Northfield Foundry & Machine Tilting Arbor Variety Saw No 4 Operation Maintenance Instructions Parts Lis Table Saws

Page 1

A\

NORTHFIELD

A

TILTING

OPERATION

MODEL

ARBOR

NO. 4

VARIETY

AND MAINTENANCE

INSTRUCTIONS

AND

PARTS

LIST

SAWS

A\

ALL PARTS

MAY BE PROCURED

Northlield Foundry

Vendor

320 North Water

P.O. Drawer 140

ilorthfteld, MN

Phone:

FA)(

WHEN

SERIAL

OF THIS iIANUAL'

FOR THIS

44142

Code

55057

(507)

645-5641

(507)

64s-400s

ORDERING PARTS

NUIIBER AS

MACHINE

FROM:

& Machine

St.

PLEASE INCLUDE

SHOWN ON

Co.

THE FRONT

Bevised 10/94

Page 2

v

v

Page 3

A\

TABLE OF CONTENTS

4

PAGE

PAGE 5

PAGE 6

PAGE B

9

PAGE

10

PAGE

11

PAGE

13

PAGE

14

PAGE

PAGE

PAGE

PAGE

PAGE 18

15

16

17

THRU

12

&

THRU

GENERAL

UNPACKING,

7

19

OPERATIONS

MAIN ASSEMBLY & STOCK

APRON

ROLLER

ROLLING

2-380

MOTOR ASSEMBLIES

AC WIRING

ELECTRIC

ELECTRIC

NUMERICAL

SAFETY

ASSEMBLY &

TOP

TABLE

LEXAN GUARD

BRAKE WIRING

BRAKE

INSTRUCTIONS,

LUBRICATION

AND ADJUSTMENTS

GUIDES

APRON

ASSEMBLIES

ASSEMBLIES

ASSEMBLY

HANDBRAKE,

ASSEMBLY

PARTS LIST

TILTING

ELECTRICAL

FLOOR

PLANS

.r\

AiIY

IS

B(lDILY

CAUTI(IN

SAFETY

MACHIT{ERY

CAPABLE

INJURY. USE

AT

RULES,

()F

LUBRICATI(IN

COilTAIi{ED

F(lR

ARE

IN THE

YOUR PR(ITECTI()T{

II{F(lRMATI(lN.

FAMILIARIZE

C(IT{TEI{TS

THE

MACHINE.

PRIOR

USED

F()R

CAUSING

EXTREME

ALL TIMES.

(IPERATI(IT{

II{STRUCTI(IilS

]YIANUAL

C(lMPLETELY

YOURSELF

T(l OPERATING

CUTTING

SERI()US

THE

AilD

AI{D

WITH

THE

Page 4

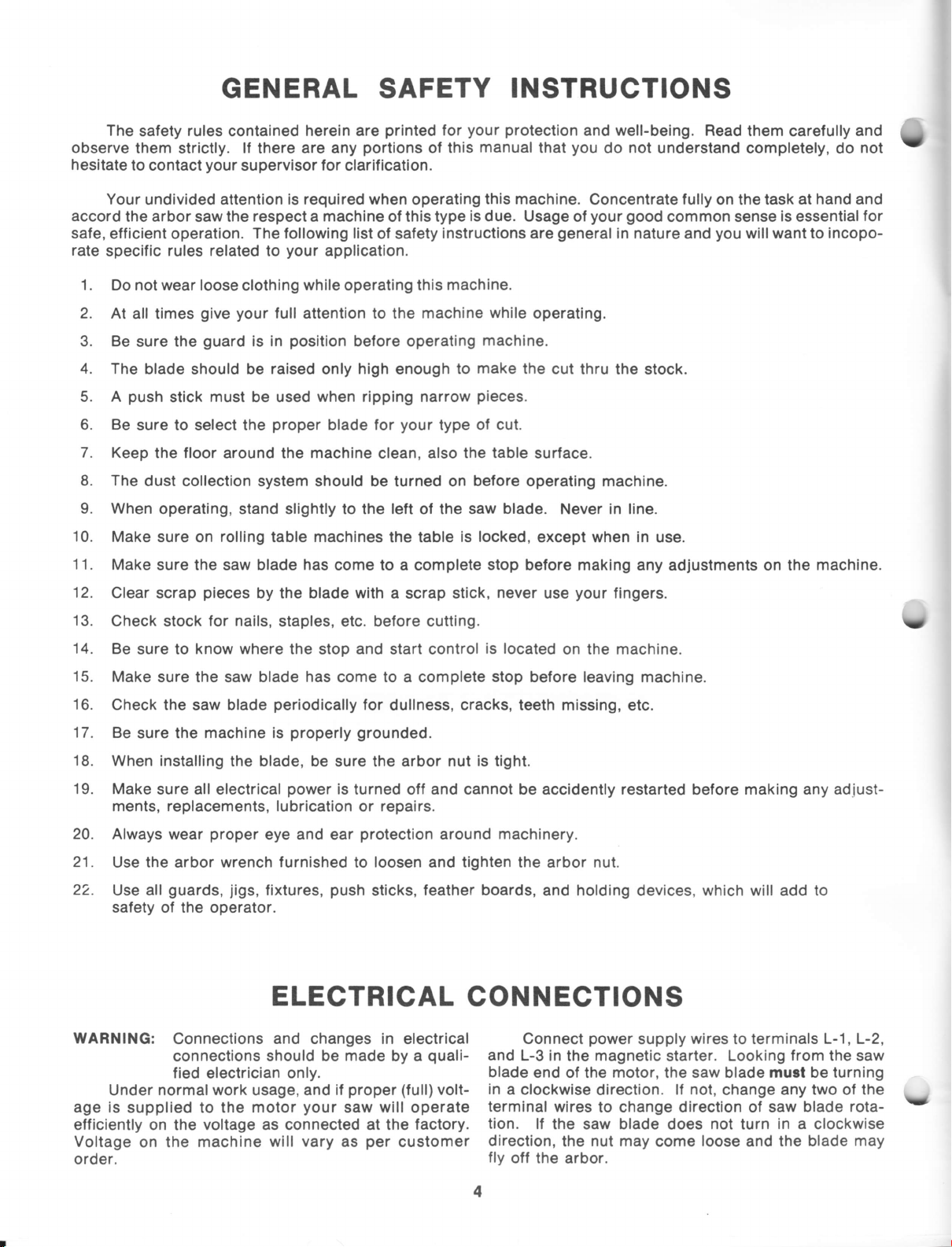

GENERAL SAFETY

INSTRUCTIONS

The

safety

observe

hesitate

accord

safe,

rate

them strictly.

to contact

Your

the

efficient operation.

specific

rules contained herein are

your

undivided

arbor

saw the

rules related

1. Do not wear loose

2.

At

3. Be

4.

The blade

5. A

6. Be

7,

Keep

8. The

9.

When

10.

Make

11.

Make

12.

Clear scrap

all times

sure

push

sure to select the

dust collection system should be

give your

guard

the

should be

stick

the lloor around the machine

operating, stand slightly to the left of the saw

sure on

sure the saw blade

pieces

printed

lf

supervisor for clarification.

attention is required when

respect a machine

The following list

clothing

is

must be used when ripping narrow

rolling

are

there

your

to

while operating this machine.

full

attention to the

position

in

raised

proper

machines

table

has

by the blade with

portions

any

of this type

of safety

application.

before operating

high

only

for

blade

clean,

turned on

the table

come to a complete

a scrap stick,

for

ol this

operating

instructions are

machine

enough

your

type

also the

to

is locked,

your protection

manual

this machine.

is

due. Usage

while

machine.

make the

pieces.

of cut.

before

stop

that

general

operating.

cut

table

surface.

operating machine.

blade.

never

Never in line.

except when in use.

before making any

use

and well-being. Read

you

do not

Concentrate

your good

of

thru the stock.

your

understand completely, do

fully

common sense

in nature

fingers.

and

adjustments on

them

on the

you

will want to

carefully

task at

hand

is

essential

the machine.

and

not

and

for

incopo-

13.

Check

14.

Be

sure

15.

Make sure the saw blade has come to a complete stop before leaving machine.

16.

Check the

17.

Be

sure the

18. When installing

19.

Make

sure all electrical

ments, replacements, lubrication

20.

Always wear

21.

22.

the

Use

Use all

safety

of

WARNING:

Under

is

age

efficiently on the voltage as connected

Voltage

normalwork usage, and il

supplied

on the

order.

for nails,

stock

to know where the

blade

saw

machine is

the blade, be

staples, etc. before cutting.

and

stop

periodically

properly

sure the arbor

power

is

start control

for

dullness,

grounded.

nut is tight.

turned off and cannot be accidently restarted before making any adiust-

is located

cracks,

on the machine.

teeth missing, etc.

or repairs.

proper

arbor

guards,

the

operator.

wrench furnished to loosen and tighten the

jigs,

and

eye

fixtures,

ELECTRICAL

Connections and changes in electrical ConnectpowersupplywirestoterminalsL-1,L-2,

connections should be

fied

electrician

to the motor

machine

only.

your

will vary

protection

ear

push

made

proper

sticks,

by a

around

feather boards,

quali-

(full)volt-

saw'wilioperate

at the factory.

per

as

customer

machinery.

nut.

arbor

and holding devices, which will add to

CONNECTIONS

and L-3

blade

in

terminal

tion.

direction,

fly

in the magnetic

end of the

a clockwise

lf

otf the

direction.

wires

to change direction oisaw-blade

the saw blade does

nut may

the

arbor.

motor,

from

the saw

any two of the

not,

Looking

change

starter.

the saw blade must be turning

lf

rota-

come

not

loose

turn

and

in a

clockwise

the blade

v

Y

may

Page 5

UNPACKING

a\

(r\

NORTHFIELD

Your

and

operated

you.

Remove crating

floor,

the

pound

sealed

grease

requiring oiling

screw

wheel.

should

The ball bearings

good grade

A

A few drops of oil should

bearing,

Apply a

before

protective

be

for the

are

life of the bearing.

recommended

or

which is

light coat

removed from

greasing.

tilting screws.

light

Use

which

inside the

has two bearings on

a

coat of oil

machine.

A multi-purpose

tilting apron

rockers as needed.

VARIETY SAW

it left the

factory

and secure the

coating of

in

the

of SAE

next

of oil

rust

all

motor are

20

oil

general

for

be applied to the tilting

to the tilting screw

to both of the elevating and

on the

the

grease

should

was

checked

to be shipped to

machine

preventive

parts

of the

to the

com-

machine

LUBRICATION

lubricated

and a multi-purpose

use on all

motor

elevating shaft,

tilting

apron located

be used on the

and

parts

hand

grade

good

by a

inflammable

all elevating

Lubricate all

make

Check

binding

to

or striking.

material.

and tilting screws

kerosene or a

of

parts

sure that

The motor elevating shaft

greased.

well

Apply a light

gauge

slides

and dry before

out saw

machine

not

week.

servicing.

slides every day.

should

Remove

dust

is hooked up to a dust collection system,

necessary to clean the dust

be

Be

sure

film

become sticky,

applying oil.

door on

from the metal chute every day.

wipe

to

good grade

must

Care

per

as

all

of oil

Keep the slides clean.

the side of the

off excess oil

be taken

are clean.

lubrication instructions.

parts

move

gears

to the two cable cross cut

wash out with

should be

machine and clean

chute but once a

and

non-

of

to

see that

freely without

kept

lf the

kerosene

lf

the

it will

grease

when

-\

7--OtL

\\,,'

-/)

_-\\./

6,/

/'\A

t-GR€ASE

&

\e

)

l

LcnEasE

qL-usE

@iRADE6SAE 20

Gl3fl!'lL-

LUffiIATE

uuLft

AS

PuRFpsE

-

N€EEO

Page 6

OPERATIONAL

CONTROLS

U

There

saw

arbor. This

reference

clockwise

To

set arbor

tilting

arbor hand

for

any

angle from

ln

pointer

degree

the

the

the

brake

motor

setting for

2-110

scale and

lf

using a

extension and

table.

ln

using the hand

push

hand

stops.

ELEVATING

is

one control

No. 5,

will raise

T!LT!NG

dwg. 2-279)

dado

button

knob

SAW

used to set the height

is

the arbor

elevating

drawing2-279)

the arbor

SAW

loosen

tilt

wheel

0

the lock

(6,

dwg. Z-279)

degrees

any angle

up with

lock in

the dado

station

to apply

place

extension when

do not hit

HAND

BRAKE

brake, first

(8,

dwg. Z-2791then

the

ARBOR

of the

hand

wheel

turning

the hand wheel

to the desired height.

ARBOR

knob and turn the

clockwise

45

to

degrees.

desired, line

with

the

degree

the angte

on the

the lock knob.

tilting make

place

any

shut off

brake and

motor

the

pull

wait till

under

on the

(see

to set

sure

at

the

For

coarse adjustment

spider

position

been

the

table

and reinsert

positioned

plate

lock

Turning

fence

into

position

plate

the

same

plate

allow

as

close

the

thumb

Then

it

will

the fence

the

to the

handle.

Coarse adjustment

as

ln

order to move

handle,

you

to

turn the hand

possible

as

your

Now

screw

by

turning

move

the fence

When

the

place

in

RIP FENCE

pins

and relocate

pins.

the

adjusting

handle

the hand

saw blade.

saw blade,

MICROMETER

and turning

knob

After the rip fence is in

of the micrometer

the

standard

the

fence,

then loosen

knob

to

the desired

fine

adjustment

back

to

the micrometer

into

desired

setting has

by

turning

of the rip

can

fence

the lence

Once the rip fence has

be

to the desired

made

by loosening

the hand knob.

oockwise will move

lock

RIP

with

FENCE

place

in

rip fence.

first loosen

the

thumb screw. This

so as

can

clamp

move

to

setting.

made

be

the adjusting

hand knob

the

saw

blade.

been

obtained, lock

the locking

plate

pull

out the

the

proper

locking

the

rip fence

the locking

will

fence

the

by

turning

shaft.

clockwise

handle.

is

y

1.

Stop

button locked

3.

Line

fuses

4.

Transformer

5. Translormer

6. Motor

ARBOR

burned

MOTOR

have

fuse

blown

HARD

blown

out

down

blown

TO

RAISE

Reset

overload

on

starter

box

Grease zerks

TROUBLE

button

&

SHOOTTNG

2. Tilting

BLADE

2.

MOTOR

Sel

DOES

screw

NOISY

D

screw

NOT

stop

TO TILT

floating

COME

Oil screw with

SAE 20

Oil bearing with

SAE

90" TO TABLE

Fleposition fan

or

fan

20

cover

oil

oil

Y

Page 7

-\

The miter

degrees

(14,

dwg.

the miter

lock

and

NOTE: Make sure

First

vided at the end

arbor shaft

2-279) by

dwg.

Then use the

the arbor

by turning

After replacing

is tight by turning

arbor

the arbor

t

MITER GAUGE

gauge

to the

either

Z-2791loosen

gauge

in

cannot

and set the

place

REPLACING

be

place

the arbor

with the

of the arbor shaft to

turning.Remove the throat

from

lifting up.

(13,

nut

dwg.

the arbor

holding

pin

go

will

right or

the

from

left,

to set the

hand knob

angle

on

0 degrees

hand knob.

BLADE

SAW

that the

power

is

off

accidently started.

holding

arbor wrench

2-279) and

nut

clockwise.

the

saw

counter clockwise, and

pin

provided

the

blade, make sure that the

before starting the

to

60

gauge

miter

(DK-3)

and turn

the degree scale

and that motor

the

pro-

motor

in the hole

keep

plate(13,

remove

to

loose

saw collar

remove

motor.

SOUARING

When checking

its highest

to

Check

the

square

the teeth of

base under

connecting

guard

Z-2801is

(10,

vertical

tilting stop

tilting screw

of

arbor

the

turn

the arbor squareness

(not

table

against

the blade).

To adjust the

the

arm

(14,

dwg.

located

2-2801, the tilting stop

dwg.

position

loosen the

Next

screw

and the tilting stop

tilting

blade.

hand wheel till the saw

the saw

Then square the

table. Once

the tilting screw

arbor tilting screw

Then replace the dust

for

squareness,

position

on

the

without forcing it at

the throat

of the saw

side

blade look on the

motor arbor and

(17,

dwg. 2-280)

2-280).

at the

of

The

far

the blade.

jam

provide a gap

in to

saw blade to

the saw blade

out until

lock in

and

mover.

Now if the tilting degree scale

not line up with the degree

does

2-2791loosen two

readjust the scale to the

and

the two

screws to

screws

lock

the degree

ARBOR

by

plate)

tilting stop

of the arbor

end

(15,

nut

it

place

(19,

dwg.

pointer.

TILT

elevate

placing

and the

blade

inside

locate

and

remove

the

a square on

leg

(not

the main

of

the arbor

(16,

screw

tilting screw

screw controls the

2-280) and turn

dwg.

between the arbor

screw

is

contacts

for adjustment

the table by turning

blade is square to

square

to the table

the end of the

with the

(20,

dwg. 2-2791

pointer (101,

2-2791on the

Then retighten

place.

in

scale

motor

the

top.

of the

against

tilting

the dust

dwg.

jam

nut.

dwg.

scale

HAYE

ARBOR MOTOR

1.

Disconnect

Remove blade

2.

Lower

3.

4.

Remove conduit

Through

5.

6.

motor

the

At this

power

motor to down

motor access

saddle

point,

motor to the

7.

The motor

Replacement

8.

With the

1.

2.

Using

contacts

should contact

atigned

can then

motor bolted loosely

a combination

the side

in

this

aciomplished

part

in

of

motor

the

rear

-

hex head bolts

source

guard,

throat

position

and wires

hole

casting.

person

one

person

on the bottom.

be lifted through the

is

accomplished

squar€,

of the saw blade.

the saw

axis, the arbor should

by clamping a combination

and out until

the apron.

may

then be tightened.

REMOYAL

from machine.

plate,

and blade from machine.

and tilt to approximately

from

starter

R.H. side of

on

grasp

can

position

blade evenly.

the square blade

When the

the

reverse

in

ARBOR MOTOR

place,

in

the

When slid back and

also be

motor is aligned in these

TABLE DOES

-

box.

machine remove

arbor through the

motor

access

order above.

mount a straight

head in

lf not, move

R.H. dovetail

the

the

positioned

square blade

just

contacts

1{OT

45o.

41/2" hex head bolts

lhe

throat

plate

hole on

ALIGNMENT

blade on

saw

forth either

motor

until

properly

between

the side

the

of the splitter

axis, the

two

slot and slide

in relation to the splitter

TO BE RETOVED

that attach the

hole in the table top

R.H.

the

tho arbor

side of

of the

side

and

the

the saw

raise the

square's

arbor, the square

this is accomplished.

tight and

loose saw collars

ways and blocks

motor can be

help feed the

and

machine.

motor

up.

blade out until

ln addition

block.

This can be

and adjusting

located on the

lowered and

motor to

it

blade

to being

lhe 41/2"

Page 8

Y

Y

Y

8

Page 9

-\

t

a

NORTHFIELD

FOUNDRY AND

P

O. BOX

NORIHFIELD UINN. 5fi57

9

t40

HACHINE

CO.

Page 10

Y

Y

10

b

Page 11

I

*-SLOTTED

SPECIFY

TABLE SHOWN.

SOLID OR SLOTTED

SHCS 1"x r

LATCH |AJSING

PIN

A

6D

\

-b

TABLE

STRIP

x

2a'

FHCS

RAIL

LOWER BUMPER

2z'

HANDLE

'I

BAR

r\

*_SPECIFY

SOLID

11

SLOTTED TABLE,

OR

Page 12

rd

-J

a

E

a

J

o

t

o

a

l.U

l-

o

-J

v)

\

F

cr)

'

*{\

^aq

(o

\t

\f

o

a

-\

o

1-

\

I

q

s

q

t{l

a

E

q

I

N

N1

"$

Y

x

(o

x

o

o

N-

-\

-J

a

(/)

C"

(j

d

-J

\

t

q

t

t

tf)

J

p

i

a

o

=

t

(-)

o

\

o

(\r

C\I

\

trJ

t'-

q

f,

E

trt

=

l-

a

$

o

t

q

tU

t{J

=

t-

a

O)

v

r)

N

(

a

ll

I

t

s

N

O)

@

(o

\t

N

\f

o

L

\

(5

I

tU

q

J

t!

=

l-

q

q

o

I

(5

&

a

ts

t-

:

f,

l{J

t

1-

UJ

(r)

$

J

o

,4

N

q

1.j-

Q

t

r

e

Ni

(o

(o

$

{\r

t{J

s

-J

x

;

a

:\

N

-\

1-

sj

sj

(j

d

o

=

-:

-r-

t

E

t

t

N

N

:J

:J

lr.

q

E

o

o

r

(l

()

r)

N

l-

t{

t{

-J

1-'

q

\

R

-x

o-

-\

a

s

v)

()

]-

{

trt

-r-

f,

=

a

a

T

=J

N

o

e

=

(r

o

s

ct

O)

o

o

\t"

\t

F-

o

o

t{

N

r)

I

N

\t

l.U

x

(D

.G

n\

=

il

uj

(o

d

(D

tJ"

t

U

t

-J

o

N

-J

'f)

l{

o

I

o

()

Nl

s

(o

$

\t

t-

t{

UJ

q

t{

a

co

F.:-

e

I

r,

\t

\j

.t

n\

.x

a.

r(

P

(/)

-J

(/)

t{t

s

o

-J

a

.r-

N

a

J

o

$

:J

p

E

q

o

o

N

*

{I

tul

:

Jl

En

x=

EI

=i

a

a

J

o

l{l

F

q.

-

s

(,

t

P)

U

t

a

P

o

a

l-

q

(

I

9

I

I

#:

Hft

:il1

*s

I{!

+

iD

(

I

{

f

:

\@

ir il,

,-ffi

.

U

*

---r

YC

-o

€

I

.@

)

6)

\:/

o-o

12

Page 13

^\

3

9

nr

o

t--

5

a

Y

()

o

l-

f,

?

Y

$

q

UJ

()

tr

v)

il

Pi;

f f ff

o

a

>-

'(r)

?

,\

u)

{

a

e

5

6

q

=

Y

N

,.)

&

r-)

u)

.-\

L.;

\8.

|

.:.J'

J..-t./

a,

13

Page 14

aMs.z-u,

PARTS INCLUDE

NAMEPLATE

DATA

MOTOR

COMPLETE

v

DADO

EXTENSION

LOCK

v

14

v

Page 15

PUSHBUTTON.

i

BUTTONS

NO RT H

HOUR

METER

F

I

E LD

y,'^8:r'iflEl

MOTOR

OPTIONAL

HOUR

METER

OPTIONAL

LIMIT

ON HAND

MAIN STARTER

SVITCH

BRAI(€

I NTERLOCK

N.O.

LINE

START

VOLTAGE

PUSH

LI NE

I

J

A

)2)

OPTIONAL

)

DISCONNECTS

&

FUSES

ll#oPrtoNAL

llF

u-

NORTHFIELD*ffi?ffifY'

MOTOR

C

A

MAGNErtcs

Ac.

WIRI

MOTOR

NG

it-

zt

-oi

Page 16

v

OCTAL

BASE D€TAIL

POWENSIAI

-TYPE

9

NORTH

FIE LD

ELECTRIC BRAKE OIAGRAM

'frXiflirr'e

N-2//4

%o

v

TRANSFORMER

(uARNER

AUXILIARY

(

904-9qLoo2)

19Ds4682Nc

o

o

uo

tr

o

F

:o

o

INTERLOCK

)

POWER

(

Mcs-8ot

/6-\

(:o:)

\-9,/

16

SUPPLY

)

N OT ES:

FUSE LOCATED UNOER TOP

COVER ON

lF 575

LINE

CONNECTED

rAPS ON

BRAKE

rorcuE 40 Ff. L0.,

DWG.

TRANSFORME R 904

rcWER

socKET cus

POWERS|AT

ltonTHFtELD

POWER

V lS

f0

VOLTAGE

PB-5OO,

l-25550

SUPPLY MCS-8OI

BE

IT

IO II5

TRANSFORMER

90 V.DC,

-8

fYPE

FouNDRy

I

ELECTRIC BRAKE

SUPPLY

POWER

MAY

8E

AND 460

PER

il-OO2

- 90

9

-

MecHllE

DIAGRAM

co.

v

Page 17

G-

/

€r

//

-.-'

6)

Y

--'/

\

N

o

o

N

i

o

r,

o

o

I

o

\

()

o

rt

o

Sl

fe

tu

q

-

l.-

l-

s

a

t

t

=

q

o

$

N

I

e

9

o

o

i

n

d

o

c:

:

o

(n

o

l*

o

6

D

N

(o

UJ

r)

I

o

o

D

()

l-

l,!

e

o

q

a

,Y

J

ci

q

!

a

-L

!

U)

F-

LU

J

=

\

a

Q

,}

\Jt

ll-l

o

=

c0

()

t"-

N

v

ra)

R

t'o

o

N

N

N

a

=

=

ar

x

LU

\i

N

I

e

UJ

=

ac

O

U)

OJ

N

t)

I

I

(o

I

e

r/)

\

l'{l

a

UJ

=

q

q

q

q

()

o

(/)

U)

F-

o

v

e

N

N

=

=

b

e

@

\

d

(o

q

lt)

l,!

0_

!

I

\

J

()

|--

a-

t-

o-

t-

-

(t)

s

(/)

=

q

r}.

e(

H

tu

UJ

uj

\

a

o

=

uj

a-

R

N')

to

N

o

to

I

rtl

()

k?

:

s:

os

(a

a

J

t{

tr

-.l--

i\

q

o

e

(r)

o

t{

\

{

aa

a

o

q

l-

o

UJ

{

=

(D

I

LJ

q

t

a

a

k

t--

o

LU

-J

UJ

ID

f,

o

t{J

(/)

fi

-J

x

o

o

q

X

o

a

J

$

(<

F-

O

t-Ll

d

t{

q

=

s

t

(4

LU

a

I

()

s

C(

UJ

a.

dg

RS

\J

_ax

J

tr

\rJ

a

Xr

-,

l-Q

?d

tj

F-

Q-

r..,

<

LLJ

t

b

17

Page 18

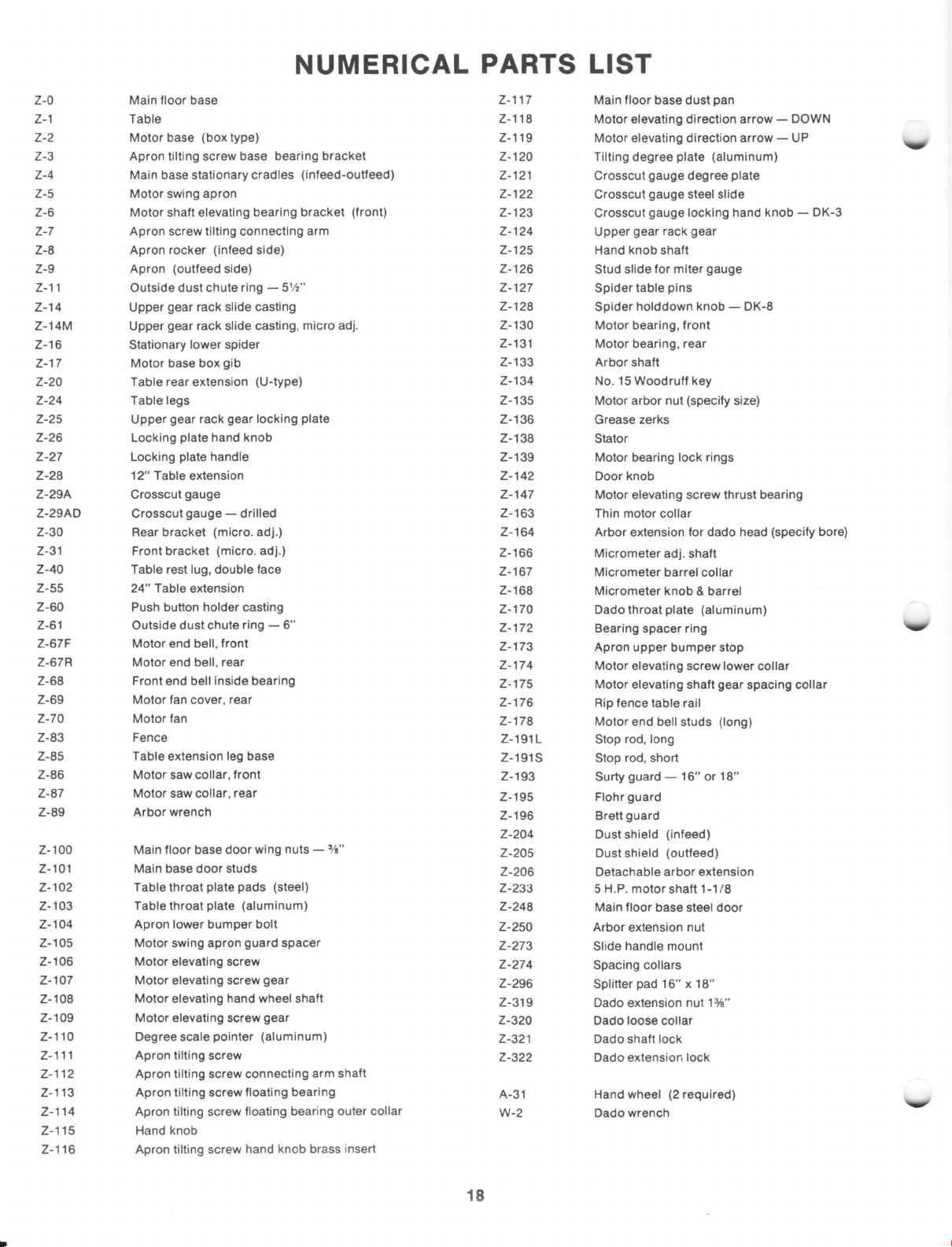

NUMERICAL

PARTS LIST

z-0 Main floor base

Z-1 Table

Z-2 Motor base

Z-3 Apron

(box

tilting screw

type) 2-1'19

base bearing bracket

Z-4 Main base stationary cradles

Z-5

Z-G Motor

Motor swing apron 2-122

elevating bearing

shaft

(infeed-outfeed)

bracket

(front)

2-117

Z-118

2:120

2-121

Z-123

Z-7 Apron screw tilting connecling arm 2-124

Z-8 Apron rocker

Z-9

Z-11

Apron

Outside dust chute

Z-14 Upper

Z-14M Upper

2-16

Z-17

Z-2O Table

Stationary

Motor

rear

(infeed

(outfeed

gear

rack

gear

rack

lower spider

box

base

extension

side) Z-125 Hand knob

side)

ring

5%" Z-127

-

slide casting

slide

casting,

micro

adj.

2-126

2-128

2-130 Motor bearing,

Z-131

gib Z-133

(U-typel 2-134

Z-24 Table legs 2-135

Z-25

Upper

gear

2-26 Locking

Z-27 Locking

plate

Z-28 12" Table

Z-294 Crosscut

Z-29AO

Crosscut

Z-30 Rear bracket

Z-31

Z-40 Table

Z-55 24"

2-60 Push

Front

bracket

rest

Table

button

2-61 Outside dust chute

Z-67F Motor end

gear

rack

plate

hand knob

handle

extension Z-142 Door knob

gauge

gauge

lug, double

drilled 2-163 Thin motor

-

(micro.

(micro.

extension

holder

casting

ring

front

bell,

Z-67e Moior end bell, rear

Z-68 Front end

Z-69 Motor fan

inside bearing

bell

rear

cover,

Z-7O Motor fan

Z-83

Z-85

2-86 Motor saw

Z-87 Motor saw

Fence

Tabl€

ext€nsion

collar,

collar,

leg base

front

raar

Z-89 Arborwr€nch

locking

adj.)

adl.)

face

6"

-

plate

2-136

2-138

2-139

2-147

2-164

2-166

2-167

2-168

Z-17O

Z-172

Z-1lg

2-174

2-175

Z-116

Z-1ZB

Z-191L

Z-191S

Z-i

93

Z-1gS Flohr

2-196

2-204 Dust shield

2-100 Mainfloorbasedoorwinghuts-t/"

Z-101

Z-1O2

Main base

Tablethroatplatepads

Z-103 Table throat

Z-104 Apron

lower

2-105 Motor swing apron

2-106 Motor elevating

Z-1O7 Motor elevating

Motor

2-108

2-109

elevating

Motor

elevating screw

2-110 Degree scale

studs

door

plate

(aluminum)

bump€r bolt

guard

screw

screw

hand wheel

pointer

(steel)

spacer

gear

shaft

gear

(aluminum)

Z-111 Apron tilting screw

2-112 Apron tilting screw connecting

Z-'l'13

Apron tilting scr€w

2-114 Apron tilting screw

floating bearing

floating bearing outer collar

arm shaft

Z-ZOS

Z-206 Detachable arbor €xtension

2-233

Z-248

Z-2SO Arbor

Z-273

2-224

2-296

2-319

Z4ZO

7421 Dado

2-322 Dado extension lock

A-31 Hand wheel

W-2 Dado wrench

2-1'15 Hand knob

Z-1'l'6

Apron tilting screw

hand knob brass

insert

floor

Main

Motor

Motor elevating

Tilting degree

Crosscut

Crosscut

Crosscut

Upper

Stud

Spider

Spider

Motor b€aring,

Arbor shatt

No.

Motor arbor

Grease zerks

Stator

Motor bearing lock

Motor elevating screw

Arbor extension

Micromet€r

Micrometer

Micrometer

Dado throat

Bearing

Apron upper

Motor

Motor elevating

Rip tence table rail

Motor

Stop

Stop

Surty

grettguard

Dustshield

5H.P.motorshaft1-1/8

Main floor

Slide

Spacing collars

Splitter

Dado

Dado

base dust

elevating diroction

gauge

gauge

gauge

gear

rack

shaft

slide for miter

table

holddown knob

15 Woodruff key

nut

collar

adj.

barrel collar

knob & barrel

plate

spacer ring

elevating screw

end bell studs

rod, long

rod,

short

guard

-

guard

(infeed)

(outf€ed)

base steel door

extension

handle mount

pad

16,, x 1g,,

extension

loose

collar

tock

shaft

pan

diroction

plate

(aluminum)

degree

st6el slido

locking

gear

gauge

pins

front

rear

(specify

rings

for

dado

shaft

(aluminum)

bumper stop

shaft

.l

6,, or

nut

nut 1%,,

(2

required)

arrow

arrow

plate

hand

DK-8

-

size)

thrust

head

lower

gear

spacing collar

(long)

18,,

DOWN

-

UP

-

knob - DK-3

bearing

(specify

collar

v

bore)

v

v

18

Page 19

ASSEMBLY

plate

mount

lock lug

(std)

Block

Key

(1)

key

pin

(1)

z-59

z-179

z-180

z-181

z-'182

z-183

z-184

z-'t85

z-186

z-187

15K

316P

HAND

BRAKE

Brake drum

Brake

Brake band

Cable

Brake spring

Brake cable

Limit switch

Mount

Cutter

Brake cable for limit switch

Woodrufl

Cotier

516-

34SHSS

Setscrew

(1)

615-

34BHCS

10145HSS

SLIDING

zRT-33

zBT-36

zRT-37

zqr-62

z-152

z-154

z-1 56

z-160

z-'t61

z-162

z-171

z-'t76

z-190

z-200

z-273

DK.8

141TS

HHCS

516-1

203BB

14HHCS

516-1

DK-3

z-188

z-192

LOWER

ZRT-31

Cap screws

Setscrews

TABLE ASSEMBLY

Sliding table,

Bevel

Bearing

Sliding stock stop

Sic,e

Stop

Gauge table

Stop

Stop

Stop

Ball bearing shaft

Slot

Hand knob

Hand knob lock

Slide

Table lock handle

Thumb screw

Cap

Ball bearings

Cap screws

Hand knob

Stop

Table

TABLE ASSEMBLY

Stalionary table

(4)

(2)

left

side

gauge

holders

handle

rod lock bolts

pins

(short)

rod

(long)

rod

rod block

(lor

tiller strip

handle mounting

(4)

screws

(2)

(6)

pin

extension

legs

ZRT-32 Lower stationary table

ZRT-34

Table supporl

arm

ZRT-35 Table support arm

ZRT-38 Hand knob lock

plates

ZRT-39 Ball bearing holders

(tor

rods)

sq.

round rods)

infeed

side

outleed side

z-146

z-147

z-'t48

z-149

z-1so

z-15'l

z-153

z-169

z-171

z-26

1

31 6-

34SP

516JN

1 4

516-1

SHSS

14-125HSS

38-214SHSS

38.JN

38W

14BHCS

38-1

HHCS

38-1

38-1SHSS

12-134HHCS

14HHCS

38-1

z-1 89

14.12RHMS

14W

6-14DS

HHCS

38-1

1O.34RHMS

12HHCS

12-1

HHCS

12-1

38-34HHCS

HHCS

516-1

516N

1 2-1 3HHCS

14-316FHCS

12-1 14HHCS

12HHCS

58-1

HHCS

38-1

38-1SOSS

12HHCS

38-1

38LN

1

2SP

31 6-1

316-134SP

38-123HSS

14HHCS

38-1

14-58RHMS

38-1SHSS

1

HHCS

2-1

38-125HSS

38-1 12HHCS

14SOSS

38-1

38LN

10-14RHMS

12-1 l2HHCS

38N

38AN

15K

5100-137

Ball bearings

Thrust bearing

Gear rack

Gear

Gear shaft

handle

Crank

Gear rack

Adiusiing

Ball bearing shalt

Table

Spring

Jam

Setscrews

Set

Set

Jam

Flai washers

Pivot

Cap screws

Set screws

Cap

Cap screws

Stop

Dust

Dust

Oust

Dust chute

Tilling

Table

Table leg to table bolts

Table

Table

Table throat

Table rear

Motor

Apron

gib

plate

lock hand

pin

(1)

(5)

nut

(5)

nuts

bolts

screws

(3)

(2)

(2)

(8)

(8)

(9)

(9)

(6)

(8)

screws

screws

pin

pan

screws

pan

washers

pan

drive screws

ring bolts

plate

degree

leg to base bolts

plate pad

throat

plate

throat

plate

exlension

guard

swing apron spacer

rocker

bolls

knobs

(8)

(8)

(7)

screws

(4)

(4)

screws

support

support

bolts

(6)

Main base stationary cradle

Apron

Apron

Apron

Apron

Motor

Motor

wing bolts

dusl

upper bumper boll

bumper screws

upper

upper bumper set screw

elevating screw

elevaling screw

Motor elevating shaft

Motor

elevating

Tilting dogree

Apron

pointer

lilting set scr€w

Apron tilling screw

Apron

tilting scr€w

base

base

gauge

guide

gib

gib

gib

bolts

(4)

Motor base

.Motor

Motor

Crosscut

Stock

Motor nuts

Motor acorn nuts

Woodrufl key

(2)

ring

Snap

(4)

lower collar spring

gear

hand wheel screws

shaft bearing bracket

screws

(1)

brackei bolls

hand wheel

holding bolts

set screws

lock nuts

plate

degree

(2)

(4)

(1)

(2)

bolts

nuts

(2)

bolts

(1)

spring

(3)

(3)

(4)

(4)

(4)

bolts

(6)

(2)

lock nut

pin

(2)

(2)

screws

(6)

screws

(2)

(1

)

pin

(1)

(1)

(2)

front screws

(2)

(4)

(2)

19

Page 20

Loading...

Loading...