Page 1

North

A

merican

Dräger

RETURN TO CD-ROM TABLE OF CONTENTS

Operator’s Instruction Manual

Part Number: 4112258-018

Rev: C

Date: 30 September 1999

© 1999 N.A.D., Inc.

Narkomed 2C

Anesthesia System

Page 2

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

Narkomed 2C

Operator’s Instruction Manual

Table of Contents

Section 1: Introduction

Operator’s Responsibility for Patient Safety ................................... 1-1

Limitation of Liability ................................................... 1-2

Restriction .......................................................... 1-2

Symbol Definition ..................................................... 1-2

How This Manual Is Organized ........................................... 1-3

Conventions Used in This Manual ......................................... 1-3

General Warnings and Cautions ........................................... 1-3

Section 2: General Description

Overview ........................................................... 2-1

Gas Delivery System ................................................... 2-1

Vaporizers ......................................................... 2-11

Absorber .......................................................... 2-12

Bain Circuit Adapters .................................................. 2-15

Scavenger Systems ................................................... 2-17

AV2+ Ventilator ...................................................... 2-19

Main Switch Panel .................................................... 2-20

Power Supply System ................................................. 2-22

Breathing System Sensor Interface Panel ................................... 2-24

Adjustable Display Arm ................................................ 2-25

Monitoring System .................................................... 2-25

Display Screen ...................................................... 2-26

Control Key Panel .................................................... 2-26

Datagrip ........................................................... 2-27

Datascan Display .................................................... 2-28

Central Alarm Display and Audio Alarm Annunciation .......................... 2-30

Manual Sphygmomanometer ............................................ 2-33

O.R. Data Manager ................................................... 2-33

RETURN TO CD-ROM TABLE OF CONTENTS

Section 3: Daily Checkout

Daily Checkout Procedure ............................................... 3-1

Section 4: Preuse Checkout

Preuse Checkout Procedure ............................................. 4-1

Section 5: Operation

Gas Delivery System

Overview .................................................... 5-1-1

Connecting the Pipeline Gas Supply ................................. 5-1-1

Connecting the Gas Cylinders .....................................5-1-2

Connecting the Fresh Gas Hose .................................... 5-1-4

Adjusting the Gas Flow .......................................... 5-1-4

Using the Oxygen Flush .......................................... 5-1-4

i

Page 4

Narkomed 2C

Operator’s Instruction Manual

Table of Contents

Vaporizer

Overview .................................................... 5-2-1

Filling Systems ................................................ 5-2-1

North American Dräger Exclusion System ............................. 5-2-2

Operating the Vaporizers ......................................... 5-2-3

Filling the Vaporizer ............................................. 5-2-4

Filling the Vaporizer During a Case .................................. 5-2-5

Draining the Vaporizer .......................................... 5-2-11

Absorber System

(Refer to separate manual) ....................................... 5-3-1

Bain Circuit Adapter

(Refer to separate manual) ....................................... 5-4-1

Open Reservoir Scavenger

Overview .................................................... 5-5-1

Connecting the Open Reservoir Scavenger System ...................... 5-5-2

Operating the Open Reservoir Scavenger System ....................... 5-5-3

RETURN TO CD-ROM TABLE OF CONTENTS

Scavenger Interface for Passive Systems

Overview .................................................... 5-6-1

Operating the Scavenger Interface for Passive Systems ................... 5-6-2

Main Switch Panel

Overview .................................................... 5-7-1

System Power Switch ........................................... 5-7-1

Testing the Battery .............................................5-7-2

AV2+ Anesthesia Ventilator

Overview .................................................... 5-8-1

Activating the Ventilator .......................................... 5-8-2

Adjusting the Tidal Volume ........................................ 5-8-4

Setting the Respiratory Frequency .................................. 5-8-4

Setting the Inspiratory/Expiratory (I:E) Phase

Time Ratio ...................................................5-8-5

Setting the Inspiratory Flow Rate ................................... 5-8-5

Setting the Inspiratory Pressure Limit ................................ 5-8-5

Problem Resolution ............................................. 5-8-6

Monitoring System

Overview .................................................... 5-9-1

Power-On Screen .............................................. 5-9-4

Using the Screen Selection Menu ................................... 5-9-5

Invoking the Machine Monitor Screen ................................ 5-9-6

Invoking a System Monitor Screen .................................. 5-9-8

Invoking the CO2System Monitor Screen ............................ 5-9-10

Invoking the NIBP System Monitor Screen ........................... 5-9-11

Invoking the Breathing Pressure System Monitor Screen ................. 5-9-11

Invoking the Respiratory Volume System Monitor Screen ................. 5-9-12

Invoking the Agent System Monitor Screen ........................... 5-9-13

Invoking the Pulse Oximetry System Monitor Screen .................... 5-9-14

ii

Page 5

Narkomed 2C

Operator’s Instruction Manual

Table of Contents

Setting Up the Monitoring System .................................. 5-9-14

Invoking the Templates Subscreen ................................. 5-9-17

Configuring the Monitoring System ................................. 5-9-21

Invoking the System Configure Screen .............................. 5-9-22

Invoking the Auto Log Screen .................................... 5-9-27

Invoking the Serial Ports Screen ................................... 5-9-29

Invoking the Datascan Configure Screen ............................. 5-9-34

Invoking the Preuse Checkout Screen ............................... 5-9-36

Invoking the Data Log Screen .................................... 5-9-38

Invoking the Data Management Screen .............................. 5-9-41

Oxygen Monitoring

Overview ................................................... 5-10-1

Monitor Display ............................................... 5-10-1

Setting Alarm Limits ............................................ 5-10-2

Calibrating the Oxygen Sensor .................................... 5-10-3

Oxygen Alarm Messages ........................................ 5-10-6

Low Oxygen Supply Whistle ...................................... 5-10-7

Problem Resolution ............................................ 5-10-8

RETURN TO CD-ROM TABLE OF CONTENTS

Respiratory Volume Monitoring

Overview ................................................... 5-11-1

Monitor Display ............................................... 5-11-2

Setting Minute Volume Low Limit .................................. 5-11-3

Setting Volume Alarms On/Off .................................... 5-11-4

Setting Minute Volume Trend Scale ................................ 5-11-4

Respiratory Volume Alarm Messages ............................... 5-11-5

Problem Resolution ............................................ 5-11-7

Breathing Pressure Monitoring

Overview ................................................... 5-12-1

Installing the Breathing Pressure Pilot Line ........................... 5-12-1

Choice of Breathing Pressure Monitoring Location ...................... 5-12-2

Monitor Display ............................................... 5-12-4

Setting Pressure High and Threshold Pressure Alarm Limits .............. 5-12-5

Setting Apnea Alarm On/Off ...................................... 5-12-7

Setting Auto-Threshold ......................................... 5-12-7

Setting Pressure Trend Scale ..................................... 5-12-7

Breathing Pressure Alarm Messages ............................... 5-12-8

Problem Resolution ........................................... 5-12-10

Manual Sphygmomanometer

Overview ................................................... 5-13-1

Selecting a Blood Pressure Cuff ................................... 5-13-2

Connecting the Cuff ............................................ 5-13-2

Placing the Cuff ............................................... 5-13-3

O.R. Data Manager

Overview ................................................... 5-14-1

Central Processing Unit with Floppy Disk Drive and Network Interface ....... 5-14-3

Keyboard ................................................... 5-14-3

Display Screen ............................................... 5-14-5

iii

Page 6

Narkomed 2C

Operator’s Instruction Manual

Table of Contents

Handling Floppy Disks .......................................... 5-14-6

General Operation ............................................. 5-14-8

Pop-up Menus ............................................... 5-14-12

Using the O.R. Data Manager ................................... 5-14-17

Starting a Case with a Floppy Disk-Based O.R. Data Manager ............ 5-14-17

Disk Error Messages .......................................... 5-14-27

Starting a case with a Network-Based O.R. Data Manager ............... 5-14-28

Data Recording During the Case ................................. 5-14-34

Ending a Case with the O.R. Data Manager ......................... 5-14-35

Patient Data Screen .......................................... 5-14-38

Pre-Anesthesia Evaluation Screen ................................ 5-14-52

Drug Administration Screen ..................................... 5-14-55

O.R. Event Record Screen ...................................... 5-14-65

QA Indicators ............................................... 5-14-78

Numeric Data Screen ......................................... 5-14-84

Graphic History Screen ....................................... 5-14-101

Printing Anesthesia Records ................................... 5-14-106

System Configuration Screen ................................... 5-14-109

Set Current Templates Sub-screen ............................... 5-14-110

Configuration Options Sub-screen ................................ 5-14-112

Import Site Lists Sub-screen ................................... 5-14-121

Transfer Case Sub-screen ..................................... 5-14-123

Configure Numeric Screen Sub-screen ............................ 5-14-130

Install Default Templates Sub-screen ............................. 5-14-134

Screen Menu Sub-screen ...................................... 5-14-136

Service Functions Sub-screen .................................. 5-14-136

RETURN TO CD-ROM TABLE OF CONTENTS

Section 6: Cleaning and Routine Maintenance

Overview ........................................................... 6-1

Routine Maintenance ................................................... 6-1

Removing Parts for Cleaning and Disinfection ................................ 6-10

Disassembling Parts for Cleaning and Disinfection ............................. 6-13

General Guidelines for Cleaning and Disinfection ............................. 6-15

Reassembly Instructions ............................................... 6-22

Section 7: Specifications

General ............................................................ 7-1

Environmental ........................................................ 7-1

Electrical ........................................................... 7-1

Gas Delivery System ................................................... 7-1

Vaporizers .......................................................... 7-2

Ventilator ........................................................... 7-3

Absorber System ...................................................... 7-3

Oxygen Monitoring .................................................... 7-3

Breathing Pressure Monitoring ............................................ 7-4

Respiratory Volume Monitoring ............................................ 7-4

Serial Interface ....................................................... 7-5

Appendix - Spare and Replacement Parts ........................................ A-1

Index ..................................................................... I-1

iv

Page 7

RETURN TO CD-ROM TABLE OF CONTENTS

Section 1

Introduction

Operator’s

Responsibility for

Patient Safety

North American Dräger anesthesia products are designed to provide the

greatest degree of patient safety that is practically and technologically

feasible. The design of the equipment, the accompanying literature, and

the labeling on the equipment take into consideration that the purchase

and use of the equipment are restricted to trained professionals, and

that certain inherent characteristics of the equipment are known to the

trained operator. Instructions, warnings, and caution statements are

limited, therefore, to the specifics of the North American Dräger design.

This publication excludes references to hazards which are obvious to a

medical professional, to the consequences of product misuse, and to

potentially adverse effects in patients with abnormal conditions. Product

modification or misuse can be dangerous. North American Dräger

disclaims all liability for the consequences of product alterations or

modifications, as well as for the consequences which might result from

the combination of North American Dräger products with products

supplied by other manufacturers if such a combination is not endorsed

by North American Dräger.

The operator of the anesthesia system must recognize that the means of

monitoring and discovering hazardous conditions are specific to the

composition of the system and the various components of the system. It

is the operator, and not the various manufacturers or suppliers of

components, who has control over the final composition and

arrangement of the anesthesia system used in the operating room.

Therefore, the responsibility for choosing the appropriate safety

monitoring devices rests with the operator and user of the equipment.

Patient safety may be achieved through a variety of different means

depending on the institutional procedures, the preference of the

operator, and the application of the system. These means range from

electronic surveillance of equipment performance and patient condition

to simple, direct contact between operator and patient (direct

observation of clinical signs). The responsibility for the selection of the

best level of patient monitoring belongs solely to the equipment operator.

To this extent, the manufacturer, North American Dräger, disclaims

responsibility for the adequacy of the monitoring package selected for

use with the anesthesia system. However, North American Dräger is

available for consultation to discuss monitoring options for different

applications.

1-1

Page 8

Section 1

Introduction

RETURN TO CD-ROM TABLE OF CONTENTS

Limitation of

Liability

North American Dräger’s liability, whether arising from or related to the

manufacture and sale of the products, their installation, demonstration,

sales representation, use, performance, or otherwise, including any

liability based upon North American Dräger’s product warranty, is

subject to and limited to the exclusive terms of North American Dräger’s

limited warranty, whether based upon breach of warranty or any other

cause of action whatsoever, regardless of any fault attributable to North

American Dräger and regardless of the form of action (including, without

limitation, breach of warranty, negligence, strict liability, or otherwise).

North American Dräger shall in no event be liable for any

special, incidental, or consequential damages (including loss of

profits) whether or not foreseeable and even if North American

Dräger has been advised of the possibility of such loss or

damage. North American Dräger disclaims any liability arising

from a combination of its product with products from another

manufacturer if the combination has not been endorsed by North

American Dräger. Buyer understands that the remedies noted in

North American Dräger’s limited warranty are its sole and

exclusive remedies.

Furthermore, buyer acknowledges that the consideration for the

products, equipment, and parts sold reflects the allocation of

risk and the limitations of liability referenced herein.

Restriction

Symbol Definition

Federal law restricts this device to sale by, or on the order of, a

physician.

The following symbols appear on the label on the back of the Narkomed

2C and are defined below.

CAUTION: Refer to accompanying documents before

operating equipment.

ATTENTION: Consulter les documents ci-joints avant de

faire fonctionner l’apparail.

CAUTION: Risk of electric shock, do not remove cover.

Refer servicing to a North American Dräger

qualified technical service representative.

ATTENTION: Risque de choc electrique, ne pas enlever le

couvercle. Ne faire reparer que par un

representant technique autorise de North

American Dräger.

Degree of protection against electric shock: Type B.

Protection contre le risque de choc electrique: Type B.

1-2

Page 9

RETURN TO CD-ROM TABLE OF CONTENTS

Section 1

Introduction

These additional symbols are used on other locations of the Narkomed

2C to provide quick and easy recognition of product functions.

Oxygen Concentration

Breathing Pressure

Breathing Volume

Audible Alarm Disable

How This Manual Is

Organized

Conventions Used

in This Manual

All users of the Narkomed 2C must read this manual completely before

using the machine. In order to make this document more convenient for

future reference, it has been divided into several independent sections.

Section 2 - General Description provides a summary of Narkomed 2C

features and functions.

Section 3 - Daily Checkout contains the checkout procedures that must

done on a daily basis.

Section 4 - Preuse Checkout contains the checkout procedures to be

performed between successive cases.

Section 5 - Operation has detailed instructions on the use and operation

of each functional component of the system.

Section 6 - Routine Maintenance provides cleaning, maintenance, and

replacement procedures.

Section 7 - Specifications contains the specifications for all system

components.

This manual has been set up with several conventions to help organize

the information contained in it. Please read about these conventions

carefully so that you understand their significance in the manual.

Typefaces

Different typefaces are used throughout the manual to differentiate

between narrative information and machine messages and labels.

1-3

Page 10

Section 1

Introduction

RETURN TO CD-ROM TABLE OF CONTENTS

Warnings and

Cautions

General Warnings

and Cautions

All parts of this manual contain warning and caution statements about

the Narkomed 2C.

• Warning statements give important information that, if ignored,

could lead directly to a patient’s injury.

• Caution statements give important information that, if ignored, could

lead directly to equipment damage and, indirectly, to a patient’s

injury.

The following list of warnings and cautions apply to general operation

and maintenance of the Narkomed 2C. Warnings and cautions about

installing and operating specific parts appear with those topics.

WARNING: Any person involved with the setup, operation, or

maintenance of the Narkomed 2C anesthesia system must

be thoroughly familiar with this instruction manual.

WARNING: This anesthesia system will not respond automatically to

certain changes in patient condition, operator error, or

failure of components. The system is designed to be

operated under the constant surveillance and control of a

qualified operator.

WARNING: No third-party components shall be attached to the

anesthesia machine, ventilator, or breathing system

(except for certain approved exceptions). Contact the North

American Dräger technical service department for further

information.

WARNING: When moving the anesthesia machine, remove all monitors

and equipment from the top shelf, remove the absorber

system, and use only the machine handles or push/pull

bars. The anesthesia machine should only be moved by

people who are physically capable of handling its weight.

North American Dräger recommends that two people move

the anesthesia machine to aid in maneuverability. Exercise

special care so that the machine does not tip when moving

up or down inclines, around corners, and across thresholds

(for example, in door frames and elevators). Do not

attempt to pull the machine over any hoses, cords, or other

obstacles on the floor.

1-4

Page 11

RETURN TO CD-ROM TABLE OF CONTENTS

Section 1

Introduction

CAUTION: Although the Narkomed 2C is designed to minimize the

effects of ambient radio-frequency interference, machine

functions may be adversely affected by the operation of

electrosurgical equipment or short wave or microwave

diathermy equipment in the vicinity.

CAUTION: Communications with external equipment may be

temporarily affected by electromagnetic interference due to

the use of electrosurgical equipment.

CAUTION: Do not place sensitive electronic equipment on or adjacent

to the display screen.

CAUTION: Do not place more than 100 pounds on top of the

Narkomed 2C monitor housing.

Recommendations

In the interest of patient safety, North American Dräger strongly

advocates the use of an oxygen analyzer, pressure monitor, and

either a volume monitor or an end-tidal CO

monitor in the breathing

2

circuit at all times.

Because of the sophisticated nature of North American Dräger

anesthesia equipment and its critical importance in the operating

room setting, it is highly recommended that only appropriately

trained and experienced professionals be permitted to service and

maintain this equipment. Please contact North American Dräger’s

Technical Service Department at (800) 543-5047 for service of this

equipment.

North American Dräger also recommends that its anesthesia

equipment be serviced at three-month intervals. Periodic

Manufacturer’s Service Agreements are available for equipment

manufactured by North American Dräger. For further information

concerning these agreements, contact the North American Dräger

Technical Service Department at (800) 543-5047.

1-5

Page 12

RETURN TO CD-ROM TABLE OF CONTENTS

Page 13

A

S

V

S

S

A

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

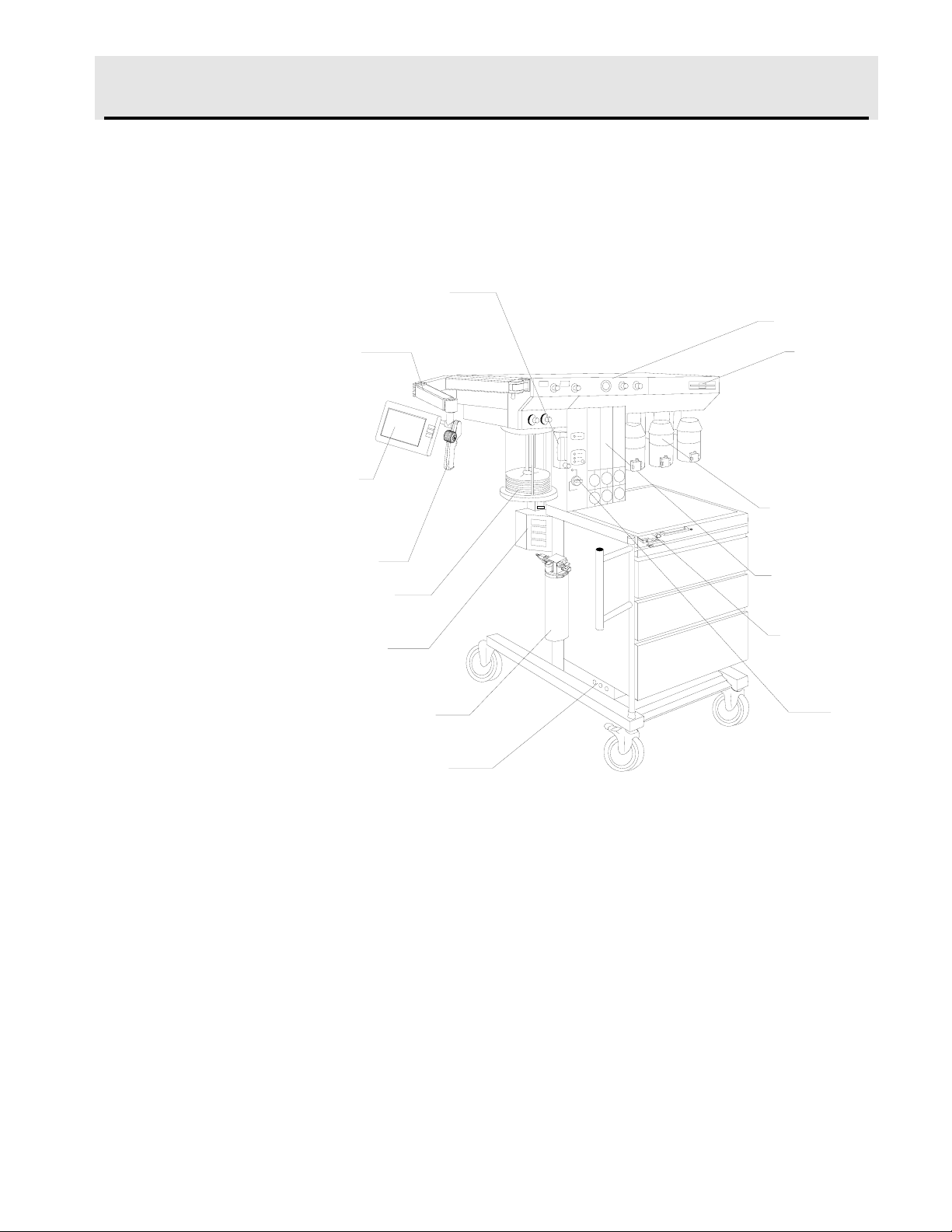

Overview

The Narkomed

®

2C is a continuous flow anesthesia system. All

Narkomed 2C machines are equipped with a monitoring system and

pneumatic circuitry for delivering gases and anesthetic vapor. A front

view of the Narkomed 2C is shown in the figure below.

UXILIARY OXYGEN

FLOWMETER (OPTIONAL)

DISPLAY

RM

DISPLAY

CREEN

DATAGRIP

ENTILATOR

BELLOWS

BREATHING

YSTEM SENSOR

INTERFACE PANEL

OPEN RESERVOIR

CAVENGER

CIRCUIT BREAKERS

VENTILATOR

O.R. DATA

MANAGER

(OPTIONAL)

VAPORIZERS

(OPTIONAL)

FLOWMETER

BANK

FRESH GAS

OUTLET

MAIN

SWITCH

PANEL

OP20999

Gas Delivery

System

The pneumatic system can simultaneously deliver up to four gases and

one anesthetic agent (from a selection of up to three). Oxygen and

nitrous oxide are standard on all Narkomed 2C machines. Optional

gases are air and carbon dioxide. Gas is supplied to the system through

pipelines and cylinders. Connections for oxygen and nitrous oxide are

standard on all machines, and a pipeline connection for air is also

available. Gas cylinder yokes are available for up to two oxygen

cylinders and two nitrous oxide cylinders, plus one additional cylinder

for a third gas.

2-1

Page 14

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

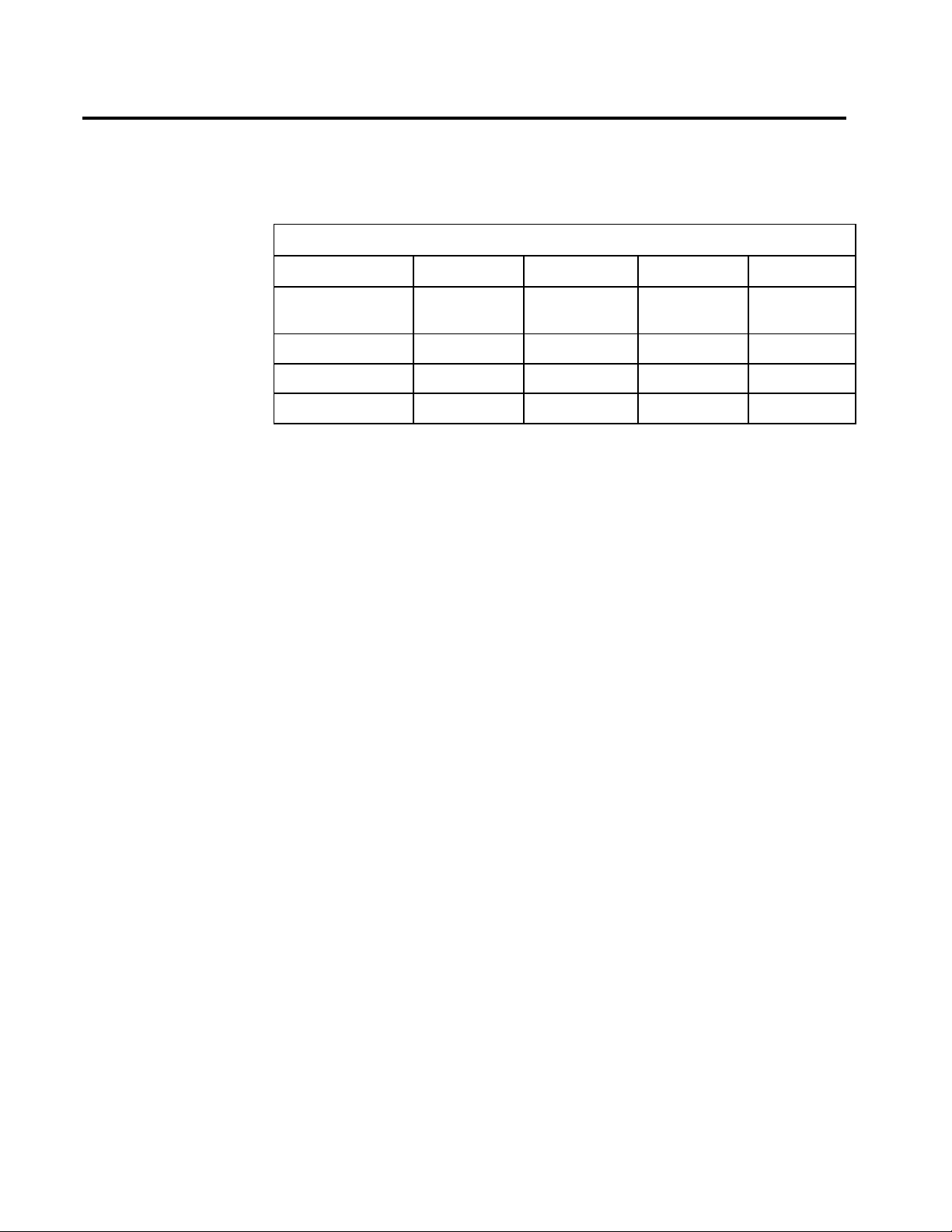

Color Coding

Gas Entry Through a

Pipeline

Each connection, valve, gauge, and flowmeter is labeled and color-coded

for the appropriate gas, as shown in the table below.

GAS SYSTEM COLOR CODING

GAS MARKING USA GERMANY ISO

Air AIR Yellow Yellow Black/White

Checkered

Carbon Dioxide CO

Nitrous Oxide N2O Blue Gray Blue

Oxygen O

2

2

Gray Black Gray

Green Blue White

Gas from the hospital pipelines enters the Narkomed 2C through hoses

connected to indexed pipeline inlets located on the side of the flowmeter

housing. The indexed connector system reduces the risk of delivering the

wrong gas to a patient by preventing incorrect connection of gas pipes.

The inlets include check valves, which prevent backflow leakage into the

atmosphere (when supply hoses are not connected) or into the attached

supply hoses (when reserve cylinders are in use). Each pipeline

connection is equipped with a filter to prevent foreign material from

entering the internal gas piping of the Narkomed 2C. Pipeline gases

should be supplied at 50–55 psi.

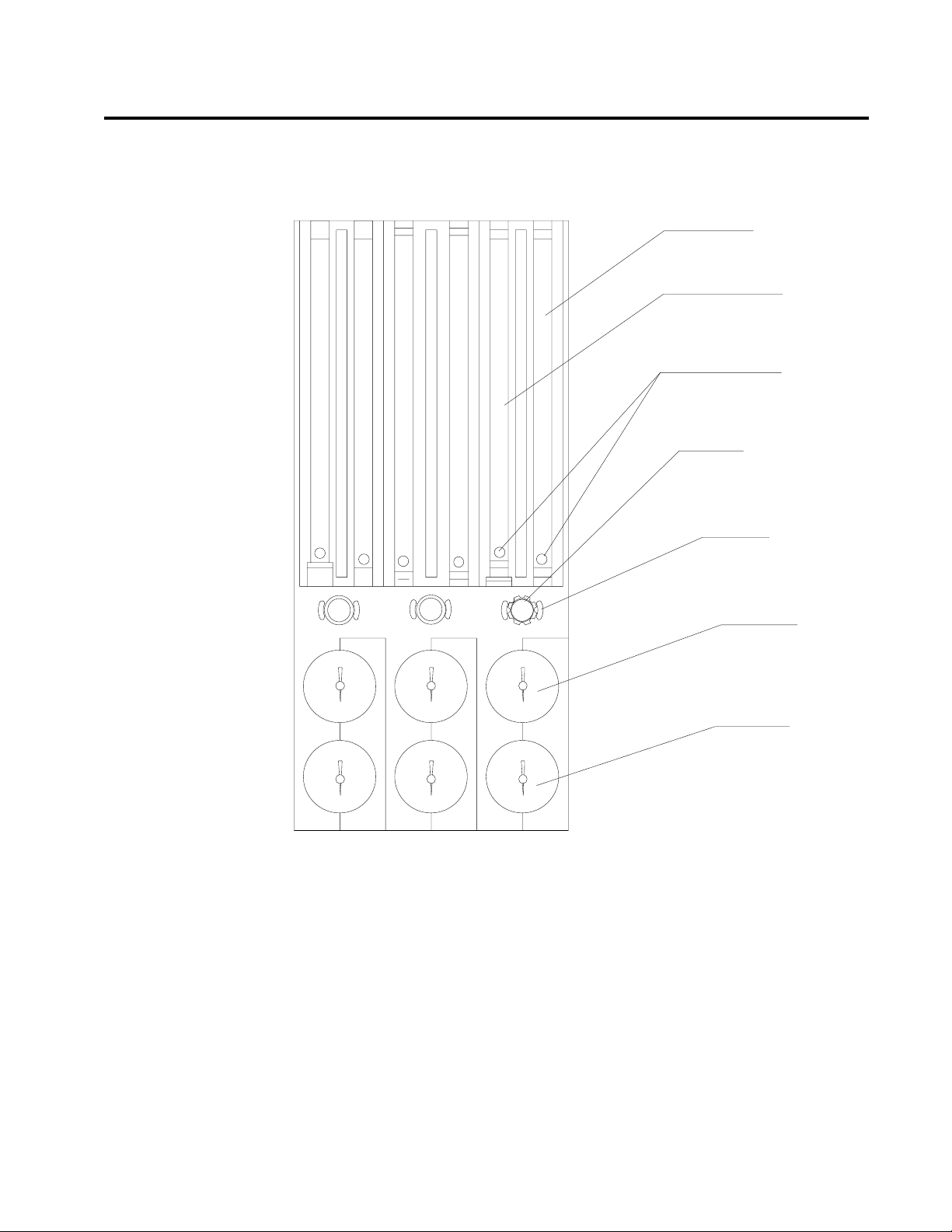

Pipeline Pressure

Gauges

Pipeline pressure gauges for oxygen and nitrous oxide are standard. If

the anesthesia machine is equipped with air, a pipeline pressure gauge

for air is also included. These gauges are located directly below their

corresponding flowmeters and flow control valves. They are labeled and

color-coded for their respective gases on the flowmeter shield. Concentric

scales in psi and kPa indicate the pipeline supply pressure. A typical

pressure gauge and flowmeter arrangement is shown in the following

figure.

2-2

Page 15

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

1000

1000

900

800

700

600

500

400

300

200

100

900

800

700

600

500

400

300

200

100

100

200

300

400

500

600

700

800

900

1000

COARSE FLOW

TUBE (l/min)

FINE FLOW

TUBE (ml/min)

INDICATOR

FLOATS

FLOWMETER

GUARD KNOB

FLOW CONTROL

VALVE

PIPELINE

PRESSURE

GAUGE

CYLINDER

PRESSURE

GAUGE

OP10006

THREE-GAS FLOWMETER

AND PRESSURE GAUGE ASSEMBLY

PIPELINE

CYLINDER

PIPELINE

CYLINDER

AIR O

2

N2O

PIPELINE

CYLINDER

N2O

AIR

O

2

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

When the machine is connected to an active pipeline supply, each gauge

should indicate 50–55 psi. A deviation from within this range indicates

that the pipeline gas supply system is improperly adjusted and may

adversely affect the operation of the Narkomed 2C. For example, a

fluctuating pipeline supply pressure would cause a corresponding

fluctuation of the gas flow delivered from that pipeline. An excessively

low pipeline pressure may activate the corresponding reserve cylinder

and deplete its contents (if the reserve cylinder valve was left in the

open position).

CAUTION: To ensure that gas supplies are at adequate pressure,

pipeline pressure gauges should indicate steady pressures

of 50–55 psi.

2-3

Page 16

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Gas Entry Through

Cylinder Yokes

The Narkomed 2C can be equipped with a maximum of two oxygen and

two nitrous oxide cylinder hanger yokes. An additional yoke for an

optional third gas is also available. To prevent a cylinder from being

improperly connected, the yokes are labeled, color-coded, and keyed for

gas-specific cylinders using the pin-indexed safety system.

A filter within each yoke prevents foreign material from entering the

internal gas piping. A check valve in each yoke prevents leakage into the

atmosphere if the cylinder is not mounted on the yoke. When the

machine is configured with two yokes for the same gas, the check valve

prevents movement of gas from one cylinder to the other. If a cylinder is

not mounted to a yoke, the attached yoke plug should be placed between

the yoke handle’s threaded bolt and the yoke’s gas inlet.

When attaching a cylinder, make sure that only one washer is installed

between the cylinder and the yoke gas inlet. Using multiple washers

may compromise the pin-indexed safety system. Be sure to verify the

integrity of both index pins whenever you install a new cylinder.

WARNING: Check cylinder yokes for the presence of two index pins

each time you attach a cylinder to the machine. Use only

one cylinder gasket per yoke. Using more than one gasket

could cause leakage of the cylinder gas and compromise

the pin-indexed safety system.

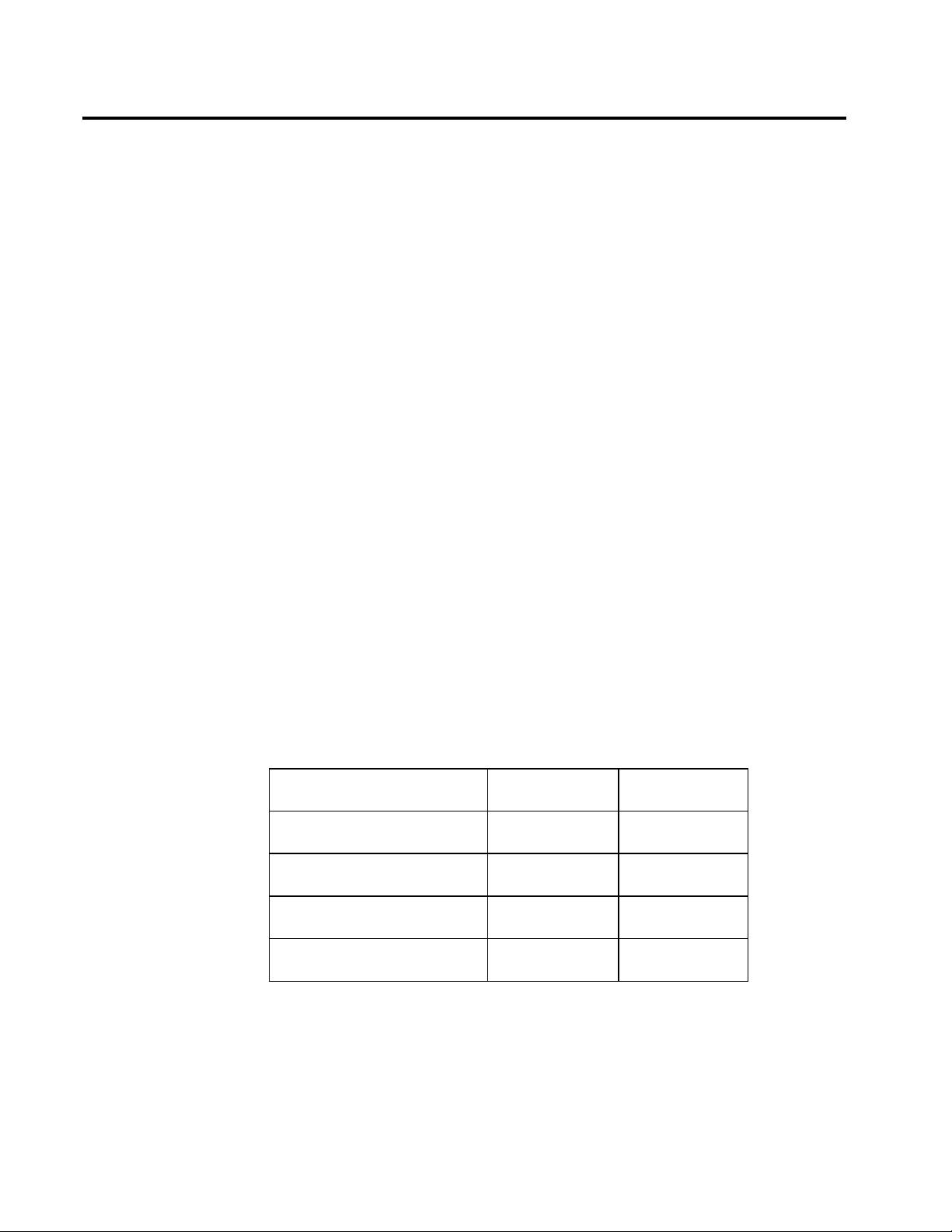

Cylinders attached to the hanger yokes must contain gas at the

recommended pressures outlined in the following table. Replace any

cylinders with less than the recommended pressure (psi-min) with full

cylinders.

GAS PSI - FULL* PSI - MIN*

Air 1900 1000

Carbon Dioxide 838 600

Nitrous Oxide 745 600

Oxygen 1900 1000

*Indicated pressures are for E-size cylinders at 70° F (21° C).

2-4

Page 17

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Cylinder Pressure

Gauges

Oxygen Supply

Pressure Failure

Protection Device

(OFPD)

Each cylinder gas circuit has a cylinder pressure gauge, located at the

bottom of the flowmeter panel on the front of the machine (see the

Flowmeter and Pressure Gauge Assembly figure earlier in this section.)

Each gauge is labeled and color-coded on the flowmeter housing for its

respective gas. When a cylinder’s valve is open, its pressure gauge

indicates the gas pressure in the cylinder. The dial is marked with

concentric scales for psi and kPa. If two reserve cylinders of the same

gas are open at the same time, the gauge indicates the pressure in the

cylinder having the higher pressure.

For nonliquefied gases (oxygen, air), the indicated pressure is

proportional to the gas content of the cylinder. For liquefied gases

(nitrous oxide, carbon dioxide), the gauge indicates the vapor pressure of

the liquefied gas in the cylinder. This pressure remains constant until

all of the liquid in the cylinder has vaporized. When the liquid has

vaporized, the cylinder pressure decreases proportionally as gas is

removed from the cylinder.

The oxygen failure protection device (OFPD) is a pneumatically operated

valve that protects the patient in the event of partial or complete oxygen

pressure loss. All gas circuits, except the oxygen circuit, are controlled by

these valves. OFPD-controlled valves respond to the gas pressure in the

oxygen supply line. When oxygen pressure is adequate, the valves open

for unrestricted gas flow. When oxygen pressure is reduced or lost, the

valves to close proportionally to the loss. Controlled gases are restricted

or shut down without affecting the oxygen flow.

Gas flow reductions are indicated on the flowmeters. When oxygen

supply pressure drops below about 37 psi, an oxygen supply pressure

alarm is activated, resulting in the following:

• The Caution message O2 SUPPLY LOW appears on the central

alarm display.

• The red O

SUPPLY PRESSURE indicator on the main switch

2

panel lights.

• An intermittent audible alarm sounds.

• A 7-second whistle may sound, depending on the machine’s

configuration.

NOTE: When one source of oxygen pressure (either pipeline or

reserve cylinders) fails, but the other source maintains proper

supply pressure in the oxygen supply lines, the oxygen supply

pressure alarms are not activated.

2-5

Page 18

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Flowmeters

Low-Flow Flowmeters

(Optional)

Minimum Oxygen

Flow

Flow Control Valves

Flowmeters, located directly above their corresponding flow control

valves, indicate the delivered flow rate of each gas in the fresh gas

mixture. Dual flowmeter tubes (fine and coarse) are used in tandem for

oxygen, nitrous oxide, and air (if provided). When other gases are

supplied, single flowmeter tubes are used. All flowmeters are color-coded

and labeled at the lower end of the flowtube. A typical flowmeter

arrangement is shown in the Flowmeter and Pressure Gauge Assembly

figure earlier in this section.

Each flowmeter has a float indicator. To determine the flow rate, read

the flowmeter scale at the center of the float.

For low-flow anesthesia, the Narkomed 2C can be configured with lowflow, dual-tube flowmeters for oxygen and nitrous oxide. These

flowmeters function the same way as the standard dual-tube flowmeters,

but they are calibrated to provide greater resolution for low-flow

anesthesia.

The oxygen dispensing system incorporates a calibrated bypass flow of

150 ±50 ml/min (at 50 psi pipeline pressure), which delivers this volume

of oxygen even if the oxygen flow control valve is fully closed.

A needle valve is located below the fine flowmeter tube for each gas.

This valve is used to adjust the flow of gas. Turning the valve knob

counterclockwise increases flow. Turning the knob clockwise decreases

flow. A zero-stop prevents damage to the flow control valve seats. If

necessary, a North American Dräger qualified technical service

representative can readjust the stop.

2-6

Each flow control knob is identified by its color code and chemical

symbol. The oxygen flow control valve is also touch-coded with a deeply

fluted knob.

CAUTION: The flow of oxygen cannot be completely shut off (see

“Minimum Oxygen Flow” earlier in this section). Do not

force the oxygen flow control knob in an effort to shut off

the minimum flow. Forcing the knob can damage the valve

seat.

Page 19

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Oxygen Flush

Oxygen Ratio

Controller (ORC)

A manually operated, self-closing oxygen flush valve is located on the

front of the machine. A bezel is mounted around the pushbutton to

prevent accidental engagement. When the valve is actuated, it delivers

an unmetered oxygen flow of approximately 55 l/min directly to the

Narkomed 2C’s fresh gas common outlet. The SYSTEM POWER switch

does not have to be in the ON position to use the oxygen flush.

The ORC is a pneumatic oxygen/nitrous oxide interlock system designed

to maintain a fresh gas oxygen concentration of 25 ±4% and independent

control of the oxygen and nitrous oxide flows.

The ORC works by proportionally limiting the nitrous oxide flow

whenever the selected oxygen and nitrous oxide flow control valve

settings would otherwise result in a hypoxic fresh gas mixture. For

example, if you open the nitrous oxide flow control valve excessively

without making a corresponding increase in the oxygen flow control

valve setting, the flow of nitrous oxide will not increase even though its

flow control valve setting has been greatly increased. Similarly, if you

decrease the oxygen flow without also decreasing the nitrous oxide flow,

the nitrous oxide flow will automatically drop in proportion to the

oxygen flow.

WARNING: In circle systems, the gas mixture in the patient circuit is

not necessarily the same as that in the fresh gas flow. This

is particularly true at low fresh gas flow rates when the

patient rebreathes a significant portion of previously

exhaled gases. It is important that the gas mixture in the

patient circuit be monitored and that the fresh gas flow is

adjusted to meet the requirements of the patient as well as

to compensate for patient uptake, any system leakage, or

any gas withdrawn through sample lines and not returned.

WARNING: The ORC interlocks only the flows of oxygen and nitrous

oxide. Hypoxic fresh gas concentrations are possible if

carbon dioxide is used as an additional gas.

2-7

Page 20

Section 2

(

)

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Fresh Gas Outlet

The fresh gas outlet delivers the fresh gas mixture (consisting of oxygen,

nitrous oxide, optional gases, and vapors of a liquid anesthetic) to the

patient breathing system. It is located on the front of the anesthesia

machine.

The outlet’s 15 mm cylindrical female fitting is designed to accept a

15 mm male fitting on the absorber fresh gas hose. The male fitting

slides into a retaining slot in the spring-loaded safety locking bar to

prevent inadvertent disconnection of the fresh gas hose. The 15 mm

male fitting on the fresh gas hose is unique to North American Dräger

design, and should not be replaced by a hose from any other

manufacturer.

TABLETOP

FRESH GAS

OUTLET

O2 FLUSH

CONTROL

FRESH

GAS

HOSE

OP10011

RELEASE TO

L

K

HANDLE

FRESH GAS

LOCKING BAR

EXTENDED POSITION

2-8

Page 21

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Fresh Gas Outlet

(Canada)

The fresh gas outlet delivers the fresh gas mixture (consisting of oxygen,

nitrous oxide, optional gases, and vapors of a liquid anesthetic) to the

patient breathing system. It is located on the front of the anesthesia

machine.

The outlet has a dual fitting for using gas hoses with these fittings:

• a 15 mm male fresh gas hose fitting, such as those supplied with

North American Dräger absorbers and Bain circuit adapters.

When using a 15 mm fitting, place the spring-loaded locking bar

over the male fitting to secure it to the female fitting.

• a 22 mm female fitting with a load-bearing threaded mount, such

as the ones for Magill circuits or ISO-type nonrebreathing

adapters. When using an ISO-type nonrebreathing adapter,

swing the spring-loaded locking bar to the side to gain access to

the threaded load-bearing fitting.

TABLETOP

O2 FLUSH CONTROL

FRESH GAS

HOSE

RELEASE TO

LOCK

HANDLE

FRESH GAS

LOCKING BAR

OP10012

2-9

Page 22

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Fresh Gas Oxygen

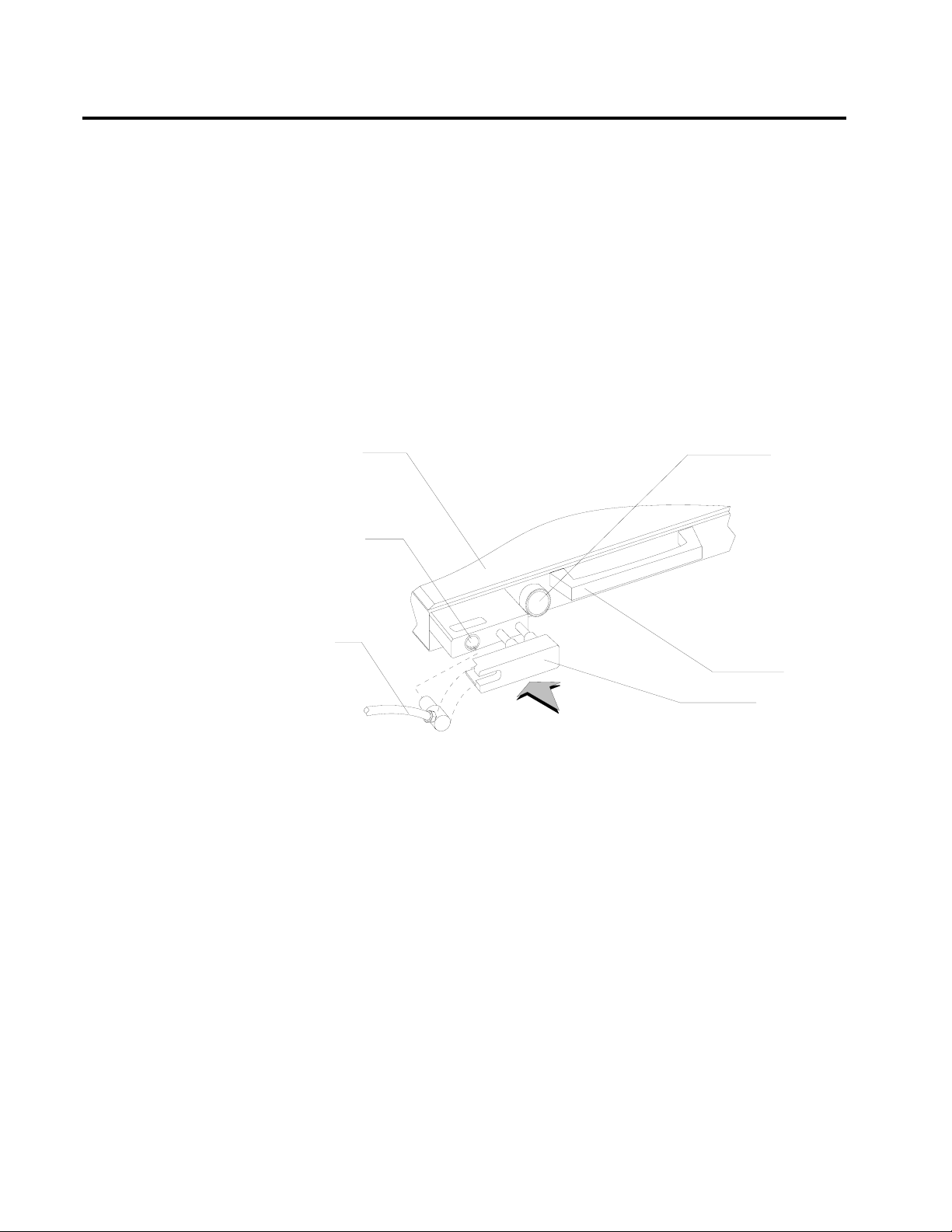

Sensor Adapter

The optional fresh gas adapter allows the Narkomed 2C to monitor the

fresh gas oxygen concentration when using a nonrebreathing circuit

(other than a Bain circuit). The fresh gas adapter fits securely into the

fresh gas outlet of the anesthesia machine. It has a port for an oxygen

analyzer sensor and a fitting for a nonrebreathing circuit.

FRESH GAS

OUTLET

OXYGEN

SENSOR

FRESH GAS

LOCKING BAR

(EXTENDED POSITION)

15MM MALE

FITTING

ADAPTER

STEM

OXYGEN

SENSOR PLUG

OP20997

FRESH G A S HOSE

BARBED FITTING FOR

NON-REBREATHING

GAS CIRCUIT

OXYGEN SENSOR PORT

WARNING: The fresh gas oxygen sensor adapter measures the fresh

gas oxygen concentration, not the inspiratory oxygen

concentration. Depending on the fresh gas flow and the

respiratory minute volume, the inspiratory oxygen

concentration may be lower than fresh gas oxygen

concentration due to rebreathing of previously exhaled

gases.

2-10

Page 23

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Auxiliary Oxygen

Flowmeter (Optional)

Vaporizers

Exclusion System

Filling Systems

For the delivery of a metered flow of pure oxygen (for example, delivery

of oxygen through a nasal cannula), an optional auxiliary oxygen

flowmeter can be mounted on the left side of the flowmeter bank. This

flowmeter can be used when the machine is turned off. A zero-stop

prevents damage to the flow control valve seat.

The Narkomed 2C can be equipped with up to three Vapor 19.1

vaporizers for administering liquid anesthetics.

A cam and lever interlock system, incorporated into the vaporizer bank,

prevents more than one vaporizer from being activated at a time. The

interlock system requires all unused vaporizers to be locked in their

zero-volume percent positions.

WARNING: Only one vaporizer can be activated at a time. If the

exclusion system permits simultaneous activation of more

than one vaporizer, do not use the anesthesia machine.

Contact a North American Dräger qualified technical

service representative for adjustment.

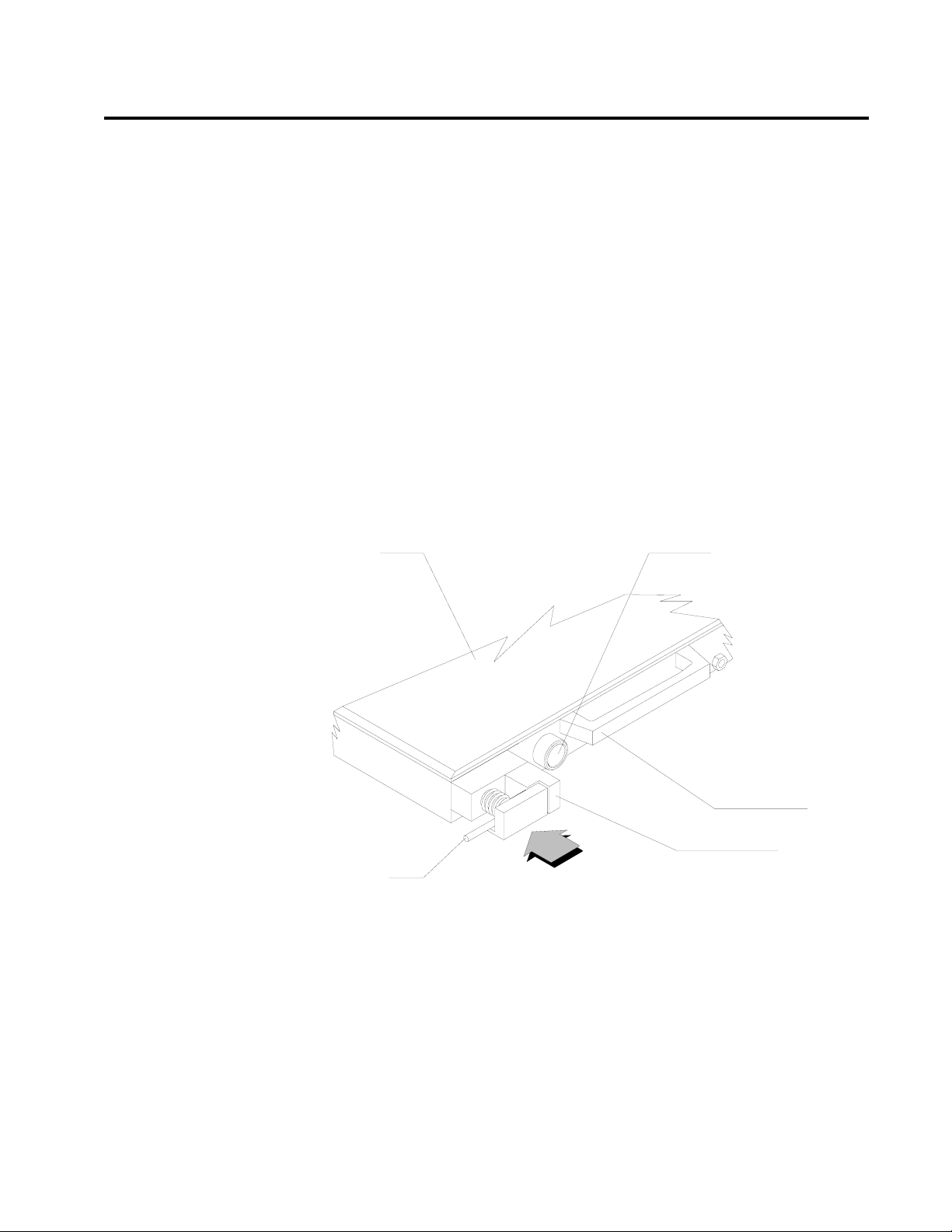

Two filling systems are available for the Vapor 19.1 vaporizer the open

funnel system and the key-indexed safety system.

OPEN FUNNEL FILLER

OP10603

KEY INDEXED

SAFETY SYSTEM

2-11

Page 24

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

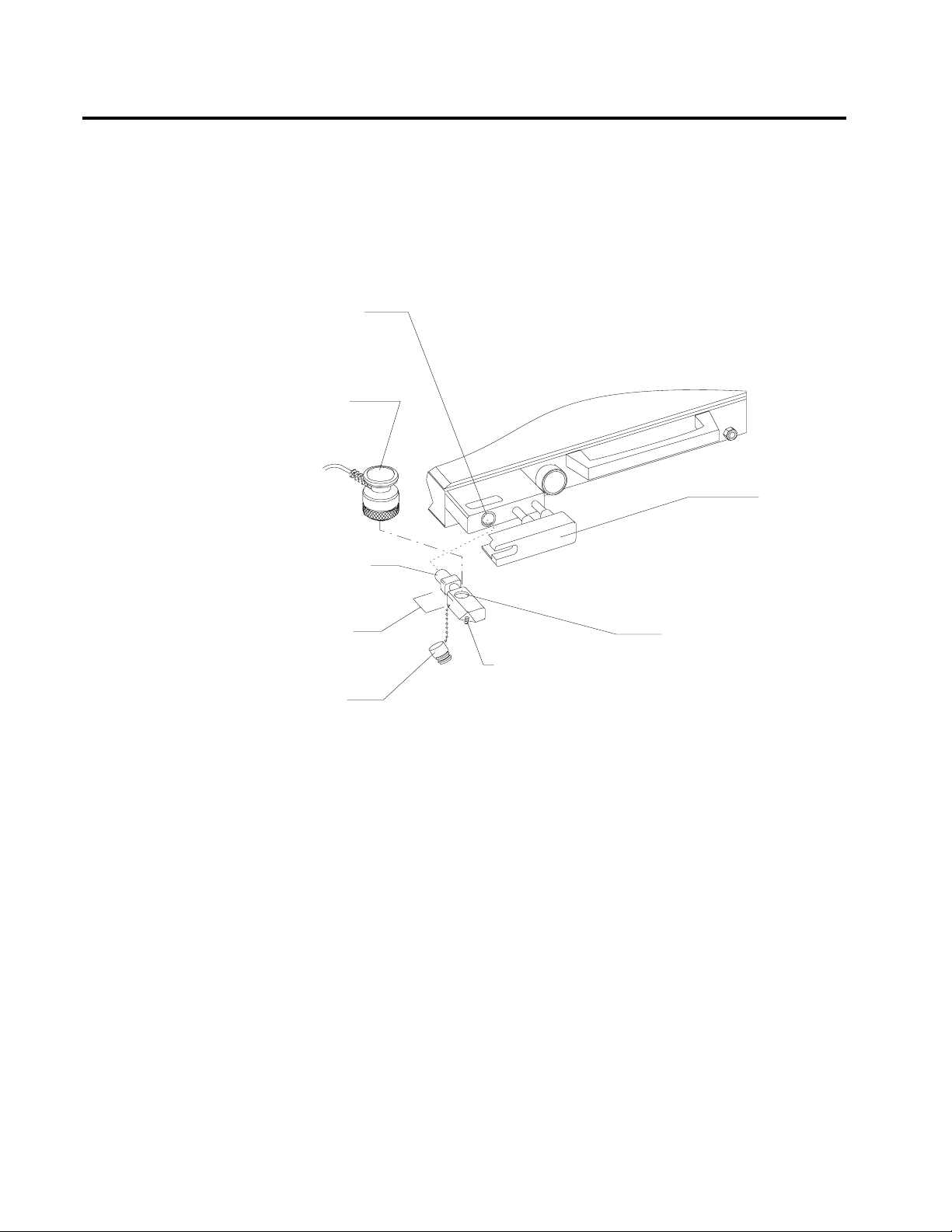

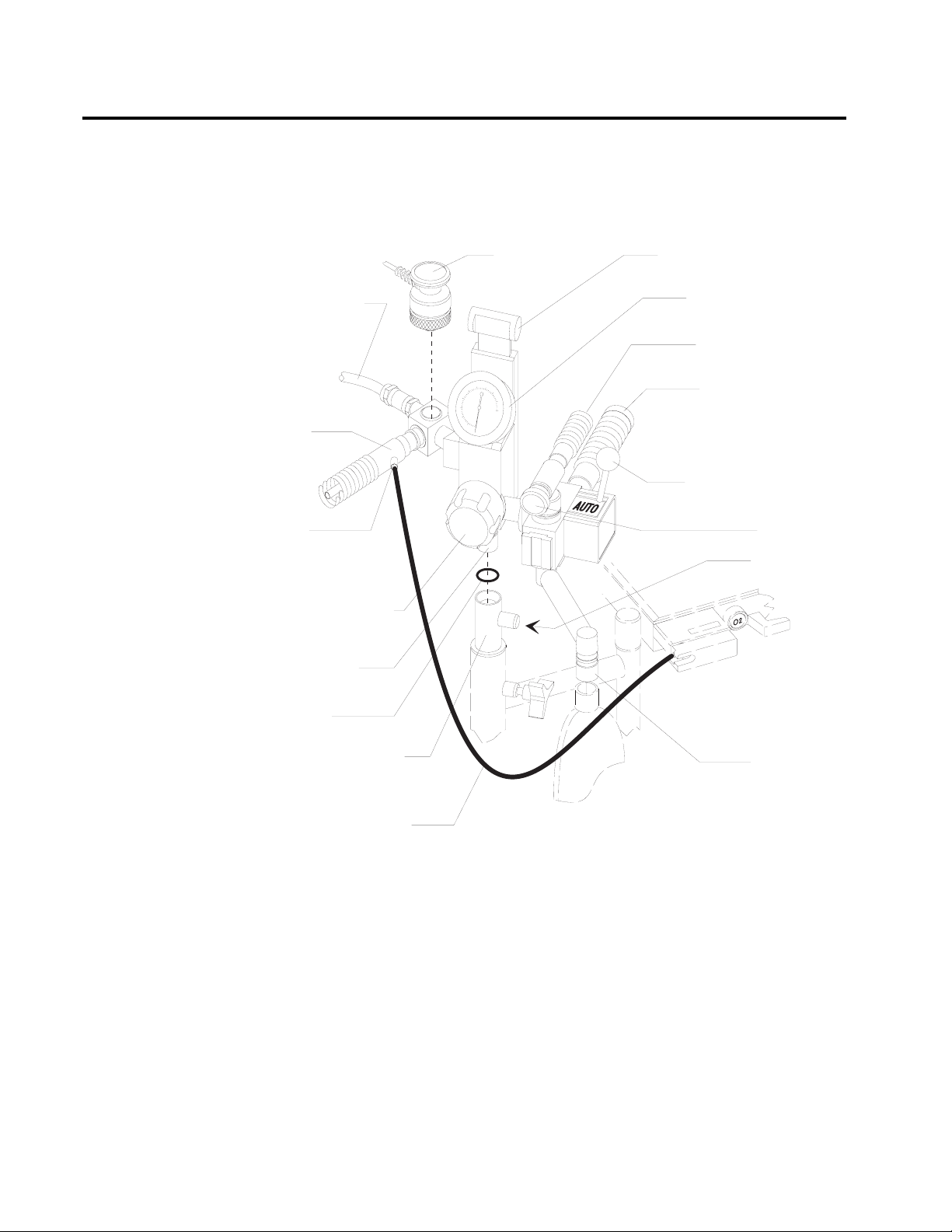

Absorber

The absorber is a dual-canister system for absorbing exhaled carbon

dioxide in the rebreathing circuit of the anesthesia machine. It has an

adjustable pressure limiter (APL) valve, a breathing system pressure

gauge, a fresh gas line, and connections for sensing breathing pressure,

respiratory volume, frequency, and oxygen concentration.

OXYG EN SENSO R

INSPIRATORY

VALVE

RESPIRATORY VOLUM E SENSOR

(ULTRASONIC FLOW SENSO R)

EXPIRATORY VALVE

PEEP BYPASS

CONTROL

APL VALVE

PEEP VALVE

(O P T IO N A L )

ABSORBENT

CANISTER

FRESH G AS

HOSE

DUST CUP

O P 98103A

MANUAL/

AUTOM ATIC

SELECTOR

VALVE

BREATHING

SYSTEM

PRESSURE

GAUGE

BREATHING

BAG M OUNT

CANISTER RELEASE LEVER

2-12

Page 25

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

The absorber system permits spontaneous, manually assisted, or

automatic ventilation of the patient. The absorber incorporates a

manual/automatic selector valve, which allows you to select either

manual or automatic ventilation. An absorber with a positive endexpiratory pressure (PEEP) valve is also available.

WARNING: Waste gas scavenging systems used with North American

Dräger absorber systems must have safety features to

ensure that excessive subatmospheric pressure (lower than

-0.5 cmH

+0.5 cmH

O) and excessive positive pressure (higher than

2

O) are not possible at the connection point.

2

Inspiratory and

Expiratory Valves

The inspiratory and expiratory valves control the direction of gas flow in

the absorber system. The inspiratory valve is labeled INSPIRATION and

the expiratory valve is labeled EXPIRATION.

The valves are unidirectional, permitting gas flow in one direction only:

• The inspiratory valve allows gas to flow toward the patient only,

with no backflow to the absorber.

• The expiratory valve allows gas to flow into the absorber only,

with no backflow to the patient.

The valves are not interchangeable. They must be connected to the

correct mounts for proper flow direction through the absorber system.

Different size mounting threads on each valve prevent connecting a

valve to the wrong mount.

WARNING: Do not use the inspiratory or expiratory valves if:

• the pins in the plastic valve domes or in the valve

bodies are bent, damaged, or missing,

• valve disks are missing or damaged,

• valve seat is damaged.

2-13

Page 26

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Canisters

Dust Cup

Breathing System

Pressure Gauge

Each absorber unit has two transparent plastic canisters that house the

absorbent. The absorbent soda lime or barium hydroxide lime can be

purchased in either loose granular or prepacked cartridge form. The

canisters are interchangeable.

A removable, transparent plastic cup below the bottom assembly collects

absorbent dust and excess moisture that could cause increased flow

resistance in the system.

The absorber system is equipped with a pressure gauge for quick visual

checks of breathing circuit pressure. The gauge is marked for

measurements from -20 to +80 cmH

O in increments of 2 cmH2O.

2

WARNING: You must frequently observe the breathing system

pressure gauge to ensure adequate pressure buildup and

relief, regardless of the mode of operation.

2-14

Page 27

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Bain Circuit

Adapters

Absorber Mount

Two types of Bain circuit adapters are available. One mounts to the

absorber. The other mounts to the absorber pole.

The absorber-mounted Bain circuit adapter mounts on the

manual/automatic selector valve of the absorber system. The adapter has

an adjustable pressure limiter (APL) valve, a breathing pressure gauge,

a quick-connect fitting for the breathing pressure pilot line, a port for

the oxygen sensor, a 15/22 mm port for nonrebreathing circuits, and a

connector for the breathing bag.

APL VALVE

CONTROL KNOB

OXYG EN

SENSO R

22M M

M/15MM F

EXPIRATIO N

TER M IN A L

BREATHING PRESSURE

PILO T LIN E

Q U IC K -C O N N E C T F IT T IN G

BAIN

CIRCUIT

BAIN CIRCUIT

HO SE BARB FOR

FRESH G AS HO SE

BREATHING

BAG

FRESH G AS

HOSE

O P 21036

BREATHING

PRESSURE G AUG E

MANUAL/AUTOM ATIC

SELECTOR VALVE

OXYG EN SENSO R

PORT CAP

2-15

Page 28

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

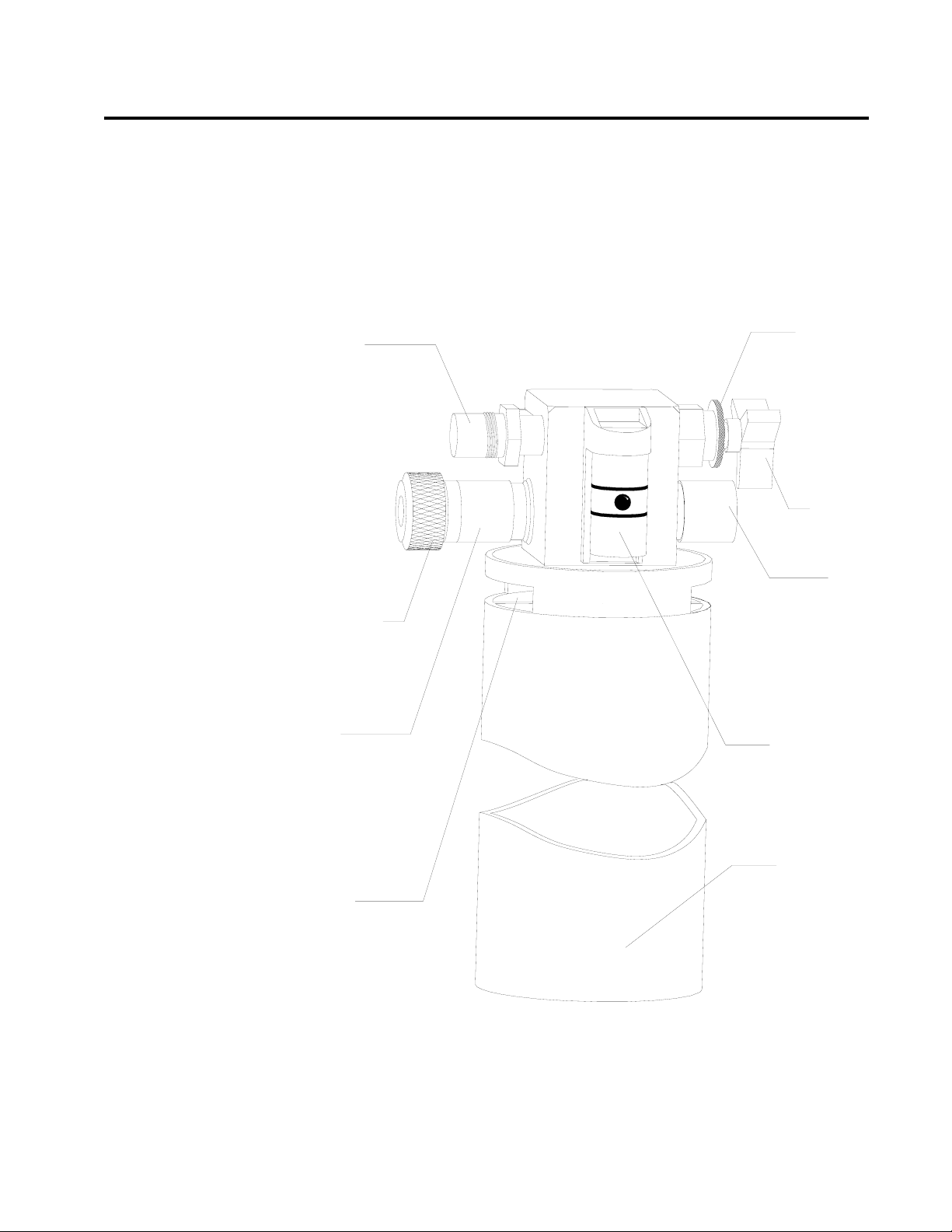

Pole Mount

The pole-mounted Bain circuit adapter mounts on the absorber pole. A

positive end-expiratory pressure (PEEP) valve is optional.

OXYG EN

SENSO R

BREATHING

PRESSURE

PILO T LIN E

BAIN

CIRCUIT

BAIN

CIRCUIT HOSE

BARB FOR FRESH

GAS HO SE

PEEP CO NTROL

KNO B (OPTIONAL)

PEEP BYPASS CO NTRO L

(O P T IO N A L )

BREATHING SYSTEM

PRESSURE G AUG E

19 MM SCAVENG ER

HOSE

22M M VENTILATO R

HO SE

MANUAL/AUTOMATIC

SELECTOR VALVE

APL VALVE

SET SCREW

MOUNTING

STUD

O-RING

ABSORBER POLE

FRESH G AS HOSE

BREATHING

BAG M OUNT

O P 00200

2-16

Page 29

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

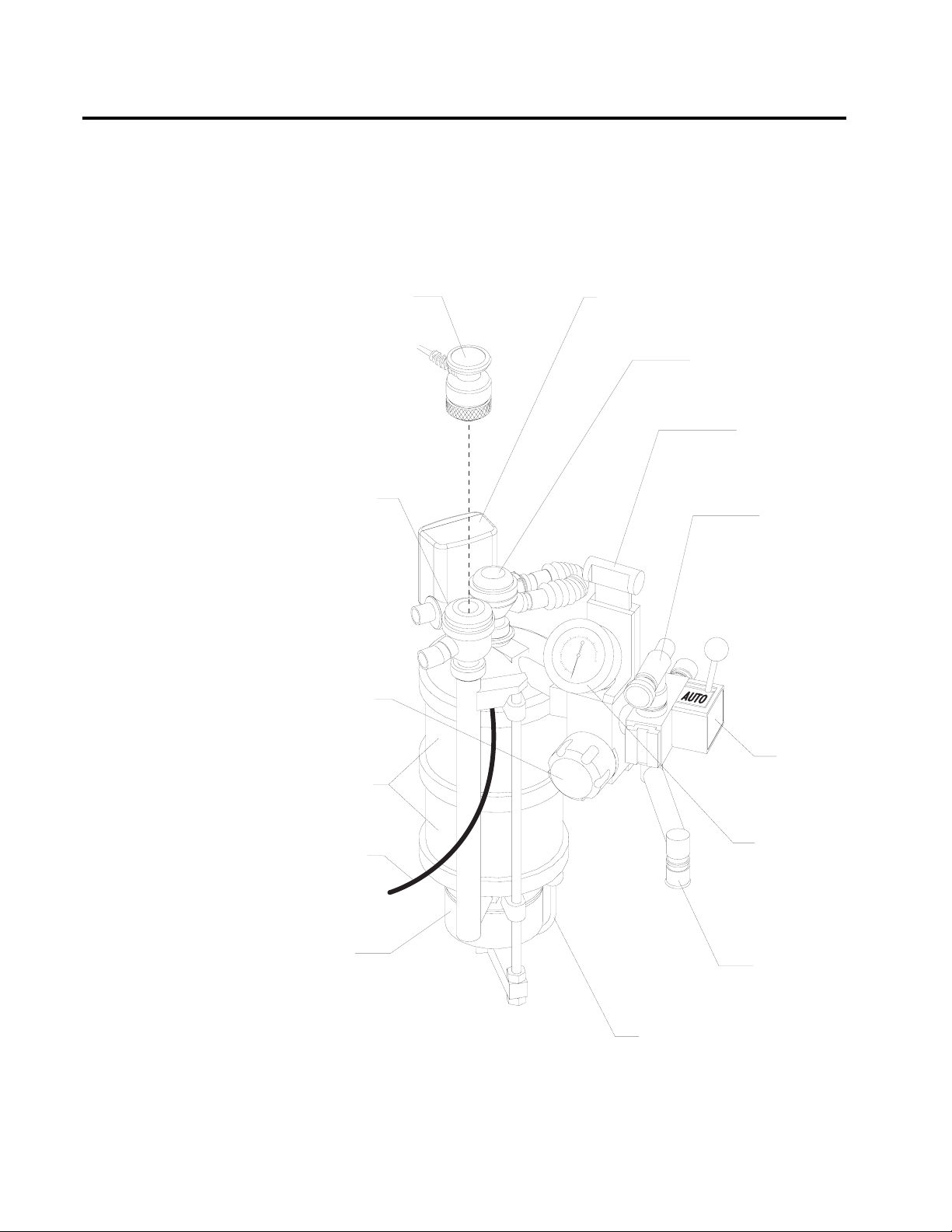

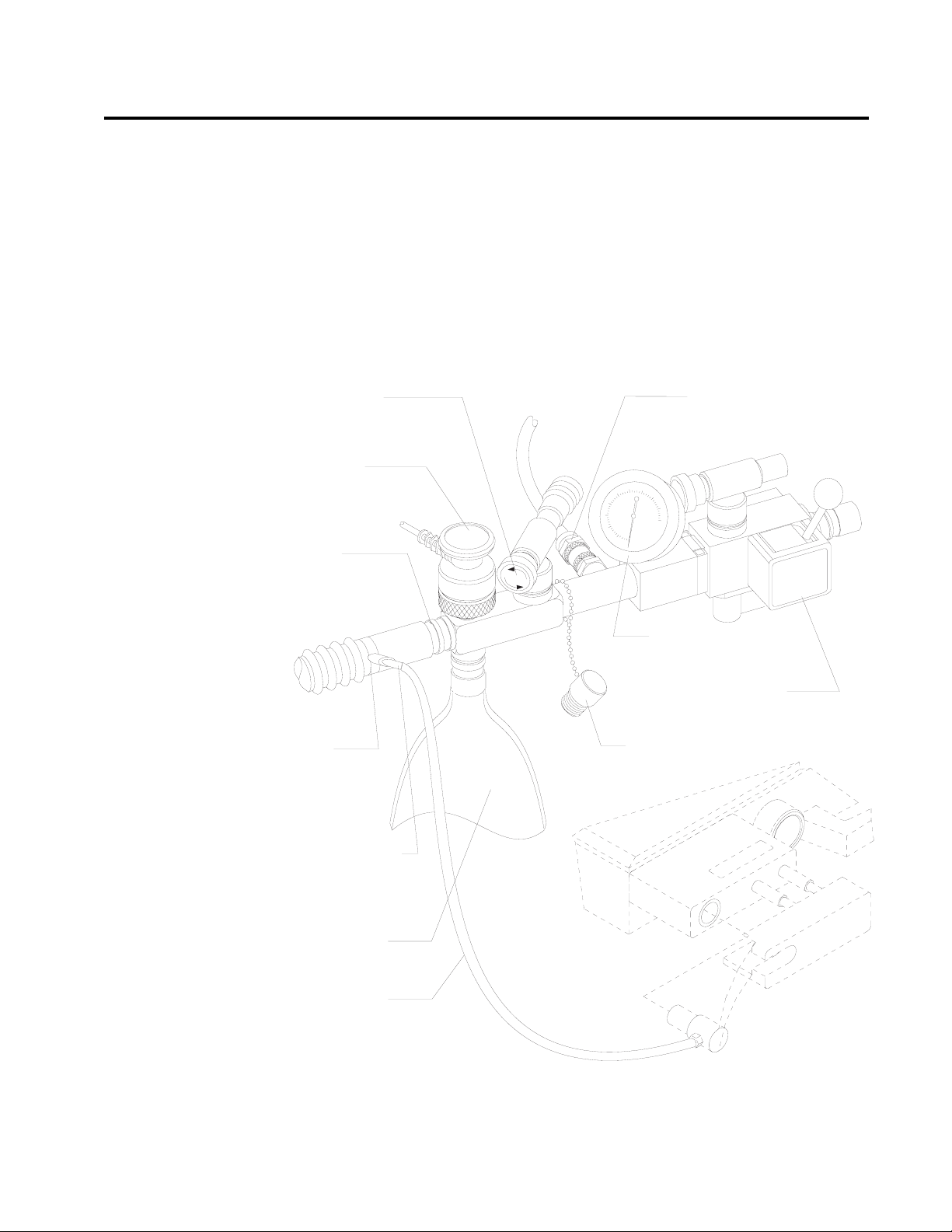

Scavenger Systems

Open Reservoir

Scavenger

The Narkomed 2C can be equipped with two kinds of scavenger systems,

for the best match with the hospital’s waste gas disposal system.

The open reservoir scavenger is used with suction (vacuum) waste gas

disposal systems. This scavenger is an “open” system with continually

open ports for positive and negative pressure control.

LOCK NUT

VACUUM

DISS HOSE

TERMINAL

NEEDLE

VALVE KNOB

19MM

SCAVENGER

HOSE TERMINAL

THREADED

INPUT

PORT CAP

19MM

SCAVENGER

HOSE TERMINAL

RELIEF

PORT

OP75121

FLOWMETER

RESERVOIR

CANISTER

2-17

Page 30

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

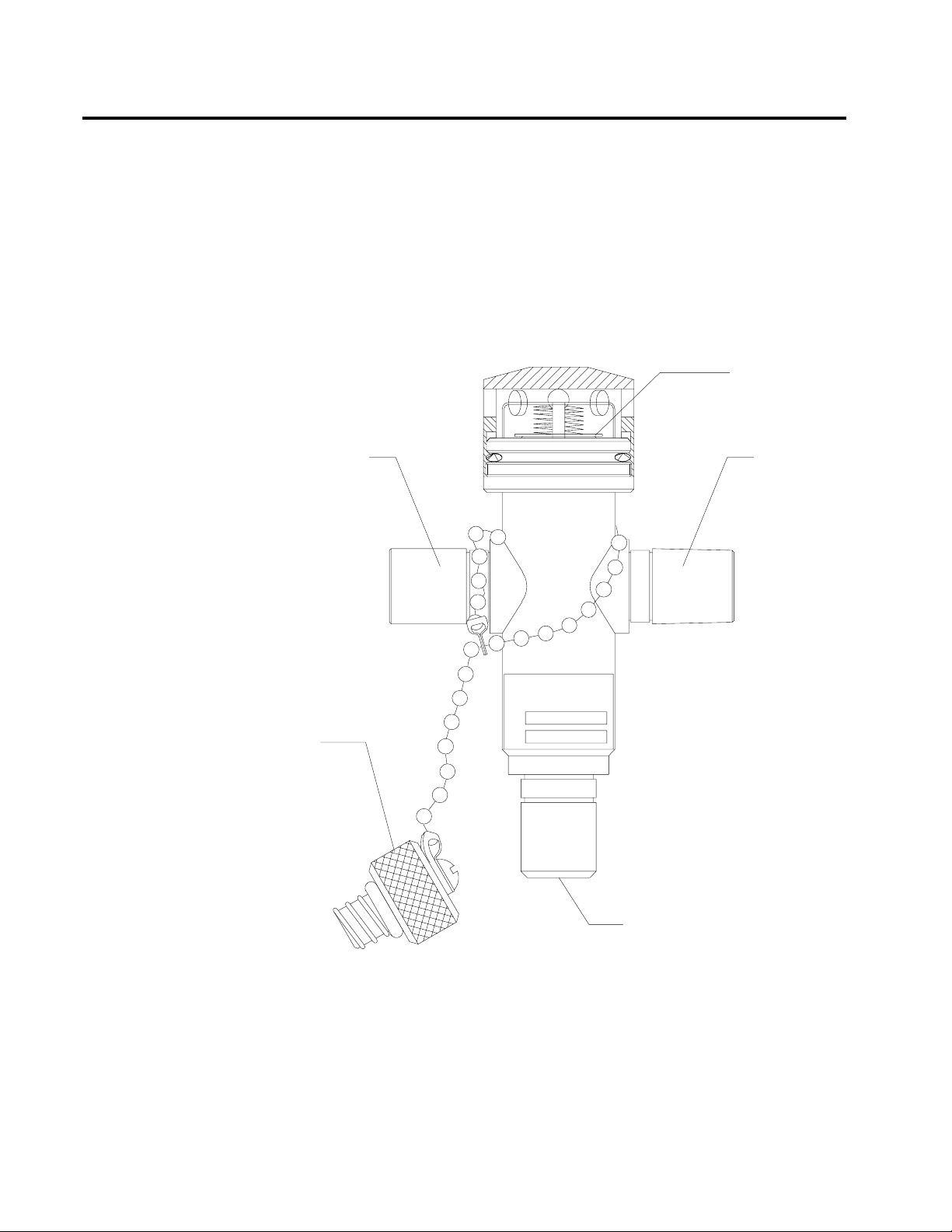

Scavenger Interface

for Passive Systems

The scavenger interface for passive systems is used with

nonrecirculating HVAC systems (also called exhaust systems). This

scavenger is a “closed” system with a spring-loaded valve for positive

pressure relief.

WARNING: Do not use this device with a waste gas disposal system

capable of applying a negative pressure to the scavenger

interface (a suction or vacuum waste gas disposal system).

SAFETY RELIEF

VALVE, SHOWN

CLOSED

WASTE GAS

INPUT PORT,

19MM HOSE

TERMINAL

WASTE GAS

INPUT PORT,

19MM HOSE

TERMINAL

2-18

INPUT

PORT CAP

OP76131

WASTE GAS EXHAUST PORT,

19MM HOSE TERMINAL

Page 31

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

AV2+ Ventilator

The AV2+ anesthesia ventilator is a volume-preset, time-cycled,

pressure-limited ventilator with electronic timing, pneumatic circuitry

and independent controls for frequency, inspiratory to expiratory (I:E)

ratio, inspiratory flow rate, tidal volume, and inspiratory pressure limit.

Pneumatic power (bellows drive gas) to the ventilator is supplied

through the hospital pipeline supply or through reserve cylinders on the

anesthesia machine. The pressure of the supply gas must be between 40

and 60 psi. The ventilator will not function properly if this pressure

drops below 32 psi. Electrical power is supplied by the AC power source.

In event of AC power failure, the backup battery supplies power. A fully

charged battery can power the ventilator for about 30 minutes.

The anesthesia ventilator is designed for use with a North American

Dräger absorber system that has a manual/automatic selector valve. Use

this valve to select the breathing bag and adjustable pressure limiter

(APL) valve for manual ventilation or the ventilator bellows for

automatic ventilation.

During automatic ventilation, the manual/automatic selector valve

isolates the absorber’s APL valve from the breathing system. The

ventilator has a relief valve mounted behind the bellows chamber to

compensate for the continuous introduction of fresh gas into the

breathing system.

When the bellows is completely filled, any excess gas in the system is

released to the scavenging system through the ventilator relief valve. As

in any ascending bellows, the force needed to overcome gravity acting on

the bellows causes a positive end-expiratory pressure (PEEP) within the

breathing system. The PEEP is about 2 cmH

2

O.

The pressure-limit control is used to set the peak inspiratory pressure

produced by the ventilator to prevent barotrauma. The pressure-limit

control can also improve ventilation for patients with reduced lung

compliance (neonatal/pediatric patients and patients with adult

respiratory distress syndrome), because it limits the peak inspiratory

pressure during the inspiratory phase of ventilation.

The AV2+ ventilator is shown in the following drawing.

2-19

Page 32

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

I:E RATIO CONTROL

EXTENDED RANGE

ACCESS

I:E RATIO DISPLAY

FREQUENCY

CONTROL

FREQUENCY

DISPLAY

10

FREQUENCY

/min

AV2+

INSPIRATORY PRESSURE LIMIT

cmH2O

1:2.5

I:E RATIO

EXTENDED

RANGE

TIDAL VOLUME

PUSH TO TURN

PRESET TIDAL VOLUME (ml)

1400

1200

1000

800

600

400

200

INSPIRATORY FLOW GAUGE

INSPIRATORY

FLOW CONTROL

VENTILATOR

ON-OFF

CONTROL

INSPIRATORY

FLOW

VENTILATOR

ON

FAULT

TIDAL VOLUME

CONTROL

PRESSURE

LIMIT CONTROL

Main Switch Panel

System Power Switch

AC Power Failure

Indicator

TIDAL

BELLOWS CANISTER

VOLUME

SETTING INDICATOR

OP91018c

BREATHING CIRCUIT

CONNECTOR

The main switch panel is located between the ventilator bellows and

flowmeter bank.

The SYSTEM POWER switch has two positions ON and STANDBY.In

the ON position, the gas (pneumatic) and electric power circuits are on.

The green indicator next to the switch lights. In the STANDBY position,

the switch shuts down the gas supplies, the monitoring system, and all

electrical power to the machine except the convenience receptacles and

battery charging circuit.

The yellow AC POWER FAIL indicator signals an AC power disruption.

The indicator lights whenever the battery supplies power to the

monitoring system and the electronic ventilator. A three-pulse tone also

sounds every 30 seconds. If the backup battery is completely discharged,

the AC power failure indicator does not have power and will not

function.

2-20

Page 33

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

O SUPPLY PRE SSURE

2

RED O2 SUPPLY

PRESSURE

LOW INDICATOR

YELLOW AC

POWER FAIL

INDICATOR

YELLOW

BATTERY LOW

INDICATOR

GREEN

BATTERY TEST

INDICATOR

POWER FAILAC

LOWBATTERY

BATTERY TEST

ON

STAND BY

SYSTEM POWER

BATTERY

TEST PUSH

BUTTON

SYSTEM

POWER

SWITCH

OP20050

Oxygen Supply

Pressure Alarm

The oxygen supply pressure alarm activates if the oxygen supply

pressure in the system decreases below about 37 psi. When the alarm is

actuated, the red O

SUPPLY PRESSURE indicator lights continuously,

2

the Caution message O2SUPPLY LOW appears on the central alarm

display, and an intermittent audible alarm sounds. Depending on the

configuration, a 7-second whistle may also sound.

NOTE: The oxygen supply pressure alarm will not activate if only one

source of oxygen supply pressure (either the cylinder or the

pipeline) fails and the other maintains proper pressure in the

oxygen supply lines.

2-21

Page 34

Section 2

E

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Power Supply

System

Convenience

Receptacles

The Narkomed 2C has a central power supply for the ventilator, alarm

system, and monitoring system. When in use, the Narkomed 2C must be

plugged into an AC outlet.

The Narkomed 2C has four convenience receptacles located on the upper

back area of the anesthesia machine. (This option is not available for the

240 VAC power supply option). The receptacles are active whenever the

Narkomed 2C is plugged into an outlet, whether or not the machine is

turned on.

The total current for devices plugged into the receptacles must not

exceed 7 amps. A 7-amp circuit breaker protects the convenience

receptacle circuit. This circuit also has an EMI filter to minimize

interference from devices plugged into the convenience receptacles.

CAUTION: Devices plugged into the convenience receptacles

contribute to the anesthesia system’s total leakage current.

The total leakage current must not exceed 100 microamps.

CIRCUIT

BREAKER

Circuit Breakers

2-22

CONVENIENC

RECEPTACLES

OP21050

The electrical system has four magnetic circuit breakers to protect

machine functions primary AC power input, convenience receptacles,

and backup battery power.

Page 35

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

The three circuit breakers located on the lower (absorber) side of the

machine are for 117 volt input power, 240 volt input power and backup

battery power. The fourth circuit breaker is for the convenience

receptacles and is located next to the convenience receptacles.

When the plunger is flush with the surface of its base, the circuit

breaker is in its normal, closed position. A circuit breaker is open

(tripped) when its plunger extends beyond its base. If a breaker is

tripped, the cause must be found and corrected before using the

anesthesia system.

Backup Battery

System

Machine Functions

on Backup Battery

Power

The backup battery system consists of a rechargeable battery and a

built-in battery charging system.

Although most hospitals have emergency generators that provide

AC power when line power fails, a delay may occur before generator

power comes on. The backup battery system automatically provides

power during the period between line power failure and activation of the

hospital’s emergency generator. The backup battery also provides power

if the anesthesia machine’s power cord is accidentally unplugged during

a case.

When the hospital’s emergency generator comes online (or when a

disconnected power cord is reconnected), the Narkomed 2C automatically

switches back to AC power and recharges its battery. The battery

charging system charges the battery any time the power cord is

connected to an active AC power source. The charger can recharge a

fully discharged battery in about 12 hours.

If the machine is receiving AC power, but the battery voltage level is low

due to a problem with the battery charging circuit or similar hardware

malfunction, the Advisory message RESERVE BATT LOW appears on the

central alarm display.

If the hospital’s primary AC power fails, the backup battery system is

activated. If this happens, the following events occur:

• The yellow AC POWER FAIL indicator on the alarm panel comes

on.

• The Caution message AC POWER FAIL appears on the central

alarm display.

• A three-pulse pattern tone sounds every 30 seconds.

These alarms signify that about 30 minutes of backup battery power

remains from the time the alarm is activated if the battery is fully

charged. All monitoring functions continue to operate, using the battery

for power.

2-23

Page 36

Section 2

General Description

When the battery reserve approaches depletion after an AC power loss:

• The yellow BATTERY LOW indicator lights.

• The Caution message AC BATTERY FAIL appears on the central

These alarms signify that about 10 minutes of backup battery power

remain from the time the alarm was activated.

The gas supply system remains operative. Because the ventilator is inoperative when battery power is cut off, you must perform manual

ventilation by bag. The machine cannot provide monitoring or alarm

functions until AC power is restored.

RETURN TO CD-ROM TABLE OF CONTENTS

NOTE: The BATTERY LOW indicator only lights during an AC

power loss when battery reserves are low.

display.

System Interface

Panel

NOTE: If the power cord is not plugged into an active AC outlet for a

period of 30 days or more, the backup battery can be depleted.

Plugging the power cord into an active AC outlet for about 12

hours recharges the battery.

The system interface panel is located on the absorber side of the

Narkomed 2C. The interface panel has receptacles for the oxygen sensor

cord, the breathing pressure pilot line, the respiratory volume sensor

cord, and the manual/automatic selector valve interface cable.

IN T E R F A C E

PANEL

RESPIRATORY

VOLUM E

MONITOR

IN T E R F A C E

MANUAL/

AUTOM ATIC

SELECTOR VALVE

IN T E R F A C E

OXYGEN

SEN SO R

VOLUM E

SEN SO R

BREATHING

PRESSURE

OXYG EN

ANALYZER

IN T E R F A C E

BREATHING

PRESSURE

MONITOR

IN T E R F A C E

SELECT OR

2-24

O P 21042

Page 37

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Adjustable Display

Arm

Monitoring System

Narkomed 2C

Screens

The adjustable display arm, mounted on the absorber side of the

machine, supports the remote display and Datagrip. It is also used to

route patient sensor lines from the patient to the anesthesia machine.

The arm can be adjusted up and down, side-to-side, and front-to-back, to

place the display and sensor lines in the most convenient position. To

adjust the arm front-to-back, pull and hold the release knob forward,

then move the arm to the preferred position and release the knob.

The monitoring system integrates the electronic monitors and organizes

information from these monitors on the screen. The screen is mounted

on the adjustable display arm.

The Narkomed 2C monitors:

• oxygen concentration measurements

• breathing pressure measurements

• respiratory volume measurements

It also monitors key anesthesia system functions such as oxygen supply

pressure and backup battery status.

The Narkomed 2C has several screens for viewing monitoring

information, adjusting alarms, and customizing the monitoring system.

The screens include:

• Machine Monitor

• System Monitor

• Set Up

• System Configuration

• Data Log

• Data Management

The screens are accessed from a Screen Selection menu. They are

described in detail in the Section 5 Operation - Monitoring System

“Using the Screen Selection Menu.”

2-25

Page 38

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Display Screen

All numerical data, waveforms, trends and alarms appear on the display

screen that is mounted on the display arm. The screen can be tilted up,

down, and sideways for optimal viewing.

DISPLAY ARM

O2

43

PEAK

43

MEAN

10

PEEP

2

MIN

VOL

7.50

TID

VOL

0.75

RR

10

8:30 9:30

WARNING

VENT PRES HI

CAUTION

O2 SUPPLY LOW

MINUTE VOLUME LOW

ADVISORY

NIBP STAT MODE

THRESHOLD LOW

RESERVE BATT LOW

8:43

VENT

SET UP

SCROLL

TREND

CLEAR TREND

CAL O

2

P

THRES

ORDM

VENT

NIBP

PRES

FLOW

AGT

SPO

SET

VENTILATION

ALARMS OFF

AUTOSET

LOG

CO

2

2

OP10757

THUMBWHEEL

DATAGRIP

Control Key Panel

DISPLAY

SCREEN

CONTROL

KEY PANEL

Each of the Control Key Panel keys, located on the right side of the

screen, performs a system function:

Silences the continuous audible alarm for 120 seconds. A

message indicating the number of seconds remaining in

the silence period is displayed in the Advisories window on

the central alarm display. If a new alarm occurs during

the 120 seconds, a single tone pattern sounds according to

the alarm priority. After 120 seconds, the audible alarm

reverts to normal operation if no alarm conditions are

active at that time.

If any Warning or Caution alarms are active at 120

seconds, the Narkomed 2C enters an extended silence

period and a single tone pattern sounds according to the

alarm priority. If a new alarm condition occurs during the

extended silence period, a single tone pattern sounds. Also,

at each one-minute interval of the extended silence period,

the highest-priority alarm tone pattern sounds.

2-26

Page 39

VENTILATION

ALARMS OFF

AUTOSET

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

The silence period can last up to three minutes. The

silence period ends if the Narkomed 2C is clear of

Warnings and Cautions for 10 seconds. When the extended

silence period ends, audio alarms revert to normal

operation.

Turns off volume and pressure-apnea alarms. If the

ventilator is on, the volume alarms are turned off, but the

pressure-apnea alarm remains on.

Function depends on the Datascan Display setting in the

System Configure screen.

If the Bar Graph Datascan is selected, pressing the

AUTOSET key sets the current measurements at the

center line of the Datascan display and resets the

endpoints. (See “Bar Graph Datascan Display” presented

later in this section.

Datagrip

If the Numeric Datascan is selected, pressing the

AUTOSET key resets the alarm limits according to the O2

ALARM AUTOSET value (WIDE, NARROW,orOFF) set in

the System Configure screen. If the Narkomed 2C is

connected to a Vitalert monitor with Alarm Autoset

capability, pressing the AUTOSET key also resets the

alarm limits on the Vitalert monitor.

For complete information on selecting the Datascan

display and setting the O2 ALARM AUTOSET value, see

Section 5 Operation - Monitoring System “Invoking the

System Configure Screen.”

The Datagrip is the user input device. The Datagrip is composed of a

trigger and thumbwheel attached to the display arm, next to the screen.

It can be tilted up and down for convenience and comfort.

Rotate the Datagrip thumbwheel to move the cursor around in screens,

change variables, and scroll through menus, lists, and trends. Rotating

the thumbwheel upward moves the cursor forward in a screen or list and

increases numbers. Rotating the thumbwheel downward moves the

cursor backward in a screen or list and decreases numbers.

Press the Datagrip trigger to invoke screens, choose parameters, enter

new values, and select soft keys that appear on the display screen.

2-27

Page 40

Section 2

General Description

An instructional dialog box, located in the lower right corner of certain

screens, guides you through the functions performed by Datagrip’s

trigger and thumbwheel for that specific screen. In the dialog box, the

icon indicates the function performed by rotating the thumbwheel.

The icon indicates the function performed by pressing the Datagrip

trigger.

RETURN TO CD-ROM TABLE OF CONTENTS

Datascan Display

Bar Graph Datascan

Display

The Datascan display is located at the top of the Data Log and System

Monitor screens. Information is presented in one of two display formats

the Bar Graph display or the Numeric display. The display format is

selected in the System Configure screen. (See Section 5 Operation -

Monitoring System “Invoking the System Configure Screen.”)

The Bar Graph Datascan display shows of six bar graphs that appear at

the top of the System Monitor screens. Use the Bar Graph Datascan to

see measurement deviations from a baseline. If information for one or

more bar graphs is not supplied, the corresponding display area is blank.

The six bar graphs include:

• end-tidal carbon dioxide

• inspiratory/expiratory anesthetic agent

• inspiratory oxygen concentration

• oxygen saturation

• pulse rate

• systolic/diastolic blood pressure

NOTE: The inspiratory agent and the systolic pressure measurements

are the larger numbers located below their respective bar

graphs.

2-28

A baseline measurement setpoint appears at the midpoint of each bar

graph, represented by a center line common to all six bar graphs.

Pointers along the left side of each bar graph mark the high and low

alarm limits. The current value for the measurement appears in

numerical form under each bar graph.

Any increase in a patient measurement causes the corresponding bar to

rise from the center line. If any patient measurement decreases, its bar

descends below the center line. Any deviation from the baseline whether

positive or negative is immediately apparent.

Page 41

OP27113

CO2 O2 SPO2 PLS NIBPISO

99

124

703943

70

1.5

1.0

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Numeric Datascan

Display

To normalize the current measurements of the Narkomed 2C, press the

AUTOSET key on the control key panel. This sets the current

measurements at the center line (baseline) and resets the endpoints.

The endpoints of the bar graph boundaries represent values above and

below the baseline determined by the scaling factor set in the Datascan

Configure screen.

The Numeric Datascan displays current values for all patient

measurements and shows where those values are in relationship to the

current alarm limits. The Numeric Datascan consists of six rectangular

display areas for:

• end-tidal carbon dioxide

• inspiratory and expiratory anesthetic agent

• inspiratory oxygen concentration

• oxygen saturation

• pulse rate

• systolic and diastolic blood pressure

If information for one or more measurements is not supplied, the

corresponding display area is blank.

The current values for the measurement are the large numbers located

in the middle of each display area. The numbers at the top and bottom

are the current alarm limits. The arrow on the left side of each display

area shows where the current value lies within the boundaries of the

alarm limits. This arrow moves move up or down as the values change.

2-29

Page 42

Section 2

General Description

RETURN TO CD-ROM TABLE OF CONTENTS

Central Alarm

Display and Audible

Alarms

CO

50

ISO SPO2PLS

2

3.0

O

2

I

100

100

100

2.3

43

20

NOTE: The inspiratory agent and the systolic pressure measurements

also appear in the display areas.

To automatically adjust the alarm limits around the current values,

press the AUTOSET key on the control key panel. This sets the oxygen

alarm limits according to the O2 ALARM AUTOSET value specified in

the System Configure screen. For complete information, see Section 5

Operation - Monitoring System “Invoking the System Configure Screen”.

If the Narkomed 2C is connected to a Vitalert monitor with Alarm

Autoset capability, pressing the AUTOSET key also resets the alarm

limits for the monitoring functions provided by the Vitalert monitor.

The Narkomed 2C presents active alarms on the central alarm display

located at the top of the display screen. Alarms are indicated with

keyword phrases and are organized into three categories, depending on

their urgency. Alarms are displayed either in a single window or in three

separate windows corresponding to each alarm category.

1.7

E

1.0

39

18

100

85

65

50

NIBP

150

124

85

100

OP21010

2-30

A central speaker produces all audible alarm signals, using three

different sound patterns to indicate the three levels of alarm urgency.

The Narkomed 2C annunciates only the highest-priority, currently active

alarm. Lower-priority alarms are temporarily suppressed to minimize

the confusion caused by simultaneous alarms. If the primary speaker on

the Narkomed 2C fails, the Advisory message SERVICE SPEAKER

appears on the central alarm display and a single tone sounds.

If the number of alarms in any of the three categories exceeds the space

provided on the display screen for that category, additional alarm

messages are retained in memory until displayed alarm conditions are

resolved.

Page 43

RETURN TO CD-ROM TABLE OF CONTENTS

Section 2

General Description

Warnings

Warnings are the highest priority alarms and require an immediate

response.

If the Bar Graph Datascan is selected, Warnings appear in a drop-down

window in the upper left portion of the System Monitor screens,

overlaying the Datascan bar graphs. If no Warning alarm conditions

exist, the display is suppressed until an alarm condition occurs. Up to

seven Warnings can appear in this window.

If the Numeric Datascan is selected, Warnings appear in the single

alarm window in top right corner of the Machine Monitor screen and the

System Monitor screens, along with any Caution or Advisory messages.

The Warning messages are displayed under a flashing heading labeled

WARNING, which is removed from the screen if no Warning alarm

conditions exist. The last space at the bottom of the alarm window is

reserved for the SILENCE message that indicates the time remaining in

the Audio Silence period.

Warnings are announced with a continuously repeating sound pattern

consisting of three audio tones. After an initial sound pattern at full

volume, there is a 6-second pause. This pause is followed by a pattern at

one-third volume, a 5-second pause, a pattern at two-thirds volume, a 4second pause, and another pattern at full volume. After the second full

volume pattern, a 3-second pause occurs, followed by a full volume

pattern until the alarm condition is removed.

Cautions

Cautions are second-priority alarms and require a prompt response.

If the Bar Graph Datascan is selected, Cautions appear in a drop-down

window in the upper middle portion of the System Monitor screens,

overlaying the Datascan bar graphs. If no Caution alarm conditions

exist, the display is suppressed until an alarm condition occurs. Up to

seven Cautions can appear in this window.

If the Numeric Datascan is selected, Cautions appear in the single alarm

window in top right corner of the Machine Monitor screen and the

System Monitor screens, along with any Warning or Advisory messages.

The Caution messages are displayed under a heading labeled CAUTION,

which is removed from the screen if no Caution alarm conditions exist or

if all space in the alarm window is needed by the higher-priority

Warning messages.

2-31

Page 44

Section 2

General Description

The last space at the bottom of the alarm window is reserved for the

SILENCE message that indicates the time remaining in the Audio