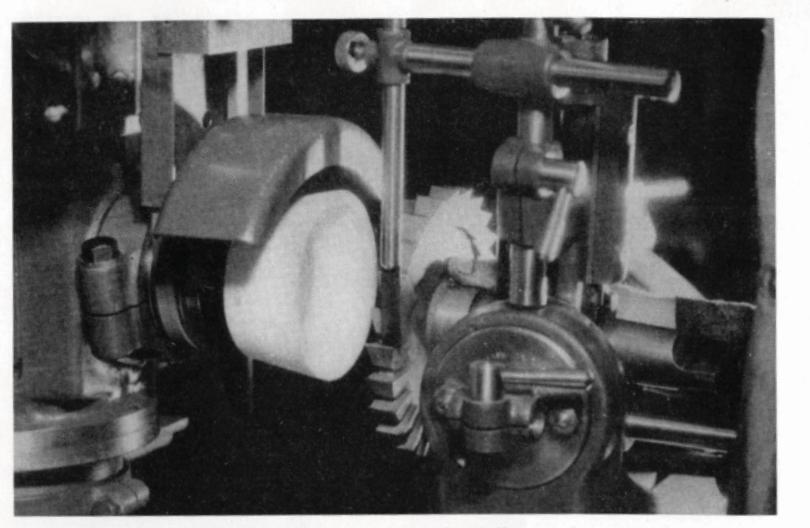

Plain (Spiral) Milling Cutters

The cutter is mounted on an arbor which is supported between centers and set sufficiently below the center of the wheel spindle to produce the desired clearance. The tooth rest must be mounted on the wheel head and adjusted so that it has a complete bearing on the tooth to be ground, on the vertical center line of the wheel. This brings the cutter, wheel and work rest into contact at a common point. Holding the cutter against the tooth rest with a slight hand pressure to maintain a uniform spiral, the cutter is traversed across the wheel face, either by moving the table or sliding the cutter on a cutter bar.

In sharpening plain milling cutters the greatest difficulty lies in keeping the peripheral cutting edges radially equal (a cutter out of truth cuts with a constant pounding action). If the wheel wear during the sharpening operation is equalized, it follows that the cutter is kept cylindrical. This is achieved by grinding around the entire cutter, then revolving it 180°, starting anew on a tooth just opposite the original starting point and taking another light cut all the

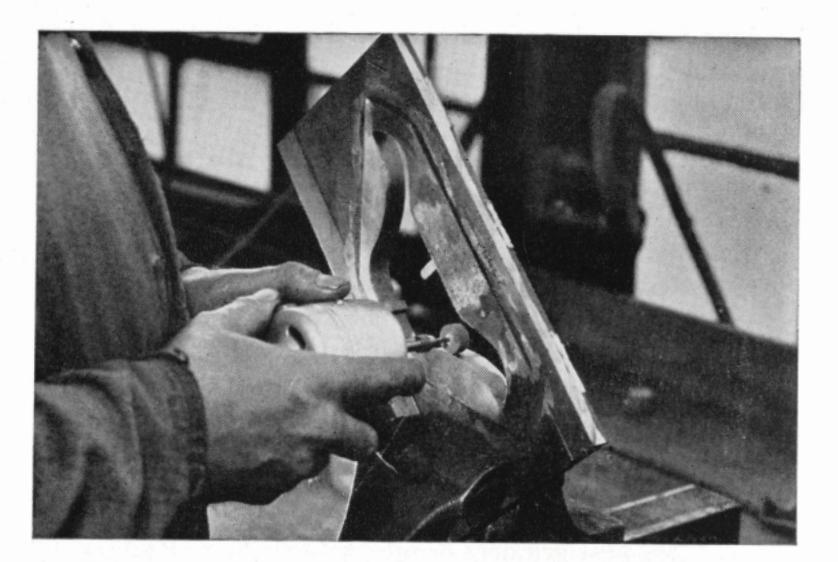

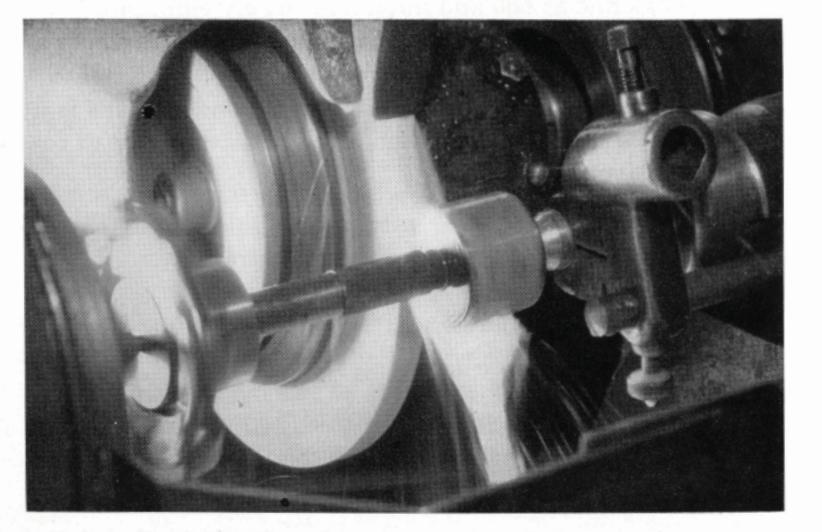

Sharpening a spiral milling cutter

Sharpening a staggered tooth milling cutter

way around the cutter. This method is repeated, taking light cuts until the cutter has been sharpened sufficiently. With the new Norton G bond wheels, slightly harder wheels can be often used which hold size all around a cutter, making this procedure unnecessary.

A cup wheel can also be used for grinding plain cutters. It possesses the advantage of producing a straight angle of clearance back of the cutting edge. To prevent the opposite side of the cup wheel from striking the cutter, the wheel head should be swiveled slightly from the zero line.

Some tool rooms have found that cutters for use on steel and cast iron will cut with less chatter and stand up longer between regrinds, if they are first ground cylindrically and then backed off to leave a land from .005" to .010" wide at the cutting edge.

Staggered Tooth Milling Cutters

Staggered tooth milling cutters, having alternately right and left-hand spiral teeth, may be sharpened at one set-up by using a tooth rest with the top of the blade either rounded or shaped with a double angle. The operation is similar to grinding a plain spiral mill, with the cutter mounted on an arbor between centers and the tooth rest fastened to the wheel head.

The blade of the special tooth rest shown in figure 7 is ground to coincide with the right and left spiral angles of the cutter teeth. The high point (c) of the tooth rest must be located in the center of the cutting face of the wheel. The wheel head is raised sufficiently to give the desired clearance.

The cutter is traversed across the wheel with the spiral edge of the tooth resting on the corresponding edge of the tooth rest. In grinding the next tooth, having the alternate spiral, the cutter is traversed in the opposite direction, using

the other edge of the tooth rest. Best results will be obtained if the face of either the straight wheel or dish wheel is beveled to about 1/8" wide at the periphery or the rim.

Side Milling Cutters

The cutter is mounted on a stub arbor and clamped in the Vee of the combination attachment or in the universal work head, which is swiveled to the required angle of clearance. The tooth rest is usually fastened to the work head.

While the set-up illustrated on page 43 shows the use of a cup wheel, a straight wheel can also be used, in which case the cutter arbor is set in a horizontal position and the wheel head raised. or lowered. to produce

Figure 7-Shape of blade of tooth rest for sharpening staggered tooth milling cutters

the required clearance. The peripheral teeth of side milling cutters are sharpened in exactly the same manner as previously described for plain cutters.

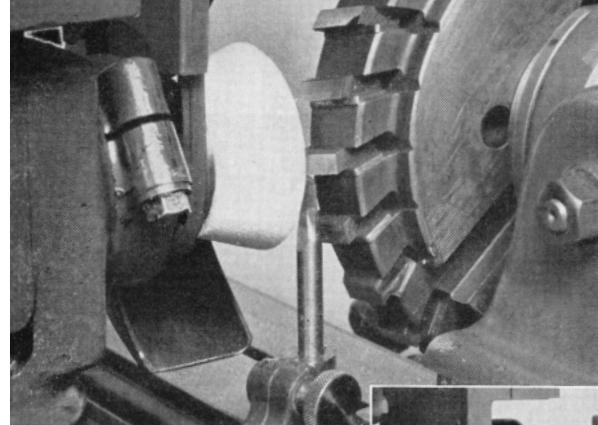

Face Milling Cutters

Special machines of suitably heavy construction are available for sharpening large face milling cutters. However, if they are not too large they may be sharpened on a universal tool and cutter grinder. They should be mounted on a tapered shank supported in the work head spindle, in

Grinding the side of a side milling cutter

Sbarpening a face mill on a special cutter grinder [43]

[ 42 ]

Grinding the periphery of the blades of an 11" face milling cutter

Grinding the face of the blades of an 11" face milling cutter

Grinding the corners of the blades of an 11" face milling cutter

the same manner as they are supported on the milling machine. The operations involved in sharpening a face milling cutter are similar to those of sharpening a shell end mill and include grinding the periphery, face or sides and corners of the blades.

The set-ups for these three operations are clearly shown in the illustrations on page 44. For cast iron, the cutting clearance on the peripheral edges should be about 4°; for soft steel, about 6°. A secondary clearance may be ground to leave a land 1/16" to 3/82" wide.

The same clearance angles are used for the face edges which for rough milling should have a land about 3/8" wide, with the remaining portion of the edge ground off at an angle of about 3° toward the center of the cutter. Finish milling is a thin shearing operation and for best results the face of the cutter should be ground off at an angle of 1° to 2° to give it a slight lead into the work. The corners of the blades are usually chamfered 45° by swiveling the work head or table and left 1/16" to 1/8" wide.

After grinding, the cutter should be carefully checked on the face with a dial indicator. If the cutter has been properly ground, taking light finishing cuts of not more than one half a thousandth per pass, will assure uniform tooth height. Here again, the new G bond wheels permit a heavier cut with less wear making it possible to hold tooth height easier

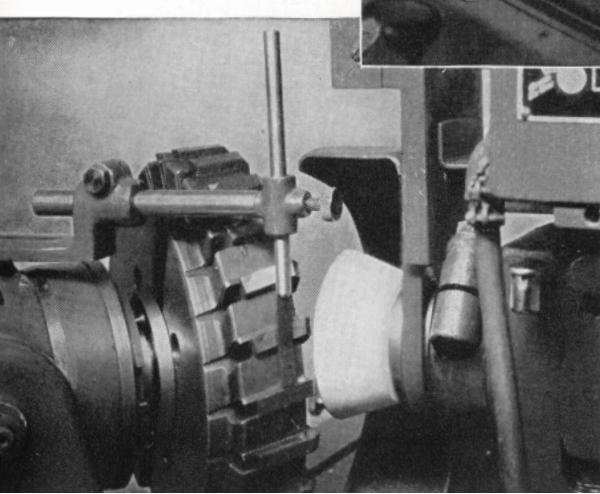

Angular Cutters

An angular cutter may be considered as made up of a number of plain milling cutters of different diameters. When grinding any cutter with a cup wheel, the clearance angle is determined from the diameter of the cutter. It follows that this method would lead to difficulties when applied to angular cutters because of the variation in the diameter of the cutter along the cutting edge. For this reason, a straight

[45]

Sharpening a double angular cutter

wheel, as shown above, is generally preferred for sharpening angular cutters.

The cutter is mounted on an arbor and supported in the universal work head or in the Vee of the combination attachment which is then swiveled to the angle of the cutter. The tooth rest is fastened to the swivel table and adjusted against the tooth to be ground. The wheel head is then raised to give the clearance desired. The cutter is held against the tooth rest by hand as it is traversed across the wheel face.

End Mills

NORTON ABRASIVES

End mills with shanks are supported in the universal work head or in the combination attachment; if of the shell type they must first be mounted on a suitable arbor. In sharpening the end teeth, the work head is generally swiveled horizontally about one-half degree from the zero line

Set-up for backing-off face cutting edges of shell end mill

so as to grind the teeth slightly low in the center of the mill and thus prevent dragging. The work head is swiveled vertically to obtain the desired clearance.

The illustration above shows a shell end mill set up for backing off the end teeth. The wheel head is tipped to the desired clearance.

Formed Cutters

Formed cutters are ground radially on the cutting face with a dish wheel. Various methods are employed for controlling the spacing of the teeth. The method illustrated involves the use of a master form as a guide for the tooth rest. The master form is milled with the same number of teeth as the cutter and its accuracy, therefore, determines the accuracy of the cutter after grinding.

Where a master form or an index center is not avail-

NORTON ABRASIVES

Sharpening a circular form cutter

Sharpening a Fellows Gear Shaper cutter [48]

able, the cutter is revolved until the face of a tooth just touches the cutting face of the grinding wheel. Previously, the wheel face and the center of the radial tooth cutter have been brought into the same vertical plane. The tooth rest is then adjusted against the back of the tooth to be ground.

Some form cutters are made with a forward rake or undercut tooth. In sharpening these, care must be taken to offset the wheel face so as to maintain the original rake angle. The amount of this offset, measured on a horizontal plane, is usually stamped on the cutter in thousandths of an inch.

The cutter is passed across the wheel face with a steady motion, using the hand traverse. While grinding, the crossfeed must not be changed as this would change the radial line of the cutter face. Instead, the cutter is given a slight forward rotation toward the wheel by slightly advancing the tooth rest. If the cutter is badly worn and there is much grinding to be done, compensation for wheel wear can be made by resetting the wheel radially just previous to a light finishing cut. To insure correct spacing of the teeth using this method, it is advisable to first grind the backs of the teeth, especially on a new cutter.

Fellows Gear Shaper Cutters

The set-up for sharpening a Fellows Gear Shaper cutter is shown in the opposite lower illustration. The cutter is supported on a face plate and tapered stud mounted in the universal work head which is swiveled horizontally to an angle of 5°, representing the rake of the cutter. After grinding, the accuracy of the cutter angle should be checked with a gauge to be sure it is exactly 5°.

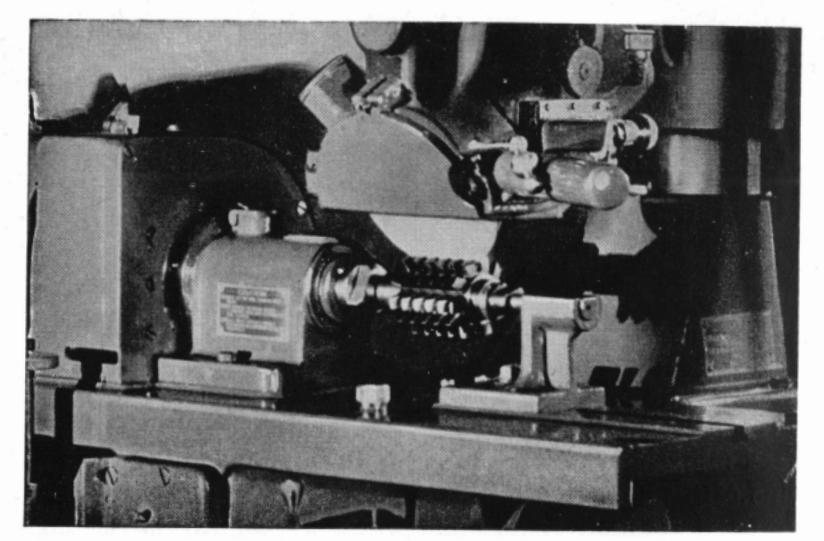

Hobs

Like formed cutters, the teeth of hobs are made with

[ 49 ]

Courtesy of Barber-Colman Company) Sbarbening a hob on an automatic hob avinder

uniform relief and are sharpened by grinding radially on the faces of the teeth, using the bevelled side of a dish wheel, or a "B" face straight wheel. The most important precaution to be observed in setting up for this operation is to line up the cutting face of the wheel with the center of the hob. Also, after each cut, the hob should be revolved toward the wheel for taking additional cuts and not adjusted to the wheel by means of the cross screw.

In the actual sharpening operation, whether it is done on a tool and cutter grinding machine or on a special hob grinder provided with automatic work spindle indexing arrangement, care must be taken to remove the same amount of stock from each tooth. It can readily be seen that if some teeth are ground back more than others, those which are left

high will have all the work to do, resulting in irregular cutting action which will affect the accuracy and finish of the teeth produced.

Hobs of average size are ground successfully with 32A60-J8VG or 19A60-I8VG Alundum vitrified wheels, dish shaped. For larger hobs, 19A54-J8VG has been found a very satisfactory specification.

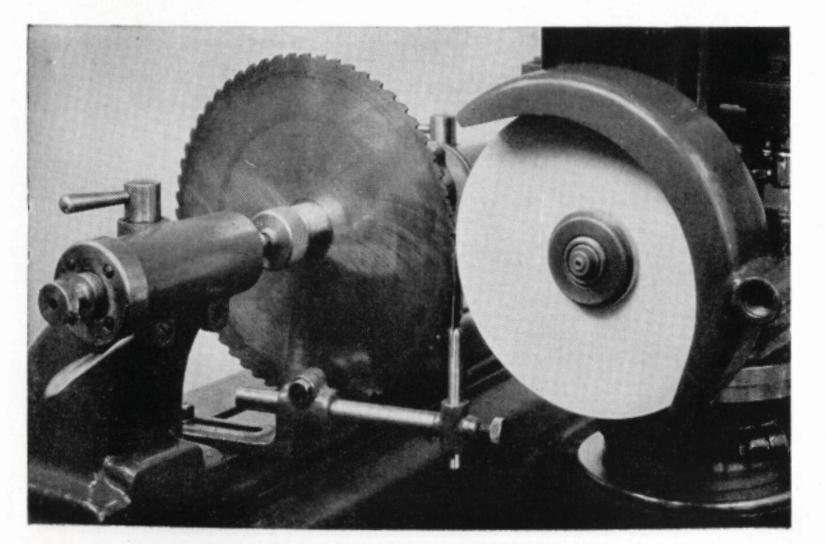

Metal Cutting Saws

Small saws are ground in essentially the same manner as milling cutters—usually with a 5° clearance angle. On very small saws the angle may advantageously be increased to about 7° while on larger saws, around 10" in diameter, for example, it should be reduced to about 3°. To minimize the effect of wheel wear, a light finishing cut should be taken completely around the saw.

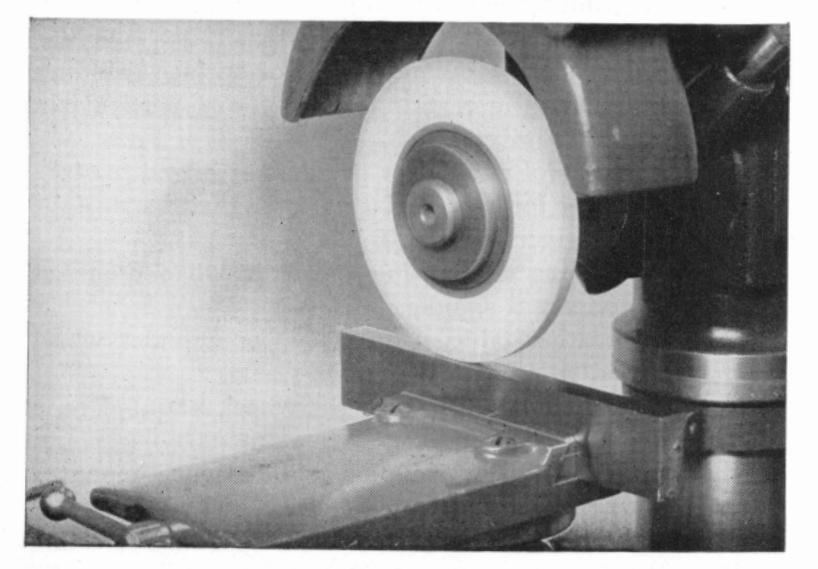

Grinding the teeth of a small metal cutting saw [51]

Either a straight or cup shaped wheel may be used. When using a straight wheel, shown in the preceding illustration, the spring tooth rest is fastened to the table and is set to rest against the tooth to be ground. The saw is usually mounted on a cutter or press arbor between centers and passed across the wheel face by traversing the table. Except in the case of very small saws, the same grain and grade of grinding wheels may be used as for sharpening milling cutters, such as 32A46-K8VG Alundum vitrified.

The set-up shown in the picture below may be used for sharpening saws which are too large for mounting between centers. The saw is supported on an arbor in the universal work head or in the Vee of the combination attachment. The tooth rest is shown mounted in the universal vise with the blade resting against the tooth to be ground. To offset the effect of wheel wear, it is common practice to divide the

A cup wheel is used to grind the teeth on this large metal cutting saw [52]

saw into quarters and start grinding on a new quarter with each complete rotation of the saw.

Chucking Reamers

There appears to be no standard method of sharpening reamers. In the case of machine or chucking reamers of the solid type, the size obviously is lost as soon as the periphery is touched with a grinding wheel. Inasmuch as most of the cutting is done by the entering corners of the blades, it is common practice to sharpen such reamers by simply grinding the lead or front bevel, usually at an angle of 45°.

When the straight cutting edges become dull to the point of requiring sharpening, the reamer is ground cylindrically to the next smaller size. The cutting edges are then backed off, leaving a land from a few thousandths to about 1/32"

Grinding the corners of the blades of a chucking reamer

ing pressure must be very light and the grinding wheel free and cool cutting to avoid drawing the temper and ruining the tap.

Considerable skill is required to properly sharpen a tap by offhand grinding and the results are usually uncertain. Special machines are available for sharpening taps accurately, insuring a uniform chamfer and the correct, uniform eccentric relief.

Grinding Wheels Recommended

Sharpening (Tap Grinders): Bench type (small taps) 32A60-K8VG Alundum vitrified Pedestal type (larger taps) 19A46-L5VG Alundum vitrified Touching up flutes: Large taps 32A60-K8VG Alundum vitrified Small taps A60-POR30 Alundum rubber Cutting off ends A60-N4E

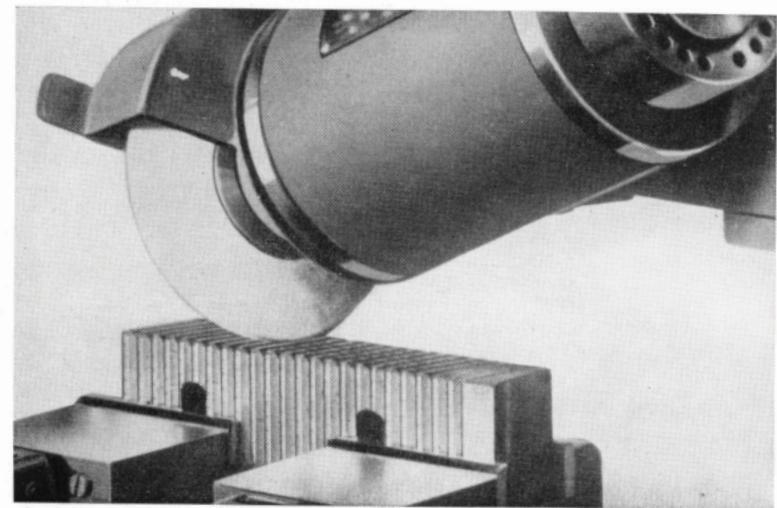

Broaches

Cutter bars, cylindrical and surface broaches are usually sharpened by grinding on the face of the teeth with a dish wheel. A small cup wheel is used for backing off the teeth to provide proper clearance or relief.

Special grinding machines are available for the sharpening of broaches of all kinds, with precision and speed. Some of these machines are designed especially for handling round, spline and cylindrical broaches. Another style is designed to take care of flat or surface broaches while a third is of a universal type for sharpening both cylindrical and surface broaches.

Universal tool and cutter grinder set up for sharpening a keyway broach

For sharpening square or rectangular broaches the machines are equipped with a swivel head slide which can also be turned in a horizontal plane. Thus broaches with teeth cut at an angle can be sharpened as easily as those with the teeth cut straight. With the broach held stationary, the grinding wheel is moved back and forth across the face of the tooth, taking light cuts.

Round broaches are sharpened by revolving on centers. Depending on the type of sharpening machine, the grinding wheel is lowered, or fed horizontally, into position adjacent to the tooth to be ground and the table then moved to bring the tooth into contact with the wheel.

The manufacturer of the broach should be consulted in regard to the correct top clearance and amount of rake or undercut. These angles depend upon the material being cut.

Set-up for grinding spiral or straight taper reamers

be taken with a ground reamer and the reamer hole tested for truth with a standard plug before using the reamer

In some tool rooms, taper reamers are sharpened by grinding cylindrically and then backing off the teeth, leaving a land a few thousandths inch wide, as in grinding straight reamers. This method insures uniform tooth height, which is important if the reamer is to cut without chattering and leave a smooth finish.

NORTON ABRASIVES

Sbarpening a large drill on a pedestal type of drill grinder

CHAPTER III

Sharpening Miscellaneous Tools

Probably no tool is given as little thought in regard to its proper use and reconditioning as the common twist drill; yet no tool is more handicapped in its effectiveness by improper sharpening, or point grinding as it is sometimes called. Excessive drilling costs and imperfect holes can in most cases be traced directly to improper grinding of the point.

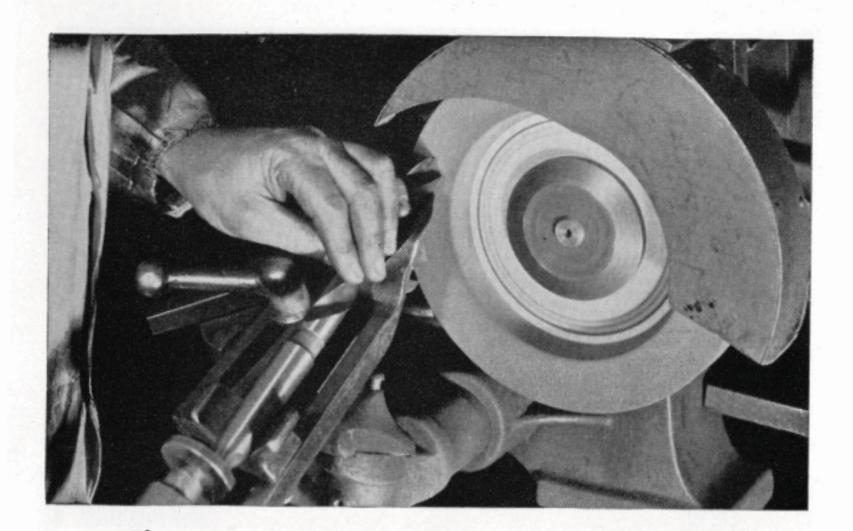

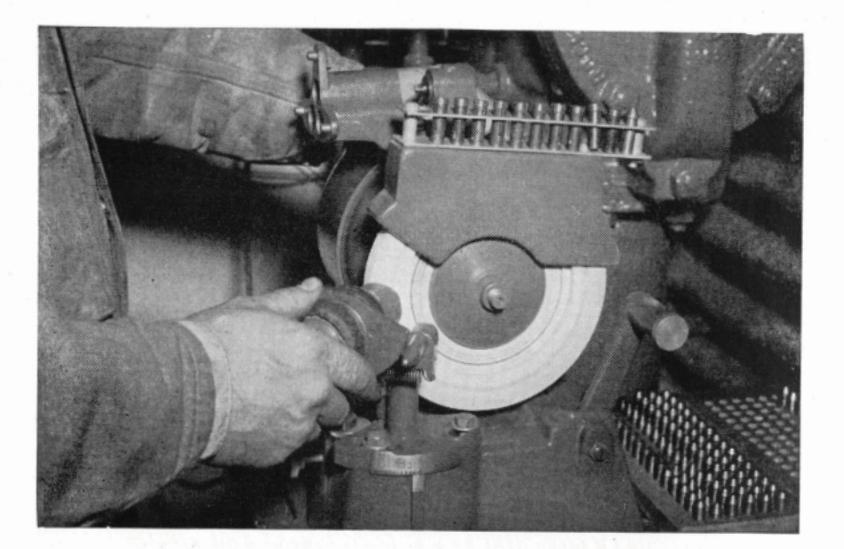

Machine grinding is recommended as the more accurate method of sharpening drills. When properly machine ground, a drill will generally cut faster, last longer and produce more accurate holes than if ground by hand. Particularly drills larger than 3/8" should be machine ground.

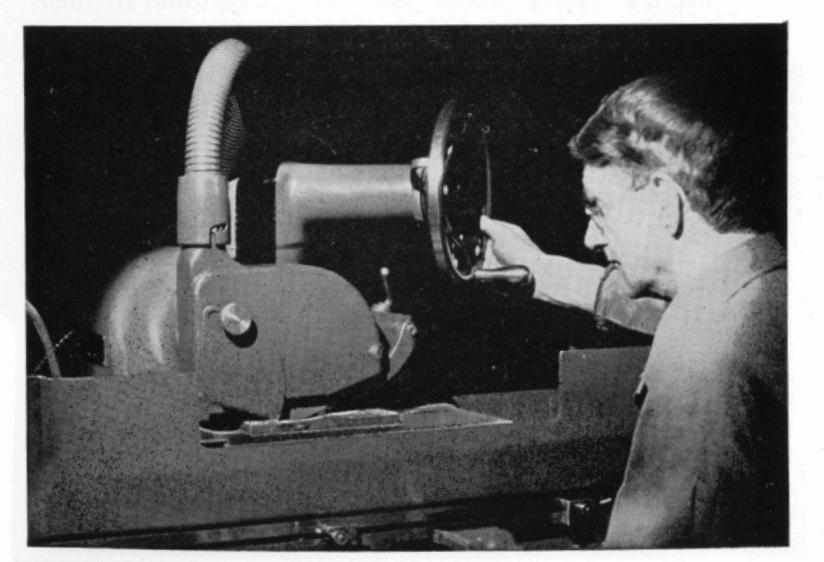

Sbarpening a small drill on a bench type of drill grinder

Reclaiming a burned drill by cutting off the end and repointing. An abrasive cut-off wheel is used [58]

In the sharpening of drills, the following precautions should be observed:

1. The lip clearance or relief behind the cutting edges should be sufficient for the drill to cut freely, yet not enough to weaken the

cutting edges.

If the lip clearance is insufficient, the drill will cut hard, heat excessively and may ultimately "split up the center." If the lip clearance is too great, the cutting edges will tend to chip and break down.

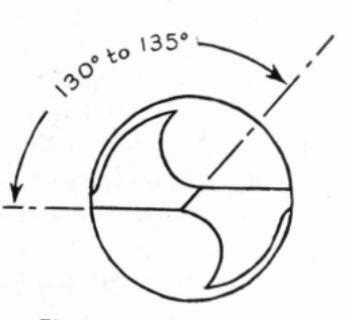

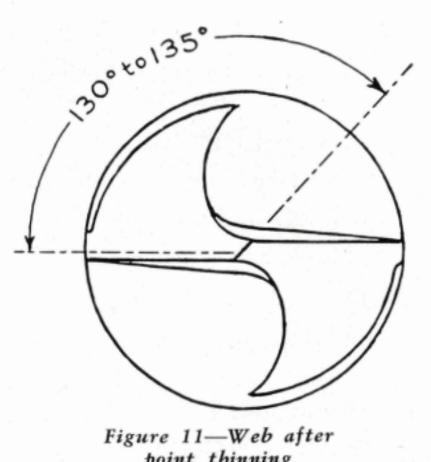

A lip clearance of 12° to 15° at the periphery of the drill (figure 8), increasing constantly toward the center, is considered standard for the average class of work. When this angle is correct, the chisel point or web intersection will be at an angle of 130° to 135° to the cutting edge (figure 10).

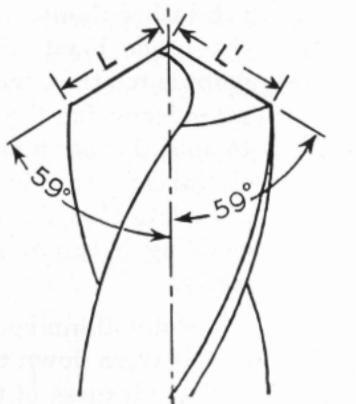

2. The two cutting lips must be inclined at the same angle with the axis of the drill (figure 9) and must be of equal length.

[ 59 ]

Figure 8—Lip clearance

Figure 9—Both lips must be at same lip angle and equal length (L = L')

If both lips are not ground at the same angle, the drill is subject to early failure as the lip having the larger angle is doing all the work; also the hole will be larger than the drill. If the lips are not exactly the same length, the point of the drill will, of necessity, be off-center and the drilled hole will be oversize

For general purpose work an included angle of 118° (commercial standard) has been found most satisfactory. For soft cast iron, a somewhat more acute angle, about 90°, will give best results. For brass, the standard angle of 118° may be used but the face of the cutting lips should be ground slightly flat.

3. After grinding the cutting edges, it may be necessary to thin the point or web (figure 11). If the width of

the point is too great, excessive pressure will be required to start the drill and it will tend to rub rather than cut. On the other hand, if the point is too thin, there is a tendency for the web to split. Proper pointing diminishes the power required to feed the drill, enabling it to cut more freely.

Figure 10—Lips properly ground but web requires tbinning

Point thinning is specially necessary when the drill is worn down to a considerable extent inasmuch as the thickness of the web increases as the shank is approached. Care should be taken not to carry the ground portion too far up the flute, and to maintain

[ 60 ]

the exact center of the drill as otherwise it will cut oversize.

Procedure in Sbarpening a Drill

1. Grind the two cutting lips so that they have the same length, the same and correct angle with the

NOPTON APPACINES

axis of the drill and the correct clearance behind the cutting edges.

2. Thin the point of the drill, if necessary, by grinding a short groove on each side of the web. The pointing may be done offhand on a round faced wheel or on a special drill point thinning machine which accurately controls the thickness of the web and automatically centers the point to insure the drill cutting true. Broken or otherwise ruined drills can often be reclaimed by cutting off the damaged section with a thin resinoid bonded cut-off wheel, and then grinding the cutting lips as in sharpening.

Grinding Wheels Recommended

Machine Sharpening:

Drills 1/4" to 1" 19A60-L5VG Alundum vitrified Numbered sizes A100-I8VG Alundum vitrified

Point Thinning:

A60-N5VG Alundum vitrified

Cutting-Off:

| Dry | Alundum | resinoid | |

|---|---|---|---|

| Wet | A60-POR30 | Alundum | rubber |

Taps

A tap used after it becomes dull works under a great strain and is apt to chip or break, cut oversize, or produce rough and poor quality of thread. The remedy is to resharpen.

A tap grinder preferably should be used, but if grinding offhand, the operator should hold the tap lightly but firmly against the face of the wheel and keep turning it slightly so that a little more will be ground off the back of the teeth to produce the necessary eccentric clearance or relief.

The amount of relief will vary with the length of the chamfer. Five degrees is ample for ordinary plug taps. Bottoming taps, which have a very short chamfer and steep taper, should be ground with correspondingly more relief in order to cut freely. For tapping brass the chamfer is often ground flat instead of with an eccentric curve to insure sufficient relief.

The length of the chamfer varies with the type of tap. It may be long as in nut taps, short as in plug taps or almost none as in bottoming taps. On the plug style of hand taps the chamfer should be ground back four or five teeth from the end.

The chamfer and the accompanying relief on the top of the threads should be identical on all of the lands of the tap. If the chamfer is uneven, the result will be holes much

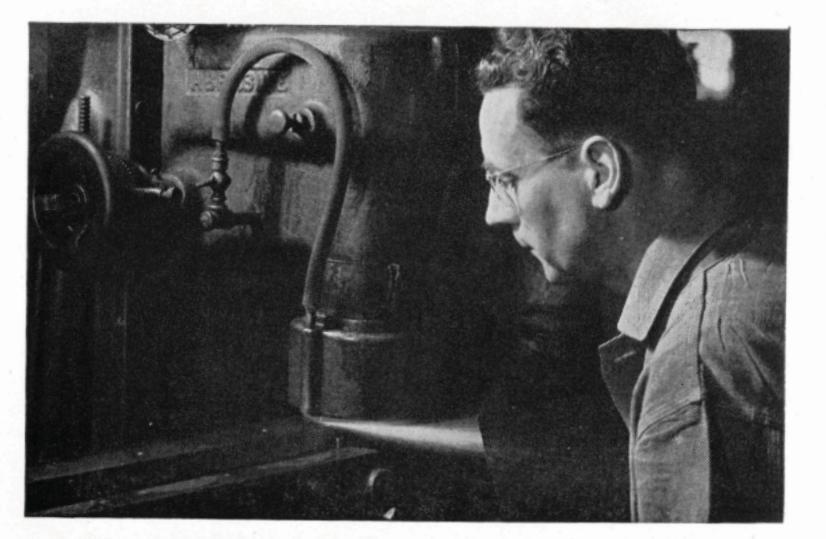

Touching up the flutes of a tap. The left hand side of this tap grinder is used for grinding the chamfer

larger than actual tap size, torn and misshapen threads, uneven wear and eventual breakage of the tap or chipping out of teeth. A good method of testing a tap to find if the lands are even is to turn about two threads through a nut and examine it from the opposite end. It can readily be seen if all of the lands are not engaging the thread.

If the edges of the teeth become dull or nicked, it is necessary to grind in the flute. This may be done either offhand by passing it under a grinding wheel having the face rounded to conform to the radius of the flute, or it may be done on a tool and cutter machine, grinding back until the cutting faces of the teeth are sharp. In either case, the grind-

ing pressure must be very light and the grinding wheel free and cool cutting to avoid drawing the temper and ruining the tap.

Considerable skill is required to properly sharpen a tap by offhand grinding and the results are usually uncertain. Special machines are available for sharpening taps accurately, insuring a uniform chamfer and the correct, uniform eccentric relief.

Grinding Wheels Recommended

Sharpening (Tap Grinders):

Bench type (small taps)

32A60-K8VG Alundum vitrified Pedestal type (larger

taps) ...... 19A46-L5VG Alundum vitrified Touching up flutes:

Large taps ....................................

Broaches

Cutter bars, cylindrical and surface broaches are usually sharpened by grinding on the face of the teeth with a dish wheel. A small cup wheel is used for backing off the teeth to provide proper clearance or relief.

Special grinding machines are available for the sharpening of broaches of all kinds, with precision and speed. Some of these machines are designed especially for handling round, spline and cylindrical broaches. Another style is designed to take care of flat or surface broaches while a third is of a universal type for sharpening both cylindrical and surface broaches.

Universal tool and cutter grinder set up for sharpening a keyway broach

For sharpening square or rectangular broaches the machines are equipped with a swivel head slide which can also be turned in a horizontal plane. Thus broaches with teeth cut at an angle can be sharpened as easily as those with the teeth cut straight. With the broach held stationary, the grinding wheel is moved back and forth across the face of the tooth, taking light cuts.

Round broaches are sharpened by revolving on centers. Depending on the type of sharpening machine, the grinding wheel is lowered, or fed horizontally, into position adjacent to the tooth to be ground and the table then moved to bring the tooth into contact with the wheel.

The manufacturer of the broach should be consulted in regard to the correct top clearance and amount of rake or undercut. These angles depend upon the material being cut.

rrtesy of LaPointe Machine Tool Company) Grinding the faces of the teeth of a flat broach

esy of Colonial Broach Company) Sbarpening the teeth of a round broach [66]

As a general rule, for cutting steel, the top clearance is 11/2° and the teeth are undercut 10° to 12°. For cast iron and non-ferrous metals, the angles are usually less.

In the process of resharpening, it is quite important to grind the radius between the teeth so that it is uniform, follows the original contour and blends into the back of the preceding tooth so as to permit the proper curling and disposal of the chips. Tearing of the surface being broached, creation of excessive heat, or unusual demands on the power required to pull the broach, may be caused by careless grinding of the radius.

Grinding Wheels Recommended

Sharpening (dish wheel) 32A60-K8VG Alundum vitrified Backing Off (cup wheel) 32A46-K8VG Alundum vitrified

Thread Chasers

Nothing contributes more to the low cost of production of accurate threads than the frequent, accurate regrinding of the chasers that comprise the cutting tools in die heads and collapsing taps.

Careful judgment must be exercised as to the length of run permitted with a set of chasers before resharpening. It is false economy to run a set of chasers to the breakdown point without taking time to resharpen them. If allowed to become excessively dulled by such treatment, the cutting edges of the teeth are subject to excessive pressure, causing more rapid wear and eventual chipping or breakage. On hard materials, especially, it is good practice to regrind the chasers frequently.

Thread chasers may be classified into five different types :

- 1. Milled chasers.

- 4. Tangent chasers.

- 2. Tapped chasers.

- 5. Circular chasers.

- 3. Collapsing tap chasers.

While all of these types of chasers are sharpened by grinding either the chamfer or the cutting face (or both), the actual methods employed may vary with the design of the chaser.

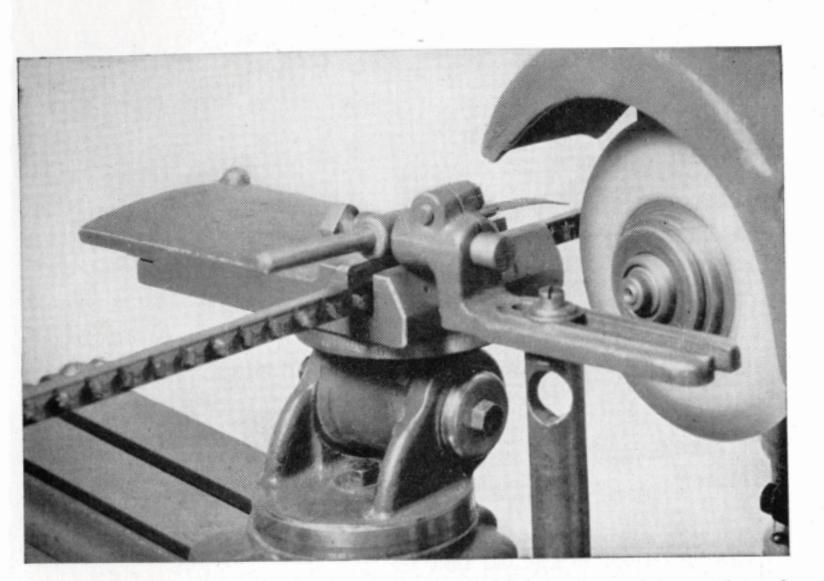

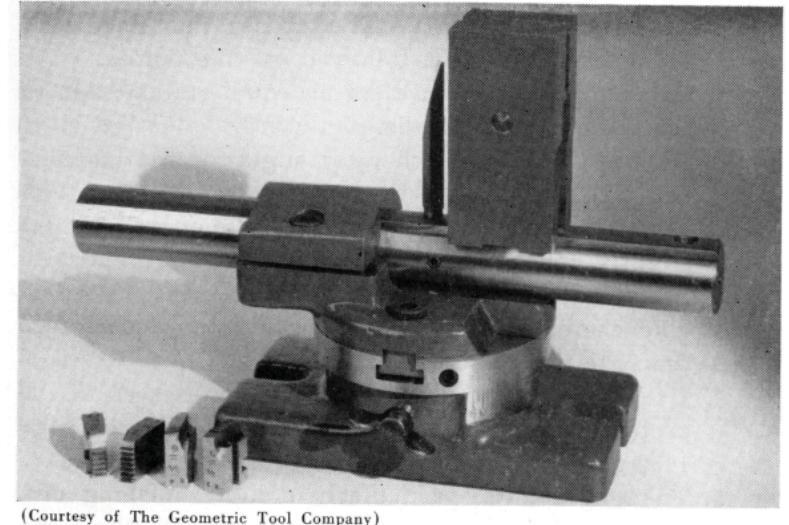

Thread chasers should not be ground by hand. Recognizing this, practically all of the manufacturers of die heads and chasers also build a chaser grinding fixture to facilitate the correct grinding of the various angles and surfaces. In addition, charts or instruction manuals are furnished on how to grind their own types of chasers. These instructions should be followed implicitly to insure accurate and uniform grinding results. The pertinent rules are outlined in a general way in the following paragraphs, according to the type of chaser.

Milled Chasers

Milled chasers are sharpened by grinding mostly on the chamfer or throat. If it is necessary to grind the cutting face, it should be done very lightly.

- 1. Grind each chaser in a set an equal amount; otherwise each chaser will not do its share of the cutting and poor threading results will follow.

- 2. Follow the original chamfer angle as closely as possible.

- 3. Use the manufacturer's recommendation as to the proper angles (see tables beginning on page 143) and settings of chaser grinding fixture.

- 4. Feed the chaser forward carefully against the periphery of the grinding wheel and at the same time traverse the chaser back and forth across the wheel face,

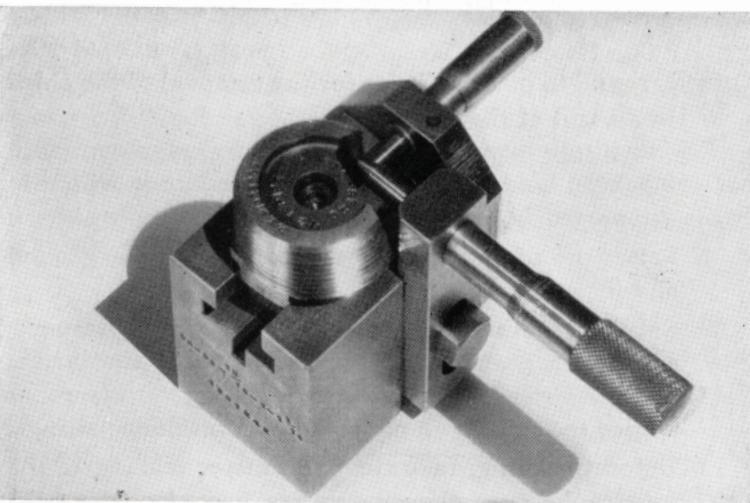

sy of The Geometric Tool Company) Fixture for grinding milled and tapped chasers

taking light cuts to be sure the chamfer angle is correct.

Grinding Wheels Recommended

On chaser grinder fixtures:

Chamfer or throat 32A80-K8VG Alundum vitrified Cutting face 32A60-J8VG Alundum vitrified On Geometric chaser grinders:

9" Straight wheel ...................................

(Model 1G only) A60-K4E Alundum shellac

9" Dish wheel ...................................

Tapped Chasers

Tapped or hobbed chasers may be sharpened by grinding on either the chamfer or the cutting face. There is some difference of opinion as to whether it is better practice to grind entirely on the chamfer and only occasionally touch

up the face, or vice versa. The chaser manufacturer's recommendations should be followed on this point.

- 1. Grind each chaser in a set an equal amount and to the same chamfer angle.

- Follow the original chamfer angle for the material being threaded.

- 3. Maintain the curvature and clearance of the chamfer slightly concave—never convex, and approximately the same curvature as the material being threaded. The chamfer should have slightly more clearance than the threads on the chaser.

- Use the manufacturer's recommendations as to the proper chamfer angles (see tables beginning on page 143) and settings of the chaser grinding fixture.

- 5. Take light cuts, particularly a light finishing cut, on each of the four chasers in a set with the same machine setting.

urtesy of The Eastern Machine Screw Corporation) Fixture for grinding the chamfers of chasers [70]

The chamfer angle is sometimes described by the terms 11/2, 2, 3, etc., thread chamfer. The following table shows the relation between the number of threads and the chamfer angle and applies to milled as well as tapped chasers.

Approximate Chamfer Grinds in Relation to Threads Recommended by The Geometric Tool Company

| Number of | Angle of Chamfer | ||||

|---|---|---|---|---|---|

|

Threads

Chamfered |

U.S.S., V, Whitworth

Thread Forms |

Acme and Similar

Thread Forms |

|||

| 1 | 45° | 330 | |||

| 11/2 | 33° | 22° | |||

| 2 | 22° | 15° | |||

| 3 | 15° | 10 | |||

esy of The Eastern Machine Screw Corporation) Fixture for grinding the cutting faces of chasers [71]

A long chamfer should be used on all chasers wherever it is possible to do so. While a 2-thread chamfer is usually satisfactory, on certain tough materials a 3-thread, or even longer chamfer, will give better results. A short 1-thread chamfer is usually used where it is required to thread close to a shoulder, but even under such circumstances it is often possible to use a 11/2-thread chamfer. It is well to remember that the longer the chamfer the less will be the stress thrown on the first full tooth of the choser

The book or rake angle will vary with the class of material to be threaded Unless otherwise ordered, tapped chasers are generally furnished with a 10° hook angle for cutting steel

The cutting edge must he the same height on each chaser in a set In resharpening, if the cutting edge is ground down nearer to the center, the hook angle should be increased slightly to give the same effect as the original amount ahead of the center. See figure 12

For example with a Figure 12-Showing increase of book 10° hook (C), and the cutting edge originally 1/2 of the diameter ahead of the center (D), the book should be increased to 20° (E) when ground down to the center

Grinding Wheels Recommended

Use same wheels as recommended for milled chasers on nage 69

Collapsing Tap Chasers

Collapsing (or adjustable) tap chasers are sharpened in essentially the same manner as tapped die head chasers, previously discussed except that the chamfer should be convey instead of concave

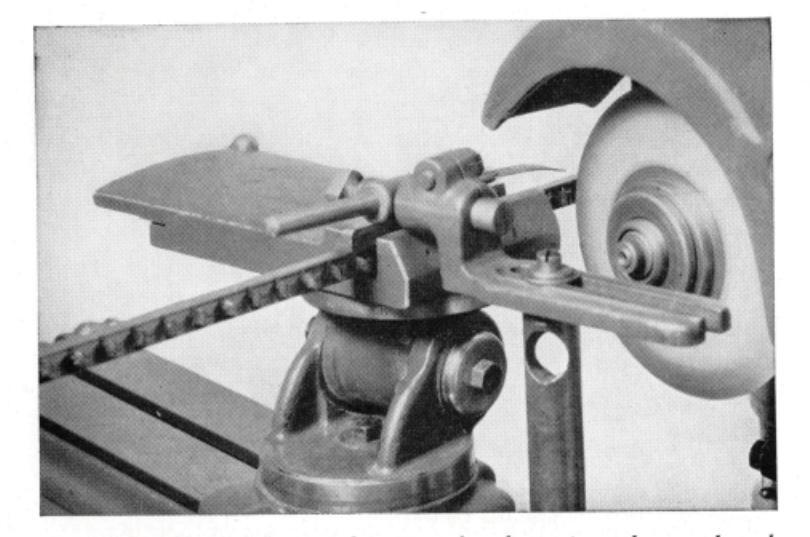

Tangent Chasers

There are two angles involved in the sharpening of tangent chasers namely the lead angle and the rake or book angle. The rake angle varies with the machinability of the material to be threaded and can be determined accurately only by experiment Tables of approximate rake angles to use as a guide are furnished by the various manufacturers of tangent chasers (See page 148)

It is impossible to lay down any general rules for sharpening tangent chasers that will have a universal application Landis Machine Company have made three general classifications affecting the grinding of their chasers which are of the non-helix type, that is, the threads are straight and the helix is in the chaser holder.

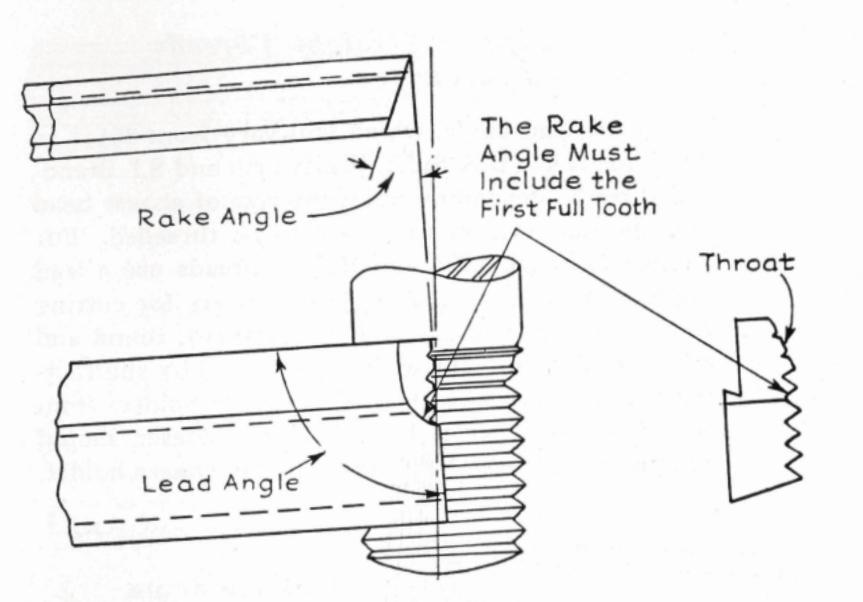

1. Straight threads out without the lead screw

2. Straight threads cut with the lead screw.

3. Tapered pine threads

ourtesy of Landis Machine Company) Grinding the rake and lead angles on a tangent chaser

The following instructions apply to the grinding of these three classifications of Landis chasers:

1. Chasers for Cutting Straight Threads Without the Lead Screw

Grind the lead angle on the cutting end of the chaser. The correct lead angle for all N.C. (U.S. Std.) Whitworth, and S.I. Standard threads is 90°. The lead angle for N.F. (S.A.E.), and B.S.F. threads is 90° for chasers of 11 pitch and coarser, and 92° for chasers of 12 pitch and finer. In the case of chasers used for cutting a special thread, the lead angle can be determined by subtracting the angle of the special chaser holder from 90° and then adding 3° to the remainder.

2. Grind the lip rake angle to include all of the throat section and the first full tooth when cutting coarse threads and the second full tooth when cutting threads of 20 pitch or finer. The first full tooth of each chaser is the finishing tooth and must be included in the lip rake angle in order for the chaser to produce cleanly-cut, well finished threads. Care must also be taken not to bevel or round the cutting edges of the chasers ground with the lip rake as otherwise they may dig into the work. For table of basic rake angles see page 148.

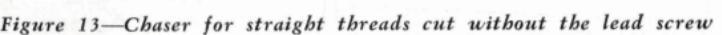

2. Chasers for Cutting Straight Threads With the Lead Screw

1. Grind the lead angle, which will vary from 861/2° to 881/4° for N.C. (U.S. Std.), Whitworth and S.I. Standard threads, depending upon the size of chaser head and the diameter of the work to be threaded. For cutting N.F. (S.A.E.) and B.S.F. threads use a lead angle of 87°. The lead angle of chasers for cutting Acme, square (with 71/2° side clearance), round and other special threads, can be determined by subtracting the lead angle of the special chaser holders from 90°. The lead angle ground on the chaser should compensate for the helix angle in the chaser holder.

Figure 14—Chaser for straight threads cut with the lead screw

[ 76 ]

Figure 15—Chaser for tapered pipe threads

thus placing the cutting edge on the center line of the work.

Grind the rake angle so that it extends across the entire width of the chaser, or without a lip rake. For table of basic rake angles see page 148.

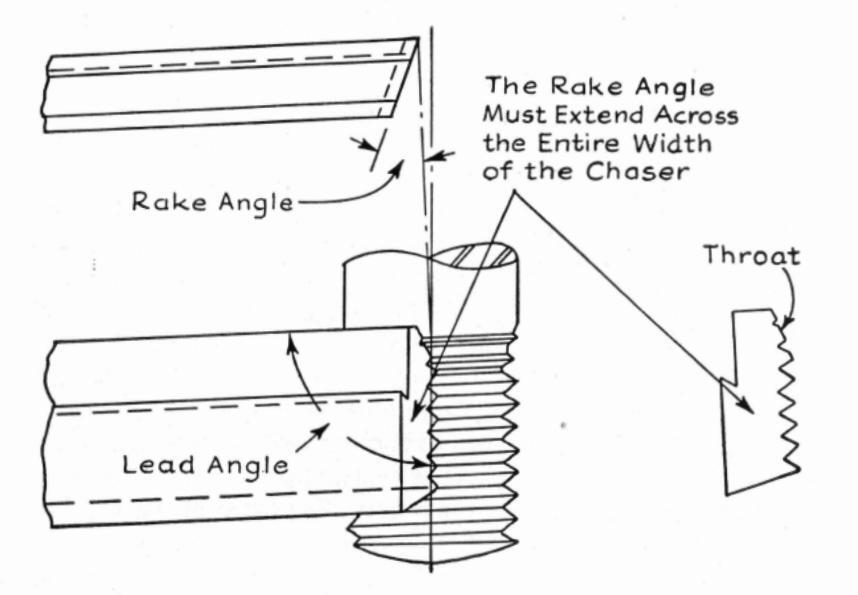

3. Chasers for Cutting Tapered Pipe Threads

The following instructions apply to chasers used for cutting tapered pipe threads without the taper attachment. When the chasers are used in conjunction with a taper attachment, they should be ground in the same manner as chasers used for cutting straight threads without a lead screw, previously described.

1. Grind the lead angle, which will vary from 88° to 901/4°, depending upon the type and size of the

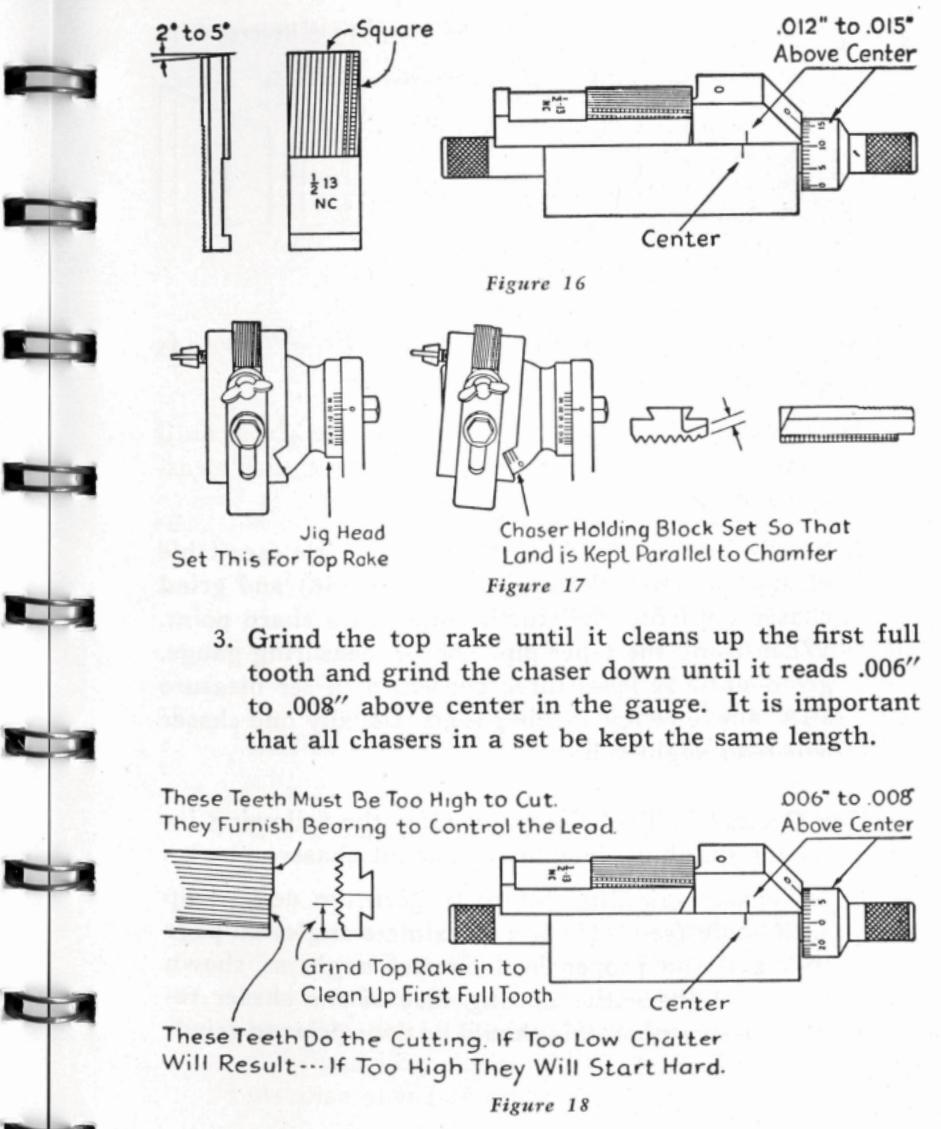

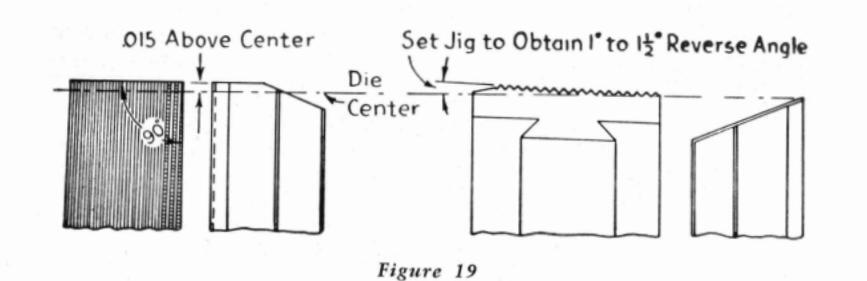

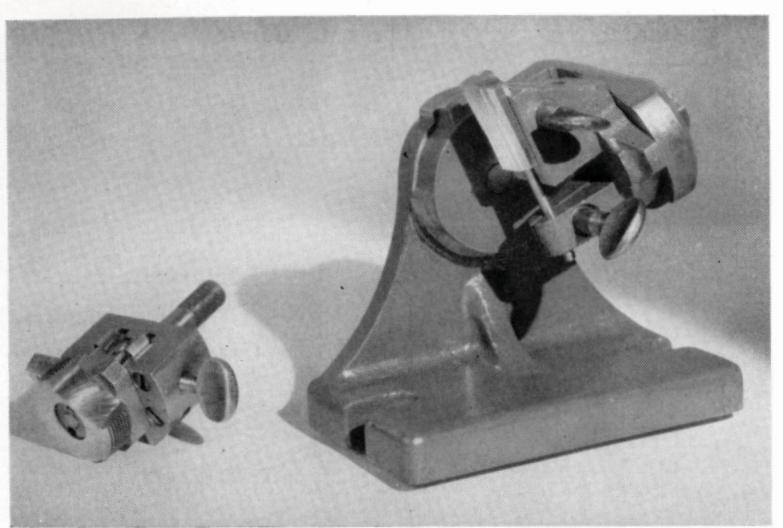

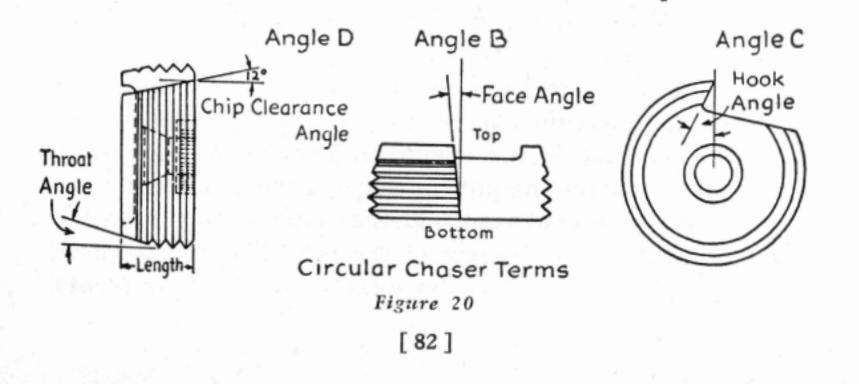

chaser head, the number of threads per inch and the taper per foot. Inasmuch as chasers for cutting taper pipe threads must cut for their entire width it is essential that the lead angle be such that the cutting edge of the chaser be directly on the center line of the work.