North Star M157551A, 157551 Owner's Manual

It em # 157551

M157551A

Proven Performance

Owner’s Manual

Pressure Washer

00078

Read a nd understand this m anual before ope rating

this machine.

Engine is shipped without oil. Use SAE 30 motor

oil.

Pump is shipped with oil. Remove the shipping

plug from the pump and replace it with the vented

dipstick.

To the Owner:

Thank you for purchasing a North Star pressure w asher. Your machine is

designed for long life, dependability, and the top performance you demand!

Take time now to read through this manual so you better understand the

machine’s operation, maintenance and safety precautions. Everyone w ho

oper ate s this machine must rea d and unders tand this m anual. The t ime

you take now will pr o long y our m a c hine ’s lif e a nd pr e pa r e y ou f or its s a fe

operation. Enjoy the exceptional performance of your North Star pressure

washer, t he in du st ry leader!

Important

If this machine is used by anyone who is not the

owner or is loaned or rented, make certain the

operato r( s) prio r t o op erat ing:

- I s inst ructed in saf e and p rop er

operation of this machine

- Reads and understands the manual(s)

pertaining to this machine

Notic e

The manufacturer reserves the right to make

improvements in design and/or changes in

specifications at any time without incurring any

obligation to install them on units previously sold.

2

Table of Content s

Sa fe ty Instr u cti o ns 4- 5

Specifications 6

Machine Comp onent Identif ic ation 6-8

Assem bling the Machine 9

Bef or e Using the M ac hine the First Time 10

Set ting up the Machine 11

St ar t-Up I nstr uc tions 12-15

Shut - Down I nstr uc tions 16

Oper ating the Machine 17-19

Routine Maintenance 20-21

Winterizing the Machine 22

Tr oubleshooting Guide 23

Accessories 24

3

Safety Instructions

Read and understand these instructions

because they deal with safety. Pay particular

at te nt ion to this s a fe t y sym bol t hr ou ghout t h is

manual. Failure to comply with these

instructions may result in property damage,

personal injury, or death.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety

and Health Act. These standards, particularly the General Standards, Part 1910, and the

Construction Standards, Part 1926, should be consulted whenever using airless spray equipment.

NEVER point the spray nozzle at people or

animals. The high pressure the machine

generates i s very dangerous.

ALWAYS place the machine on a level

surface.

ALWAYS seek emergency medical care if

any fluid penetrates the skin. The cut may

be dee per and mor e ser io us tha n it app ear s.

NEVER put hands or fingers over the tip of

the spray nozzle.

NEVER use your hands to stop or detect

leaks.

NEVER spray flammable liquids or toxic

chemi cals such as weed killer or insecticide.

NEVER all ow children to operate or play on

or around the machine.

ALWAYS wear safety glasse s and

appropriate clothing when operating the

machine.

NEVER operate the machine in or around

an explosive environment.

ALWAYS locate the machine so it is

protected from external damage.

NEVER oper ate gasol ine pow er ed mach i nes

indoors. Carbon monoxide fumes are

deadly.

NEVER operate the machine with broken or

mis sing parts.

NEVER alter the machine from the

manufacturer’s original design.

ALWAYS keep all safety devices active on

the mac hin e.

ALWAYS follow the chemical

manufacturer’s instructions when using

chemicals.

ALWAYS understand all safety precautions

and first aid for any chemicals bei ng used.

NEVER exceed the pressure or temperature

ratings of the system. Be sure all accessory

equipment used will withstand the system

pressure.

ALWAYS keep the pressure hose

connected to the m achi ne and the spray gun

while the system is pressurized.

NEVER move the machine by pulling on the

hose.

NEVER secure the spray gun in the “ON” or

“SQUEEZED” position.

4

Safety Instructions

NEVER use the machine when under the

influence of alcohol or any other drug.

NEVER smoke while operating or fueling

thi s machine. Only add fuel to the machine

when the power is OFF.

NEVER attempt to clean the machine with

its o w n spray. Cleaning should be done wi th

a damp sponge wi th the power OFF.

NEVER leave an operating machine

unattended. Always shut the engine OFF

and relieve the pressure before leaving the

machine.

NEVER let the pump run without water

flowing through the machine.

ALWAYS respect and be alert to the

pot entia l haz ar do us hi gh pr essure s pr ay .

ALWAYS keep machine decals clean and

legible, replace any decals that become

damaged or lost.

NEVER ro ute ho ses in a ma nne r tha t will

cause sharp bending, kinking, cutting,

abrasion, or other damage from vehicles or

falling objects.

NEVER use a hose if exterior damage is

evident.

NEVER attempt field repairs through an

unauthorized hydraulic hose repair shop.

Replace any damaged hoses.

ALWAYS use water that is clear and free of

parti cles.

NEVER run preheated water over 140° F

into the machine.

ALWAYS check and maintain proper oil

level s in the pump and engine.

NEVER operate the machine with

insufficient water supply to the pump.

Damage occurs to the pump if run with an

insufficient water supply.

ALWAYS protect your machine from

freezing during storage as descri bed in this

manual .

ALWAYS follow all other guidelines and

safety instructions as described in this

manual .

A ny Q uestions?

Call 1- 800- 270- 0810

Customer Se r vice

5

Specifications

8

It em Nu mber #157551

Pressu re Rating (psi ) 2500

Flow Output (gpm) 3

Pump Type Triplex Ceramic Plunger

Water Supply Standard tap water @ 20-100psi

En gine Hor s e pow e r 5

Fuel Ca pa c ity (qua r t s ) 3

D ischarge Hose 3/8” x 30’

Dimensions

Length 28”

Width 19.5”

Height 24”

Approximate Weight 88 l bs.

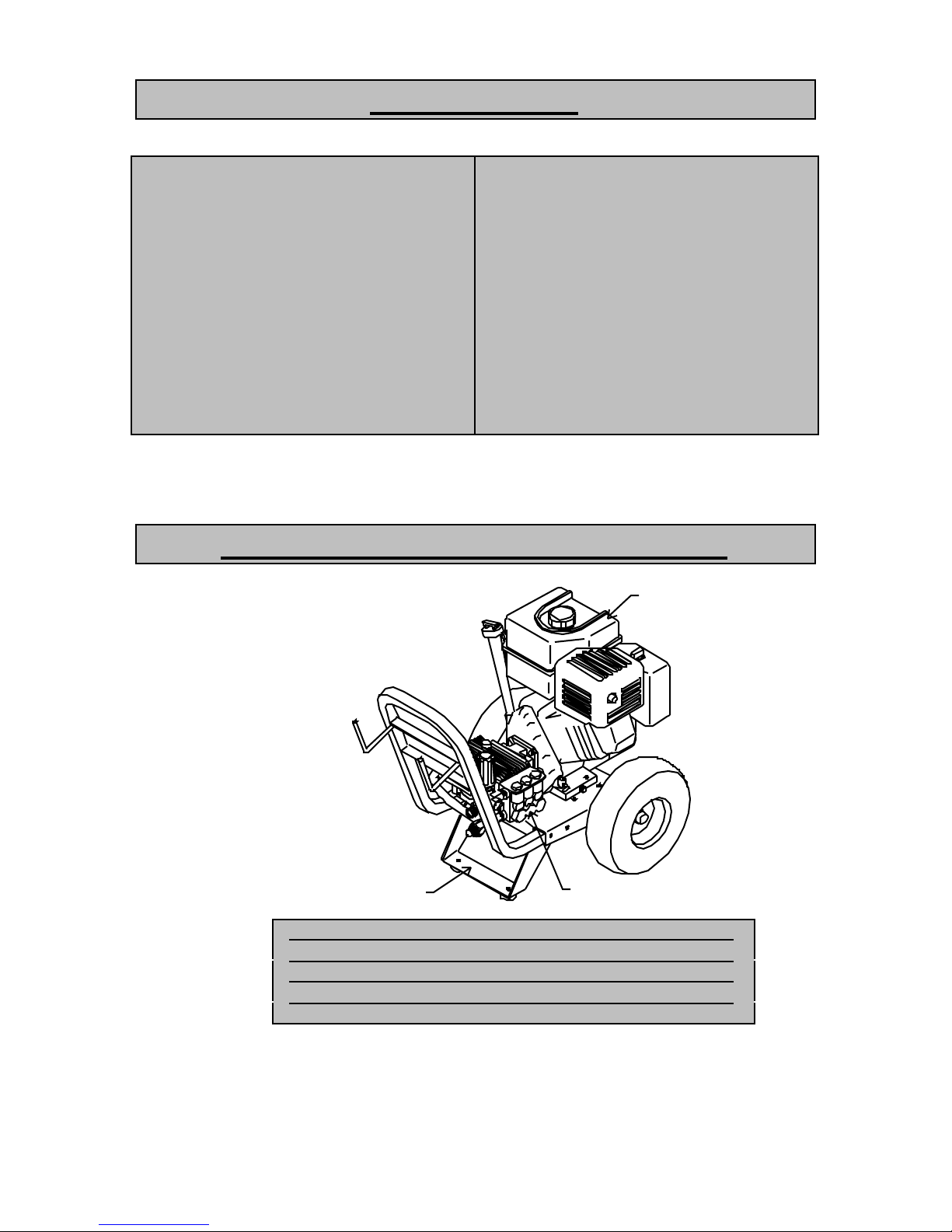

M achine Component Identification

3

1. Engine

2. Pump

3. Cart

1

0007

2

6

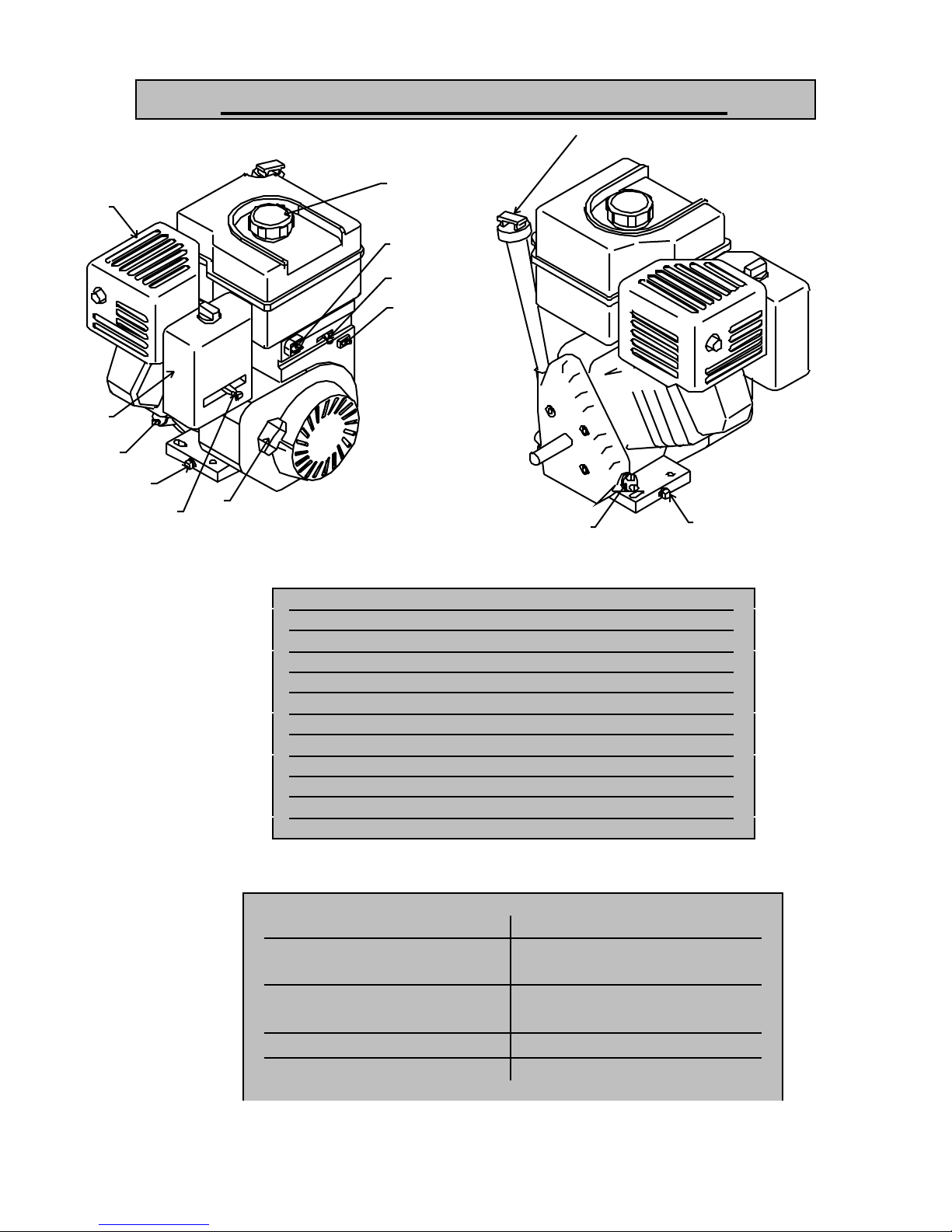

M achine Component Identification

3

2

0

9

0

7

5

1

4

1

9

0008

8

6

0007

7

8

1. Engine ON-Off Switch

2. Choke

3. Fuel Shut-OFF

4. Throttle

5. Fuel Tank Fill

6. Recoil

7. Oil Fill

8. Oil Dr ain

9. Air Filter

10. Muffler (Cauti o n H ot! )

En gine Fea tur e s Benefits

• Overhead Valves

(OHV)

• Cast Iron Cylinder

• More f uel efficient

• More powerful

• Less wear, longer l ife

Sleeve

• Low Oil Shutd own • Won’t r un without oil

7

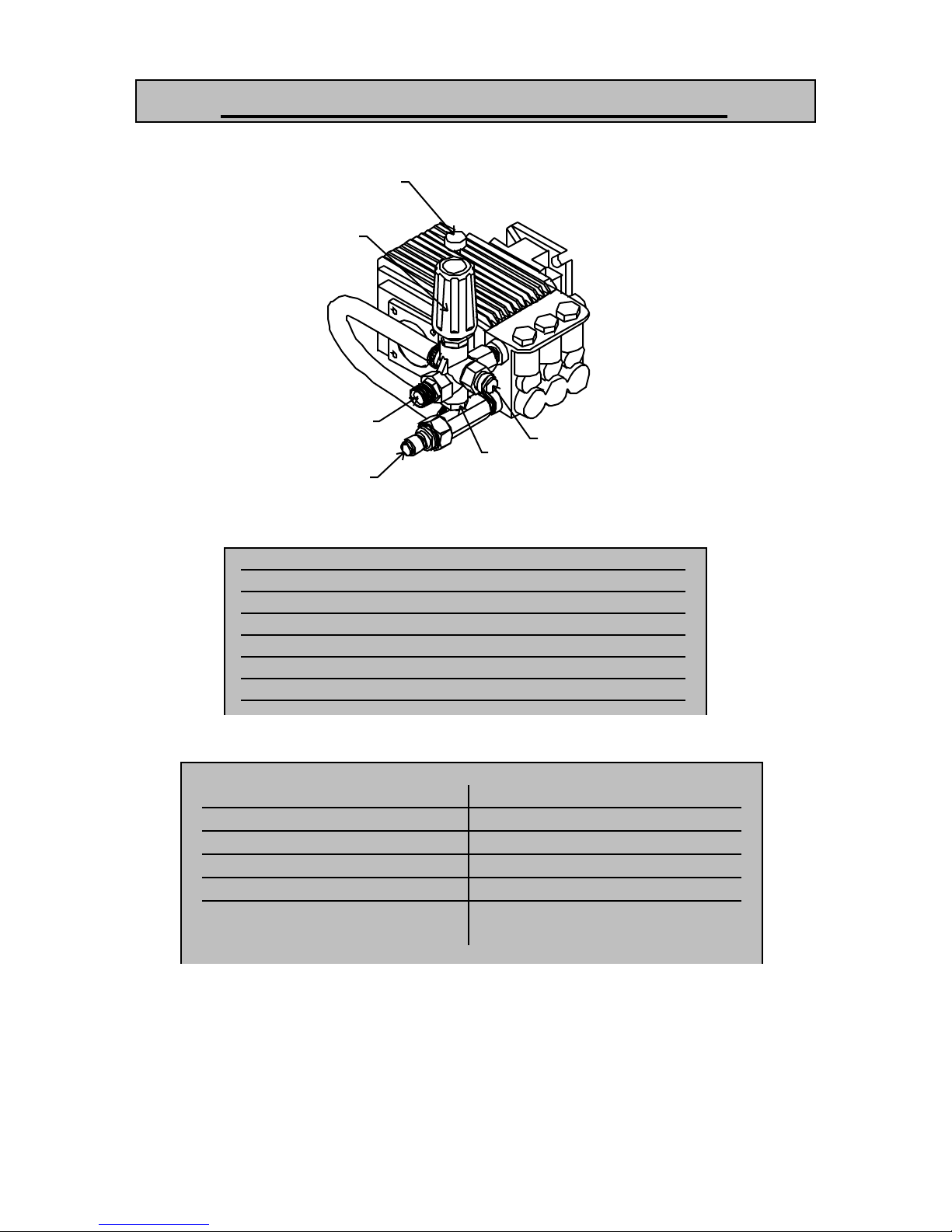

M achine Component Identification

6

1

5

2

00089

3

4

1. U nloader Valve

2. Thermal Protector

3. Safety Relief Valve

4. Inlet

5. Outlet

6. Dipstick

Pump Features Benefits

•Triplex ceramic p lungers •Long life, no cor rosio n

•Triplex desi gn •Less vibration

•Industr ial crankshaft •Dependa ble, proven design

•Thermal protec tor •P r otects pump fr om hot water

•S afety r elief v alve •P r ev ents pu mp fr om

overpressuriz ing

8

Loading...

Loading...