Northern Lights M864 User Manual

M864

Soundshield Assembly Instructions

Corporate Headquarters

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Alaska Branch Office

1200 West Int’l Airport Road

P.O. Box 190208

Anchorage, AK 99519

Tel: (907) 562-2222

Fax: (907) 563-1921

www.northern-lights.com

Southeastern U.S.A.

1415 S.W. 6th Court

Pompano Beach, FL 33069

Tel: (954) 946-7601

Fax: (954) 946-7409

East Coast Branch

Northern Lights Industrial Park

8 Connector Road

Andover, MA 01810

Tel: (978) 475-7400

Fax: (978) 475-7745

L616 04/05

M864 Soundshield Part Number: 05-78705

ITEM # DESCRIPTION P/N QTY NOTES

1. Base board 05-78733 1

2. Extrusion, vertical 05-78702 4

3. Extrusion, horizontal, sides 05-78703 2

4. Extrusion, horizontal, ends 05-78734 2

5. Center post, top 05-78736 1

6. Center post, vertical 05-78706 2

7. Corner casting 05-70001 4

8. Bolting assembly 00-75714 22

9. Tie bracket 23-78701 2

10. Rear panel assembly 05-78742 1

11. Front panel assembly 05-78737 1

12. LH side panel forward assembly 05-78739 1 with vent box

13. LH side panel aft assembly 05-78728 1

14. RH side panel forward assembly 05-78729 1 no vent box

15. RH side panel aft assembly 05-78731 1

16. Top panel forward assembly 05-78747 1

17. Top panel aft assembly 05-78752 1

18. Penetration panel assembly 39-78008 1

19. Panel retainer bracket, 30R 23-70036 6

20. #10 screw s/s x 5/8” long 12-72002 12

21. Toe bracket, 30R 23-70038 4

22. Hex nut, nylock 1/4-20 14-00112 10

Specifications

Enclosure:

Length (OA) 52.65 in (1337 mm)

Width 26.88 in (682.7 mm)

Height 28.16 in (715 mm)

Base:

Length 53.15 in (1350 mm)

Width 27.38 in (695.4 mm)

Height 0.75 in (19.05 mm)

Assembled Height:

28.91 in (734 mm)

Assembled Weight (est):

140 lbs (63.5 kg)

1

1

Prior to assembly, inspect all components for damage. Report any damage to the

shipping company. Check the packing list to be sure all parts have been included.

2

3

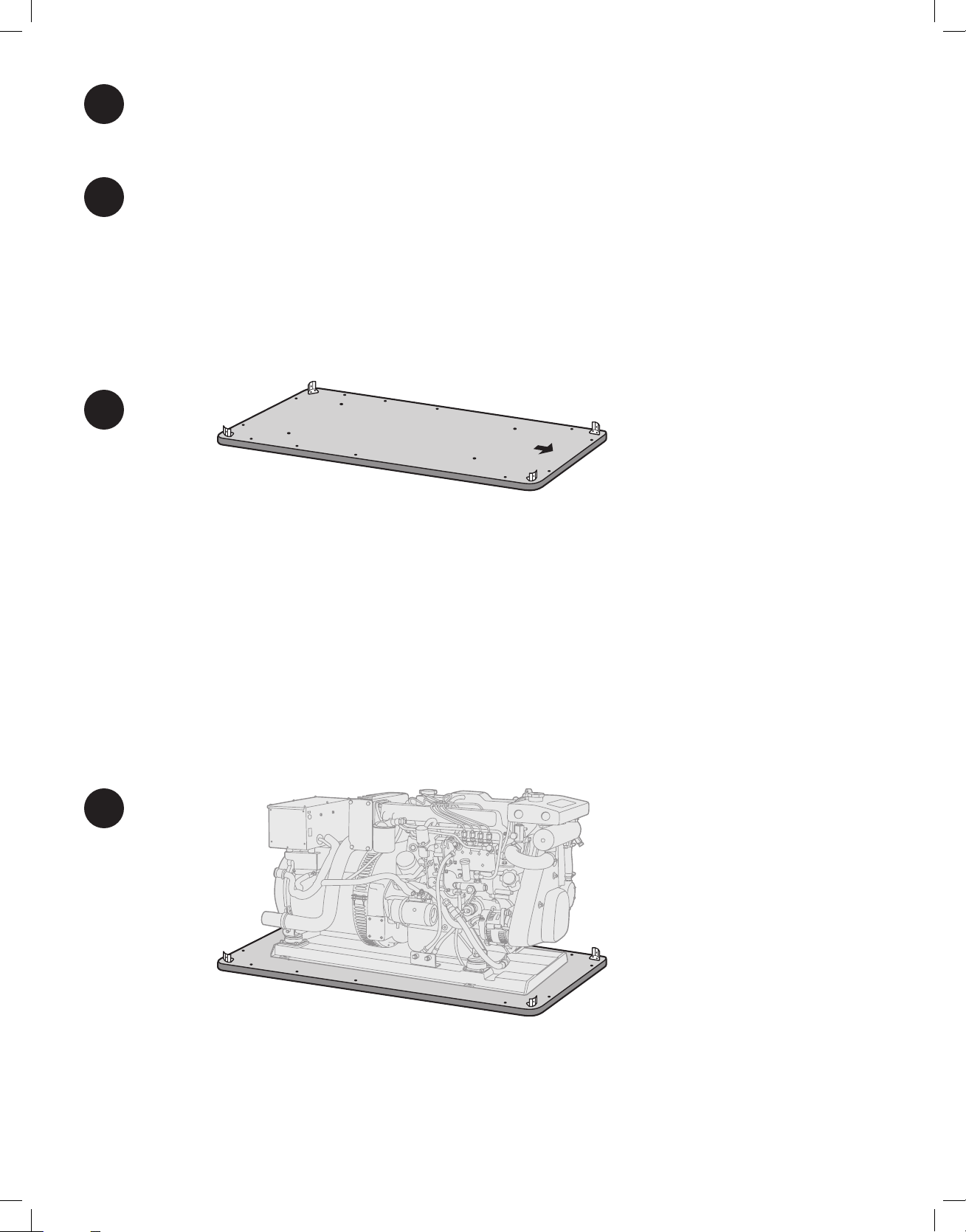

Select a mounting location in accordance with the guidelines in the IM1000 Installation Manual (supplied with the generator set). The generator set must typically be

mounted on a rigid, flat surface above a strong structure, such as the vessel’s stringers, to minimize vibration transference to the hull. CAUTION: THE BASEBOARD

IS A NON-STRUCTURAL MATERIAL AND MUST BE FULLY SUPPORTED TO

MINIMIZE FLEX.

Note that the generator set is designed for single side service. When viewed from

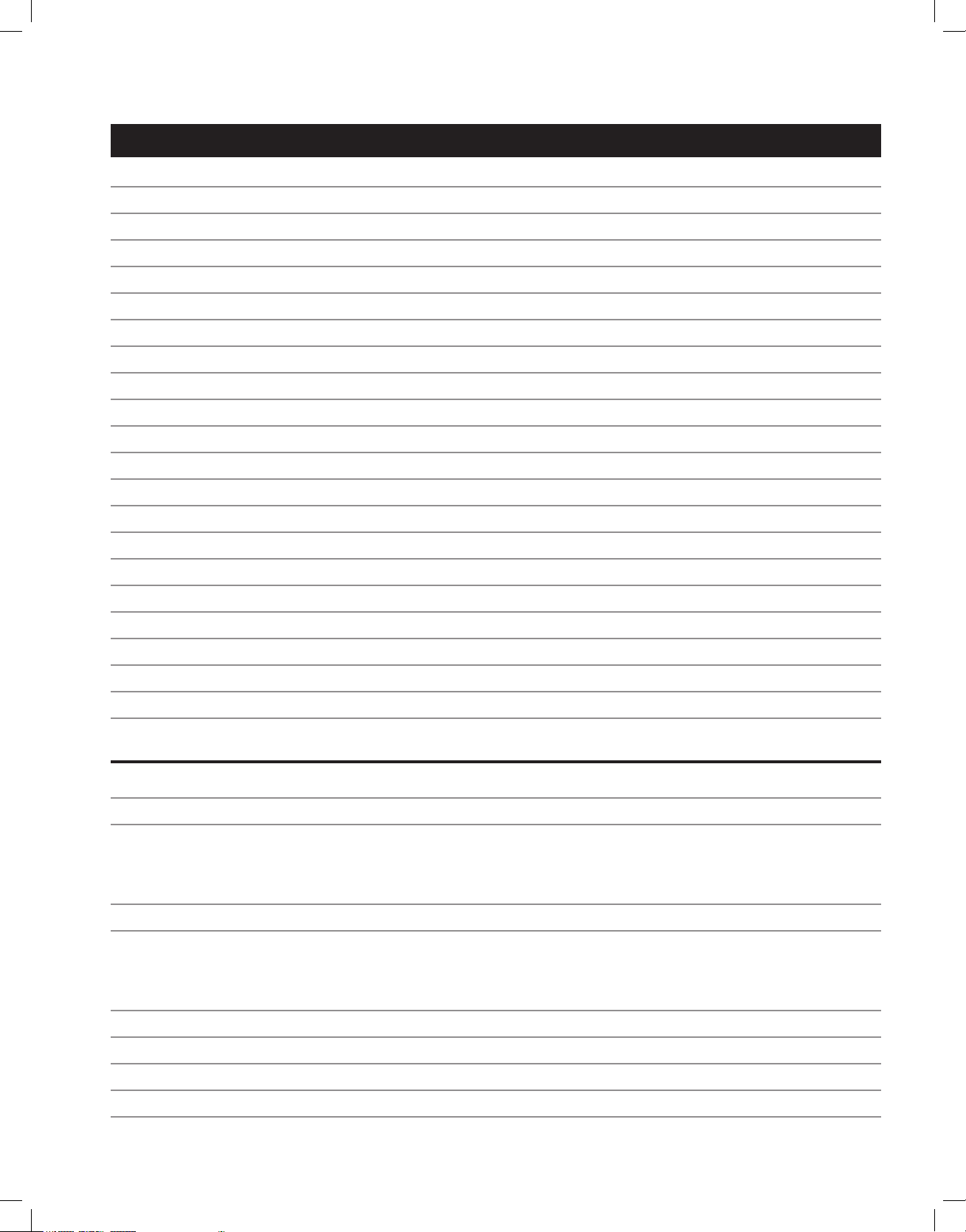

Install the base board (item 1) in the vessel in as near a level attitude as possible.

Observe the arrow symbol on the board’s topside surface. This indicates the top and

forward end orientation of the genset / soundshield. Make sure arrow is correctly

positioned or the unit will not mount correctly within the shield.

4

Install toe bracket (item 21) to each corner of the base board with screws (item 20)

into pre-drilled holes. See figure 1.

Note that there are pre-drilled “through” holes on each side of the baseboard. Use

these holes as guides to drill into the supporting substructure for through-bolting.

Place the generator set onto the baseboard, lining up the thru-holes with the mounting holes in the genset base frame. Use 3/8” or 9 mm bolts of appropriate length to

secure the genset and baseboard to the underlying structure.

2

Loading...

Loading...