Page 1

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

KIT,AIRDISS&CO2YOKE

INSTALLATIONPROCEDURE

NOTE: Thisprocedureoutlinesanextremelycomplexmodificationoftheanesthesia

machine.InstallationofthiskitshallbeperformedonlybyaNorthAmerican

DrägerqualifiedTechnicalServiceRepresentativewiththenecessaryknowledge

andexperience.

NOTE: Thisprocedureappliesto2-gasmachineswithearliertubingarrangements,fluted

flowknobguards,andflowcontrolknobslocatedbelowthe100to1000ml/min.

(fine)flowmeters.

1. TurntheSystemPowerswitchto

ONanddisconnectallpipeline

hoses.

2. Closeallcylindervalvesexceptthe

O

cylindervalve.

2

3. Settheoxygenflowrateto5l/min.

4. OpentheN

Oflowcontrolvalveto

2

drainpressurefromthesystem.

5. ClosetheO

cylindervalve,and

2

closetheflowcontrolvalves.Press

theO

FLUSHbuttontodrain

2

pressurefromthesystem.

6. TurntheSystemPowerswitchto

STANDBYandremoveACpower

fromthemachine.Disableallcircuit

breakers.

7. Removethescrewssecuringthe

tabletop,andremovethetabletop.

CAUTION: Use ESD control when

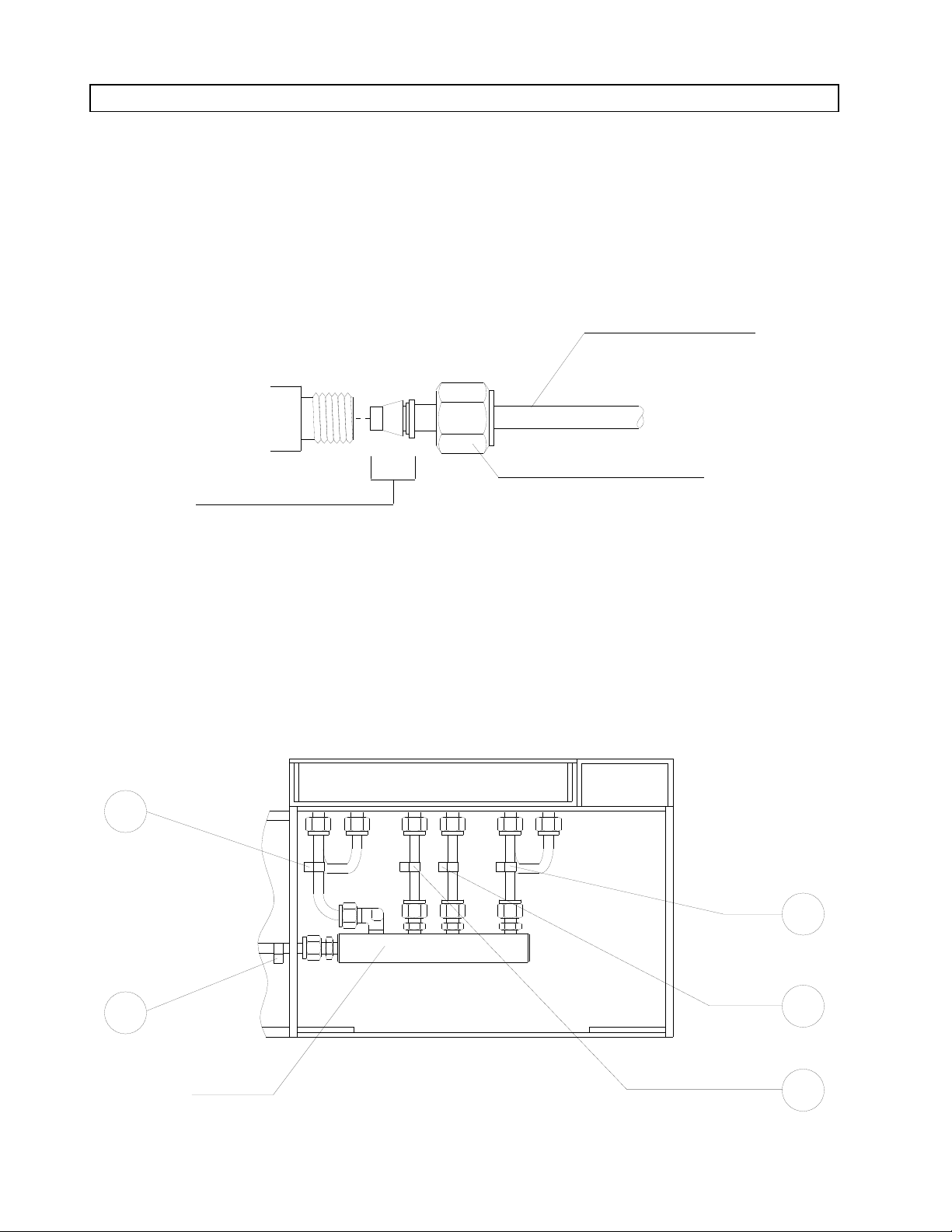

handling any electronic

componentsorassemblies.

9. Removethevaporboxfrontcover.

FormachineswithaMultispec

analyzer,removeallconnectionsto

thePCBassemblyonthevaporbox

frontplate,andremovethePCB

fromtheplate.

10. Removethevaporboxbackcover.

11. Removethescrewsholdingthe

angledfrontplateatthetopofthe

flowmetershield,andremovethe

plate.

12. Removeallflowcontrolknobs.

13. Removethetwoscrewssecuringthe

knobguard;removetheguardand

theflowmetershield.

8. Removetheflowmeterhousingback

cover.

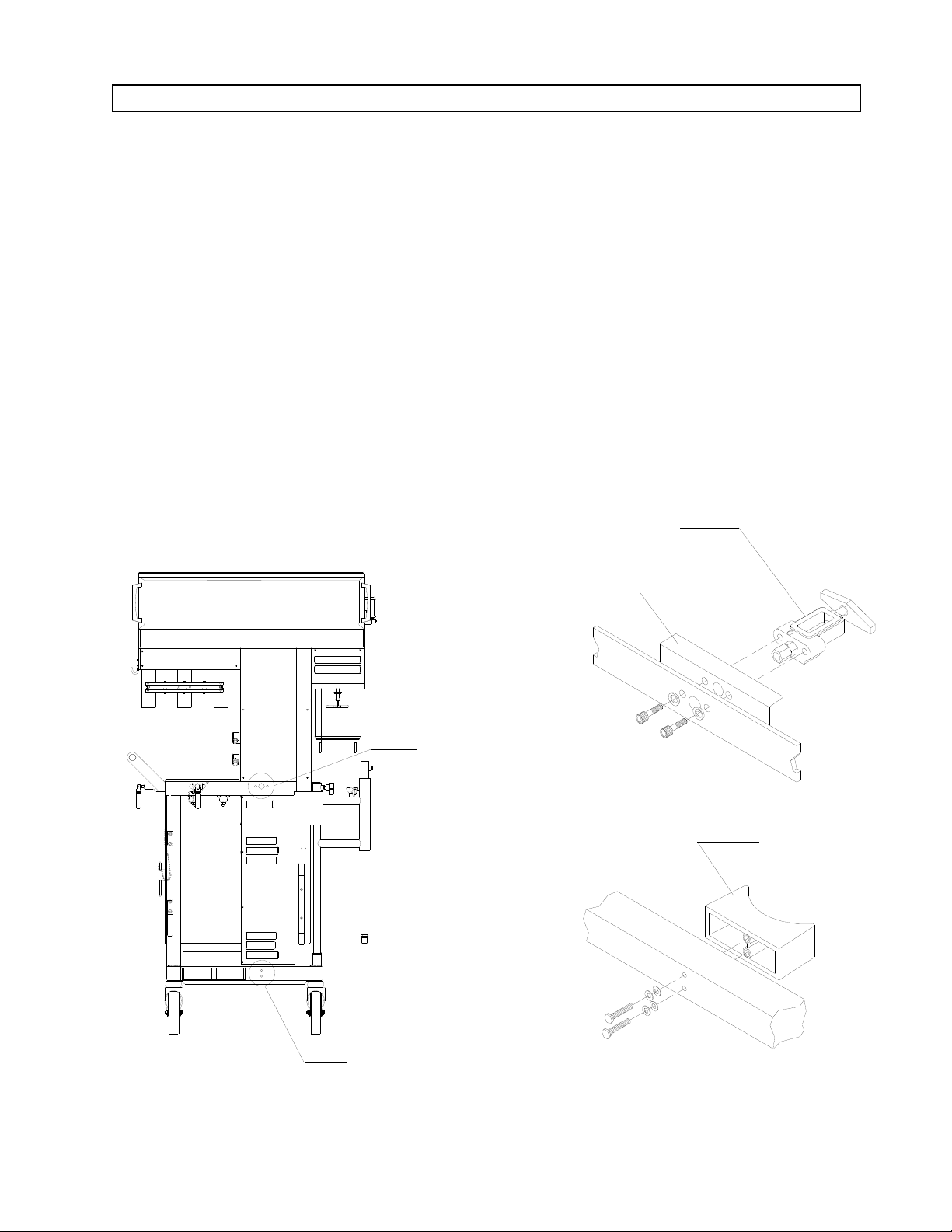

1

Page 2

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CAUTION: Use ESD control when

handling any electronic

components or assemblies.

14. Remove the flowmeter lights PCBs

and channels from the studs on the

O

and N2O flow channels.

2

15. Remove the stop pin hex nuts from

each flow control valve.

16. Remove the flow control valves: hold

each at the wrench flats and turn it

counter-clockwise.

17. Remove each flowmeter tube by

turning its retaining insert at the

top of the assembly counterclockwise until there is enough

clearance to remove the tube from

the channel.

18. Disconnect theflextubing connected

to the N

remove the O

O restrictor housing, and

2

and N2O restrictor

2

assemblies.

19. Remove the cross-over tubes

connecting the O

and N2O fine and

2

coarse flowmeter ports.

24. Remove the three socket head cap

screws securing the bottom

flowmeter block to the channel

assembly.

25. Pull the bottom block forward,

disconnect the small diameter flex

tubing from the block, and remove

the block.

26. Disconnect the flex tubing from the

O

and N2O pipeline gauges.

2

27. Remove the three socket head cap

screws securing the flowmeter

assembly, and remove the assembly.

28. Remove the kep nuts securing the

cylinder and pipeline gauges to the

flowmeter channel and remove the

gauges.

29. Remove the socket head cap screws

securing thetop block to the channel

assembly.

30. Apply masking tape to the raised

surfaces of and the entire inside

area ofthe center flowmeter channel

to prevent scratching.

20. Remove the manifold assembly

connected to the O

and N2O outlets

2

at the top of the flowmeters.

21. Disconnect the 4-way fitting and

restrictor assembly’s lower copper

tube from the O

flowmeter inlet

2

port.

22. Disconnect the copper tube attached

to the N

O flowmeter valve port.

2

23. Disconnect the copper tubes from

the O

and N2O cylinder gauges.

2

31. Temporarilyattach the 4-gas bottom

block to the channel with the screws

that were previously removed from

the original block.

32. Using the bottom block as a

template, mark the circumference of

the 4th gas flow control housing

onto the channel: (Insert a

flowmeter gasket (P/N 4102725) into

the housing. This will provide a

smaller diameter hole to aid in

locating the center point.) The hole

location is shown in Figure 1.

2

Page 3

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

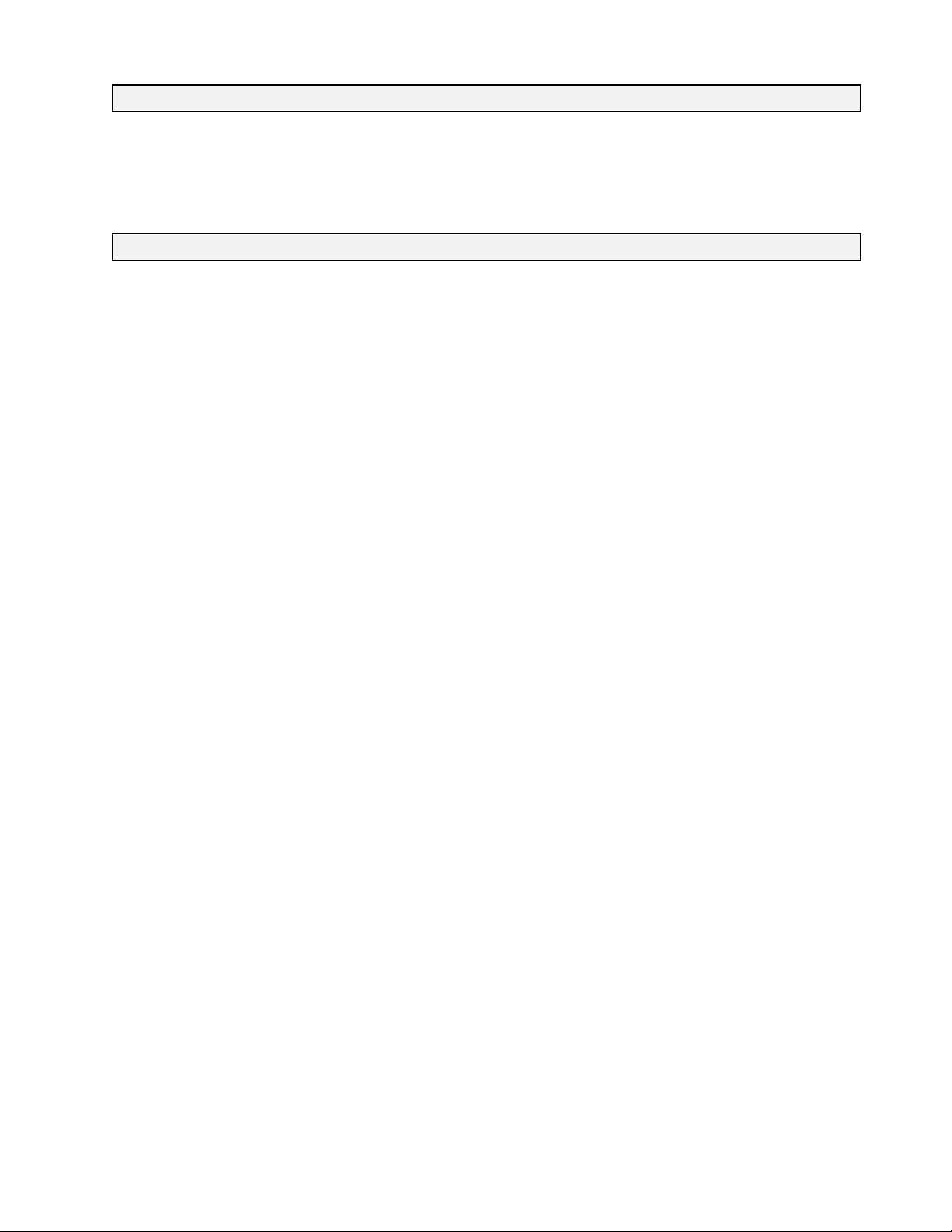

SP10501

7/64 IN. DIA. HOLE

(DRILL)

11/16 IN. DIA.

CLEARANCE HOLE

(DRILL)

(LOCATE CENTER

USING 4-GAS BLOCK

AND GASKET AS

TEMPLATE)

1 7/8 IN.

Figure 1: DRILLING LOCATIONS: 4-GAS CONVERSION

3

Page 4

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

33. Remove the 4-gas bottom block and

centering gasket.

CAUTION:

Perform the next four steps in a

suitable location away from the

anesthesia machine to prevent

drilling chips from entering the

pneumatic system.

34. Center punch the marked hole and

drill an 11/16 in. dia. hole into the

flowmeter channel. A hole saw is

recommended. De-burr any sharp

edges.

35. Measure and mark a location 1 in.

up from the lower center spacer

hole, and centered in the channel as

shown in Figure 1.

36. Carefully drill a 7/64 in. dia. hole at

this location, and de-burr any sharp

edges.

37. Remove all masking tape previously

applied, and carefully clean up any

metal chips from the flowmeter

assembly and surrounding area.

38. Using a small amount of Loctite

#271 (red), thread a 3/16 in. tube

straight fitting (P/N 4109402) into

the back of a high pressure gauge

(P/N 4110575-002).

39. Apply a small amount of Loctite

#271 (red) to the threads of a 1/16

in. hose barb (P/N 4111771) and

pipeline pressure gauge (P/N

4110575-001). Assemble the fittings

with coupling (P/N 4103668) as

shown in Figure 2.

4

Page 5

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

40. Place the pipeline gauge assemblies

into the upper holes of the gauge

channel and secure each gauge with

two 10-32 kep nuts (P/N HW55002

x2). See Figure 2. Reuse the original

hardware to secure the O

and N2O

2

gauges.

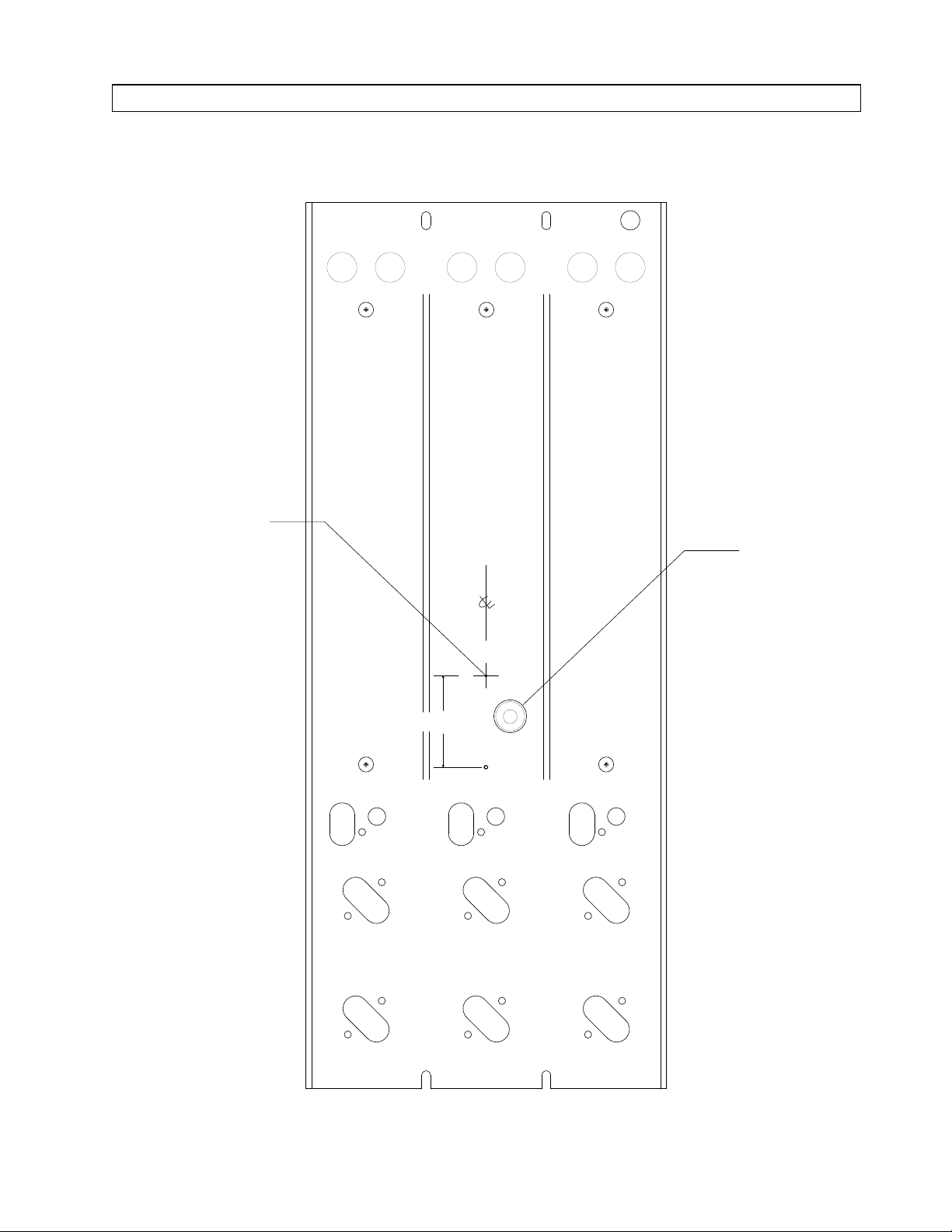

FLOWMETER CHANNEL

PIPELINE

PRESSURE

GAUGE

41. Place the cylinder gauge assemblies

SIDE VIEW

into the lower holes of the gauge

channel and secure each gauge with

two 10-32 kep nuts (P/N HW55002

x2). Reuse the original hardware to

secure the O

and N2O gauges.

2

HOSE BARB

SP10502

FITTING

CYLINDER

PRESSURE

GAUGE

GAUGE MOUNTING NUTS

Figure 2: PIPELINE AND CYLINDER GAUGE ASSEMBLY AND MOUNTING

5

COUPLING

STRAIGHT

FITTING

(2X EACH GAUGE)

Page 6

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

42. Apply a small amount of Loctite

#271 (red) to the threads of two 2-56

x ¼ in. pan head screws (P/N

HW02000 x2). Place a #2 lock

washer (P/N HW67012 x2) on each

screw, and secure the two shoulder

spacers (P/N4110843 x2) to the

inside of the center flowmeter

channel.

43. Reinstall the top block assembly to

the flowmeter channel using the

hardware previously removed.

44. Threadtwo inserts (P/N4102506 x2)

into the center locations of the top

flowmeter block until snug.

45. Secure the 4-gas bottom block (P/N

4110572) to the flowmeter channel

using the hardware previously

removed from the original block.

47. Install a #113 O-ring (P/N 4102792

x4) in the grove of each flowmeter

insert on all four inserts. Apply a

small amount of Parker Super-OLube to these O-rings.

48. Thread the chromed flowmeter

insert into the upper hole of the

bottom block, and the remaining

brass inserts into the lower holes

until snug. DO NOT overtighten the

inserts.

49. Install the flow control valves (P/N

4103352 x2) into the flowmeter

inserts. Reuse the original O

N

O flow control valves. CAUTION:

2

2

and

Before tightening the cartridge,

rotate the valve shaft several turns

counter-clockwise to prevent

bottomingthe valve element into the

seat when the cartridge is tightened.

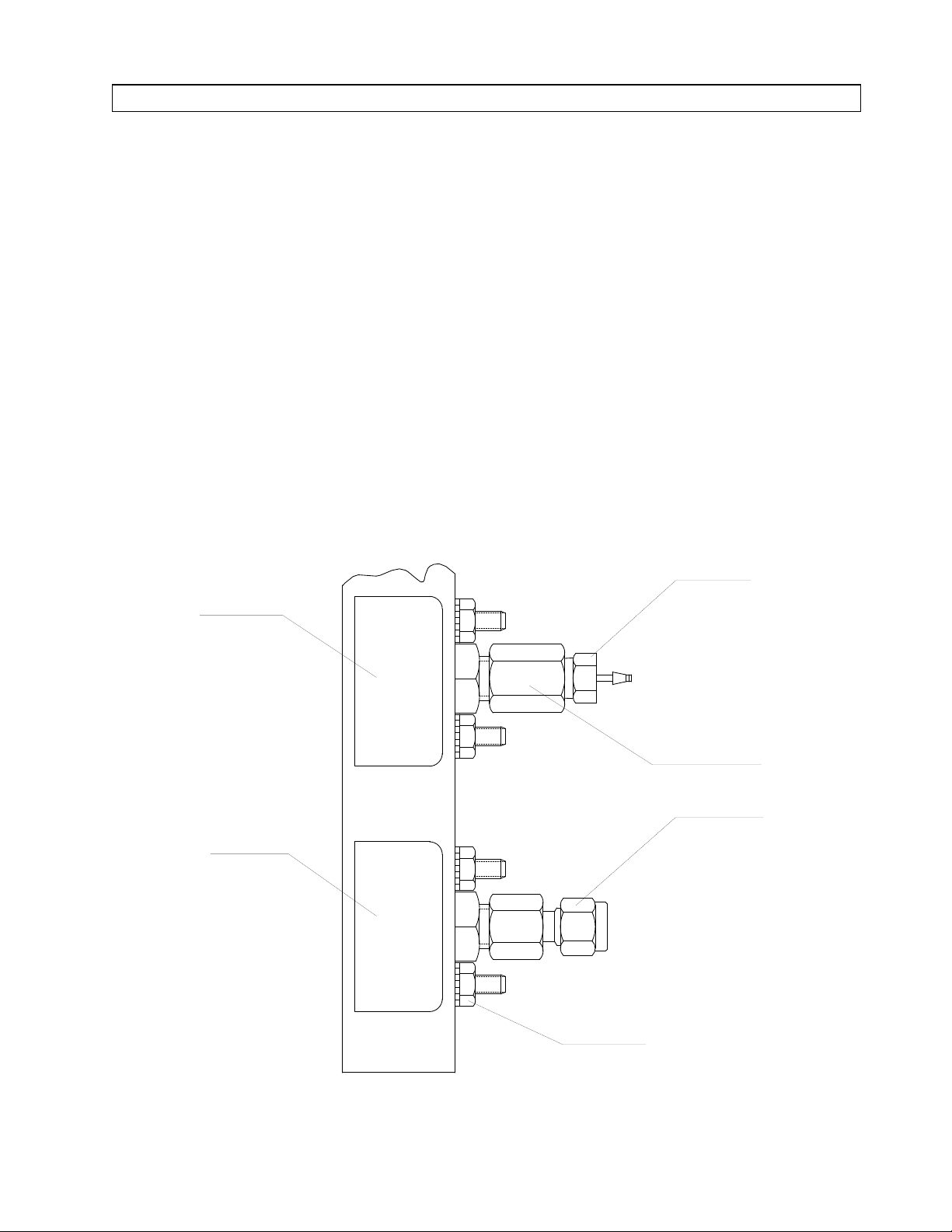

46. Install a #018 O-ring (P/N 4102336

x4) at the shoulder of each of the

four bottom flowmeter inserts

(consisting of P/N 4110576 x3 and

4110573) as shown in Figure 3.

50. Install the stop pin nuts (P/N

4103382 x2) onto the flow control

assemblies. Reuse the original stop

pin nuts for the O

and N2O

2

assemblies.

51. Thread two 10-32 x 1/16 in. hose

barb fittings w/seal (P/N 4112707001 x2) into the back of the bottom

flowmeter block.

52. Remove the nuts and ferrules from

eight ¼ in. tube straight fittings

(P/N 4109408 x8). Apply a small

amount of Loctite #271 (red) to the

threads of each fitting, and thread

the fittings into the top and bottom

blocks at the locations marked A

Figure 3.

6

Page 7

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

REAR VIEW OF FLOWMETER CHANEL

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

SP10503

AA

HOSE BARB

FITTING W/SEAL

BOTTOM BLOCK

MOUNTING SCREWS (3X)

STOP PIN

NUT

FLOW CONTROL

VALVE

A

AA AAA

DETAIL OF FLOW CONTROL

INSERT ASSEMBLY

CROSS-OVER

TUBES (2X)

HOSE BARB

FITTING W/SEAL

(SIDE VIEW)

O-RING, #113

INSERT

O-RING, #018

Figure 3: INSTALLATION OF FITTINGS AND FLOW CONTROL VALVE INSERT ASSEMBLY

7

Page 8

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

53. Assemble the compression fittings

onto the open ended tubes on the 4gas manifold assembly (consisting of

P/Ns 4108483, 4109408 x4,4109410,

4110834-009 x3, and 4110837-013

x2) as shown in Figure 5. Ensure

that the Swagelok fittings with the

two-piece ferrules are assembled as

shown in Figure 4.

TWO-PIECE

FERRULE

Figure 4: ASSEMBLY OF SWAGELOK FITTINGS

Insert the copper tubes into the

manifold assembly as shown in

Figure 5. Before tightening the

compression nuts, ensure that the

tubing is inserted into the fittings as

far as possible.

COPPER

TUBING

COMPRESSION

NUT

SP10504

54. Attach the copper tubes on the

manifold assembly on the ports at

the top of the flowmeter bank as

shown in Figure 5. Ensure that the

tubing is inserted into the fittings as

far as possible, and tighten the

compression nuts.

O2

MIX

55. Attach the correct gas-identifying

label (P/N 4109871, 4109872,

4109873, 4109874, and 4109901) to

each tube on the manifold assembly

as shown in Figure 5.

SP10505

N20

AIR

MANIFOLD

TOP VIEW

Figure 5: FOUR GAS MANIFOLD ASSEMBLY WITH LABELS

8

CO2

Page 9

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

56. Reinstall the flowmeter channel

assembly using the hardware

previously removed.

57. Reinstall the cross-over tubes

connecting the oxygen and nitrous

oxide fine and coarse flowmeters.

Verify that the correct identification

labels are attached to each tube.

58. Mount the cylinder support (P/N

4106690) on the bottom frame rail at

the back of the machine (see Figure

6) using two ¼-20 x 2½ in. hex head

screws (P/N HW08009 x2), lock

washers (P/N HW65010 x2) and flat

washers (P/N HW66004 x2).

REAR VIEW

59. Mount the CO

(consisting of P/Ns 4111792,

HW06006, 1101624, 4104716,

4105929 x2, and 4112755-001), (and

spacer block (P/N 1101593) on

earlier models) on the upper frame

rail of the machine as shown in

Figure 6. Use two 5/16-24 x 1¾ in.

socket head screws (P/N HW01058

x2) andlock washers (P/N HW65005

x2). Apply a CO

1101639) on this yoke.

YOKE ASSEMBLY

CO2

SPACER

yoke assembly

2

label (P/N

2

YOKE

MOUNTING

LOCATION

SP10506

CYLINDER SUPPORT

MOUNTING LOCATION

Figure 6: CO2YOKE AND CYLINDER SUPPORT MOUNTING LOCATIONS

9

CYLINDER

SUPPORT

Page 10

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

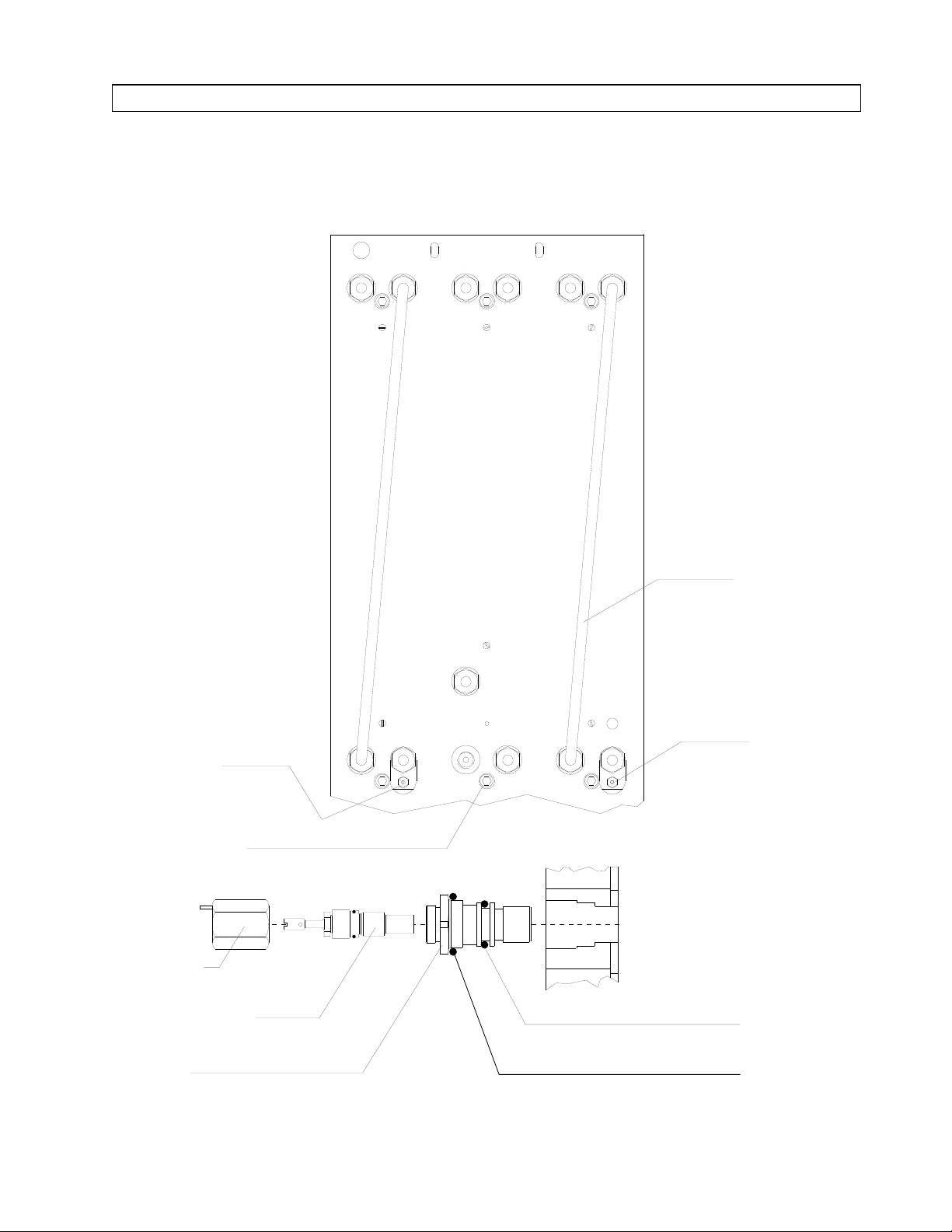

60. Position the CO

cylinder pressure

2

regulator assembly (consisting of

P/Ns 4103591, 4109415, 4102906x2,

4109409, and 4109401) as shown in

Figure 7, with the Inlet marking

toward the front of the machine.

61. Install two 10-32 x ½ in. set screws

(P/N HW10001 x2) in the regulator

mounting bracket and secure the

regulator.

62. Connect a 3/16 in. dia. (P/N

4104215) pre-bent copper tube

between the CO

the inlet fitting on the CO

cylinder yoke and

2

cylinder

2

regulator.

TOP VIEW OF MACHINE

Ensure that the tubing is inserted

into the ferrules correctly, and

tighten the fittings securely. Install

aCO

label (P/N 4109873 x2) on

2

each end of this tube.

63. Connect a 3/16 in. dia. (P/N

4104214) pre-bent copper tube

between the CO

cylinder gauge and

2

the port marked "HP" on the CO

cylinder regulator. Ensure that the

tubing is inserted correctly, and

tighten the fittings securely. Install

aCO

(P/N 4109873 x2) label on

2

each end of this tube.

2

CO2

CYLINDER

YOKE

3/16 IN. DIA.

COPPER TUBE

SP10507

3/16 IN. DIA. COPPER TUBE

TO CYLINDER PRESSURE GAUGE

"HP"

PORT

SET

SCREWS (2X)

CO2 CYLINDER

PRESSURE

REGULATOR

"INLET" PORT

Figure 7: CO2CYLINDER REGULATOR MOUNTING AND H.P. CONNECTIONS

10

Page 11

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

64. Reattach the copper tubespreviously

removed from the O

and N2O

2

cylinder gauges, and tighten the

fittings securely. Verify that the gas

identification labels are correct.

65. Reattach the ¼ in. dia. copper tubes

previously removed from the O

N

O flow control valve ports and the

2

2

and

top flowmeter blocks, and tighten

the fittings securely.

66. Remove the ¾ in. dia. plastic plug

from the flowmeter housing directly

abovethe O

pipelineinlet assembly.

2

67. Install a DISS air inlet housing

assembly (consisting of P/Ns

4113363 and 4102886) in the hole

where the plug was removed, using

a -18 hex nut (P/N HW52002) and

lock washer (P/N HW67001). Orient

the DISS connector at a 70° angle as

shown in Figure 8. Apply an AIR

label (P/N 4102742) to the inlet

housing.

68. Apply a small amount of Loctite

#271 (red) to the threads of the filter

assembly (consisting of P/Ns

4102532 and 4106897) and install it

into the air inlet housing.

69. Apply a small amount of Loctite

#271 (red) to the threads of tee

fitting (P/N 4102760). Install it into

the filter assembly as shown in

Figure 8, with its side port facing

downward.

70. Apply a small amount of Loctite

#271 (red) to the threads of a NPT

x 1/16 in. hose barb fitting (P/N

4111771). Install it into the end port

of the tee as shown in Figure 8.

71. Remove the nut and ferrules from ¼

in. tube to NPT elbow fitting (P/N

4109410). Using a small amount of

Loctite #271 (red) install it in the

remaining port as shown in Figure

8. Reattach the nut and ferrules on

the fitting (ref. Figure 4).

72. Install an 8 in.length of flex tubing

(P/N ML08003 x8) between the air

pipeline gauge and the hose barb

fitting installed in the previous step.

Secure each end of the tubing with a

press-on clamp (P/N 4104161 x2),

and install an AIR label (P/N

4109872 x2) on each end of this

tube.

73. Reattach the flex tubing previously

removed from the O

and N2O

2

pipeline gauges. Secure the

connections with the press-on

clamps previously removed (use tie

straps P/N 4106068 x2 for early

style nylon fitting), and verify that

the gas identification labels are

correct.

74. Remove the ¼ in. x 10-32 plug from

the left port of the 4-way fitting and

restrictor assembly, and insert a 1032 x 1/16 in. hose barb fitting w/seal

(P/N 4112707-001) into this port.

11

Page 12

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

SP10508

SIDE VIEW

FILTER

AIR INLET

HOUSING

O

70

ELBOW

FITTING

REAR VIEW

TEE FITTING

HOSE BARB FITTING

PRESS-ON

HOSE CLAMP (2X)

FLEX TUBING

AIR LABEL (2X)

Figure 8: AIR PIPE LINE INLET ASSEMBLY

12

Page 13

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

75. Connect the short end of a ¼ in. dia.

"L" tube (P/N 4110837-015) to the

CO2cylinder pressure regulator as

shown in Figure 9. Install a CO

label (P/N 4109873 x2) on each end

of this tube.

76. Connect the other end of the "L"

tube to a ¼ in. T fitting (P/N

4108636), and install a ¼ in. plug

(P/N 4103072) in the side port of the

T fitting, and tighten the fittings

securely.

77. Connect the short end of a ¼ in.dia.

pre-bent tube (P/N 4110279) to the

remaining port on the tee fitting as

2

shown in Figure 9. Install a CO

2

label (P/N 4109873 x2) on each end

of this tube.

SP10509

1/4 IN. DIA. TUBE

TO CO2 OFPD

PLUG

Figure 9: CO2CYLINDER REGULATOR L.P. CONNECTIONS

1/4 IN. DIA.

"L" TUBE

TEE FITTING

13

Page 14

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

78. Connect either end of a ¼ in.dia. S

tube (P/N 4110836-006) to the CO

flow control valve port. See Figure

10. Install a CO

label (P/N 4109873

2

x2) on each end of this tube.

79. Position the CO

OFPD (consisting

2

of P/Ns 4111771, 4103681, 4102713,

4109408, and 4109410) in the

flowmeter housing and connect the

side fitting on the OFPD to the

previously installed S tube from the

CO

flow control valve. Tighten the

2

fittings securely

80. Connect the bottom fitting on the

CO

OFPD to the copper tube from

2

the CO

regulator that was

2

previously installed. Tighten the

fittings securely.

81. Position the Air OFPD (consisting of

2

P/Ns 4111771, 4103681, 4102713,

4102784, 4015815, and 4109410 x2)

in the flowmeter housing and

connectan Stube (P/N4110836-004)

between the Air flow control valve

and the side fitting on the OFPD.

Tighten the fittings securely. See

Figure 10. Install an AIR label (P/N

4109872 x2) on each end of this

tube.

82. Connect a copper tube (P/N

4108803) between the air pipeline

inlet assembly elbow fitting and the

elbow fitting at the lower end of the

check valve on the Air OFPD, and

tighten the fittings securely. Install

an AIR label (P/N 4109872 x2) on

each end of this tube.

83. Attach the minimum flow cutoff

valve assembly (consisting of P/Ns

4111771, 4102055, 4110792-013,

4103549,and 4112707-001 x2) to the

N

O flowmeter crossover tube with

2

two tie straps (P/N 1101732 x2) as

shown in Figure 10.

14

Page 15

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

TIE STRAP (2X)

MINIMUM FLOW

CUTOFF VALVE

SP10510

FROM CO2

FLOW CONTROL

VALVE

FROM AIR

FLOW CONTROL

VALVE

AIR OFPD

CO2 OFPD

FROM CO2

REGULATOR

FROM AIR PIPELINE INLET

Figure 10: OFPD AND MINIMUM FLOW VALVE INSTALLATION

15

Page 16

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

84. Mount the gas selector valve

(consisting of P/Ns 4112707-001 x4,

HW02028 x2, 4108749 x2, 4103621

x2, and 4110518) to the floor of the

vapor box, oriented as shown in

Figure 11, with two 10-32 x 5/16 in.

socket head screws (P/N HW01022

x2), lock washers (P/N HW67006 x2)

and flatwashers (P/N HW66003 x2).

NOTE:

Skip the next nine steps if the

ORMC does not have a wire harness

and switch.

85. Securethe pressureswitch assembly

(consisting of P/Ns 4103444,

4106367, and 4112707-001 x2 to the

copper tubing in the vapor box with

two tie straps (P/N 1101732 x2) as

shown in Figure 11.

86. Disconnect all wires from the ORMC

wire harness adapter.

87. Attach the female connector of the

ORMC wire harness adapter to the

terminal on the right side of the

pressure switch.

88. Attach the female connectors of the

AIR OPT/PRESS SW wire harness

(P/N 4106324) to the male

connectors on the wire harness

adapter.

89. Connect the WHT/YEL wire from

the ORMC to the AIR OPT/PRESS

SW wire harness.

90. Connect the WHT wire from the

alarm channel to the remaining

terminal on the AIR OPT/PRESS

SW wire harness.

SP10511

TO 4-WAY

FITTING

PORT "A"

TO AIR OFPD

TO MINIMUM

FLOW VALVE

FROM

ALARM

CHANNEL

FROM ORMC

WH/YEL

WH

WH/YEL

VAPOR BOX

TOP VIEW

NYLON TEE

FITTING

GAS SELECTOR

VALVE ASSEMBLY

PRESSURE SWITCH

ASSEMBLY

Figure 11: GAS SELECT VALVE AND PRESSURE SWITCH CONNECTIONS

16

Page 17

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

91. Connect the WHT/YEL wire from

the alarm channel harness to the

remaining terminal on the pressure

switch assembly.

92. Install a 16 in. length of flex tubing

(P/N ML08003 x16) between the

right side port of the pressure switch

and the front port on the gas

selector switch assembly. Secure

each end of the tubing with a presson clamp (P/N 4104161 x2). Install

an O

label (P/N 4109871 x2) on

2

each end of this tube.

93. Connect a 14 in. length of flex

tubing (P/N ML08003 x14) to the

left side port of the pressure switch

in the vapor box, and secure it with

a press-on clamp. Connect the other

end of the tubing to the top hose

barb on the minimum flow valve

and secure it with a press-on clamp

(P/N 4104161 x2). Install an O

label

2

(P/N 4109871 x2) at each end of this

tube.

NOTE: Skip the next step if the

ORMC has a wire harness

and switch.

94. Connect a 33 in. length of flex

tubing (P/N ML08003 x33) between

the front port on the gas selector

switch and secure it with a press-on

clamp. Connect the other end of the

tubing to the top hose barb on the

minimum O

flow valve and secure

2

it with a press-on clamp (P/N

4104161 x2). Install an O

label (P/N

2

4109871 x2) at each end of this tube.

95. Connect an 8 in. length of flex

tubing (P/N ML08003 x8) from the

side port of the rear valve on the gas

selector and secure it with a presson clamp (P/N 4104161). Connect

the other end of the tubing to the

center port of the nylon tee fitting

(P/N 4102337), and secure it with a

tie strap (P/N 4106068). Install an

O

label (P/N 4109871 x2) on each

2

end of this tube.

96. Connect an 11 in. length of flex

tubing (P/N ML08003 x11) to the

side port of the front valve on the

gas selector, and secure it with a

press-on clamp (P/N 4104161).

Connect the other end of the tubing

to the nylon tee fitting installed in

the previous step, and secure the

connection with a tie strap (P/N

4106068). Install an O

label (P/N

2

4109871 x2) on each end of this

tube.

97. Connect a 24 in. length of flex

tubing (P/N ML08003 x24) from the

rear port on the gas selector

assembly to the hose barb on the top

of the air OFPD in the flowmeter

housing. See Figures 11 and 12.

Secure each end with a press-on

clamp (P/N 4104161 x2). Install an

O

label (P/N 4109871 x2) on each

2

end of this tube.

98. Cut the flex tubing two inches above

the hose barb on the top of the air

OFPD and install a nylon tee fitting

(P/N 4102337) as shown in Figure

12. Install an O

label (P/N 4109871

2

x2) on each end of this junction.

17

Page 18

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

FROM PRESSURE

SWITCH ASSEMBLY

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

FROM TEE

FITTING

IN VAPOR BOX

TEE FITTING "C"

(EXISTING)

4-WAY

FITTING

FROM GAS

SELECTOR

TEE FITTING

(INSTALL)

2 IN. LENGTH

6 IN. LENGTH

N2O OFPD

AIR OFPD

SP10512

Figure 12: FLEX TUBING CONNECTIONS

CO2 OFPD

18

Page 19

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

99. Connect a 6 in. length of flex tubing

(P/N ML08003 x6) to the side port of

the nylon tee installed in the

previous step.Connect the other end

of this tube to hose barb on the top

of the CO

OFPD, and secure this

2

connection with a press-on clamp

(P/N 4104161). Secure all nylon tee

fitting junctions with tie straps (P/N

4106068 x3). Install an O

label (P/N

2

4109871 x2) on each end of the

tubing.

100. Connect a 17 in. length of flex

tubing (P/N ML08003 x17) from the

remaining port of the nylon tee

fitting in the vapor box and secure it

with a tie strap (P/N 4106068).

Connect the other end of the tubing

to the side port "A" on the 4-way

fitting and secure it with a press-on

clamp (P/N 4104161). Install an O

label (P/N 4109871 x2) on each end

of this tube. See Figure 12.

101. Remove the existing tubing from

side port "B" on the 4-way fitting.

Connect an 8 in. length of flex

tubing (P/N ML08003 x8) from side

port "B" on the 4-way fitting to the

bottom port of the minimum flow

valve, and secure each connection

with a press-on clamp (P/N 4104161

x2). Install an O

label (P/N

2

4109871 x2) on each end of this

tube. See Figure 12.

102. Cut the tie strap securing the flex

tubing on the side port of tee fitting

"C" in the flowmeter housing and

remove the tubing.

103. Connect a 10 in. length of flex

tubing (P/N ML08003 x10) to the

side port of nylon tee fitting "C", and

secure it with a tie strap (P/N

4106068). Connect the other end of

the tubing to the side port of the

minimum flow valve, and secure it

with a press-on clamp (P/N

4104161). Install an O

label (P/N

2

4109871 x2) on each end of this

tube.

104. Reconnectthe flex tubing previously

removed from the hose barb located

below the O

flow control valve, and

2

secure the connection with the

press-on clamp previously removed.

Verify that an O

label is attached to

2

each end of this hose.

105. Reconnectthe flex tubing previously

2

removed from the hose barb located

below the N

O flow control valve,

2

and secure the connection with the

press-on clamp previously removed.

Verify that a N

O label is attached

2

to each end of this hose.

106. ConnecttheAir pipeline supplyhose

to the machine.

107. Install a CO

cylinder in the new

2

yoke. Verify the presence of two

index pins on the yoke assembly and

the correct engagement with the

cylinder index holes. Open one

cylinder valve each of Oxygen,

Nitrous Oxide and CO

108. Close the N

O flow control valve;

2

.

2

ensure that all other valves are fully

open.

19

Page 20

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

109. Turn the System Power switch ON,

and depress the rear gas selector

valve to flush any debris from the

new piping, and return the switch to

the STANDBY position.

110. Install the CO

restrictor housing

2

(P/N 4103440) with a yellow

restrictor (P/N 4110738-006) and Oring (P/N 4101872) as shown in

Figure 14.

111. Place gaskets (P/N 4102724 x2) on

top of the CO

restrictor housing and

2

in the insert at the top flowmeter

block for CO

112. Carefully install the CO

.

2

flowtube

2

(P/N 4112557-001) with the CO

marking facing forward as shown in

Figure 14.

113. Install the AIR restrictor housing

(P/N 4103440) with an O-ring (P/N

4101872) as shown in Figure 14.

114. Place gaskets (P/N 4102724 x2) on

top of the AIR restrictor housing and

in the insert at the top flowmeter

block for AIR.

115. Carefully install the AIR flowtube

(P/N 4112558-001) with its AIR

marking facing forward as shown in

Figure 14.

116. Close the AIR and CO

flow control

2

valves.

117. Reinstall the O

restrictor assembly

2

that was previously removed from

the bottom flowmeter block.

119. Turn the System Power switch to

ON to flush any debris from the new

piping, and return the switch to the

STANDBY position.

120. Carefully reinstall the O

flowtube with the O

marking facing

2

2

coarse

forward as shown in Figure 14.

121. Turn the System Power switch ON

to flush any debris from the new

piping, and return the switch to the

STANDBY position.

122. Reconnectthe flex tubing previously

removed from the N

O restrictor

2

assembly and verify that the

connection is secured with a press-

2

123. Reinstall the N

on clamp.

O restrictor

2

assembly that was previously

removed from the bottom flowmeter

block.

124. Turn the System Power switch ON.

Set the O

N

O flow control valve fully to its

2

flow to 4 l/min. Open the

2

stop to flush any debris from the

new piping. Return the System

Power switch to STANDBY.

125. Carefully reinstall the N

flowtube with the N

O fine

2

O marking

2

facing forward as shown in Figure

14.

126. Turn the System Power switch ON

to flush any debris from the new

piping, and return the switch to the

STANDBY position. Close the N

O

2

flow control valve.

118. Carefully reinstall the O

flowtube with the O

marking facing

2

forward.

fine

2

20

Page 21

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

SP10513

GASKET

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

LABEL "CAUTION-

HYPOXIC MIXTURE"

LABEL "O2 & N2O"

GASKET

LABEL "ALL GASES"

CO2 FLOWMETER TUBE

4-GAS CO2 FLOWMETER SHIELD

AIR FLOWMETER TUBE

GASKET

RESTRICTOR (YELLOW)

P/N 4110738-006

RESTRICTOR HOUSING

O-RING, #010

FLOW CONTROL KNOB

AND CO2 LABEL

GASKET

RESTRICTOR HOUSING

O-RING, #010

FLOW CONTROL KNOB

AND O2 LABEL

Figure 13: AIR AND CO2FLOWTUBE INSTALLATION

21

FLOW CONTROL KNOB

AND AIR LABEL

FLOW CONTROL KNOB

AND N2O LABEL

Page 22

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

127. Carefully reinstall the N

flowtube with the N

O coarse

2

O marking

2

facing forward as shown in Figure

14.

128. Slidethe4-gas flowmeter lights PCB

(P/N 4110857) into the flow lights

channel (P/N 4110582) and attach

the wire harness to the assembly.

(The black wire is connected to the

terminal at the back of the PCB.)

Insert the assembly into the

shoulder studs at the center

flowmeter. Reinstall the remaining

lights in the same manner.

129. Install the 4-gas flowmeter shield

(P/N 4110587-004).

130. Reattach the 3-gas flowmeter knob

guard to the flowmeter assembly

reusing the hardware previously

removed.

131. Use the appropriate vapor box front

plate (P/N 4111510 or 4111520) on

machines with a multigas analyzer.

Assemble the gas selector switch

cam assembly (consisting of P/Ns

4111693, 4103169, 4103423,

4108461, 4108462, 4109866, and

4109867) to the new vapor box front

panel with two 8-32 x in. socket

head screws (P/N HW01012 x2) and

lock washers (P/N HW67000 x2).

See Figure 13.

132. If applicable, attach the vapor

indicator PCB assembly to the front

panel with the hardware that was

previously removed. Restore all wire

connections to the vapor indicator

PCB.

133. Installthe vapor box front panel and

ensure that the selector switch cams

operate the gas select valves

correctly. Set the selector to the ALL

GAS position. Attach a HYPOXIC

MIXTURE label (P/N 4110953) to

the left of the gas selector switch. If

applicable, apply arrow indicator

labels (P/N 4112055 x3) at the three

locations shown in Figure 13.

134. Reinstall the angled front plate at

the top of the flowmeter shield

reusing the hardware previously

removed. On earlier machines this

plate is retained by two screws

inside the flowmeter housing. (On

later machines with a one-piece

plate, this plate was installed in the

previous step as part of the vapor

box front cover.)

135. Install the AIR and CO

flow knobs

2

(P/N 4103736 x2) and reinstall the

N

O and O2flow knobs.

2

136. Turn the System Power switch ON.

Set the Gas Selector switch to ALL

GAS. Verify that the O

and CO

flowmeters operate

2

2,N2

O, AIR,

properly over their full range. Close

all flow control valves.

137. Connect the 15 mm connector to a

Capnomed flowmeter test stand and

verify that each "off stop" is properly

set. Readjust the stops as necessary.

Removethe testflowmeter. Turnthe

System Power switch ON. Verify

that all flow meters operate properly

over their full range.

22

Page 23

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

VAPOR BOX TOP VIEW

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

GAS SELECTOR

SWITCH ASSEMBLY

HYPOXIC MIXTURE

CAUTION LABEL

SP10514

VAPOR BOX FRONT VIEW

Figure 14: GAS SELECTOR SWITCH ASSEMBLY

SWITCH ASSEMBLY

MOUNTING SCREWS AND

LOCK WASHERS (2X)

VAPOR BOX

FRONT PANEL

ARROW

LABELS (3X)

23

Page 24

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

138. Enable the circuit breakers and

connect AC power to the machine.

139. Removeany existing labels from the

flowmeter knobs. Install the correct

label (P/Ns 4103905, 4103908,

4103904, and 4103178) on each

flowmeter knob.

TOP VIEW OF MACHINE

WITH DRAWER OPEN

140. Attach a new instruction label (P/N

4104818) to the inside of the top

drawer as shown in Figure 15.

INSTRUCTION

LABEL

System Power

Figure 15: NEW INSTRUCTION LABEL LOCATION

24

TOP

DRAWER

SP10515

Page 25

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CO2AND AIR CIRCUIT ADJUSTMENT AND TEST

1.0 CYLINDER PRESSURE REGULATOR

ADJUSTMENT

1.1 Open the CO

flow control valve

2

to the full open position.

1.2 Loosen or remove the acorn nut

from the CO

regulator.

2

1.3 Turn the System Power switch

to ON.

1.4 Set the Gas Select switch to the

ALL GAS position.

1.5 Open the O

and CO2cylinder

2

valves.

1.6 Turn the CO

regulator

2

adjustment screw until the CO

flowmeter indicates a flow rate

of 550 ml/min.

2.0 HIGH PRESSURE CYLINDER LEAK

TEST

2.1 Turn the System Power switch

to STANDBY.

2.2 Open all cylinder valves and

allow the gauge pressures to

stabilize.

2.3 Close all cylinder valves and

remove all cylinders from their

yokes. If applicable, close the

Auxiliary O

flowmeter valve.

2

Observe the cylinder pressure

gauges. The pressure should not

drop more than 50 psi over the

next two minutes.

2

2.4 Reattach the cylinders to the

yokes.

Replace the acorn nut on the

regulator.

2.5 Turn the System Power switch

to ON and repeat the high

pressure leak test.

25

Page 26

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CO2AND AIR CIRCUIT ADJUSTMENT AND TEST (continued)

3.0 LOW PRESSURE LEAK TEST

3.1 Ensure that all flow control

valves are closed.

3.2 Turn the System Power switch

to STANDBY.

3.3 Remove the 15mm connector

from the FRESH GAS

OUTLET. Connect a test gauge

and B.P. bulb to the fresh gas

outlet, and pressurize the

system to 50 cm H

O.

2

3.4 The pressure should not drop

more than 10 cm H

O in thirty

2

seconds.

3.5 Disconnect the test gauge.

Reconnect the 15mm connector

to the FRESH GAS OUTLET.

5.0 FLOWMETER TEST

5.1 Open the O

cylinder valve.

2

5.2 Adjust the flow of AIR over the

full range of the flowmeter. The

float should move freely over

the entire range.

5.3 Adjust the flow of CO

maximum position. The flow

should be between 500 and 600

ml/min. If the flow is not

correct, repeat test procedure

1.0 (cylinder pressure regulator

adjustment).

5.4 Adjust the O

flowmeter to 3

2

l/min.

5.5 Adjust the flow of N

O over the

2

full range of the flowmeter. The

float should move freely over

the entire range.

to the

2

4.0 OFPD TESTS

4.1 Turn the System Power switch

to ON.

4.2 Open the O

,N2O, and CO

2

cylinder valves.

4.3 Set the O

,N2O, and AIR flow

2

rates to 1.0 l/min.; set the CO

flow rate to 500 ml/min.

4.4 Close the O

cylinder valve.

2

When the oxygen flow stops, the

N

O, AIR and the CO2flows

2

must also drop to zero.

6.0 GAS SELECTOR SWITCH TEST

6.1 With the switch in the ALL

GAS position, open all of the

2

flow control valves and verify

that all gases are able to flow.

6.2 Turn the Gas Select switch to

O

2

+N2O. The flow of AIR and

2

CO

should stop.

2

6.3 Close all of the flow control

valves. There should be a

minimum oxygen flow.

6.4 Turn the Gas Select switch to

ALL GAS. The minimum flow

should stop.

26

Page 27

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CO2AND AIR CIRCUIT ADJUSTMENT AND TEST (continued)

7.0 OXYGEN CONCENTRATION

VERIFICATION TEST

7.1 Connect a 22mm hose between

the bellows VENTILATOR

HOSE andthe inspiratory valve

terminals.

7.2 Activate the waste gas

scavenger.

7.3 Set theManual/Automaticvalve

to BAG.

7.4 Occlude the bag mount.

7.5 Insert the sensor from a

calibrated O

Med into the valve

2

dome on the inspiratory valve.

7.6 Set the O

7.7 Verify that the O

flow to 4 l/min.

2

concentration

2

is between 97% and 100%

within 3 minutes.

7.8 Set the N

7.9 Verify that the O

O flow to 2 l/min.

2

concentration

2

is between 64% and 70% within

3 minutes.

7.12 Verify that the O

concentration

2

is between 71% and 77% within

3 minutes.

7.13 Close the AIR flow control

valve.

7.14 Set the O

7.15 Set the CO

7.16 Verify that the O

flow to 1 l/min.

2

flow to 500 ml/min.

2

concentration

2

is between 64% and 70% within

3 minutes.

7.17 Close the CO

and O2flow

2

control valves.

7.18 Remove the occlusion from the

bag mount.

7.19 Remove the 22mm hose from

the bellows VENTILATOR

HOSE and inspiratory valve

terminals.

7.10 Close the N

O flow control

2

valve.

7.11 Set the AIR flow to 2 l/min.

27

Page 28

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CO2AND AIR CIRCUIT ADJUSTMENT AND TEST (continued)

8.0 ORMC TEST

NOTE:

If the alarm channel on the machine

does not have an O

2/N2

lamp, disregard the alarm functions

in the following tests.

8.1 Fully open the N

O flow control

2

valve. Slowly open and close the

O

flow control valve, and

2

observe that the ORMC is

controlling the flow of nitrous

oxide. There should be no

ORMC alarm with the Gas

Select switch in the ALL GAS

position.

8.2 Turn the Gas Select switch to

O

+N2O. Slowly open and close

2

the O

flow control valve, and

2

observe that the ORMC is

controlling the flow of nitrous

oxide. The ORMC alarm should

function correctly with the Gas

Select switch in the O

position.

O alarm

+N2O

2

9.0 RE-ASSEMBLY & FINAL TESTING

9.1 Close all cylinder valves except

the O

9.2 Set the O

9.3 Open the N

cylinder valve.

2

flow rate to 5 l/min.

2

O flow control valve

2

to drain pressure from the

system.

9.4 Close the O

open the O

and press the O

cylinder valve,

2

flow control valve,

2

FLUSH button

2

to drain pressure from the

system.

9.5 Turn the System Power switch

to STANDBY.

9.6 Reinstall the table top on the

machine.

9.7 Reinstall the vapor box back

coverandthe flowmeter housing

back cover.

9.8 Perform a complete PMS

procedure on the machine.

28

Page 29

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

Technical Service Department

3122 Commerce Drive

Telford, PA 18969

(215) 721-5402

(800) 543-5047

(215) 723-5935 Fax

Quality Service for Life

®

Part Number: SP00105

Rev: B

Date: June 21, 1996

© 1996 N.A.D., Inc.

Loading...

Loading...