Northern Lights OM3-80 Owner's Manual

OM3-80

For Models: M80A13

OPERATOR’S MANUAL

Marine Generators | Marine Diesel Engines | Land-Based Generators

— CALIFORNIA —

Proposition 65 Warning:

Diesel engine exhaust and some of its constitu-

ents are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Northern Lights

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2015 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

PART NO.: OM3-80 9/15

OPERATOR'S MANUAL

#OM3-80 for Models:

M80A13

Read this operator's manual thoroughly before starting to operate your equipment.

This manual contains information you will need to run and service your new unit.

Table of Contents

INTRODUCTION ..................................................2

Models Included .................................................2

Model Numbers ..................................................2

Serial Numbers ...................................................2

WARRANTY ...........................................................3

SAFETY RULES ..............................................3 - 7

LOCKOUT / TAG OUT PROCEDURES ........ 8

COMPONENT LOCATIONS

M80A13 ........................................................... 10

CONTROL PANELS

Series 3B ...........................................................11

OPERATING PROCEDURES

Emission-Related Instructions .......................... 12

Before Starting .................................................. 12

Shutdowns and Alarms ..................................... 13

ENGINE OPERATION

Normal Engine Operation ................................ 14

Break-In Service ...................................... 14 - 16

Engaging & Disengaging Front PTO (If equipped) ......

Cold Weather Operation

Using a Booster Battery or Charger ............... 17

Welding Near Electronic Control Units .......... 18

Keeping Electronic Control Units Clean

.........................................

.............

16

16

18

SERVICE INTERVAL CHARTS

Propulsion and Prime Power Units .................. 20

Standby Generator Sets .................................... 21

LUBRICATION AND MAINTENANCE

Daily Pre-starting Checks ........................ 22 - 24

250 Hour/6 Month ................................... 25 - 30

500 Hour/12 Month ................................. 31 - 41

2000 Hour/24 Month

Service as Required

TROUBLESHOOTING

General Troubleshooting Information ............. 59

Precautions for Welding ................................... 60

EC Engine Electrical System Layout .............. 61

Wiring Diagrams ...................................... 62 - 77

Engine Troubleshooting ........................... 78 - 82

Electrical Troubleshooting ............................... 83

Diagnostic Trouble Codes ........................ 84 - 87

Intermittent Fault Diagnostics ....................... 88

Displaying Diagnostic Gauge Software ... 88 - 89

STORAGE .................................................... 89 - 91

SPECIFICATIONS ............................................. 92

................................. 42 - 49

................................... 50 - 58

It may not be reproduced in whole or in part without the written permission of Northern Lights, Inc.

© Northern Lights, Inc. All rights reserved. Litho U.S.A. Publication number OM3-80 9/15

Proprietary Information

This publication is the property of Northern Lights, Inc.

OM3-80 9/15

I

Introduction

Servicing of marine engines and generator sets

presents unique problems. In many cases boats cannot

be moved to a repair facility. Marine engines cannot

be compared to the servicing of automobiles, trucks or

even farm equipment. Failures often occur in remote

areas far from competent assistance. Marine engines

are taxed far more severely than auto or truck engines;

therefore, maintenance schedules must be adhered to

more strictly.

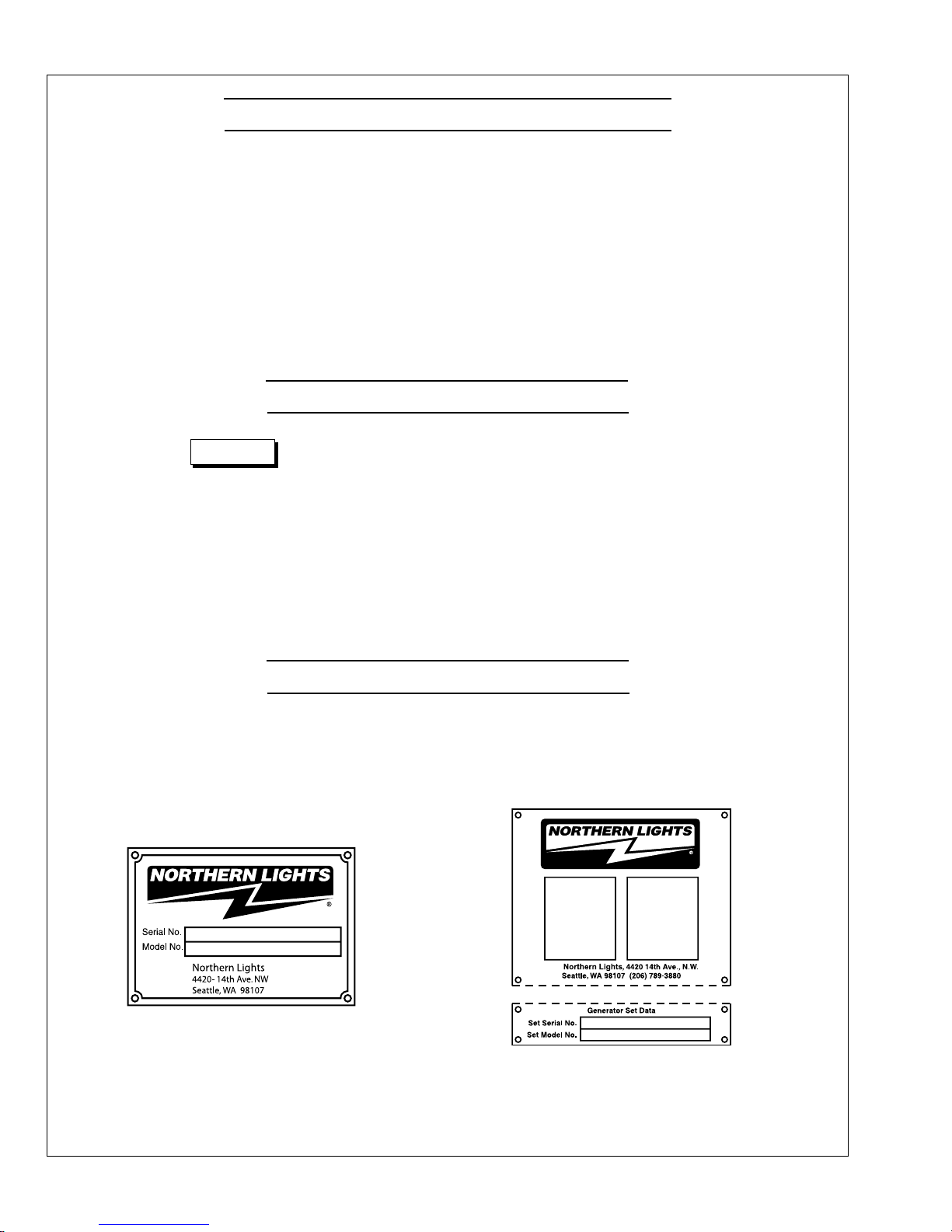

Model Numberss

M80A13

80 kW Northern Lights® commercial marine generator with a John Deere

=

Powertech Tier III 6068 engine block and an electronically controlled fuel

system.

Failures begin with minor problems that are overlooked

and become amplied when not corrected during

routine maintenance.

As operator, it is your obligation to learn about your

equipment and its proper maintenance. This is not a

comprehensive technical service manual. Nor will it

make the reader into an expert mechanic. Its aim is to

aid you in maintaining your unit properly.

Serial Numberss

When referencing Northern Lights equipment by serial number, please refer only to the number

stamped on the Northern Lights® serial number plate.

OM3-80 9/15

2

Warranty

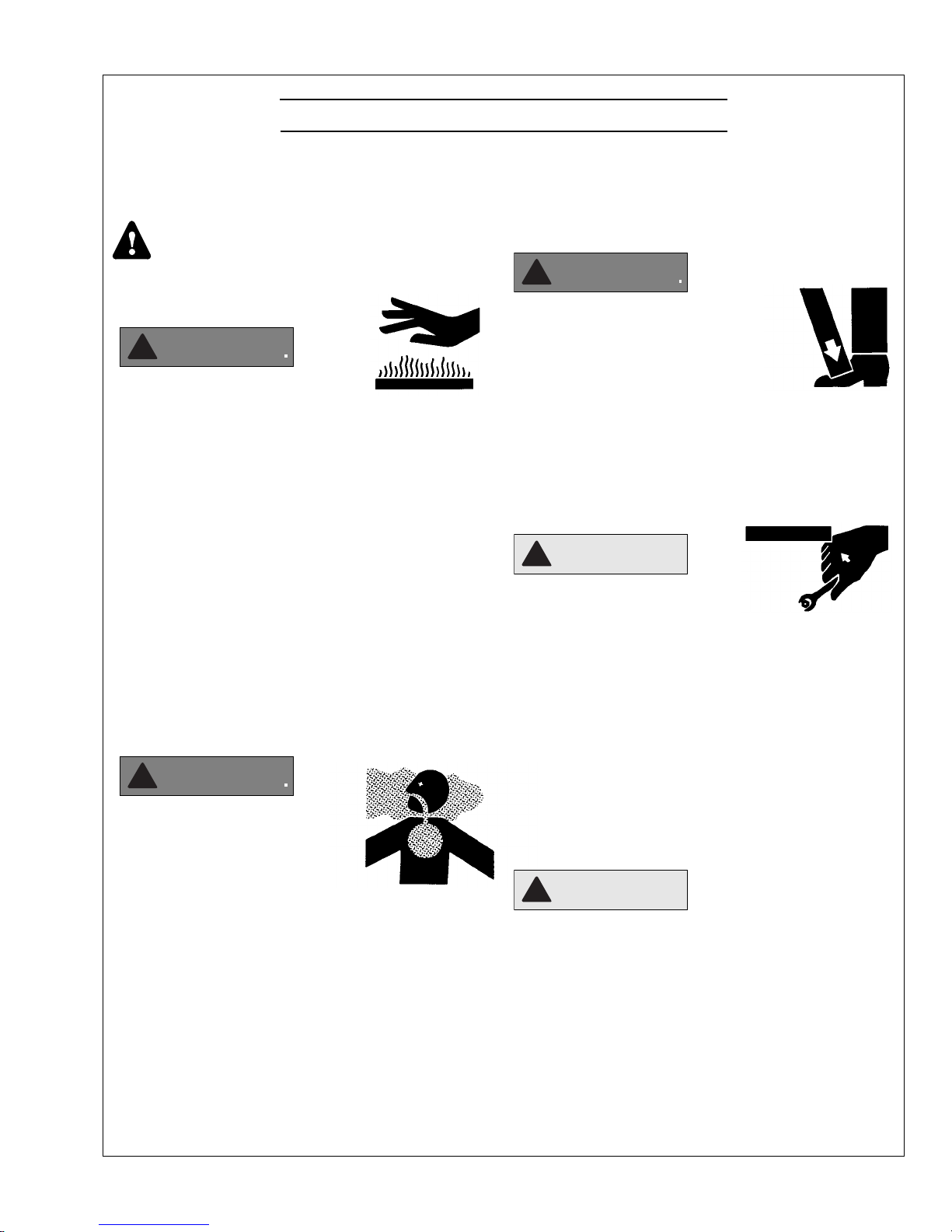

WARNING

WARNING

DANGER

WARNING

!

CAUTION

A warranty registration certicate is supplied

with your set. The extent of coverage is described

in the Limited Warranty Statement. We recommend

that you study the statement carefully.

Safety Rules

NOTICE: Accident reports show that careless use of engines causes a high percentage of accidents.

You can avoid accidents by observing these safety rules. Study these rules carefully and enforce them on the job.

IMPORTANT SAFETY INSTRUCTIONS.

Electromagnetic equipment, including generator sets

and their accessories, can cause bodily harm and

life threatening injuries when improperly installed,

operated or maintained. To prevent accidents be aware

of potential dangers and act safely.

READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN THIS MANUAL,

PRIOR TO THE INSTALLATION

OF ANY GENERATOR SET OR

ACCESSORY. KEEP THESE

INSTRUCTIONS FOR FUTURE

REFERENCE.

Recognize Safety Symbols and Instructions

In addition to the information found in this section, this

operator’s manual uses three dierent signal words to

outline potential dangers of a specic nature.

!

!

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

NOTE: If the warranty is to apply, the servicing

instructions outlined in this manual must be

followed. If further information is needed, please

contact an authorized dealer or the factory.

on parts and components from outside suppliers

that is not reproduced in this manual. Consult the

suppliers for additional safety information.

Learn how to operate the machine and how to use

the controls properly. Only trained personnel should

operate machines, or work on or around them.

Keep you machine in proper working condition.

UNAUTHORIZED MODIFICATIONS TO THE

MACHINERY MAY IMPAIR ITS FUNCTION

AND SAFETY PARAMETERS.

Prevent Bypass and Accidental Starting

!

Do not start engine by shorting

across start terminal. Engine will

start if normal circuitry is bypassed,

creating a hazard by runaway

machinery.

Start engine only from operator’s station.

Follow All Safety Instructions

Carefully read and understand

all safety messages in this

manual and on your machine’s

safety signs. Keep signs in good

and clean condition. Replace

missing or damaged signs. Be

sure new equipment components and repair parts

include the current safety signs. For replacement signs,

proper placement of safety signs or clarication on any

safety issue, consult your Northern Lights dealer or the

factory.

There can be additional safety information contained

Handle Fuel Safely - Avoid Flames

!

Diesel is highly ammable and should be treated

with care at all times. Do do not refuel while

smoking or when near sparks or open ame.

ALWAYS STOP ENGINE

BEFORE FUELING

MACHINE. Always ll

portable fuel tank outdoors.

Never fuel a hot engine.

OM3-80 9/15

3

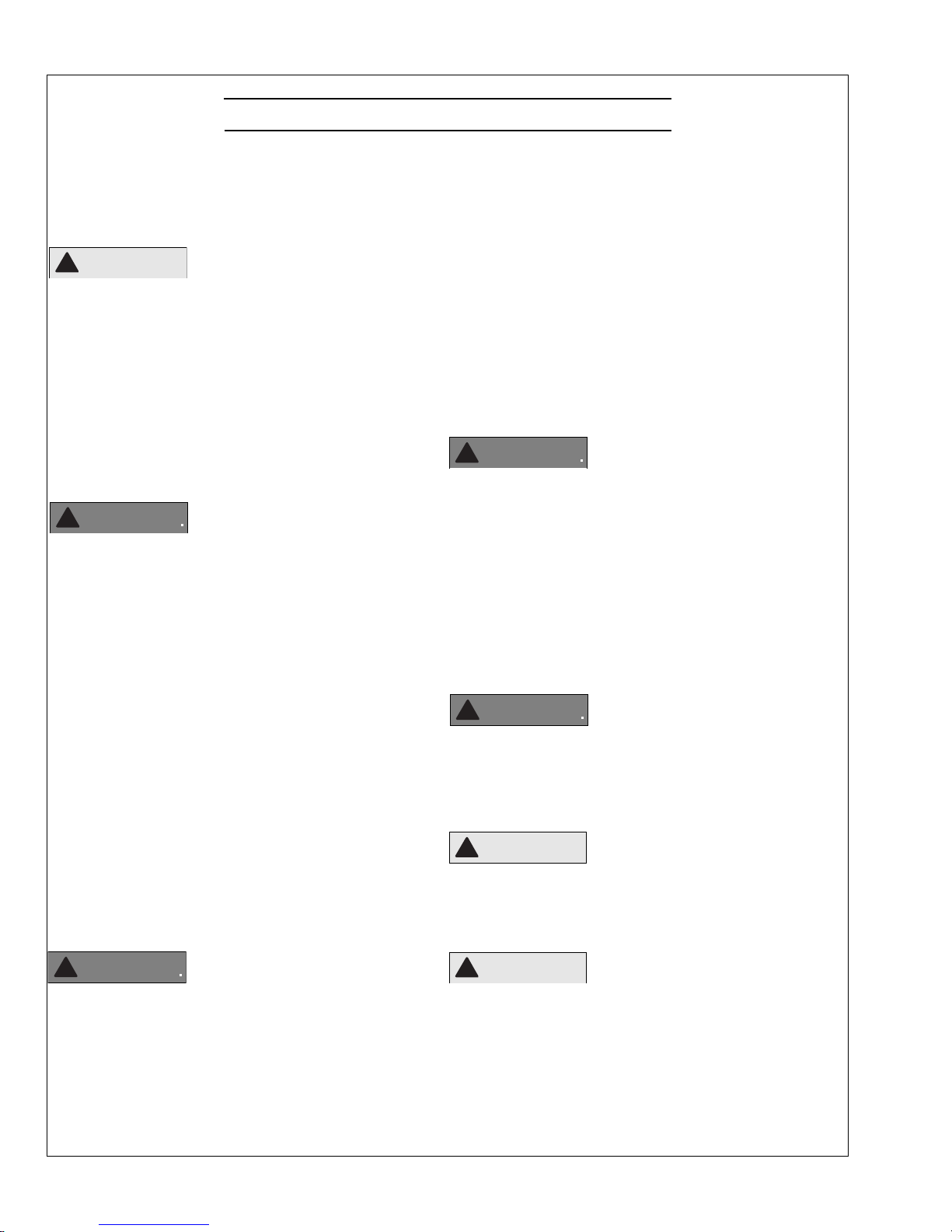

Safety Rules (Continued)

CAUTION

DANGER

DANGER

WARNING

Prevent accidental discharge of starting uids by

storing all cans in a cool, safe place, away from sparks

or open ame. Store with cap securely on container.

Never incinerate or puncture a fuel container.

Prevent res by keeping machine clean of accumulated

trash, grease and debris. Always clean any spilled fuel

as swiftly as possible. Do not store oily rags, which

can ignite and burn spontaneously.

Be prepared if a re starts. Keep a rst aid kit and re

extinguisher handy. Keep emergency contact numbers

for re department, doctors, ambulance and hospital

near the telephone.

Service Machines Safely

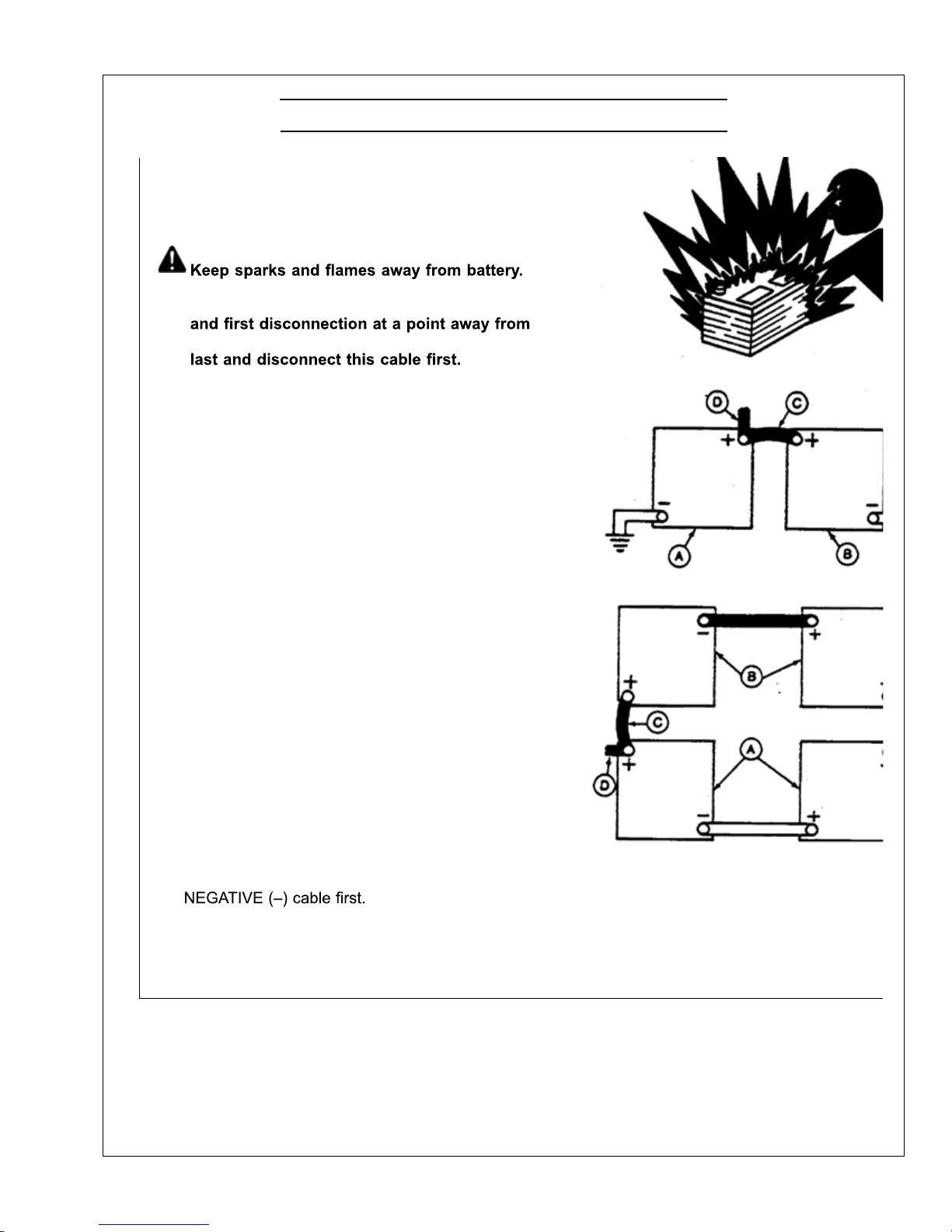

!

Do not wear a necktie, scarf,

necklace, rings or other

jewelry, or any loose clothing

when working near moving

parts. Tie long hair behind your head. If any of these

items get caught in moving machinery, severe injury or

death could result.

Check for any loose electrical connections or faulty

wiring.

Look completely around engine to make sure that

everything is clear before starting.

Operating equipment requires the full attention of

the operator. Do not use radio or music headphones

while operating machinery.

Practice Safe Maintenance

!

Understand all service procedures

before starting work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is

in operation.

Keep hands, feet and clothing away from powerdriven equipment. When shutting down an engine,

disengage all power and operator controls. Allow

the engine to cool completely before beginning any

service work.

Securely support any machinery elements that must

be raised for service work with support or lifting

machinery specically intended for that purpose.

Keep all parts in good conditions and properly

installed. Fix damage immediately. Replace any

worn or broken parts. Remove any build up of

grease, oil or debris.

Disconnect battery ground cable (-) before making

any adjustments or service work.

Stay Clear of Rotating Drivelines

Wear Protective Clothing

!

To prevent catching anything in moving machinery,

always wear close tting clothes and safety equipment

appropriate to the job.

Prolonged exposure to loud noise can cause hearing

loss or impairment.

Wear suitable authorized

hearing protection, such

as earmus or plugs to

protect against loud noises.

!

Entanglement in rotating drivelines can cause serious

injury or death. Keep shields in place at all times.

Make sure that rotating shields turn freely in pace

with the drivelines.

Do not wear loose tting equipment around rotating

drivelines. Stop the engine and make sure that all

moving parts have stopped

before making any adjustments,

connections, or performing

any other type of service to

the engine or other driven

equipment.

OM3-80 9/15

4

Safety Rules (Continued)

WARNING

WARNING

WARNING

WARNING

Install all Safety Guards

!

Direct contact with rotating

fans, belts, pulley and drives

can cause serious injury.

Keep all guards in place at all

times during engine operation.

Wear close-tting clothes. Stop the engine and be

sure all fans, belts, pulleys and drives are stopped

before making adjustments, connections, or cleaning

near fans and their components.

Do not allow anything on your person to dangle into

or come in contact with a moving fan, belt, pulley or

drive. Fans can act as vacuums and pull materials

up from below, so avoid that area as well while in

service.

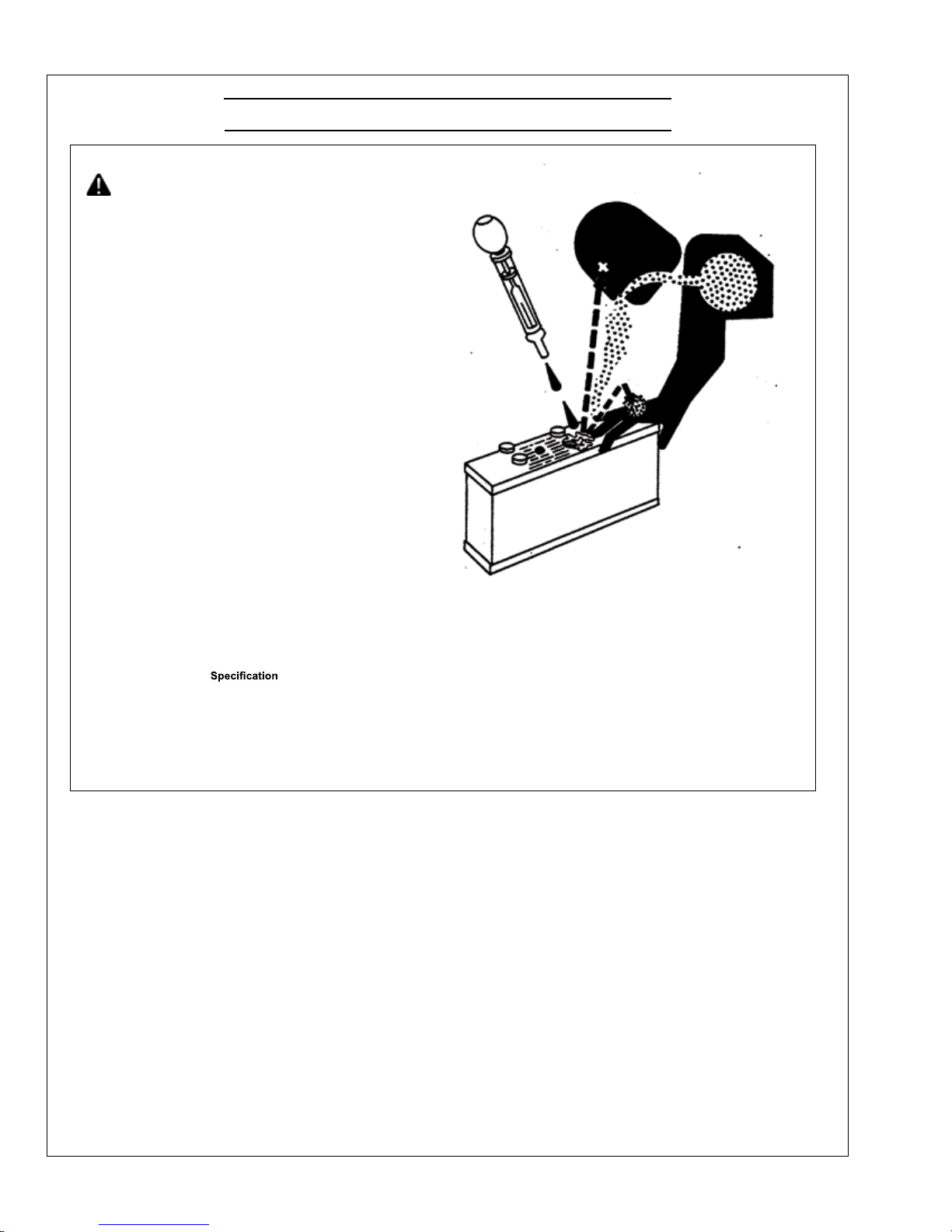

Safe Battery Handling

To Avoid Hazards:

• Fill batteries only in well-ventilated areas.

• Wear appropriate eye protection and rubber gloves.

• Never use air pressure to clean batteries.

• Wear appropriate ventilation equipment to avoid

inhaling fumes when adding electrolyte.

• Do not spill or drip electrolyte.

• Use correct jump-start procedure if required.

If acid is spilled on skin or in eyes:

1. Flush skin with water.

2. Apply baking soda or lime to

help neutralize acid.

3. Flush eyes with water for

15-30 minutes.

4. Get medical attention

immediately.

If acid is swallowed:

1. DO NOT induce vomiting.

2. Drink large amounts of

water or milk, without

exceeding 2 liters

(2 quarts)

3. Get medical attention immediately

!

Prevent Battery Explosions

Battery gas is highly

ammable. Battery

explosions can cause severe

injury or death. To help

prevent battery explosions, keep sparks, lighted

matches and open ame away from the top of battery.

When checking battery electrolyte level, use a

ashlight.

Never check battery charge by contacting the posts

with a metal object. Use a volt-meter or hydrometer.

Frozen batteries may explode if charged. Never

charge a battery that has not been allowed to warm to

at least 16oC (60oF).

Always remove grounded (-) battery clamp rst and

replace ground clamp last.

ulfuric acid in battery electrolyte is poisonous and

S

strong enough to burn skin, eat holes into clothing and

other materials, and cause blindness if splashed into eyes.

!

Battery posts, terminals, and related accessories

can contain lead and lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Handle Chemical Products Safely

!

Direct exposure to hazardous

chemicals can cause serious injury.

Among the potentially hazardous

chemicals that may be used

with Northern Lights

products are lubricants,

coolants, paints and adhesives.

All potentially hazardous chemicals come with a Material

Safety Data Sheet (MSDS). The MSDS provides specic

details on chemical products, including physical hazards,

safety procedures and emergency response techniques

OM3-80 9/15

5

Safety Rules (Continued)

CAUTION

WARNING

WARNING

WARNING

WARNING

DANGER

Read and understand the MSDS for each chemical before

you start any job that includes it. Follow the procedures

and use appropriate equipment exactly as recommended.

Contact your Northern Lights dealer or Northern Lights

factory for MSDS’s used on Northern Lights products.

Work in Well Ventilated Areas

!

Exhaust fumes from engines contain carbon monoxide

and can cause sickness or death. Work in well ventilated

areas to avoid prolonged exposure to engine fumes. If it

is necessary to run an engine in an enclosed area, route

the exhaust fumes out of the area with an approved, leak

proof exhaust pipe extension.

Remove Paint Before Welding or Heating

!

Hazardous fumes can be generated

when paint is heated by welding,

soldering or using a torch. To avoid

potentially toxic fumes and dust,

remove paint before heating.

Remove paint a minimum of 100

•

mm (4 in.) from the

area that will be aected by heat.

•

If paint cannot be removed, wear an approved respirator.

• If you sand or grind paint, use an approved respirator.

• If you use solvent or paint stripper, remove stripper

with soap and water before welding. Remove

solvent or paint stripper containers from the area.

• Allow at least 15 minutes for fumes to disperse

before welding or heating.

Do not use a chlorinated solvent in an area where welding

will occur. Work only in areas that are well ventilated.

Dispose of paint and solvent properly.

engine has been shut o. Do not remove a ller cap

unless it

hands. Slowly loosen cap to relieve pressure before

opening fully.

Avoid High Pressure Fluids

is cool enough to comfortably grip with bare

!

Relieve pressure prior to

disconnecting pressurized lines.

Escaping uid under pressure

can penetrate the skin causing

serious injury. Always relieve pressure before

disconnecting hydraulic or other pressurized lines.

Tighten all connections rmly before re-applying

pressure.

If searching for leaks, use a piece of cardboard.

Always protect your hands and other body parts from

high-pressure uids.

If an accident occurs, see a doctor immediately. Any

high pressure spray injected into the skin must be

removed within a few hours to prevent the risk of

gangrene or other infection.

Avoid Heating Near Pressurized Fluid Lines

!

Flammable spray can be generated

by heating near pressurized uid

lines, resulting in severe burns and

bodily injury. Pressurized lines

can rupture when heat goes beyond the immediate

ame area. Do not weld, solder or use a torch or

open ame near pressurized lines or other ammable

uids.

Do Not Open High-Pressure Fuel System

Service Cooling System Safely

!

Opening a pressurized cooling

system can release explosive

uids and causing serious burns.

Before opening any pressurized

cooling system, make sure the

!

Many Northern Lights engines use high-pressure

fuel injection. High-pressure uid remaining in fuel

lines can cause serious injury. Do not disconnect or

attempt any repair of fuel lines, sensors, or other

OM3-80 9/15

6

Safety Rules (Continued)

WARNING

!

CAUTION

!

CAUTION

WARNING

WARNING

components between the high-pressure fuel pump

and nozzles on engines with high pressure fuel

systems.

ONLY AUTHORIZED TECHNICIANS

CAN PERFORM REPAIRS ON AN HIGH

PRESSURE FUEL INJECTION SYSTEMS.

material containing asbestos. Keep all bystanders

away from any area where asbestos dust may be

generated.

Use Proper Lifting Equipment and Techniques

!

Avoid Hot Exhaust

!

Avoid exposure to and physical

contact with hot exhaust

gases. Exhaust parts and streams can reach high

temperatures during operation, leading to burns or

other serious injury.

Cleaning exhaust lters can also lead to exposure to

hot exhaust gas and the injury risk associated with

it. Avoid exposure to and physical contact with hot

exhaust gases when cleaning exhaust lters.

During auto or manual/stationary exhaust lter

cleaning operations, the engine will run at

elevated temperatures for an extended period of

time. Exhaust parts and streams can reach high

temperatures during operation, leading to burns or

other serious injury.

Avoid Harmful Asbestos Dust

!

Inhaling asbestos bers may cause

lung cancer. Avoid breathing any

dust that may be generated when

handling components containing

asbestos bers, including some

gaskets.

The asbestos used in these components is usually

found in a resin or otherwise sealed. Normal

handling of these components is not dangerous,

as long as airborne dust containing asbestos is not

generated.

Avoid creating dust. Never use compressed air for

cleaning. Avoid brushing or grinding materials

containing asbestos. When servicing, wear an

approved respirator. A special vacuum cleaner is

recommended to clean asbestos. If this vacuum is

not available, apply a mist of oil or water on the

Lifting heavy components incorrectly

can cause severe injury or damage

to machinery. Avoid unbalanced

loads. Do not use lifting eyes. Lift the

generator set using lifting bars inserted

through the lifting holes on the skid.

Follow all recommended removal and installation

procedures in this and associated Northern Lights

manuals.

Use Proper Tools

Makeshift tools and procedures

can create safety hazards.

Always use appropriate tools for

the job.

Use power tools only to loosen threaded parts and

fasteners. For loosening and tightening hardware,

always use the correct sized tools.

Do not use US measurement tools on metric

fasteners, or vice versa. Use only service parts that

meet Northern Lights specications.

Dispose of Waste Properly

Disposing of waste improperly can threaten the

environment and lead to unsafe working conditions.

Potentially harmful waste used in Northern Lights

equipment can include oil, fuel, coolant, lters and

batteries.

Use leakproof containers to drain uid. Do not

use food or beverage containers that may mislead

someone into drinking from them.

Do not pour waste onto the ground, down a drain or

into any water source.

OM3-80 9/15

7

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

Lock Out / Tag Out Procedures

Scope

During maintenance, repairs or retooling of a Northern Lights generator set, simply turning the machine o or unplugging

it while it is being worked on does not give enough protection to others who are not performing the maintenance or

repair. Many serious accidents happen when someone thought the machine was turned o, or all of its energy was

safely blocked or released.

General Policy

To avoid dangerous or hazardous situations, refrain from

any of the following:

• Removing or bypassing a guard or other safety device

• Placing any part of your body in a position where you

could be caught by moving machinery.

• Cleaning or oiling machinery when in operation.

• Adjusting circuits, chillers, pumps, air handlers, valves,

circuit breakers or fans while in operation.

• Working on piping or high pressure systems.

Lock Out/Tag Out Instructions Electrical Equipment

Be sure the equipment’s ON/OFF switch is in the OFF

position and is unplugged from any electrical source before

attempting to perform any type of work on the equipment.

Obtain an electrical plug cap cover with a lockset. Secure

the plug terminal end using the electrical plug lockout cap.

Lock the cap and retain the key.

If the equipment is directly wired into an electrical box with

a shut o switch, obtain a lock pad and/or the appropriate

colored tags and place the lock and tag through the shut

o lever. Retain the key until the repair is completed and

the machine is safe to start. Be certain the shut o lever

is in the OFF position before restarting. NEVER give a

lock out key to unauthorized personnel.

If the equipment is directly wired into an electrical box

without a shut o switch and lock out capability, then a

circuit breaker lock out will be required. Obtain a circuit

lock and tag set. Install the lock onto the circuit breaker

box. Ensure the unit ON/OFF switch is in the OFF position

before restarting.

Lock Out/Tag Out Instructions Pneumatic and Hydraulic Equipment

If shutting o of air, water or other material cannot be

achieved at the local supply valve, shut o valves further

back in the system and re-check the bleed-o point until

complete shut-o is achieved.

Ax a DO NOT OPERATE tag to each valve handle that

requires shut o. Each DO NOT OPERATE tag must be

signed and dated by the authorized technician servicing

the equipment.

Lock Out/Tag Out Instructions Air Hose Connected Pneumatic Equipment

Equipment connected to the compressed air system

through an air hose with a detachable tting must be

shutdown and unplugged. Excess air must be bled prior

to removing the air hose, prior to any maintenance or

repair activities.

Ax a DO NOT OPERATE tag to the air hose near the

detachable tting. Each DO NOT OPERATE tag must be

signed and dated by the authorized technician servicing

the equipment. Check that the equipment cannot be

operated by activating the ON switch.

Stored Energy

Immediately after applying Lock Out or Tag Out devices,

ensure that all potentially hazardous stored or residual

energy is relieved, disconnected, restrained and otherwise

rendered safe.

Verication of Isolation

Verify the machinery or equipment is actually isolated and

de-energized prior to beginning work on a machine or on

equipment that has been locked out.

Restarting Procedures

For servicing pneumatic and hydraulic equipment, the

following additional procedures must be implemented,

following completion of lock out/tag out procedures for

the unit to be serviced:

Shut o air, water or supply valves at the equipment to

be serviced.

Check the local bleed-o point for completed release of

pressurized air, water or oil.

Follow the procedures below prior to restoring energy:

• Ensure that all machinery or equipment is properly

reassembled. Inspect the machinery or equipment to

verify non-essential items have been removed.

• Ensure that all personnel are safely outside danger

zones. Notify personnel that lock out/tag out devices have

been removed and energy will be reapplied.

• Only authorized personnel may remove lock out/tag out

devices or notices.

OM3-80 9/15

8

Notes

OM3-80 9/15

9

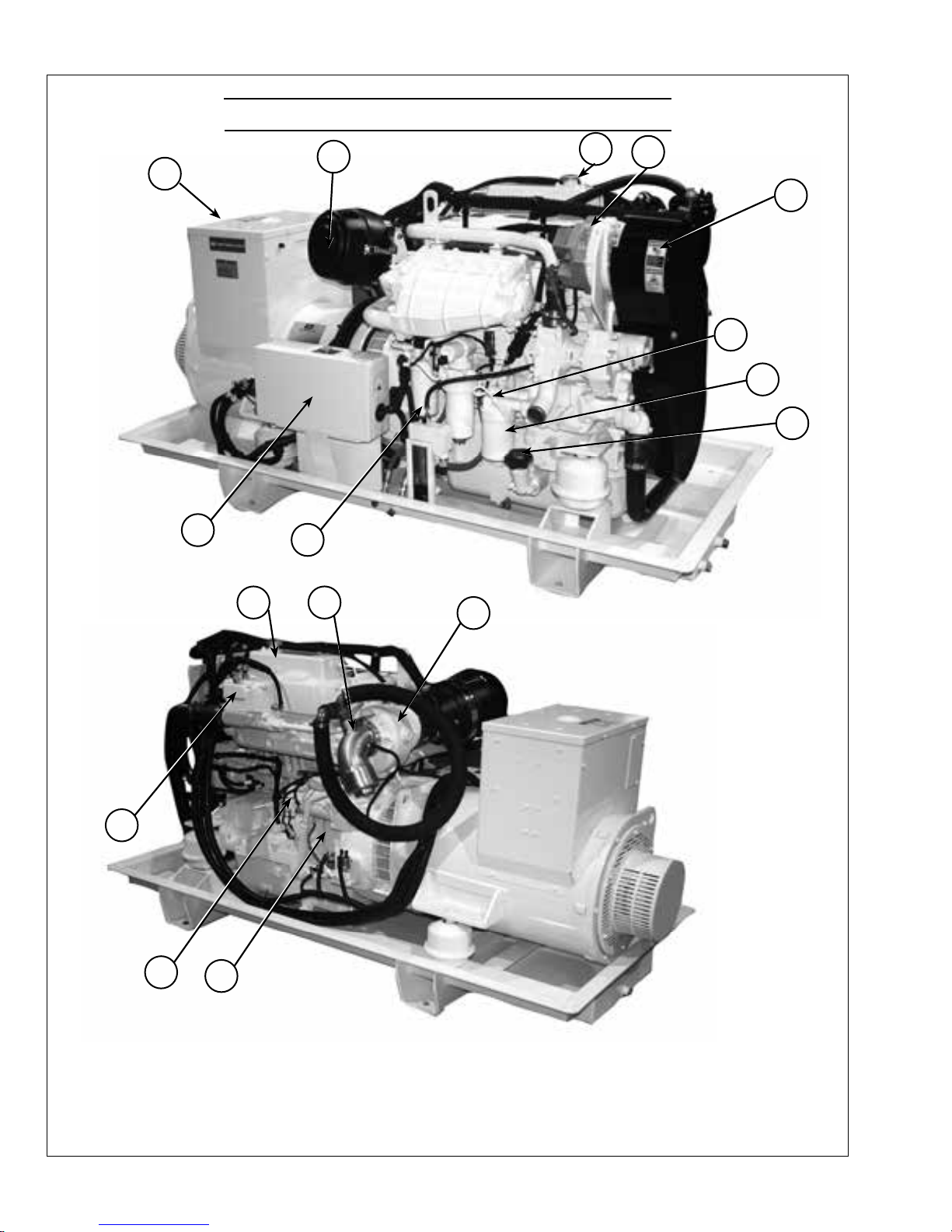

Component Locations

2

3

4

1

5

6

7

8

10

9

13

12

1. AC Junction Box

2. Air Cleaner

3. Coolant Fill

4. Alternator

5. Belt Guard

11

14

15

6. Lube Oil Dipstick

7. Lube Oil Filter

8. Lube Oil Fill

9. Fuel Filter

10. DC/Control Junction Box

16

M80A13 (Shown with optional equipment)

11. Fuel Injection Lines

12. Starter

13. Thermostat Cover

14. Expansion Tank

15. Exhaust Elbow

16. Turbocharger

OM3-80 9/15

10

Northern Lights Control Panels

Figure 7: Series 3B Generator Control Panel

1. SHUTDOWN BYPASS SWITCH

This switch bypasses the safety shutdown feature

during the starting process.

2. ENGINE CONTROL SWITCH

To start the engine, hold this switch in the START

position until the engine is running.

NOTE: Excessive cranking of marine sets equipped

with water lift muer systems can cause engine

damage.

After the engine starts, release the switch and it will

return to RUN position. To stop the engine, hold

the switch in the STOP position.

3. OIL PRESSURE GAUGE

The oil pressure gauge shows the oil pressure in

the engine lubricating system. If the pressure drops

below 15 PSI at a speed higher than idling, stop the

engine and investigate.

4. COOLANT TEMPERATURE GAUGE

Water temperature gauge shows the temperature of

the cooling water. If the gauge registers over 200°F

(93.30C) or drops below 140°F (600C), stop the

engine and investigate.

5. HOUR METER

Keeps track of the engine running time.

6. DC VOLTMETER

When the engine is running, it indicates the

voltage output of the alternator.

OM3-80 9/15

11

Emission-Related Installation & Instructions

Failing to follow these instructions when installing

a certied engine in a vessel violates federal law (40

CFR 1068.105(b)), subject to nes or other penalties as

described in the Clean Air Act.

The installed exhaust system should not create exhaust

back pressure greater than 30” (760 mm) of water for

Operating Procedures

BEFORE STARTING

1. Check the water level by removing the pressure

cap from the expansion tank. In order to give the

cooling water room to expand, the level should be

about 1 3/4 in. (4-5 cm) below the ller cap sealing

surface when the engine is cold. When lling with

coolant, the venting cock on top of the turbocharger

should be opened to ensure that no air pockets form

in the cooling system (see Service Point #14).

CAUTION: Use protective clothing and open

the ller cap carefully when the engine is warm

to prevent burns.

2. Check the oil level in the crankcase with the dipstick.

The oil level should be between the “waed area”

and the “oo”. Never allow the level to go below

the “oo”. Always add the same viscosity of oil as is

already in the crankcase (see Service Point #1).

3. Check the fuel tank level and open any fuel valves.

4. Disengage clutch, if equipped.

5. Close the seacock, check and clean the strainer and

reopen the seacock.

6. Place the battery switch in the ON position.

NOTE: The battery switch must always be kept ON

while the engine is running. If the switch is turned

OFF while the engine is running, the battery charging

regulator could be ruined.

a turbocharged engine and 48” (1200 mm) for a non-

turbocharged unit, measured at the engine exhaust elbow.

If you install the engine in a way that makes the engine’s

emission control information label hard to read during

normal engine maintenance, you must place a duplicate

label on the vessel, as described in 40 CFR 1068.105.

NOTE: If there is a governor locked at a specic

speed on the generator set, there may not be a slow

idle function, so in that case operate the engine at

high idle for 1 to 2 minutes before adding load. If

the stand-by generator set is loaded as soon as it

reaches rated speed, this procedure would not apply.

Operating

1. Check Gauges Often: Oil pressure must be above

29 PSI (if not above 15 PSI within 5 seconds of

starting, the engine should be stopped and the

problem should be explored). Normal oil pressure

is 50 PSI at rated load speed (1800 to 2500 RPM).

Oil temperature should be 1150C (2400F) for normal

operating temperature. The D.C. voltmeter should

read between 13 and 14 volts (26-28 volts, 24 volt

systems).

2. Check AC voltage and frequency meters (Series 4

Panel). If gauges deviate from normal levels, shut

down the set and investigate.

3. Check belt for good alignment.

4. Let the unit run unloaded for a three to ve minute

warm-up period before applying load.

5. Do not add full electrical load until engine is at

maximum operating temperature.

NOTE: If engine dies while under load, immediately

remove load and restart engine. Turbocharger parts

could overheat if the oil ow stopped.

Starting

1. While holding the Shutdown Bypass switch in the

ON position, push the Engine Control switch to the

START position.

2. As soon as the engine starts, release both switches.

Do not crank the starter for more than 20 seconds.

3. If the engine fails to start the rst time, be sure

the starter has stopped before re-engaging. Wait 2

minutes before starting engine again.

Shutdown

1. Move the Engine Control Switch to the OFF

position.

2. Close the sea cock and fuel valves, and put the

battery switch in the OFF position if the unit will be

o for an extended period.

NOTE: Do not turn the battery switch to OFF while

the engine is running.

OM3-80 9/15

12

Operating Procedures

3. Fill the fuel tank to minimize possible water

condensation problems. Filling tanks at end of day

drives out moisture-laden air.

4. For Heat Exchanger Engines: If the engine will be

subjected to temperatures at or below 0°C(32°F),

open the sea water pump end cover to drain the sea

water from the system to prevent freezing. The sea

water pump will require priming before starting the

engine.

5. Observe the hour meter reading on diagnostic gauge/

hourmeter to determine if periodic maintenance is

necessary. Make appropriate entries in maintenance

logs. (See LUBRICATION AND MAINTENANCE

RECORDS Section.)

6. Perform required periodic maintenance on all other

equipment, as recommended by the equipment

manufacturers.

SHUTDOWNS AND ALARMS

1. Your unit is tted with a system to protect it from

high water temperature or low oil pressure.

a. Generator sets have shutdown systems to stop the

engine. They have no warning horns.

b. Other alarms and shutdowns are available as

optional equipment.

NOTE: Do not rely on your warning or shutdown

system to the exclusion of careful gauge monitoring.

Watching your gauges can prevent damage to the unit

and dangerous power losses.

2. Do the following when your shutdown system is

activated:

a. Check the temperature gauge. If the temperature is

above 205°F (97°C), shut o the engine immediately.

b. Use the Trouble Shooting Guide on pages 22- 24

to isolate the cause of the overheat.

CAUTION: Do not remove the water ll cap of an

overheated engine. Escaping high temperature steam

can cause severe burns. Allow the engine to cool and

then remove the cap slowly, using

protective clothing.

c. Make repairs and restart after the temperature

gauge registers below 180°F (83°C).

d. Watch the temperature gauge regularly and turn

o the unit if the temperature rises above 200°F

(94°C). Repeat the troubleshooting process.

3. If the shutdown is activated and the temperature

gauge shows temperature within normal temperature

range:

a. Check the engine crankcase oil level.

b.

If the oil level is low, ll with recommended lubricating

oil and restart. Watch the oil pressure gauge carefully

and shut o the engine if it does not show a normal

reading after a few seconds of operation.

c. If the oil level was normal, DO NOT restart the

engine. Call your Northern Lights or Lugger

dealer for assistance.

OM3-80 9/15

13

Normal Engine Operation

Engine Operation

Observe engine coolant temperature and engine

oil pressure.Temperatures and pressures will vary

between engines and with changing operating conditions,

temperatures, and loads.See GENERALENGINE

your engine.

If coolant temperaturerises abovethe maximum coolant

engine. Unless temperature drops quickly, stopengine

and determine cause before resuming operation.

Operatethe engineunder a lighter load and at slowerthan

runengine at slow idle unless necessaryfor maneuvering

out of dock and harbor.

Break-In Service

The engineis ready for normal operation. However, extra

more satisfactory long-term engineperformanceand life.

DO NOT exceed 100 hoursof operation with break-in

oil.See GENERALENGINE SPECIFICATIONSin

Stop engine immediatelyifthereare anysigns of part

failure.Symptomsthatmay be early signs of engine

problemsare:

Sudden drop in oilpressure

•

Abnormal coolant temperatures

•

High marine gear oil temperature

•

Unusualnoise or vibration

•

Sudden loss of power

•

Excessive black exhaust

•

Excessive fuel consumption

•

Excessive oil consumption

•

Fluid leaks

•

OUOD006,000008F -19-21JUN07-1/1

Northern Lights

Break-in Oil. Operate theengine at heavy loads with

minimal idling during thebreak-in period.

idle, constant speeds, and/or light load usage,or

a longerbreak-in periodmay be required. In these

situations,anadditional 100 hour break-in periodis

recommended usinganew changeof Northern Lights

Northern Lights

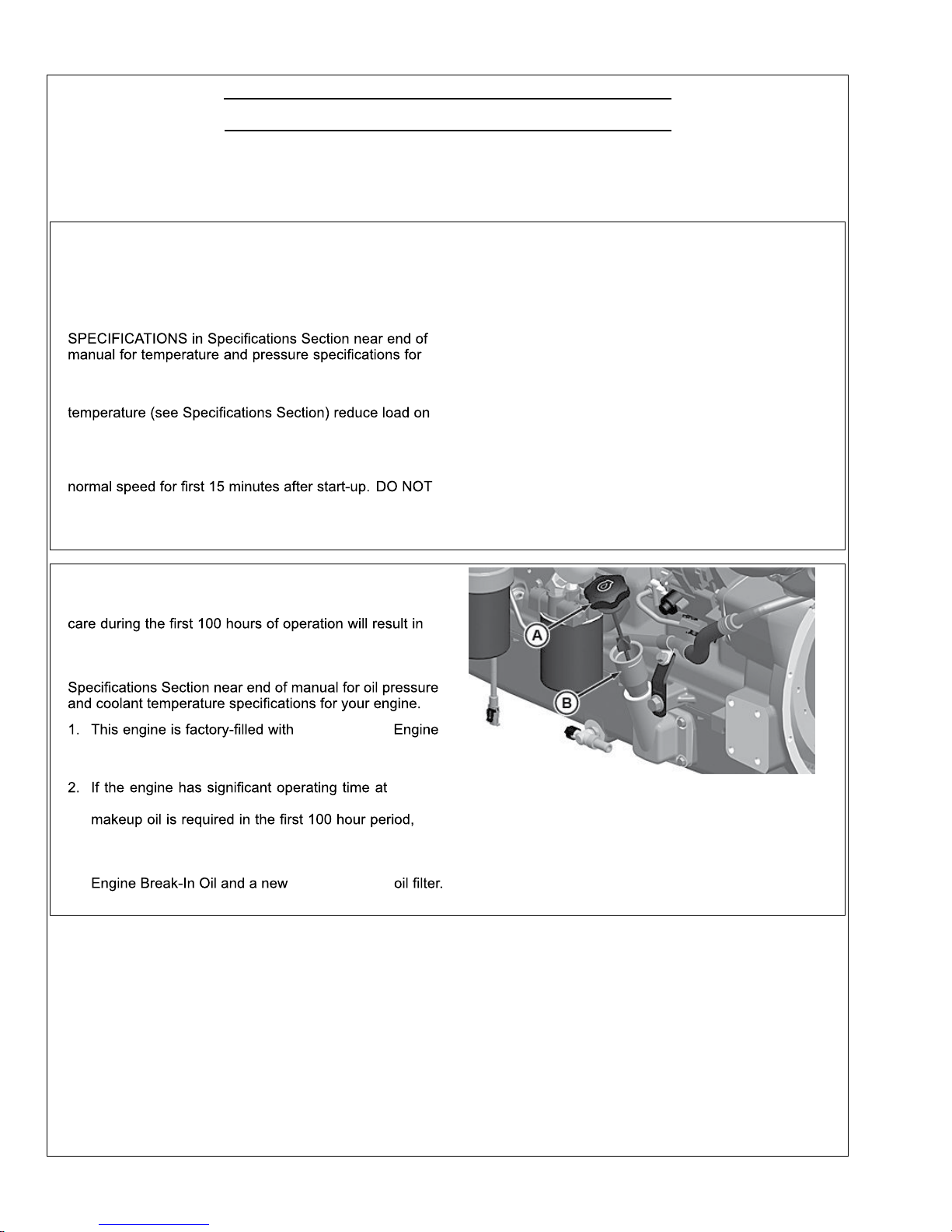

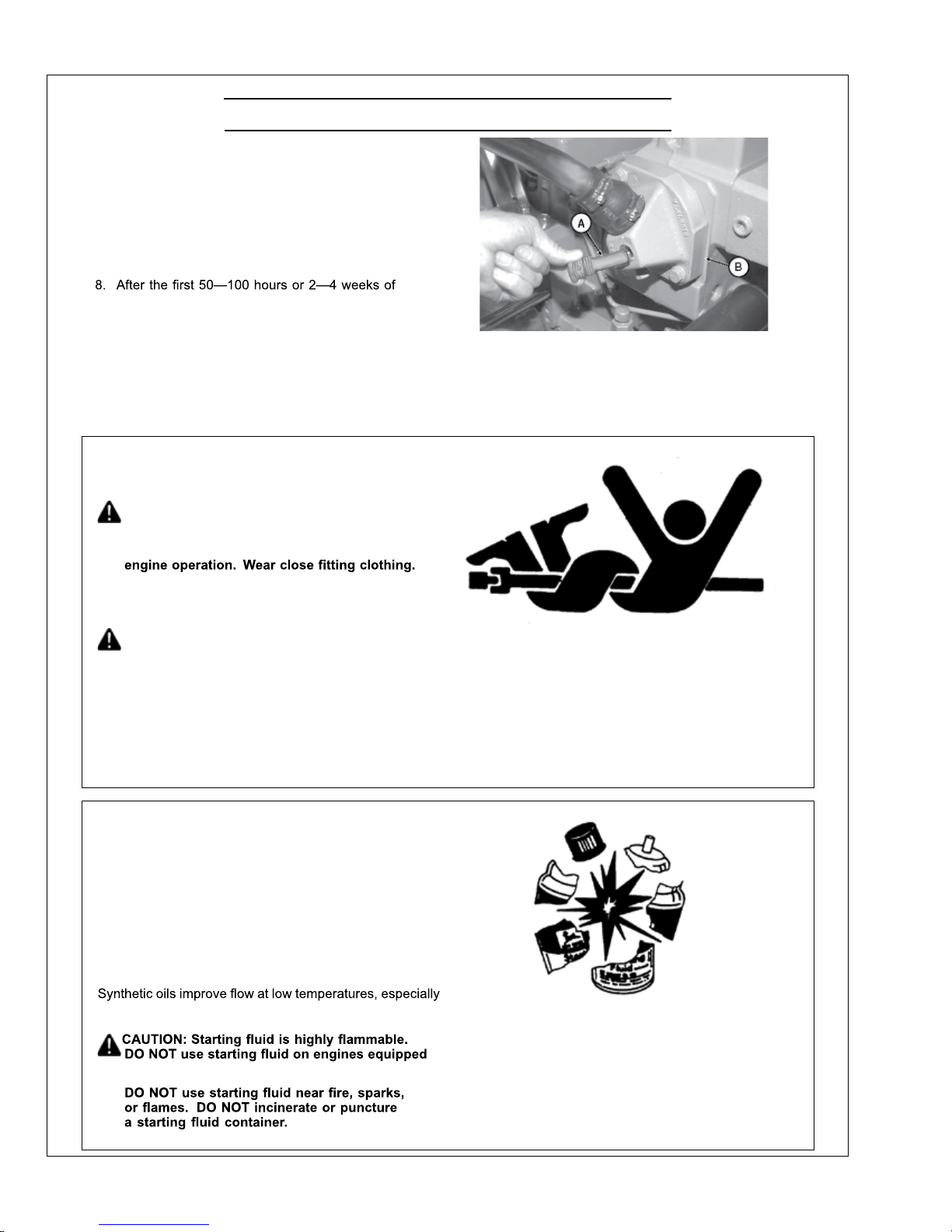

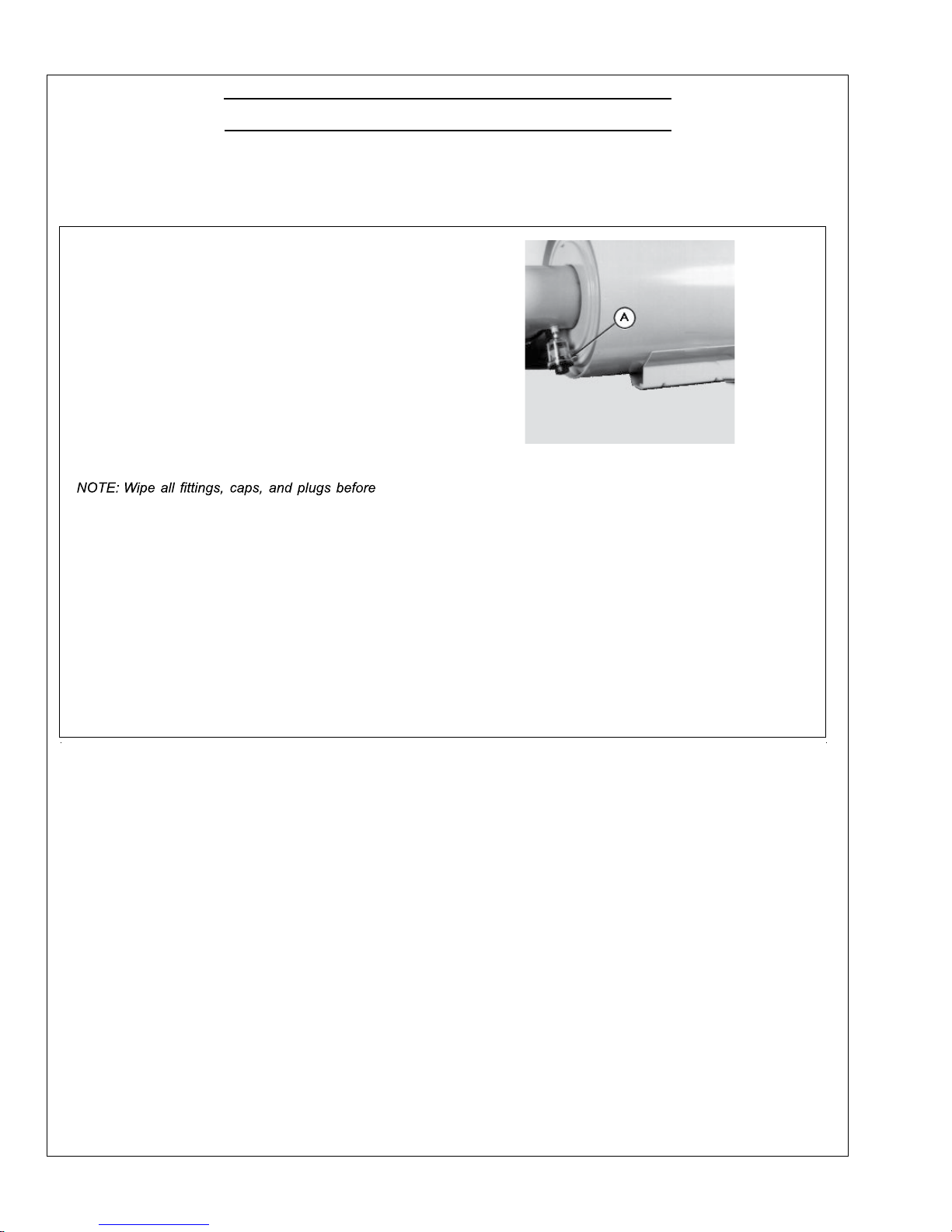

CheckEngine Oil

A—Engine Oil Dipstick

Continued on next page RG19661,00003BC-19-28FEB13-1/5

OM3-80 9/15

B—Dipstick Tu be

14

RG22038—UN—28NOV12

Engine Operation (Continued)

RG19661,00003BC-19-28FEB13-2/5

RG19661,00003BC-19-28FEB13-3/5

Continued on next page RG19661,00003BC-19-28FEB13-4/5

IMPORTANT:DONOT add makeupoil untilthe oil

levelisBELOW the ADD markon dipstick.

John Deere Engine Break-In Oil (TY22041)

shouldbe usedtomake up anyoil consumed

during thebreak-in period.

3. Check engine oil level more frequently during engine

break-in period.Ifoil must be added duringthisperiod,

John DeereEngine Break-InOil is preferred.See

ENGINEBREAK-IN OIL,inFuels, Lubricants, and

CoolantSection.

IMPORTANT:DONOT usePLUS-50® Engine Oil

during thebreak-in periodofanew engineor

enginethathas hadamajor overhaul. PLUS-50

oil will not allowanewor overhauled engine to

properly wearduring thisbreak-inperiod.

RG8028A—UN—15JAN99

CheckEngine Oil

A—Crosshatch Pattern On

Dipstick

theFULLmark, whichever is present. Oillevels

anywherewithin thecrosshatchare considered

in the acceptable operatingrange.

PLUS-50isatrademark of Deere&Company

ENGINE OIL ANDFILTERin Lubricationand

Maintenance/250 HourSection.) Fill crankcase with

seasonalviscosity grade oil. (See DIESEL ENGINE

OIL,in Fuels,Lubricants, and CoolantSection.)

NOTE:Someincreasein oil consumptionmay be

expectedwhen low viscosity oilsare used.

Check oil levelsmorefrequently.

If air temperatureis below -10°C (14°F), use

an engine block heater.

RG22045 —UN—29NOV12

RemoveOil Filter

A—Oil Filter

A

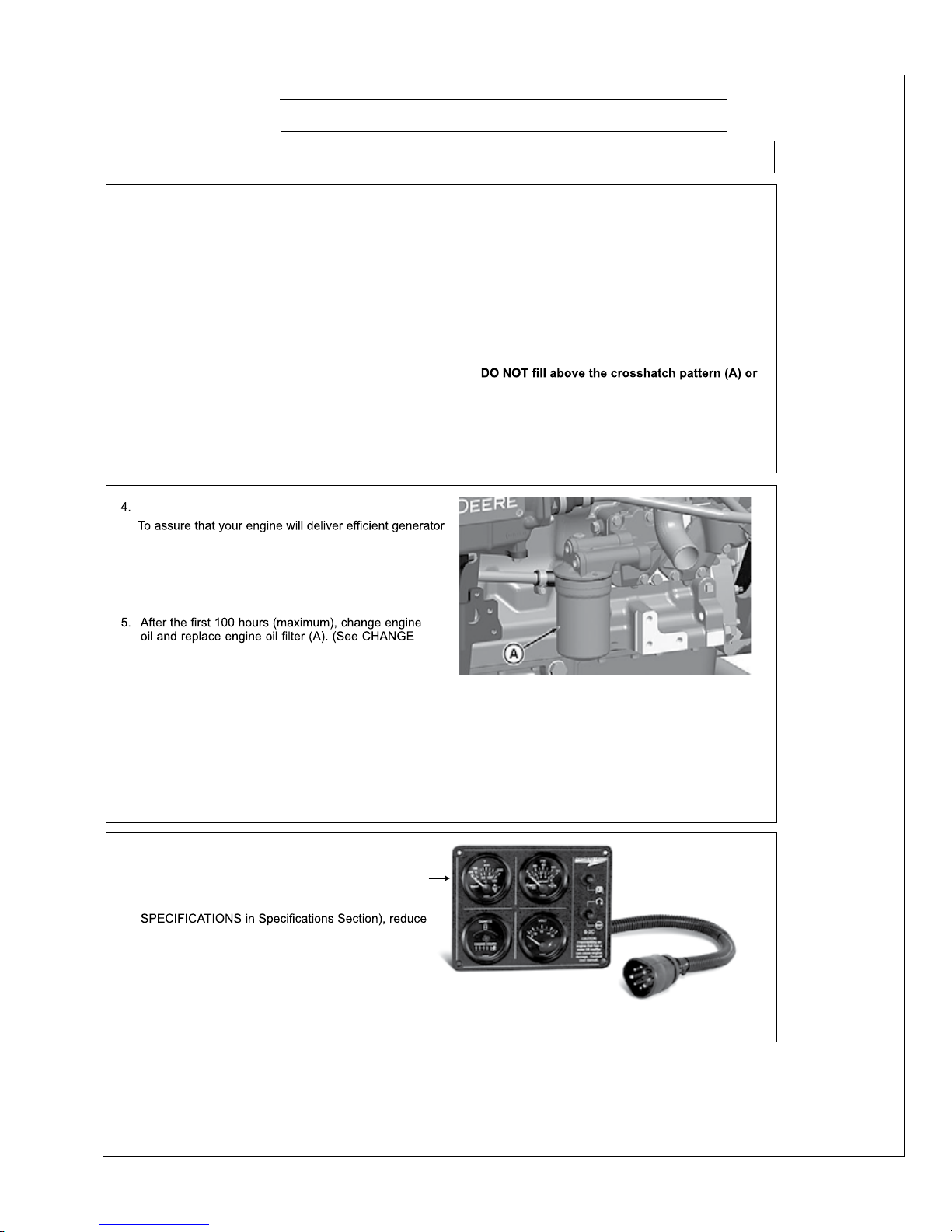

6. Watch coolanttemperature gauge (A) closely.

If coolant temperaturerises above maximum

coolant temperature (seeGENERAL ENGINE

loadonengine. Check sea (raw) water strainer

for pluggingon heat exchanger engines. Unless

temperature drops quickly, stop theengine and

determinethe causebeforeresumingoperation.

A—Coolant Temperature

Gauge

RG13133—UN—07OCT03

CoolantTemperature Gauge -ElectronicallyControlledEngine

GeneratorSet Power Units

operation when needed, start engine and runatrated

speed (with 50%—70%load) for30 minutes every2

weeks.DONOT allow engine to run extended periodof

time with no load.

OM3-80 9/15

15

Engine Operation (Continued)

7. Check poly-vee beltfor proper alignment and seating

in pulley grooves.

Two zincplugs (A) are installedinthe seawater

cooling systemto help neutralizethe corrosive action

of salt wateron internal cavitiesofmarine engine

components.The reactionofthe zinc, when exposed

to the saltwater, causes the plugstodeteriorate

instead of criticalengine components.

operation, remove zinc plug fromeachheat exchanger

end cap (B) and inspectfor corrosion to getanidea

of rateof deteriorationinsea water.

If rate of corrosion is slightat50—100hoursor

2—4 weeks initialinspection, zinc plugs shouldbe

inspectedat 250 hour intervals thereafter. (See

INSPECTAND REPLACE ZINCPLUGS in Lubrication

&Maintenance/250Hour Section)

EngagingAnd Disengaging FrontPTO (If

Equipped)

CAUTION: Entanglementinrotatingdriveline

can cause serious injuryordeath.Keep shield

on PTO driveshaftbetween clutch housingand

the engine driven equipment at alltimes during

A—Zinc Plugs

B—End Cap

Stopthe engine andbe surePTO drivelineis

stoppedbeforemaking adjustments.

CAUTION:Metal surfaces of PTO housing may be

hottothe touch during operationorat shutdown.

The optional front power take-off (PTO)

transfersenginepowertoauxiliaryequipment or moving

components.

ThePTO clutchiselectric and engaged by aswitch.

Engage Gen-Setengines at no loadrpm.

ColdWeather Operation

Additional information on cold weatheroperation is

available from your engine distributoror authorized

servicing dealer.

Some engines are equippedwithan air intake heater

whichwillmake startingthe engine easier in cold weather.

If equipped, follow steps1-3as listed underSTA RTING

THEENGINE, earlierin this section.

in arctic conditions.

TS198 —UN—23AUG88

AvoidEntanglement

If thepowertake-off does not work properly,contactyour

authorized servicing dealeror engine distributor.

OURGP11,0000144-19-08DEC03-1/1

TS1356—UN—18MAR92

Starting FluidisFlammable

with air intake heaters.

OUOD006,0000080-19-22JUN07-1/1

OM3-80 9/15

16

Engine Operation (Continued)

RG,RG34710,5564 -19-03JAN02-1/1

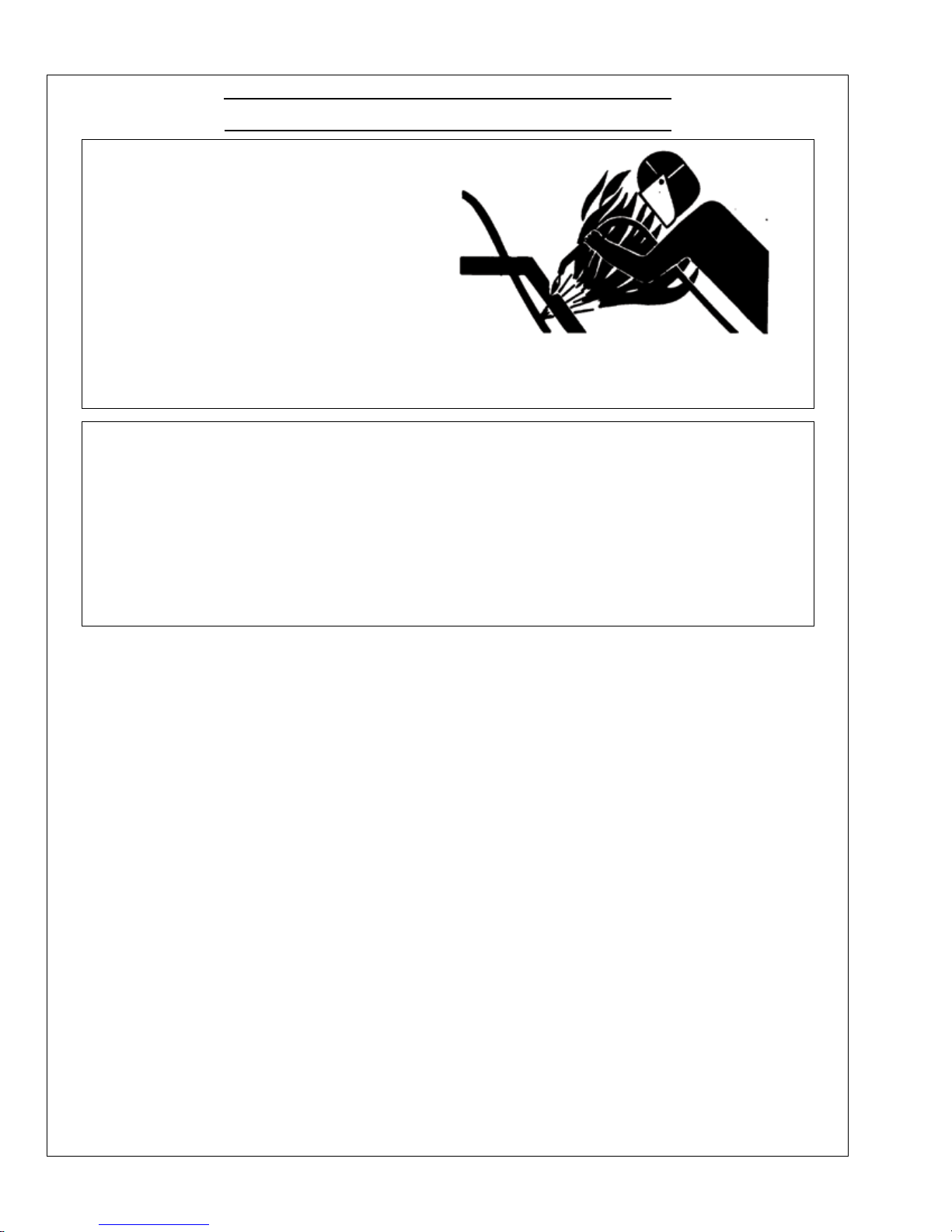

UsingaBoosterBattery or Charger

A12-volt booster batterycan be connectedin parallel with

battery(ies)onthe unittoaid in cold weather starting.

ALWAYS use heavyduty jumper cables.

CAUTION:Gas given offbybattery is explosive.

Before connectingor disconnectingabattery

charger,turn chargeroff. Make lastconnection

battery. Always connectNEGATIVE(–) cable

IMPORTANT:Besurepolarity is correct before making

connections. Reversed polarity willdamage

electrical system.Always connectpositiveto

positive andnegativetoground. Always use

12-volt booster battery for 12-volt electrical

systems and24-volt boosterbattery(ies)for

24-volt electricalsystems.

1. Connect booster battery or batteriestoproduce the

required system voltagefor your engine application.

NOTE:Toavoid sparks,DONOT allowthe free ends

of jumper cablesto touchthe engine.

2. Connect one end of jumper cabletothe POSITIVE (+)

postofthe boosterbattery.

3. Connectthe other end of the jumper cable to the

POSITIVE (+) post of battery connectedto starter.

4. Connect one end of the other jumper cableto the

NEGATIVE(–) postofthe booster battery.

5. ALWAYS completethe hookup by making the last

connectionofthe NEGATIVE(–) cabletoagood

ground on theengine frame and away from the

battery(ies).

6. Startthe engine. Disconnect jumper cables

immediately after engine starts. Disconnect

TS204—UN—23AUG88

Exploding Battery

RG4678 —UN—14DEC88

12-Volt System

RG4698 —UN—14DEC88

24-Volt System

A—12-VoltMachine Battery

(ies)

B—12-VoltBoosterBattery

(ies)

C—Booster Cable

D—Cableto StartingMotor

OM3-80 9/15

17

Engine Operation (Continued)

WeldingNear ElectronicControl Units

IMPORTANT:Do not jump-start engines witharc

welding equipment. Currents andvoltages are

too highand may causepermanent damage.

1. Disconnect thenegative(-) battery cable(s).

2. Disconnect the positive (+) battery cable(s).

3. Connectthe positive and negative cables together. Do

not attach to vehicle frame.

4. Clear or move any wiring harness sections awayfrom

weldingarea.

5. Connect welder ground closeto welding point and

away from control units.

TS953—UN—15MAY90

6. After welding,reverse Steps 1—5.

DX,WW,ECU02-19-14AUG09-1/1

Keep ElectronicControl Unit Connectors

Clean

IMPORTANT:Donot opencontrol unit anddonot

clean withahigh-pressure spray.Moisture,

dirt, andother contaminants may cause

permanent damage.

1. Keep terminals clean and free of foreign debris.

Moisture, dirt, and other contaminantsmay cause the

terminals to erodeovertime and notmakeagood

electrical connection.

2. If a connector is not in use, put on theproper dust cap

or an appropriate sealtoprotectitfromforeign debris

and moisture.

3. Control units are not repairable.

4. Since controlunitsare the componentsLEASTlikely

to fail,isolate failure before replacing by completing a

diagnosticprocedure. (See your John Deeredealer.)

5. Thewiring harnessterminals and connectorsfor

electronic control units arerepairable.

DX,WW,ECU04-19-11JUN09-1/1

OM3-80 9/15

18

Notes

OM3-80 9/15

19

Lubrication and Maintenance

OUOD006,0000081 -19-18AUG11-1/1

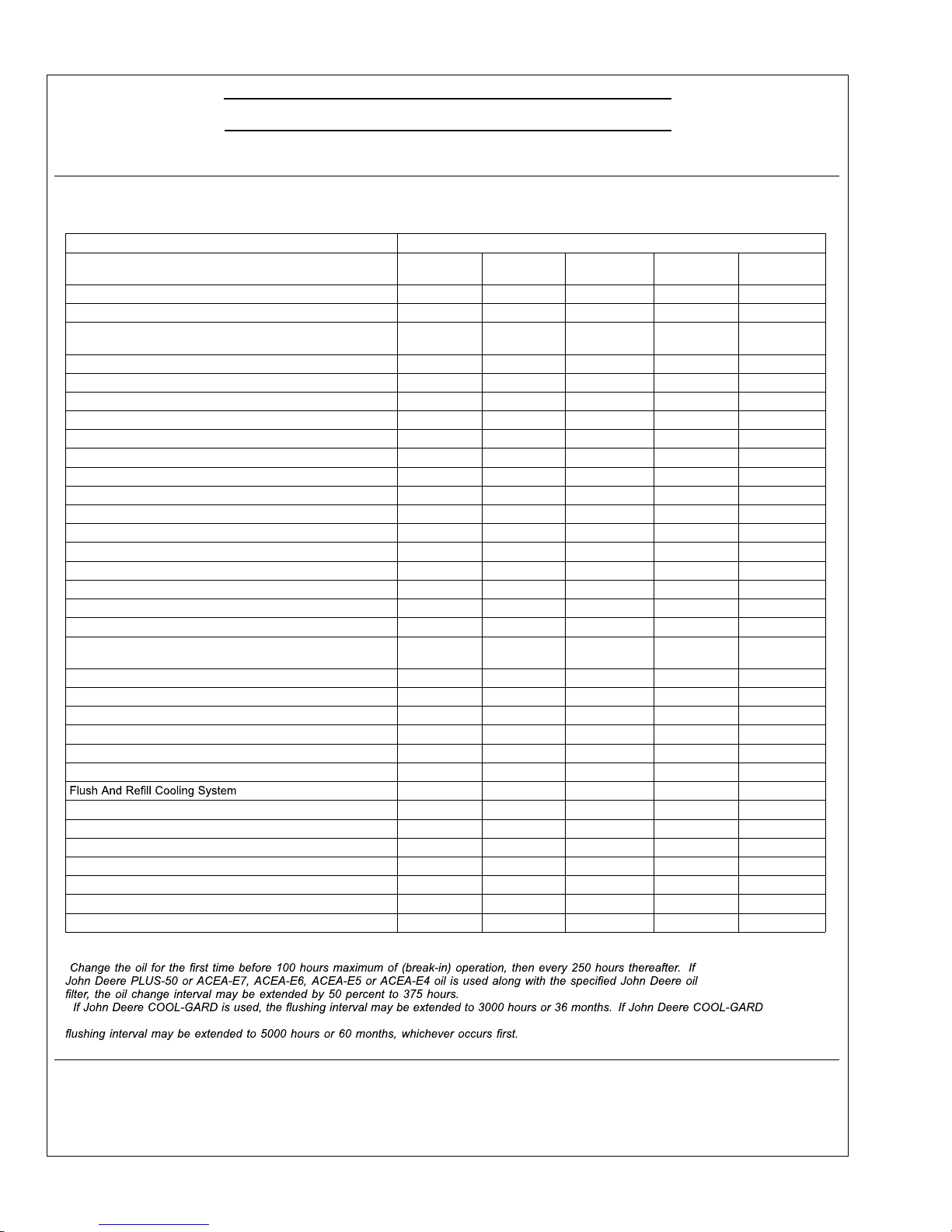

Lubricationand MaintenanceService Interval

Chart—Propulsion andPrime PowerUnits

Lubricationand Maintenance ServiceIntervals

Item

Daily/Before

Every Startup

250Hour/6

Month

500Hour/12

Month

2000Hour/24

Month

Service As

Required

Check EngineOil Leveland Coolant Level

•

CheckSea Water Strainer

•

CheckAir CleanerDustUnloader Valve&Restriction Indicator

Gauge

a

•

VisualWalkaround Inspection

•

Drain WaterFromFuel Filter

••

Change EngineOil AndReplace OilFilter

b

•

Service Fire Extinguisher

•

Service Battery

•

Inspect and Replace Zinc Plugs

•

Check BeltTension and Wear (Manual Tensioner)

•

Check EngineMounts

•

Replace Crankcase Ve nt Filter (If Equipped)

•

CleanCrankcase Ventilation Assembly

•

CheckAir Intake Hoses,Connections, & System

•

Replace Fuel Filter Elements

•

CheckAutomatic Belt Tensioner and BeltWear

•

CheckCooling System

•

Coolant Solution Analysis-AddSCAs as required

•

Inspectand CleanHeat ExchangerCoreand Aftercooler Core

(If Equipped)

•

Check Engine Speeds

•

Check Engine ElectricalGround

•

CheckCrankshaftVibration Damper (6-Cylinder)

•

Pressure Te st Cooling System

•

Inspectand RepairSea Water Pump

•

Checkand Adjust EngineValveClearance

•

c

•

Test Thermostats

•

AddCoolant

•

Replace AirCleaner Element

•

Service DryAir CleanerElement

•

Replace Alternator DriveBelt

•

CheckFront PTO(If Equipped)

•

BleedFuel System

•

a

Replace primary air cleaner elementwhenrestriction indicatorshows avacuum of 625mm (52 in.) H2O,orwhen

reset button has poppedup(6068SFM75 /AFM75 only).

b

c

is used and the coolantis tested annuallyAND additives arereplenished as neededby addingasupplementalcoolant additive, the

OM3-80 9/15

20

Lubrication and Maintenance (Continued)

OUOD006,0000082 -19-27OCT11 -1/1

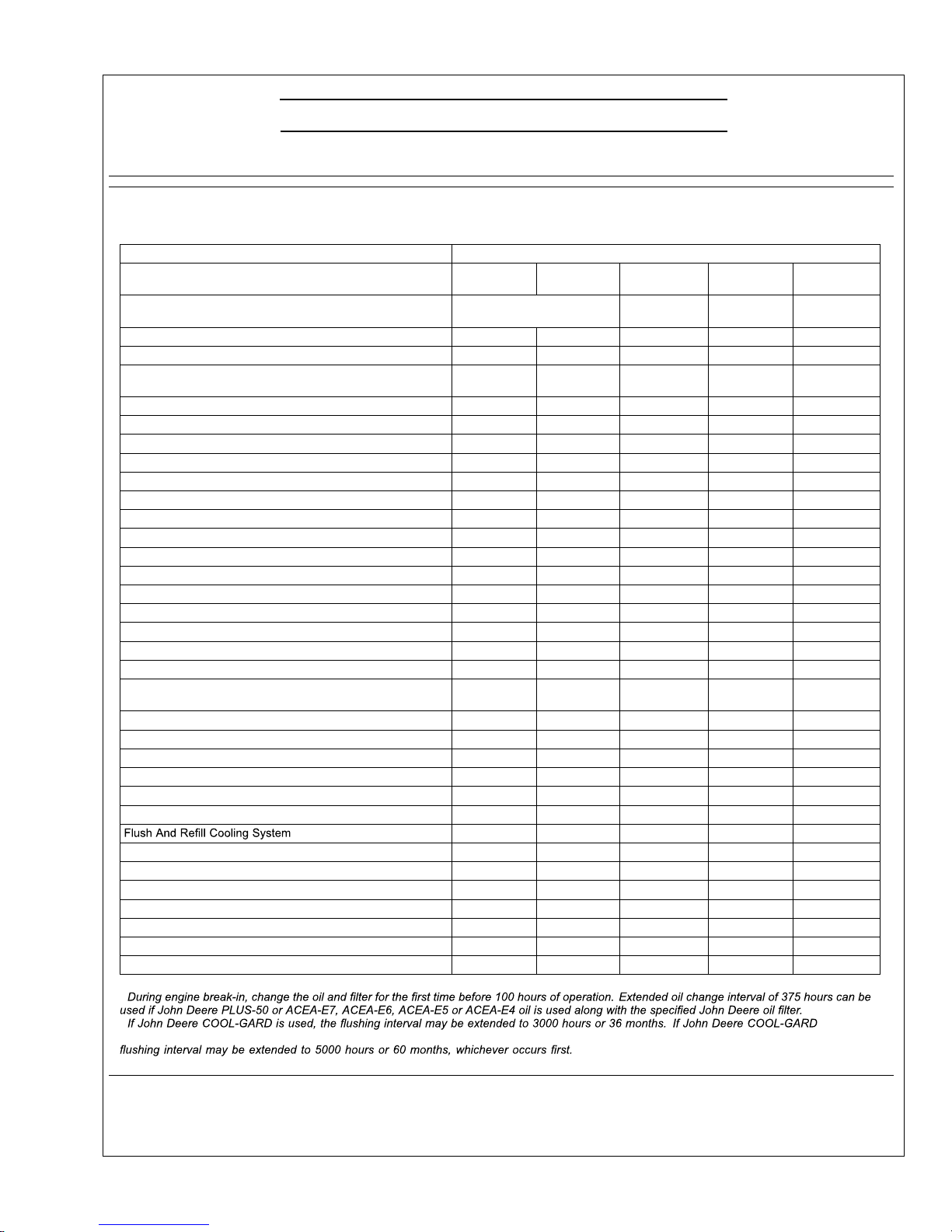

Lubricationand MaintenanceService Interval

Chart—Standby GeneratorSets

Lubricationand Maintenance ServiceIntervals

Item

Daily/Before

Every Startup

250Hour/6

Month

500Hour/12

Month

2000Hour/24

Month

Service As

Required

Operate EngineatRated Speed and 50%—70% Loadfor a

Minimum of 30 Minutes.Perform every 2weeks.

Check EngineOil Leveland Coolant Level

•

CheckSea Water Strainer

•

CheckAir CleanerDustUnloader Valve&Restriction Indicator

Gauge

a

•

VisualWalkaround Inspection

•

Drain WaterFromFuel Filter

••

Change EngineOil AndReplace OilFilter

b

•

Service Fire Extinguisher

•

Service Battery

•

Inspect and Replace Zinc Plugs

•

Check BeltTension and Wear (Manual Tensioner)

•

Check EngineMounts

•

Replace Crankcase Ve nt Filter (If Equipped)

•

CleanCrankcase Ventilation Assembly

•

CheckAir Intake Hoses,Connections, & System

•

Replace Fuel Filter Elements

•

CheckAutomatic Belt Tensioner and BeltWear

•

CheckCooling System

•

Coolant Solution Analysis-AddSCAs as required

•

Inspectand CleanHeat ExchangerCoreand Aftercooler Core

(If Equipped)

•

Check Engine Speeds

•

Check Engine ElectricalGround

•

CheckCrankshaftVibration Damper (6-Cylinder)

•

Pressure Te st Cooling System

•

Inspectand RepairSea Water Pump

•

Checkand Adjust EngineValveClearance

•

c

•

Test Thermostats

•

AddCoolant

•

Replace AirCleaner Element

•

Service DryAir CleanerElement

•

Replace Alternator DriveBelt

•

CheckFront PTO(If Equipped)

•

BleedFuel System

•

a

Replace primaryair cleaner elementwhenrestriction indicator showsavacuum of 625mm(52 in.)H2O.

b

c

is used and the coolantis tested annuallyAND additives arereplenished as neededby addingasupplementalcoolant additive, the

OM3-80 9/15

21

Lubrication & Maintenance/Daily

Continued on next page RG19661,00003D3 -19-29JAN13-1/4

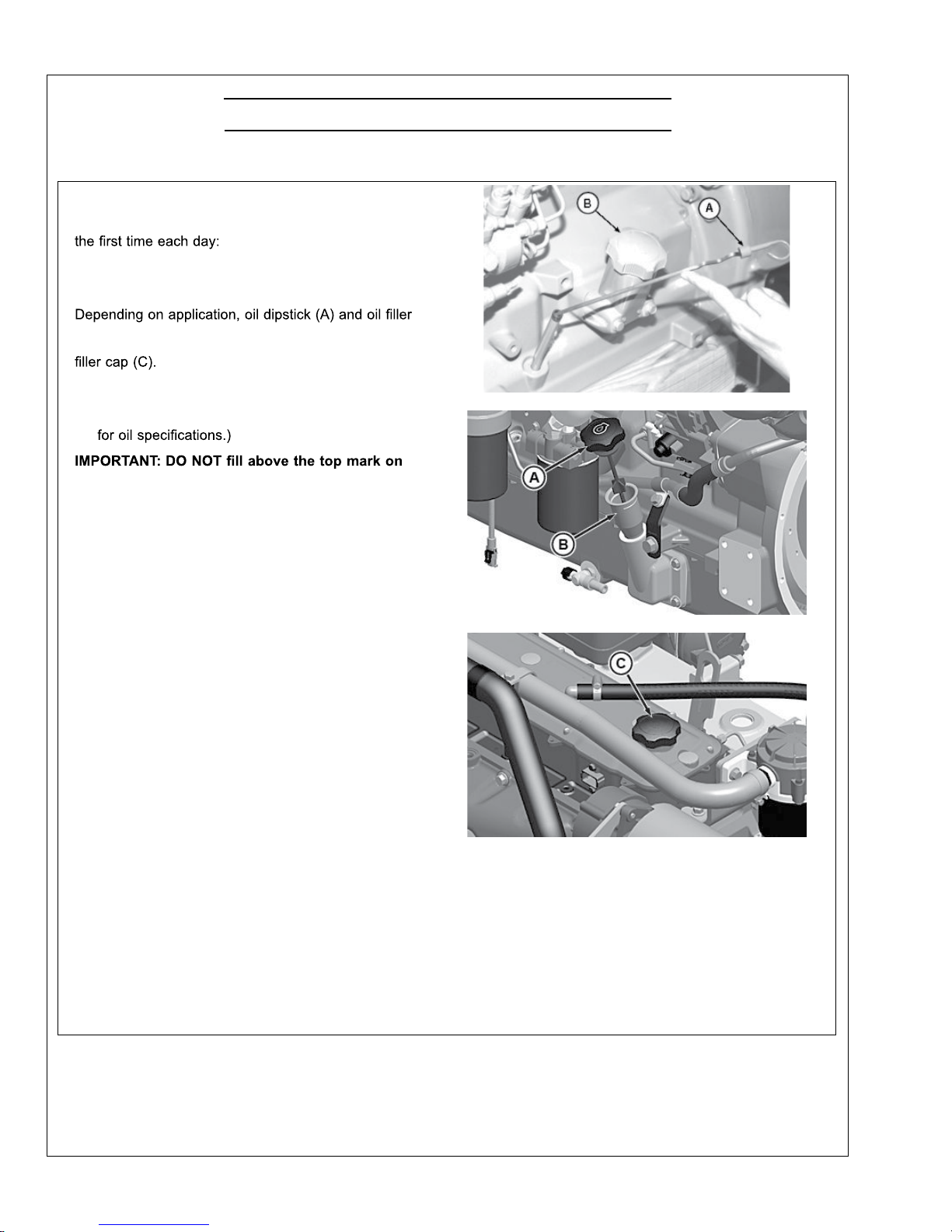

DailyPrestartingChecks

Do the following BEFORESTARTINGTHE ENGINEfor

IMPORTANT:DONOT add makeupoil untilthe oil

levelisBELOW theadd mark.

cap (B) maybe locatedon eitherthe left or the right side

of engine.In addition,oil maybeadded at rocker arm

1. Check engine oil levelondipstick (A). Addas required,

using seasonal viscositygrade oil. (See DIESEL

ENGINE OIL in Fuels, Lubricants, and CoolantSection

the dipstick. Oil levelsanywhere within

crosshatch (D)are considered in the

acceptable operatingrange.

A—Dipstick

B—Left Side Oil FillerCap

C—Rocker ArmFillerCap

D—CrosshatchOnOil Dipstick

RG9837 —UN—12JAN99

Left SideDipstick -4CylinderOnly

RG22038—UN—28NOV12

Left Side OilFillerand Dipstick Location

RG22037 —UN—28NOV12

Rocker Arm CoverFiller Cap

RG22039—UN—08JAN13

OilFill Level on Dipstick

OM3-80 9/15

22

Lubrication & Maintenance/Daily (Continued)

RG19661,00003D3-19-29JAN13-2/4

Continued on next page RG19661,00003D3 -19-29JAN13-3/4

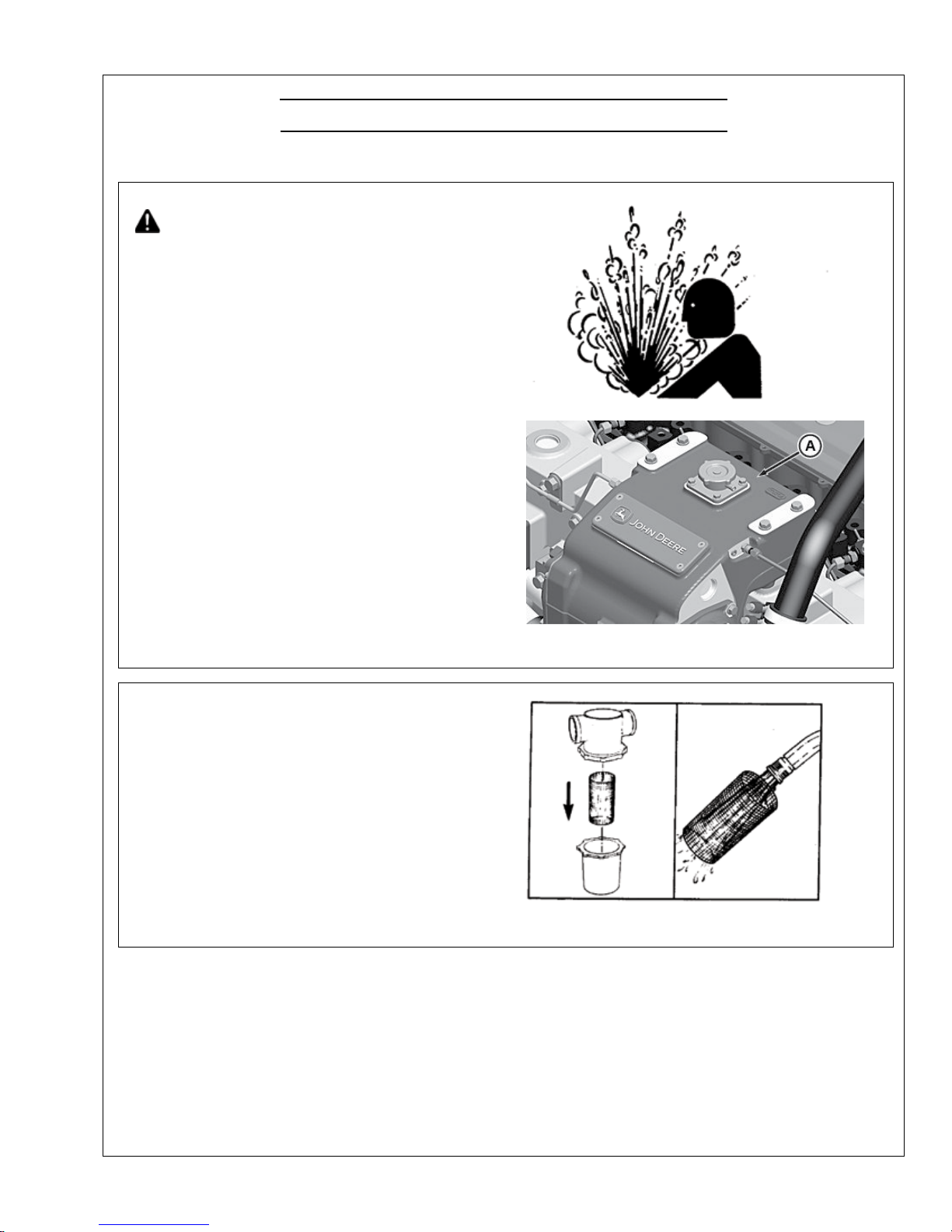

A—Engine To pTank

TS281—UN—23AUG88

High-Pressure Fluids

RG22040—UN—28NOV12

Engine To pTank

IMPORTANT:Arestrictedorclogged sea waterstrainer

willresult in hotter than normal (or overheated)

engine coolantand marinegear oil temperatures.

3. Thesea water strainershouldbe checked dailyand

cleanedas required, depending uponthe operating

environment.

RG5993 —UN—27JAN92

Sea Wa terStrainer

OM3-80 9/15

23

Lubrication & Maintenance/Daily (Continued)

RG19661,00003D3-19-29JAN13-4/4

4. If equipped withair intake restriction indicator gauge

(A), check gauge to determineifair cleaner needsto

be serviced. The reset button will pop up when air

cleanerneeds to be serviced.

IMPORTANT: Maximum air intake restriction is 625

mm (25 in. H

2

O).Acloggedair cleaner element

willcause excessive intake restriction anda

reduced air supplytothe engine.

5. Makeathorough inspectionofthe engine

compartment. Lookfor oilor coolant leaks, worndrive

belts, loose connections and trash build-up. Remove

trash buildup and haverepairs madeasneededif

leaksare found.

performing any maintenanceto reduce the

chanceof system contamination.

Inspect:

•

Engine shields and guardsfor trash build-up.

•

Airintake system hoses and connectionsfor cracks

and loose clamps.

•

Alternator drivebelt for cracks, breaksorother

damage.

•

Waterpumpfor coolant leaks.

•

Coolant system for leaks.

NOTE:Itisnormalforasmall amount of leakage to

occurasthe engine coolsdown and parts contract.

RG9874 —UN—12FEB99

AirIntakeRestriction Gauge

A—Air IntakeRestriction

Gauge

Excessive coolant leakage may indicatethe needto

replacethe waterpump seal. Contact yourengine

distributor or servicing dealer forrepairs.

6. Move switch to “ON” position and checkinstruments

forproper operation. Turn key switch “OFF”.

7. Refertomanufacturer'sliteraturefor

generator set daily service recommendations.

OM3-80 9/15

24

RG19661,00003D3-19-29JAN13-4/4

IMPORTANT: Maximum air intake restriction is 625

mm (25 in. H

2

O).Acloggedair cleaner element

willcause excessive intake restriction anda

reduced air supplytothe engine.

5. Makeathorough inspectionofthe engine

compartment. Lookfor oilor coolant leaks, worndrive

belts, loose connections and trash build-up. Remove

trash buildup and haverepairs madeasneededif

leaksare found.

performing any maintenanceto reduce the

chanceof system contamination.

Inspect:

•

Engine shields and guardsfor trash build-up.

•

Airintake system hoses and connectionsfor cracks

and loose clamps.

•

Alternator drivebelt for cracks, breaksorother

damage.

•

Waterpumpfor coolant leaks.

•

Coolant system for leaks.

NOTE:Itisnormalforasmall amount of leakage to

occurasthe engine coolsdown and parts contract.

RG9874 —UN—12FEB99

AirIntakeRestriction Gauge

A—Air IntakeRestriction

Gauge

Excessive coolant leakage may indicatethe needto

replacethe waterpump seal. Contact yourengine

distributor or servicing dealer forrepairs.

6. Move switch to “ON” position and checkinstruments

forproper operation. Turn key switch “OFF”.

7. Refertomanufacturer'sliteraturefor

generator set daily service recommendations.

Continued on next page RG19661,00003D4 -19-28FEB13-1/3

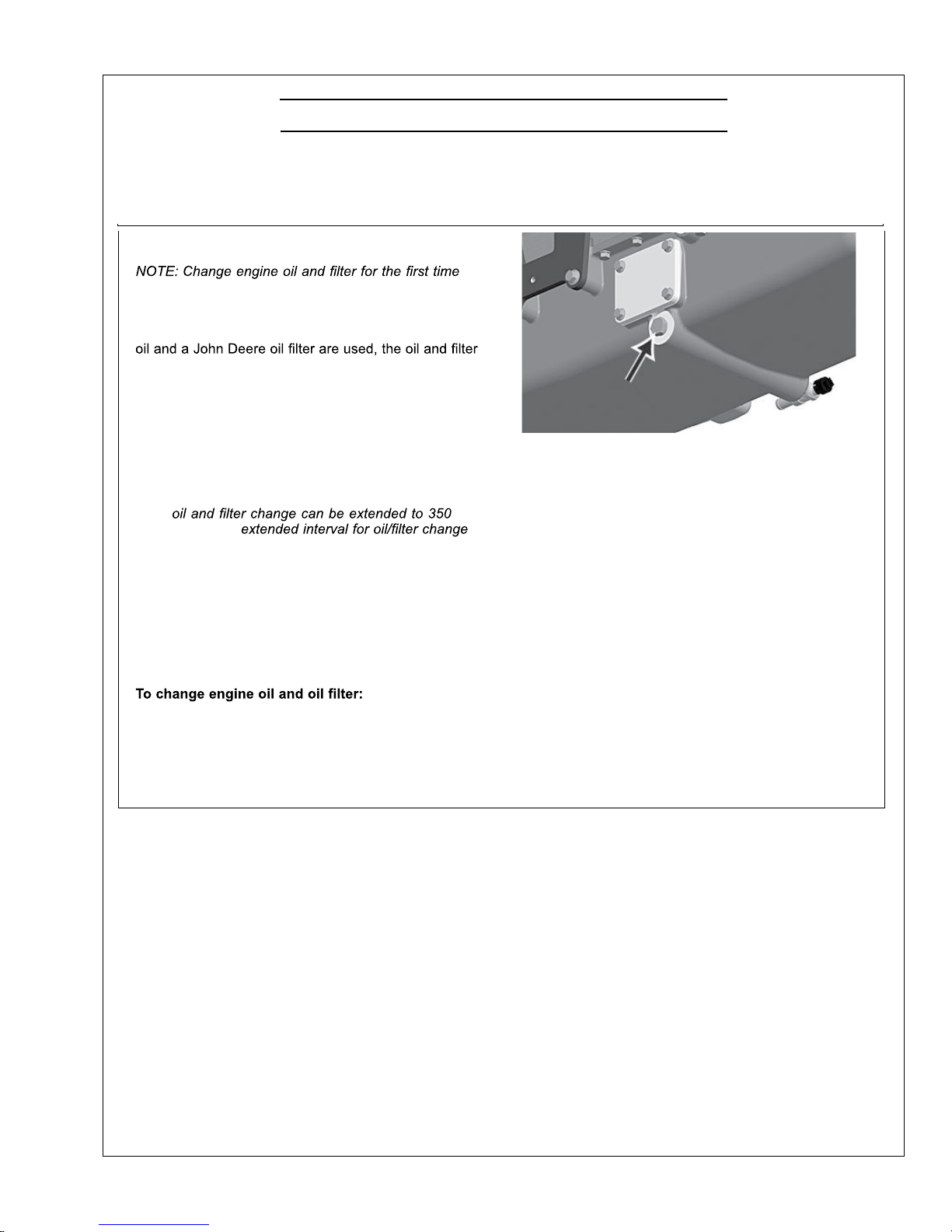

Changing Engine Oil and Replacing Oil Filter

before 100 hoursmaximum of operation, then

every250 hoursthereafter.

If John DeerePLUS-50™ or ACEA-E7/E6/E5/E4engine

change intervalmay be extended by 50 percentorto375

hours.

IMPORTANT:Ifusing BIODIESEL blends greater

than B20,shorten oil change intervaltohalf

therecommendedservice interval or monitor

engine oil using OILSCAN to ensure thatfuel

dilution doesnot exceed 5%.

NOTE:OnGen Setengines usedasstandby units,

hours. No

is allowed beyond 350 hours.

OILSCAN™ or OILSCANPLUS™ is a John Deere

samplingprogram to help you monitormachine

performanceand identify potential problemsbefore

they cause serious damage. OILSCAN™ or OILSCAN

PLUS™ kits are available from your John Deere dealer.

Oil samples should be takenprior to the oil change. Refer

to instructions provided with kit.

1. Run engine approximately5minutestowarmup oil.

Shut engineoff.

RG22041—UN—07JAN13

OilPan DrainPlug

2. Remove oilpan drainplug(arrow).

3. Drain crankcase oilfrom engine while warm.

NOTE:Drain plug location may vary, depending

on theapplication.

PLUS-50isatrademark of Deere&Company.

OILSCAN is atrademarkofDeere &Company.

OILSCAN PLUS is atrademarkofDeere&Company.

Lubrication & Maintenance/250 Hour/6 Month

OM3-80 9/15

25

Lubrication & Maintenance/250 Hour/6 Month (Continued)

Continued on next page RG19661,00003D4 -19-28FEB13-2/3

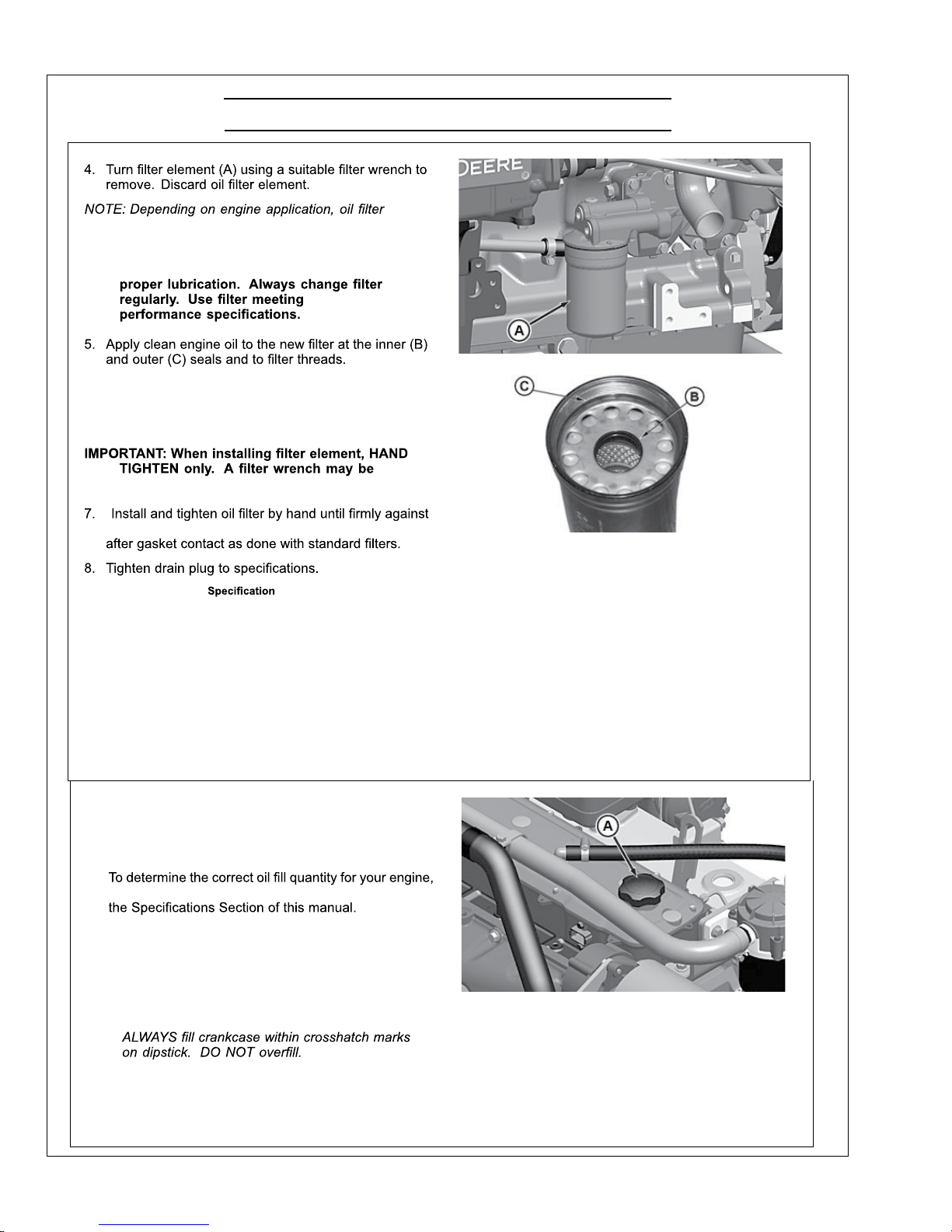

maybe locatedon either sideofthe engine in

a high-orlow-mount location.

IMPORTANT: Filtrationof oilsiscriticalto

6. Wipe both sealing surfacesofthe header(D, E) witha

clean rag.Ensure thatthe notchesin dust seal(F) are

properly installedinthe slotsofthe housing. Replace

if damaged.

usedfor REMOVALONLY.

dustseal (F).DONOT apply an extra 3/4to 1-1/4 turn

OilPan Drain

PlugWithCopper

Washer—Torque.............................................................70 N·m (52 lb-ft)

OilPan Drain PlugWith

O-Ring—Torque............................................................. 50 N·m (37 lb-ft)

A—Oil Filter Element

B—Inner Seal

C—OuterSeal

D—SealingSurface On Header

E—SealingSurface On Header

F— Dust Seal

RG22045 —UN—29NOV12

OilFilter

RG11617—UN—24OCT01

OilFilter Seals

RG22046—UN—29NOV12

OIlFilter Mounting Header

Northern Lights

RG19661,00003D4 -19-28FEB13-3/3

9. Fillengine crankcase with correct John Deere engine

oil through rockerarm cover opening (A). (See

DIESEL ENGINEOIL in Fuels, Lubricants, and

CoolantSection for determining correctengine oil.)

seeENGINE CRANKCASE OIL FILLQUANTITIESin

IMPORTANT: Immediately after completing any

oil change, crank enginefor 30 seconds

without permitting engineto start. This will

help insure adequate lubrication to engine

components beforeengine starts.

NOTE: Crankcaseoil capacitymay vary slightly.

10. Start engine and runto check forpossible leaks.

11.Stop engineand checkoil level after 10 minutes. Oil

levelreading should be within crosshatch on dipstick.

A—Rocker ArmCover Oil Filler

Opening

OM3-80 9/15

26

Lubrication & Maintenance/250 Hour/6 Month (Continued)

Continued on next page RG,RG34710,5568 -19-20MAY96-1/2

Servicing Battery

CAUTION:Battery gas can explode. Keepsparks

to check battery electrolyte level.

Nevercheck battery charge by placing

a metal object across the posts. Use a

voltmeter or hydrometer.

Always removegroundedNEGATIVE(–) battery

WARNING: Battery posts, terminals, and related

accessoriescontain lead and lead compounds, chemicals

knowntothe Stateof Californiato cause cancer and

reproductive harm. Wash hands after handling.

1. On regular batteries, check electrolyte level. Filleach

NOTE:Low-maintenanceor maintenance-freebatteries

shouldrequire littleadditional service.However,

electrolyte levelcan be checkedbycutting the

center sectionofdecal on dash-line, andremoving

cell plugs.If necessary, add clean, soft water

2. Keep batteries cleanby wiping them withadamp

cloth.Keep all connections clean and tight. Remove

TS204—UN—23AUG88

Exploding Battery

any corrosion, and washterminalswithasolution

of 1 part baking soda and4parts water.Tighten all

connections securely.

NOTE:Coat battery terminals and connectors

with a mixture of petroleum jelly and baking

sodatoretard corrosion.

3. Keep battery fully charged, especially during cold

weather.Ifabatterycharger is used,turn charger

off before connecting charger to battery(ies). Attach

POSITIVE (+) battery charger lead to POSITIVE (+)

battery post. ThenattachNEGATIVE (–)battery

charger lead toagoodground.

OM3-80 9/15

27

Lubrication & Maintenance/250 Hour/6 Month (Continued)

RG,RG34710,5568 -19-20MAY96-2/2

CAUTION:Sulfuric acid in battery electrolyte is

poisonous.Itisstrong enough to burnskin,

eat holesin clothing,and cause blindness

if splashed into eyes.

Avoid thehazard by:

1. Fillingbatteries in a well-ventilated area.

2. Wearing eyeprotection andrubber gloves.

3. Avoidingbreathing fumes when

electrolyte is added.

4. Avoidingspilling or dripping electrolyte.

5. Use proper jump startprocedure.

If youspill acidonyourself:

1. Flushyour skin with water.

2. Apply baking sodaor limeto help

neutralizethe acid.

3. Flushyour eyes with waterfor 10–15 minutes.

Getmedical attentionimmediately.

If acid is swallowed:

1. Drinklarge amountsof waterormilk.

2. Thendrink milk of magnesia, beaten

eggs, or vegetable oil.

3. Get medical attention immediately.

In freezing weather,run engineat least30 minutesto

assure thorough mixing after adding waterto battery.

If necessar yto replace battery(ies), replacements must

meetor exceedthe followingrecommended capacitiesat

-18°C (0°F):

12 Volt StandardDuty

Starter—ColdCranking

Amps.................................................................................................. 640

12 Volt HeavyDuty

Starter—ColdCranking

Amps.................................................................................................. 800

TS203—UN—23AUG88

Sulfuric Acid

24 Volt StandardDuty

Starter—Cold Cranking

Amps.................................................................................................. 570

OM3-80 9/15

28

Loading...

Loading...