Page 1

OWN-GEN

WaveNet Digital Monitoring System

General Installation

and User Manual

Marine Generators | Marine Diesel Engines | Land-Based Generators

Page 2

Northern Lights

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2012 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

PART NO.: OWN-GEN 1/12

Page 3

USER MANUAL

for WaveNet Generator Set Controllers

Table of Contents

WaveNet Specifi cations .....................................2

GROUP 1 - WAVENET CONTROLLER SERIES

1.1 This Manual...........................................3

GROUP 2 - RECEIVING, HANDLING & STORAGE ..4

GROUP 3 - INSTALLATION & WIRING

3.1 Safety Information ................................. 5

3.2 12/24 VDC System Operation ...............5

3.2.1 Relays ................................................6

3.2.2 Relay Fuses .......................................6

3.3 WaveNet Terminals ........................6 - 10

3.3.1 Current Transformer Wiring Note .....10

GROUP 4 -

4.1 Power-Up ............................................ 10

4.2 Controller Alarming ............................. 10

4.3 Controller States ..........................11 - 12

4.3.1

4.4 WaveNet Start / Stop Behavior ....12 - 13

4.5 Controller Sleep ..................................13

4.6 WaveNet Menu System Operation ......13

4.7 Basic Menu .........................................14

4.7.1 Clock Setup ......................................14

4.7.2 Basic Setup ...................................... 15

OPERATION & BASIC USER CONFIGURATION

Locking the WaveNet Screen in Run Mode

. 12

4.7.3 Event History Log ...........................16 - 17

4.8 WaveNet LED Status Indicators ..........18

4.9 Lamp Indication Meanings ............18 -19

4.10 Warnings & Failures ...................19 - 20

4.11 Genset Online ...................................20

GROUP 5 GROUP 6 RECOMMENDED MAINTENANCE

GROUP 7 - WAVENET REMOTE PANEL

7.1

7.2

7.2.1 Genset Controller’s Name ................22

7.2.2 State .................................................22

7.2.3 Status Mark ...................................... 22

7.3 On-Line Genset Parameter Mode 22 - 23

GROUP 8 - APPENDEX A: ACCESSORY LIST

8.1

8.2 CT’s (Current Transformers) ...............24

8.3

8.4 WaveNet Fusing ..................................24

GROUP 9 - APPENDIX B: ADDITIONAL DRAWINGS

ADVANCED SETUP ..........................20

.....20

Remote Unit Settings

On-Line Genset Status Mode

WaveNet Controller Harness - Accessories

WaveNet Replaceable 12/24 VDC Relays

................................21

...............21 - 22

....23

..24

.2 6

It may not be reproduced in whole or part without the expressed written permission of Northern Lights, Inc.

© Northern Lights, Inc. 2012. All rights reserved. Litho U.S.A. Publication number:

Proprietary Information

This publication is the sole property of Northern Lights, Inc.

OWN-GEN 8/12

1

Page 4

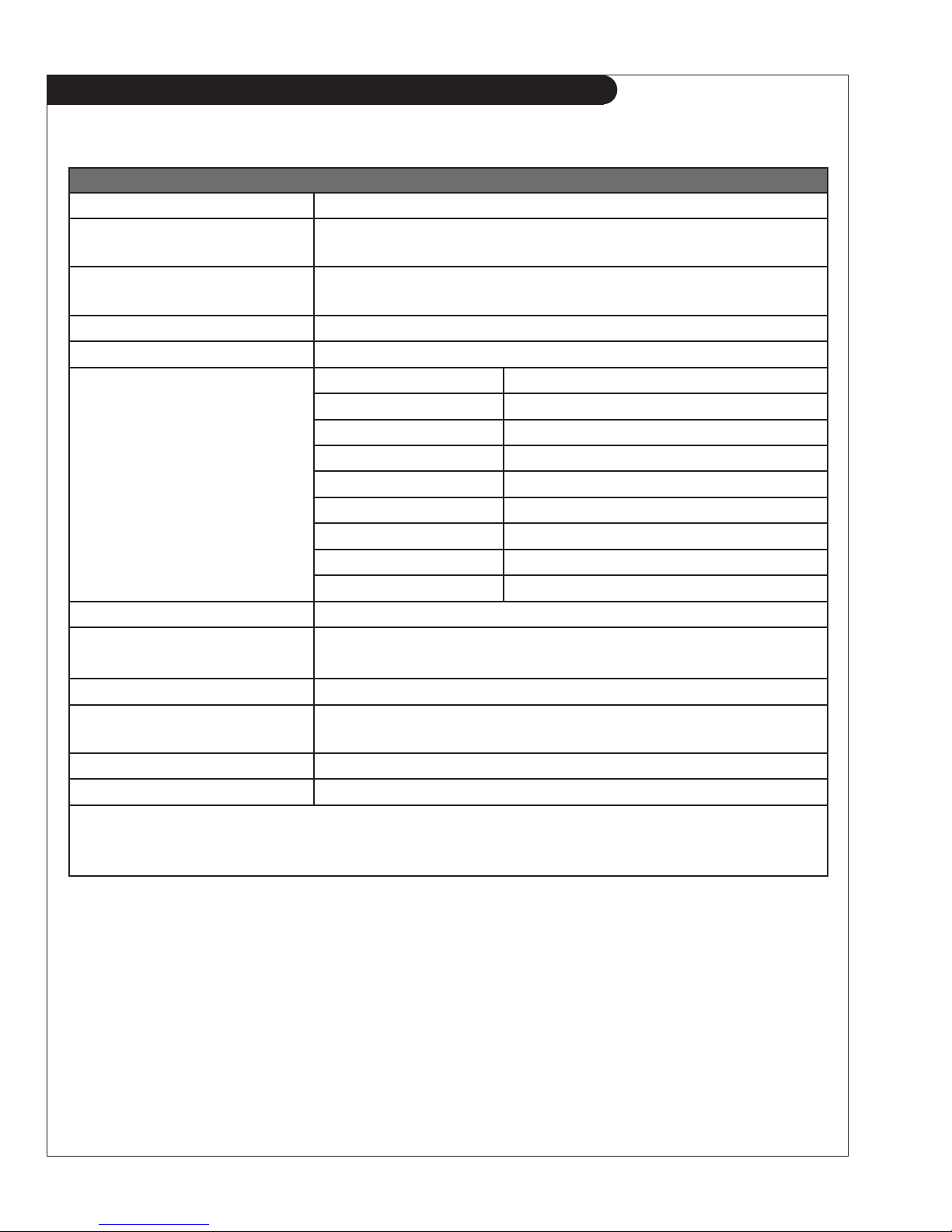

WAVENET SPECIFICATIONS

Table 1: Wavenet Specifi cations

VDC Rating 12/24 VDC

Standby Current

50 mA @ 12 VDC

Consumption

Load Equivalency Number

WaveNet: 1 / WaveNet remote:2(NMEA 2000® Spec. : 1 LEN=50mA)

(LEN)

Operating Temp -40oC to +85oC (-40oF to +185oF)

o

LCD Operating Temp. ** -20

Function

Range

C to +70oC (-4oF to +158oF)

Function Range

Speed Sensing 0-300vac, 0-3600rpm

Voltage Sensing Max 700vac, +/- 1%

Current Sensing * Max 5A, +/- 2%

Frequency Sensing 1 - 100 HZ

o

Engine Temp 10-265

F

Oil Pressure 0-90 PSI

Analog Input 7mA Max

Digital Input 7mA Max

o

LCD Display 128 x 60 Graphic Display, Backlit, 60

viewing angle

LED Display Red, Green, Yellow LED representation, Daytime visible, 60

viewing angle

®

NMEA 2000

Connector DeviceNet Micro-C

Relays replaceable relays for Run signal and Preheat signal, 12 or

24VDC Coil

Dimensions W x H x D: 139 x 113 x 65 mm (5.7 x 4.45 x 2.56 in.)

Weight 0.45 kg (1.0 lb)

* Use of industry standard CT required.

** The LCD display will exhibit color and response time changes at high and low

temperatures respectively but will not be damaged as long as within Operating Temp.

o

OWN-GEN 01/12

2

Page 5

1. WAVENET CONTROLLER SERIES

The WaveNet is designed for use on generator sets

with mechanical engines. It can monitor analog

data from senders on the engine and generator

such as oil pressure, coolant temperature, current,

voltage, engine speed and generator frequency

.

In addition to the monitoring features, the

WaveNet controller can be used to provide

protective warnings or shutdowns.

WaveNet Front View

This manual is divided into two sections:

1. Hardware installation

2. Operation / Confi guration

1.1 THIS MANUAL

WaveNet Back View

OWN-GEN 01/12

3

Page 6

2. RECEIVING, HANDLING & STORAGE

Receiving:

Every effort is made to ensure that your WaveNet gen-set controller arrives at its destination

undamaged and ready for installation. The packaging is designed to protect the WaveNet internal

components as well as the enclosure. Care should be taken to protect the equipment from impact at

all times. Do not remove the protective packaging until the equipment is at the installation site and

ready to be installed.

When the WaveNet reaches its destination, the customer should inspect the shipping box and controller

for

any signs of damage that may have occurred during transportation. Any damage should be reported

to a Northern Lights representative after a thorough inspection has been completed.

A shipping label affi xed to the shipping box includes a variety of product and shipping information,

such as items and Customer numbers. Make certain that this information matches your order

....

information.

Each WaveNet controller is packaged in its own box. Do not discard the packing material until the

controller is ready for installation.

Handling:

As previously mentioned, each WaveNet gen-set controller is packaged in its own individual box.

Protect the equipment from impact at all times and do not carelessly stack. Once the controller is at

the installation site and ready to be installed, the packaging material may be removed.

Storage:

Although well packaged, this equipment is not suitable for outdoor storage. WaveNet is to be stored

indoors for any period of time, it should be stored with its protective packaging in place. Protect the controller

at all times from excessive moisture, dirty conditions, corrosive conditions, and other contaminants. It is

strongly recommended that the package-protected equipment be stored in a climate-controlled environment

of -20 to 65°C (-4 to 149°F), with a relative humidity of 80% or less. Do not stack other equipment on top

of the stored controllers.

OWN-GEN 01/12

4

Page 7

updated 1-17-12

3. WAVENET SERIES INSTALLATION AND WIRING

3.1 SAFETY INFORMATION

Generator systems contain high voltage circuits. Working on powered equipment can cause damage to

equipment, injury, or death. The following symbols will be used in this document to classify information:

Caution: This is used to indicate something that you should take

special notice of but that is not normally a threat to safety.

Danger: This is used to indicate a potential for injury or death.

Danger - High Voltage: This is similar to Danger above but relates

specifi cally to conditions where high voltage is encountered.

The following general safety precautions should be headed:

1. The WaveNet may carry high Voltage/Current which can cause serious injury or death.

Extreme caution must be exercised when connections are being installed to or from the

controller. All wiring connections must be de-energized before any installations are performed.

Wiring of the WaveNet should be performed by qualifi ed electricians only.

2. AC power may carry high Voltage/Current which can cause serious injury or death.

De-energize all AC power sources before any connections are performed.

3. NEVER energize AC power with AC current sensing connector unplugged. An energized,

unplugged connector could result in severe injury or death. Never unplug an energized

connector.

4.

WaveNet is connected on a NMEA 2000 network. Installation must be made by an

NMEA 2000 certifi ed technician.

3.2 WAVENET 12/24VDC SYSTEM OPERATION

The WaveNet controller can be placed in either 12V or 24V electrical systems.

OWN-GEN 01/12

5

Page 8

3.2.1 RELAYS

The WaveNet controller is designed to operate on 12 or 24 VDC systems. When operating on 12VDC

systems the fuel and preheat outputs require 12VDC relays, and 24VDC relays when operating on

24VDC systems. The WaveNet comes preinstalled with the correct relays depending on the product

number specifi ed when ordered.

Contact Northern Lights if replacement relays are required.

Relays for 12 or 24VDC system operation are as follows:

• 22-42047 for 12VDC operation

• 22-40085 for 24VDC operation

3.2.2 RELAY FUSES

CAUTION: needs to be taken when connecting relay outputs to an inductive load. Due to the

inductive nature of certain loads (starters, pull coils), initial current draw may be higher than stated

in the load specs which could damage the onboard relays.

Output relays are protected by onboard 40A fuse protection. Smaller amperage fuses from many

automotive stores may be used in place of the higher current 40A. If installing lower amperage fuse

protection, be certain that the current draw on each relay does not exceed the fuse current limit.

An approved 40A fuse is: LITTLEFUSE – 257040 (32VDC, 40A, auto fast action)

3.3 WAVENET TERMINALS

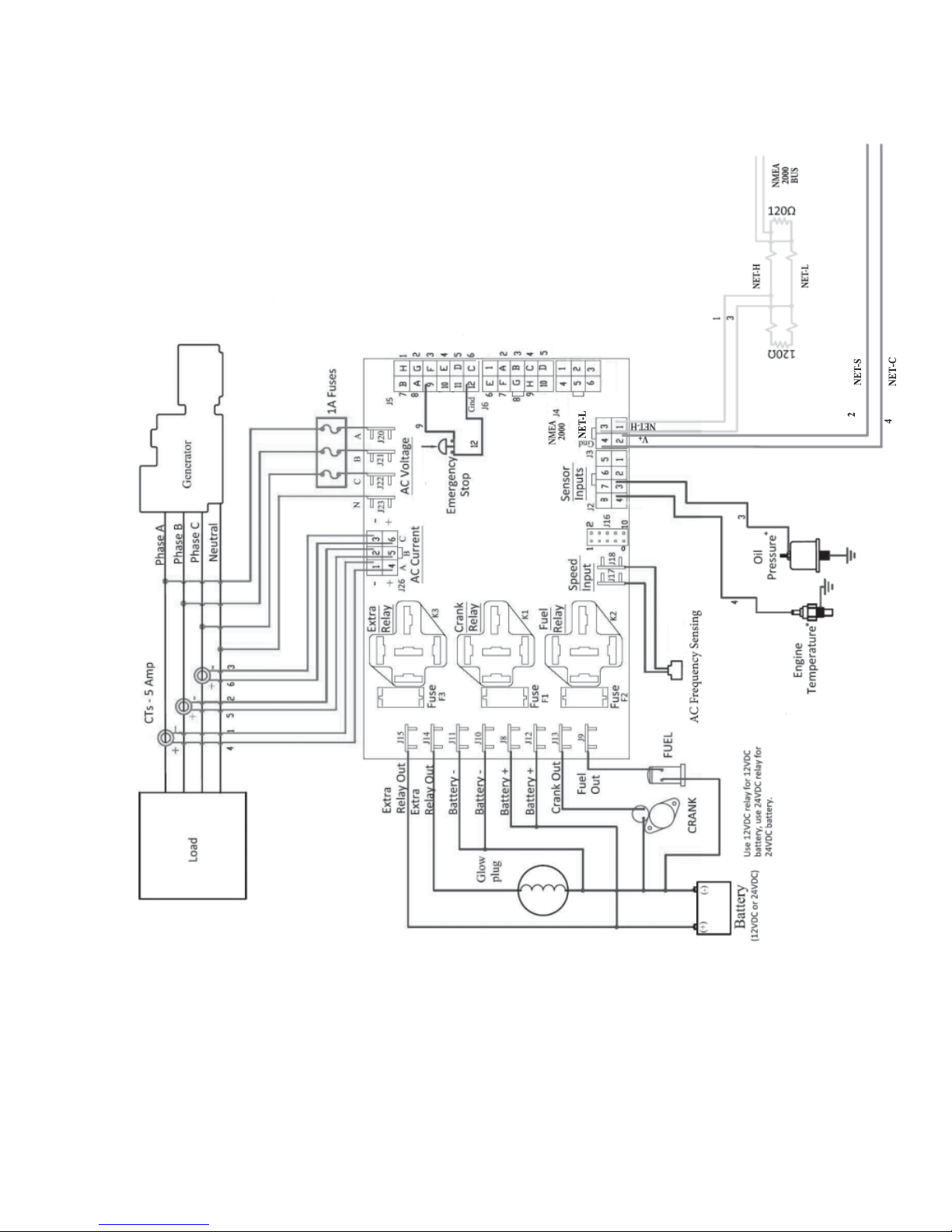

Figure 1 on page 6 shows the location of all terminals on the controller and the numbering of all

circuits.

Table 2 lists the minimum wire size, maximum current capacity, name, and function of each circuit.

The wire gauges given in the table are the minimum recommended only.

OWN-GEN 01/12

6

Page 9

updated 1-17-12

WaveNet is connected on a NMEA 2000 network. Installation must be made by an NMEA 2000

certifi ed technician.

Figure 1 - General WaveNet System Wiring Diagram

7

Page 10

TABLE 2

Table 2: WaveNet Terminal Details

Quick

Fit

Terminals

Analog

Inputs

Digital

Inputs

Terminal Wire Size

Current Max* Functions

(AWG)

Crank 12 40A Crank Output Terminal

1

Battery +

Battery -

12 40A Positive Battery Terminal

1

12 40A Negative Battery Terminal

Fuel 12 40A Fuel Output Terminal

Extra Relay

12 40A Pre-Heat Input Terminal

Extra Relay 12 40A Pre-Heat Output Terminal

Speed 1 18 100mA Speed Signal Connection

Speed 2 18 100mA Speed Signal Connection

Total controller current output (max 60A)

*

1

Ensure wire gauge is suffi cient: otherwise (especially during cranking) there could be a voltage drop across the cable to

the controller from the battery related features of the controller.

Terminal

Detail

Terminal

Location

Wire Size

(AWG)

Current Max. Function

Ground 1 18 7mA N/A

Input 2 2 18 7mA N/A

Input 3 3 18 7mA Engine Temperature Sender

(Low Resistance, Gain of 3)

Input 4 4 18 7mA Oil Pressure Sender

(Low Resistance, Gain of 3)

Input 5 5 18 7mA N/A

Input 6 6 18 7mA N/A

Input 7 7 18 7mA N/A

5V out 8 18 7mA N/A

Terminal

Detail

Input H - GND

Input G - GND

Input F - GND

Input E - GND

Input D - BAT

Input C - BAT

Input B - BAT

Input A - BAT

Emer. Stop

Terminal

Location

Wire Size

(AWG)

Current Max. Function

1 18 7mA N/A

2 18 7mA N/A

3 18 7mA Auxiliary Failure

1

4 18 7mA Option Coolant Level Switch

5 18 7mA N/A

6 18 7mA N/A

7 18 7mA N/A

8 18 7mA N/A

9 18 7mA

Allows Manual Emergency Stop

(Open = Active)

10 10 18 7mA

N/A

1

Ground

Ground

1

Ground input to generate logic high.

11 18 7mA

12 18 7mA

Ground

Ground

OWN-GEN 01/12

8

Page 11

TABLE 2 (CONTINUED)

Digital

Outputs

RS485

(Modbus)

AC

Voltage

Sensing

Terminal

Detail

+ V Bat 1 18 1.5A N/A

Output A 2 18 200mA N/A

Output B 3 18 200mA N/A

Output C 4 18 200mA N/A

Output D 5 18 200mA N/A

Output E 6 18 200mA N/A

Output F 7 18 200mA N/A

Output G 8 18 200mA N/A

Output H 9 18 200mA N/A

+ V Bat 10 18 1.5A N/A

Terminal

Detail

RS485-A 1 18 7mA N/A

Ground 2 18 7mA N/A

RS485-B 3 18 7mA N/A

RS485-A 4 18 7mA N/A

Ground 5 18 7mA N/A

RS485-B 6 18 7mA N/A

Terminal

Detail

Phase A * 1 18 7mA Monitor Generated AC Voltage

Phase B * 2 18 7mA Monitor Generated AC Voltage

Phase C * 3 18 7mA Monitor Generated AC Voltage

Terminal

Location

Terminal

Location

Terminal

Location

Wire Size

(AWG)

Wire Size

(AWG)

Wire Size

(AWG)

Current Max. Function

Current Max. Function

Current Max. Function

Neutral 4 18 7mA AC Voltage Neutral connection

* Place 1A fuse between the hot lines and the voltage sensing terminals of WaveNet.

AC

Current

Sensing

Terminal

Detail

Phase A 1 18 5A Phase A Current Sensing CT Phase B 2 18 5A Phase B Current Sensing CT Phase C 3 18 5A Phase C Current Sensing CT Phase A 4 18 5A Phase A Current Sensing CT +

Phase B 5 18 5A Phase B Current Sensing CT +

Phase C 6 18 5A Phase C Current Sensing CT +

The current transformers (CTs) negative leads must be terminated individually into the WaveNet AC

Current connector. DO NOT CONNECT TOGETHER.

Terminal

Location

It is extremely important to connect each phase to the appropriate terminal location. Never

misphase inputs. Always match terminal details to the matching terminal location

Wire Size

(AWG)

OWN-GEN 01/12

Current Max. Function

9

Page 12

TABLE 2 (CONTINUED)

updated 1-17-12

NMEA

®

2000

Terminal

Detail

Terminal

Location

Wire Size

(AWG)

Current

Max.

NET-H 1 22 7mA NMEA2000

NET-S 2 22 7mA NMEA2000

NET-L 3 22 7mA NMEA2000

NET-C 4 22 7mA NMEA2000

3.3.1 CURRENT TRANSFORMER (CT) WIRING NOTE

The current transformers (CTs) negative leads must be terminated individually into the

WaveNet AC Current connector. Do not tie the negative leads together to a common ...

neutral or ground. The negative lead of the CT is usually black.

WaveNet is connected on a NMEA 2000 network. Installation must be made by an NMEA

2000 certifi ed technician.

4 WAVENET OPERATION & BASIC USER CONFIGURATION

4.1 POWER-UP

Function

®

Data High

®

Bus Power +

®

Data Low

®

Bus Ground

T

he controller will display the fi rmware and hardware version on the screen and fl ash the indicator lamps

on the side of the controller.

The controller will then enter the OFF mode. By default, it is possible to manually start the generator in

the OFF mode. The user can disable manual start in OFF mode in the basic menu (in which case the

WaveNet must be in the AUTO mode to manually start the generator). See section 4.7.2 on page 15.

Pressing the Info key will cause the controller to enter the AUTO mode. From this mode, the user

can put the controller into RUN mode (i.e. start the generator) manually or from a WaveNet Remote

Panel.

The controller has the ability to remember whether it was in the OFF or AUTO mode the last time it

was powered up and will reenter that mode when it is repowered.

4.2 CONTROLLER ALARMING

If the emergency stop input of the digital input terminal is not connected to ground the controller will

alarm and display “Emergency Stop” when powered. Emergency Stop also forces the controller to the

OFF mode.

To prevent this ground the emergency stop input (pin 9) to ground (pin 12) on the digital input

terminal. See Figure 1 on page 6.

OWN-GEN 01/12

10

Page 13

The WaveNet incorporates 3 primary modes of operation:

1. OFF Mode

2. AUTO Mode

3. RUN Mode

1. OFF Mode – When the WaveNet

is set to the OFF mode, automatic

starting will be disabled. No automatic

controls will be initiated. The OFF

mode may be initiated when no

generator controls are required or

when the controller confi guration

requires adjustment by pressing the

Stop button. The user can disable

manual start in OFF mode in the basic

menu. See section 4.7.2 on page 15.

4.3 CONTROLLER STATES

All of the failures and most of the warnings are disabled when the controller is in the OFF mode.

The controller will beep every few seconds to alert the user that the unit is in the OFF mode and

cannot automatically start. To silence this alarm, press the Stop key.

In OFF mode, you may simultaneously press the Up and Down arrow keys to perform a lamp

test.

2. AUT O Mode - When the WaveNet is set

to the AUT O mode by pressing the Info key,

automatic starting will be enabled.

engine is started,

failures will be automatically

If the

detected allowing for safe engine operation.

While in AUTO mode the controller will

display engine temperature, battery

voltage and engine hours.

OWN-GEN 01/12

11

Page 14

4.3 CONTROLLER STATES (CONT’D)

3. RUN Mode – The controller starts the engine/generator and enters the RUN mode

when it receives the command from a WaveNet Remote Panel or the user manually

starts the engine/generator by pressing the Start key.

The controller will automatically shut the

engine/generator down and re-enter the

auto mode if it initiated an engine/

generator start. When the controller is in

the OFF mode automatic starting is

disabled.

When the controller is in the RUN mode,

generator parameters will be displayed on

the screen to allow the user to monitor the

engine status. These include engine speed, generator voltage and current, and

engine temperature as well as others. The parameters are displayed in groups and the

screen scrolls between the various groups. The Page Roll Display menu option

controls how long each parameter group is displayed on the screen before moving on to

the next group. See Table 5 on page 15 for more information.

4.3.1 LOCKING THE WAVENET SCREEN WHILE IN RUN MODE

When in the RUN mode the WaveNet LCD screen can be locked to display a particular parameter

group. To do this press the Up and Down keys to scroll to the parameter group you wish to view

and then press the Enter key to lock the screen. You will see a lock symbol displayed on the top

right hand side of the display just under the date and time.

To unlock the screen press Enter again or use the arrow keys to scroll to a different parameter

group which causes the lock symbol to disappear. The screen will automatically unlock after 10

minutes.

4.4 WAVENET START / STOP BEHAVIOR

There are two ways to start the generator (start conditions):

1. Start key – Located on the WaveNet front panel.

2. Remote WaveNet panel Start key

OWN-GEN 01/12

12

Page 15

4.4 WAVENET START / STOP BEHAVIOR (CONT’D)

When the controller is in the AUTO mode the two manual start conditions above can be used to

start the generator. When the controller is in the RUN mode it will display the reason for start on

the screen (NMEA 2000 Run, Manual Run).

Stopping the Generator

The Stop key on the front panel can be used to place the WaveNet in OFF regardless of the start

condition.

4.5 CONTROLLER SLEEP

The controller has a low power sleep mode that it can enter when in the OFF or AUTO states. In

this state the LCD screen backlighting is turned off. The time it takes to enter the sleep mode is

confi gurable in the menu. It is recommended that the Sleep Delay is set as short as possible to

prolong the life of the backlighting and to reduce battery consumption.

The backlight display will illuminate automatically when a key is pressed. A key press will only

cause the controller to exit the sleep mode. The key must be pressed again to perform its normal

function.

4.6 WAVENET MENU SYSTEM OPERATION

The WaveNet incorporates a menu system to allow the end user to adjust basic settings.

In the OFF state press Enter to access the

WaveNet menu system. This is called the

Basic Menu. The following keys perform the

menu navigation:

1. Scroll up using the Up key

2. Scroll down using the Down key

3. Enter menus by pressing the Enter key.

Each menu has a “Back” selection. To go back to the previous menu scroll up to the Back selection

and press the Enter key. When in the basic menu you can go back to the OFF mode by pressing

the Stop key.

OWN-GEN 01/12

13

Page 16

4.7 BASIC MENU

When you press the Enter key in the OFF mode you will enter the Basic Menu which includes the

Clock Setup, Basic Setup, Advanced Setup, and Failure History submenus.

1. Clock Setup

2. Basic Setup

3. Advanced Setup

4. Failure History

Table 3: Basic Menu Layout

Basic Menu: Clock Setup Year, Month, Date, Day, Hour, Minute, 12/24

Basic Setup

Failure History

Contrast Adj, Page Roll Delay, State Roll Delay, Sleep

Delay, Maintenance, Not In Auto, Off Mode Start

4.7.1 CLOCK SETUP

The Clock Setup menu will allow you to set the clock. The clock is important if you are planning to

use the Event Log (records all failures and warnings and when they occurred).

Table 4 – Clock Setup Menu

Menu SELECTION AND RANGE

Year 2000-2099

Month January - December

Date 01-31

Day Monday - Sunday

Hour 00 - 23

Minute 00 - 59

12/24 12 Hours - 24 Hours

The WaveNet internal clock information can remain “in memory” for approximately 2 weeks

when no DC power is supplied to the controller. Two week memory storage is available in a

completely charged controller clock. DC power is required to be supplied continually to the

WaveNet for approximately 1 hour to allow a complete clock charge.

OWN-GEN 01/12

14

Page 17

4.7.2 BASIC SETUP

The Basic Setup menu will allow the user to customize the basic features of the WaveNet to their

preference.

The Contrast Adjustment allows the user to adjust the contrast of the LCD.

The Page Roll Delay controls how long each group of parameters are displayed in the RUN state

(i.e. when the engine/generator is running) before displaying the next set of parameters.

The second line of the WaveNet LCD screen is usually dedicated to displaying warnings,

and events. The State Roll Delay determines how long the warning or event message is

displayed before moving on to the next message.

Setting the State Roll Delay to a larger value may cause some warning or event

The Sleep Delay determines how long to wait after the last key press before turning off the LCD

backlighting.

ler exits

delay, and fi nally goes into sleep mode after the third sleep delay. The Sleep Delay does not work

in the RUN Mode or during cranking.

messages to not be displayed if the event or warning is of a short duration.

The Sleep Delay also controls the automatic exit from the menu system. First the control-

to the Basic Menu after the fi rst sleep delay, exits to the OFF state after the second sleep

The controller can be made to NOT sound the alarm when the controller is not in the AUTO mode.

This is controlled by the Not In Auto setting.

The OFF Mode Start setting can be set to Enable to allow a manual start from the OFF mode.

Otherwise a manual run can only be performed when the controller is in the AUTO mode.

Table 5 – Basic Setup Menu

Menu SELECTION AND RANGE

Contrast Adjust 5-95 %

Page Roll Delay 1-10 s

State Roll Delay 1-10 (1 is shortest delay, 10 is longest)

Sleep Delay 10-600s. Shorter is ideal to extend the backlighting life.

Maintenance

Read only. Displays the amount of hours until next service if this

feature is enabled. If service is overdue the hours become negative.

Not In Auto Disable Beep, Enable Beep

OFF Mode Start Disable, Enable

OWN-GEN 01/12

15

Page 18

4.7.3 EVENT HISTORY LOG

The WaveNet incorporates an event history logging

system. When engine failures or events occur, an

entry is created in the WaveNet Event History Log.

See Table 6 – Event Log Entries below for the possible

events that are stored.

A total of 70 entries can be recorded. Entries may be viewed simply by scrolling up or down using

the Up and Down keys. In addition to the entry reason information, the associated date and time of

the entry will be displayed.

The 70 entries are subdivided into a maximum of 30 events and 40 failures. This prevents one

type from fl ushing the other types from the log.

Simply scroll through the Failure History Log by

pressing the Up or Down arrow keys located on

the WaveNet.

The event history log can store up to 30 event and 40 failures entries. If these are

exceeded the oldest entry is replaced with the newest entry. The events and failures are

displayed together in the log in reverse chronological order (i.e. newest entry fi rst).

EVENT LOG ENTRIES

An “*” beside the Event Entry indicates the Event is a WaveNet event. All other events are failures. (See page section 4.10 on page 19)

Event Entry Description

ADC SWITCH FAILURE These are internal WaveNet failures. Try power cycle the

ADE READ FAILURE

ADE WRITE FAIL

AUTO ENABLE * Info button on the front face of controller pressed. WaveNet

AUXILIARY FAIL The Auxiliary Fail digital input has been triggered.

EEPROM FAILURE

EMERGENCY STOP The emergency stop input (located on the digital input terminal)

EPS LOADS ERROR AC current sensing indicating that the generator is not running.

HIGH BATTERY Failure occurred due to high battery voltage.

HIGH ENGINE TEMP Failure occurred due to high engine coolant temperature.

Table 6: Event Log Entries

WaveNet. If failure occurs repeatedly the unit could be defective.

placed in AUTO mode.

This is an internal WaveNet failure. Try to power cycle the

WaveNet. If the failure occurs repeatedly the unit could be defective.

has been activated.

This could indicate something is wrong with the WaveNet.

(See section 4.11 on page 20.)

OWN-GEN 01/12

16

Page 19

EVENT LOG ENTRIES

Event Entry Description

INITIALIZING *

KEY BOARD FAILURE This is an internal WaveNet failure. Try to power cycle the

LOCKED ROTOR Cranking attempt failed on locked motor.

LOSS OF ECM COMM NMEA2000 messages required by the WaveNet have not been

LOW BATTERY Low battery voltage failure.

LOW COOLANT (LEVEL) Low coolant level failure.

LOW OIL PRESSURE Low oil pressure failure.

MANUAL START * Generator started manually from the front panel Start key

MANUAL STOP * Generator stopped manually from the front panel Stop button

OFF ENABLE * Front panel Stop key pressed to disable automatic starting.

OPEN ENG TEMP

OPEN ENGINE TEMP

OPEN OIL PRES

OVER CRANK The engine did not start after multiple attempts.

OVER CURRENT Over current failure.

OVER FREQUENCY Generator frequency over the failure threshold.

OVER SPEED Generator RPM too high.

OVER VOLTAGE Generator voltage high.

POWER ON * WaveNet was powered up from unpowered state.

SHORT ENG TEMP Analog sender reads zero volts or close to zero. This could be

SHORT ENGINE TEMP

SHORT OIL PRES

TLE6230 FAILURE These are internal WaveNet failures. Try power cycle int WaveNet.

UNDER FREQUENCY The generator frequency is too low.

UNDER SPEED The engine speed is too low.

UNDER VOLTAGE

EEPROM is being loaded with factory defaults. This occurs on fi rst

power up.

WaveNet. If failure occurs repeatedly, the unit could be defective.

received. The generator has shut down.

Analog sender always reads the maximum voltage. Could indicate

that the sender is not connected to the analog input. (i.e. broken wire)

caused by a shorted sender.

If the failure occurs repeatedly the unit could be defective.

The generator voltage is too low.

OWN-GEN 01/12

17

Page 20

4.8 WAVENET LED STATUS INDICATORS

Some industry standard failures, warnings, and events

on the WaveNet are indicated by a series of LEDs on the

left side of the controller.

Specifi c LED indicators will be illuminated depending

upon the condition of the controller. The WaveNet LED

indicators allow a quick check of the controller’s condition.

The WaveNet displays multi color LED’s for specifi c

condition representation.

Red

- Represents Failure Conditions

Yellow

- Represents Warning Conditions

Green

- Represents Normal/Active Conditions

An LED test may be performed by the

user for illumination of all controller

LED’s. The LED test may be per-

formed

by simultaneously pressing

the Up key and the Down key on the

WaveNet.

4.9 LAMP INDICATION MEANINGS

Table 7: WaveNet Lamp Indication Meanings

LED

Description

Over Crank

High Engine

Temp

Low Oil

Press

LED color LED Status Indication

Red

Yellow

Red

Yellow

Red

Yellow

Solid Red

Solid Yellow

Solid Red

Solid Yellow

Solid Red

Solid Yellow

A solid red illuminated LED represents an Over Crank

condition on the fi nal crank attempt. This is a Failure.

A solid yellow illuminated LED represents an Over

Crank Warning condition when there are crank attempts

still remaining.

A solid red illuminated LED represents a High engine

Temp Failure condition

A solid yellow illuminated LED represents a High engine

Temp Warning Condition

A solid red illuminated LED represents a Low Oil

Pressure Failure condition.

A solid yellow illuminated LED represents a Low Oil

Pressure Warning condition.

OWN-GEN 01/12

18

Page 21

LED

Description

Over

Speed

4.9 LAMP INDICATION MEANINGS (CONT’D)

Table 7: WaveNet Lamp Indication Meanings (cont’d)

LED color LED Status Indication

A solid red illuminated LED represents an Over Speed

Red

Solid Red

Failure condition.

Battery

Status

Low

Coolant

Pre-Heat

Genset

Online

Yellow

Green

Yellow

Red

Yellow

Green

Green

Red

Solid Yellow

Solid Green

Flashing

Green

Solid Yellow

Solid Red

Solid Yellow

Solid Green

Solid Green

Solid Red

A solid yellow illuminated LED represents an Over

Speed Warning condition.

A solid green illuminated LED represents a normal battery

condition.

Controller in Auto mode - Waiting to start

A solid yellow illuminated LED represents a Low Battery

condition.

A solid red illuminated LED represents a Low Coolant

(Temperature and/or Level) failure condition

A solid yellow illuminated LED presents a Low Coolant

Temperature Warning condition.

A solid green illuminated LED represents an active Pre-Heat

condition

A solid green illuminated LED indicates that the generator

is supplying load and is operating normally.

A solid red indicated load is detected on the generator

when none should be.

Failure

Red

The WaveNet incorporates many types of warnings and failures. Warnings and failures can be triggered

from a Digital Input, Analog Input, AC Voltage, AC Current, Speed Signal Input, as well as others.

When a warning occurs, the second line (the area under the time and date display) of the LCD is used to

display the warning text. Also, after the warning is displayed, instructions are displayed showing the user

how to silence the warning. When in the AUTO or RUN modes the instructions are to press the Info key

and when in the OFF mode press the Stop key.

Solid Red

See Section 4.11 on page 20 for more information

about the EPS Supplying Load.

A solid red illuminated LED represents a general Failure

condition.

4.10 WARNINGS AND FAILURES

OWN-GEN 01/12

19

Page 22

updated 1-17-12

4.10 WARNINGS AND FAILURES (CONT’D)

When a failure occurs the controller exits the RUN mode and goes to the FAILURE mode and displays

the failure message. The alarm will sound and remain on until it is silenced by the user. The Info key can

be pressed to silence the alarm. Once the alarm is silenced it can be reset by pressing the Info key and

then the Stop key. This returns the controller to the OFF mode.

The failure is recorded in the event log accessible from the Basic Menu.

4.11 GENSET ONLINE

When the generator is started and load is detected on the generator when the WaveNet is in the RUN

mode the “Genset Online” LED on the WaveNet front panel will turn green. This indicates that the generator is supply load as normal. If load is detected on the generator when it is not in the RUN mode (e.g.

the WaveNet is cranking, preheating, etc.) the WaveNet terminates starting and enters the FAILURE

mode and the “Genset Online” LED on the WaveNet front panel will turn red.

The generator is considered loaded when either the AC current is equal to or greater than 5% of full load

current.

5. ADV ANCED SETUP

The WaveNet incorporates an Advanced Setup menu. Only advanced and knowledgeable users should

change these parameters.

WaveNet is connected on a NMEA 2000 network. Installation must be made by an NMEA 2000

certifi ed technician.

6 RECOMMENDED MAINTENANCE

The actions in Table 8 should be performed routinely.

WARNING: When performing any WaveNet or Engine maintenance be certain

controller is in OFF mode, is isolated from all possible sources of power,

and the crank wire is removed from the Controller.

Table 8: Recommended Maintenance

PROCEDURE ACTION

Making the controller safe for inspection

and maintenance.

Inspect controller mounting location for

possible safety issues.

Inspect controller for loose fasteners,

terminals and wiring connections.

Clean area around controller. Periodically inspect and remove any debris/dirt

Check for any overheating due to loose

connections.

Perform regular testing of controller Perform regular testing of the controller to

Disconnect all possible power sources before

controller inspection.

nspect mounting location for any safety or fi re issues.

I

Inspect for dirt, wiring damage and mechanical damages.

Check all hardware including controller wiring,

terminals etc. for any looseness due to vibrations etc.

from within or near the controller.

Check for any discoloration, melting or blistering

of any wiring or connections

check for proper operation.

OWN-GEN 01/12

20

Page 23

7 WAVENET REMOTE PANEL

There are 3 main display pages for remote unit: the REMOTE UNIT SETTINGS page, ON-LINE GENSET

STATUS page and ON-LINE GENSET PARAMETERS page. When the WaveNet Remote unit powers on,

it will go to the ON-LINE GENSET STATUS page.

7.1 REMOTE UNIT SETTINGS

Access this mode by pressing the Info key from the ON-LINE GENSET STATUS page. Press Info or hold

Stop to return to the ON-LINE GENSET STATUS page.

On the REMOTE UNIT SETTINGS page, there

are 3 settings menus. The Clock Setup, Basic

Setup and Advanced Setup will allow the user

to change various WaveNet Remote panel settings.

Clock Setup - Allows the user to adjust current

real time like year, month, week, day, hour,

minute and 24/12 display format.

Basic Setup - Allows the user to adjust the LCD

display contrast, on-line genset message update

speed, parameters page scrolling speed and

status page backlight shutdown delay.

Advanced Setup - To go into this menu, the user needs to input the password. The default

password is

0000. Within Advanced Setup there are 3 sub-menus, Networking, Set Units and Set Password.

In Networking, the user can enlist the WaveNet Remote to on-line genset controllers. This will Enable or

Disable the WaveNet Remote unit to start and stop a genset. The user can also edit the Genset On-Line

Timeout Delay. If the Genset On-Line Timeout Delay elapses for an on-line genset without receiving

an update from the local WaveNet panel the remote unit will remove that genset from the list of on-line

gensets. (Note: “-----” indicates the lack of an on-line genset controller. The ability to enable or disable

selections on these “-----” names is unavailable.)

In the Set Unit sub-menu, users can set the WaveNet Remote panel to display the temperature in

Fahrenheit or Celsius, and the pressure in KPa or PSI.

In Set Password the user can change the Advanced Menu access password, the default password is 0000.

The 3 main line positions display the current available on-line genset controllers. Each line displays the

on-line Genset Controller’s Name, State and the Status Mark. On the second line of the display, the

relevant message of the selected genset controller, like warning, running detail etc., is shown.

7.2 ON-LINE GENSET STATUS MODE

OWN-GEN 01/12

21

Page 24

7.2 ON-LINE GENSET STATUS MODE (CONT’D)

Move the cursor between the genset controller names using the Up and Down keys and press the Enter

key to switch to the ON-LINE GENSET PARAMETERS mode. (Note: only while the selected genset

controller is in the AUTO, RUN or FAIL state.) Also from this page, press the Info key to access the

settings menus.

7.2.1 GENSET CONTROLLER’S NAME

This is used to distinguish WaveNet controlled

gensets on the WaveNet Remote display. A “-----”

indicates there is no on-line genset controller for

that position.

7.2.2 STATE

The state of the genset controller will be one of the

following 5 states: “AUTO, RUN, FAIL, OFF or MENU.”

AUTO - The local WaveNet panel is in the AUTO mode and the genset can be started from any enlisted

WaveNet Remote by pressing the Start key.

RUN - The local WaveNet panel is running and the genset can be stopped from any enlisted WaveNet

Remote by pressing the Stop key. This state includes some sub-states like “Cranking, Preheat, Running, etc.”

The detail sub-state messages will show on the second line of the LCD display.

FAIL - The local WaveNet panel has shutdown and is in FAILURE mode. The failure must be cleared at the

local WaveNet panel before the generator can be restarted.

OFF - The local WaveNet panel is in the OFF state and therefore cannot be started from a WaveNet Remote

panel.

MENU - The local WaveNet panel is in the menu settings or off sleep state.

7.2.3 STATUS MARK

The status mark indicates the on-line genset controller’s control status. The Genset Controller Name with

status marked “x” means this genset controller cannot be controlled by this WaveNet Remote panel. The

Genset Controller Name with status mark “” means this genset was enabled to start or stop by this WaveNet

Remote panel.

7.3 ON-LINE GENSET PARAMETER MODE

The ON-LINE GENSET PARAMETER mode has 3 different pages corresponding to the on-line genset

controller, the AUTO, RUN and FAIL states. Start and stop functionality is the same in this mode as the

ON-LINE GENSET STATUS mode. Press the Info key to return to the ON-LINE GENSET STATUS mode.

OWN-GEN 01/12

22

Page 25

updated 1-17-12

7.3 ON-LINE GENSET PARAMETER MODE

AUTO - Displays 4 parameters: the engine

temperature, engine hours, battery voltage and

local WaveNet Remote unit board temperature.

RUN - Displays all selected genset running

parameters like engine speed, engine temperature,

AC voltage current, etc. The display area will cycle

to display the different parameters. Operation here

is the same as the local WaveNet panel.

FAIL - Displays current active failures that caused

the genset shutdown.

Note: the remote display will switch automatically according to current selected genset controller state. For example, remote unit is displaying AUTO parameters page, if the selected genset goes into running, the remote unit display will switch to display RUN parameters page. If

genset was in shutdown state due to some failure happen or user shutdown, the remote unit will switch back to on-line genset status page.

8 APPENDIX A: ACCESSORY LIST

8.1 WAVENET CONTROLLER HARNESS - ACCESSORIES

Figure 2 – WaveNet terminal names and layout. View from rear of controller.

The Following Identifi es all the wiring harnesses as parts of the WaveNet Controller:

Table 9 – WaveNet Wiring Harness Part List

Harness Description Part Number

AC Harness Assembly 22-40541

DC Harness Assembly 22-40612

673 AC Wire Harness 22-40575

673 DC Wire Harness 22-40570

WaveNet NMEA Panel Connector 22-40598 (for Remotes, use 22-40597)

WaveNet is connected on a NMEA 2000 network. Installation must be made by an NMEA 2000 certifi ed technician.

OWN-GEN 01/12

23

Page 26

8.2 CT’S (CURRENT TRANSFORMERS)

Current transformers are required for display of AC current. One CT is required for each phase to

be displayed. The wiring for CT’s is as follows:

In single phase applications:

• Phase A to terminals Phase A*

• Phase B to terminals Phase B*

In three phase applications:

• Phase A to terminals Phase A*

• Phase B to terminals Phase B*

• Phase C to terminals Phase C*

In center tap delta applications:

• Phase A to terminals Phase A*

• Phase B to terminals Phase B*

• Phase C to terminals Phase C*

* White wire assumed positive. Black wire assumed negative.

Table 10 – Current Transformers Part List

CT Description Part No.

75A:5A 22-40021

100A:5A 22-40022

150A:5A 22-40023

200A:5A 22-40024

250A:5A 22-40221

300A:5A 22-40025

Figure 3 - AC Current sensing conections

8.3 WAVENET REPLACEABLE 12/24VDC RELAYS

The WaveNet controller is designed to operate in either 12 or 24 VDC battery start systems. When

operating in 12VDC systems the fuel, crank and extra relays need to be rated 12VDC coil. When

operating in 24VDC systems these relays need to be rated 24VDC coil.

Relay Description Part No.

12VDC SPDT 22-42047

24VDC SPDT 22-40085

8.4 WAVENET FUSING

Output relays are protected by onboard 40A fuse protection. Smaller amperage fuses from many

automotive stores may be used in place of the higher current 40A. If installing lower amperage fuse

protection be certain that current draw does not exceed the fuse current limit.

Fuse Description Manufacturer Part No.

40A, 32VDC Auto Fast Action

Table 11 – Relay Part List

Table 12 – WaveNet fuse part list.

Littlefuse-257040

OWN-GEN 01/12

24

Page 27

updated 1-17-12

WAVENET INSTALLATION TO SOUND SHIELD

M673L/TF276D Sound Shield

(05-78000)

WaveNet is connected on a NMEA 2000 network. Installation must be made by an NMEA 2000 certifi ed technician.

B-9802A

OWN-GEN 01/12

27

Page 28

WAVENET INSTALLATION TO SOUND SHIELD

M673L3/LD3/TF276D

Sound Shield

(05-78010)

B-9917

OWN-GEN 01/12

28

Page 29

CONNECTION HARNESS

A

MODULE ENCLOSURE

A

MODULE ENCLOSURE COVER

B

[4X] #6 STAINLESS HELICAL LOCKWASHER

[4X] #6 FLATWASHER, USS STAINLESS.

[4x] 6-32 x 1/2" LONG

PAN HEAD STAINLESS STEEL

MACHINE SCREWS.

revised 8-4-11

WAVENET INSTALLATION IN SOUND SHIELD PANEL

[2X] STRAIN RELIEF BUSHINGS.

WAVENET MODULE

SOUND ENCLOSURE PANEL.

(SEE TABLE BELOW FOR MODIFICATION INSTRUCTIONS.)

B

B

COUNTERSUNK, STAINLESS

OVAL HD MACHINE SCREWS.

[4X] 6-32 x 1/2" LONG

FAC EP LAT E

COUNTERSUNK, STAINLESS

[3X] 8-32 x 3/4" LONG

FLAT HD MACHINE SCREWS.

B

M773LW3 B-9947

M843NW3 B-9948

B-10057

B-10057

B-9949

M844W3/M844LW3

M864W3 TBD

M944W3 B-10059

B-10058

PANEL MOUNT NMEA RECEPTACLE.

(INSTALLS FROM INSIDE)

NOTE:

PUSH HARNESS LOOM THROUGH

STRAIN RELIEF BUSHING, APPROX.

1/2" PROTRUSION FROM END.

CURRENT STYLE SHIELD (w/ BASE PAN)

MODEL PANEL MODIFICATION DWG

AND CUT OUT LOCATION WILL VARY,

EXAMPLE SHOWN IS TYPICAL FOR ALL

WAVENET COMPONENTS USED.

NOTE: ACTUAL SHIELD PANEL CONFIGURATION

C

C-6773C

OWN-GEN 01/12

29

MODEL PANEL MODIFICATION DWG

EARLY STYLE SHIELD (w/ BASE PLATE)

C

M773/W2/LW2/LW3

M843/JK/NK/NW2/NW3

M844W2/LW2/W3/LW3 B-9973 (FOAM)/B-9974 (PANEL)

M864W/W3 B-9728 (FOAM)/B-9729 (PANEL)

M944W3

Page 30

added 8-4-11

WAVENET INSTALLATION TO SOUND SHIELD

M773W3 Sound Shield

CENTERPUNCH.

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

5. DEBURR HOLES, BREAK SHARP EDGES.

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

51.2 [2.02]

0.16]

Ø

4.1 [

Ø

4 HOLES

117.3 [4.62]

146.0 [5.75]

8.0 [0.31]

209.9 [8.26]

52.7 [2.07]

161.9 [6.38]

114.3 [4.50]

STEP 1.

B-9947

REMOVE FILLER PIECE.

OWN-GEN 01/12

30

Page 31

added 8-4-11

WAVENET INSTALLATION TO SOUND SHIELD

M773 / W3 / LW2 / LW3 and

M843/ JK / NK / NW2 / NW3 Sound Shield

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

STEP 2.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

279.4 [11.00] 146.1 [5.75]

CENTERPUNCH.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

5. DEBURR HOLES, BREAK SHARP EDGES.

55.5 [2.19]117.6 [4.63]

0.16] 4 HOLES.

Ø

4.0 [

Ø

162.0 [6.38]

8.0 [0.31]

57.2 [2.25]

EXTERIOR FACE (PANEL)

114.3 [4.50]

PANEL STIFFENER EDGE

B-10057

184.0 [7.24] 245.3 [9.66]

30.8 [1.21]

140.0 [5.51]

OWN-GEN 01/12

31

INTERIOR FACE (SOUND FOAM)

THE AREA TO BE REMOVED AS SHOWN WITH DIMENSIONS.

STEP 1.

1. WITH THE INTERIOR (SOUND FOAM) SIDE FACING YOU, LAY OUT

FOLLOWING LINES. USE OF STRAIGHT EDGE TO GUIDE BLADE

IS RECOMMENDED.

THE DIMENSIONS ARE TAKEN FROM THE EDGE OF THE PANEL STIFFENER.

2. USING A BOX CUTTER WITH FRESH BLADE, MAKE CUT

DOWN PRESSURE TO CUT THROUGH PVC BARRIER LAYER.

4. MAKE INITIAL CUT SHALLOW, DOWN TO THE FOAM BARRIER.

5. WHEN ALL FOUR EDGES ARE DEFINED, APPLY ADDITIONAL

DO NOT USE M.E.K. OR SOLVENT TO CLEAN RESIDUE FOAM/GLUE

(MAY CONTAMINATE REMAINING GLUED AREAS).

GENTLE SCRAPING ACTION OF SAFETY BLADE OR GASKET SCRAPER TOOL

IS RECOMMENDED. CLEAN UNTIL RESIDUE IS MINIMAL, AND ALLOWS

6. REMOVE FOAM. SOME AREA CLEAN UP WILL BE REQUIRED FOLLOWING STEP 2.

CONTROL PANEL TO SEAT.

Page 32

added 8-4-11

WAVENET INSTALLATION TO SOUND SHIELD

M843W3 / NW3 Sound Shield

CENTERPUNCH.

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

STEP 2.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

5. DEBURR HOLES, BREAK SHARP EDGES.

50.9 [2.00]

117.9 [4.64]

146.1 [5.75] 266.5 [10.49]

8.0 [0.31]

162.1 [6.38]

52.7 [2.07]114.3 [4.50]

0.16] 4 HOLES

Ø

4.1 [

Ø

B-9948

STEP 1.

REMOVE FILLER PIECE.

OWN-GEN 01/12

32

Page 33

added 8-4-11

WAVENET PANEL INSTALLATION: STEP 1

INTERIOR

FACE

M844L / 844 Sound Shield,

RH (Service) Side Aft Panel.

THIS SURFACE

NOTES:

1. WITH THE INTERIOR (SOUND FOAM) SIDE FACING YOU, ALIGN THE

OUTSIDE EDGES OF THE PANEL STIFFENER FRAME.

OUTER EDGE OF THIS DRAWING TO THE CORNER, TOP AND LH SIDE

CHECK AND CONFIRM DIMENSIONS NOTED ON DWG.

2. SECURE TEMPLATE TO PANEL SURFACE WITH MASKING TAPE.

3. USING A BOX CUTTER WITH FRESH BLADE, MAKE CUT

FOLLOWING LINES. USE OF STRAIGHT EDGE TO GUIDE BLADE

IS RECOMMENDED.

4. MAKE INITIAL CUT SHALLOW, DOWN TO THE FOAM BARRIER.

DOWN PRESSURE TO CUT THROUGH PVC BARRIER LAYER.

DO NOT USE M.E.K. OR SOLVENT TO CLEAN RESIDUE FOAM/GLUE

5. WHEN ALL FOUR EDGES ARE DEFINED, APPLY ADDITIONAL

6. REMOVE FOAM. SOME AREA CLEAN UP WILL BE REQUIRED FOLLOWING STEP 2.

(MAY CONTAMINATE REMAINING GLUED AREAS).

GENTLE SCRAPING ACTION OF SAFETY BLADE OR GASKET SCRAPER TOOL

IS RECOMMENDED. CLEAN UNTIL RESIDUE IS MINIMAL, AND ALLOWS

CONTROL PANEL TO SEAT.

5.50 [140]

3.33 [85]

7.25 [184]

REMOVE THIS AREA

B-9973

(SEE DETAIL AT RIGHT)

OUTSIDE EDGE OF PANEL STIFFENERS

3.07 [78]

OWN-GEN 01/12

33

Page 34

added 8-4-11

DYNAGEN PANEL INSTALLATION: STEP 2

M844L / 844 Sound Shield,

RH (Service) Side Aft Panel.

4.42 [112]

4.11 [104]

0.16 [5/32]

Ø

4 HOLES.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

RIGHT HAND CORNER, TOP, & RH SIDE EDGES OF SHIELD PANEL.

3. ALIGN THE OUTER EDGE OF THIS DRAWING WITH UPPER

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

NOTES:

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

CENTERPUNCH.

CHECK AND CONFIRM DIMENSIONS NOTED ON DWG.

4. SECURE TEMPLATE TO PANEL SURFACE WITH MASKING TAPE.

5. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

6. DEBURR HOLES, BREAK SHARP EDGES.

EXTERIOR

FACE

THIS SURFACE

EDGE OF PANEL

(SEE DETAIL BELOW)

5.75 [146]

B-9974

6.38 [162]

4.38 [111]

4.31 [110]

REMOVE THIS AREA

4.50 [114]

4.63 [117]

OWN-GEN 01/12

34

Page 35

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

STEP 2.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

added 8-4-11

WAVENET INSTALLATION TO SOUND SHIELD

CENTERPUNCH.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

5. DEBURR HOLES, BREAK SHARP EDGES.

0.16]

Ø

4 HOLES

4.1 [

Ø

M844W3 / LW3 Sound Shield

48.5 [1.91]

146.0 [5.75]

8.0 [0.32]

199.0 [7.83]

50.3 [1.98]

117.9 [4.64]

162.1 [6.38]

114.3 [4.50]

B-9949

REMOVE FILLER PIECE.

STEP 1.

OWN-GEN 01/12

35

Page 36

revised 8-2-11

WAVENET PANEL INSTALLATION STEP 1

M864W3 / M944T Sound Shield

THIS SURFACE

INTERIOR

FACE

NOTES:

OUTER EDGE OF THIS DRAWING TO THE CORNER, TOP AND LH SIDE

EDGES OF THE PANEL BOX RISER.

1. WITH THE INTERIOR (SOUND FOAM) SIDE FACING YOU, ALIGN THE

CHECK AND CONFIRM DIMENSIONS NOTED ON DWG.

2. SECURE TEMPLATE TO PANEL SURFACE WITH MASKING TAPE.

FOLLOWING LINES. USE OF STRAIGHT EDGE TO GUIDE BLADE

IS RECOMMENDED.

3. USING A BOX CUTTER WITH FRESH BLADE, MAKE CUT

DOWN PRESSURE TO CUT THROUGH PVC BARRIER LAYER.

4. MAKE INITIAL CUT SHALLOW, DOWN TO THE FOAM BARRIER.

5. WHEN ALL FOUR EDGES ARE DEFINED, APPLY ADDITIONAL

DO NOT USE M.E.K. OR SOLVENT TO CLEAN RESIDUE FOAM/GLUE

(MAY CONTAMINATE REMAINING GLUED AREAS).

GENTLE SCRAPING ACTION OF SAFETY BLADE OR GASKET SCRAPER TOOL

6. REMOVE FOAM. SOME AREA CLEAN UP WILL BE REQUIRED FOLLOWING STEP 2.

IS RECOMMENDED. CLEAN UNTIL RESIDUE IS MINIMAL, AND ALLOWS

3.19

(SEE DETAIL AT RIGHT)

EDGE OF PANEL BOX RISER

5.50

REMOVE THIS AREA

2.19 7.25

B-9728A

OWN-GEN 01/12

36

Page 37

revised 8-2-11

WAVENET PANEL INSTALLATION: STEP 2

M864W3 / M944T Sound Shield

EDGE OF PANEL

(SEE DETAIL BELOW )

3.63

5.75

3.31

6.38

4 HOLES.

0.16 [5/32]

Ø

THIS SURFACE

REMOVE THIS AREA

EXTERIOR

FACE

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

RIGHT HAND CORNER, TOP, & RH SIDE EDGES OF SHIELD PANEL.

3. ALIGN THE OUTER EDGE OF THIS DRAWING WITH UPPER

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

NOTES:

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

4.38

4.31

CENTERPUNCH.

CHECK AND CONFIRM DIMENSIONS NOTED ON DWG.

4. SECURE TEMPLATE TO PANEL SURFACE WITH MASKING TAPE.

5. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

6. DEBURR HOLES, BREAK SHARP EDGES.

4.50

4.63

B-9729A

OWN-GEN 01/12

37

Page 38

added 8-4-11

WAVENET INSTALLATION TO SOUND SHIELD

M944W3 Sound Shield

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

55.7 [2.19]

0.16] 4 HOLES.

Ø

4.0 [

Ø

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

STEP 2.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

117.6 [4.63]

CENTERPUNCH.

5. DEBURR HOLES, BREAK SHARP EDGES.

146.1 [5.75]

8.0 [0.31]

190.9 [7.52]

57.4 [2.26]

179.9 [7.08]

PANEL STIFFENER EDGE

162.0 [6.38]

114.3 [4.50]

(PANEL)

EXTERIOR FACE

184.0 [7.24]

B-10058

30.8 [1.21]

140.0 [5.51]

INTERIOR FACE

(SOUND FOAM)

OWN-GEN 01/12

38

THE AREA TO BE REMOVED AS SHOWN WITH DIMENSIONS.

STEP 1.

1. WITH THE INTERIOR (SOUND FOAM) SIDE FACING YOU, LAY OUT

FOLLOWING LINES. USE OF STRAIGHT EDGE TO GUIDE BLADE

IS RECOMMENDED.

THE DIMENSIONS ARE TAKEN FROM THE EDGE OF THE PANEL STIFFENER.

2. USING A BOX CUTTER WITH FRESH BLADE, MAKE CUT

DOWN PRESSURE TO CUT THROUGH PVC BARRIER LAYER.

4. MAKE INITIAL CUT SHALLOW, DOWN TO THE FOAM BARRIER.

5. WHEN ALL FOUR EDGES ARE DEFINED, APPLY ADDITIONAL

DO NOT USE M.E.K. OR SOLVENT TO CLEAN RESIDUE FOAM/GLUE

(MAY CONTAMINATE REMAINING GLUED AREAS).

GENTLE SCRAPING ACTION OF SAFETY BLADE OR GASKET SCRAPER TOOL

IS RECOMMENDED. CLEAN UNTIL RESIDUE IS MINIMAL, AND ALLOWS

6. REMOVE FOAM. SOME AREA CLEAN UP WILL BE REQUIRED FOLLOWING STEP 2.

CONTROL PANEL TO SEAT.

Page 39

CONTAMINANTS PRIOR TO ANY MODIFICATION WORK.

STEP 2.

1. PANEL SURFACE MUST BE CLEAN AND FREE OF OILS AND

146 [5.75]

DIMENSIONS ARE TAKEN FROM THE OUTER PANEL EDGE.

COVER A LARGE ENOUGH AREA TO PERFORM TASK.

2. PROTECT POWDERCOATED SURFACE WITH 2" WIDE MASKING TAPE.

3. LAYOUT AREA TO BE CUTOUT USING DIMENSIONS AS SHOWN.

40.8 [1.61]117.6 [4.63]

added 8-4-11

CENTERPUNCH.

4. LOCATE HOLE CENTERS AND CUTOUT CORNERS USING

5. DEBURR HOLES, BREAK SHARP EDGES.

Ø4.0 [Ø.16]

4 HOLES

WAVENET INSTALLATION TO SOUND SHIELD

M944W3 Sound Shield

76.2 [3.00]

REMOVE FILLER PIECE.

STEP 1.

8.0 [.31]

162 [6.38]

42.4 [1.67]

EXTERIOR FACE (PANEL)

114.3 [4.50]

B-10059

INTERIOR FACE (FOAM)

OWN-GEN 01/12

39

Page 40

WAVENET REMOTE PANEL INSTALLATION DIMENSIONS

B-9829

OWN-GEN 01/12

40

Page 41

Page 42

www.northern-lights.com

4420 14th Ave. NW., Seattle WA 98107

Tel: (206) 789-3880 • 1-800-762-0165 • Fax: (206) 782-5455

Northern Lights and Lugger are registered trademarks of Northern Lights, Inc.

© 2012 All rights reserved. Litho USA.

Loading...

Loading...