Page 1

Proven Performance

K-BAR Industries, Faribault, MN, 55021

M157305G

ITEM NUMBER: 157305,306,307,308

SERIAL NUMBER:

HP:______ Volts:______ Amp:______ Ph:_____

RPM:____ PSI:____ GPM:____ Nozzle Size:_____

Pump:___________ Hose:______ Lance:_______

Max. Discharge Temperature:_____________

Installation, Operation, and Maintenance Manual

HOT WATER PRESSURE WASHER: Cleans dirty surfaces with high-

pressure hot water.

To the Owner:

Thank you for purchasing a Northstar hot water pressure washer. Your machine is designed for long life,

dependability, and the top performance you demand! Take time now to read through this manual so you will

better understand the machine’s operation, maintenance and safety precautions. Everyone who operates this

machine must read and understand this manual. The time you take now will prolong your machine’s life and

prepare you for its safe operation. Enjoy the exceptional performance of your Northstar hot water pressure

washer, the industry leader! The manufacturer reserves the right to make improvements in design and/or

changes in specifications at any time without incurring any obligation to install them on units previously sold.

Quick Facts

Pump Oil Pump is shipped with oil. Change oil plug if and check pump oil level before starting.

Use UTTO for Comet and Cat Pump oil (item# 22158) for Cat oil changes.

Water Make sure your water flow is 20% higher than the pressure washer’s flow rate.

Make sure your water is clean and particle free.

Storage Do not allow water to freeze in the pump, hose, coil, or spray gun.

Spraying

Chemicals

Maintenance

Schedule

Use any North Star brand or equivalent pressure washer chemicals.

Pump Oil: change after first 50 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

Any Questions, Comments, Problems or Parts Orders

In the United States

Northstar Customer Service

Call 1-800-270-0810 Northern Tool and Equipment Co. (UK) Ltd.

Hours: Monday - Friday 7:00 AM to 5:30 PM Unit 2, Keel Close,

Saturday 7:30 AM-11:30 AM Central Time Portsmouth, Hants PO3 5QD, England

In the United Kingdom

Call 02392639752

Page 2

Table of Contents

Important Safety Instructions 2 Safety Features 13

Grounding Instructions 3 Maintenance Instructions 13-16

Extension Cords 3 Moving and Handling Instructions 17

Specifications 4 Long Term Storage 17

Machine Component

Identification

Installation Instructions 6-9 Parts Breakdowns 19-21

Operation Instructions 10-12 Wiring Diagram 22-24

5 Troubleshooting 18

Important Safety Instructions

WARNING -Risk of Injection or Injury to Persons - Do Not Direct Discharge Stream at Persons - Do not use

a hose if exterior damage is evident.

-Risk of explosion - Do not spray flammable liquids - Do not operate in a flammable environment.

CAUTION -Risk of Asphyxiation - Exhaust fumes are deadly. For outdoor use only. Avoid inhaling exhaust

fumes.

-Risk of fire. Do not add fuel when the product is operating or hot.

-Gun kicks back. Hold with both hands.

-To reduce the risk of injury, read operating instructions carefully before use.

WARNING - When using this product basic precautions should always be followed, including the following:

1.) Read all the instructions before using the product.

2.) To reduce the risk of injury, close supervision is necessary when the product is used near children. Do

not allow irresponsible use by children. Always stop the product and bleed pressures before leaving

unattended, disconnecting hoses, or servicing the pump.

3.) Know how to stop the product and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate the product when fatigued or under the influence of alcohol or drugs. Never smoke while

operating or fueling this machine.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces - Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.) Do not operate this machine with broken or missing parts - Never alter the manufacturer’s original

design or deactivate any safety device on the machine.

11.) Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid for

all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning filters.

Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories meet

or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.) Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.)To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

motor OFF.

16.) NEVER attempt to immediately run or re-light the burner if it doesn’t ignite the first time. Unburned oil or

gas may have accumulated causing potential explosion or fire hazard.

17.) Always make sure all switches and controls are in the OFF position prior to plugging in the electrical

cord. Do not stand in water while plugging and unplugging electrical cord.

18.) This product is provided with a ground fault circuit interrupter built into the power cord plug. If

replacement of the plug or cord is needed, use only identical replacement parts.

2

Page 3

Grounding Instructions

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electrical shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment - grounding conductor can result in a risk of electrocution. Check with a

qualified electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product - if it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not

use any type adapter with this product.

1. For a product rated 125 volts or less:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

This pressure washer is provided with a ground fault circuit interrupter (GFCI) built into the plug of the power supply cord.

This device provides additional protection from the risk of electric shock. Should replacement of the plug or cord become

necessary, use only identical replacement parts that include GFCI protection.

2. For a product rated more than 125 volts:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electric Code (NFPA 70) and to provide additional protection from the risk of electric shock,

this pressure washer should only be connected to a receptacle that is protected by a ground fault circuit interrupter

(GFCI).

Extension Cords

Use only 3-wire extension cords that have 3 prong grounding-type plugs and 3-pole cord connectors that accept the plug

from the product. Use only extension cords that are intended for outdoor use. These extension cords are identified by a

marking “Acceptable for use with outdoor appliances; store indoors while not in use.” Use only extension cords having an

electrical rating not less than the rating of the product. Do not abuse extension cord and do not yank on any cord to

disconnect. Keep cord away from heat and sharp edges. Always disconnect the extension cord from the receptacle

before disconnecting the product from the extension cord.

Warning - To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch plug with wet

hands.

SAVE THESE INSTRUCTIONS

3

Page 4

Specifications

Item Number

Pressure Rating 1700 psi 2700 psi 2000 psi 2750 psi

Flow Output 1.5 gpm 2.5 gpm 1.5 gpm 2.5 gpm

Pump Type Ceramic Triplex

Water Supply Standard tap water

Motor Horsepower 1.5 hp 5 hp 2.0 hp 5 hp

Maximum

Temperature

Approved Fuels #1 or 2 Diesel,

Fuel Capacity 8.25 gal. 8.25 gal. 8.25 gal. 8.25 gal.

Discharge Hose 3/8” x 50’ 3/8” x 50’ 3/8” x 50’ 3/8” x 50’

Power

Requirements

Dedicated NEMA

Receptacles

Volts 115V 230V 115V 230V

Amps 20A 30A 20A 30A

Hertz 60Hz 60Hz 60Hz 60Hz

Phase single single single single

Dimensions

Length 38” 38” 38” 38”

Width 26” 26” 26” 26”

Height 43” 43” 43” 43”

Ship Weight 385 lb. 415 lb. 385 lb. 415 lb.

157305 157306 157307 157308

Ceramic Triplex

Plunger

@ 20-100psi

250°F 250°F 250°F 250°F

Kerosene, Fuel Oil

5-20R 6-30R 5-20R 6-30R

Plunger

Standard tap water

@ 20-100psi

#1 or 2 Diesel,

Kerosene, Fuel Oil

Ceramic Triplex

Plunger

Standard tap water

@ 20-100psi

#1 or 2 Diesel,

Kerosene, Fuel Oil

Ceramic Triplex

Plunger

Standard tap water @

20-100psi

#1 or 2 Diesel,

Kerosene, Fuel Oil

4

Page 5

Machine Component Identification

157305, 157306, 157307, 157308

Ref # Description Ref # Description Ref # Description

1 Exhaust Vent 10 Flow Switch 19 Fuel Filter

2 High Pressure Water Outlet 11 Tee 20 Quick Connector

3 Motor 12 Safety Relief Valve 21 Spray Gun

4 Burner 13 Pump 22 Grip

5 Fuel Fill Cap 14 Gun Hooks 23 Lance Wand

6 Fuel Tank 15 Power Switch 24 Power Cord Hangers

7 Control Box 16 Thermostat 25 High Pressure Hose Hanger

8 Elbow 17 Service Panel 26 Garden Hose Water Inlet

9 Swivel Fitting 18 Nozzles

5

Page 6

Installation Instructions

I.) Unpack

Separate and identify all components. Use the assembly instructions in this manual for assembly.

Spray Gun & Grip

Qty-1

High Pressure Hose

Qty-1

Fastener Bag

Qty-1

Wheel Retainer

Qty-2

Wheel

Qty-2

Pressure Washer

Qty-1

Nozzle

Qty-6

6

Page 7

II.) Assembly Instructions

A

A. 1. Carefully raise the pressure washer off the floor by

using blocks or ramps. Make sure the pressure

washer is secure before proceeding.

2. Install the two wheels as shown with grease zerk

away from frame.

3. Slide the two wheel retainers onto the end of the

axle. Tighten the set-screw with a hex wrench.

Description Qty.

Wheel 2

Wheel Retainer 2

B. 1. Install the pressure hose onto the pressure washer

as shown.

2. Connect the other end of the pressure hose to the

spray gun as shown.

3. Make sure all plumbing connections are tight.

Description Qty.

Spray Gun/ Lance 1

Spray Hose 1

Wheel Retainer

xle

Wheel

Grease Zerk

7

Page 8

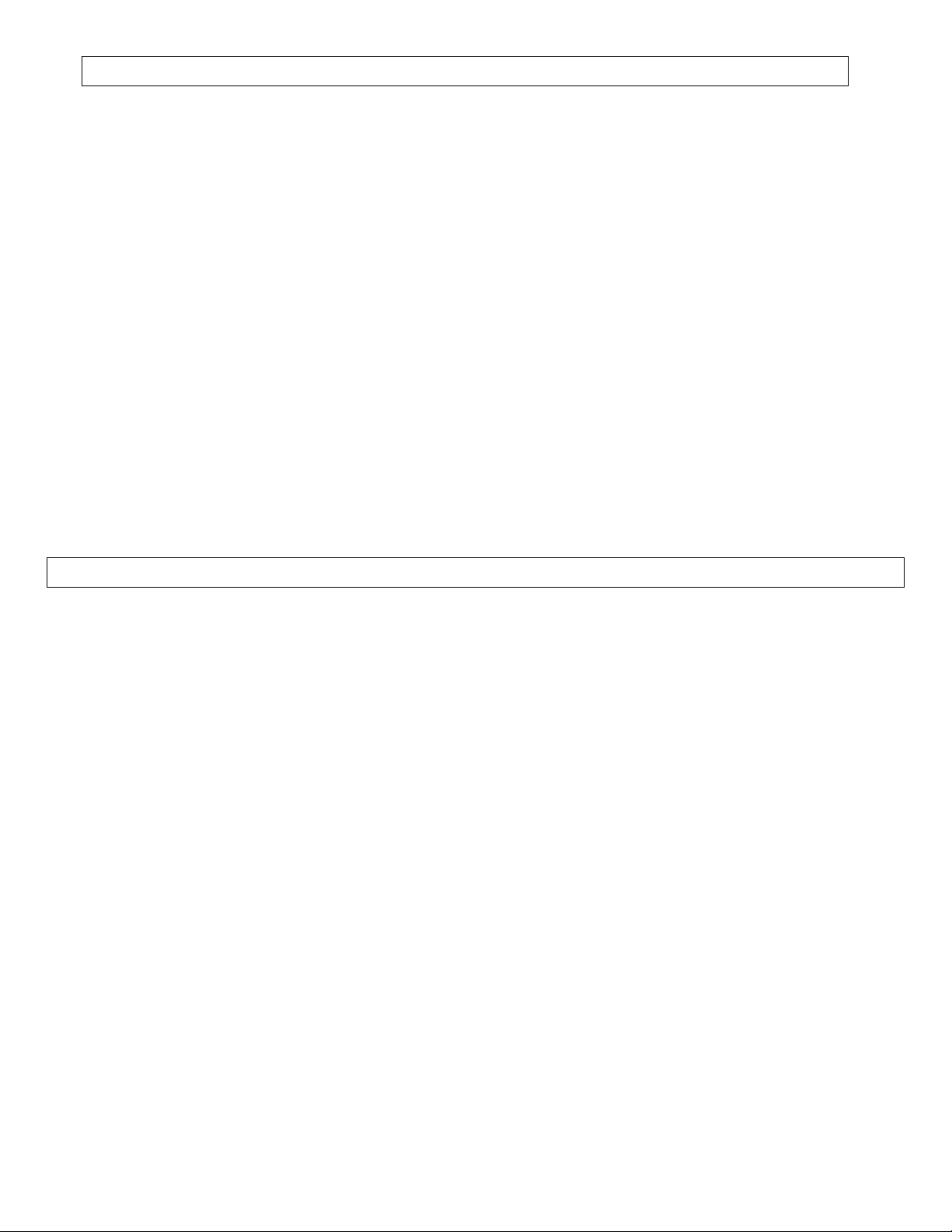

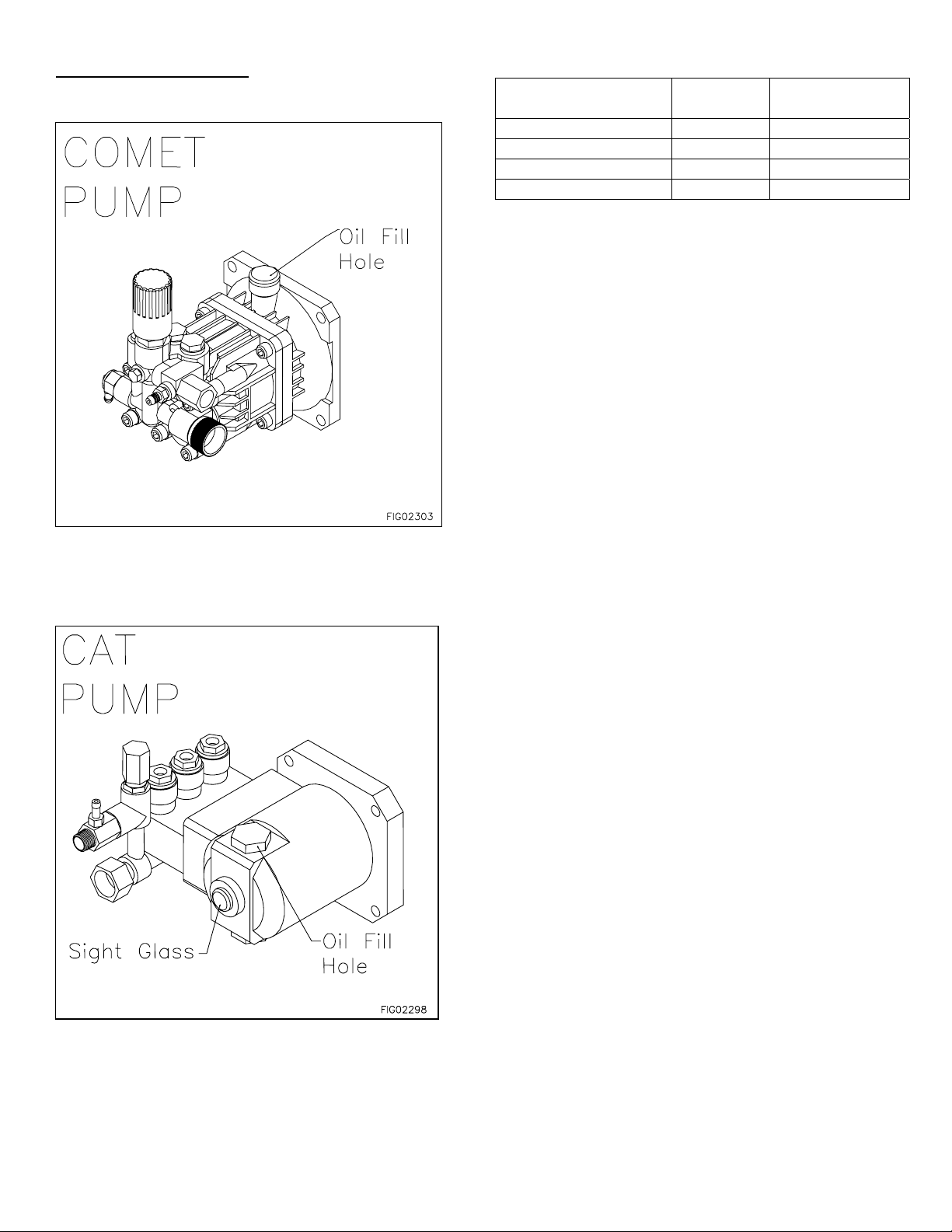

III.) Pump Preparation

*Comet Pumps Only

A.) Replace shipping oil plug with vented plug.

**Cat Pumps Only

A.) Remove shipping tape from oil fill cap

B.) Make sure the oil is 1/2 way up oil sight glass.

Quantities Of Fluid

Pump Type of

Fluid

Comet GXD 1617-E UTTO* 5.0oz (0.15L)

Comet GXD 2527G UTTO* 5.0oz (0.15L)

Cat 2DX SAE 30** 8.5oz (0.25L)

Cat 3DX SAE 30** 8.5oz (0.25L)

*Universal Tractor Transmission Oil or Mobil 1 15W50

**SAE Non-Detergent (order Cat Pump Oil Item# 22158)

QTY

8

Page 9

V.) Getting Started

A

r

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life, and lower maintenance cost.

Make sure the pressure washer is on a level surface and

in a protected area where it is not readily influenced by

outside forces such as strong winds, freezing

temperatures, rain, etc. Locate the pressure washer for

easy access for filling fluids, adjustments, and

maintenance.

It is recommended that a partition be made between the

wash area and the pressure washer to prevent direct

nozzle spray from coming in contact with the pressure

washer. Moisture reaching the equipment will reduce

the pressure washer’s service life.

Partition

V.) Venting

DANGER: Do not run machine indoors or in an

enclosed area without adequate ventilation, or in

areas where flammable vapors, (gasoline, solvents,

etc.) may be present. Do not vent exhaust gases into

a wall, a ceiling, or a concealed space.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local

ordinances. Consult local heating contractors.

Poor draft will cause the pressure washer to soot and

not operate properly. When selecting the location for

installation, beware of poorly ventilated locations or

areas where exhaust fans may cause an insufficient

supply of oxygen. Proper combustion can only be

obtained when there is a sufficient supply of oxygen

available for the amount of fuel being burned. If it is

necessary to install a unit in a poorly ventilated area,

outside fresh air may have to be piped to the burner and

a fan installed to bring sufficient air into the unit

VI.) Oil Burner

Burner Air Adjustment: The oil burner is preset and

performance tested at the factory (elevation 1100 feet).

A one-time initial correction of the burner for your

location will pay off in economy, performance, and

extended service life.

ir Band

White

Arrow

Locking

Screw

1.) Turn the pump and heat switches on (Refer to

“Operation” for details). Have someone operate the

spray gun so the burner fires.

2.) Loosen the locking screw and close the air band

until black smoke appears from the burner exhaust

vent. Note the position of the white arrow on the air

band.

3.) Slowly open the air band until white smoke just

starts to appear.

4.) Turn the air band half way back to the black smoke

position previously noted. Tighten the locking

screw.

5.) Fine tune the burner air by loosening the shutter lock

screw and turning the shutter until the exhaust is

Shutte

Shutter Lock

Screw

cleanest. Tighten the shutter lock screw.

CAUTION: If white smoke appears from the burner

exhaust vent during start-up or operation,

discontinue use and readjust air bands.

Burner

9

Page 10

Operating Instructions

Follow these instructions every time you use the pressure washer.

I.) Pre-Operation

; A.) Position the machine for easy access to all

controls.

; B.) Position the machine on a solid surface, with

less than a three degree slope, and so it is

protected from external damage.

; C.) Position the machine so that ambient lighting is

sufficient for the surface you are cleaning to be

seen with ease. Use artificial light if needed.

; D.) Check hoses, fittings, wand, trigger gun and fuel

connections for signs of wear, cracks and

looseness, and replace as required.

; E.) Check and clean the nozzle orifice.

; F.) Check and clean the water inlet screen and

filter.

; G.) Read entire manual, especially the important

safety instructions listed on page 2.

; H.) Check and maintain proper oil level in the pump.

II.) Check Your Water Supply

; A.) Make sure the water supply is clean. Debris can

cause excess pump wear and reduce

performance.

; B.) An insufficient water supply will damage your

pump. Make sure the water supply is steady

and is 20% over the rated flow of your pump.

Use a stopwatch to time how long it takes to fill a

5 gallon bucket with your garden hose.

Example: If the rated flow is = 3 gpm

Then required flow = 3 x 1.20 = 3.6 gpm

5 gallons / 3.6 gpm = 1.39 minutes

1.39 min x 60 sec/min = 83 seconds

Therefore, you must be able to fill a

5 gallon bucket in 83 seconds or faster.

; C.) The water supply garden hose must have an

inside diameter of at least 5/8”. If the hose is

more than 100 ft. long, the diameter must be at

least 3/4”.

; D.) Never use a reservoir tank as a water source.

This pressure washer is designed for a

pressurized water source such as a city water

faucet. Sucking water out of a tank may cause

pump cavitation and damage to your pump.

However, the inlet pressure of the pump must

not exceed 115 psi (8 bar).

; E.) Always use a flexible rubber hose for your water

supply. Do not use rigid piping.

; F.) Do not pump flammable liquids or liquids

containing incompatible chemicals or solvents.

III.) Before Starting

WARNING: Make sure all switches and controls are

in the OFF position prior to plugging in the cord.

DO NOT stand in water while plugging or unplugging

electrical cord.

WARNING: Use a UL recognized receptacle

protected by a ground fault interrupter and

extension cord of proper voltage and amperage at

all times.

1. Connect electrical cord to specified NEMA receptacle.

See page 4.

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness. Replace as required.

2. Connect water supply hose to the garden hose

connector located on the pump.

3. Fill the burner fuel tank. We recommend kerosene

because it burns cleanest. #1 grade home heating

oil, #1 or #2 diesel can also be used. DO NOT USE

GASOLINE OR CRANKCASE OIL.

4. If detergents will be used, only use detergents

intended for pressure washers. Follow instructions

on the detergent container.

IV.) To Start

DANGER: Do not point the spray wand at yourself or

at any person. Bodily injury may result from water

under high pressure.

WARNING: Wear eye, ear, hand, foot and skin

protection at all times while operating this pressure

washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

1. Turn water supply ON.

2. Squeeze the trigger to allow air to purge from the

system. (This step goes faster with the pressure nozzle

removed)

10

Page 11

V.) Attach Nozzle

j

Nozzle

Color of Nozzle:

Red 0 Highest Impact

Yellow 15 Tough Stains/

Green 25 General

White 40 Light Cleaning

Yellow 15 Steaming

Black 65 Chemical

Spray Angle Used For:

Stripping

Your pressure washer is equipped with six nozzles. To

install a nozzle simply pull back the collar towards the

lance and push the nozzle into the coupler. Once the

connection is made, pull on the nozzle to assure a tight

connection.

Lance

Nozzle

CORRECT INCORRECT

WARNING: Make sure the nozzle is correctly

inserted. The nozzle may become a projectile if not

inserted correctly. Do not attempt to use different

types of nozzles that may not fit the coupler.

Collar

Coupler

VI.) Turn the pump switch ON.

1. Make sure the hose is not kinked. A kinked hose

will provide insufficient water supply to the pump and

will reduce its life. Make sure the hose remains

unkinked after moving the pressure washer.

VII.) For Hot Water

1. If HOT water is desired, make sure there is fuel in

the fuel tank, turn the heat switch ON, and adjust the

thermostat to the desired temperature. The burner

will fire when the trigger is squeezed. You may need

to initially adjust your burner for peak performance.

See the “Oil Burner” section under INSTALLATION.

When the trigger is released or the temperature

setting is reached, the burner will automatically turn

off.

IMPORTANT: Do not run the machine in hot mode

without any fuel in the fuel tank. The fuel pump will

be damaged if it is run dry.

To Clean

WARNING: Wear eye, ear, hand, foot and skin

protection at all times while operating this pressure

washer.

DANGER: Do not point the spray wand at yourself or

at any person. Bodily injury may result from water

under high pressure.

CAUTION: Be careful on painted or delicate

surfaces. The pressure may damage the surface if

the nozzle is too close.

IMPORTANT: Your spray gun is equipped with a

built-in trigger safety latch to guard against

accidental trigger actuation and potentially

dangerous high pressure spray. Rotate the safety

latch to the locked position when not spraying.

NOTE: Your pressure washer is equipped with a low

pressure chemical injector. You do not need to use

chemicals for every job, however, the proper

chemical used for the proper application can speed

up cleaning jobs tremendously.

WARNING: Only use North Star pressure washer

chemicals or chemicals specifically formulated for

pressure washers. Follow the chemical

manufacturer’s recommendations. Understand all

safety precautions and first aid for all chemicals.

1. Press the braided chemical hose over the chemical

injector on the pump and submerge the suction

strainer connected to the braided chemical hose into

the chemical solution.

Chemical

In

ector

Braided Hose

and Strainer

Diluted

Chemical

11

Page 12

Chemical

j

ector

In

Braided Hose

and Strainer

Diluted

Chemical

2. The black, low pressure chemical nozzle must be

used to spray chemicals.

3. Squeeze the spray gun trigger. The chemical injector

will draw the chemical into the water stream.

4. Spray detergent onto the surface and allow it to soak.

Chemicals need time to work properly. Follow the

chemical manufacturer’s recommendations for the

recommended time.

5. Change back to high pressure to rinse by inserting

one of the high pressure nozzles.

6. Hold the lance with two hands in a sturdy stance

position.

7. Point lance at dirty surface and squeeze trigger.

8. Wash from the bottom to the top, using side to side

motions. This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

9. Use the width of the spray pattern to wash in a wide

path. Overlap spray paths for complete coverage.

10.The nozzle should be 12” to 24” from the work, closer

for tough areas.

Caution: Be careful on painted or delicate surfaces,

the pressure may damage the surface if the nozzle is

too close.

11. Small parts should be washed in a basket so the

pressure does not push them away. Larger, light

weight parts should be clamped down.

12. The pressure washer is set to the maximum rated

pressure when it leaves the factory. To adjust the

pressure, turn the unloader knob counter-clockwise.

Unloader

Unloader

WARNING: Do not alter the unloader valve’s

maximum pressure. Excess pressures could cause

serious injury and/or pump damage. Any alteration

other than turning the adjustment knob will void

your warranty.

For Steam (Optional)

1. Set the thermostat to 250°F.

2. Turn the Heat switch ON.

3. Insert the steam nozzle into the nozzle holder.

To Stop

1. If detergents were used, draw clear water through the

2. If the burner was used, turn off the “Heat” switch and

3. Turn the pump switch OFF.

4. Turn OFF the water supply.

5. Squeeze the trigger to relieve the system pressure.

detergent inlet line to purge detergent. Failure to do

so may clog the chemical injector.

pump cold water through the coil for 3 minutes.

Insufficient cool down period of high pressure hose

will cause excessive wear and eventual rupturing of

hose.

12

Page 13

Safety Features

I.) Safety Relief

The safety relief valve is a backup safety feature. If the

unloader malfunctions, the safety relief valve will open

Safety

Relief

00789

and relieve system pressure.

WARNING: If the safety relief valve ever discharges

water, turn the unit off and do not use the machine.

See a dealer or call Customer Service at

1-800-270-0810.

II.) High Temperature Limit

High Temp.

Limit

00790

Maintenance Instructions

WARNING: Unauthorized machine modification or use of non-approved replacement parts may cause personal

injury and/or property damage and will void the manufacturer warranty.

All mechanical equipment, no matter how well designed, will need repairs. A North Star pressure washer is no exception.

At times, a North Star pressure washer may be inoperable because repairs are required. North Star Customer Service

will assist in these repairs as needed, but if an inoperable pressure washer creates a major expense to your business

then we strongly recommend the following:

1. Have someone on staff who is trained in the operation of the pressure washer and is capable of making minor repairs

and performing all preventative maintenance procedures as outlined in the provided manuals.

2. Keep a stock of recommended service parts for maintenance and minor repairs.

Maintenance Mode

Before performing any maintenance on the pressure

washer, it must be placed in maintenance mode.

A.) Turn off water supply

B.) Bleed water from system

C.) Turn off and unplug power cord

Maintenance Schedule

What to Check When To Check What to Do

Fuel Filter 500 hrs Change

Inlet Filter Each Use Clean

Tires Each Use Check Pressure

Hoses Each Use Check for Wear

Bolts Each Use Check for Loose

Bolts

13

Page 14

Cleaning The Inlet Filter

(

)

p

A

WARNING: Check whether dangerous chemicals have

been used, and take precautions when handling filters.

Screen

Checking the Hoses

WARNING: Do not use a finger or skin to check for

leaks. Escaping fluid under pressure has sufficient

force to penetrate the skin, causing serious injury. Do

not operate the pressure washer if the hose is

cracked, worn, or leaking.

A.) Check all hoses for leaks

B.) Check all hoses of worn areas

Good

Bad

Water

A.) Unscrew clear tube by hand.

B.) Remove Inlet filter

C.) Run water though to clean filter

Checking the Tire Air Pressure

A.) Remove air fill cap

B.) Fill tire to 20psi (1.4bar)

C.) Replace air fill cap

Air Fill Stem

ir Fill Cap

Burner Fuel Filter

Drain water which has accumulated in the fuel filter

bowl and replace the filter as needed.

Bad

Wire Mesh

Changing The Pump Oil

*Change oil after first 50 hours, then every 3 months or

500 hours

1.) Remove oil drain plug on Cat pumps.

2.) Drain pump oil.

3.) Replace oil drain plug.

4.) Fill pump oil according to table below.

5.) Use dip stick to fill to proper level or sight glass on Cat

pumps. On Comet pumps, fill with the correct measured

amount of UTTO.

Quantities Of Fluid

Pump Type of Fluid QTY

Comet UTTO* 5.0 oz (0.15L)

CAT SAE 30** 8.5 oz (0.25L)

*Universal Tractor Transmission Oil of Mobil 1 15W50

*

*Non-Detergent Oil (order pump oil Item #22158)

Comet

Pump

Cat

Pum

00425

Filter

Water Drain

Oil

Fill/Drain

Oil Fill

Oil Drain Plug

Underneath

14

Page 15

Coil Descaling

In hard water areas, scale build-up within the

heating coil will occur. Scale deposits will decrease

the water temperature rise and may eventually clog

the heating coil.

1. Mix scale remover in a 5 gallon bucket and

elevate the bucket so it is higher than the pump.

2. Attach the high pressure hose to the high

pressure water outlet on the machine. Do not

hook up the spray gun.

3. Place the other end of the high pressure hose in

the 5 gallon bucket.

4. Attach a short length of hose to the garden hose

inlet on the pump.

5. Prime the pump by filling the hose with water,

then place the end of the hose in the bucket.

Coil Desooting

Poor grades of fuel oil or inadequate combustion

air will cause heavy soot build-up on the outside

surface of the heating coil. These deposits will

insulate the coil. This will restrict the air flow

through the coil, further aggravating the soot buildup.

Most coils will never require desooting. However,

to desoot a coil...

1. Wear protective clothing, goggles, and gloves.

2. Remove the fittings from the inlet and outlet of

the coil.

3. Remove the lid from the heating chamber and

hoist the coil out. Be careful, the coil is very

heavy.

Important: Be careful not to damage the threads

on the coil inlet and outlet. If the threads get

damaged, it will be hard to reconnect and seal

the fittings on the coil inlet and outlet.

Lid

Insulation Cap

00791

Clean Inlet Strainer

When Finished

6. Run the pressure washer in cold mode for 1 to 3

hours recirculating the cleaning solution.

Warning: Do not run the burner.

7. Dispose of the cleaning solution where it is not

harmful to animals or the environment.

8. Flush with fresh water and clean the inlet strainer

when finished.

00792

Heating Coil

Heating Chamber

Short High

Pressure Hose

4. Clean the coil.

5. Reassemble the coil to the machine. Make sure

the white insulation remains in place.

6. Make sure all fittings are tight before using the

machine. Use thread sealant on all threads.

15

Page 16

Electrodes

On a yearly basis the electrodes should be

inspected and any necessary adjustments made.

1. Tip the machine back until it rests on the frame.

4. Clean off carbon deposits, which may have

accumulated on the tips of the electrodes.

5. Reset the spacing as shown below.

Electrodes

4 Nuts

00793

2. Remove the 4 nuts that attach the burner to the

heating chamber. You do not have to

disconnect the fuel lines or the electric cords.

3. Let the burner fall away from the heat exchanger.

00794

1/16”

1/8”

7/16”

16

Page 17

Moving and Handling Instructions

Maneuvering Your Pressure Washer

1.) Pull the handle back with both hands.

2.) Rotate the handle downward to a comfortable height.

3.) Push the pressure washer forward as you walk.

Lifting Your Pressure Washer

1.) To reduce risk of injury, it is recommended to use a

hoist to lift this pressure washer.

2.) Lift from lifting point (see picture_.

Lift Here

Long Term Storage

During cold weather, store the pressure washer indoors and move it outdoors before starting.

Follow these instructions to prevent the pump from freezing during storage.

Winter Storage:

Items needed: 12” piece of garden hose or equivalent,

funnel and RV antifreeze (approximately 2 gallons).

1.) Attach the garden hose with funnel to the pump inlet

(see illustration).

2.) Pour RV antifreeze into the funnel.

3.) Turn the unit on and make sure the burner is off.

4.) Let the pump run no more than 15 seconds at a time

until antifreeze comes out the high pressure outlet.

5.) It will take about 1.5 gallons of antifreeze to fill the

pump and heat exchanger coil.

6.) Drain all water from the high pressure hose. Depress

trigger on gun and drain all water out of gun/lance.

Handle

RV Antifreeze

Funnel

Hose

Water Inlet

17

Page 18

Troubleshooting Guide

Pressure Washer Will Not Run - No Power

Causes Solutions

Machine not plugged in Plug machine in

GFCI tripped Make sure machine is dry

Press RESET on the GFCI

Machine turned OFF Turn Pump switch ON

Line circuit breaker tripped Check for tripped circuit breaker in building

Circuit Breaker Trips During Operation

Causes Solutions

Voltage too low Check the voltage

Circuit Breaker Overloaded Make sure to use NEMA specified receptacle

Make sure there is no other equipment using the same circuit

- see Specifications

Pressure set too high Check/adjust pressure setting on unloader

Pressure Washer Runs But No Pressure

Causes Solutions

Partially clogged or damaged nozzle Clean or replace nozzle

Low water flow Make sure the water supply is more than the required flow

Pressure Washer Surges Or Cycles While In Bypass

Causes Solutions

Leak between pump and gun Check all connections between pump and gun for leaks

Tighten loose components and replace damaged components

Gun leaking internally Replace spray gun

Smoke From Heat Exchanger

Causes Solutions

Air band not adjusted properly due to

different elevation

Poor quality fuel Use Kerosene for the cleanest burn

Adjust the air band until the burner burns cleanly

See Oil Burner under Installation Instructions

Water Not Heating Sufficiently

Causes Solutions

Scale build-up in coil See Coil Descaling under Maintenance Instructions

Coil is full of soot See Coil Desooting under Maintenance Instructions

Safety Relief Valve Sprays Water

Causes Solutions

Unloader/Burner Control Problem Call customer service

Poor Or No Detergent Supply

Causes Solutions

Inadequate detergent supply Refill detergent container

Make sure the chemical strainer is fully submerged

High pressure hose too long Use less hose

Move machine closer to the work

Chemical strainer or injector clogged Clean the strainer and injector. Always start with a clean detergent

container. Run clean water through the injector after each use.

18

Page 19

M157305G - 157305,157306,157307, 157308

Parts Breakdown

19

Page 20

M157305G - 157305,157306,157307, 157308

Parts List

ITEM PART # DESCRIPTION QTY MODEL

1 38525 50’ PW Hose Assy 1 ALL 35 38379 Swivel Fitting, 6MP-8FPS 1 ALL

2 777914 Quick Couple, 3/8” FPT 1 ALL 36 5027 Elbow, 8MP-FP 1 ALL

3 777915 Quick Couple Nipple, 3/8” FPT 1 ALL 37 38509 Threaded Gun Hook 2 ALL

6 777904 Quick Coupler, 1/4” FPT 1 ALL 38 38510 Threaded Hose Hook 3 ALL

7 779166 Lance Assembly 1 ALL 39 777111 Grommet 1 ALL

8 313107 Quick Couple, 3/8” FPT 1 ALL 40 778092 Hot Water Frame 1 ALL

9 779168 Gun Trigger Assembly 1 ALL 41 32308 Fuel Filter, Water Separator 1 ALL

10 22622 Gun Grip 1 ALL 42 30388 Pneumatic Wheel/Tire 2 ALL

11 38398 Insulation Cap Assembly 1 ALL 43 305408 Axle 1 ALL

12 36302 Fiberglass Rope 49” ALL 44 305200 Wheel Retainer 2 ALL

13 35331 Heat Exchanger Lid 1 ALL 777165 Braided Chemical Hose, 1/4” 36” 157305, 157306

14 305410 ~Caution Hot~ Decal 1 ALL

15 777913 Quick Couple Nipple, 3/8” 1 ALL 46 2212 Chemical Strainer 1 ALL

16 30048 Reducer, 8MP – 6FP 1 ALL 47 778236 Thread-on Coupler, 22mm 1 157305, 157306

17 305208 Tee, 8FP 1 ALL 778153 Comet GXD 1617-E 1 157305

18 778179 Kink Guard 1 ALL 778162 Comet GXD 2527G-E 1 157306

19 779228 Coil Assembly 1 ALL 778154 Cat 2DX 1 157307

20 33387 Insulation Can 1 ALL

21 779232 Fire Chamber 1 ALL 777616 Leeson, 1.5 HP Motor 1 157305

37530 Vented Wrap 1 157305, 157306 778670 Leeson 5 HP Motor 1 157306, 157308

22

36180 Vented Wrap, Stainless 1 157307, 157308

23 38120 Insulation Gasket 1 ALL 50 779303 Control Box Cover 1 ALL

24 778111 Heat Exch. Mount Weld. 1 ALL 51 31985 Grommet 1 ALL

777166 Burner, 120V 1 157305, 157307 52 779301 Control Panel Weldment 1 ALL

25

778189 Burner, 230V 1 157306, 157308 53 35198 Grommet, 7/16” ID 6 ALL

26 305267 Strain Relief Nut 2 ALL 778197 Nozzle 5-pack, #2.0 1 157305, 157307

27 22502 Strain Relief 1 157306, 157308

28 777340 Hose Barb, 1/4” MPT x 1/4” 4 ALL 55 778198 Steam Nozzle, 15 Deg 1 ALL

29 777834 Hose Clamp, 1/4” 4 ALL 778151 DP Contactor, 120V/25A 1 157305, 157307

30A 777345 Fuel Line, 1/4” Burner-Tank 25” ALL

30B 777345 Fuel Line, 1/4” Filter -Burner 10” ALL 57 30754 Leather Washer 4 ALL

30C 777345 Fuel Line, 1/4” Tank to Filter 25” ALL 58 3054007 Fuel Tank 1 ALL

35104 Pop Off Valve, 3/8” 1 157305, 157307 59 305206 Printed Fuel Cap 1 ALL 31

22392 Pop Off Valve, 3/8” 1 157306, 157308 60 777410 Elbow, 3/8” NPT 1 157305,157306

778195 3000PSI RXS Hose, 3/8x18” 18” 157305, 157306 61 305266 Strain Relief, 1/2” NPT 1 157306,157308

32

778193 3000PSI RXS Hose, 3/8x26” 26” 157307, 157308 778194 Motor Power Cord 14/3 1 157305

777347 Tee, 6MP-6FP-6FP 1 ALL

33

34 37537 Flow Switch 1 ALL 778141 GFCI Cord, 120V/20A, 36 ft 1 157305, 157307

ITEM PART # DESCRIPTION QTY MODEL

45

777165 Braided Chemical Hose, 1/4” 36” 157307, 157308

48

38518 Cat 3DX 1 157308

49

777617 Leeson, 2 HP Motor 1 157307

54

38531 Nozzle 5-pack, #3.0 1 157306, 157308

56

778152 DP Contactor, 230V/30A 1 157306, 157308

62

778191 Motor Power Cord 12/3 1

63

778142 GFCI Cord, 240V/30A, 36 ft 1 157306, 157308

157306, 157307,

157308

20

Page 21

ITEM PART # DESCRIPTION QTY MODEL

778153 Comet GXD 1617-E 1 157305

1

778162 Comet GXD 2527-E 1 157306

778154 Cat 2DX 1 157307

38518 Cat 3DX 1 157308

2 35918 Thermal Protector, 1/4” 1 157307, 157308

3 777340 1/4” MPT x 1/4” Hose Barb 1 157308

4 778236 22mm Thread-On Coupler 1 157305

5 777410 3/8” Street Elbow 1 157305, 157306

6

38584 3/8” NPT Easy Start Valve 1 157308

777837 3/8 Plug 1 157307

7 777411 3/8” Tee 1 157307, 157308

8 38596 Inlet Filter 1 157307, 157308

9 777165 Braided Chemical Hose, ¼” 12” 157308

21

Page 22

22

Page 23

23

Page 24

24

Loading...

Loading...