Page 1

MODEL 13000 PTOG

ITEM # 165929

Proven Performance

O W NE R’S MA NUAL

Power T

ake-Off Generator

M165929A

00293

13000 PTOG

Any Questions, Comments, or Problems?

Call Cust omer Service at 1-800- 270- 0810

Hours: Monday - Friday 7:30 AM to 5:30 PM

Saturday 7:30 to 11:30 AM CST

Page 2

THANK YOU

Thank you for purchasing a NorthStar Power Take-Off Generator. Your machine is

designed for l ong life, dependability, and the top performance you demand. Please take

time now to read through this manual so you can better understand the machine’s operation,

maintenance and safety precautions. Everyone who operates this generator must read and

understand this manual. The time you take now will prolong your generator’s life and

prepare you for its safe operation. Enjoy the exceptional performance of your NorthStar PT O

Generator.

IM PORTANT

If this machine i s used by anyone who is not the owner or i s l oaned or rented, make certain

the operator:

- Is instructed in safe and proper operati on of this machine.

- Reads and understands the manual s pertaining to this m achine.

NOTICE

K-BAR Industries Incorporated reserves the ri ght to m ake improvements in design and/or

changes in specifications at any time without incurring any obli gati on to install them on uni ts

previously sold.

TABLE OF CONTENT S

Thank you 1

Specifications 2

A NSI safety definitions 2

Machine component ident ificat ion 3

Gener ator features 4

Introduction 4

Rules f or safe oper ation 4-5

Installation 5-6

Load applicat ion 6-7

Pre- star t up prepar ations 7-8

Gener ator care 8

Troubles hooting 9

1

Page 3

SPECIFICATIONS

Item Number #165929

Ma ximum Outp ut 13000 Watts (W)

Continuous Output 12000 Watts (W)

Voltage 120 / 240 Volt ( V)

Phase Single phase (4-wire)

Frequency 59.0- 63.0 Hertz (Hz)

Power Factor 100 %

Mi nimum P TO HP 24 HP at 540 RP M

Input Shaft 1 3/8” Diameter , 6 spline

120V Receptac le (2) 20 Amp (A) duplex (NEMA 5- 20R)

30 Amp (A) twistloc k ( NE MA L5-30R)

120/240V Receptacle 50 Amp (A) St r aight blade (NEMA 14-50R)

Circuit Breaker (2) 20 Amp (A) thermal, push to reset style

30 Amp (A) ther mal, push to r eset style

(2) 40 Amp (A) t her mal, push to r eset style

Gear B ox

Gear Ratio 1:7

Gear Oil SAE 80W-90

Oil Capac ity .86 Qt. (.82 L)

Dim ensions

Length 28.38” ( 72.1 cm)

Width 14.25” ( 36.2 cm)

Height 12.50” (31.1 cm)

Gr oss W eight 127 lb. ( 57.7kg)

ANSI SAFETY DEFINITIONS

DANG ER indicates an im minently hazardous situation which, if not avoi ded,

will result in death or serious injury. This signal word is to be limited to the

most extreme si tuations.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in a death or serious injury.

CAUTION indi cates a potentially hazardous si tuation, which if not avoided,

may result in m i nor or moderate injury. It may also be used to alert agai nst

unsafe practices.

2

Page 4

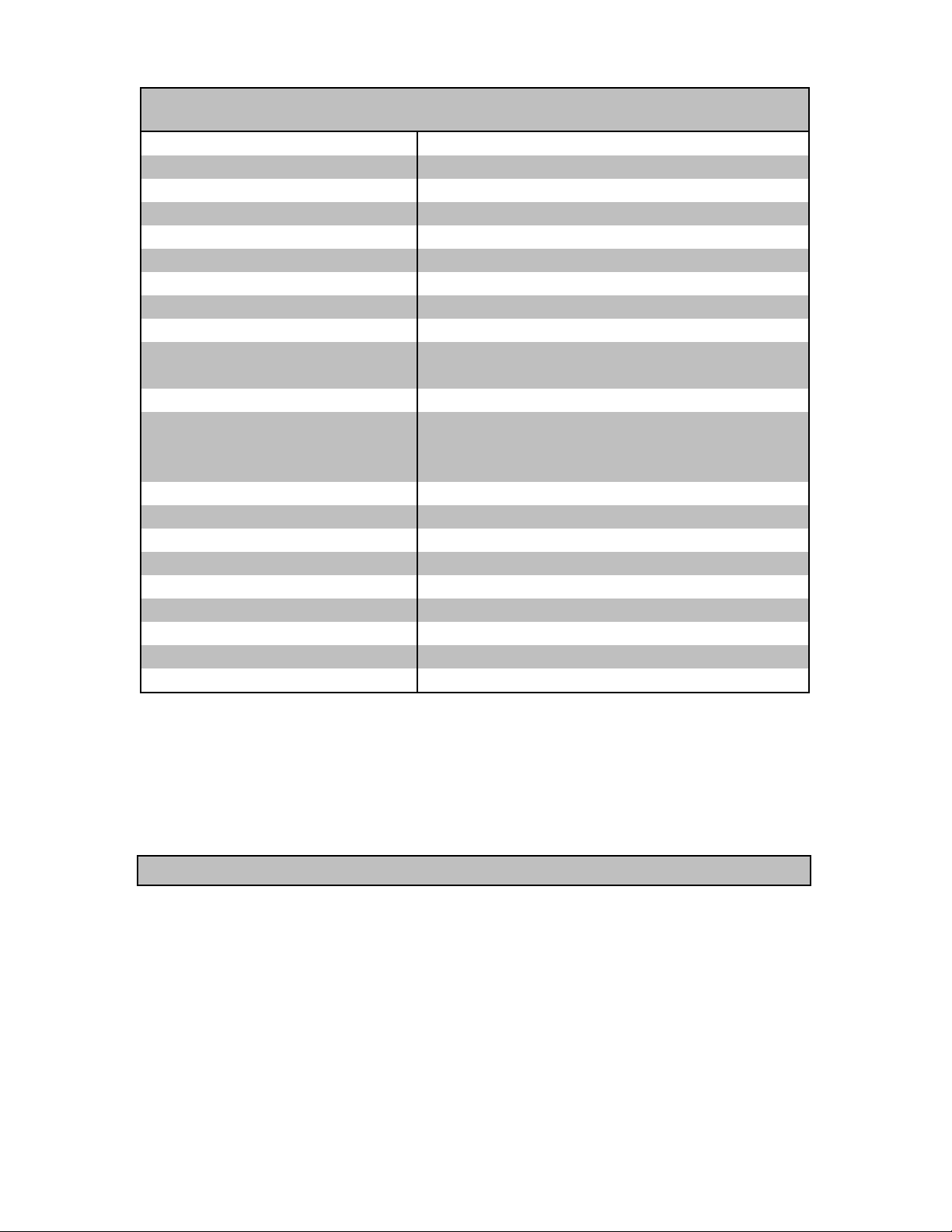

MA CHINE COMPO NENT IDENTIF ICATION

Figure 1 ( Ref. 1- 10)

Ref. Des cription Ref. Des cription

1 50A Ci rcuit Breakers 10 120/240V 50A Receptacle

2 30A Circui t Breaker 11 Shield

3 20A Ci rcuit Breakers 12 Gear Box

4 Warning Decal s 13 Grounding Screw

5 1 3/8”, 6 Spline Input Shaft 14 Mounting Holes

6 Oil Drai n Plug 15 Fan Vents

7 Voltmeter 16 Oil Level Sight

8 120V 20A Duplex

Receptacles

9 120V 30A Twistlock

Receptacle

17 Breather/Oil Fill Plug

00294

3

Page 5

GENERATOR FEATURES

References 1-3 Circuit Breakers.

• Reference 1 - two 50A push-to-reset circuit

breakers.

• Reference 2 - one 30A push-to-reset circuit

breaker.

• Reference 3 - two 20A push-to-reset circuit

breakers.

References 4 - Warning Decals. Read and

follow all warnings.

References 5 - 1 3/8” Diameter 6 Spline Input

Shaft. 540 RPM. PTO driveline i s availabl e from

Northern, Item #165936.

References 6 - Oil Drain Plug. Change oil

after the first 50 hours of use, then after every 500

hours.

References 7 - Voltmeter. Voltmeter needle

shoul d be in green area during all generator load

conditions. The black line in the center on the

green area indicates 120V. During no load

conditions, the needle should be at or above the

black l i ne.

References 8-9 120V Receptacles.

• Reference 8 - 120V Receptacle. The

generator has a control panel with two 120V 20A

straight bl ade receptacl e duplexes (two receptacles

in a common housing). National Electrical

Manufacturer’s Association (NEMA) number is 520R.

• Reference 9 - This twistlock receptacle is a

120V 30A receptacl e, NEMA number L5-30R. Thi s

Figure 2 (Ref. 10-16)

receptacle accepts NEMA plug number L5-30P,

which i s suppli ed with the generator.

Reference 10 - 120/240V Receptacle. This

straight blade receptacle is 120/240V 50A. This

receptacle accepts a NEMA plug number 14-50P.

ALWAYS use grounded male plugs. The

neutral line of the generator is mechanically

grounded to the frame. Matching NEMA male

plugs must always be used.

References 11 - Shield. Plastic implement

shield. NEVER operate generator without shiel d i n

place.

Reference 12 - Gear Box. Cast iron fram e. 1:7

gear ratio.

Refe r ence 1 3 - Groundi ng Screw. Ground the

generator via the ground screw, to a copper pi pe or

rod that is driven into moist soi l .

Reference 14 - Mounting Holes. Use these

three locations to mount the generator head in

place with 7/16” grade 5 bolts. Mounting plates

(i tem #165935) for mounting generator to a cement

pad are available through Northern and the

NorthStar parts catalog.

Reference 15 - Fan Vents. Never block the

vent slots or insert objects through the slots. The

closest object should be at least 3 feet away from

the vents.

Reference 16 - Oil Level Sight. When oil is

even with the red dot, the oil level is correct. Check

oil level daily. Sight is m ounted on the gear box

service panel. If panel is removed for whatever

reason, reseal usi ng Dow Corning seal ant #732.

4

00295

Page 6

Reference 17 - Breather/Oil Fill Plug. Use

SAE 90 gear oil. Maintain the correct oil level.

Over filling can cause the oil to over heat and

damage seals and bearings. The gear box is

shipped with temperary plastic plug, remove and

repl ace with the metal breather plug that is in the

manual bag.

INTRODUCTION

Before attempting to mount your generator,

thoroughly study the i nstructions and cautions in this

manual to assure you are full y acquainted with the

operation of al l components of this generator. Proper

preparation, operation and maintenance will result

in operator safety, best perform ance and long l ife of

the generator. NorthStar is constantly improving its

products. The specifications outlined herein are

subj ect to change wi thout prior notice or obl igation.

The purchaser and/or user assumes liability of any

modification and/or alterations on this equipment

from original design and m anufacture. Before using,

the user shall determine the suitability of this product

for its intended use and assumes l iability therein.

RULES FOR SAFE OPERATIONS

Safety precautions are essential when operating

this generator. Respectful and cautious operation

will considerably lessen the possibilities of a

personal i njury. Thi s manual will warn of specific

personal injury potential, and these will be

desi gnated by the symbol:

WARNING This generator is equipped

with a grounding screw, located on the generator

frame for your protection. Always complete the

grounding path from the generator to a copper

pipe/rod that is driven into m oist earth, to prevent

electrical shock.

ALWAYS use electrical cords that are in good

condition. Worn, bare, frayed or otherwise

damaged cords can cause electri c shock.

ALWAYS use a ground fault circuit interrupter

(GFCI) in damp or highly electrical conductive

areas and on construction job sites to prevent

electric shock.

ALWAYS remove PT O dri vel ine before worki ng

on the generator.

ALWAYS provide adequate ventilation. Do not

operate generator in any encl osed or narrow space.

Engines consume oxygen and give off deadly

carbon monoxide, a poisonous gas. Improper

ventilation will cause damage to generator and

possible inj ury to people.

ALWAYS remove all oil or gasoline deposits

and accumulated dirt from generator and

imm ediate area. Keep generator head and engi ne

clean.

ALWAYS wear ear protection while operating

generator.

ALWAYS keep area around generator clean.

NEVER operate the generator without proper

guardi ng.

NEVER operate the generator continuously

when PTO driveline is at angle greater than 15°

both horizontally and vertically .

NEVER operate the generator while wearing

loose fitting clothing such as neckties, scarves or

untucked shi rts.

NEVER operate the generator, or handle any

electrical equipment whi le standing i n water, while

barefoot, whi l e hands are wet or while i n the rain or

snow. Electric shock may result.

NEVER operate the generator under the

following conditions:

A. Excessive change in engine speed, sl ow

or fast.

B. Overheating in load connecti ng devices.

C. Sparking or arcs from generator.

D. Loss of electrical output.

E. Damaged receptacles.

F. Engine misfire.

G. Excessive vib rat io n.

H. Enclosed compartments, or confined areas.

I. Flame or smoke.

J. Rain, snow or wet conditions.

K. Operator non-attendance.

L. Without proper guarding in place.

WARNING Keep fire extinguisher close

by your generator and be familiar with how to use

it. Consult your local fire department for correct

extinguisher type.

DANG E R Remember, exhaust fumes are

deadly carbon monoxide, a poisonous gas and

must be vented to the outside where there are no

people. Cooling air of sufficient amounts must be

brought in and exhausted out to ensure proper

cooling of the engine and generator.

INSTALLATION

5

Page 7

Choose a location where the generator will not

be exposed to rain, snow or direct sunlight.

Common places for m ounti ng your PT O generator

are to a trailer or a cement slab. However you

choose to mount the generator, make sure it can

get as close to the load as possibl e. T hi s will make

using the generator more convenient and reduce

voltage drop.

The installation site must be free from water,

moisture, or dust. Foreign matters, such as d u st, d irt,

sand, l int, or abrasive materi als can cause damage

if allowed inside the generator. All electrical

components should be protected from excessive

moisture or the insulation system will deteriorate

and result in grounding or shorting out of the

generating system.

When trailer mounting the generator select a

trail er that is wide enough to withstand the torque

of start-up and l oading torque. Wheel s that are not

spaced properly coul d cause the trail er to tip over.

The constant vibration of the generator can cause

metal fatigue of the trai ler base if the steel used i s

not thick enough.

DANGER Trailer may tip over and cause

serious injury or death. Never stand near an

operating PTO generator.

When mounti ng the generator on a cem ent slab

use the optional mount kit (item #165935),

available in the Northern catal og and the NorthStar

parts catalog. The kit comes with two mounting

plates and three grade 5, 7/16-14 bolts. Use grade

5 3/8” anchor bolts to mount plates to the concrete.

After the the generator is firmly mounted ,

attach the PT O driveline to the generator then the

tractor. Use a synchronized PTO dri vel ine rated at

24 HP minimum.

DANGER Always have proper guarding

of rotating parts. Failure to guard the power

transmission mechanisms may result in serious

inj ury or death.

Whi le seated on the tractor and the engi ne at

idl e, engage the PTO. Slowly i ncrease the throttle

until the needle i n the generator voltmeter i s at or

above the black line in the green area. A l oad can

now be applied to the generator. Remember to

stay clear of the rotating PTO driveline. From the

tractor seat re-adjust the speed until the needle on

the generator voltmeter i s close to the black l ine in

the green area. If the needle will not rise to the

green area no matter what the engine speed, the

generator is either overloaded or there is a

probl em . Use the troubleshooting gui de at the end

of the manual for assistance with possi ble probl em s.

Before each use check the gear box oil level.

Use SAE gear oil and fill to the dot on the sight

glass.

If the control box is not located on the correct

side for your application, it can be rotated to the

opposite side. First remove the fan vents, then

remove the four drive end bracket bolts. Remove

securing stud cap, loosen the securing stud nut.

Rotate the dri ve end bracket 180°, re-torque bolts to

17 lb•ft. Re -torque securing stud nut to 88.5 lb•ft.

Reinstall the fan vents. Remove the four screws at

the base of control box, rotate the control box 180°.

The voltmeter is now on the back of the machine

instead of the front. See bel ow for terminology.

00345

00346

6

Page 8

LOAD APPLICATION

It is i mportant to determine the total el ectri cal

load before it is connected to the generator. The

two major factors in determining the life of a

generator head are: heat build up, caused by

overloading the generator and corrosive

contaminants, that attack the wiring insulation. If

the generator is overloaded, the wires become

excessively hot and cause the insulation to break

down, reducing its ability to resist corrosive

contaminants. Over time the effectiveness of the

insulation is el iminated and a dead short can result.

Always compare the generator nameplate data

with that of the equipment to be used to ensure that

watts, volts, amperage, and frequency requirements

are suitabl e for operating equi pment. T he wattage

listed on the equipment nameplate is its rated

output. However, some equipment may require

three to ten times more wattage than i ts rati ng on

the nameplate, as the wattage i s influenced by the

equipment efficiency, power factor and starting

system. NOTE: If wattage is not given on

equipment nameplate, approximate wattage may

be determined by multiplying nameplate voltage

by nameplate amperage.

VOLTS X AMPS = WATTS

Example: 120V X 5A =

600W

When connecting a resistive load such as

incandescent lights, heaters or common electric

power tools, a capacity of up to the generator ful l

rated wattage output can be used.

When connecti ng a resi stive-i nductive load such

as a fluorescent or mercury light, transformers or

inductive coils, a capacity of up to 0.6 times the

generator’s ful l rated output can be used.

Always allow the generator to reach operating

speed before a load is appli ed.

00402

STARTIN G ELE C TR IC MOTORS

Electric motors require much more current

(amps) to start than to run. Some motors,

particularly low cost split-phase motors, are very

hard to start and requi re 5 to 7 times more current

to start than to run. Capaci tor m otors are easier to

start and usually require 2 to 4 times as much

current to start than to run. Repulsion Induction

motors are the easi est to start and require 1.5 to 2.5

times as much to start than to run.

Most fractional motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or SplitPhase (SP) type. The following chart shows the

approximate current required to start and run

various types and si zes of 120 volt 60 cycl e e le ctric

motors under various conditions.

120V, 60 Hz

Motors

Hp motor Running

Watts

1/6 525 7-11 9-18 16-22

1/4 700 9-15 12-23 22-32

1/3 875 11-18 14-29 26-35

1/2 1175 15-25 20-40 NA

1 1925 24-40 32-64 NA

1 1/2 2400 30-50 40-80 NA

2 2900 36-60 48-96 NA

3 4075 51-85 68-136 NA

5 6750 84-140 112-224 NA

The figures given above are for an average

load such as a blower or fan. If the electric m otor i s

connected to a hard starting load such as an air

compressor, it will require more starti ng current. If it

is connected to a light load or no load such as a

power saw, it will requi re l ess starting current. The

exact requirement will also vary with the brand or

desi gn of the motor.

Generators respond to severe overloading

differently than the power line. When overloaded,

the engine is not able to suppl y enough power to

bri ng the el ectric motor up to operating speed. The

generator responds to the high initial starting

current, but the engine speed drops sharply. The

overload may stall the engine. If allowed to

operate at very low speeds, the electric motor starter

winding will burn out in a short time. The

generator head windi ng m i ght al so be damaged.

Running the generator under these conditions

may result in dam age to the generator stator as well

RI t y pe Cap

Starting Amps

type

SP

type

7

Page 9

as the electric motor windings. Because the heavy

surge of current is requi red for only an instant, the

generator will not be damaged if it can bring the

motor up to speed in a few seconds. If difficul ti es i n

starti ng a motor are experienced, turn off all other

electrical l oads and if possi ble reduce the load on

the electric motor.

EXTENSION CORDS

When el ectric power is to be provided to various

loads at some distance from the generator,

extension cords can be used. These cords should

be sized to allow for distance in length and

amperage so that the voltage drop between the set

and point of use i s hel d to a mi nimum.

Current/PowerM aximum E xtension Cord Length

Amps

at

240V

10 2400 250’ 150’ 100’ 75’

20 4800 125’ 75’ 50’ 25’

30 7200 60’ 35’ 25’ 10’

40 9600 30’ 15’ 10’ *

50 12000 15’ * * *

the low vol tage caused by using an extension cord

with a small wire si z e.

generator.

Devic e Running Watts

Air Conditioner (12,000 Btu) 1700 (a)

Battery Charger (20 Amp) 500

Belt Sander (3”) 1000

Chain Saw 1200

Circular S aw (6-1/2”) 900

Coffee Maker 1000

Co mpresso r (1 HP) 2000 (a)

Compressor (3/4 HP) 1800 (a)

Co mpresso r (1/2 HP) 1400 (a)

Curl ing Iron 700

Dis hwasher 1200

Edge Trimmer 500

Electric Nail Gun 1200

Electric Range (one element) 1500

Electric Skillet 1250

Load

(watts)

CAUT ION: Equipment damage can result from

Use this chart to esti mate the total l oad on your

For Determi ni ng Genera tor Load Requi r ements

Ge nerator Load Requireme nts Continued

#10

Ga.

Cord

#12

Ga.

Cord

#14

Ga.

Cord

*Not recommended

#16

Ga.

Cord

Freezer 800 (b)

Furnace Fan (1/3 HP) 1200 (a)

Hair Dryer 1200

Hand Drill (1”) 1100

Hand Drill (1/2”) 875

Hand Drill (3/8”) 500

Hand Drill (1/4”) 250

Hedge Trim m er 450

Home Computer 150

Impact Wrench 500

Jet Pum p 800 (a)

Lawn Mower 1200

Light Bulb 100

Microwave Oven 700

Milk Cooler 1100 (a)

Oil Burner on Furnace 300

Oil Fired Space Htr (140,000 Btu) 400

Oil Fired Space Htr (85,000 Btu) 225

Oil Fired Space Htr (30,000 Btu) 150

Oven 4500

Paint Sprayer, Airless (1/3 HP) 600 (a)

Paint Sprayer, Airless (handheld) 150

Radio 200

Refrigerator 600 (b)

Slow Cooker 200

Submersible Pum p (1-1/2 HP) 2800 (a)

Submersible Pum p (1 HP) 2000 (a)

Submersible Pum p (1/2 HP) 1500 (a)

Sump Pump 600 (a)

Tabl e Saw (10”) 2000 (a)

Tel evision 500

Toaster 1000

Vacuum cl eaner 250

VCR 70

Water Heater 3000

Weed T rimmer 500

(a) Hard-starting motors require 3 to 5 ti mes the

rated running watts.

(b) These loads may requi re up to 15 minutes to

restart due to its normal build up of compressor

head pressure.

NOT E: For extremely hard to start loads such as

air conditioners and air compressors, consult the

equipment dealer to determine the maximum

wattage.

PRE-START UP PREPARATI ONS

Your generator has been thoroughly tested prior

to shipment from the factory. However, damage

can occur during shi pping, so be sure to check for

damaged parts, loose or missi ng nuts and bolts. If

the these problems occur, call Customer Servi ce at

1-800-270-0810.

8

Page 10

GROUNDING - All units must be grounded.

Dri ve a 3/4” or 1” copper pipe or rod into the ground

close to the generator. The pipe/rod must

penetrate moist earth. Connect an approved

ground clamp to the pipe. Run a 8 gauge wire

from the clamp to the generator ground screw. Do

not connect to a water pipe or a ground used by a

radi o system.

OPER A TIN G SPEED

The generator m ust be run at the correct speed

in order to produce the proper electrical voltage

and frequency.

The output voltage should be checked to

ensure the generator is working properly subsequent

to connecting a load to the generator. Failure to

do so could result in damage to equipment

plugged into the unit and possible injury to the

indi vidual.

All engines have a tendency to sl ow down when

a load is applied. When the electrical load is

connected to the generator, the engine is more

heavily loaded, and as a result the speed drops

slightly. This slight decrease in speed, together

with the voltage drop within the generator itself,

results in a slightly lower voltage when the

generator i s loaded to its full capacity than when it

is running with no l oad. T he sl i ght vari ation has no

appreciabl e effect in the operation of motors, lights

and most appliances. Electronic equipment and

clocks will be effected if correct RPM is not

maintai ned. See Load vs. Output chart

Load Output

Percent of

Generator

Output

0 % 3780 63.0 125V

50 % 3600 60.0 122V

100 % 3480 58.0 118V

Speed

(RPM)

Frequency

(Hz)

Generator

voltage at

120V

Receptacle

GENERATOR CARE

The generator head i s a two pole, 3600 RPM,

60 Hz, brushless, revolving field and synchronous

type with two sealed radi al beari ngs.

Proper care and maintenance are necessary to

ensure a long troubl e free life.

Exercising The Generator - The generator

should be operated ev ery four w eeks. This is

accompl ished by starting the engine and applying

a load for 15 minutes. This will dry out any

moisture that has accumul ated in the windi ngs. If

left, this moisture can cause corrosion in the

winding. Frequent operation of the generator will

also ensure that the set is operati ng properly should

it be needed in an em ergency.

Ge nera tor Ma intena nce - The generator head

is brushless and maintenance free. Any major

generator service including the installation or

repl acement of parts shoul d be performed onl y by a

quali fi ed electrical servi ce technician. USE ONLY

NorthStar APPROVED REPAIR PART S AVAILABLE

AT 1-800-270-0810.

A. Bearing - The beari ngs used in thi s generator

are a heavy duty, sealed ball bearing type. They

requi re no maintenance or lubrication.

B. Receptacl es - Quality receptacles have been

utilized. If a receptacle shoul d become cracked or

otherwise damaged, replace it. Using cracked or

damaged receptacles can be both dangerous to the

operator and destructive to the equipm ent.

WARNING, Stand-by Operation

If your generator is to be used as a standby

electric power source in case of utility failure, it

must be installed by a registered and licensed

electrician and in compliance with all applicable

state and local electrical codes. Also, local Fire

Departments must be consulted concerning proper

and safe handling procedures for gasol ine. NEVER

connect any generator to any existing electrical

system without an isolating, UL approved transfer

switch, install ed by a licensed electrician.

Output voltage should be checked periodically

to ensure continued proper operation of the

generating plant and appliances, it can be checked

with a portabl e meter. Frequency can be checked

by using an electric clock with a sweep second

hand. T imed against a wrist watch or a stop watch

the clock should be correct wi thin +/- 2 seconds per

minute. All speed setting adjustments should be

done by a qualified technician.

9

Page 11

TROUBLESHOOTING

Proble m Possible Causes Possible Remedies

Voltage too low. a) Engine speed too slow.

b) Generator i s overloaded.

Circuit breaker trips. a) Defecti ve load connected to

generator.

b) Defective receptacle.

c) Generator overloaded.

d) Defective circuit breaker.

Voltage too high. a) Engine speed too high. a) Contact Customer Service for

Generator

overheating.

No output voltage. a) Defective load connected to

Excessive gear box

noise.

a) Generator i s overloaded.

b) Insufficient ventilation.

generator.

b) Broken or l oose wire.

c) Defective receptacle.

d) Defective stator.

e) Defective rotor.

f) Defective capacitor.

g) Defective circuit breaker.

h) Engi ne speed too slow.

I) PTO not engaged.

j) Gear box is mal functioning.

a) Defective bearing.

b) Defective gear.

c) No or low gear oil.

d) PT O driveline is operating at an angle

of greater than 15°.

e) Unsynchronized PTO driveli ne.

a) Increase tractor RPMs.

b) Reduce the load. (See Load

Application section of this manual.)

a) Di sconnect l oad.

b) Repl ace receptacle.

c) Reduce the load. (See Load

Application section of this manual.)

d) Contact Customer Service for

the nearest servi ce center.

the nearest servi ce center.

a) Reduce the load. (See Load

Application section of this manual.)

b) Make sure there is at least 3

feet of clearance on al l si des of

generator.

a) Di sconnect l oad.

b) Repl ace/tighten wi re.

c) Replace receptacle.

d) Contact Customer Service for

the nearest servi ce center.

e) Contact Customer Service for

the nearest servi ce center.

f) Contact Customer Service for the

nearest service center.

g) Contact Customer Service for

the nearest servi ce center.

h) Increase tractor RPMs.

I) Engage PTO.

j) Contact Customer Service for the

nearest service center.

a) Contact Customer Service for

the nearest servi ce center.

b) Contact Customer Service for

the nearest servi ce center.

c) Fill gear box to oil level sight.

d) Repostition the tractor or generator

so the angle is reduced to less than 15°

both vertically and horizontally.

e) Disassembl e PTO driveli ne and

reassembl e wi th CV j o ints

synchronized.

10

Loading...

Loading...