Northern Lights PX-300K2 A.C. Generators, PX-308K2, PX309K2, PX-310K2, PX-312K2 Installation Manual

...

OPERATOR ’ S

OPERATOR ’ S

&

&

MAN UAL

MAN UAL

PX-300K2 SERIES A.C. GENERATORS

PARTS

PARTS

For Generator Models:

PX-308K2, PX309K2, PX - 310K2, PX-312K2,

PX-316K2, PX-320K2, PX-320C2, PX-325K2,

PX-332K2, and PX-332C2

— CALIFORNIA —

Proposition 65 Warning:

Diesel engine exhaust and some of its constitu-

ents are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Northern Lights

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2009 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

PART NO.: OPX300K2 09/10

OPERATOR’S &

PARTS MANUAL

PX-300K2 SERIES A.C. GENERATORS

For Generator Models:

PX-308K2, PX-309K2, PX-310K2, PX-312K2, PX-316K2,

PX-320K2, PX-320C2, PX-325K2, PX-332K2, and PX-332C2

Read this manual thoroughly before starting your equipment.

This manual contains information needed to operate your set correctly and safely.

Table of Contents

Introduction. .....................................................................4

Safety Rules .....................................................................4

Models and Serial Numbers ...........................................5

Mechanical Construction .................................................6

INITIAL INSPECTION AND COUPLING

Initial Inspection..........................................................6

Coupling with Prime Mover........................................6

Grounding ...................................................................6

PERFORMANCE AND FUNCTION

Excitation System........................................................7

Automatic Voltage Regulator (AVR) ..........................7

Under Speed Protection...............................................7

Rotary Rectifi er and Surge Suppressor .......................7

CHARACTERISTICS

Voltage Regulation ......................................................8

Response .....................................................................8

Voltage Stability ..........................................................8

Motor Starting .............................................................8

Short Circuit ................................................................8

Phase Rotation .............................................................8

OPERATION - GENERATOR SET

Starting ........................................................................9

Voltage Adjustment .....................................................9

Running .......................................................................9

Stopping ......................................................................9

OPERATION - VOLTAGE REGULATOR

Safety Rules ............................................................. 10

Operation ................................................................. 10

Adjustment ............................................................... 10

MAINTENANCE

Bearing Inspection ....................................................11

Insulation Resistance Measurement Method ............11

Rotating Rectifi er Assembly ....................................11

Parts Replacement Method ...............................11 - 12

Automatic Voltage Regulator Maintenance ............. 13

SPECIFICATIONS

Generator Specifi cations.................................. 14 - 15

Voltage Regulator Specifi cations ............................. 16

TROUBLESHOOTING ........................................... 17

STANDARD VOLTAGE SELECTION TABLE .........8

It may not be reproduced in whole or in part without the written permission of Northern Lights, Inc.

© Northern Lights, Inc. 2010. All rights reserved. Litho U.S.A. Publication number OPX-300K2 09/10

PARTS LIST ....................................................... 18 - 26

WIRING DIAGRAM

AVR DST-100-2FAK ............................................. 27

Proprietary Information

This publication is the property of Northern Lights, Inc.

OPX300K2 05/12

3

Introduction

This manual describes procedures for operation,

maintenance, inspection and adjustment. It will help the

operator realize peak performance through effective,

economical and safe operation.

• Read this manual carefully BEFORE operating the

generator.

• Study this manual until proper operation becomes

personal habit.

• Operation, inspection, and maintenance should be

carried out carefully. Safety must be given the fi rst

priority.

Safety Rules

• To insure years of trouble-free operation, the

specifi ed maintenance is important and should be

performed.

• Insulation Resistance and Dielectric: When

measuring insulation resistance and dielectric, be

sure to disconnect the AVR and rectifi er.

• Be sure that the regulator is shut of f by switching the

CPR (circuit breaker) on the AVR to the off position

when the unit is run ning at less than rated speed, or

when the unit is to be run but no power generation is

required.

• Before starting your generator, be sure oper ating

conditions are safe.

• Ventilation: When selecting the installation site, be

sure that the area is well ventilated and that ambient

temperature does not exceed 40°C. If the

temperaure exceeds 40°C, de-rate the generator

output as per “data sheet” for operation.

• Be sure to provide generator with cover and

protection when op erating outside.

• Electrical equipment should always be kept

clean. Oil, dust, moisture and salt are all harmful

to genera tors.

• Be careful with electricity. Do not touch rotating

parts.

• Ambient Environmental Conditions

a) Gas: Do not use in an environment of corrosive

or fl ammable gas (gasoline, hydrogen sulfi de,

meth ane gas, etc.)

b) Sandy Dust: Do not use equipment in places

with excessive sand and dust.

c) Humidity: Do not use in very humid

environments for long periods of time.

d) Salt/Seawater: Protect your generator from

exposure to salt, water, and water vapor.

PX-300K2 Series AC generators are based on

BS 4999 part 20 and IEC34-5, IP21.

OPX300K2 05/12

4

Model and Serial Numbers

GENERATOR END MODEL NUMBERS

Generator Set Model No ................PXK Generator Model

M and NL753W2 ..........................................PX-308K2

M and NL773LW2 / LW3 ..............................PX-309K2

M and NL843JW ..........................................PX-310K2

M and NL843NW2 / NW3 .............................PX-312K2

M844W2 / W3 ..............................................PX-316K2

M844LW2 / LW3 ..........................................PX-320K2

M20CRW2/ CRW3 .......................................PX-320C2

M864W / W3 ................................................PX-325K2

M944W / W3 ................................................PX-332K2

M30CW / CW3 .............................................PX-332C2

M984W .........................................................PX-332K2

M33CW ........................................................PX-332C2

SERIAL NUMBERS

• When referencing Northern Lights equip ment by serial

number, it is important to differentiate between the engine,

generator end, and generator set serial numbers.

• The engine serial number is either on a metal tag or stamped

directly into the engine block.

• The generator END serial number is on a metal tag attached

to the generator end.

• The generator SET serial number is on a separate metal tag

attached to the generator end. It may be a fi ve by one inch tag

installed directly below the gen erator end tag. Or, it may look

like the illustrations below. Please use the generator SET number

in cor respondence or when ordering parts.

Set Serial

Set Model

Model No.

Serial No.

DUTY

HERTZ

PHASE

°C RISE

RULE

Generator Set Data

KW

KVA

RPM

Northern Lights, Inc., WA USA

www.northern-lights.com

AC Generator Data

WIRE

INSUL

AMB°C

PF

VOLTS

VOLTS

AMPS

AMPS

Figure 1: Generator Set Serial Number Plate

OPX300K2 05/12

5

Mechanical Construction

STATOR

The stator frame is fabricated from rolled steel. The

round construction provides rigidity and strength to

resist excessive mechanical shocks. The stator core is

made of high quality silicon steel plates coated with

insulating fi lm for prevention of eddy currents. The

core is positioned along the internal surface of the

frame. The exciter fi eld core is made of special steel

plates capable of retaining a high degree of residual

magnetism.

BEARINGS

The long-life ball bearings are sealed to prevent grease

from escaping and to keep dirt out.

ROTOR

The rotor shaft is made of high quality carbon steel,

and is designed and manufactured to be mechanically

durable. The rotor is a salient revolving fi eld type

with the main fi eld core made from special steel plates

having superior magnetic characteristics. The fi eld

core elements, exciter rotor, rotary rectifi er and

cooling fan are integral parts of the same shaft.

COUPLING WITH PRIME MOVER

PX-300K series single bearing generators make

centering and direct coupling easy. Coupling bolt size

and torque will vary according to the engine

manufacturer.

GROUNDING

The generator frame should be electrically grounded

to the base of the generator set. The neutral is not

grounded to the frame unless specifi ed.

VENTILATION

Cooling is provided by the cooling fan of the rotor

through suction ports and exhausted through outlet

ports. Every machine conforms to the cooling code

ICO1 of BS.

Initial Inspection and Coupling

INITIAL INSPECTION

If the generator is stored for long periods of time, store

in a clean, dry, ventilated area. After extensive storage time, check the resistance of the coil insulation in

accordance with this manual (see MAINTENANCE,

page 11) before operation. Be sure there are no abnormal sounds or any overheating during operation. It is

recommended that standby generators utilize a space

heater (op tional) in order to keep the coil insulation in

optimum working condition.

OPX300K2 05/12

6

Performance and Function

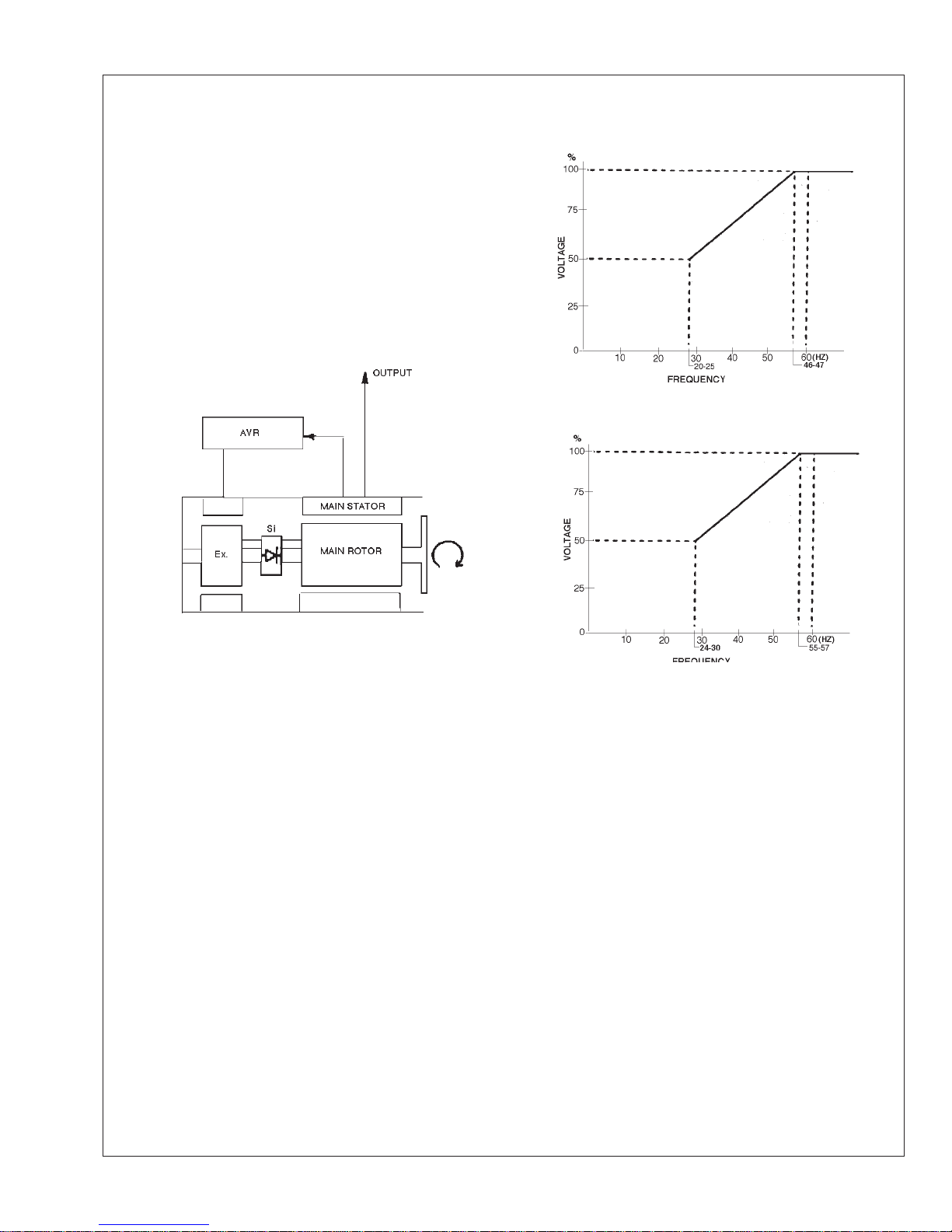

EXCITATION SYSTEM

The excitation system of the PX-300K Series genera tor uses

an Automatic Voltage Regulator (AVR) which uses a portion

of the output power to supply controlled DC power to the

exciter fi eld (EX) as show in Figure 2. When DC power is

supplied to the exciter fi eld, output from the exciter armature

is rectifi ed by a 3-phase bridge rotary rectifi er (Si) and

supplied to the main fi eld coils. See Figure 2.

AVR: Automatic Voltage

Regulator

EX: Exciter

Si: Rotating Rectifi er

Figure 3: For 50 Hz

Figure 2: PX-300K2 Block Diagram

AUTOMATIC VOLTAGE REGULATOR (AVR)

The PX-300K2 Series generators use a DST-100-2FAK

AVR. This is a compact voltage regulator for generators

with an output up to 50kW. The AVR can be used in 120V

single phase applications and is installed inside the generator

junction box.

The AVR obtains sensing input from the main stator coils

and compares the rectifi ed value of the sensing voltage with

the reference voltage produced inside the AVR. Input power

is obtained from the main stator.

Rectifi ed output power to the exciter fi eld is controlled by

switching a transistor on and off. This AVR will control

terminal voltage even if the input sine wave is distorted.

Figure 4: For 60 Hz

UNDER SPEED PROTECTION

A frequency sensing circuit is built into the AVR.

When the generator speed drops to 90% of rated

speed this circuit protects the AVR by reducing

the voltage in proportion to the decrease in engine

speed. In addition, when the generator is hit with a

rapid overload, this circuit will lower the voltage to

protect the engine. See Figures 3 & 4.

ROTARY RECTIFIER AND SURGE

SUPPRESSOR

The rotary rectifi er assembly, consisting of six

diodes, functions as a 3-phase full wave rectifi er for

the output of the exciter armature and supplies this

to the main fi eld. To protect the diodes from large,

instanta neous voltage surges, surge absorbers are

provided as part of the rotating rectifi er assembly.

OPX300K2 05/12

7

Characteristics

VOLTAGE REGULATION

Generator terminal voltage regulation is within ±1% of the

rated voltage in lagging power factor. 1.0 to 0.8, when the

load is varied gradually from no load to full load. This value

includes the temperature drift and rotating variation.

RESPONSE

After supplying a load instantaneously, the generator voltage

should be restored to the steady condition in accordance with

BS4999 Part 40, grade VR2.11 to VR2.23.

VOLTAGE STABILITY

In constant load and engine speed, voltage stability remains

0.25% of the rated voltage.

MOTOR STARTING

The generator is capable of enduring up to 300% of the rated

current for 10 seconds at power factor of 0.

SHORT CIRCUIT

PX-300K2 Series AC generators can provide over 300%

of the rated current for a short period of time, with an

excitation support system (optional).

PHASE ROTATION

Phase sequence is T1-T2-T3 (U-V-W, A-B-C) with a

counterclockwise rotation of generator viewed from the

anti-coupling side.

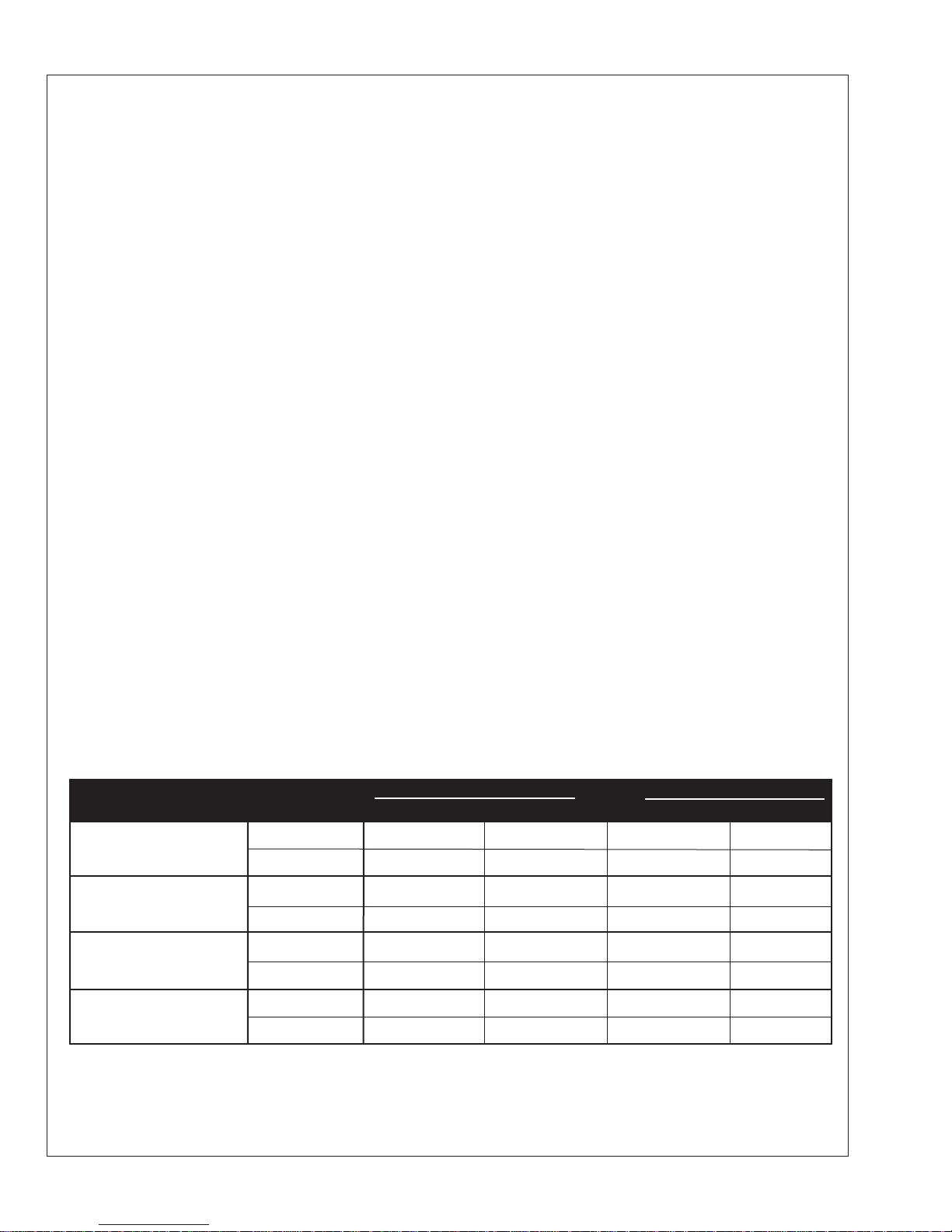

Standard Voltage Tables and Connection Diagrams

Standard voltage selection table and connection diagram for PX-300K2 Series 1-phase 4-wire and 3-phase 12-wire AC

generators.

Winding Connection Frequency Voltages

3 Phase Series Star

(High Wye)

3 Phase Parallel Star

(Low Wye)

1 Phase

60 Hz 120

1 Phase

50 Hz 110

50 Hz 415/240 400/231 380/219

50 Hz 208/120 200/115 190/110

60 Hz 120/240

50 Hz 100/200 110/220 115/230 120/240

Figure 5: Standard Voltage Table

60 Hz 480/277 460/266 440/254 416/240

60 Hz 240/139 230/133 220/127 208/120

OPX300K2 05/12

8

Operation – Generator Set

STARTING

Before starting generator, check the following:

1. Make sure that the wiring is correct.

2. Be sure that nothing is blocking the air inlet/ outlet.

3. Make sure that the inside of the generator is clean.

4. Be sure the main line circuit breaker is switched

OFF.

After checking each of the above, start the generator in the

following procedure:

1. Start engine in accordance with instructions in the

Operator’s Manual. Be sure there is no abnormal

sound or vibration.

2. The voltage will rise due to the increase in generator

speed. After making sure that each interphase voltage

is balanced, set the voltage and frequency to the rated

level. Be sure the CPR switch is “ON”. The voltage

will not rise with CPR “OFF”.

3. After running the generator without load, switch the

circuit breaker ON to start the load operation.

VOL TAGE ADJUSTMENT

The generator has been adjusted to obtain optimum

voltage at the factory. If the voltage is different, adjust

the voltage with the Voltage Adjust provided on the

AVR.

STOPPING

After putting the running generator in a no-load condition

by removing the generator load, stop the engine in

accordance with the Engine Manual.

RUNNING

Check the following while operating the generator:

1. Abnormal vibration and/or sound

2. Load

3. Environment:

Keep the air inlet/outlet clean and clear for optimum

cooling. Insuffi cient cooling causes over heating of the

generator.

Note: When a 3-phase generator is used at single phase

load, each phase current should be balanced and should

not exceed 50% of the rated current. In addition,

allowable unbalanced load is listed on the Data Sheet.

OPX300K2 05/12

9

Loading...

Loading...