Northern Lights 281PSL1500, 281PSL1501, 281PSL1502, 282PSL1503, 282PSL1504 User Manual

...

MAGNAPLUS® GENERATOR

www.marathonelectric.com

280–430 Frame

Installation, Operation,

and Maintenance Manual

Marathon Electric Mfg. Corp.

A Subsidiary of Regal-Beloit Corp.

P.O. Box 8003

Wausau, WI 54402-8003

Phone: (715) 675 3359

Fax: (715) 675 8026

CONTENTS

Safety 2

Receiving and Storage 2

Principles of Operation 3 - 4

Installation 4 - 6

Wiring Connections 6 - 9

Operation 9 - 10

Maintenance 10 - 11

Testing 11 - 12

Service 12 - 14

Troubleshooting 14 - 17

Specifications 18

Parts List & Recommended Spare Parts 19 - 20

SAFETY

When in doubt, ask. Questions are much easier to handle

than mistakes caused by a misunderstanding of the

information presented in this manual.

RECEIVING AND STORAGE

RECEIVING AND STORAGE

Upon receipt of the generator, it is recommended that it be

carefully examined for possible shipping damage. The

generator was given to the freight carrier in good condition;

thus, the carrier is responsible for the product from the

factory dock to the destination. Any damage should be

noted on the freight bill before accepting the shipment. Any

claims for damage must be promptly filed with the delivering

carrier.

PLEASE REMEMBER SAFETY FIRST. If you are not sure

of the instructions or procedures contained herein, seek

qualified help before continuing.

This service manual emphasizes the safety precautions

necessary during the installation, operation, and

maintenance of your MagnaPLUS generator. Each section

of this manual has caution and warning messages. These

messages are for your safety, and the safety of the

equipment involved. If any of these cautions or warnings

are not readily understood, seek clarification from qualified

personnel before proceeding.

Before any service work is done, disconnect all power

sources and lock out all controls to prevent an unexpected

start-up of the generator set driver. Proper grounding

(earthing) of the generator frame and distribution system in

compliance with local and national electrical codes and

specific site requirements must be provided. These safety

precautions are necessary to prevent potential serious

personal injury, or even death.

The hazards associated with lifting or moving your

MagnaPLUS generator are pointed out in the installation and

maintenance sections. Incorrect lifting or moving can result

in personal injury or damage to the unit.

Prior to start-up of the unit ensure that all generator leads

are properly connected to the generator link board located

inside the connection box. Always assume that there will

be voltage present at the generator terminals whenever the

generator's shaft is rotating, and proceed accordingly.

Residual voltage is present at the generator terminals and at

the automatic voltage regulator panel connections even with

the regulator fuse removed. Caution must be exercised, or

serious injury or death can result.

UNPACKING AND HANDLING

Carefully read all instruction tags shipped with the unit.

When lifting, attach an overhead crane to the lifting lug(s)

on the generator frame. Apply lifting forces in a vertical

direction. When transporting single bearing generators, the

generator’s rotor must be adequately supported to prevent

damage.

WARNING

THE LIFTING LUG(S) ON THE GENERATOR ARE

DESIGNED TO SUPPORT THE GENERATOR ONLY.

DO NOT LIFT A COMPLETE GENERATOR AND

DRIVER ASSEMBLY BY MEANS OF LIFTING

LUG(S) ON THE GENERATOR. PERSONAL INJURY

OR EQUIPMENT DAMAGE MAY RESULT.

STORAGE

In the event that the generator is not immediately installed

on its prime mover, it is recommended that the unit be

stored indoors in a clean, dry area which is not subject to

rapid changes in temperature and humidity. If the generator

is stored for a long period of time, the generator should be

tested, cleaned and dried as required before being put into

service. See the maintenance section of this manual for

further information. If the unit has been stored in an area

where it has been subject to vibration, it is recommended

that the bearing(s) be inspected and replaced as necessary.

This manual is not intended to be a substitute for properly

trained personnel. Installation and repairs should only be

attempted by qualified, trained people. The cautions and

warnings point out known conditions and situations that are

potentially hazardous. Each installation may well create its

own set of hazards

2

PRINCIPLES OF OPERATION

PMG (optional)

PMG Field

(rotor)

N

S

PMG

Armature

(stator)

PMG Input Power (optional)

Exciter Field

(stator)

(+)

DC

(in)

(-)

Exciter Field Power

(1 phase, 300/250 hertz)

Rotating Assembly

Exciter Armature

(rotor)

3 Phase AC (out)

Rotating Rectifier Assembly

3 Phase -- Full Bridge

(DC out)

Automatic

Voltage

Regulator

Main Field

(rotor)

(+)

DC

(in)

(-)

Input Power -- Single Phase

(shunt powered regulator)

Sensing Input -- Single Phase

FIGURE 1 -- MagnaPLUS Circuit Diagram

Main Armature

3 Phase AC (out)

3 phase (optional)

(stator)

L

1

L

2

L

3

FIGURE 2 -- Typical MagnaPLUS Layout Diagram

3

PRINCIPLE OF OPERATION

horsepower per generator KW in motor starting capability.

For specific data contact Marathon Electric.

MagnaPLUS generators are a brushless, self excited,

externally voltage regulated, synchronous AC generator.

The generator is made up of six major components: main

stator (armature), main rotor (field), exciter stator (field),

exciter rotor (armature), rectifier assembly, and voltage

regulator. In understanding the above terminology, note the

following: stators are stationary, rotors rotate, a field is an

electrical input, and an armature is an electrical output.

These system components are electrically interconnected as

shown in figure 1 and physically located as shown in

figure 2.

The generator’s exciter consists of a stationary field and a

rotating armature. The stationary field (exciter stator) is

designed to be the primary source of the generator’s

residual magnetism. This residual magnetism allows the

exciter rotor (armature) to produce AC voltage even when

the exciter stator (field) is not powered. This AC voltage is

rectified to DC by the rotating rectifier assembly and fed

directly to the main rotor (field). As the generator shaft

continues to rotate, the main rotor (field) induces a voltage

into the generator's main stator (armature). At rated speed,

the main stator’s voltage produced by the residual

magnetism of the exciter allows the automatic voltage

regulator to function. The regulator provides voltage to the

exciter resulting in a build-up of generator terminal voltage.

This system of using residual magnetism eliminates the

need for a special field flashing circuit in the regulator. After

the generator has established the initial residual voltage, the

regulator provides a controlled DC field voltage to the exciter

stator resulting in a controlled generator terminal voltage.

PARALLEL OPERATION

All MagnaPlus generators are built with 2/3 pitch main stator

windings and full amortisseur (damper) windings. These

features make the MagnaPlus generators suitable for

parallel operation when equipped with the proper voltage

regulators and voltage regulator accessories. Consult with

the factory for further information relative to parallel

operations.

NONLINEAR LOADING

Solid state electronic control devices (variable frequency

drives, precision motor controls, battery chargers, etc.)

utilize electronic switching circuits (thyristors, SCRs, Diodes,

etc.). These switching circuits introduce high frequency

harmonics which distort the normal wave form of the

generator. This creates additional heat in the generator

windings and may cause the generator to over-heat.

Problems which can occur are not limited to the generator.

Poor wave shape may adversely effect various loads

connected to the generator. Consult Marathon Electric for

further information relative to nonlinear loads.

INSTALLATION

PREPARATION FOR USE

Voltage Regulation

In the standard configuration (shunt excited), the automatic

voltage regulator receives both its input power and voltage

sensing from the generator's output terminals (See

Figure 1). With the optional PMG configuration, the

regulator receives input power from the PMG. The regulator

automatically monitors the generator's output voltage

against an internal reference set point and provides the

necessary DC output voltage to the exciter field required to

maintain constant generator terminal voltage. The

generator's terminal voltage is changed by adjusting the

regulator's reference set point. Consult the regulator

manual for specific adjustment and operating instructions.

MOTOR STARTING

When a motor is started, a large surge of current is drawn

by the motor. This starting current is equivalent to the

motors locked rotor or stall current and is 5 to 10 times

normal full load current. When the generator supplies this

in-rush of starting current, the generator voltage dips

temporarily. If the motor is too large for the generator, the

generator’s voltage dips greater than 30 percent. This may

result in the motor starter de-energizing or the motor

stalling. MagnaPlus generators generally supply .3 to .4

Although the generator has been carefully inspected and

tested in operation prior to shipment from the factory, it is

recommended that the generator be thoroughly inspected.

Check all bolts for tightness and examine the insulation on

lead wires for chafing prior to proceeding with installation.

Remove all shipping tapes, bags, skids and rotor support

blocking. For two bearing units, rotate the shaft by hand to

ensure that it rotates smoothly without binding.

4

WARNING

DISABLE AND LOCKOUT ANY ENGINE CRANKING

DEVICES BEFORE ATTEMPTING TO INSTALL OR

SERVICE THE GENERATOR. FOR ELECTRIC

START SETS, DISCONNECT THE CRANKING

BATTERY. FOR AIR START, DISCONNECT THE AIR

SUPPLY. FOR MOTOR GENERATOR SETS, OPEN

THE POWER SUPPLY TO THE DRIVE MOTOR.

FAILURE TO COMPLY WITH THESE SAFETY

PROCEDURES COULD RESULT IN SEVERE

PERSONAL INJURY OR EQUIPMENT DAMAGE.

NEVER "BAR OVER" THE ENGINE GENERATOR

SET USING THE GENERATOR'S FAN. THE FAN IS

NOT DESIGNED FOR THIS PURPOSE. BARRING

OVER THE SET WITH THE FAN COULD DAMAGE

THE FAN AND RESULT IN PERSONAL INJURY OR

EQUIPMENT DAMAGE.

driver and the generator's shaft. Aligning the generator and

its driver as accurately as possible will reduce vibration,

increase bearing life, and ensure minimum coupling wear. It

may be necessary to shim the generator feet for proper

support and alignment. Secure the feet of the generator

with grade 5 or greater bolts through the holes provided in

the mounting feet. Consult the coupling manufacturer's

instructions for alignment specifications and procedures.

GENERATOR MOUNTING

Two Bearing Units -- Belt Driven

Two bearing MagnaPLUS generators can be belt driven

provided belts are sized and applied correctly. Please refer

to your supplier of belts and sheaves for correct sizing and

tensioning specifications. A bearing life calculation should

be performed. Marathon Electric recommends a minimum

B-10 life of 40,000 hours. If cog type belts are used, a

vibration may be introduced which could lead to premature

failure of the bearings.

GENERATOR MOUNTING

Single Bearing Units.

Single bearing units are provided with an SAE flywheel

housing adapter flange and flexible drive discs. Coupling

the generator's shaft to the engine flywheel is accomplished

with special steel drive discs bolted to the shaft. In addition

to the drive discs, there may be a hub spacer, spacer discs,

or a combination of hub spacer and spacer discs inserted

between the drive discs and the shaft to achieve the proper

shaft extension ("G" dimension per SAE J620c). Holes are

provided in the periphery of the coupling discs which

correspond to tapped holes in the prime mover's flywheel.

The outside diameter of the drive discs fit in a rabbet in the

flywheel so that concentricity is assured.

Grade 8 place bolts and hardened washers are

recommended to mount the drive discs to the flywheel. DO

NOT USE SPLIT TYPE LOCK WASHERS. Split lock

washers when biting into the drive disc cause stress risers

which may result in the disc fracturing.

The SAE flywheel housing adapter ring and the engine

flywheel housing are designed to match each other with no

further alignment necessary. Use grade 5 or greater

mounting bolts. MagnaPLUS generator frames are

constructed with two or three bolt holes per foot. The feet

should be shimmed where necessary to obtain solid contact

with the sub-base. With the frame securely bolted to the

engine flywheel housing, there is no side thrust or pull on

the generator frame, thus no real need to secure the feet

with more than one bolt per foot.

END PLAY TESTING

Refer to the engine manual for recommended end play

specifications and measurement procedures. If end play is

not to specification, it is an indication that the generator

shaft is not moving freely in the assembly, and normal life of

the thrust bearing could be impaired. Probable causes of

this problem are:

1. Improper seating of drive discs in the flywheel resulting

in misalignment.

2. Improper mating of generator frame to engine flywheel

housing resulting in misalignment.

3. Improper "G" dimension per SAE J620c on either the

engine or generator.

TORSIONAL VIBRATION

Torsional vibrations are generated in all rotating shaft

systems. In some cases, the amplitude of these vibrations

at critical speeds may cause damage to either the

generator, its driver, or both. It is therefore necessary to

examine the torsional vibration effect on the entire rotating

system. IT IS THE RESPONSIBILITY OF THE

GENERATOR SET ASSEMBLER TO ASSURE THE

TORSIONAL COMPATIBILITY OF THE GENERATOR AND

ITS DRIVER. Drawings showing pertinent dimensions and

weights of the rotating assembly will be supplied by

Marathon Electric upon request.

GENERATOR MOUNTING

Two Bearing Generators -- Direct Drive

Two bearing generators are provided with a keyed shaft

extension. For direct drive generators, the assembler

furnishes a flexible coupling which is installed between the

5

ENVIRONMENTAL CONSIDERATIONS

380

219

The MagnaPLUS generator is designed for heavy duty

industrial applications; however, dirt, moisture, heat and

vibration are enemies of rotating electrical machinery.

Excessive exposure to the elements may shorten generator

life. The temperature of the cooling air entering the intake

openings of the generator should not exceed the ambient

temperature shown on the generator’s nameplate.

Generators intended for outdoor application should be

protected with housings having adequate ventilation.

Although the standard insulation systems are moisture and

humidity resistant, space heaters are recommended for

extreme conditions. If the generator is to be installed in an

area where blowing sand and dust are present, the

enclosure should be fitted with filters. Filters reduce erosion

on the generator's insulation by blocking high velocity

abrasive particles generated by the flow of cooling air

through the generator. Consult the factory for appropriate

filters and generator deratings required.

WIRING CONNECTIONS

Wiring of the generator and accessories should be

done in accordance with good electrical practices.

Follow government, industry and association

standards.

The generator conduit box construction allows cable entry

from multiple sides. A hole saw or other appropriate tool

may be used to provide for conduit entrance. Protect the

interior of the generator from shavings when drilling or

sawing. An approved connector must be used in

conjunction with the conduit. To minimize the transmission

of vibration, it is essential that flexible conduit be used for all

electrical entrance to the generator conduit box.

All MagnaPLUS generators are equipped with link boards

(terminal strips) for both internal and external connections.

All connections made to the studs of the link board should

be made with high quality ring terminals. Ring terminal

sizes are: 6 mm (280 Series Frames) and 10 mm (360 and

430 Series Frames). Torque link board connections to the

following specifications: 280 frame -- 5.4 NM (4 Ft Lb); 360

& 430 frame -- 27 NM (20 Ft Lb).

Refer to the connection diagram supplied with the generator

and / or the proper diagrams shown in this manual. Install

all inter-component and external wiring in accordance with

national and local electrical codes. The neutral in the

following connection diagrams shown below may be either

grounded (earthed) or left above ground potential (floating).

See national and local codes and / or the system

distribution wiring schematic diagram for the proper

connection of the neutral.

The following connection diagrams are shown for

twelve lead generators. Ten lead generators have the

same terminal designations except for leads T10, T11,

and T12. These three leads are internally connected

inside the generator and brought out as a single lead

(T0). Ten lead generators can only be connected in a

wye configuration

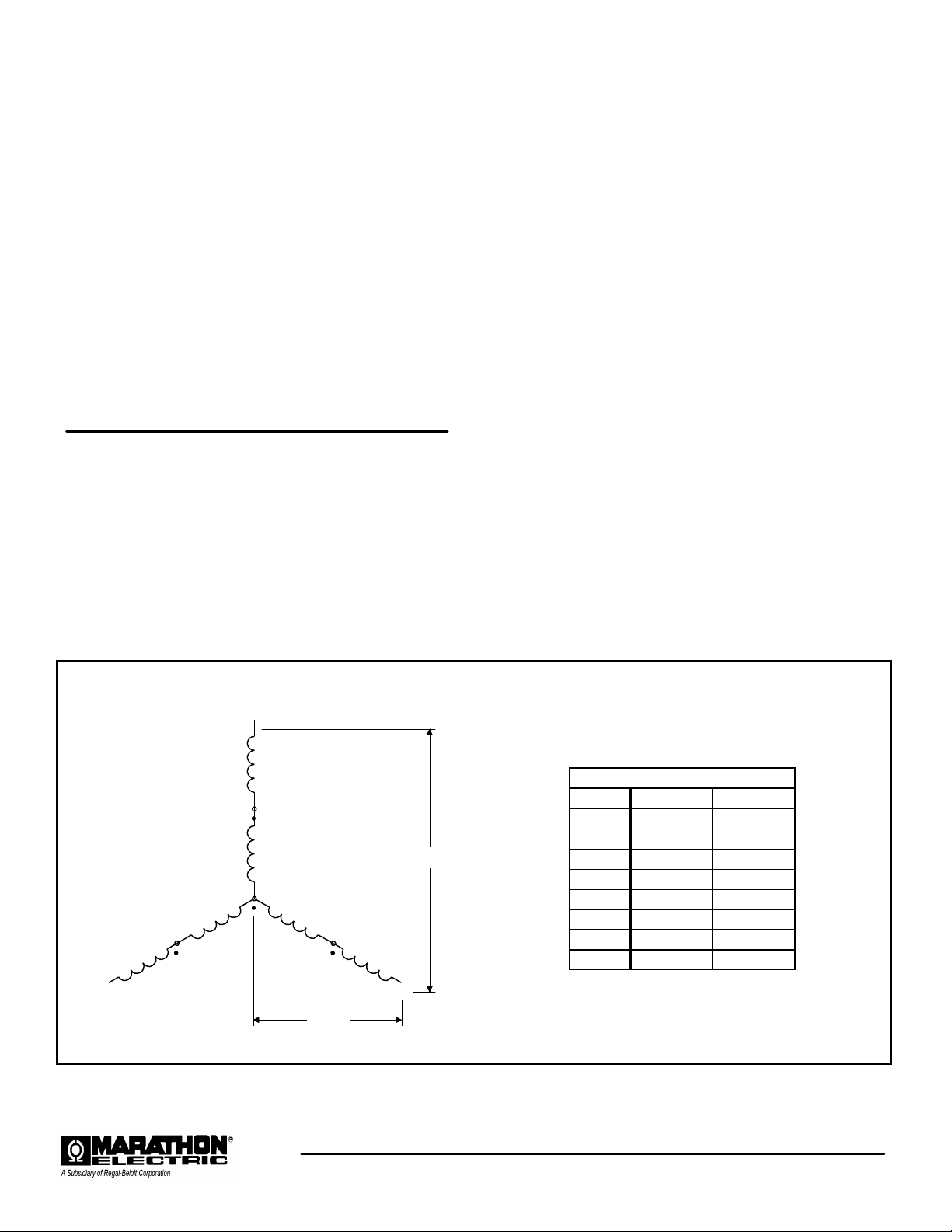

HIGH (SERIES) WYE CONNECTION

L

1

T

1

VOLTAGE (HIGH WYE)

T

4

T

7

T

T

12

T

9

T

6

T

3

L

3

10

T

11

T

8

T

5

L - N

L - L

T

2

L

2

Hz L-L L-N

60 480 277

460 266

440 254

416 240

380 219

50 416 240

400 231

6

Loading...

Loading...