North Slope Chillers NSC0500, NSC1000, NSC2000, NSC5000, NSC5000E Data Sheet

...

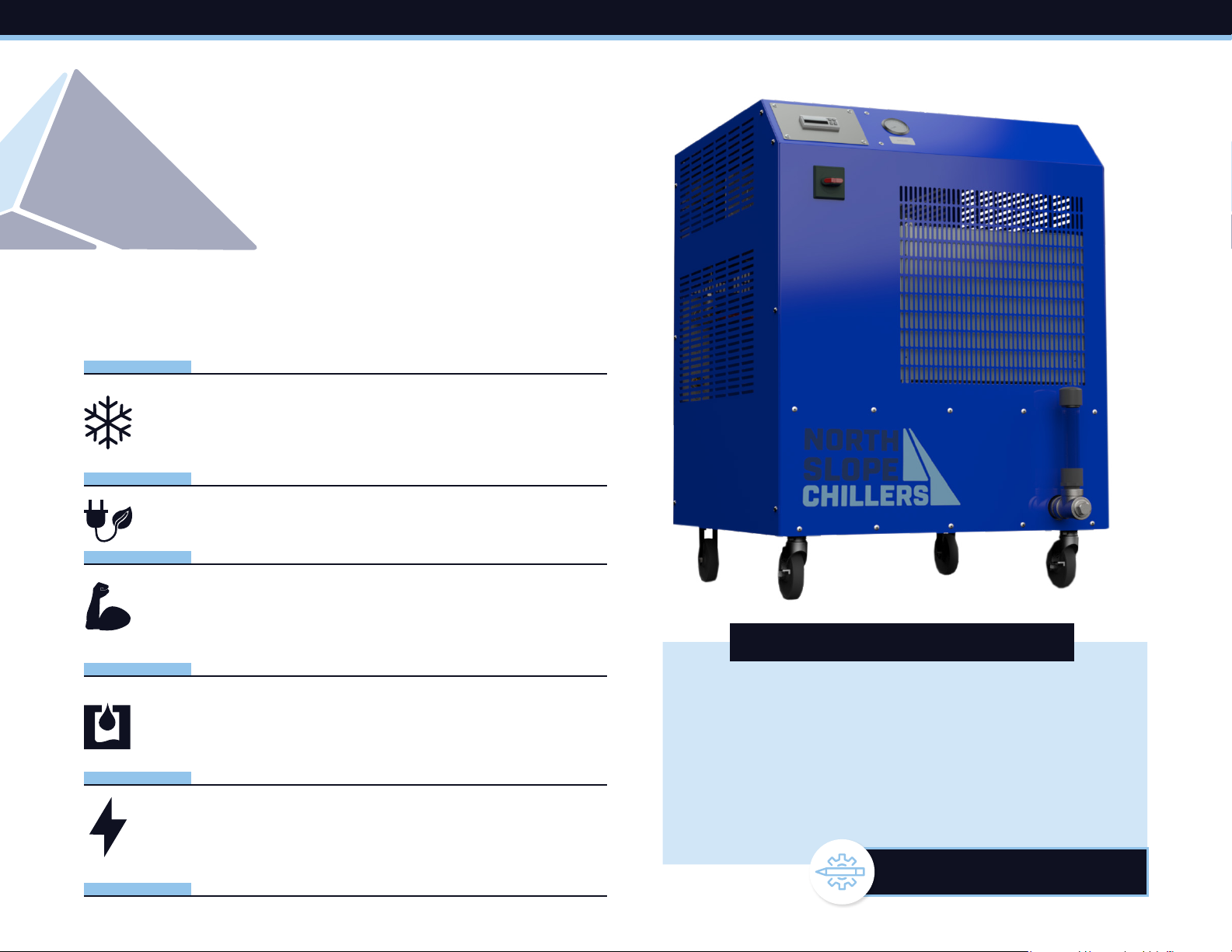

THE COLD

STANDARD

Meet the compact chiller that is both dependable and powerful. Freeze is

North Slopes’ standard industrial chiller that cools uids between 40°F-75°F

(1/2-2 ton) and 40°F-65°F (5-10 ton). A small workhorse, Freeze boasts a

robust condensing unit and high horsepower. It’s a lot of chilling power in a

lile package.

CHILLER: Air-cooled, stand-alone chiller designed with indoor and

outdoor opons. Capacity is up to 12,000 BTU’s/hr at rated condions. Set up for ambient temperatures 40º F to 100º F (for higher

or lower ambient condions please consult North Slope).

SPEC SHEET

COMPRESSOR/CONDENSING UNIT: The Copeland Condensing

Unit is the most energy ecient and reliable of its size.

PUMP: This chiller is equipped with a connuous duty, non-ferrous,

or stainless steel pump. The uid types are to be water or water/

glycol (for other uids consult factory). Output pressure gauge is

standard.

RESERVOIR: Stainless steel or plasc tank with fully welded stainless steel or plasc couplers it will include: drain, sight glass, and

manual ll tube. The sight glass is easily visible from the exterior of

the chiller.

ELECTRICAL:

• Available as 200V/3/50-60Hz or 460/3/50-60Hz, depending

on model

• On/O

STANDARD CHILLER FEATURES

• Rated at ambient temperatures from 40°F - 100°F

• Copeland, hermecally sealed, compressor

• Connuous duty, non-ferrous pump

• Non-ferrous piping system

• 0-100 PSI Discharge Pressure Gauge

• Environmentally acceptable R134a or R404a refrigerant

• Powder-coated steel cabinet (stainless steel is also available)

NEED A CUSTOM SOLUTION?

we’ve got you covered!

FREEZE by North Slope Chillers

SPEC SHEET

WANT GREATER PEACE OF MIND?

Try North Slope with Beacon Controllers

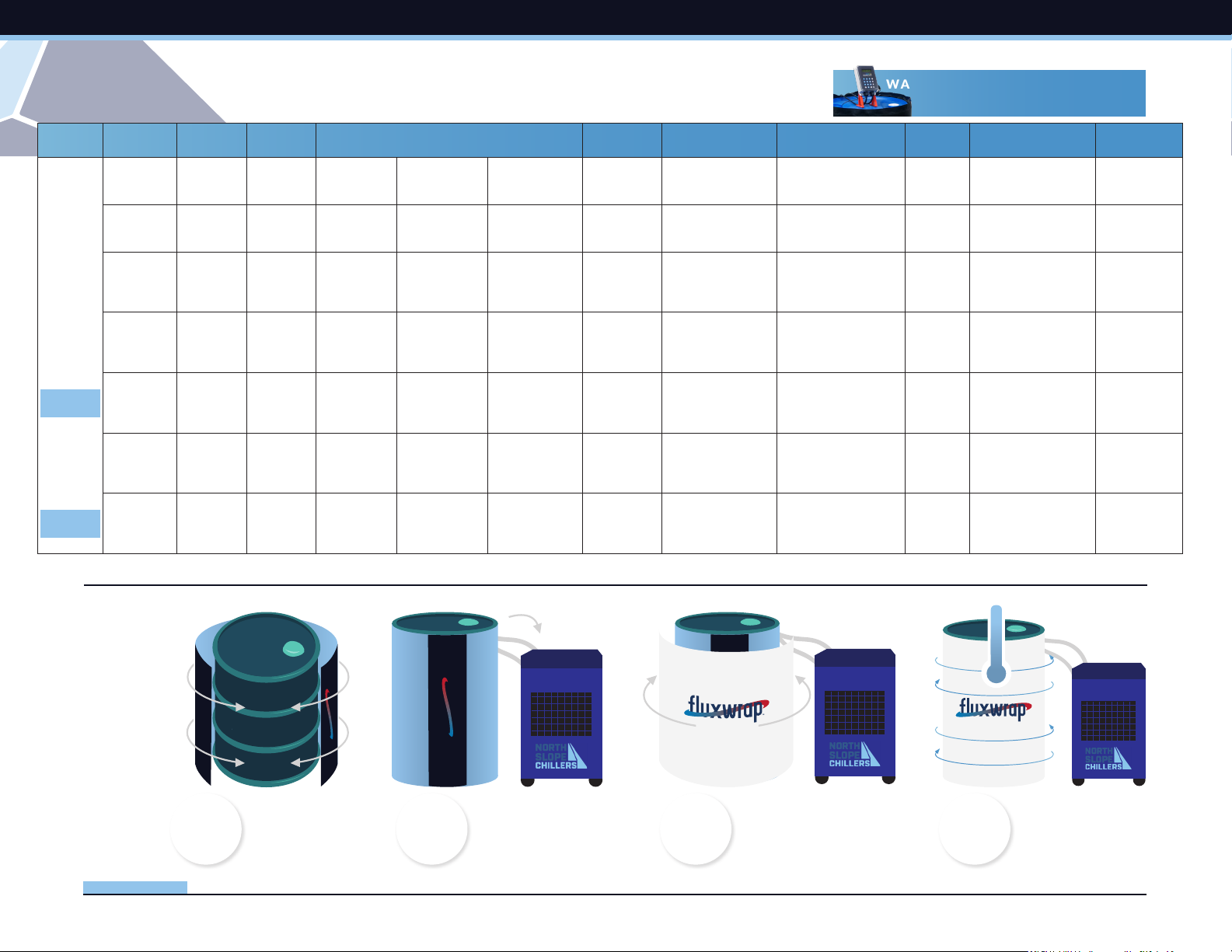

Product

Type

FREEZE

FREEZE

OUTDOOR

FREEZE

OUTDOOR

Model

Number

Fluid Temp

Range (F)

Refrigerant Pump

NSC0500 40°F - 75°F R134a

NSC1000 40°F - 75°F R134a

NSC2000 40°F - 75°F R134a

NSC5000 40°F - 65°F R404a

NSC5000E 40°F - 65°F R404a

NSC10000 40°F - 65°F R404a

NSC10000E 40°F - 65°F R404a

Connuous

Duty,

non-ferrous

Connuous

Duty,

non-ferrous

Connuous

Duty,

Stainless Steel

Connuous

Duty, Stainless

Steel

Connuous

Duty, Stainless

Steel

Connuous

Duty, Stainless

Steel

Connuous

Duty, Stainless

Steel

1/3 HP Fixed

Displacement

Pump

1/3 HP Fixed

Displacement

Pump

3/4 HP

Centrifugal

Pump

1-1/2 HP

Centrifugal

Pump

1-1/2 HP

Centrifugal

Pump

2 HP

Centrifugal

Pump

2 HP

Centrifugal

Pump

4 GPM Fixed

50 PSI Max

4 GPM Fixed

50 PSI Max

15 GPM @ 28 PSI

25 GPM @ 23 PSI

35 GPM @ 16 PSI

45 GPM Max

15 GPM @ 39 PSI

30 GPM @ 35 PSI

45 GPM @ 28 PSI

60 GPM Max

15 GPM @ 39 PSI

30 GPM @ 35 PSI

45 GPM @ 28 PSI

60 GPM Max

15 GPM @ 54 PSI

30 GPM @ 48 PSI

45 GPM @ 40 PSI

65 GPM Max

15 GPM @ 54 PSI

30 GPM @ 48 PSI

45 GPM @ 40 PSI

65 GPM Max

Reservoir

Capacity

3.5 Gallon

Stainless Steel

Reservoir

13 Gallon

Stainless Steel

Reservoir

13 Gallon

Stainless Steel

Reservoir

50 Gallon

Plasc

Reservoir

50 Gallon

Plasc

Reservoir

50 Gallon

Plasc

Reservoir

50 Gallon

Plasc

Reservoir

Cooling Capacity

(BTU/hr)

40°F - 3,800 BTU/hr

65°F - 6,000 BTU/hr

40°F - 7,600 BTU/hr

65°F - 12,000 BTU/hr

40°F - 16,100 BTU/hr

65°F - 25,400 BTU/hr

40°F - 41,400 BTU/hr

65°F - 60,500 BTU/hr

40°F - 41,400 BTU/hr

65°F - 60,500 BTU/hr

40°F - 83,000 BTU/hr

65°F - 120,000

BTU/hr

40°F - 83,000 BTU/hr

65°F - 120,000

BTU/hr

Dimensions

Weight

(Approx)

28¼"L x 22½"W x 32½"H 220 lbs

34½"L x 28¼"W x 39"H 350 lbs

34¾"L x 43¼"W x 40"H 550 lbs

34”L x 65”W x 62”H 1000 lbs

34”L x 65”W x 62”H 1000 lbs

34”L x 65”W x 62”H 1150 lbs

34”L x 65”W x 62”H 1150 lbs

Amps Voltage

16.0A @ 110/1/60 (Std)

7.6A @ 230/1/60

14.1 A 230/1/60 (Std)

10.9A 230/3/60

46.1 A60/3/60

24.0A @ 230/1/60 (Std)

20.2A @ 230/3/60

10.7A @ 460/3/60

13.7A @ 460/3/60 (Std)

28.6A @ 230/3/60

34.7A @ 230/1/60

13.7A @ 460/3/60 (Std)

28.6A @ 230/3/60

34.7A @ 230/1/60

26.6A @ 460/3/60 (Std)

55.5A @ 230/3/60

26.6A @ 460/3/60 (Std)

55.5A @ 230/3/60

110/1/60 (Std)

230/1/60

230/1/60 (Std)

230/3/60

460/3/60

230/1/60 (Std)

230/3/60

460/3/60

460/3/60 (Std)

230/3/60

230/1/60

460/3/60 (Std)

230/3/60

230/1/60

460/3/60 (Std)

230/3/60

460/3/60 (Std)

230/3/60

PERFECT PAIR

Flux wrap can chill

materials in drums,

totes, tanks and all

manner of vessels.

Fluxwrap applies

chilling to many

vessels that were

previously dicult

or nancially

unfeasible to chill.

IT’S

SIMPLE

Wrap the jacket around

your container and aach

the exible neoprene ends

1

to secure the Fluxwrap.

www.northslopechillers.com | 1-866-826-2993 | 3130 S 1030 W | Salt Lake City, UT 84119

M

T

m

o

c

.

s

r

e

l

l

i

h

c

e

p

lo

s

h

t

r

o

n

w.

w

w

fluxwrap

TM

www.northsl opechillers.co m

fluxwrap

Aach the hoses to the

temperature control unit

2

TM

www.northsl opechillers.co m

fluxwrap

Install the provided insulaon

to increase thermal control

and reduce condensaon.

3

TM

Turn on the temperature

control unit and begin

regulang temperatures.

4

Loading...

Loading...