Northern Lights Newage / Stamford User Manual

Publication No: BCH-018

12th Edition

01/01

Installation, Service &

Maintenance Manual

For the BC Range of Generators.

SAFETY PRECAUTIONS

Before operating the generating set, read the generating set

operation manual and this generator manual and become

familiar with it and the equipment.

SAFE AND EFFICIENT OPERATION CAN

ONLY BE ACHIEVED IF THE EQUIPMENT IS

CORRECTLY OPERATED AND

MAINTAINED.

Many accidents occur because of failure to follow fundamental

rules and precautions.

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

• Ensure installation meets all applicable safety and

local electrical codes. Have all installations performed by a

qualified electrician.

• Do not operate the generator with protective covers, access

covers or terminal box covers removed.

• Disable engine starting circuits before carrying out

maintenance.

• Disable closing circuits and/or place warning notices on

any circuit breakers normally used for connection to the

mains or other generators, to avoid accidental closure.

Observe all IMPORTANT, CAUTION, WARNING, and

DANGER notices, defined as:

Important ! Important refers to hazard or unsafe

method or practice which can result in

product damage or related equipment

damage.

Caution refers to hazard or unsafe method

Caution !

Warning !

or practice which can result in product

damage or personal injury.

Warning refers to a hazard or unsafe

method or practice which CAN result in

severe personal injury or possible death.

Danger refers to immediate hazards which

will result in severe personal injury or death.

Danger !

Due to our policy of continuous improvement, details in this manual which were

correct at time of printing, may now be due for amendment. Information included

must therefore not be regarded as binding.

Front Cover Photograph

This photograph is representative only. Several variations are available within the

range of generators covered by this manual.

FOREWORD

ELECTROMAGNETIC COMP A TIBILITY

The function of this book is to provide the user of the Stamford

generator with an understanding of the principles of operation,

the criteria for which the generator has been designed, and the

installation and maintenance procedures. Specific areas where

the lack of care or use of incorrect procedures could lead to

equipment damage and/or personal injury are highlighted, with

WARNING and/or CAUTION notes, and it is IMPORTANT

that the contents of this book are read and understood before

proceeding to fit or use the generator.

The Service, Sales and technical staff of Newage International

are always ready to assist and reference to the company for

advice is welcomed.

Incorrect installation, service or

replacement of parts can result in severe

personal injury or death, and/or equipment

damage . Service personnel must be

Warning !

qualified to perform electrical and

mechanical service.

EC DECLARA TION OF INCORPORATION

All Stamford generators are supplied with a declaration of

incorporation for the relevant EC legislation, typically in the form

of a label as below.

Additional Information

European Union

Council Directive 89/336/EEC

For installations within the European Union, electrical products

must meet the requirements of the above directive, and Newage

ac generators are supplied on the basis that:

● They are to be used for power-generation or related function.

●They are to be applied in one of the following environments:

Portable (open construction - temporary site supply)

Portable (enclosed - temporary site supply)

Containerised (temporary or permanent site supply)

Ship-borne below decks (marine auxiliary power)

Commercial vehicle (road transport / refrigeration etc)

Rail transport (auxiliary power)

Industrial vehicle (earthmoving, cranes etc)

Fixed installation (industrial - factory / process plant)

Fixed installation (residential, commercial and light industrial

home / office / health)

Energy management (Combined heat and power and/or peak

lopping)

Alternative energy schemes

EC DECLARATION OF INCORPORATION

IN ACCORDANCE WITH THE SUPPLY OF MACHINERY (SAFETY) REGULATIONS 1992

AND THE SUPPLY OF MACHINERY (SAFETY) (AMENDMENT) REGULATIONS 1994

IM P L E M E N TING THE E C MAC H IN E RY DIR EC T IV E 89/39 2 /E E C A S AM EN D E D B Y 9 1/3 6 8 /E E C.

TH IS W AS

STAMFORD A.C. GENERATOR

MANUFACTURED BY OR ON BEHALF OF

BARNACK ROAD STAMFORD LINCOLNSHIRE ENGLAND.

THIS COMPONENT MACHINERY MUST NOT BE PUT INTO SERVICE UNTIL THE

MACHINERY INTO WHICH IT IS TO BE INCORPORATED HAS BEEN DECLARED IN

CONFORMITY WITH THE PROVISIONS OF THE SUPPLY OF MACHINERY (SAFETY)

FOR AND ON BEHALF OF NEWAGE INTERNATIONAL LIMITED

THIS COMPONENT MACHINERY CARRIES THE CE MARK FOR COMPLIANCE WITH THE STATUTORY

REQUIREMENTS FOR THE IMPLEMENTATION OF THE FOLLOWING DIRECTIVES

The EMC D irective 89/336/EEC

This Component Machinery shall not be used in the Residential, Com mercial and

WARNING!

Light Industrial environment unless it also conforms to the relevant standard

(EN 50081 - 1) REFER TO FACTO RY FO R DETAILS

ii) The Low Voltage Directive 73/23/EEC as am ended by 93/68/EEC

When this manual is supplied to support a specific generator

at point of sale, the generator identity is clearly displayed on the

front cover of this book.

NEWAGE INTERNATIONAL LTD

REGULATIO NS 1995/MACHINERY DIRECTIVE.

POSITION: TECHNICAL

SIGNATUR E:

DIRECTOR

●The standard generators are designed to meet the ‘industrial’

emissions and immunity standards. Where the generator is

required to meet the residential, commercial and light industrial

emissions and immunity standards reference should be made

to Newage document reference N4/X/011, as additional

equipment may be required.

●The installation earthing scheme involves connection of the

generator frame to the site protective earth conductor using a

minimum practical lead length.

●Maintenance and servicing with anything other than factory

supplied or authorised parts will invalidate any Newage liability

for EMC compliance.

●Installation, maintenance and servicing is carried out by

adequately trained personnel fully aware of the requirements

of the relevant EC directives

1

CONTENTS

SAFETY PRECAUTIONS IFC

FOREWORD 1

CONTENTS 2&3

SECTION 1 INTRODUCTION 4

1.1 INTRODUCTION 4

1.2 DESIGNATION 4

1.3 P ACKAGED LOOSE ADAPT OR HARDWARE 4

1.4 SERIAL NUMBER LOCA TION 4

1.5 RA TING PLA TE AND CE MARK 4

SECTION 2 PRINCIPLE OF OPERA TION 5

2.1 SELF-EXCITED A VR CONTROLLED GENERAT ORS 5

2.1.1 MAIN STATOR POWERED AVR 5

2.1.2 AUXILIARY WINDING POWERED A VR 5

2.2 TRANSFORMER CONTROLLED GENERA TORS 5

SECTION 3 APPLICA TION OF THE GENERAT OR 6

SECTION 4 INST ALLA TION - P ART 1 8

4.1 LIFTING 8

4.2 ASSEMBL Y T O ENGINE 8

4.2.1 TWO BEARING GENERAT ORS 8

4.2.2 SINGLE BEARING GENERA TORS 9

4.2.2.1 SINGLE BEARING 4-POLE & 2-POLE 9

4.2.2.2 SINGLE BEARING 2-POLE GENERA TOR TO ENGINE

4.2.3 TAPER SHAFT ARRANGEMENTS 10

4.3 EARTHING 1 1

4.4 PRE-RUNNING CHECKS 1 1

4.4.1 INSULA TION CHECK 1 1

4.4.2 DIRECTION OF ROT ATION 1 1

4.4.3 VOLT AGE AND FREQUENCY 1 1

4.4.4 A VR INITIAL SETTINGS 1 1

4.4.4.1 TYPE SX460 A VR 1 1

4.4.4.2 TYPE SA465 A VR 12

4.4.5 TRANSFORMER CONTROLLED EXCITA TION SYSTEM 12

4.5 GENERA TOR SET TESTING 12

4.5.1 TEST METERING/CABLING 12

4.6 INITIAL STAR T-UP 13

4.7 LOAD TESTING 13

4.7.1 A VR CONTROLLED GENERA TORS - A VR ADJUSTMENTS 13

4.7.1.1 UFRO (Under Frequency Roll Off) 13

4.7.2 TRANSFORMER CONTROLLED GENERAT ORS -

4.8 ACCESSORIES 1 4

ASSEMBL Y INSTRUCTIONS (WITH DOWELED FLYWHEELS) 10

TRANSFORMER ADJUSTMENT 14

SECTION 5 INST ALLA TION - P ART 2 15

5.1 GENERAL 15

5.2 GLANDING 15

5.3 EARTHING 15

5.4 PROTECTION 15

5.5 COMMISSIONING 15

SECTION 6 ACCESSORIES 16

6.1 REMOTE VOL T AGE ADJUST (All A VR T ypes) 16

6.2 P ARALLEL OPERA TION 16

6.2.1 DROOP 16

6.2.1.1 SETTING PROCEDURE 17

6.2.2 AST A TIC CONTROL 17

2

CONTENTS

SECTION 7 SERVICE AND MAINTENANCE 18

7.1 WINDING CONDITION 18

7.1.1 WINDING CONDITION ASSESSMENT 18

7.1.2 METHODS OF DRYING OUT GENERA TORS 18

7.2 BEARINGS 20

7.3 AIR FIL TERS 20

7.3.1 CLEANING PROCEDURE 20

7.3.2 RECHARGING (Charging) 20

7.4 FAUL T FINDING 20

7.4.1 ALL A VR TYPES - FAUL T FINDING 20

7.4.2 TRANSFORMER CONTROL - FAUL T FINDING 20

7.4.3 RESIDUAL VOL TAGE CHECK 20

7.5 SEP ARATE EXCIT A TION TEST PROCEDURE 21

7.5.1 GENERAT OR WINDINGS AND ROT ATING DIODES 21

7.5.1.1 BALANCED MAIN TERMINAL VOLT AGES 21

7.5.1.2 UNBALANCED MAIN TERMINAL VOL TAGES 21

7.5.2 EXCIT ATION CONTROL TEST 23

7.5.2.1 A VR FUNCTION TEST 23

7.5.2.2 TRANSFORMER CONTROL 23

7.5.3 REMOV AL AND REPLACEMENT OF COMPONENT

7.5.3.1 REMOV AL OF BEARINGS 2 4

7.5.3.2 MAIN ROTOR ASSEMBL Y 2 4

7.5.3.3 RE-ASSEMBL Y OF GENERA TOR ENGINE 25

7.6 RETURNING TO SERVICE 2 5

ASSEMBLIES 23

SECTION 8 SP ARES AND AFTER SALES SERVICE 26

8.1 RECOMMENDED SP ARES 2 6

8.1.1 A VR CONTROLLED GENERAT ORS 26

8.1.2 TRANSFORMER CONTROLLED GENERAT ORS 26

8.1.3 ASSEMBL Y TOOLS 26

8.2 AFTER SALES SERVICE 26

P ARTS IDENTIFICA TION

Fig. 6 TYPICAL SINGLE BEARING GENERA TOR 28

Fig. 7 TYPICAL SINGLE BEARING - TAPER SHAFT ARRANGEMENT 30

Fig. 8 TYPICAL SINGLE BEARING - SERIES 5 TRANSFORMER

Fig. 9 TYPICAL TWO BEARING GENERA TOR 34

Fig. 10 ROTATING RECTIFIER ASSEMBL Y 35

WARRANTY DET AILS IBC

CONTROLLED GENERA TOR 32

3

1.1 INTRODUCTION

SECTION 1

INTRODUCTION

1.4 SERIAL NUMBER LOCA TION

The BC16/18 range of generators is of brushless rotating field

design, available up to 660V/50Hz (1500 rpm, 4 pole and 3000

rpm, 2 pole) or 60Hz (1800 rpm, 4 pole and 3600 rpm, 2 pole),

and built to meet B.S. 5000 Part 3 and international standards.

The BC16/18 range are self-excited with excitation power derived

from the main output windings, using either the SX460/SA465

AVR or transformer controlled excitation system.

The BC184 may be supplied fitted with an auxiliary winding in

the main stator, using the SA465 AVR.

Detailed specification sheets are available on request.

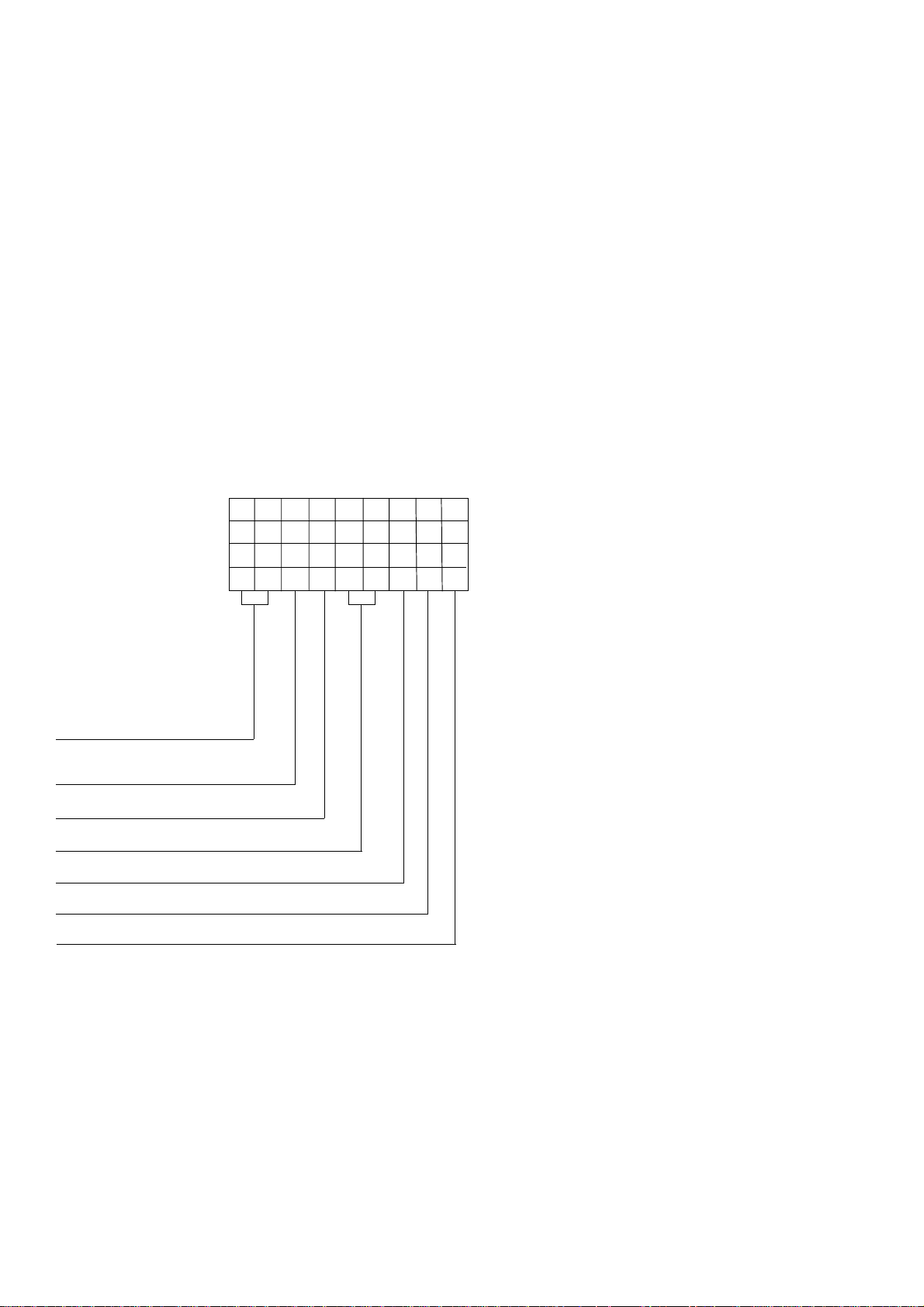

1.2 DESIGNA TION

To provide standardisation of systems with minimal change to

customers.

B

C

L

I

1

6

B

C

.

I

1

6

B

C

A

I

1

6

B

C

.

M

1

8

A

4

D

2

D

2

F

4

Each generator has its unique serial number stamped into the

upper section of the non-drive end frame.

Inside the terminal box two adhesive rectangular labels have

been fixed, each carrying the generator's unique identity number.

One to the inside of the terminal box sheet metal work, and the

second label fixed to the main frame of the generator.

1.5 RA TING PLA TE AND CE MARK

The generator has been supplied with a self adhesive rating

plate label to enable fitting after final assembly and painting. It

is intended that this label will be stuck to the outside of the

terminal box on the left hand side when viewed from the driveend. To assist with squarely positioning the label, location

protrusions have been made in the sheet metalwork.

A CE Mark label is also supplied loose for fitment after final

1

assembly and painting. This should be attached to an external

surface of the Generator at a suitable location where it will not

1

be obscured by the customer's wiring or other fittings. Before

1

fitting the CE Mark label the genset builder must address the

requirements of the relevant EC legislation to ensure the

2

compliance of the genset as a whole. CE compliance will also

need to be addressed when installed on site.

GENERATOR TYPE BC

SPECIFIC TYPE L = TS OR TR ENGINE

A = ALPHA ENGINE

INDUSTRIAL = (I) OR MARINE = (M)

SHAFT HEIGHT IN CM ON BC/UC

NUMBER OF POLES 2 or 4

CORE LENGTH

NUMBER OF BEARINGS 1 OR 2

1.3 PACKAGED LOOSE ADAPT OR HARDWARE

Several adaptors are only partially fitted to generators to simplify

removal prior to engine-generator assembly. The remaining

hardware is contained within a plastic bag located in the terminal

box.

The surface on the area where a label is to be stuck must be

flat, clean and any paint finish must be fully dry before attempting

to attach label. Recommended method for attaching label is

peel and fold back sufficient of the backing paper to expose

some 20mm of label adhesive along the edge which is to be

located against the sheet metal protrusions. Once this first

section of label has been carefully located and stuck into

position the backing paper can be progressively removed, as

the label is pressed down into position. The adhesive will

achieve a permanent bond in 24 hours.

Adaptor Types

SAE2

SAE3

SAE5 Spacer Rings

SAE6

Coupling Plate Dowel Pins

4

SECTION 2

PRINCIPLE OF OPERATION

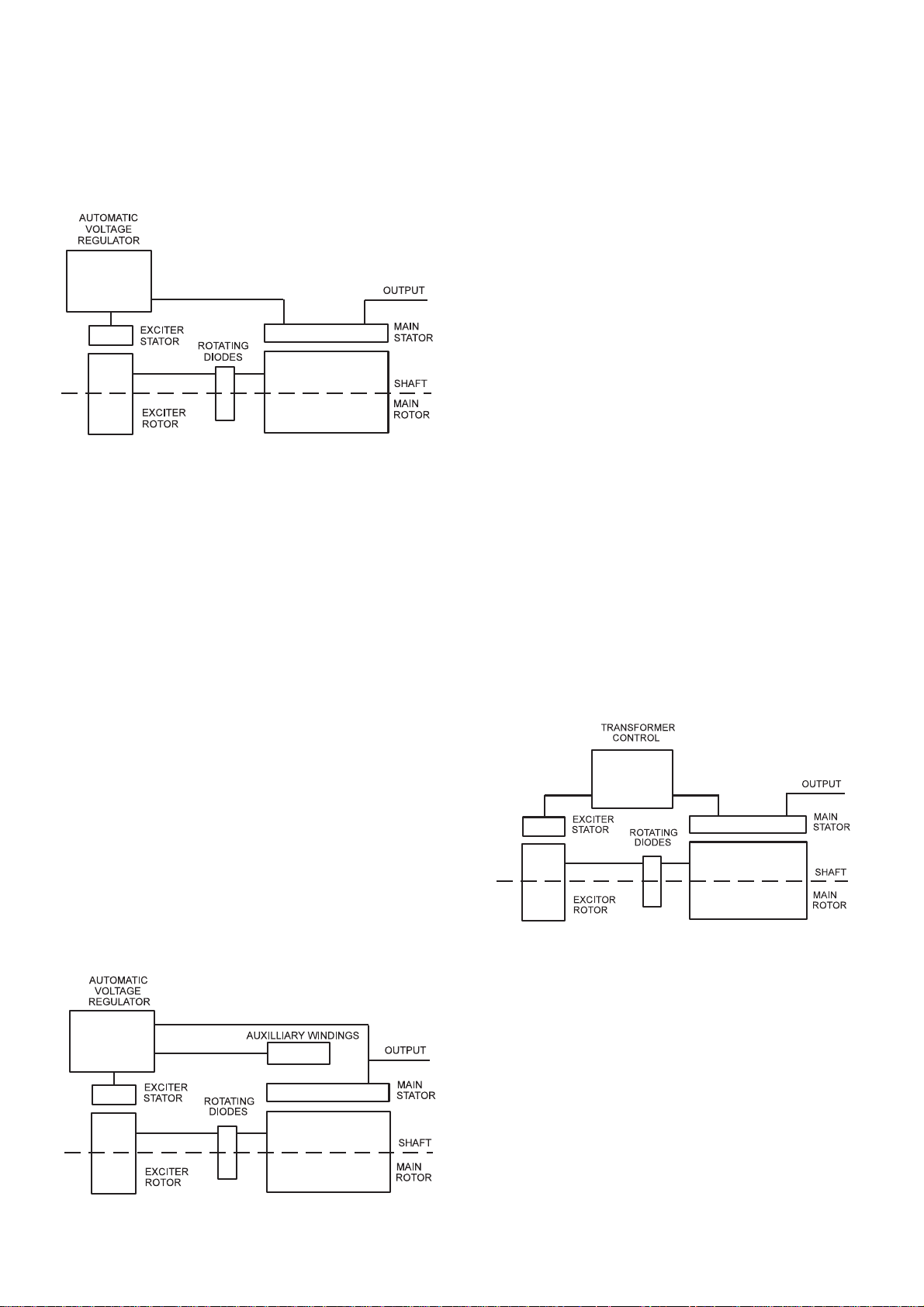

2.1 SELF-EXCITED AVR CONTROLLED GENERA T ORS

2.1.1 MAIN ST A TOR POWERED A VR

The main stator provides power for excitation of the exciter field

via the SX460 (SA465) AVR which is the controlling device

governing the level of excitation provided to the exciter field. The

AVR responds to a voltage sensing signal derived from the main

stator winding. By controlling the low power of the exciter field,

control of the high power requirement of the main field is achieved

through the rectified output of the exciter armature.

The AVR senses average voltage on two phases ensuring close

regulation. In addition it detects engine speed and provides

voltage fall off with speed, below a pre-selected speed (Hz)

setting, preventing over-excitation at low engine speeds and

softening the effect of load switching to relieve the burden on the

engine.

The detailed function of the A VR circuits and their adjustment are

covered in the load testing section.

The auxiliary winding provides power for excitation of the exciter

field via the SA465 AVR which is the controlling device governing

the level of excitation provided to the exciter field. The AVR

responds to a voltage sensing signal derived from the main

stator winding. By controlling the low power of the exciter field,

control of the high power requirement of the main field is

achieved through the rectified output of the exciter armature.

The A VR senses average voltage on two phases ensuring close

regulation. In addition, it detects engine speed and provides

voltage fall off with speed, below a pre-selected speed (Hz)

setting, preventing over-excitation at low engine speeds and

softening the effect of load switching to relieve the burden on

the engine.

Under fault conditions on the main stator output the auxiliary

winding continues to generate voltage from the harmonic

content of the magnetic field in the main stator core providing

the necessary power via the SA465 AVR, to maintain short circuit

fault currents.

The detailed function of the AVR circuits and their adjustment

are covered in the load testing section.

Function and adjustment of the accessories which can be fitted

inside the generator terminal box are covered in the accessories

section of this book.

Separate instructions are provided with other accessories

available for control panel mounting.

2.2 TRANSFORMER CONTROLLED GENERA TORS

In addition the SA465 A VR incorporates circuits which, when used

in conjunction with accessories, can provide for parallel operation

either with 'droop' or 'astatic' control and VAR/PF control.

Function and adjustment of the accessories which can be fitted

inside the generator terminal box are covered in the accessories

section of this book.

Separate instructions are provided with other accessories

available for control panel mounting.

2.1.2 AUXILIARY WINDING POWERED A VR

The main stator provides power for excitation of the exciter field

via a transformer rectifier unit. The transformer combines voltage

and current elements derived from the main stator output to

form the basis of an open-loop control system, which is self

regulating in nature. The system inherently compensates for

load current magnitude and power factor and provides short

circuit maintenance in addition to a good motor starting

performance.

Three phase generators normally have a three phase

transformer control for improved performance with unbalanced

loads but a single phase transformer option is available.

No accessories can be provided with this control system.

5

SECTION 3

APPLICATION OF THE GENERATOR

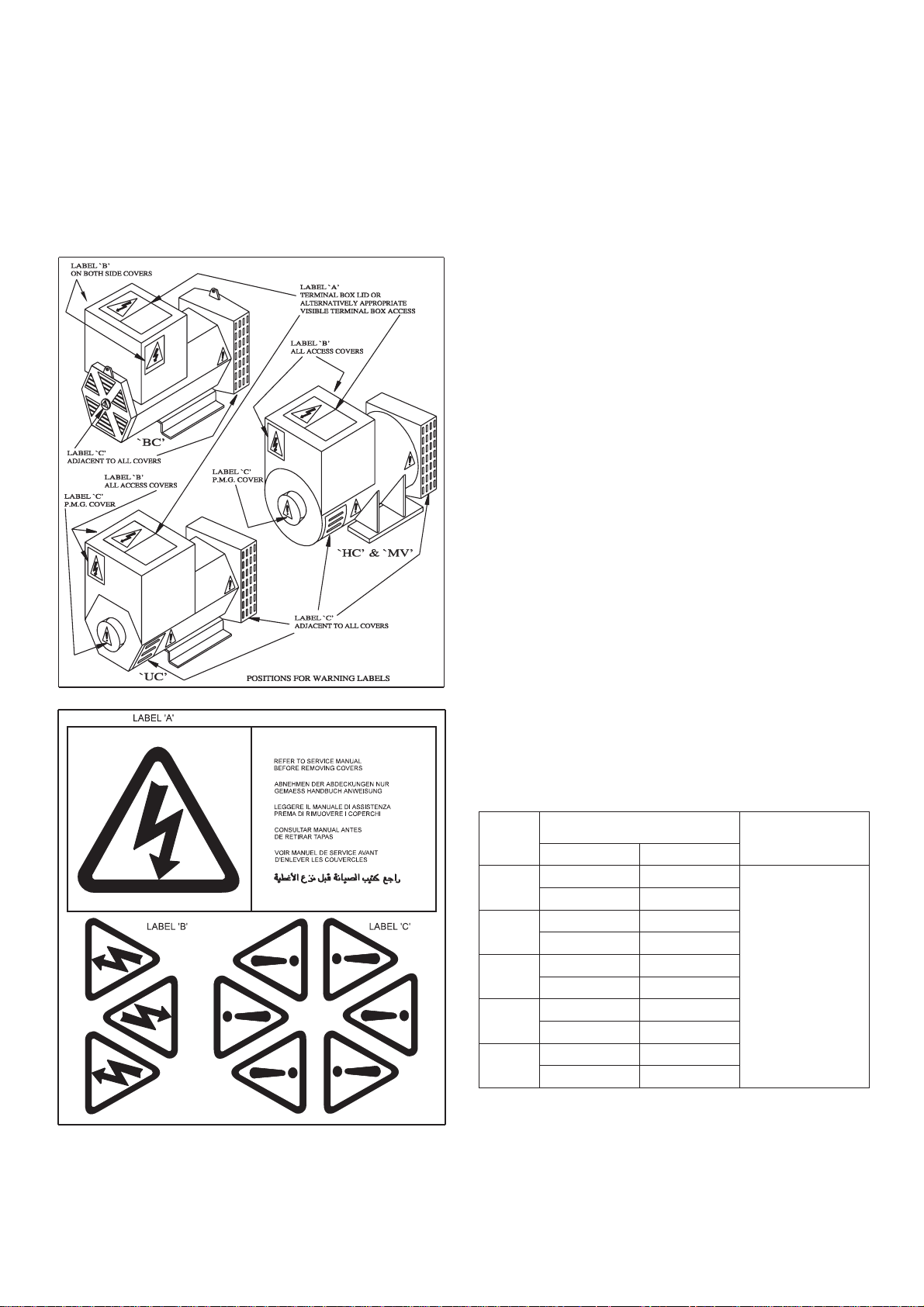

The generator is supplied as a component part for installation

in a generating set. It is not, therefore, practicable to fit all the

necessary warning/hazard labels during generator

manufacture. The additional labels required are packaged with

this Manual, together with a drawing identifying their locations.

The generators have been designed for use in a maximum

ambient temperature of 40°C and altitude less than 1000 metres

above sea level in accordance with BS 5000.

Ambients in excess of 40°C and altitudes above 1000 metres

can be tolerated with reduced ratings - refer to the generator

nameplate for rating and ambient. In the event that the generator

is required to operate in an ambient in excess of the nameplate

value or at altitudes in excess of 1000 metres above sea level,

refer to the factory.

The generators are of air-ventilated screen protected drip-proof

design and are not suitable for mounting outdoors unless

adequately protected by the use of canopies. Anti-condensation

heaters are recommended during storage and for standby duty

to ensure winding insulation is maintained in good condition.

When installed in a closed canopy it must be ensured that the

ambient temperature of the cooling air to the generator does not

exceed that for which the generator has been rated.

The canopy should be designed such that the engine air intake

to the canopy is separated from the generator intake, particularly

where the radiator cooling fan is required to draw air into the

canopy. In addition the generator air intake to the canopy should

be designed such that the ingress of moisture is prohibited,

preferably by use of a 2 stage filter.

The generator air intake is through the non drive end cover and

the generating set and canopy design must be such that the

intake is not restricted. It is recommended that a minimum

clearance of 50mm is allowed between the generator air intake

and any vertical flat surface.

The air intake/outlet must be suitable for the air flow given in the

following table with additional pressure drops less than or equal

to those given below:

emarF

zH05zH06

461CB

481CB

GFE

481CB

JH

261CB

281CB

mfc051mfc091

mfc002mfc052

mfc813mfc304

mfc304mfc784

mfc835mfc446

wolFriA

ces/³m170.0ces/³m90.0

ces/³m590.0ces/³m911.0

ces/³m51.0ces/³m91.0

ces/³m91.0ces/³m32.0

ces/³m452.0ces/³m403.0

lanoitiddA

)teltuo/ekatni(

porDerusserP

retawmm3

)"1.0(eguag

It is the responsibility of the generating set manufacturer to

ensure that the correct labels are fitted, and are clearly visible.

If specified at the time of ordering, the generator itself may be

fitted with air filters.

The BCL construction has no fan fitted to the generator. The engine

flywheel fan draws air through the generator and additional

restrictions on air flow such as filters on the generator or canopies

are not permissible.

6

Important ! Reduction in cooling air flow or

inadequate protection to the generator

can result in damage and/or failure of

windings.

Dynamic balancing of the generator rotor assembly has been

carried out during manufacture in accordance with BS 6861

Part 1 Grade 2.5 to ensure vibration limits of the generator are

in accordance with BS 4999 Part 142.

It is expected that the generator will be incorporated into a

generating set operating in an environment, where the

maximum shock load experienced by the generator will not

exceed 3g. in any plane. If shock loads in excess of 3g are to be

encountered, anti-vibration mountings must be incorporated

into the generating set to ensure they absorb the excess.

The maximum bending moment of the engine flange must be

checked with the engine manufacturer.

The main vibration frequencies produced by the component

generator are as follows:-

4 pole 1500 r.p.m. 25 Hz

4 pole 1800 r.p.m. 30 Hz

2 pole 3000 r.p.m. 50 Hz

2 pole 3600 r.p.m. 60 Hz

However, vibrations induced by the engine are complex and

contain frequencies of 1, 3, 5 or more times the fundamental

frequency of vibration. These induced vibrations can result in

generator vibration levels higher than those derived from the

generator itself. It is the responsibility of the generating set

designer to ensure that the alignment and stiffness of the

bedplate and mountings are such that the vibration limits of BS

5000 Part 3 are not exceeded.

In standby applications where the running time is limited and

reduced life expectancy is accepted, higher levels than specified

in BS 5000 can be tolerated, up to a maximum of 18mm/sec.

Two bearing generators require a substantial bedplate with

engine/generator mounting pads to ensure a good base for

accurate alignment. Close coupling of engine to generator can

increase the overall rigidity of the set. For the purposes of

establishing set design the bending moment at the engine

flywheel housing to generator adaptor interface should not

exceed 125ft.lb. (17 kgm). A flexible coupling, designed to suit

the specific engine/generator combination, is recommended

to minimise torsional effects.

Belt driven applications of two bearing generators require the

pulley diameter and design to be such that the side load or

force applied to the shaft is central to the extension and does

not exceed the values given in the table below:-

emarF

eloP4/2

fgkN

61CB2900928

81CB371007128

daoLediS

tfahS

mmnoisnetxe

In instances where shaft extensions greater than specified in

the table have been supplied, reference must be made to the

factory for appropriate loadings.

Important ! Single bearing drive end brackets are

designed to be bolted to the engine

flywheel housing using cap head screws.

Torsional vibrations occur in all engine-driven shaft systems

and may be of a magnitude to cause damage at certain critical

speeds. It is therefore necessary to consider the torsional

vibration effect on the generator shaft and couplings.

It is the responsibility of the generator set manufacturer to

ensure compatibility, and for this purpose drawings showing

the shaft dimensions and rotor inertias are available for

customers to forward to the engine supplier. In the case of

single bearing generators coupling details are included.

Important ! T orsional incompatibility and/or excessive

vibration levels can cause damage or

failure of generator and/or engine

components.

The terminal box is constructed with removable panels for easy

adaptation to suit specific glanding requirements. Within the

terminal box there are insulated terminals for line and neutral

connections and provision for earthing. A hole is provided on

the generator foot which may be tapped to give an additional

earthing point.

The neutral is NOT connected to the frame.

The main stator winding has 12 leads brought out to the

terminals in the terminal box.

No earth connections are made on the

generator and reference to site regulations

for earthing must be made. Incorrect

earthing or protection arrangements can

Warning !

result in personal injury or death.

Fault current curves (decrement curves), together with generator

reactance data, are available on request to assist the system

designer to select circuit breakers, calculate fault currents and

ensure discrimination within the load network.

Alignment of single bearing generators is critical and vibration

can occur due to the flexing of the flanges between the engine

and generator. As far as the generator is concerned the

maximum bending moment at this point must not exceed

125ft.lb. (17 kgm).

Single bearing generators require a substantial bedplate with

engine/generator mounting pads to ensure a good base for

accurate alignment.

7

Warning !

Incorrect installation and/or protective

systems can result in personal injury and/or

equipment damage. Installers must be

qualified to perform electrical installation

work.

SECTION 4

INSTALLATION - PART 1

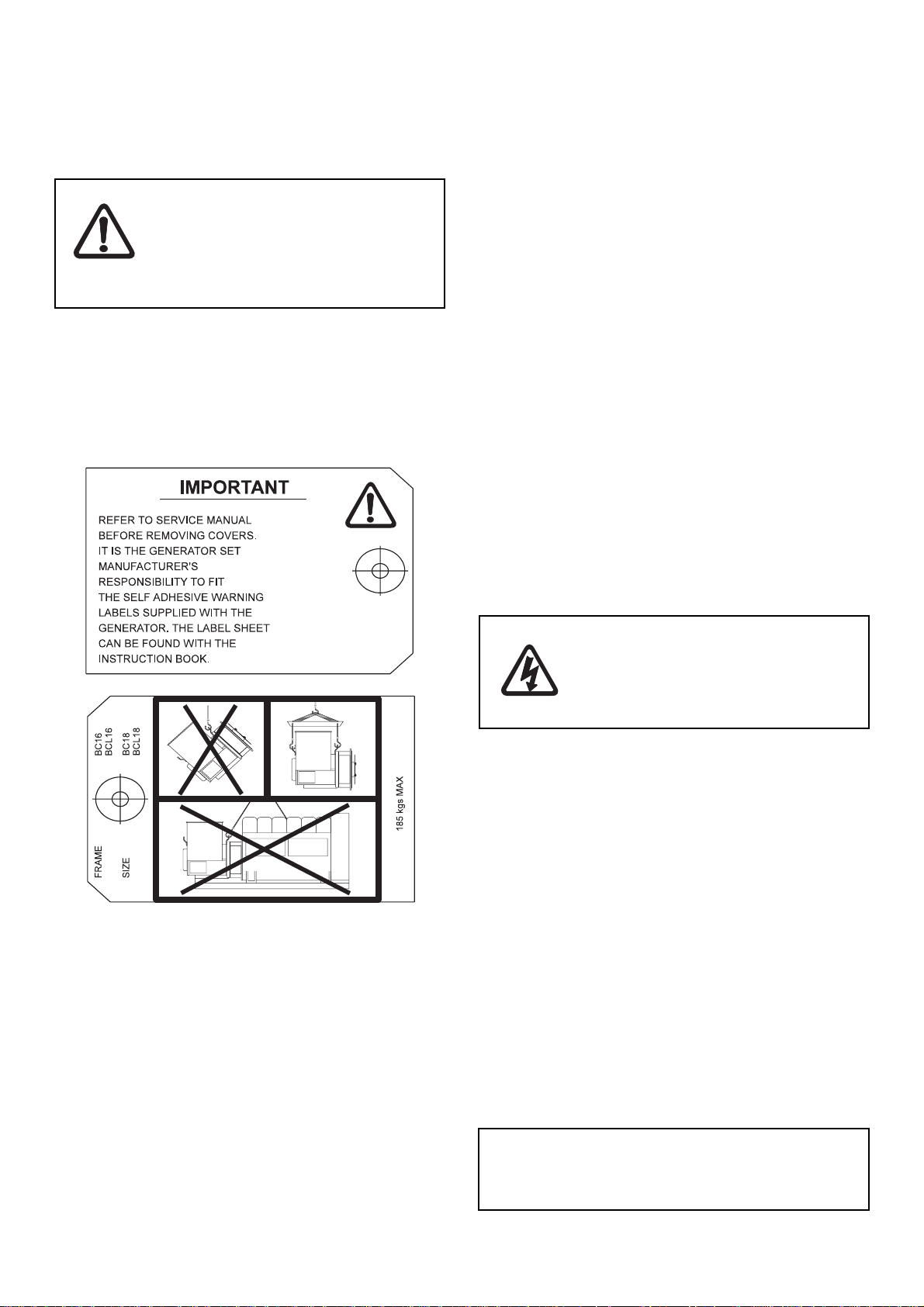

4.1 LIFTING

Incorrect lifting or inadequate lifting

capacity can result in severe personal

injury or equipment damage. MINIMUM

LIFTING CAPACITY REQUIRED IS 250kg.

Warning !

Lifting lugs are provided at each end of the generator for use

with a shackle and pin type lifting aid or lifting hooks. Chains of

suitable length and lifting capacity, with spreader bar to avoid

damage to the terminal box, must be used.

The correct lifting arrangement is shown on a label attached to

the generator. A typical example is shown below.

Generator lifting lugs should not be used

for lifting the complete generator set.

ing of the coupling bolts. This requirement to rotate the combined assemblies exists for both single and two bearing units.

During the assembly of single bearing units it is necessary to

align the generator's coupling holes with the engine flywheel

holes: it is suggested that two diametrically opposite location

dowel pins are fitted to the engine flywheel, over which the

generator coupling can slide into final location into the engine

flywheel spigot recess. The dowels must be removed and

replaced by coupling bolts before the final bolt tightening sequence.

While fitting and tightening the coupling bolts it will be necessary to rotate the Engine crankshaft - Generator rotor assembly. Care should be taken to ensure that rotation is carried out

in an approved manner that ensures safe working practice when

reaching inside the machine to insert or tighten coupling bolts,

and that no component of the assembly is damaged by nonapproved methods of assembly rotation.

Engine Manufacturers have available a proprietary tool designed

to enable manual rotation of the crankshat assembly. This tool

must always be used, having been engineered as an approved

method of assembly rotation, by engaging the manually driven

pinion with the engine flywheel starter ring-gear.

BCL generators have no fan to support the drive end and are

supplied fitted with a transit strap clamping the coupling hub to

the drive end adaptor ring.

Once the transit strap is removed the rotor is free to move in the

frame, and care is needed during coupling and alignment to

ensure the frame is kept in the horizontal plane.

UNDER NO CIRCUMSTANCES SHOULD A LEVER BE USED

AGAINST THE FAN BLADES OR BAFFLE T O ROTA TE THE GENERAT OR ROTOR / ENGINE CRANKSHAFT ASSEMBL Y.

Before working inside the generator, during

the aligning and fitting of coupling bolts, care

should be taken to lock the assembly to

ensure there is no possibility of assembly

Danger !

rotational movement.

4.2.1 TWO BEARING GENERA TORS

A flexible coupling should be fitted and aligned in accordance

with the coupling manufacturer's instruction.

If a close coupling adaptor is used the alignment of machined

faces must be checked by offering the generator up to the engine.

Shim the generator feet if necessary. Ensure adaptor guards are

fitted after generator/engine assembly is complete. Open coupled

sets require a suitable guard, to be provided by the set builder.

In the case of belt driven generators, ensure alignment of drive

end and driven pulleys to avoid axial load on the bearings. Screw

type tensioning devices are recommended to allow accurate

adjustment of belt tension whilst maintaining pulley alignment.

Belt and pulley guards must be provided by the set builder.

4.2 ASSEMBL Y TO ENGINE

ENGINE TO GENERA TOR COUPLING ASSEMBL Y

During the assembly of the Generator to the Engine it will be

necessary to firstly carefully align, then rotate, the combined

Generator rotor - Engine crankshaft assembly, as part of the

construction process, to allow location, insertion and tighten-

Important ! Incorrect belt tensioning will result in

excessive bearing wear.

Caution !

8

Incorrect guarding and/or generator

alignment can result in personal injury and/

or equipment damage.

4.2.2 SINGLE BEARING GENERAT ORS

Alignment of single bearing generators is critical. If necessary

shim the generator feet to ensure alignment of the machined

surfaces.

For transit and storage purposes the generator frame spigot

and rotor coupling plates have been coated with a rust

preventative. This

A practical method for removal of this coating is to clean the

mating surface areas with a de-greasing agent based on a

petroleum solvent.

For coupling to the various engine flywheel housings, the

MUST BE removed before assembly to engine.

Important ! When fitting drive disc ensure that

flywheel fixing bolt holes fall between fan

blades to allow access for flywheel bolts.

Use engine pulley to turn rotor.

4.2.2.1 SINGLE BEARING 4-POLE & 2-POLE

GENERA TORS

Generators offered in the BCA range can be specified to suit

different engine build configurations of specific flywheel and

flywheel housing combinations.

Important ! It is most important that the appropriate

generator build is ordered with prior

knowledge of the intended engine flywheel/

housing arrangement.

Care should be taken not to allow any

Caution !

cleaning agent to come into prolonged

contact with skin.

generators can be supplied with an endbracket-adaptor

arrangement as outlined below.

EndBracket/Adaptor

SAE5

SAE4

SAE3

SAE2

SAE5 Plus SAE6 Adaptor Ring

Important ! Drive end adaptors are designed for use

with cap head screws.

BC18 generators fitted with an SAE 5 drive

end adaptor must also be fitted with a

reduced diameter fan and must be

operated at reduced output.

Fan securing screws should be tightened

to 0.59kgm (6Nm 4.4lb. ft.)

The sequence of assembly to the engine should generally be as

follows:

1. On the engine check the distance from the coupling

mating face on the flywheel to the flywheel housing mating

face. This should be within 0.5mm of nominal dimension.

This is necessary to ensure that a thrust is not applied

to the a.c. generator bearing or engine bearing.

2. Check that the bolts securing the coupling disc to

the coupling hub are tight and locked into position.

Torque tightening is 7.6kgm (75Nm; 55 lb ft).

3. Remove covers from the drive end of the generator to

gain access to coupling disc and adaptor bolts.

4. Check that coupling disc is concentric with adaptor

spigot. This can be adjusted by suspending the rotor by

means of a rope sling through the adaptor opening.

5. Offer the a.c. generator to engine and engage both

coupling disc and housing spigots at the same time, finally

pulling home by using the housing and coupling bolts.Use

heavy gauge washers between bolt head and discs on

disc to flywheel bolts.

6. Tighten coupling disc to flywheel. Refer to engine manual

for torque setting of disc to flywheel bolts.

Important ! During assembly , loss of residual voltage

may occur. Refer to subsection 7.4.3 for

field flashing.

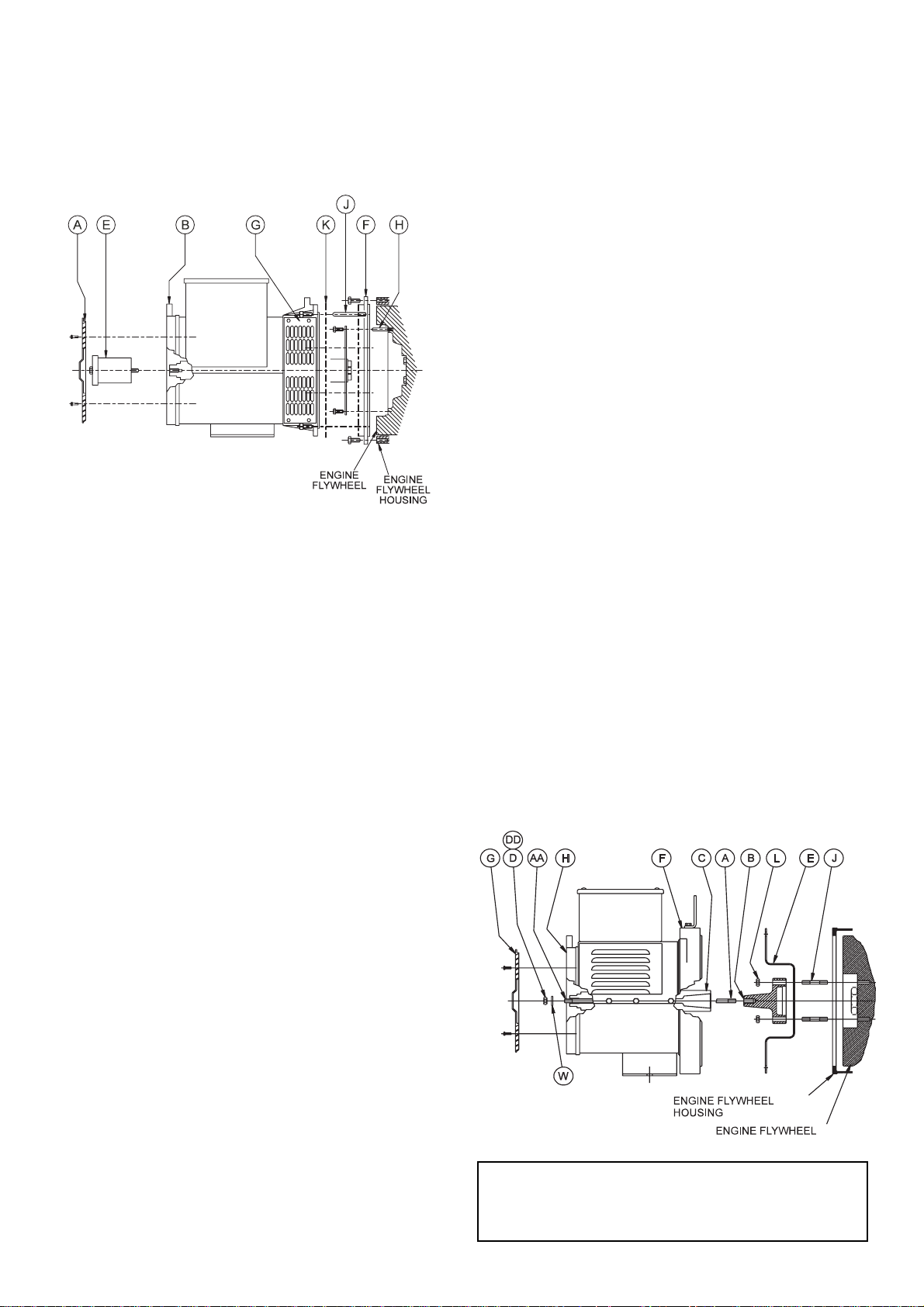

GENERAT OR TO ENGINE ASSEMBL Y INSTRUCTIONS

1. Remove louvered cover "A" from non-drive endbracket "B".

2. Assemble locating bar "E" (Newage No AF1609)

by screwing into shaft.

3. Remove transit bar "K".

4. Remove side screens "G".

5. If the adaptor ring is an individual item, as indicated

"F", bolted to the generator D.E. bracket, remove from

generator and fit to engine flywheel housing.

6. Thread two locating pins "H" into two top flywheel holes.

7. Fit two locating pins "J" into two top holes of the engine

flywheel housing/adaptor location holes.

8. Pick up generator by the cast lifting lugs on both ends

with 1/2 ton shackles (TO BS3032) or lifting hooks

(Newage No.LE130) using suitable lifting equipment.

9. Rotate generator rotor such that two top holes of

coupling disc are in close axial alignment.

10. Push the generator rotor forward only half (50mm)

the available movement provided by locating bar "E". It

may be necessary to tap bar "E" with a hide mallet to

ease the bearing out of housing.

Important ! Do not push the rotor forward too far.

There is a risk that the rotor will rest on the

stator winding outhang resulting in

winding damage especially if any

rotational movement occurs during

alignment with pins "H".

11. Support the weight of the rotor at the coupling end whilst

sliding the rotor forward to locate coupling disc holes over

support pins "H". Locating bar "E" will allow the rotor to

move forward a further 50mm, the total movement bar "E"

allows being 100mm. With coupling discs

positioned against flywheel location fit securing screws

and washers. Remove pins "H" and fit two final

securing screws and washers.

12. Push generator onto engine guiding adaptor over locating

pins "J" and onto engine flywheel housing location, or

ring "F", secure with screws and washers. Remove pins

and replace with two screws and washers.

9

13. Remove locating bar "E". Replace M10 screw "C" for

barring purposes.

14. Remove lifting tackle and replace side screens "G" and

louvered cover "A".

4.2.3 T APER SHAFT ARRANGEMENTS

This arrangement is used on the BCL style generators.

As with single bearing generators alignment is critical. If

necessary shim the generator feet to ensure alignment of the

machined surfaces.

The following procedure should be adopted to assemble the

generator to the engine:-

1. Remove louvred endcover "G" from non drive endbracket

"H" and M10 Hex Nut "D" from shaft securing stud "AA".“

Remove transit bar "E" and withdraw stub shaft/shaft

securing stud "A/B" from rotor.

2. Ensure alternator , engine flywheel and flywheel housing

locating spigots, faces and recesses are free from paint

or preservatives.

3. Locate stub shaft/shaft securing stud assembly "A"/"B"

on engine flywheel spigot and secure with studs "J", M12

hex. nut "L" or bolts. Refer to engine manual for torque

settings.

4.2.2.2 SINGLE BEARING 2-POLE GENERA TOR TO ENGINE ASSEMBL Y INSTRUCTIONS

(WITH DOWELED FL YWHEELS)

1-5. Follow steps 1-5 from 4 pole instruction procedure.

6. Fit the two location dowels pins into appropriate

diametrically opposite holes in engine flywheel, leaving

sufficient parallel diameter exposed to allow for positive

location of the disc-spacer-ring and coupling discs.

7. Fit the disc-spacer-ring over the two dowel pins and

position firmly against the flywheel face.

8. Follow steps 6-8 from 4 pole instruction procedure.

9. Rotate generator rotor such that the two coupling disc

dowel holes align with flywheel dowel pins, and two top

holes of coupling discs are in close axial alignment

with the two flywheel location pins "H".

10. Follow step 10 from 4 pole instruction procedure.

1 1. Support the weight of the rotor at the coupling end whilst

sliding the rotor forward to locate coupling disc holes over

support pins "H".

4. Ensure both tapers are clean and free of burrs, oil or

grease. Slide alternator complete with rotor towards

engine, ensuring that shaft securing stud "A" enters

central hole in rotor shaft. Refer to engine manual for

torque settings.

5. Secure alternator adaptor "F" to engine flywheel housing.

T ap adaptor into place before tightening. Refer to engine

manufacturer for torque setting.

6. Fit M10 Binx nut "DD" to protruding shaft securing

stud "AA". M10 Binx nut tightening torque 45.0Nm (33.0

lbs.ft).

7. Fit louvred endcover "G" to non drive endbracket "H".

8. Check for excessive vibration at time of initial run-up.

Important ! Ensure coupling disc dowel pin holes are

in correct alignment.

With the coupling disc positioned against flywheel location

fit securing screws and washers.

Remove pins "H" and fit two final securing screws

and washers.

12. Follow steps 12-14 from 4 pole instruction procedure.

10

Caution!

Incorrect guarding and/or generator

alignment can result in personal injury and

/or equipment damage

Loading...

Loading...