Northstar Trailers SPORTSTAR III User Manual

NORTHSTAR TRAILERS

Assembly Guide for SPORTSTAR III Trailer

Congratulations! You are the proud owner of a NORTHSTAR trailer. Please follow

the instructions and steps in this manual for proper assembly. You can also watch

our clip on YouTube to help you through the assembly process.

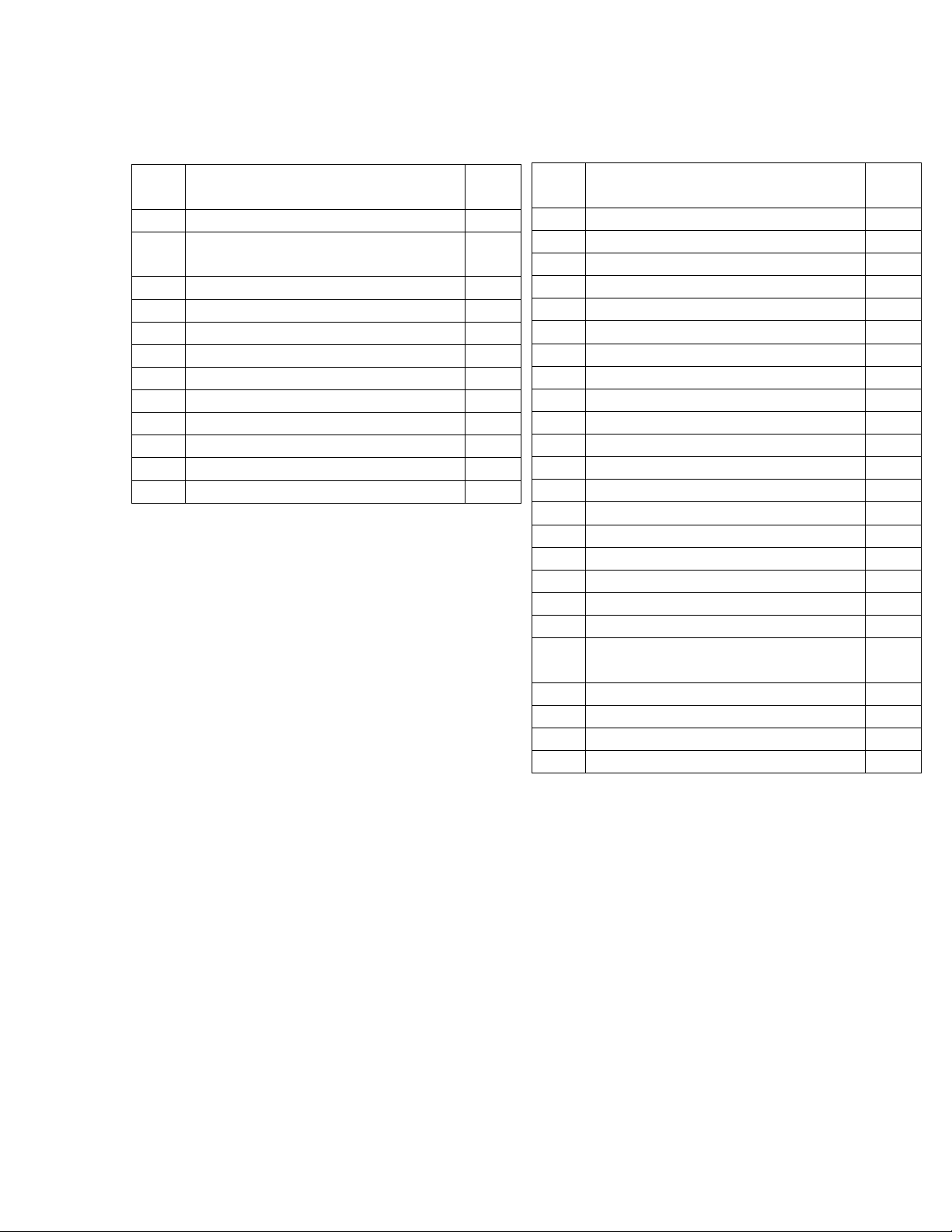

Part

No.

Part Description

Qty.

1

Frame (deck)

1

2

Tongue (with wiring harness)

and Coupler (hitch)

1

3

Side-Rail

2

4

Front Corner Bracket

2 5 Ramp

2 6 Wheel and Hub Assembly

2 7 Leaf-Spring

2

8

Axle

1

9

Fender

2

10

Tongue Side Brace

2

11

Rear Gate

1

12

Rear Corner Bracket

2

Part

No.

Description

Qty.

A

U-Bolt

4

B

Spring Plate

2 C Large Locknut

3 D 3 ½” threaded Pin-Bolt

5 E 3 5/8” threaded Pin-Bolt

2

F

Side-Rail/Gate-Pin

10

G

Ramp Pin-Bolt

2 H Large Nut

7 I Large Lock-Washer

2 J Small Lock-Washer

2

K

Small Flat-Washer

22

L

Small Bolts 1”

4 M Cotter-Pin

15

N

Spare Tire Lug Nut

2 O Taillight/Brake Light

2

P

Running Light

2

Q

Taillight/Brake Light L-Bracket

2 R License Plate Bracket

1 S Retaining Cable with Cotter-Pin

2

T

Small Brass Screw (included in

bag with blue wire connectors)

4

U

Wire Connectors

8 V Small Locknut

30

W

3 ¾” Bolt

8

X

3” Bolt

12

TRAILER PARTS LIST HARDWARE

Make sure that all parts, as listed above, are included in your shipment. If any parts

are missing please contact NORTHSTAR at 1-855-375-3088.

Other tools needed for assembly: grease gun, flathead screwdriver, socket set,

wrench set, small zip-ties, small rubber mallet.

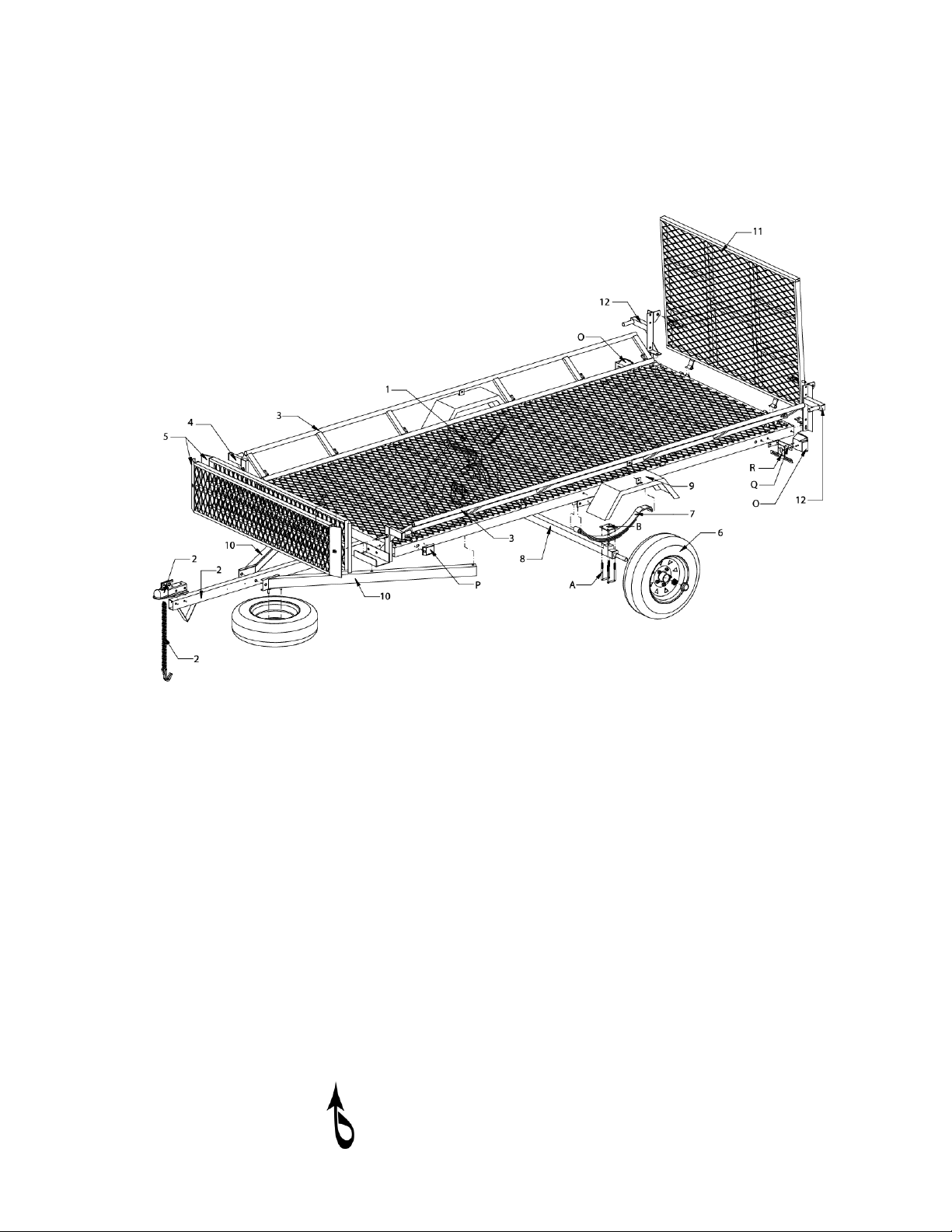

IMAGES OF PARTS AND HARDWARE

**On some trailers the spare tire mount is found on the top of the tongue.**

INVERTED ASSEMBLY

[

This trailer requires inverted assembly. (Assembled upside-down). Start by turning

the trailer frame upside-down so the trailer deck is facing the ground. Use a table

robust enough to support the weight of the trailer frame and high enough to elevate

the frame to waist-height, or place the corners of the frame on buckets, or use

sawhorses to elevate each end.

CAUTION: This trailer is heavy. More than one person is required to flip the trailer

frame and assembly this trailer. Personal injury may occur if you try to assemble this

trailer alone.

STEP 1: LEAF SPRING & AXLE ASSEMBLY

a. Flip the trailer frame (1) upside-down, and place the frame on a waist-high

table or other elevated supports in order to facilitate assembly.

b. Position the leaf-spring (7) on the frame’s spring casing (welded to the

frame) so the eye in the leaf-spring is positioned toward the front of the

trailer and aligns with the bolt eyehole in the spring casing.

c. Fasten the leaf-spring to the casing with 3 ½” pin-bolt (D) and a large nut (H)

by inserting the bolt through the leaf-spring and through the eyeholes in the

casing. (Leave tension loose to allow play when aligning the axel; you will

securely tighten bolts in step “i”.)

d. Secure the hooked end of the leaf-spring to the casing by running a 3 ½” pin-

bolt (D) through the eyeholes of the leaf-spring casing and over the flat side

of the leaf-spring. Fasten the bolt with a large nut (H).

e. Lay the axel (8) on top of the leaf-springs, and align the holes in the axel

knobs with the posts on the leaf-springs. The axle will lie snug on top of the

springs.

FASTEN AXLE TO LEAF SPRINGS

f. Take two U-bolts (A) and slide them over the axle, so the bolts hang over the

axle and on both sides of the leaf-springs. Attach the spring-plate (B) to the

U-bolts using the small locknuts (V), and then tighten the locknuts to fingertightness.

g. Once all of the locknuts are on the U-bolts, tighten the locknuts in alternating

sequence in order to ensure an even, level plate pressure.

h. Continue to tighten the locknuts until the spring-plate just begins to bend

and conform to the shape of the leaf-spring. (Approximately 35 ft-lbs of

torque).

i. Securely tighten the bolts from step “c” and “d”. After tightening the bolts,

insert a cotter-pin (M), then secure the cotter-pin by bending at least one leg

to 90 degrees.

Loading...

Loading...