Page 1

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Field

Service

Procedure

Part Number: SP00189

Date: 12 June 2002

© 2002 Draeger Medical, Inc.

Rev: C

D-TEC Desflurane Vaporizer Installation

on Machines With

Removable Vaporizer Mounting Systems

Page 2

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

D-TEC Desflurane Vaporizer Installation on

Machines with Removable Vaporizer Mounting Systems

Installation Procedure

NOTE: This procedure only applies to installation of D-Tec Desflurane vaporizer

on Narkomed 6000, Narkomed M, Narkomed GS Euro, Julian, Fabius GS and

Fabius machines with removable vaporizer mounting systems. Refer to Field

Service Procedure SP00091 for other desflurane vaporizer installations.

¡¡¡¡WARNING: Do not install a D-Tec vaporizer in the right hand position of a

Narkomed 6000 as this will result in an incorrect fit and may cause leaks in the

fresh gas delivery system.

¡¡¡¡WARNING: Do not install a D-Tec vaporizer on a Narkomed Mobile without the

correct vaporizer support block as this will result in an incorrect fit and may

cause leaks in the fresh gas delivery system. Refer to this procedure to verify

correct vaporizer support block prior to D-Tec vaporizer mounting.

¡¡¡¡WARNING: The O-rings supplied with this vaporizer are incompatible for use on

the Narkomed 6000, Narkomed GS Euro, Narkomed M, Fabius GS or the USA

manufactured Fabius. These systems shall only use O-RING #113 (NITRILE) P/N

4115864.

NOTE:Proceed to Section 2.0 if you are not

removing an existing vaporizer.

1.0 Vaporizer Draining, Drying and

Removal Procedure:

¡¡¡¡WARNING: Do Not install a D-Tec

vaporizer in the right hand position

of a Narkomed 6000 as this will result

in an incorrect fit and may cause

leaks in the fresh gas delivery

system.

Before removing an existing vaporizer

from the machine perform a fresh gas

leak test at the fresh gas outlet to verify

the initial gas circuit integrity. Refer to

the device service manual for specific

instructions.

¡¡¡¡Caution: The steps in this section

must be performed in the following

sequence:

1.1 Activate the waste gas scavenger.

1.2 Attach a breathing bag to the bag

mount port.

1.3 Open the APL valve to the minimum

position.

1.4 Connect the inspiratory and

expiratory valves using a 22 mm

hose.

1.5 Ensure the fresh gas hose is

connected between the absorber

system and the machine.

If there is an existing vaporizer in place,

it must be drained and dried as follows:

1.6 Turn the System Power switch to

ON.

1

Page 4

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

1.7 Set the ventilation control to Manual

or MAN/Spont mode.

1.8 Set all vaporizer handwheels to their

“0” position.

¡¡¡¡WARNING: Do Not inhale anesthetic

vapors as this could result in

personal injury.

1.9 Open the filler and drain plugs and

drain the vaporizer into a suitable

container. Dispose of the residual

agent in an approved manner.

1.10 Close the filler and drain plugs.

1.11 Move the exclusion lever away from

the vaporizer being removed.

Depress the Zero release button and

rotate the vaporizer handwheel to

the maximum concentration setting.

1.12 Set the oxygen flow to 10 L/min. for

at least 20 minutes.

1.13 Turn the vaporizer handwheel to the

Zero position, set the oxygen flow to

minimum, and turn the System

Power switch to STANDBY.

1.14 Locate the vaporizer lock down lever

at the rear of the vaporizer, and turn

the lever 90° counter-clockwise.

NOTE: Earlier units are not configured as

“User Removable” and therefore

require a special wrench (P/N

4114522) to be inserted into the

keyed spline which is covered by a

“DO NOT REMOVE” label. Remove

this label for access to the keyed

spline through the rocker plate at the

rear of the vaporizer, and turn the

tool 90° counter-clockwise. See

Figure 1.

1.15 Verify that the exclusion slider bar is

disengaged from the vaporizer being

removed.

1.16 Hold the vaporizer with two hands

and lift it up until it clears the

mounting block, then bring it

forward to clear the machine.

2.0 Machine Preparation:

2.1 Before installing a vaporizer,

perform a fresh gas leak test at the

fresh gas outlet to verify gas circuit

integrity. Refer to the device service

manual for specific instructions.

2.2 Examine the vapor mount O-rings

and replace them if needed.

¡¡¡¡WARNING: The O-rings supplied with

this vaporizer are incompatible for

use on the Narkomed 6000,

Narkomed GS Euro, Narkomed M,

Fabius GS or the USA manufactured

Fabius. These systems shall use only

O-ring #113 (NITRILE) P/N 4115864.

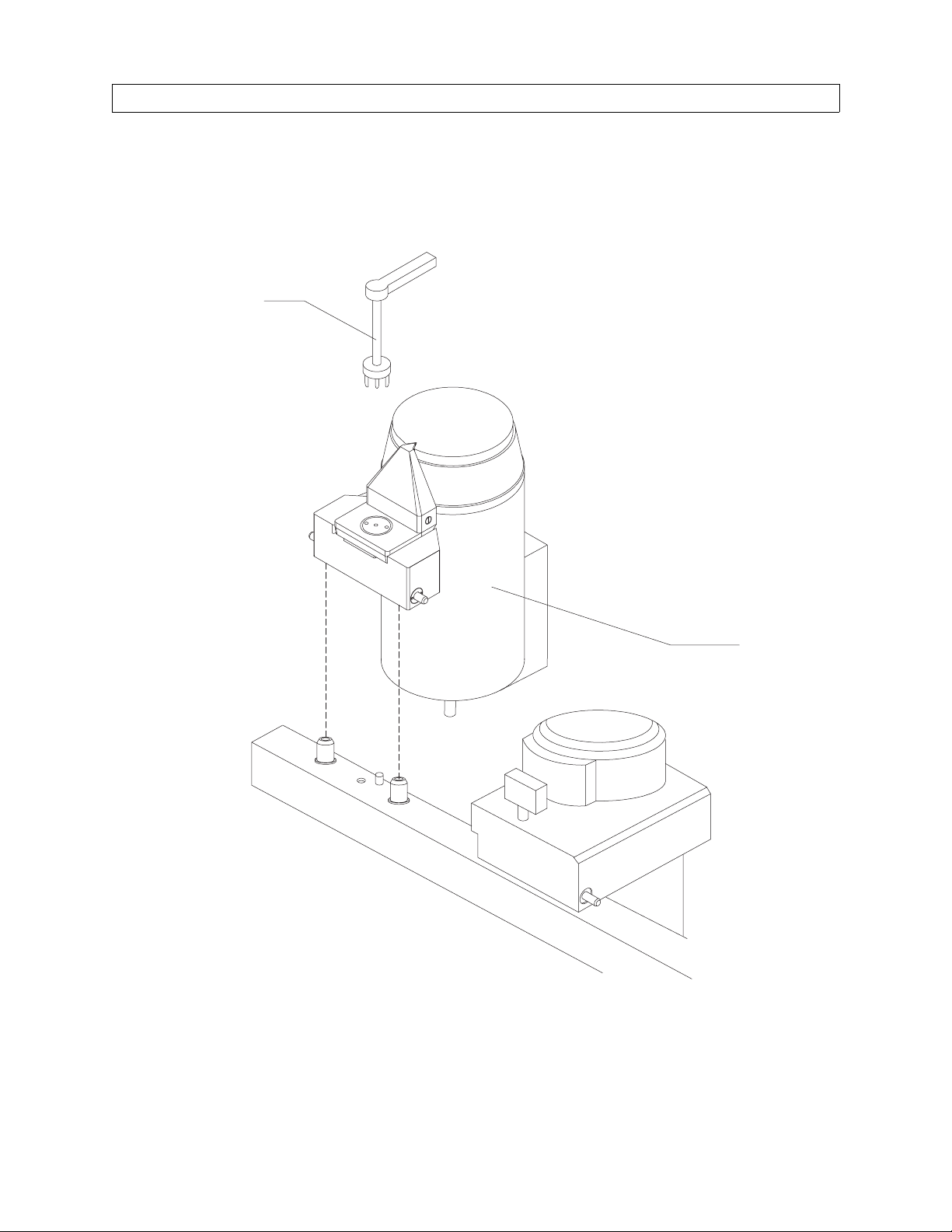

Note: The following two steps apply to

the Narkomed Mobile and Fabius

machines.

2.3 Verify the correct vaporizer support

block is installed on the vaporizer

mount. See Figure 2.

2

Page 5

Installation Procedure (continued)

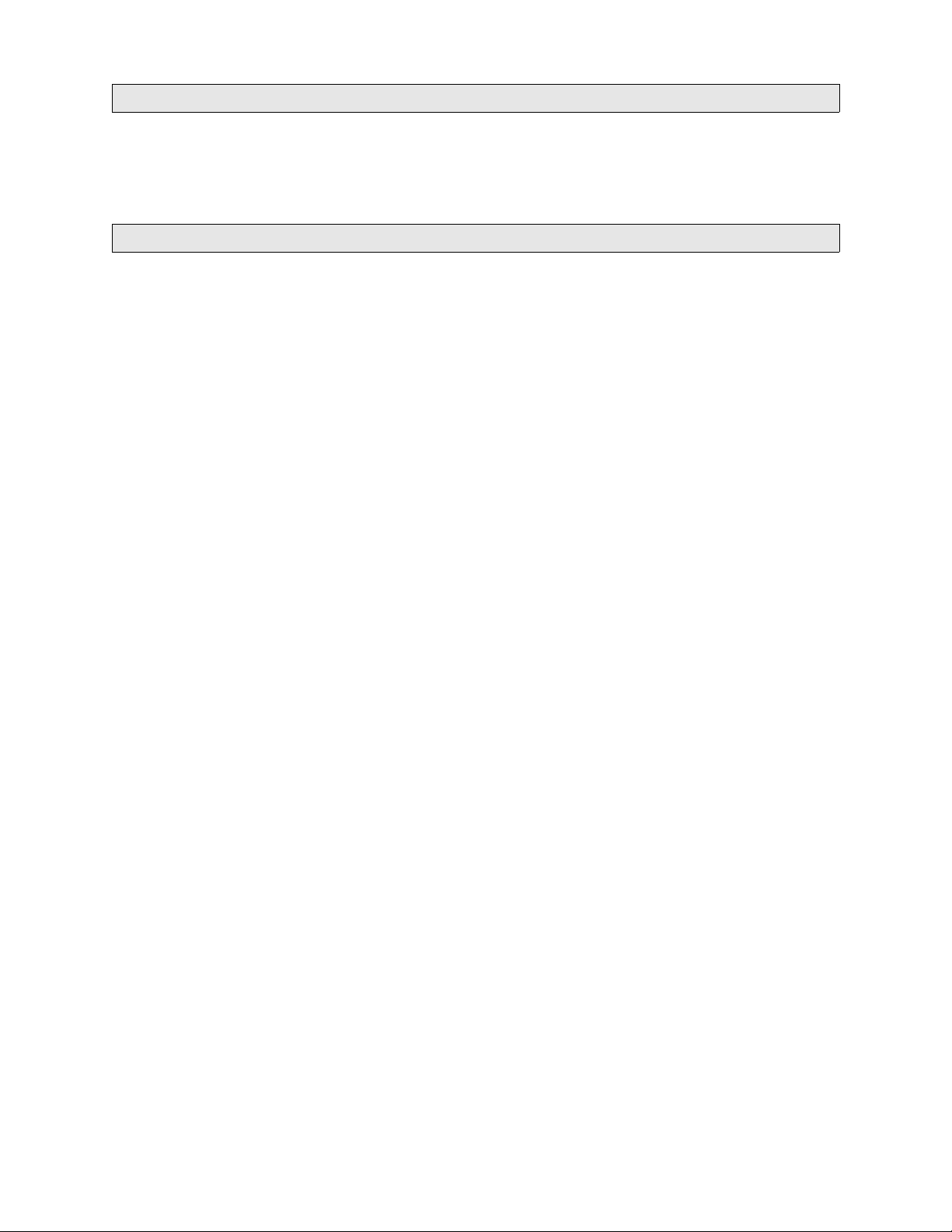

LOCK DOWN TOOL

P/N 4114522

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

FIGURE 1. Vapor 19.3 Vaporizer Installation

VAPOR 19.3

MOUNT

VAPORIZER

SP18901

3

Page 6

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

Installation Procedure (continued)

¡¡¡¡WARNING: Do not install a D-Tec

vaporizer on a Narkomed Mobile or

Fabius without the correct vaporizer

support block as this will result in an

incorrect fit and may cause leaks in the

fresh gas delivery system. Refer to this

procedure to verify correct vaporizer

support block prior to D-Tec vaporizer

mounting.

RETURN TO CD-ROM TABLE OF CONTENTS

2.4 If applicable, remove the original

vaporizer support block and install

the appropriate vaporizer support

block using the original hardware as

shown in Figure 2.

SP18902

INCORRECT

VAPORIZER

SUPPORT BLOCK

CORRECT

VAPORIZER

SUPPORT BLOCK

FIGURE 2. Vaporizer Support Block

(NM Mobile and Fabius only)

VAPORIZER

SUPPORT BLOCK

P/N 4116999

USE EXISTING

SUPPORT BLOCK

HARDWARE (2X)

4

Page 7

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

Installation Procedure (continued)

3.0 Vaporizer Preparation Procedure:

RETURN TO CD-ROM TABLE OF CONTENTS

¡¡¡¡Caution: Use only a Duracell 1604, or

VARTA Energy 2000 9-volt battery in

this vaporizer. If any other battery is

installed, it may damage the

vaporizer.

¡¡¡¡WARNING: The battery terminals

must be firmly clipped onto the

battery to help prevent a possible

disconnection when the vaporizer is

moved.

¡¡¡¡WARNING: When routing the mains

cord to the electrical supply, ensure

that it does not interfere with the

correct functioning of other

equipment.

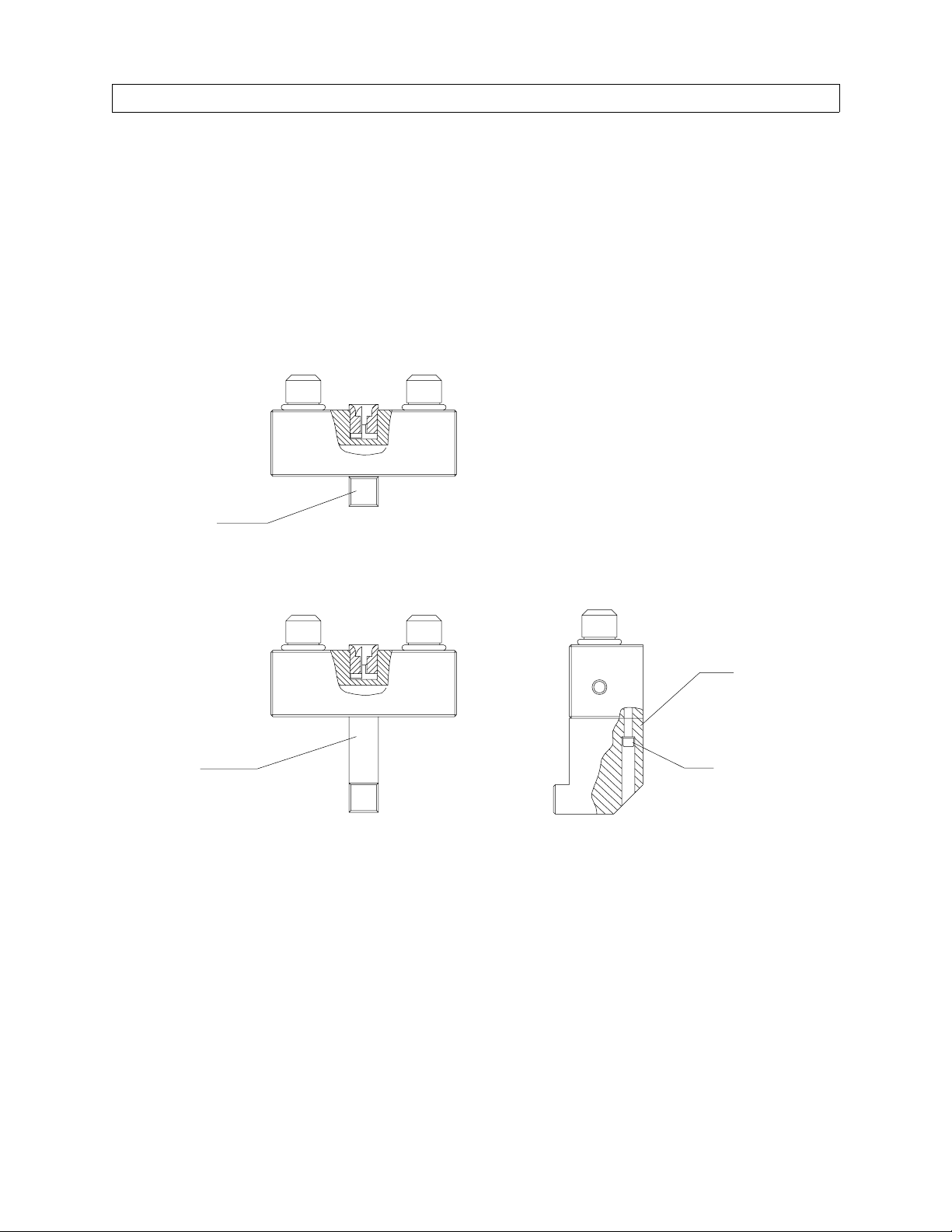

BATTERY COVER

SECURING SCREW

3.1 Invert the vaporizer, unscrew the

battery cover and remove the battery

from the base of the vaporizer as

illustrated in Figure 3.

3.2 Attach the battery terminals firmly

onto the new battery, observing the

correct polarity. Insert the battery

into the vaporizer and tighten the

cover screw.

BATTERY

CONNECTOR

SP18903

FIGURE 3. Vaporizer Battery Installation

VAPORIZER

(INVERTED)

DURACELL 1604

OR VARTA

ENERGY 2000

BATTERY

5

Page 8

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

3.3 Remove the mains lead retaining

plate illustrated in Figure 4. Fit the

power cord to the channel, and then

reinstall the power cord retaining

plate.

SP18904

3.4 Feed the mains lead around the back

of the vaporizer.

MAINS LEAD

MAINS LEAD

CHANNEL

FIGURE 4. Fitting the Mains Lead

MAINS LEAD

RETAINING PLATE

6

Page 9

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

4.0 Vaporizer Installation and Initial

Checks:

¡¡¡¡Caution: Use only the Dräger plug-in

mounting system.

¡¡¡¡WARNING: Do not install a D-Tec

vaporizer in the right hand position of

a Narkomed 6000 as this will result in

an incorrect fit and may cause leaks in

the fresh gas delivery system.

LOCKING LEVER

(SHOWN IN UNLOCKED POSITION)

4.1 Remove the protective plugs from the

vaporizer’s ports.

4.2 Verify that the locking lever is set to

the “unlocked” position. See Figure 5.

With both hands, hold the main body

of the vaporizer in an upright

position and lower it onto the mount,

ensuring that the vaporizer ports

correctly engage the port valves.

MANIFOLD

PORT

SP18905

O-RING

TURN TO LOCK

FIGURE 5. Vaporizer Installation

7

Page 10

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

¡¡¡¡Caution: The vaporizer must be

completely seated horizontally onto

the system manifold ports and

should not require excessive force to

attach.

4.3 Lock the vaporizer onto the manifold

by turning its locking lever 90°

clockwise. See Figure 5.

4.4 Verify that the vaporizer cannot be

lifted off the manifold and is fully

seated on the block.

4.5 Connect the power cord from the

vaporizer to an approved hospital

grade outlet.

¡¡¡¡Caution: Do Not use the convenience

receptacle on the Dräger machine.

4.6 Press the D-Tec Audio Mute key for

at least four seconds and verify that

the alarm and display test is

automatically operated for a period

of approximately two seconds as

follows:

• Each light and all the LCD agent

level indicator bars on the front

display panel flash four times.

• The audio alarm is activated four

times.

4.7 At the end of the test sequence,

verify that the amber LOW AGENT

lamp is illuminated.

5.0 Filling the Vaporizer:

¡¡¡¡WARNING: Do Not fill the vaporizer

with any substance other than

Suprane™ (desflurane). If any

substance other than Suprane™

(desflurane) is used, patient injury

could occur.

¡¡¡¡WARNING: Do Not fill the vaporizer

during testing.

¡¡¡¡WARNING: The vaporizer must only

be filled when it is in an upright

position. Failure to observe this

precaution may result in the

vaporizer being overfilled.

¡¡¡¡WARNING: The vaporizer must only

be filled when it is connected to an

electrical supply. This enables

observation of the agent level on the

display. Do Not attempt to fill the

vaporizer when the level display

indicates that it is full.

5.1 Remove the Suprane™ (desflurane)

bottle cap and ensure that the O-ring

is correctly fitted to the bottle probe.

5.2 Insert the bottle probe into the filler

port on the vaporizer, and push the

bottle firmly against the spring

pressure until it is fully engaged

with the filler port.

4.8 Verify that the ALARM BATTERY

LOW indicator is Not illuminated.

8

Page 11

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

¡¡¡¡WARNING: Ensure that the bottle is

fully engaged into the filler port

before attempting to lift the bottle. If

the bottle can not easily be lifted, do

not force it - otherwise the valve may

be broken.

5.3 When the probe cannot be inserted

any further into the filler port,

attempt to lift the bottle upwards.

ENSURE BOTTLE IS

5.4 If the bottle cannot easily be lifted, it

may be because the bottle has not

been completely inserted. Therefore,

firmly push the bottle straight into

the filler port to its full extent to

make sure that it is fully inserted.

5.5 When the bottle moves easily, lift it

upward to lock the bottle onto the

filler port as illustrated in Figure 6.

FULLY ENGAGED

IN FILLER PORT

SP18906

LIFT BOTTLE

UPWARDS TO FILL

FIGURE 6. Starting Vaporizer Fill

5.6 When the bottle reaches the upper

stop, bubbling of agent will occur for

a period of up to 45 seconds before

the agent flows from the bottle

through the filler port and into the

vaporizer.

5.7 Hold the bottle in position at the

upper stop and continue filling until

the bottle is empty or the indicator

on the front panel shows that the

sump is full.

9

Page 12

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

¡¡¡¡WARNING: Grip the bottle firmly

while rotating it downwards from

the upper stop to the lower stop

position, and hold the bottle firmly in

the filler port until the small amount

of agent in the filler has drained

back into the bottle. Failure to do so

may result in spilled agent.

5.8 Grip the bottle firmly and lower it

from the upper stop position to the

lower stop position as shown in

Figure 7.

5.9 When the bottle reaches the lower

stop position, hold the bottle firmly

in the filler port for a minimum of 5

seconds to allow the small amount of

agent in the filler system to drain

back into the bottle.

5.10 To avoid dropping the bottle, support

the bottle as it is automatically

unlocked from the filler port and

released from the filler.

SP18907

FIGURE 7. Stopping the Fill

10

Page 13

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

6.0 Testing Procedure:

6.1 After a warm-up period of up to 10

minutes, verify that the amber

WARM-UP light extinguishes and

the green OPERATIONAL light

illuminates, indicating the vaporizer

is ready for use.

6.2 Turn off all vaporizers and perform a

low-pressure fresh gas leak test as

described in the relevant anesthesia

machine’s operator’s or service

manual.

6.3 Turn the D-Tec vaporizer to the 1%

setting by fully depressing the

release bar at the rear of the dial,

and then turning the dial. Repeat the

fresh gas leak test.

6.4 Disconnect the vaporizer AC power

cord. Wait for at least 15 seconds and

verify that the red NO OUTPUT

light and audio alarm are activated.

7.1.2 Turn on the safety analyzer and

set the function switch to the

GROUND WIRE RESISTANCE

position. Attach the test lead to

the SINGLE LEAD connector.

7.1.3 Set the safety analyzer GROUND

switch to the NORMAL position.

Set the POLARITY switch to the

OFF position.

7.1.4 The safety analyzer shall indicate

Ω or less when the test lead is

0.1

applied to the cylinder yoke.

7.2 Chassis Leakage Current

7.2.1 Set the safety analyzer to the

CHASSIS LEAKAGE CURRENT

position.

7.2.2 Record the total leakage current

with the polarity and ground

switches set to the following

positions:

¡¡¡¡Caution: Do Not use the convenience

receptacle on the Dräger machine.

7.0 Electrical Safety Testing:

7.1 Protective Ground Continuity

Note: Do not plug the safety analyzer into

a line isolation monitor as inaccurate

readings may occur. To prevent an

alternate path to ground, the

anesthesia’s AC power cord must be

temporarily disconnected.

7.1.1 Plug the D-Tec vaporizer power

cord into the safety analyzer, and

plug the power cord of the safety

analyzer into a 120 VAC

receptacle.

Ground

Polarity

Open Normal

Normal Normal

Open Reversed

Normal Reversed

Verify that the leakage current is

250 microamps or less in each of

the switch positions.

7.2.3 Connect the anesthesia machine’s

AC power cord to a hospital grade

outlet.

7.2.4 Reconnect the vaporizer AC

power cord to a hospital grade

outlet.

11

Page 14

Installation Procedure (continued)

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

8.0 Concentration Verification:

8.1 While depressing the opposite

vaporizer’s “0” release button, verify

that its handwheel can not be

turned.

8.2 Move the exclusion lever to the

opposite position. Verify that the

slider bar disengages the original

vaporizer and engages the D-Tec

without binding. Verify that the DTec vaporizer can not be turned on.

Press the opposite vaporizer’s “0”

release button and verify that its

handwheel can be turned. Return all

vaporizers to “0”.

8.3 Verify that the Riken Gas Indicator

Model 18D bears a current

calibration sticker.

8.4 Zero the Riken as per its operator’s

manual.

8.5 Activate the waste gas scavenger.

8.6 Configure the anesthesia machine’s

gas delivery system to test the

installed vaporizers output

concentration. Refer to the device

service manual for specific

instructions.

8.7 Set the oxygen flow rate to 5.0 L/min.

and verify all other gases are at “0”.

8.8 Verify that the Riken indicates 0.0%

vol. and re-zero if needed.

8.9 Move the exclusion lever to allow

activation of the D-Tec vaporizer.

8.11 Draw a gas sample into the Riken

and read the gas volume % per the

operator’s manual. Record the

reading on the desflurane vaporizer

concentration verification form.

8.12 Verify that the value obtained is

within the sum tolerances of the

Riken and the vaporizer. (Refer to

the desflurane vaporizer

concentration verification form for

High and Low limits.) Place a check

mark in the appropriate Pass/Fail

box on the form.

Note: The D-Tec vaporizer is calibrated by

the manufacturer at an ambient

pressure of 760 mm Hg (sea level).

The partial pressure of the delivered

agent at any selected dial setting

varies directly with changes in

ambient air pressure. Refer to the

operator’s instruction manual for

required dial settings at higher

altitudes.

8.13 Repeat the previous steps at

desflurane vaporizer dial settings of

6%, 10%, 12% and 16%.

Note: The dial release must be depressed

again to obtain the 16% setting.

8.14 Turn the vaporizer to the “0”

position.

8.15 Press the O2 Flush to purge the

system of residual agent. Close the

O2 flow control valve and return all

controls to their original settings.

8.10 Press the dial release bar and rotate

the dial to the 4% setting.

12

Page 15

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DESFLURANE VAPORIZER CONCENTRATION VERIFICATION

Customer _________________________________ AHA # ____________________________

Address _________________________________ Dealer ____________________________

City _____________________________________ State ___________ Zip ______________________

PO # _____________ Machine Serial # _______________ Vaporizer Serial # _____________

Machine Model ____________________________

Dial

Setting

4% 3.28% 4.72%

6% 4.92% 7.08%

10% 8.20% 11.8%

12% 9.84% 14.16%

16% 13.12% 18.88%

Low Lim.

Tol erance

High Lim.

Tol erance

Pass Fail

Comments___________________________________________________________________

_____________________________________________________________________________________

____________________________________________________________________________

Service Representative: I.D. No.: Date:

S010245-

Page 16

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 17

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 18

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DrägerService is a division of

Draeger Medical, Inc.

3122 Commerce Drive

Telford, PA 18969

Tel: (215) 721-5402

(800) 543-5047

Fax: (215) 721- 5784

Web: www.draegermedical.com

Printed in the U.S.A.

Loading...

Loading...