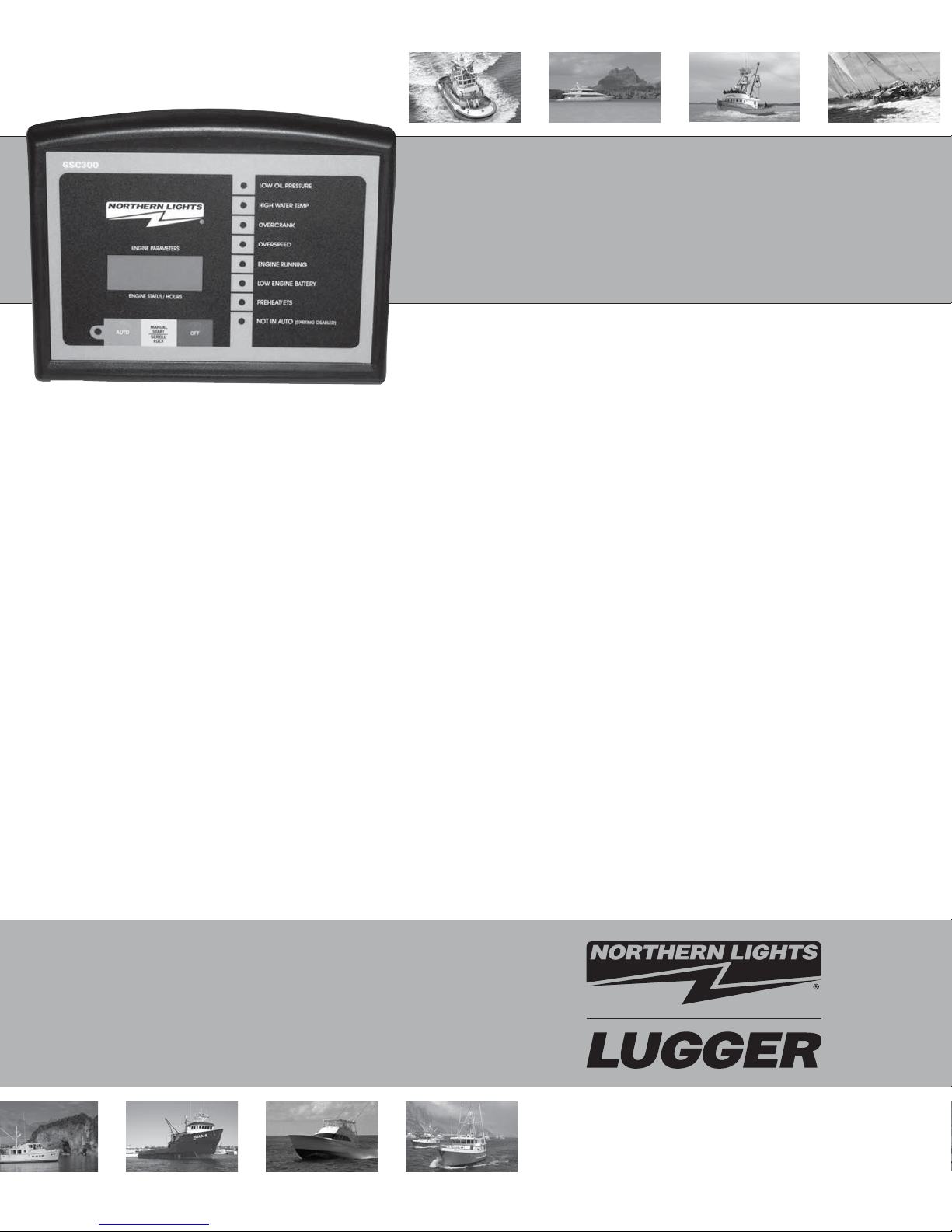

Northern Lights OGSC300, GSC300 Owner's Manual

OGSC300

Auto Start Generator Set Controller

OPERATOR’S MANUAL

Marine Generators | Marine Diesel Engines | Land-Based Generators

Northern Lights

4420 14th Avenue N.W.

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2012 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

PART NO.: OGSC300 08/12

OPERATORS MANUAL

for GSC300

Auto Start Generator Set Controller

Please Read Manual Before Installing Unit

Table of Contents..........................................................................................................................................I

Warranty Policy ...........................................................................................................................................II

GSC300 Specifi cations..........................................................................................................................III- IV

Table of Contents

1 - GSC300 Product Number Itentifi cation ...................................................1

2 - Wiring Installation Guidelines ...............................................................1-2

2-1 - Wiring Guidelines ...............................................................................3

2-2 - 12/24 VDC System Operation ............................................................ 4

2-3 - Terminal Description ...........................................................................5

2-4 - Wiring Connection Diagram .................................................................

2-5 - Back Panel Layout ...............................................................................

6

6

3 - Controller Operation .................................................................................7

3-1 -

3-2 - LED Layout .........................................................................................8

Controller Overview

................................................................................. 7

3-3 - LED Indicators .................................................................................... 8

4 - Programming The GSC300 Settings........................................................9

4-1 - Numbering of LED’s and Location of Mode Switch .......................... 10

4-2 - Sample Screen from PC Interface .....................................................11

5 - Troubleshooting Guidelines ................................................................... 12

6 -

Technical Notes/Frequently Asked Questions

................................................13

It may not be reproduced in whole or part without the expressed written permission of Northern Lights, Inc.

© Northern Lights, Inc. 2011. All rights reserved. Litho U.S.A. Publication number: OGSC300 8/12

Proprietary Information

This publication is the sole property of Northern Lights, Inc.

I

GSC300 Warranty Policy

LIMITED WARRANTY POLICY: The Northern Lights GSC300 engine controller is warranted by the original

manufacturer, DynaGen Technologies Inc. DynaGen Technologies Inc. hereafter known as the Seller warrants

articles sold hereunder to be free from defects in material and workmanship. These express warranties are the

sole warranties of the Seller and any other warranties, expressed, implied in law, or implied in fact, are

hereby specifi cally excluded. The Seller’s sole obligation under its warranty shall be, at its option, to either

issue a credit, or repair or replace any article or part thereof, which is proved to be defective. Any adjustment

of credits will be based upon original billing prices. All warranties shall expire 5 years from date of shipment by

the seller, unless otherwise specifi ed in other written communications from the Seller. Any replacement prod-

uct provided to the Buyer shall be subject to the original warranty period, which will expire 5 years from the

date of shipment of the original article. Notice of claimed breach of warranty must be given within the applicable period. No allowances shall be made to the Buyer for any transportation, duties, brokerage fees, labor

costs, or parts adjustments or repairs, or any other work, unless said charges are authorized in writing, in

advance, by the Seller. The Seller shall, in no event, be liable for special or consequential damages or for loss

of profi t. The warranty shall not extend to any articles or parts thereof which have been installed, used, or ser-

viced, other than in conformity with the Seller’s application specifi cations, manuals, bulletins, or instructions,

or, if none, shall have been subjected to improper installation, misuse, or neglect. The warranties shall not

apply to any materials or parts thereof, furnished by the Buyer, or acquired from others at the Buyer’s request

and/or to the Buyer’s specifi cations or designs. The foregoing limitations on the Seller’s liability in the event of

breach of warranty shall also be the absolute limit of the Seller’s liability in the event of the Seller’s negligence

in manufacture, installation, service, or otherwise, with regard to the articles covered hereby, and upon the

expiration of the stated warranty period, all such liabilities shall terminate.

RETURNS: If any article is claimed to be defective in material or workmanship, the Seller, upon notice

promptly given, will issue a written return material authorization (RMA) with shipping instructions for return to

the Seller. All returns must be accompanied by an RMA number or shipments will not be accepted by the

Seller. Articles which are returned as defective, but are found to meet the specifi cations agreed upon, will be

subject to a re-testing charge. At the discretion of the Seller, unused and undamaged Standard Products may,

under certain circumstances, be accepted back for credit or exchange. A restocking charge of 15% will apply.

Unused custom designed products will not be accepted back for credit or exchange.

For questions or comments regarding this product, contact:

Northern Lights

Phone (206) 789-3880

Fax (206) 782-5455

Email: info@northern-lights.com

Web: www.northern-lights.com

OGSC300 08/12

4

II

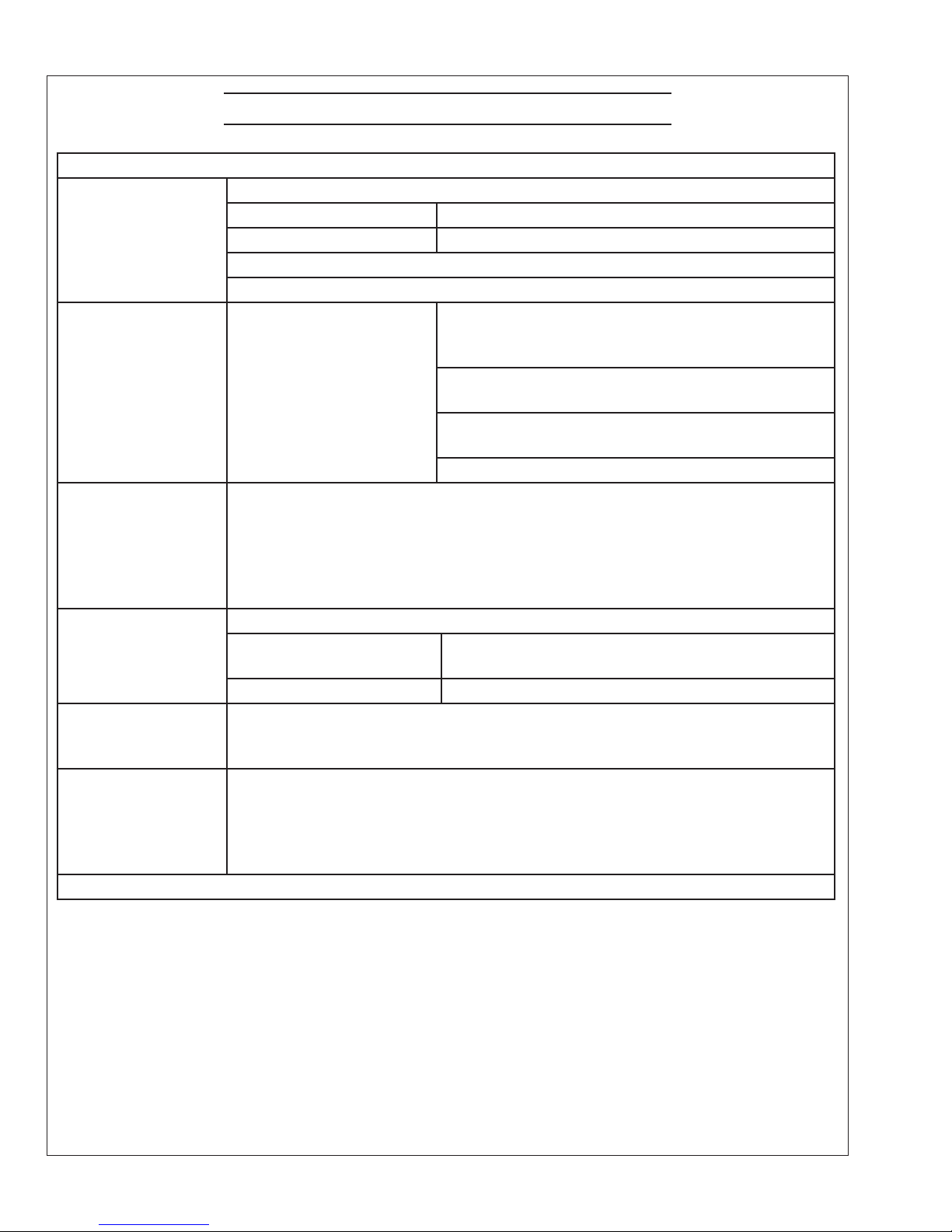

GSC300 Specifi cations

Operating Voltage: 7 to 30 VDC continuous

Zero volts operation for 100mS (assumes supply was 12 VDC before initiating

starting)

Operating Temperature:

Physical Dimensions:

Actual Unit Weight: 0.458 lbs

Enclosure: High Impact Resistant, Injection Molded Plastic Enclosure

Front Panel Indications

LED Display -

Adjustments

Warm-up: 0 - 200 Seconds (After Oil Bypass Feature)

Cool-Down: 0 - 812 Seconds

Crank Disconnect: 12 - 140 Hz

Overspeed: 40 - 200 Hz

Crank Rest: 4 - 32 Seconds

Delay on Start: 0 - 59 Seconds

Crank Tries: 1 - 10

Oil Bypass: 10 - 55 Seconds

Low Battery Indica-

tion:

Timer Adjustments

Glow Plug/Preheat: 0 - 255 Seconds

Energize To Stop

(ETS):

-400C to +850C (LCD Display operates from to -160C to 700C)

4.5” (H) x 5.5” (W) x 1.25” (D)

-High intensity LED’s with regulated brightness

Ultra-bright, Backlight LCD display with optimum viewing angle of 0 - 250 from perpen-

dicular

-Display Size (mm) 8 (W) x 32 (H) x 12.8 (D) x (2 line x 8 character display)

7 - 35 VDC

Energizes for 15 Seconds on failures, or energizes until 5 Seconds after engine speed

goes to zero upon removing power from Start/Stop terminal or removing the unit from

manual mode using the front panel buttons.

OGSC300 08/12

5

III

GSC300 Specifi cations (Continued)

Inputs

Speed Sensing: -Generator Output Speed Sensing

Maximum Input Voltage: 300VAC RMS

Minimum Input Voltage: 0.7VAC RMS Generator Output Sensing

-60Hz Rejection Filter Included

-Loss of Speed Signal Included

Sender/Failure

Inputs:

Oil Pressure

Coolant Temperature

Fuel Level / Auxiliary

Input

Protection -Three on-board replaceable 40A fuses protect Fuel, Crank, and Timer Out-

puts

-Reverse polarity protected

-Short circuit & overload protection on annunciation outputs

-Inputs are electrostatic discharge protected

-Maximum power supply surge before damage: 1500V for 250us

Outputs -All outputs switched to +battery (sourcing)

-Fuel, Crank, and Timer

Outputs:

-Annunciation Outputs: 300mA individually, 350mA combined

Connections -Removable terminal block for annunciation outputs and low power connec-

tions

-0.25” spade terminals for high current and Main power inputs

Programming -Windows based software interface utilizing the parallel port of your PC

-Option of programming through 3-button interface (limited parameter adjustment) on

the front panel or the PC Interface that has full parameter programming ability.

-Needs no power to program using the PC Interface – uses power from parallel port of PC

-Specifi cations May Change Without Notifi cation

-Accepts standard industry low impedance (0-500

ohm) sender inputs (VDO, Stewart-Warner, Datcon,

Murphy, etc.)

-Custom senders can be accommodated for in PC programming

-Programmable for either switch or sender confi gu-

ration

-Adjustable failure set-points

40A each, using standard 40A automotive relays

OGSC300 08/12

6

IV

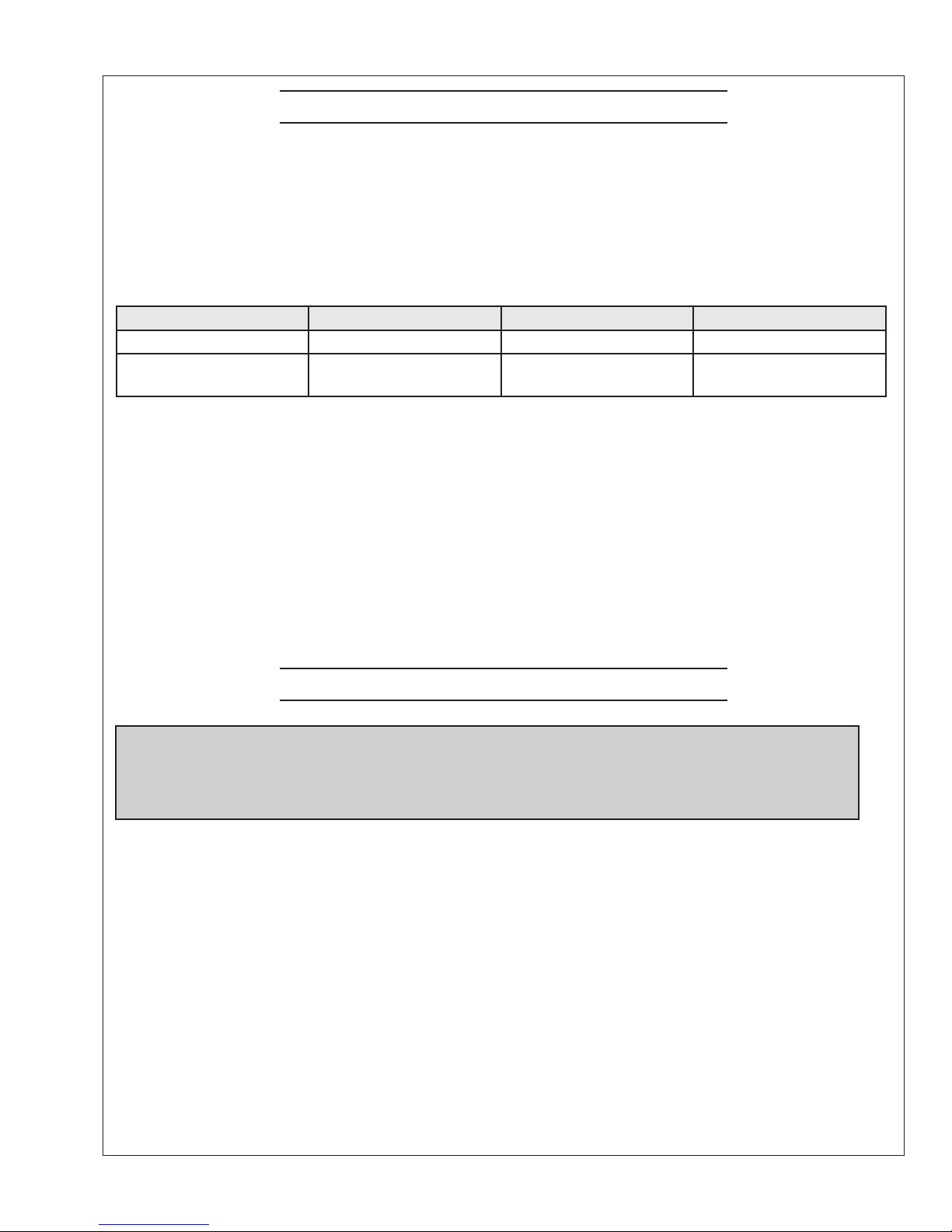

1. GSC300 PRODUCT NUMBER IDENTIFICATION

The GSC300 series catalog order number provides information pertaining to a specifi c model. The

Product Number Identifi cation Table (see Table 1) provides details on the breakdown of the model

number.

Table 1 - IDENTIFICATION TABLE

Position 1-6 Position 8 Position 10-11 Position 13-14

Series Speed Range DC Voltage Labeling

GSC300=GSC300 L=Low

H=High (Consult Factory)

Example: The product number GSC300-L-12-LS would be described as follows:

A GSC300 series automatic engine controller confi gured for a 12 VDC system.

The controller is factory confi gured for low speed range (generator speed range) which includes standard

labeling.

A GSC300 serial number would be displayed as:

GSC300-L-12-LS-00000

12=12 VDC

24=24 VDC

LS=Standard

LX=Customized

2 WIRING INSTALLATION GUIDELINES

Danger: Never work on the engine while its power is on. This controller does

not generate a warning signal prior to automatic engine start. Warning signs should

be placed on engine equipment indicating this important safety measure.

INSTRUCTIONS

Following these instructions will help avoid common installation problems during wiring and setup.

• Battery must be disconnected before any wiring connections are made.

• Wire length from the engine to the controller should not exceed 6 meters (20 feet).

Wiring size and type should be as specifi ed below. Use stranded wire, since solid wire has a tendency to

crack, break and loosen over time.

OGSC300 08/12

1

2 WIRING INSTALLATION GUIDELINES (CONTINUED)

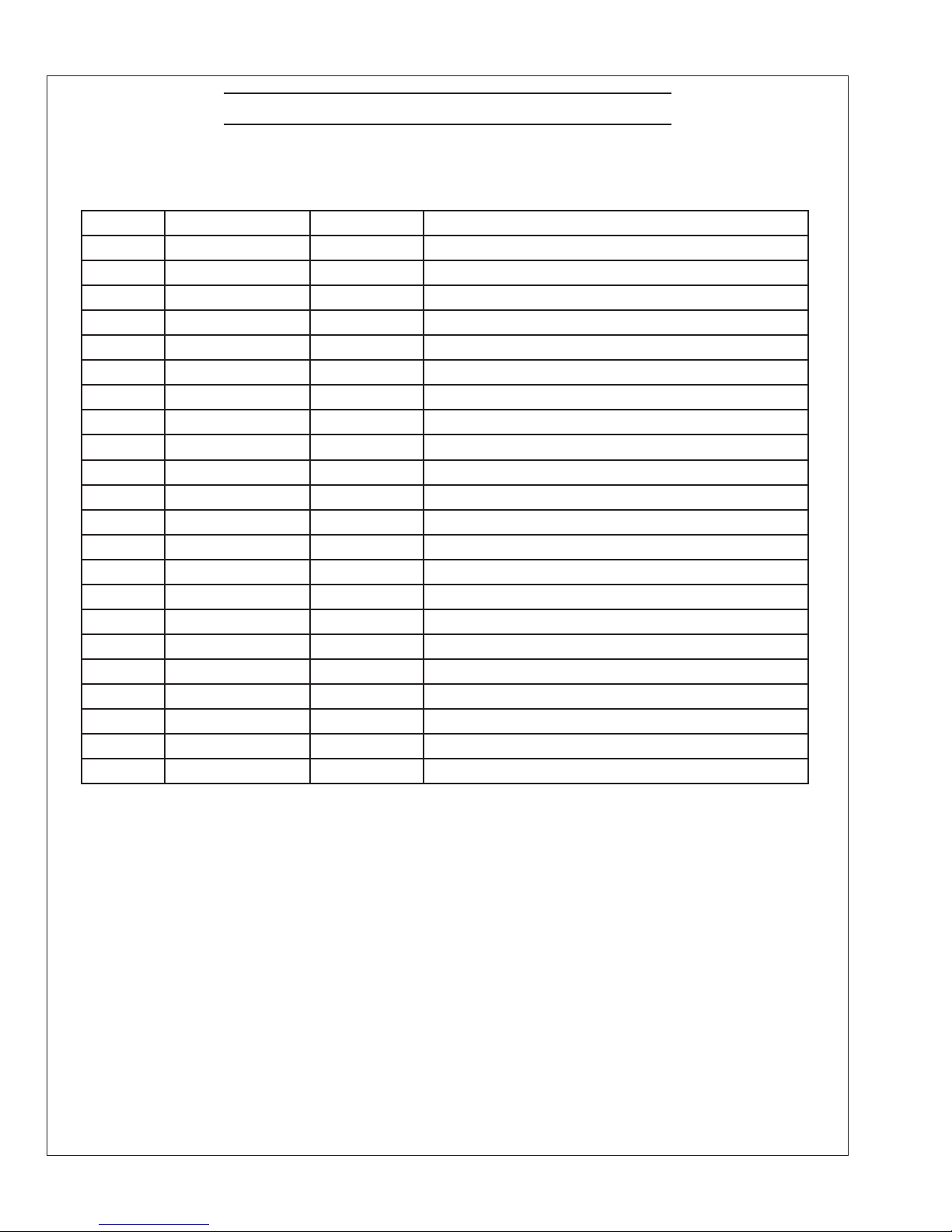

Types and Sizes:

Terminal Wire Size (AWG) Current Max Function

1 12 40A Fuel Output Terminal

2 12 40A Auto(Battery +) Terminal Connection

3 12 40A Auto(Battery +) Terminal Connection

4 12 40A Crank Output Terminal

5 12 40A Ground Terminal Connection

6 12 40A Ground Terminal Connection

7 12 40A Preheat/ETS Terminal

8 12 40A Preheat/ETS Terminal

9 18 100mA Speed Signal Connection

10 18 100mA Speed Signal Connection

11 18 300mA Overcrank (failure to start) Output

12 18 300mA Overspeed Output

13 18 300mA High Termp Output

14 18 300mA Low Oil Output

15 18 300mA Low Battery Output

16 18 300mA Engine Run Output

17 18 100mA Not In Auto Output

18 18 300mA General Failure Output

19 18 7ma Start/Stop Input

20 18 7mA Oil Pressure Sender/Switch Input

21 18 7mA Temperature Sender/Switch Input

22 18 7mA Fuel Level/Auxiliary Sender/Switch Input

OGSC300 08/12

2

Loading...

Loading...