Northern Lights PowerView Installation and Operation Manual

PV-02124N page 1 of 18

Installation and Operations Manual

PV-02124N

Revised 05/04

Section 78

00-02-0528

Please read the following information before installing. A visual inspection of this product for damage during shipping is

recommended before mounting. It is your responsibility to have a qualified person install this unit.

GENERAL INFORMATION

Description

The PowerView is a powerful new display in a line of components manufactured

by FWMurphy as part of its J1939 MurphyLink™

†

Family. The J1939

MurphyLink™ Family of products have been developed to meet the needs for

instrumentation and control on electronically controlled engines communicating

using the SAE J1939 Controller Area Network (CAN).

The PowerView System is comprised of the PowerView and the Mlink™

PowerView Gages. The PowerView is a multifunction tool that enables equipment

operators to view many different engine or transmission parameters and service

codes. The system provides a window into modern electronic engines and transmissions. The PowerView includes a graphical backlit LCD screen. It has excellent

contrast and viewing from all angles. Back lighting can be controlled via menu or

external dimmer potentiometer. The display can show either a single parameter or a

quadrant display showing four parameters simultaneously. Diagnostic capabilities

include fault codes with text translation for the most common fault conditions.

The PowerView has four buttons using self-calibrating charge transfer activation

technology, which eliminates the concern for pushbutton wear and failure. In addition, operators can navigate the display with ease.

The enhanced alarm indication has ultra bright alarm and shutdown LEDs (amber

& red). It has a wide operating temperature range of -40 to +85º C (-40 to185º F),

display viewing -40 to +75º C (-40 to 167º F), and increased environmental sealing

to +/- 5 PSI (± 34kPa). It also features Deutsch DT style connectors molded into

the case and fits quickly and easily into existing 2-1/16 in. (52 mm) gage opening

with little effort.

Other components in the system are microprocessor-based Mlink™

PowerView Gages for displaying critical engine data broadcast by an electronic engine or transmission’s Engine Control Unit (ECU): engine RPM, oil

pressure, coolant temperature, system voltage, etc. and a combination audible alarm and relay unit for warning and shutdown annunciation. Up to 32

components may be linked to the PowerView using a simple daisy chain

wire connection scheme using RS485. The PowerView and all connected

components can be powered by 12- or 24-volt systems.

Warranty

A limited warranty on materials and workmanship is given with this

FWMurphy product. A copy of the warranty may be viewed or printed by

going to www.fwmurphy.com/warranty.html

Display Parameters

The following are some of the engine and transmission parameters displayed

by the PowerView in English or Metric units as well as in Spanish, French,

or German (when applicable, consult engine or transmission manufacturer

for SAE J1939 supported parameters):

❖

Engine RPM

❖

Engine Hours

❖

Machine Hours

❖

System Voltage

❖

% Engine Load at the current RPM

❖

Coolant Temperature

❖

Oil Pressure

❖

Fuel Economy

❖

Throttle Position

❖

Engine Manifold Air Temperature

❖

Current Fuel Consumption

❖

Transmission Oil Pressure

❖

Transmission Oil Temperature

❖

Transmission Gear Position

❖

Active Service Codes

❖

Stored Service Codes (when supported)

❖

Set Units for display (English or Metric)

❖

Engine Configuration Parameters

† MurphyLink

TM

is a registered trademark of FWMurphy. All other trademarks and

service marks used in this document are the property of their respective owners.

Specifications

Display: 1.3 x 2.6 in. (33 x 66 mm), 64 x 128 pixels.

Operating Voltage: 8 VDC minimum to 32 VDC max.

Reversed Polarity: Withstands reversed battery terminal polarity indef-

initely within operating temperatures.

Operating Temperature: -40 to +85ºC (-40 to185ºF).

Display Viewing Temperature: -40 to +75ºC (-40 to 167ºF).

Storage Temperature: -40 to +85ºC (-40 to185ºF).

Environmental Sealing: IP68, +/- 5 PSI (+/- 34.4 kPa).

Power Supply Operating Current: (@ 14 VDC)=

52 mA minimum; 268 mA maximum (LCD heater on).

CAN BUS: SAE J1939 Compliant.

Case: Polycarbonate / Polyester.

Clamp: Polyester (PBT).

Connectors: 6-Pin Deutsch DTO6 Series.

Maximum Panel Thickness: 3/8 in. (9.6 mm).

Mounting Hole: 2.062 inch (52 mm) in diameter.

Auxiliary Communications: Either:

Gages: One (1) RS485 port, MODBUS RTU master.

MODBUS: One (1) RS485 port, MODBUS RTU slave, selectable

baud rate; 9600; 19.2K; 38.4K.

Potentiometer (External Dimmer)Input: 1K ohm, 1/4 W

Shipping Weights (all models): 1/2 lb. (225 g.)

Shipping Dimensions (all models): 6 x 6 x 6 in. (152 x 152 x 152 mm).

WARNING

BEFORE BEGINNING INSTALLATION OF THIS MURPHY PRODUCT

✔ Disconnect all electrical power to the machine.

✔ Make sure the machine cannot operate during installation.

✔ Follow all safety warnings of the machine manufacturer.

✔ Read and follow all installation instructions.

PV-02124N page 2 of 18

Table of Contents

General Information page #

Description.................................................1

Display Parameters....................................1

Specifications.............................................1

Key Pad Functions.....................................2

Mechanical Installation

Typical Mounting Dimensions

...................2

Typical Quick-connect Diagram................3

Electrical Installation

PIN Connectors Nomenclature..

................3

Typical Wiring Diagrams...........................4

Operations

First Time Start Up

...................................5

Main Menu Navigation.............................5

Selecting a Language.................................5

Stored Fault Codes....................................6

Engine Configuration Data.......................6

Faults and Warnings................................7

Active Fault Codes...................................8

Shutdown Codes......................................8

Back Light Adjustment............................9

Contrast Adjustment..............................10

Select Units...............................................10

Setup 1-Up Display...................................11

Setup 4-Up Display..................................14

Utilities.....................................................15

MODBUS Setup.......................................15

J1939 Parameters....................................17

Glossary...................................................18

GENERAL INFORMATION

continued

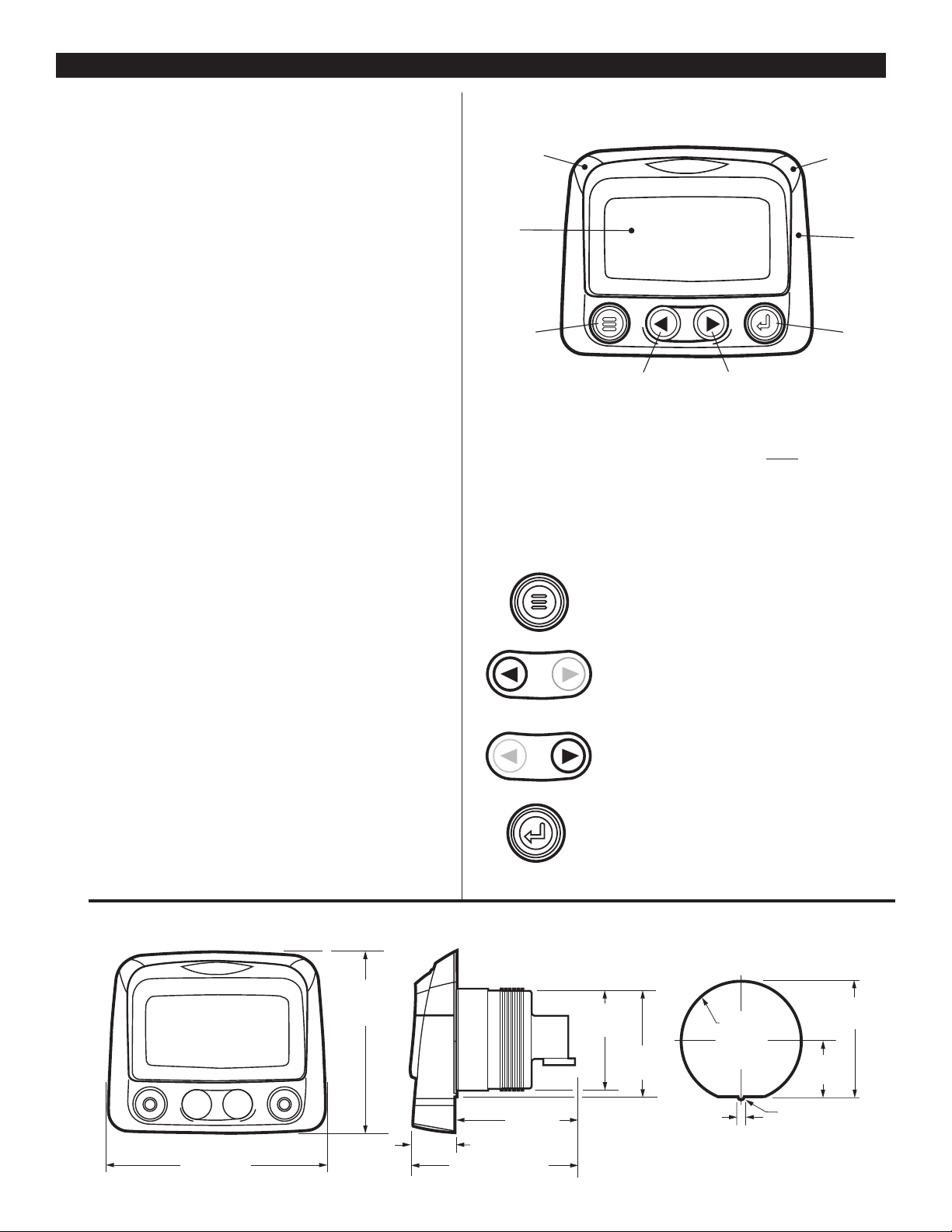

Keypad Functions

The keypad on the PowerView is a capacitive touch sensing system.

There are no mechanical switches to wear or stick, and the technology

has been time proven in many applications. It operates in extreme temperatures, with gloves, through ice, snow, mud, grease, etc., and it allows

complete sealing of the front of the PowerView. The ‘key is touched’

feedback is provided by flashing the screen. The keys on the keypad perform the following functions:

–

Menu Key

- The Menu Key is touched to either

enter or exit the menu screens.

–

Left Arrow

- The Left Arrow Key is touched

to scroll through the screen either moving the parameter selection toward the left or upward.

–

Right Arrow

- The Right Arrow Key is touched

to scroll through the screen either moving the parameter

selection toward the right or downward.

–

Enter Key

- The Enter Key (also known as Enter

Button) is touched to select the parameter that is highlighted on the screen.

Faceplate Features

Typical Mounting Dimensions

4.25 in.

(108 mm)

FRONT

SIDE

HOLE CUTOUT

2.41 in.

(61 mm)

0.78 in. (20 mm)

3.18 in. (81 mm)

3.489 in.

(89 mm)

2.070 in.

(53 mm)

1.94 in.

(50 mm)

1.972 in.

(50 mm)

R 0.063 in.

(1.6 mm)

0.125 in.

(3 mm)

2.062 in.

(52 mm)

diameter

.953 in.

(24 mm)

Amber

Warning LED

Display

Menu Key Enter Key

Left Arrow Key (Scroll Up) Right Arrow Key (Scroll Down)

Red Shutdown

Derate LED

Bezel

PV-02124N page 3 of 18

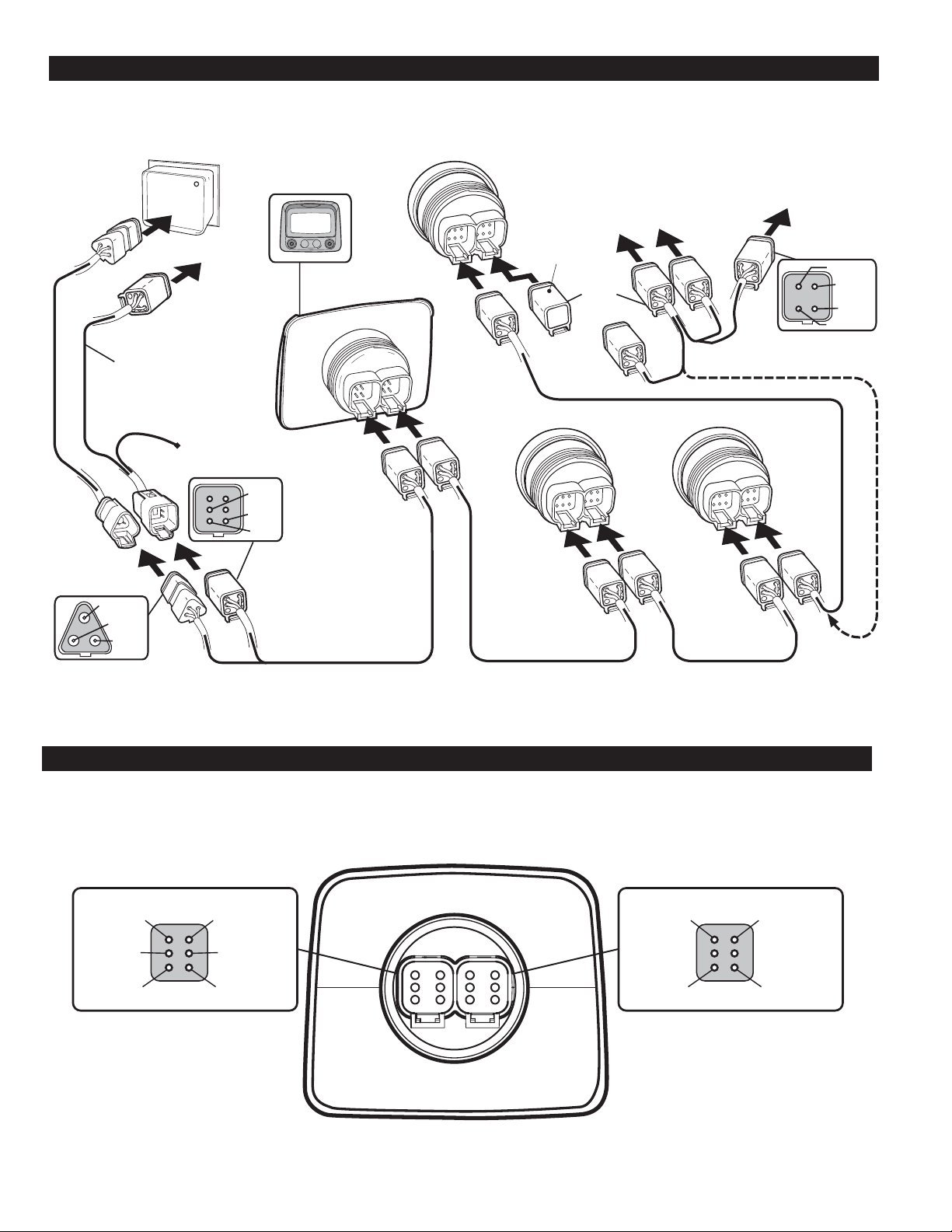

MECHANICAL INSTALLATION

Typical Quick-Connect Diagram

ELECTRICAL INSTALLATION

PVW-CH

Customer provided wire

harness or CAN extension

harnesses or power

extension harnesses.

PVW-PH

CAN–SHLD

CAN–LO

CAN–HI

To Engine

ECU

External Dimmer

Wire 24 inch.

To Battery

Power

External

Dimmer

B+

GRND

PVAA Audible Alarm

B

A

Last PVA Gage or

To PVAA

Audible Alarm

To optional

external device

Terminating

Resistor PVJR

B

POWERVIEW

PV100

A

OR

B

A

Optional PVW-A wire harness

(includes terminating resistor)

PVA Gage Next PVA Gage

B

A

B

A

Wire harness PVW-P Wire harness PVW-J Wire harness PVW-J

Wire harness

PVW-J

Relay N.O.

Relay N.C.

Ext.

Sonalert

Relay Comm.

PIN 2 CAN–HI

PowerView Unit Back View

Deutsch DT06-6S Style Connections

Plug A Plug B

PIN 4 CAN–SHLDPIN 3 CAN–LO

PIN 5 Dimmer

Potentiometer

PIN 6 GRNDPIN 1 V+

BA

Recommended Connectors:

Body: Deustch DT06-6S

Wedge Lock: W6S

Terminals: 0462-201-16141

Sealing Plug: 114017

PIN 4 RS485–PIN 3 RS485+

PIN 6 GRNDPIN 1 V+

PV-02124N page 4 of 18

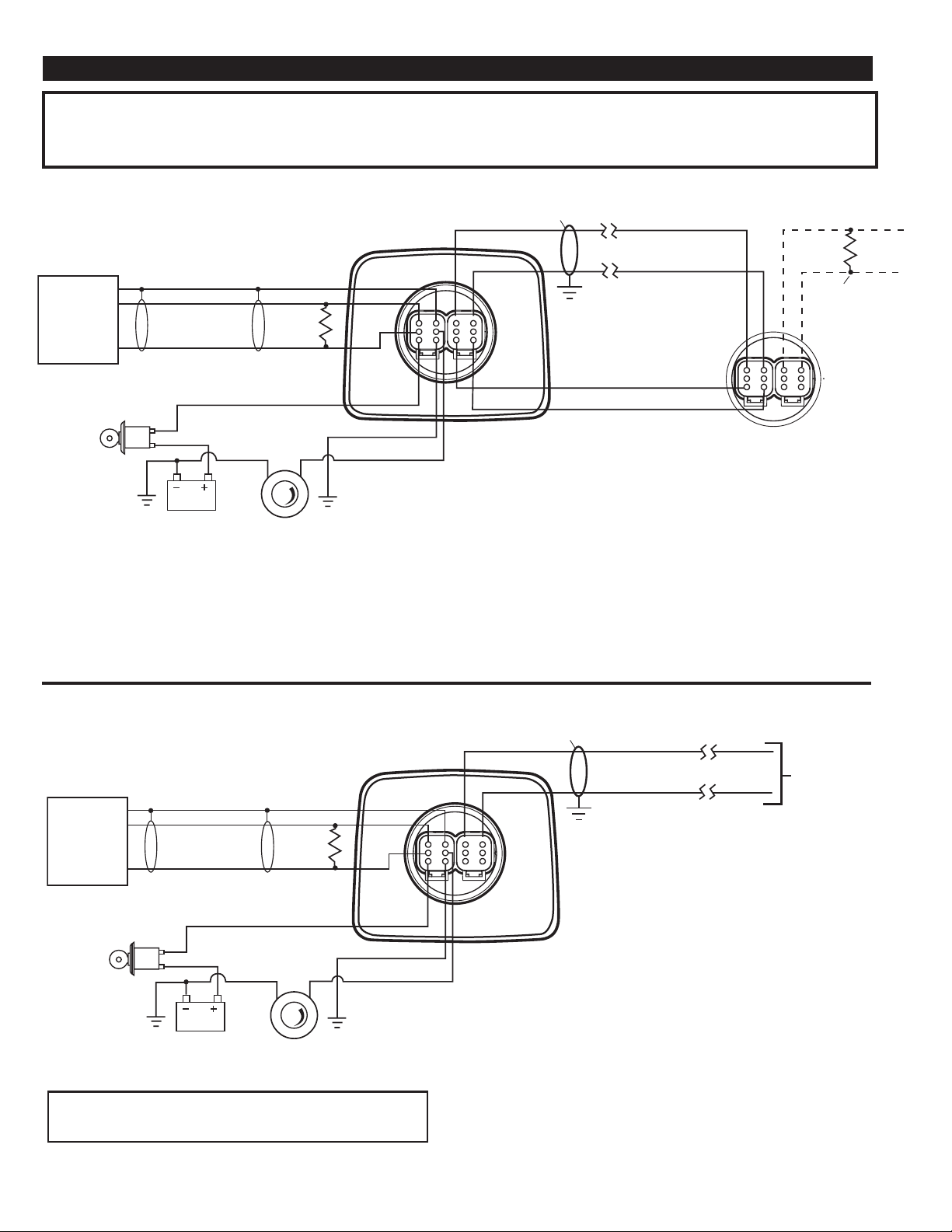

TYPICAL WIRING DIAGRAMS

IMPORTANT:

To eliminate external interference: RS485(+) and RS485(-) should be twisted pair cable or twist wires together, one twist per

inch minimum. CAN–L,CAN–H and CAN Shield should be approved J1939 CAN bus cable (CAN wire for example: RADOX plug and play cable,

from Champlain cable). (RS485 wire for example: BELDEN 9841 or 3105A).

PowerView Deutsch DT06-6S Style Unit to PVA Gage

ENGINE

CONTROL

MODULE

(SAE J1939

Compliant)

Ignition

Switch

NOTE 2

Gray-CAN_SHLD

Green-CAN_L

Yellow-CAN_H

Battery

Back View

120 Ω

See Note

NOTE 1

Red-V+

Gray-Ground

Illumination

Control*(optional)

NOTE 3

Pin 4

Pin 3

Pin 2

Pin 1

Blue-Back Light

NOTE 7

NOTE 5

Pin 3

Pin 4

Pin 1

Pin 6

Pin 5

Pin 6

Note 1:

Place Resistor between

CAN–H and CAN–L Line near

PowerView (included in PVW-P or

factory purchased panels).

Note 2: Use SAE J1939 compliant

wiring or equipment.

Note 3: Electronic dimmer switch

recommended with 4A, capacity

or heavy duty rheostat switch,

1000 ohm, 0.25 watt.

RS485 (+) Data

RS485 (-) Data

V+

GRND

NOTE 4

120 ohms

See

NOTE 6

PVA Gage

Note 4: Only use 120 ohm

characteristic impedance cable,

ex Belden 9841.

Note 5: RS485 shield connected

to PowerView end only.

Note 6: Place Resistor at End of

Line on last PVA gage. (Included

for factory purchased panels.)

Note 7: If a backlight dimmer is not

used, connect the blue backlight wire

to ground. Do not leave the blue

backlight wire unconnected.

PowerView Deutsch DT06-6S Style Unit to MODBUS Output

NOTE 2

ENGINE

CONTROL

MODULE

(SAE J1939

Compliant)

Gray-CAN_SHLD

Green-CAN_L

Yellow-CAN_H

120 Ω

See Note

NOTE 1

Pin 3

Pin 2

Red-V+

Ignition

Gray-Ground

Switch

Blue-Back Light

NOTE 7

Battery

NOTE 3

Illumination Control*(optional)

For a complete listing of MODBUS Registers

visit our website at www.fwmurphy.com

Pin 4

NOTE 5

Pin 3

Pin 4

Pin 1

Pin 6

Pin 5

Note 1: Place Resistor between

CAN–H and CAN–L Line near

PowerView (included in PVW-P

or factory purchased panels).

Note 2: Use SAE J1939 compliant

wiring or equipment.

Note 3: Electronic dimmer switch

recommended with 4A, capacity

or heavy duty rheostat switch,

1000 ohm, 0.25 watt.

RS485 (+) Data

NOTE 4

RS485 (-) Data

to MODBUS Output

See NOTES 6 and 8

Note 4: Only use 120 ohm

characteristic impedance cable,

ex Belden 9841.

Note 5: RS485 shield connected

to PowerView end only.

Note 6: Place Resistor at End of Line.

(Included for factory purchased panels.)

Note 7: If a backlight dimmer is not

used, connect the blue backlight wire

to ground. Do not leave the blue

backlight wire unconnected.

Note 8: PVA gages cannot be used

with the MODBUS feature.

PV-02124N page 5 of 18

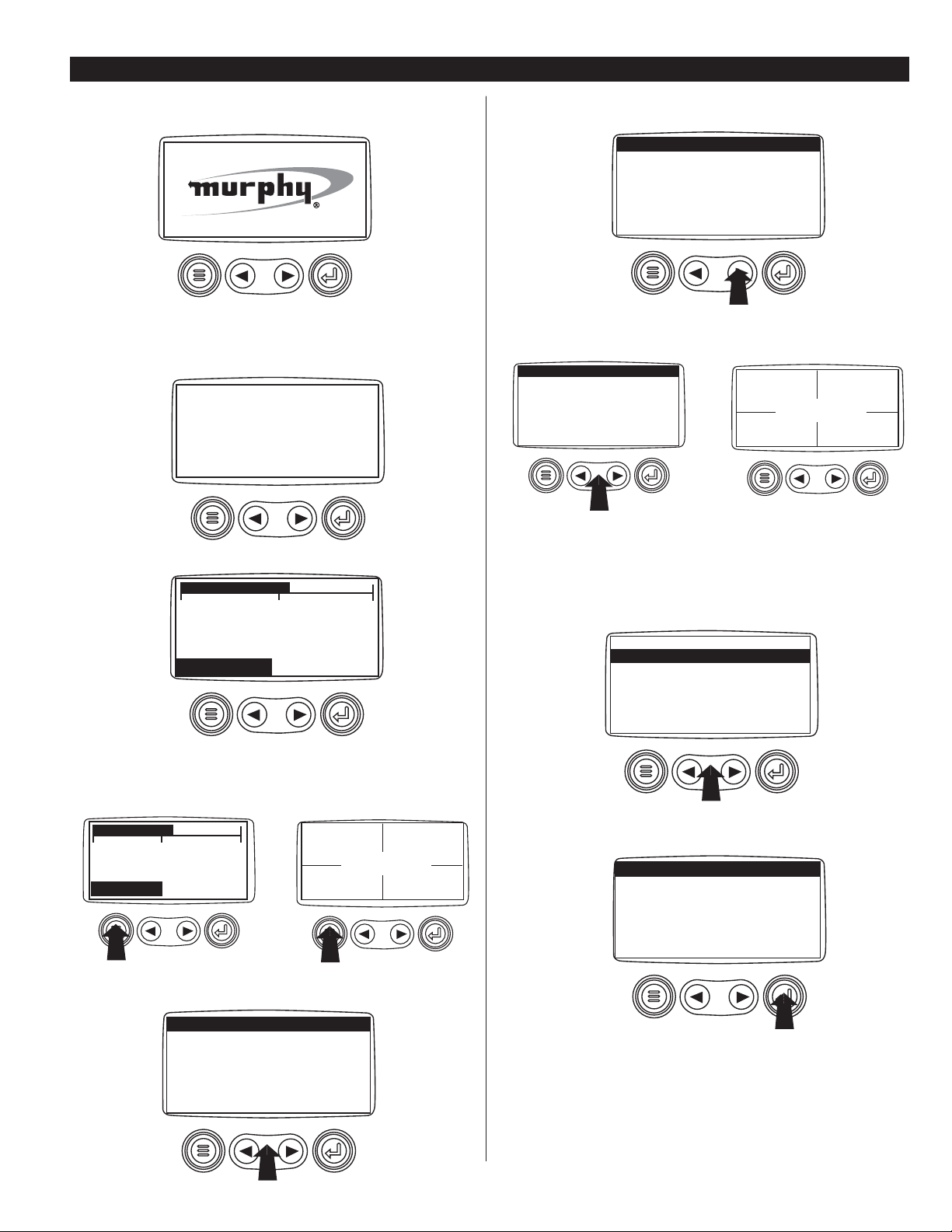

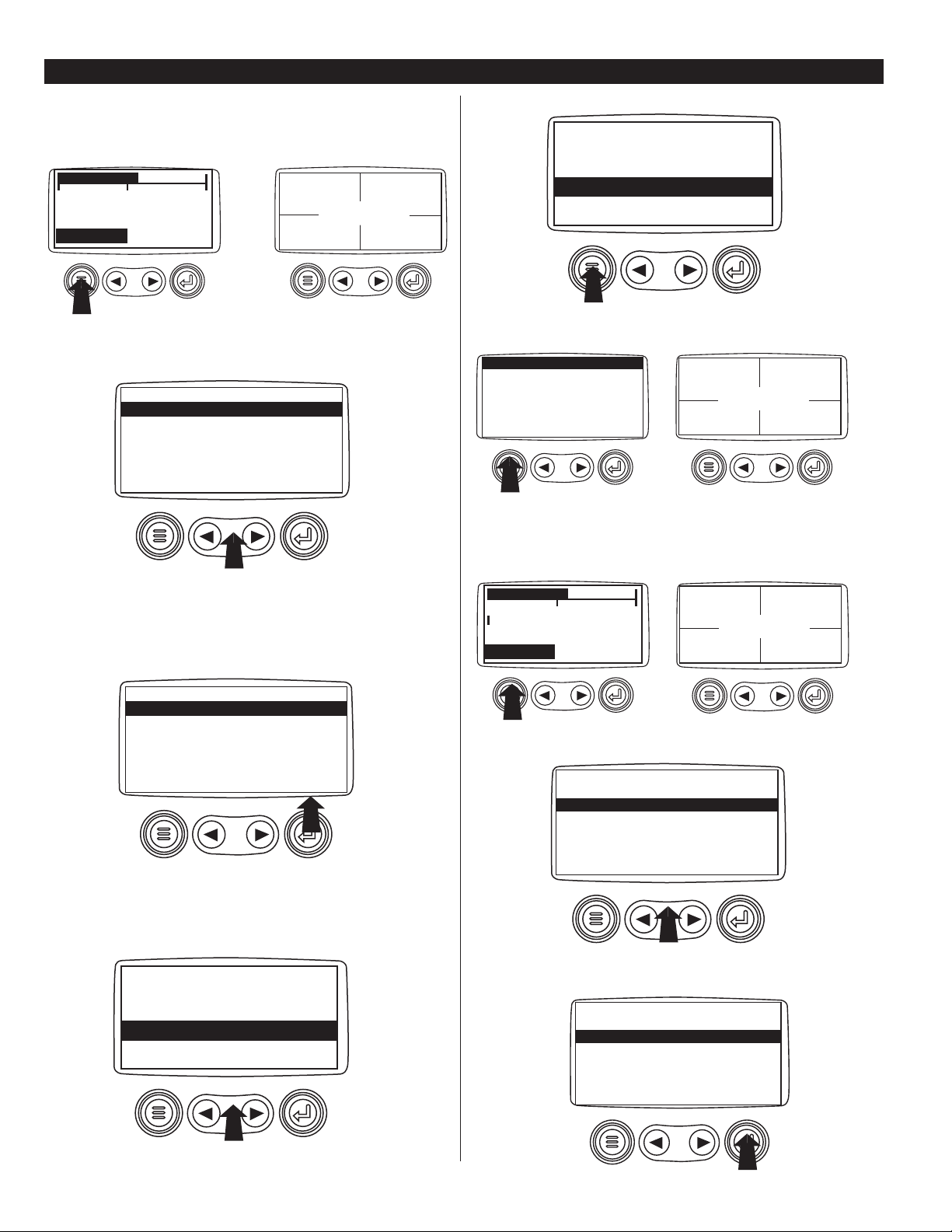

PowerView Menus (First Time Start Up)

1

. When power is first applied to the PowerView, the "Logo" is displayed.

2

. The "Wait to Start" message will be displayed for engines with a

pre-startup sequence. Once the "Wait to Start" message is no longer displayed the operator may start the engine. Note: Displays only when SAE

J1939 message is supported by engine manufacturer.

3

. Once the engine has started the single engine parameter is displayed.

Main Menu Navigation

1

. Starting at the single or four engine parameter display, touch "Menu".

2

. The first seven items of the “Main Menu” will be displayed.

Touching the "Arrow Buttons" will scroll through the menu selection.

3

. Touching the right arrow button will scroll down to reveal the last

items of “Main Menu” screen highlighting the next item down.

4

. Touch the "Arrows" to scroll to the desired menu item or touch "Menu"

to exit the Main menu and return to the engine parameter display.

Selecting a Language

1

. Starting at the main menu display use the "Arrows" to scroll to the

"Language" menu and once highlighted touch the "Enter" button.

2

. The language choices will be displayed. Use the "Arrow" buttons to

scroll through the selections and touch "Enter" to make a selection.

3

. Now that you have selected the language, touch the "Menu" button to

return to the main menu display.

POWERVIEW OPERATION

WAIT TO

START

PREHEAT

1800 RPM

COOL TEMP

98%

LOAD@RPM

14.2

BAT VOLT

57 PSI

OIL PRES

1000 RPM

ENG RPM

98%

LOAD@RPM

14.2

BAT VOLT

57 PSI

OIL PRES

1000 RPM

ENG RPM

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

GO TO 1-UP DISPLAY

ENG RPM

ENG RPM

ADJUST CONTRAST

UTILITIES

ADJUST BACKLIGHT

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

GO TO 1-UP DISPLAY

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

LANGUAGES

ESPAÑOL

FRANÇAIS

DEUTSCH

ENGLISH ❋

0 1500

3000

1800 RPM

COOL TEMP

0 1500 3000

PV-02124N page 6 of 18

Stored Fault Codes

1

. Starting at the single or the four engine parameter display touch the

"Menu button".

2

. The main menu will pop up on the display. Use the "Arrow Buttons" to

scroll through the menu until the Stored Fault Codes is highlighted.

3

Once the "Stored Fault Codes" menu item has been highlighted touch

the "Enter Button" to view the "Stored Fault Codes" (when applicable,

consult engine or transmission manufacturer for SAE J1939 supported

parameters).

4

. If the word "MORE" appears above the "Arrow Buttons" there are

more stored fault codes that may be viewed. Use the "Arrow Buttons" to

scroll to the next Stored Diagnostic Code.

5

. Touch the "Menu Button" to return to the main menu.

6

. Touch the "Menu Button" to exit the Main menu and return to the

engine parameter display.

Engine Configuration Data

1

. Starting at the single or four engine parameter display touch the

"Menu Button".

2

. The main menu will pop up on the display. Use the "Arrow Buttons"

to scroll through the menu until the "Engine Configuration" is highlighted.

3

. Once the "Engine Configuration" menu item has been highlighted

touch the "Enter Button" to view the engine configuration data.

POWERVIEW OPERATION

continued

98%

LOAD@RPM

14.2

BAT VOLT

57 PSI

OIL PRES

1000 RPM

ENG RPM

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

STORED CODES

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

STORED CODES

1 of x

SPN110 FMI10

MORE HIDE

HIGH COOLANT TEMP

▼

▼

1 of x

SPN110 FMI10

MORE HIDE

HIGH COOLANT TEMP

▼

▼

98%

LOAD@RPM

14.2

BAT VOLT

57 PSI

OIL PRES

1000 RPM

ENG RPM

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

GO TO 1-UP DISPLAY

98%

LOAD@RPM

14.2

BAT VOLT

57 PSI

OIL PRES

1000 RPM

ENG RPM

1800 RPM

COOL TEMP

0 1500 3000

1800 RPM

COOL TEMP

0 1500 3000

ENG RPM

ENG RPM

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ENGINE CONFG

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP 4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ENGINE CONFG

Loading...

Loading...