Northern Lights M944T, M38CR2 Owner's Manual

OM944T

For Models: M944T & M38CR2

OPERATOR’S MANUAL

Marine Generators | Marine Diesel Engines | Land-Based Generators

— CALIFORNIA —

Proposition 65 Warning:

Diesel engine exhaust and some of its constitu-

ents are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Northern Lights

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2008 Alaska Diesel Electric, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Alaska Diesel Electric, Inc.

Printed in U.S.A.

PART NO.: OM944T 10/08

OPERATOR'S MANUAL

for Northern Lights® M944T & M38CR2 Diesel Generator Sets

Read this operator's manual thoroughly before starting to operate your equipment.

This manual contains information you will need to run and service your new unit.

Table of Contents

INTRODUCTION ....................................................4

Model Numbers ..................................................4

Serial Numbers ...................................................4

WARRANTY ............................................................5

SAFETY RULES .....................................................5

COMPONENT LOCATIONS

M944T Generator Set ..................................6 - 7

CONTROL PANELS

Northern Lights Generator Sets .........................8

OPERATING PROCEDURES

Break-in Period ...................................................9

Before Starting ....................................................9

Starting ............................................................. 10

Operating ......................................................... 10

Stopping ........................................................... 10

Shutdowns and Alarms .....................................11

Spare Parts ........................................................11

SERVICING SCHEDULE CHART ............ 12 - 13

SERVICING (Continued)

V-Belts ............................................................. 15

Valve Clearances .............................................. 16

Fuels - General ................................................. 17

Fuel Filters ....................................................... 17

Bleeding the Fuel System ................................ 18

Injector Service ................................................ 19

Injection Pump ................................................. 20

Cooling System ............................................... 21

Heat Exchanger ................................................ 22

Raw Water Pump ............................................. 22

Zinc Electrodes ................................................ 22

Electrical System - General ............................. 23

Booster Batteries .............................................. 23

Battery Care ..................................................... 24

Winterizing / Out-of-Service ........................... 24

TROUBLESHOOTING

Electrical .......................................................... 25

Engine ...................................................... 26 - 28

WIRING DIAGRAMS

AC Electrical ................................................... 29

DC Electrical ........................................... 30 - 31

SERVICING

Lubrication - General ....................................... 14

Checking Oil .................................................... 14

Oil Changes ..................................................... 14

Changing Oil Filter .......................................... 15

Air Filter .......................................................... 15

It may not be reproduced in whole or in part without the written permission of Alaska Diesel Electric, Inc.

© Alaska Diesel Electric, Inc. All rights reserved. Litho U.S.A. Publication number OM944T 10/08

Proprietary Information

This publication is the property of Alaska Diesel Electric, Inc.

OM944T 10/08

3

Introduction

The servicing of marine engines and generator sets

presents unique problems. In many cases, boats cannot

be moved to a repair facility. Marine engines cannot be

compared to the servicing of automobiles, trucks, or

even farm equipment. Failures often occur in remote

areas far from competent assistance. Marine engines are

taxed far more severely than auto or truck engines;

therefore, maintenance schedules must be adhered to

more strictly. Failures begin with minor problems that

are overlooked and become amplied when not corrected

during routine maintenance.

As operator, it is your obligation to learn about your

equipment and its proper maintenance. This is not a

comprehensive technical service manual. Nor will it make

the reader into an expert mechanic. Its aim is to aid you in

maintaining your unit properly.

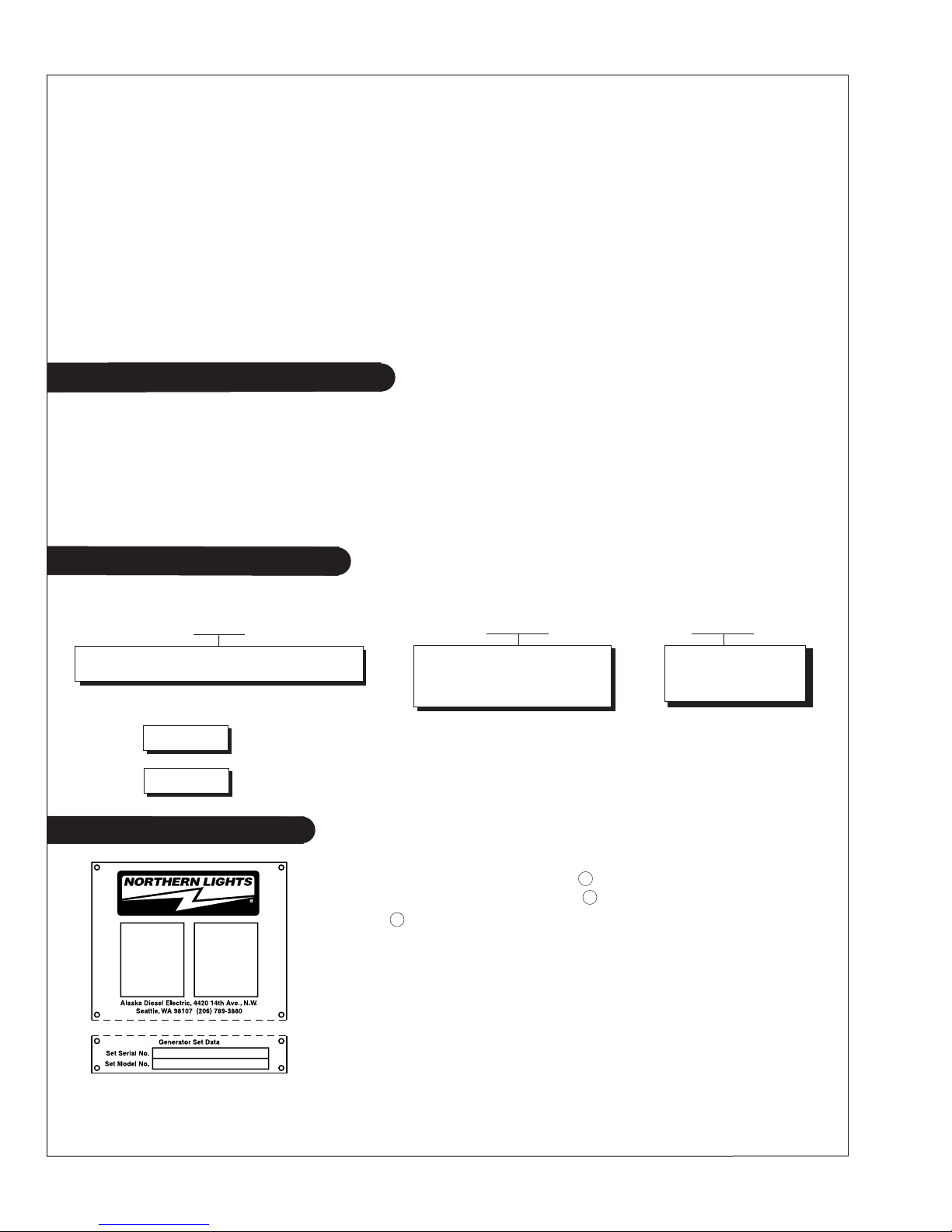

Unit Identication

MODELS INCLUDED

This manual covers the operating instructions for:

M944T & M38CR2 marine generator sets, which use the 944 engine block.

Model Numbers

Model numbers give the unit's application, block model, aspiration, and RPM:

M

944

T, C

M - Northern Lights marine generator set

Northern Lights marine diesel generator set with

M944T

M38CR2

=

a 944 engine and a LX-E 34E series generator end.

Northern Lights commercial diesel generator set with

=

a 944 engine and a UCI224 Stamford generator end.

Serial Numbers

Figure 1: Generator set

serial number plate.

Model number of engine block

+

Bore Cylinders

94 mm 4

T - Turbocharged

+

C - Commercial

Your set has three serial numbers: 1 an engine number stamped on

a plate attached to the valve cover, 2 a generator end serial number,

and 3 a generator set serial number.

NOTE: Always use the generator set serial number when ordering parts

or in correspondence. The generator set serial number plate is found on

the service side of the generator and resembles the drawing in Figure 1.

OM944T 10/08

4

Warranty

A warranty registration certicate is supplied with your

set. It entitles the original purchaser of our equipment

to a warranty covering material or assembly faults. The

extent of coverage is described in the Limited Warranty

Statement. We recommend that you study the statement

carefully.

CAUTION: Accident reports show that careless use of engines causes a high percentage

of accidents. You can avoid accidents by observing these safety rules. Study these rules carefully

and enforce them on the job.

• Never leave engine without proper security.

• Turn the coolant tank cap slowly to relieve pressure

before removing. Add coolant only when the engine

is stopped and cool.

• Mount a re extinguisher near engine.

• Always disconnect the battery ground strap before

making adjustments.

• Operate engines in properly ventilated areas.

• Keep trash and other objects away from engine.

• Escaping uids under pressure can penetrate your

skin. Use a piece of cardboard or wood, not your

hands, to search for leaks.

• Avoid wearing loose clothing without a belt when

working around engines.

NOTE: If the warranty is to apply, the servicing

instructions outlined in this manual must be followed.

If further information is needed, please contact an

authorized dealer or the factory.

Safety Rules

• Use caution in handling fuel. Never refuel a hot or

running engine. Do not smoke while lling fuel tank

or servicing fuel system.

• Keep your hands, feet, hair and clothing away from

power-driven parts.

• Check for any loose electrical connections or faulty

wiring.

• Engines should be operated only by knowledgeable,

qualied personnel.

• Look completely around engine to make sure that

everything is clear before starting.

• Do not operate an engine that isn't in proper working

order. If an unsafe operating condition is noted, tag the

set and control panel so others will also know about the

problem.

• Do not oil or grease engine while it is running.

• Remove the negative (-) battery terminal cable before

servicing electrical components or welding.

• Provide rst aid kits.

CAUTION: This symbol is used throughout

this book to alert you to possible danger areas.

Please take special notice of these sections.

OM944T 10/08

5

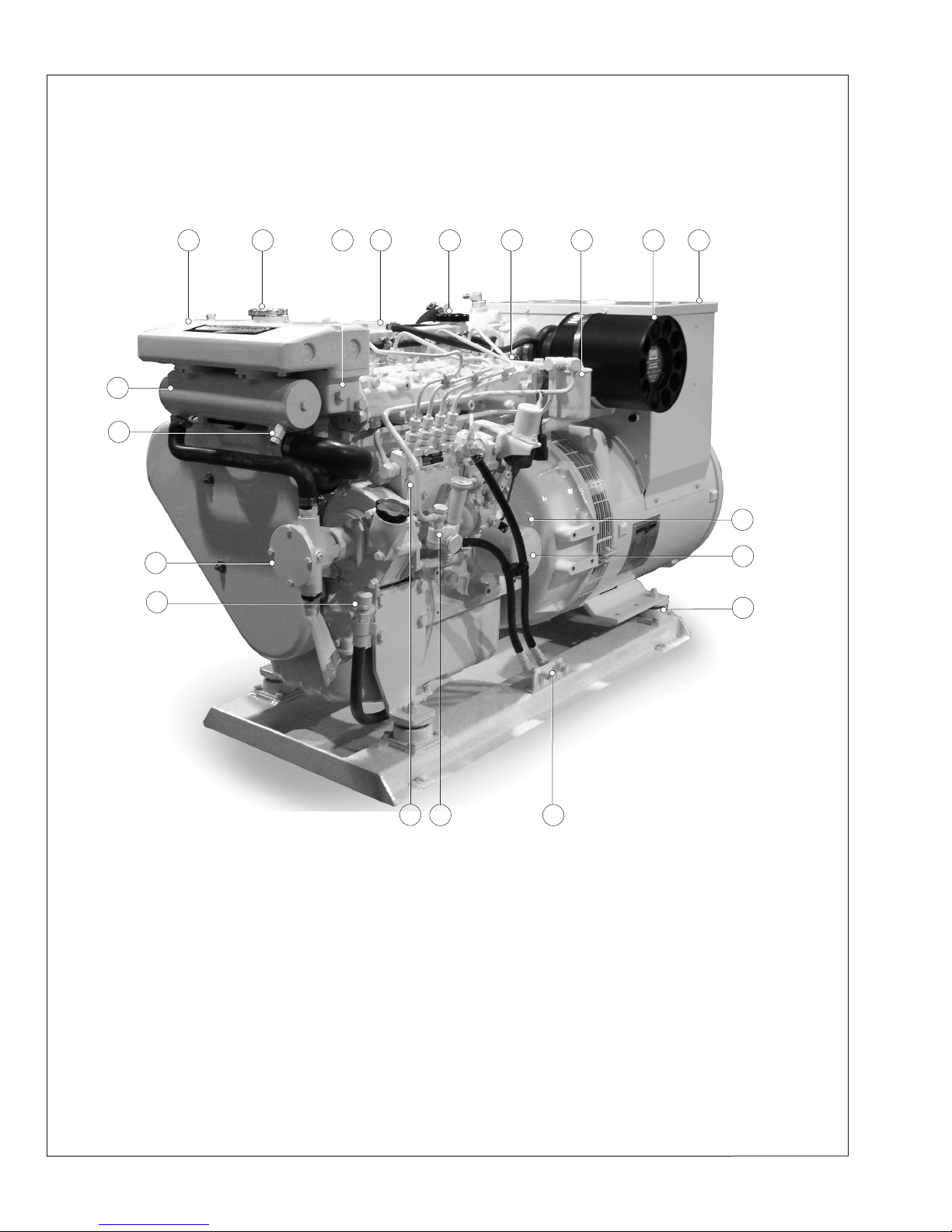

M944T Generator Set Component Locations

19

18

17

16

4

1

2

3

5 6

7

8

9

10

11

12

Figure 2: M944T Service Side

1. Expansion Tank

2. Coolant Fill

3. Thermostat Housing

4. Rocker Arm Cover

5. Lube Oil Fill

6. Intake Manifold

7. Fuel Filter

1415

8. Air Cleaner

9. Junction Box

10. Lube Oil Dipstick

11. Oil Filter

12. Vibration Mounts

13. Fuel Manifold

14. Fuel Primer Pump

OM944T 10/08

6

13

15. Injection Pump

16. Lube Oil Drain

17. Raw Water Pump

18. Heat Exchanger Raw Water

Drain and Zinc

19. Heat Exchanger

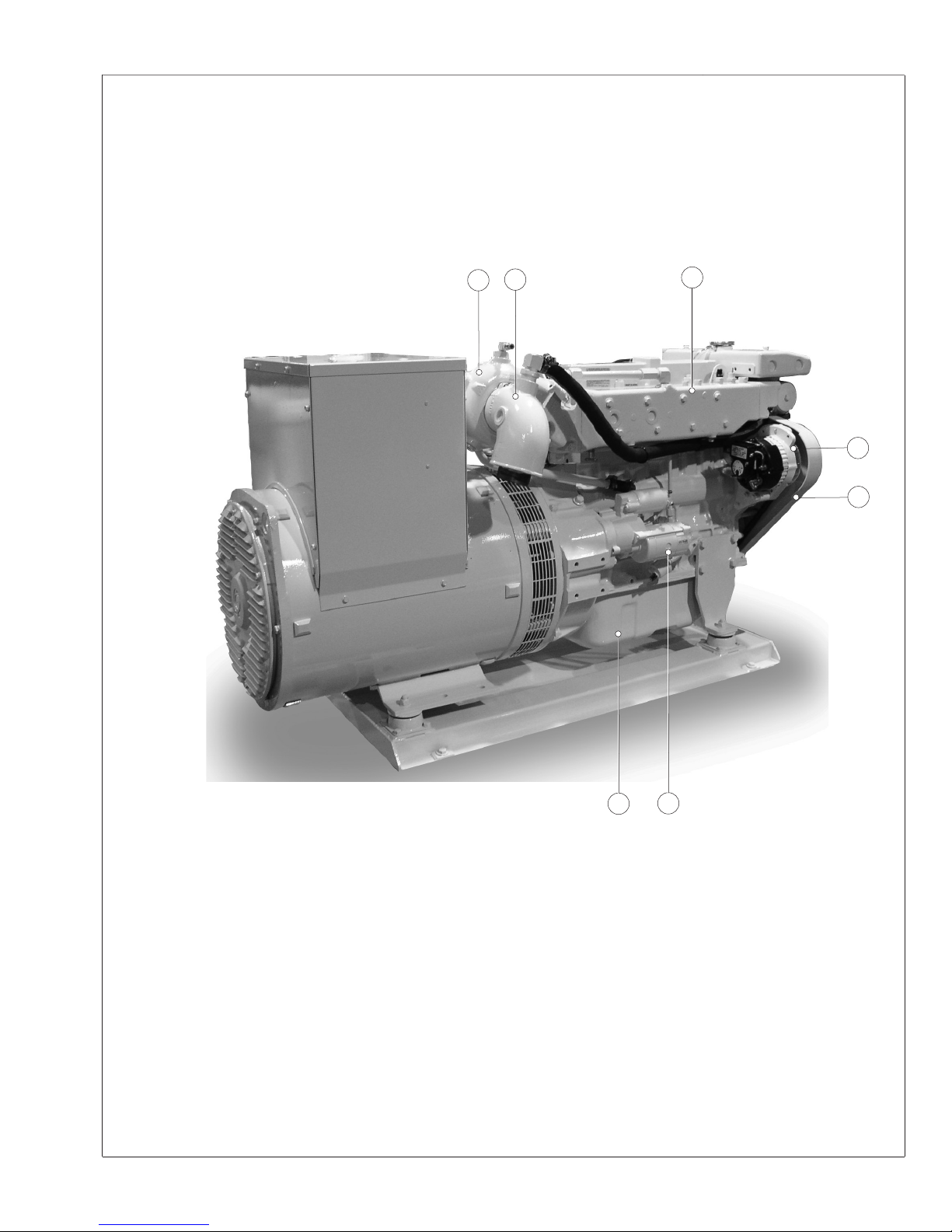

M944T Generator Set Component Locations

19

20

21

22

23

Figure 3: M944T Non-Service Side

19. Turbocharger

20. Wet Exhaust Elbow

21. Exhaust Manifold

22. Alternator

23. Belt Guard

24. Starter

25. Oil Pan

OM944T 10/08

7

25

24

Control Panels

Figure 4-A: Series 1-B Generator Control Panel

1. PREHEAT/ SHUTDOWN BYPASS

This switch serves two functions:

1. Preheats air before beginning the starting process.

Press switch for 10-20 seconds before attempting

startup.

2. Bypasses the safety shutdown feature during the

starting process. Keep switch engaged while starting

engine, and for 2 to 3 seconds afterwards, allowing oil

pressure to build beyond shutdown setpoint.

2. ENGINE CONTROL SWITCH

To start the engine, hold this switch in the START

position until the engine is running. After the engine

starts, release the switch and it will return to RUN

position. To stop the engine, hold the switch in the

STOP position.

NOTE: The rocker switch is used on Series 1 panels

only, and has a light that glows when the set is

running.

3. HOUR METER

Keeps track of engine running time.

Figure 4-B: Series 3 Generator Control Panel

4. OIL PRESSURE GAUGE

Shows the oil pressure in the engine lubricating system.

5. WATER TEMPERATURE GAUGE

Registers the temperature of the cooling water.

6. D.C. VOLTMETER

When the engine is stopped, the voltmeter indicates the

condition of the battery. When the engine is running,

the voltmeter indicates the voltage output of the alternator.

For Series 4 Control Panels only:

7. A.C. VOLTMETER

Shows the generator output voltage.

8. FREQUENCY METER (Hertz)

The frequency meter indicates alternating current

frequency: 60 Hz (1800 rpm) or 50 Hz (1500 rpm).

9. AMMETER/VOLTMETER SELECTOR

Used to check the voltage and current of each phase.

Return to “Amps Off” position when not monitoring.

Figure 4-C: Series 4 Generator Control Panel

10. A.C. AMMETER

Shows the generator load on each phase. The phase is

selected with the Ammeter Selector switch (#9).

OM944T 10/08

8

Operating Procedures

BREAK-IN PERIOD

1. The rst 100 hours on a new or reconditioned

engine are critical to its life and performance.

2. Constantly check the engine temperature and oil

pressure gauges.

3. Oil consumption is greater during break-in as

piston rings take time to seat.

4. Break-In Oil Changes: Change engine oil and

lter at 50 hours. Change oil and lter again at

100 hours (consult Lubricants section for oil

recommendation).

Operating Instructions:

Maintain at least a 75% load on your generator

set for the rst 100 hours. If this is not possible,

maintain no less than a 50% load to ensure proper

seating of the piston rings. Vary the load to help

seat the rings.

BEFORE STARTING

1. Check the water level by removing the pressure

cap from the expansion tank. In order to give the

cooling water an opportunity to expand, the level

should be about 1 in. (2.5 cm) below the ller cap

sealing surface when the engine is cold.

CAUTION: Use protective clothing and open

the ller cap carefully when the engine is warm

to prevent burns.

2. Check the oil level in the crankcase with the

dipstick. The oil level must be between high and

low marks on the stick. Never allow the level to go

below this area. Always add the same viscosity of

oil as is already in the crankcase.

3. Check the fuel tank level and open any fuel valves

on the tank and at the secondary fuel lter.

4. Close the sea-cock, check and clean the sea strainer,

and reopen the sea-cock.

5. Place the battery switch in the ON position.

NOTE: The battery switch must always be kept ON

while the engine is running. If the switch is

turned OFF while the engine is running,

the battery charging alternator could be

damaged.

OM944T 10/08

9

Operating Procedures

STARTING

1. Hold the Shutdown Bypass switch in the ON

position.

2. While holding the Shutdown Bypass switch in the

ON position, push the Engine Control switch to the

START position.

3. As soon as the engine starts, release both switches.

Do not crank the starter for more than 10 seconds

consecutively. If the engine fails to start with the

rst attempt, be sure that it has stopped completely

before re-engaging the starter.

NOTE: Excessive cranking of the starter on marine

setsequippedwithawaterliftmufercan

cause engine damage. If the engine does not

start after 3 consecutive 10-second cranks,

remove the impeller from the seawater

pump.Thiswillpreventthemuferfrom

llingwithwaterandbackllingtheexhaust

line and engine. Once the engine starts, shut

if off immediately and reinstall the impeller.

Restart and check the exhaust overboard

outlet for gushes of water.

OPERATING

1. Units with Series 3 and Series 4 Control Panels:

check gauges often. Oil pressure must be above

15 PSI. The D.C. voltmeter should read between

11 and 15 volts at 80° F (25° C) ambient temperature.

The water temperature gauge must be below 200°

F (94° C). Check the A.C. voltage and frequency

meters (Series 4 panel). If the gauges deviate from

normal levels, shut down the generator set and

investigate.

2. Add electrical load.

STOPPING

1. Remove electrical load from the generator set.

2. Run the engine for a two to three minute cool-down

period.

3. Move the Engine Control switch to the STOP

position.

OM944T 10/08

10

Loading...

Loading...