Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Technical Service Manual

Fabius Tiro ®

Anesthesia System

Emergency Care • OR/ Anesthesia • Critical Care • Home Care

Revision B

5/25/04

6020.002

4118302-002

Because you care

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Copyright by Dräger Medical AG & Co. KGaA, Lübeck, Germany.

No reproduction allowed for commercial purposes.

Read and understand the Instructions for Use/Operator’s Manual.

This Technical Documentation does not replace the Instructions for Use/Operator’s

Manual.

The warranty and liability conditions of the general terms and conditions for business

transactions of Dräger Medical AG & Co. KGaA are not extended by this Technical

Documentation.

Observe all applicable technical laws and regulations.

Insofar as reference is made to laws, regulations or standards, these are based on the

legal system of the Federal Republic of Germany. Observe the laws and regulations

applicable in your country.

Page 3

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Service Manual Table of Contents

What's New in Rev. B

DESCRIPTION

PAGE

General......................................................................................................................................... 1

Recommendations ............................................................................................................... 3

How To Use This Manual ..................................................................................................... 3

General Troubleshooting Guidelines.................................................................................... 3

Copyright.............................................................................................................................. 6

Trademark Notices...............................................................................................................6

Disclaimer ............................................................................................................................ 6

Function Description.................................................................................................................. 7

General Information about the Fabius Tiro .......................................................................... 9

Fabius Tiro Function Diagram............................................................................................ 14

Battery Backup................................................................................................................... 16

Fabius Tiro Piping Diagram................................................................................................ 17

Function Description of Gas Box........................................................................................ 19

SORC (Sensitive Oxygen Ratio Controller) ....................................................................... 20

Compact Breathing System, Cosy II .................................................................................. 22

Manual Ventilation..............................................................................................................25

Spontaneous Breathing...................................................................................................... 28

Volume/Pressure Mode Ventilation .................................................................................... 32

Cosy II Absorber ................................................................................................................37

Ventilator ............................................................................................................................ 37

High Pressure Safety Valve ............................................................................................... 39

Negative Pressure Relief Valve.......................................................................................... 40

Pneumatic System ............................................................................................................. 40

PEEP/Pmax Valve Control ................................................................................................. 41

APL Bypass Valve Control ................................................................................................. 41

Electronic Block Diagram................................................................................................... 43

Control PCB ....................................................................................................................... 44

Flowmeter .......................................................................................................................... 44

Patient Interface................................................................................................................. 44

Ventilator ............................................................................................................................ 44

Front Panel Functions........................................................................................................ 44

Pneumatic Assembly Control............................................................................................. 44

Serial Port Interface ...........................................................................................................44

Battery................................................................................................................................ 44

Control Panel Assembly..................................................................................................... 45

FiO2 Measurement ............................................................................................................ 47

Respiratory Flow Measurement ......................................................................................... 48

Gas Flow Rate Measurement ............................................................................................ 49

I

Page 4

CONTENTS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

FABIUS TIRO

DESCRIPTION

PAGE

Vaporizer ............................................................................................................................ 50

ELECTROMAGNETIC TESTING AND COMPLIANCE ............................................................. 51

Electromagnetic Testing and Compliance.......................................................................... 53

Guidance and manufacturer’s declaration-electromagnetic emissions.............................. 53

Guidance and manufacturer’s declaration-electromagnetic immunity ............................... 54

Guidance and manufacturer’s declaration-electromagnetic immunity ............................... 55

Recommended separation distances between portable and mobile RF communications

equipment and the Fabius Tiro.................................................................................. 57

TROUBLESHOOTING GUIDE ................................................................................................... 61

Troubleshooting .................................................................................................................63

Power Supply and Voltage Distribution .............................................................................. 63

Battery................................................................................................................................ 68

Troubleshooting Guides..................................................................................................... 68

DIAGNOSTICS ........................................................................................................................... 81

Diagnostics ........................................................................................................................ 83

System Service Screen...................................................................................................... 87

Main Service Screen.......................................................................................................... 89

Service Log ........................................................................................................................ 91

Service Log Entries............................................................................................................ 91

Real Time Values ............................................................................................................... 97

Preventive Maintenance .................................................................................................. 101

Activate Preventive Maintenance Date ............................................................................ 101

General ............................................................................................................................ 103

Serial Number .................................................................................................................. 103

Reset Hours Run ............................................................................................................. 104

Reset Last Service Date .................................................................................................. 105

Select Market Kit.............................................................................................................. 106

Calibration........................................................................................................................ 109

Fresh Gas Flow Calibration.............................................................................................. 109

Pressure Calibration..........................................................................................................110

O2 Zero Calibration...........................................................................................................111

PEEP Valve Calibration.....................................................................................................112

Configure ..........................................................................................................................115

System Settings (US and Non-US)...................................................................................115

Model Type .......................................................................................................................116

Standard Options ..............................................................................................................117

Flowmeter .........................................................................................................................118

O2 Position (Virtual Flowtubes).........................................................................................119

Gas Selection...................................................................................................................120

Flowtube Resolution ........................................................................................................ 121

O2 Whistle ....................................................................................................................... 122

II

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

FABIUS TIRO

CONTENTS (continued)

DESCRIPTION PAGE

Alarms.............................................................................................................................. 123

No Fresh Gas................................................................................................................... 124

Fresh Gas Low Alarm ...................................................................................................... 125

Threshold Low Alarm ....................................................................................................... 126

Pressure........................................................................................................................... 127

Ambient Pressure ............................................................................................................ 128

Plateau-Mean Display Screen.......................................................................................... 128

Secure Options ................................................................................................................ 129

Serial Port ........................................................................................................................ 131

Serial Port Parameters..................................................................................................... 131

Pump On/Off .................................................................................................................... 133

REPLACEMENT PROCEDURES ............................................................................................ 135

Replacement Procedures................................................................................................. 137

Core Module Inversion..................................................................................................... 139

Core Module Inversion Disassembly................................................................................ 139

Core Module Inversion Reassembly ................................................................................ 139

Wall Mount Service Access Procedure (If Applicable)..................................................... 143

Cylinder Yokes (Fixed) and Regulators............................................................................ 145

Cylinder Pressure Gauges............................................................................................... 149

Auxiliary Oxygen Flow Meter ........................................................................................... 151

Vaporizers ........................................................................................................................ 153

O2 Flush Valve................................................................................................................. 155

Caster .............................................................................................................................. 157

Ventilator .......................................................................................................................... 159

Gas Inlet Assembly (including O2 supply pressure switch) ............................................. 171

Battery.............................................................................................................................. 173

Power Supply................................................................................................................... 175

Control PCB Assembly..................................................................................................... 177

Pneumatic (PEEP Control) Assembly.............................................................................. 183

Flow Meter Bezel Assembly............................................................................................. 185

Fresh Gas Flow Meter...................................................................................................... 187

Flow Control Valves ......................................................................................................... 189

Fresh Gas Flow Sensors and Filter Assembly................................................................. 191

Pipeline Pressure Gauges ............................................................................................... 193

SORC (Sensitive Oxygen Ratio Controller) ..................................................................... 195

Fresh Gas Display PCB ................................................................................................... 197

Monitor Bezel Assembly................................................................................................... 199

Spirolog Sensor and Cable .............................................................................................. 201

ADJUSTMENT AND CALIBRATION PROCEDURES............................................................. 203

Cylinder Pressure Regulator Adjustment......................................................................... 205

Gas Inlet Regulator Output Adjustment ........................................................................... 207

Oxygen Supply Pressure Alarm Switch Adjustment ........................................................ 209

Sensitive Oxygen Ratio Controller (SORC) Adjustment ...................................................211

III

Page 6

CONTENTS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

FABIUS TIRO

DESCRIPTION

PAGE

Oxygen Sensor Calibration .............................................................................................. 214

Pressure Calibration......................................................................................................... 216

Fresh Gas Flow Calibration.............................................................................................. 217

PEEP Valve Calibration.................................................................................................... 218

Vacuum Adjustment ......................................................................................................... 219

Vacuum Pressure Pump Assembly (Software Version 2.N)............................................. 221

Pump Calibration - If Applicable....................................................................................... 221

SOFTWARE UPDATE PROCEDURE ...................................................................................... 225

Software Update Procedure............................................................................................. 229

Requirements................................................................................................................... 229

Boot Strap Download Procedure...................................................................................... 229

PMS PROCEDURE ...................................................................................................................241

SPARE AND REPLACEMENT PARTS LIST........................................................................... 307

IV

Page 7

General

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

1

Page 8

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

2

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

General Fabius Tiro

1 Recommendations Because of the sophisticated nature of Draeger Medical, Inc. anesthesia

equipment and its critical importance in the operating room setting, it is highly

recommended that only appropriately trained and experienced professionals

be permitted to service and maintain this equipment. Please contact

DrägerService® at (800) 543-5047 for service of this equipment in North

America. For service in Europe, call 49 (451) 882-4222. For service in other

countries, call (215) 721-5402.

Draeger Medical, Inc. recommends that the Fabius Tiro be serviced at six

month intervals. Periodic Manufacturer’s Certification agreements are available for equipment manufactured by Draeger Medical, Inc. Please contact us

for further information concerning these agreements.

Draeger Medical, Inc. products/material in need of factory repair shall be sent

to:

2 How To Use This

Manual

For North America and other countries except Europe:

DrägerService®

3124 Commerce

Drive Telford, PA 18969

U.S.A.

(Include RMA Number)

The manual is divided into several sections. The DIAGNOSTICS section

describes self-test and service diagnostics for checking the system functions.

An understanding of the on-board service capabilities is necessary before

any attempt is made to troubleshoot the unit. The TROUBLESHOOTING section lists error codes and provides troubleshooting guides to assist the Technical Service Representative in locating the source of a problem. The

REPLACEMENT PROCEDURES section contains instructions for removal

and replacement of assemblies that are considered field-replaceable. The

ADJUSTMENT AND CALIBRATION PROCEDURES section contains the

field procedures needed to restore original system specifications. The Periodic Manufacturer’s Service (PMS) PROCEDURE section outlines the steps

required to verify the electrical, mechanical, and pneumatic safety of the unit

and also, identifies components requiring periodic replacement. The SPARE

PARTS section is provided for use as a reference only to obtain part numbers

and descriptions for parts and assemblies for replacement purposes. For

items not shown in the Spare Parts section, contact DrägerService®.

For service in Europe:

Dräger Medical AG & Co. KGaA

Moislinger Allee 53-55

Reparaturannahme

23542 Lübeck

Germany

3 General Trouble-

shooting Guidelines

All rights reserved. Copyright reserved.

K6020002_GeneralUSA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Troubleshooting the Fabius Tiro should always begin by communicating with

those who observed or experienced a problem with the unit. This may eliminate unnecessary troubleshooting steps. Once a general problem is identified, refer to the flow charts in the Troubleshooting Section to determine the

proper corrective action to be taken.

After any component is replaced, verify that the unit is operating properly by

running the appropriate diagnostic procedure. The PMS PROCEDURE must

also be performed after any component is replaced.

3

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro General

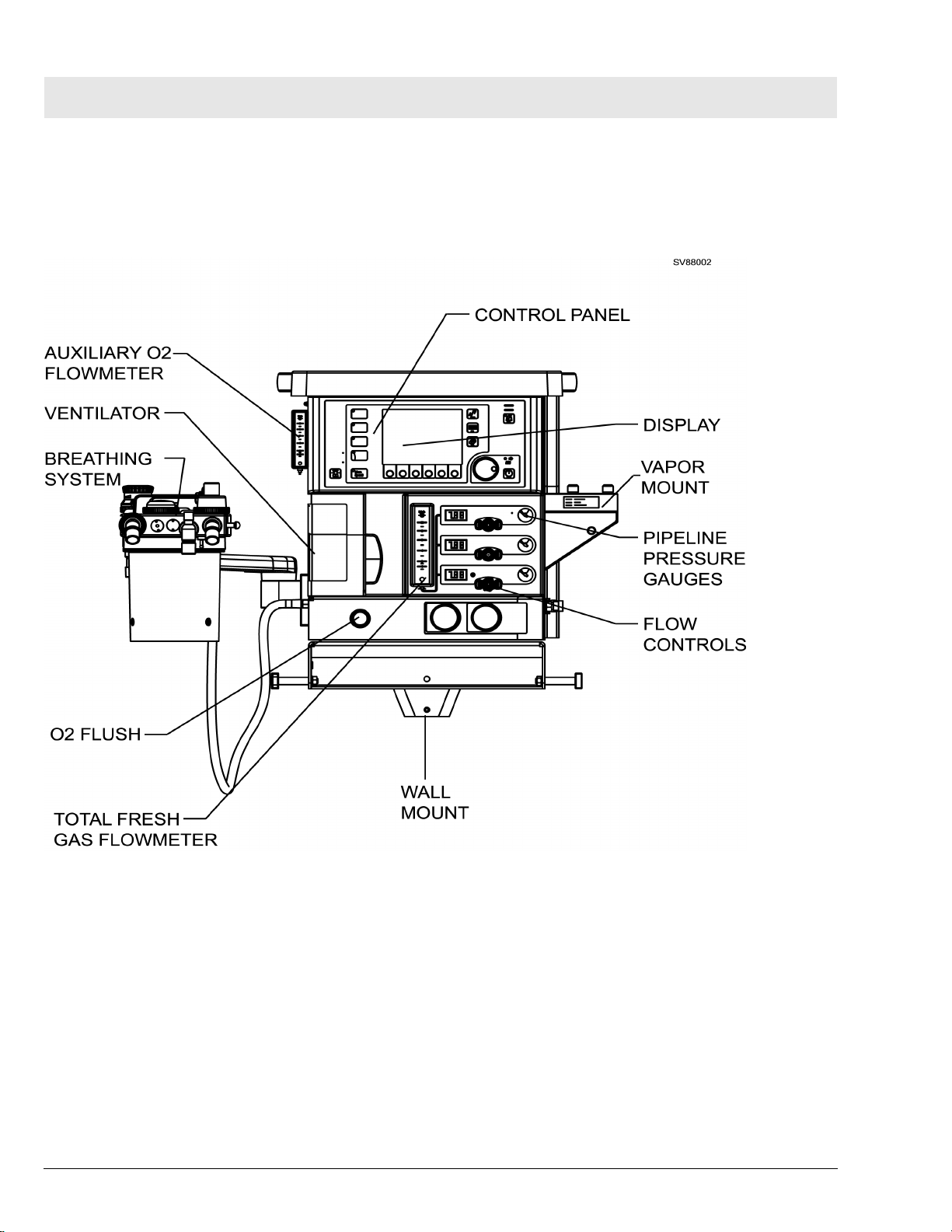

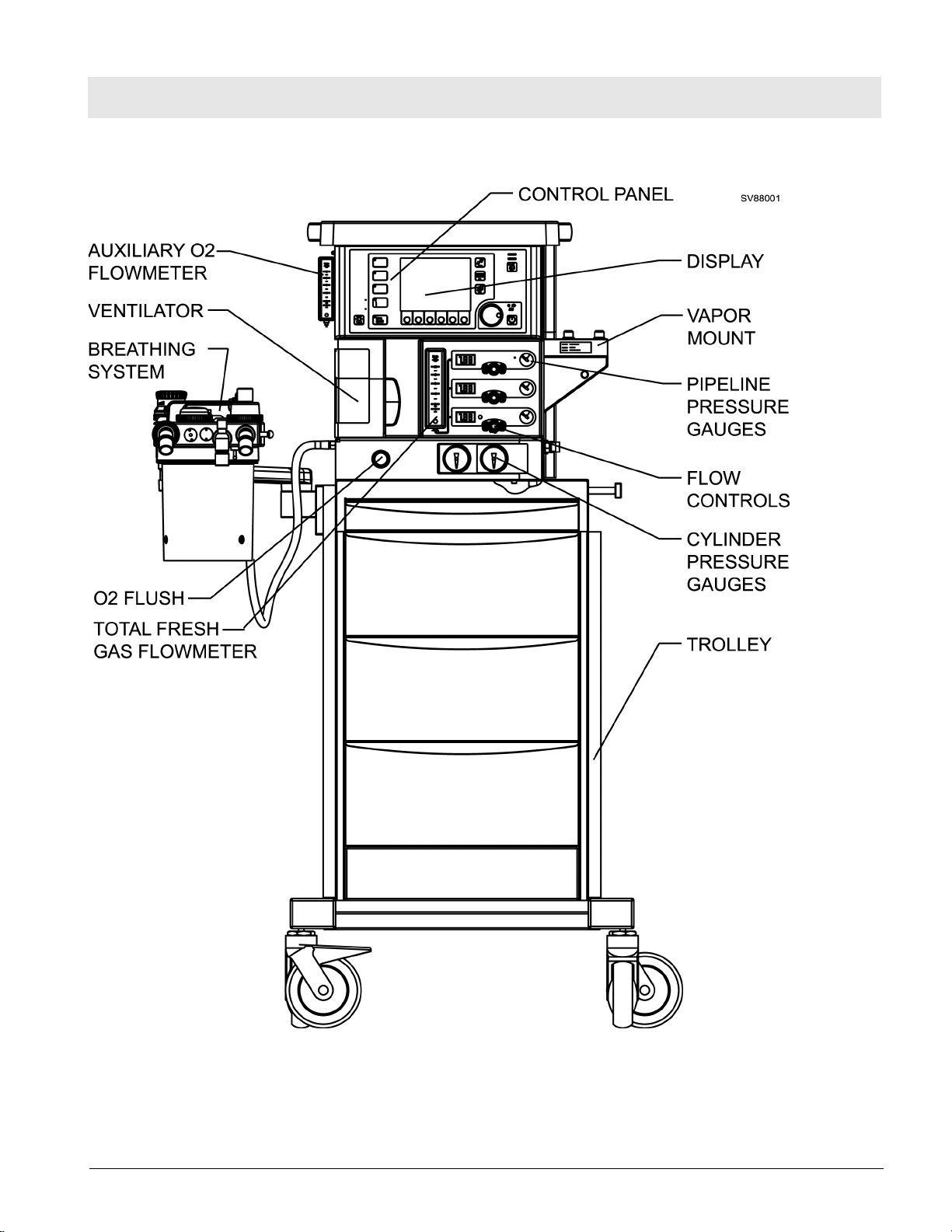

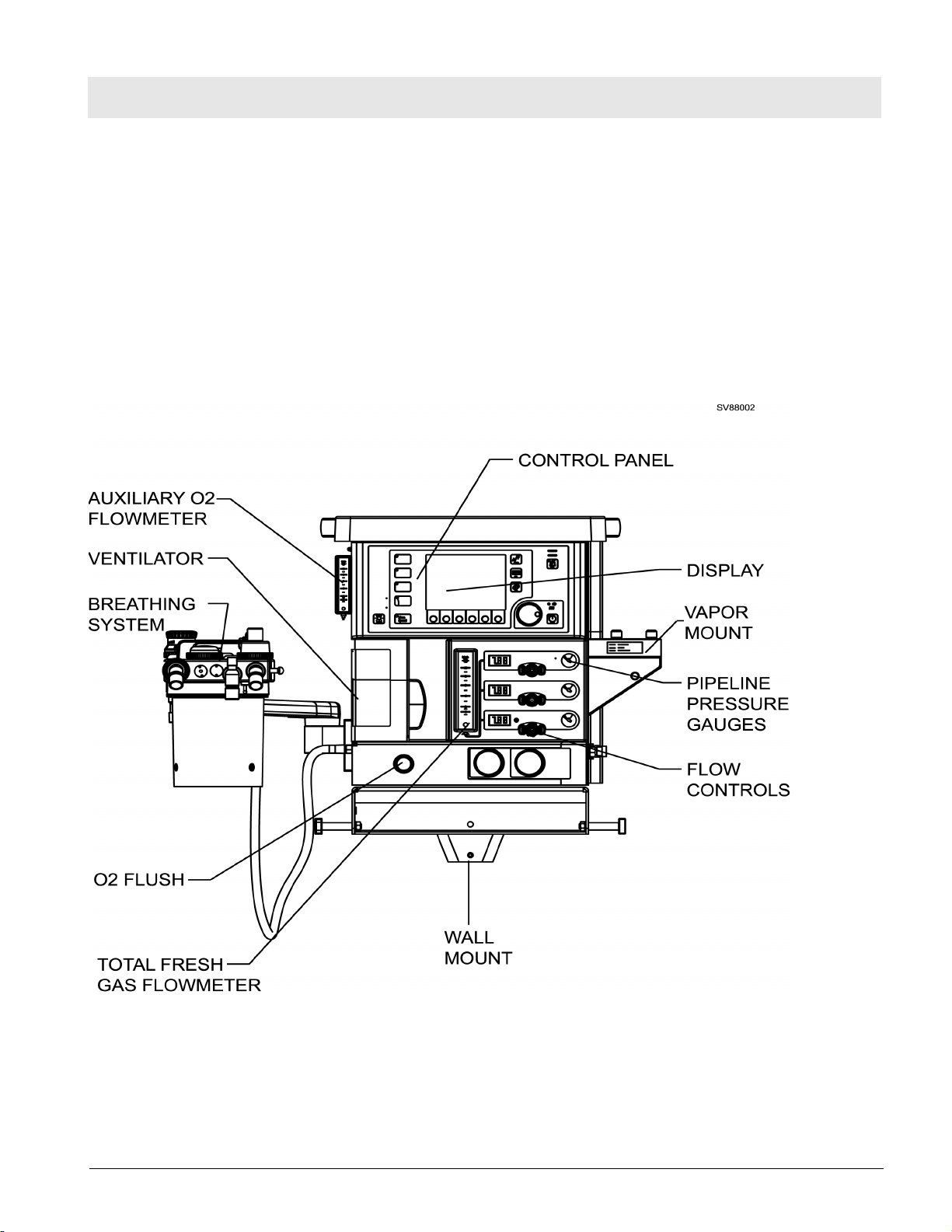

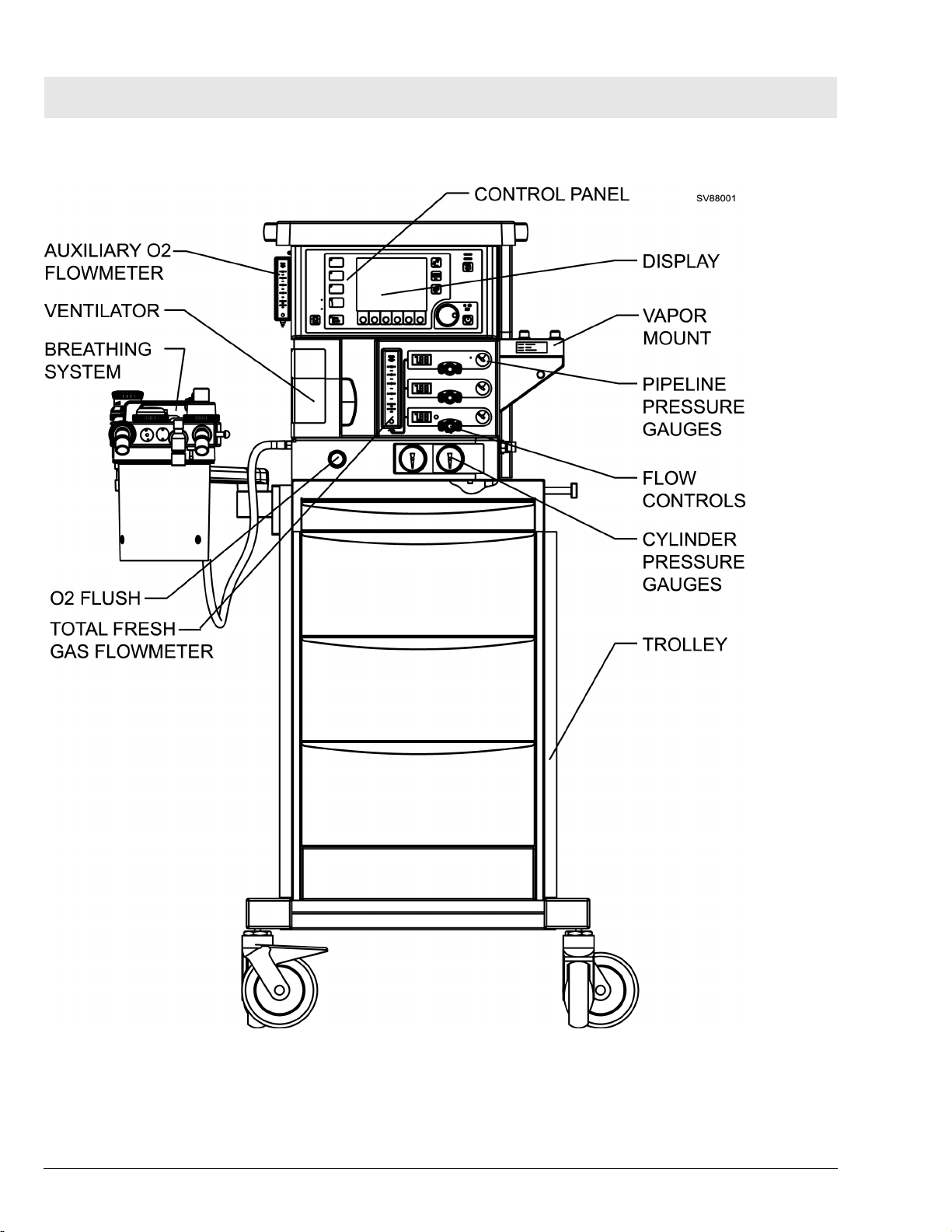

There are two possible mounting configurations for the Fabius Tiro, a wall

mounted unit and a trolley mounted unit. A general arrangement of both

mounting configurations of the Fabius Tiro anesthesia system are shown in

Figure 1 and Figure 2.

Figure 1 Fabius Tiro - Wall Mount Configuration

4

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

K6020002_GeneralUSA.fm 17.06.04

Page 11

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

General Fabius Tiro

Figure 2 Fabius Tiro - Trolley Mount Configuration

All rights reserved. Copyright reserved.

K6020002_GeneralUSA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

5

Page 12

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro General

4 Copyright Copyright© 2004 by Draeger Medical, Inc. All rights reserved. No part of this

publication may be reproduced, transmitted, transcribed, or stored in a

retrieval system in any form or by any means, electronic or mechanical,

including photocopying and recording, without written permission of Draeger

Medical, Inc.

5 Trademark Notices Datagrip, DrägerService, ORM, Quality Service For Life, Respitone, Narko-

med, Vigilance Audit, Vitalert, Vitalink, Narkomed GS, Fabius, Fabius Tiro,

and Fabius GS are registered trademarks of Draeger Medical, Inc. All other

products or name brands are trademarks of their respective owners.

6Disclaimer The content of this manual is furnished for informational use only and is sub-

ject to change without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or inaccuracies that may appear in this manual.

6

All rights reserved. Copyright reserved.

K6020002_GeneralUSA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

Function Description

RETURN TO CD-ROM TABLE OF CONTENTS

7

Page 14

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

8

Page 15

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

1 General Information

about the Fabius

Tiro

The Fabius Tiro comprises the following assemblies:

– Bezel assembly: Display and Control Panel

– Flowmeter assembly

– Gas Box: Gas Inlet Assembly and related items

– Breathing system

– Pneumatic Assembly

– Ventilator

– Anesthetic Vaporizer(s)

– Trolley Mount and Wall Mount

Figure 1 Front View of Fabius Tiro Anesthesia System - Wall Mount Configuration

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

9

Page 16

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 2 Front View of Fabius Tiro Anesthesia System - Trolley Mount Configuration

10

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 17

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

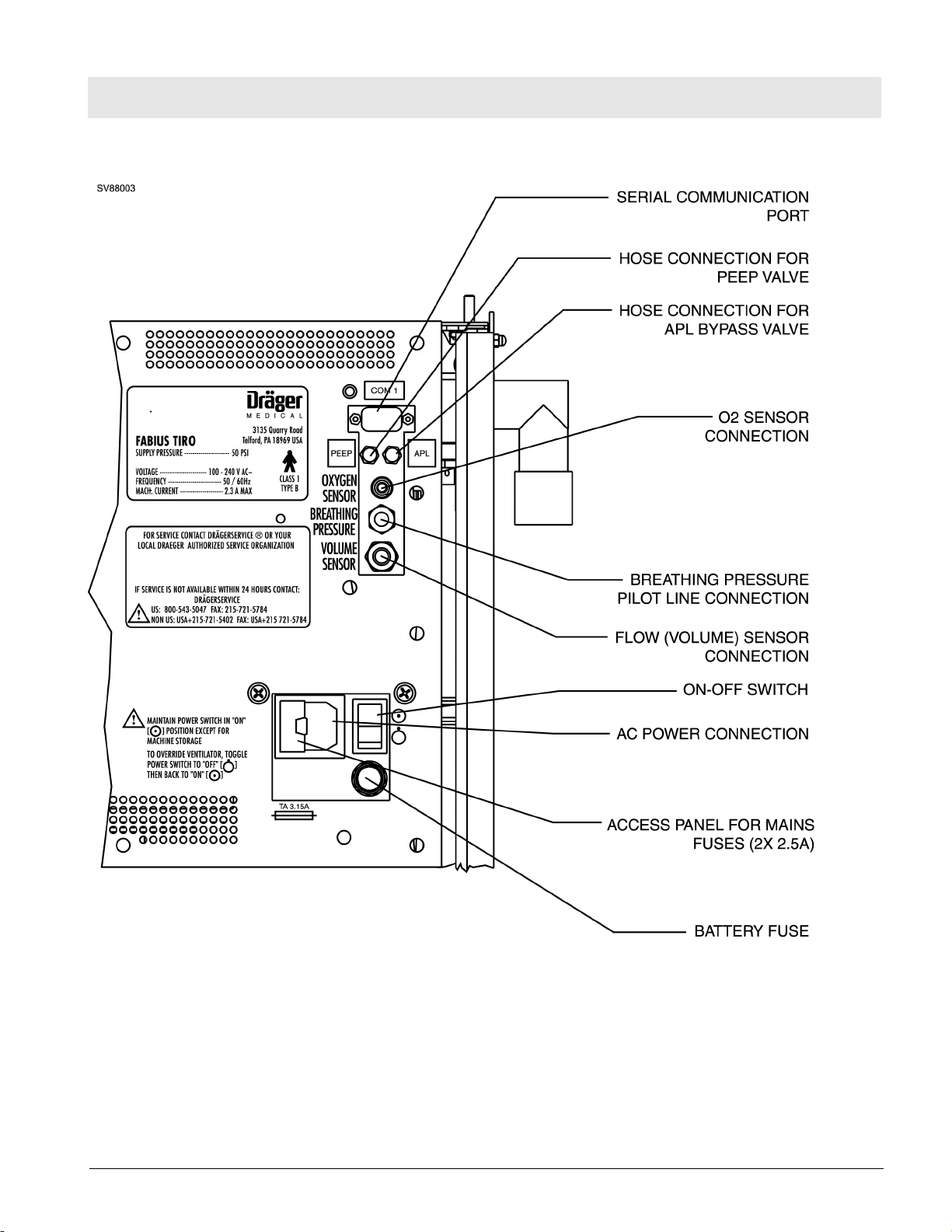

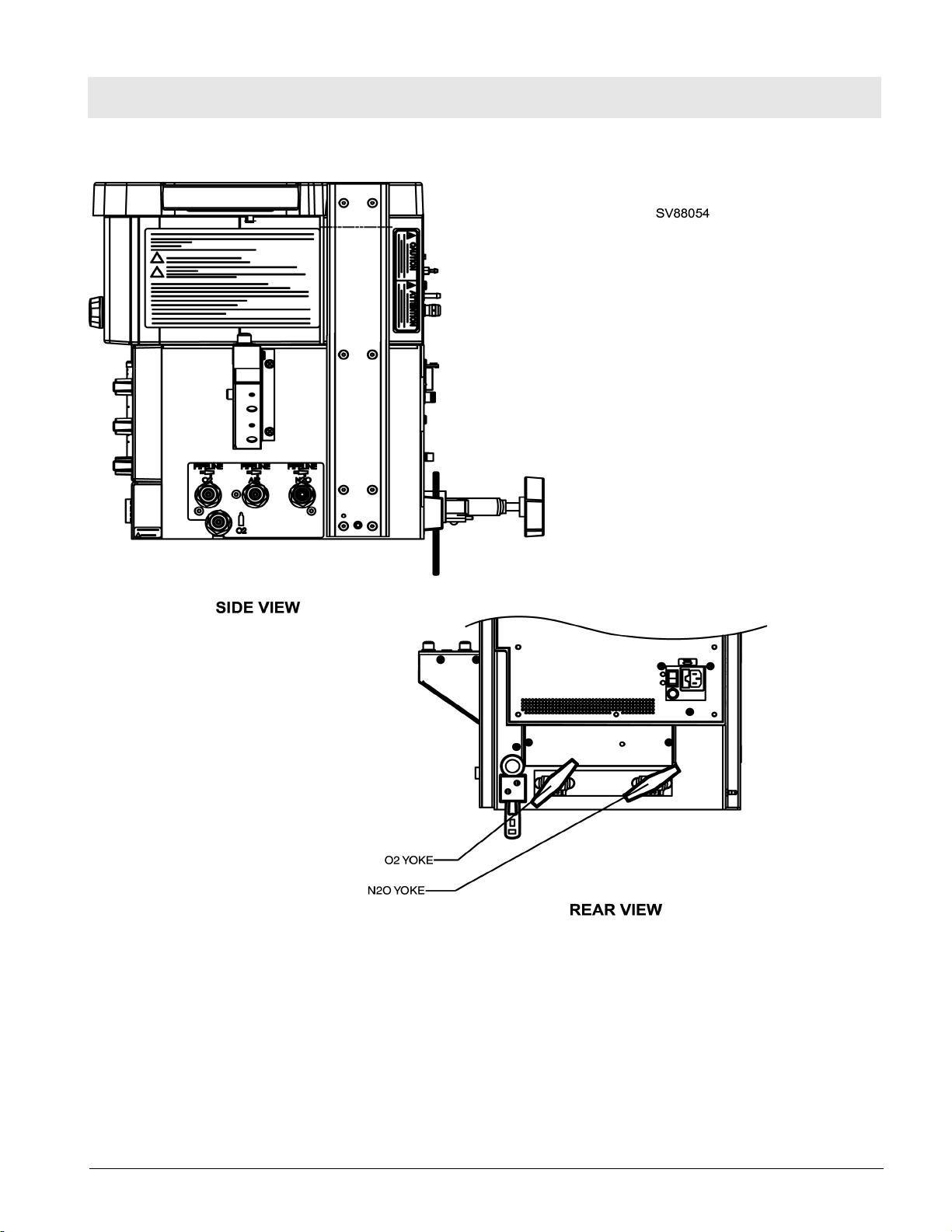

Figure 3 Back View - Interface Panel and Power Entry

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

11

Page 18

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

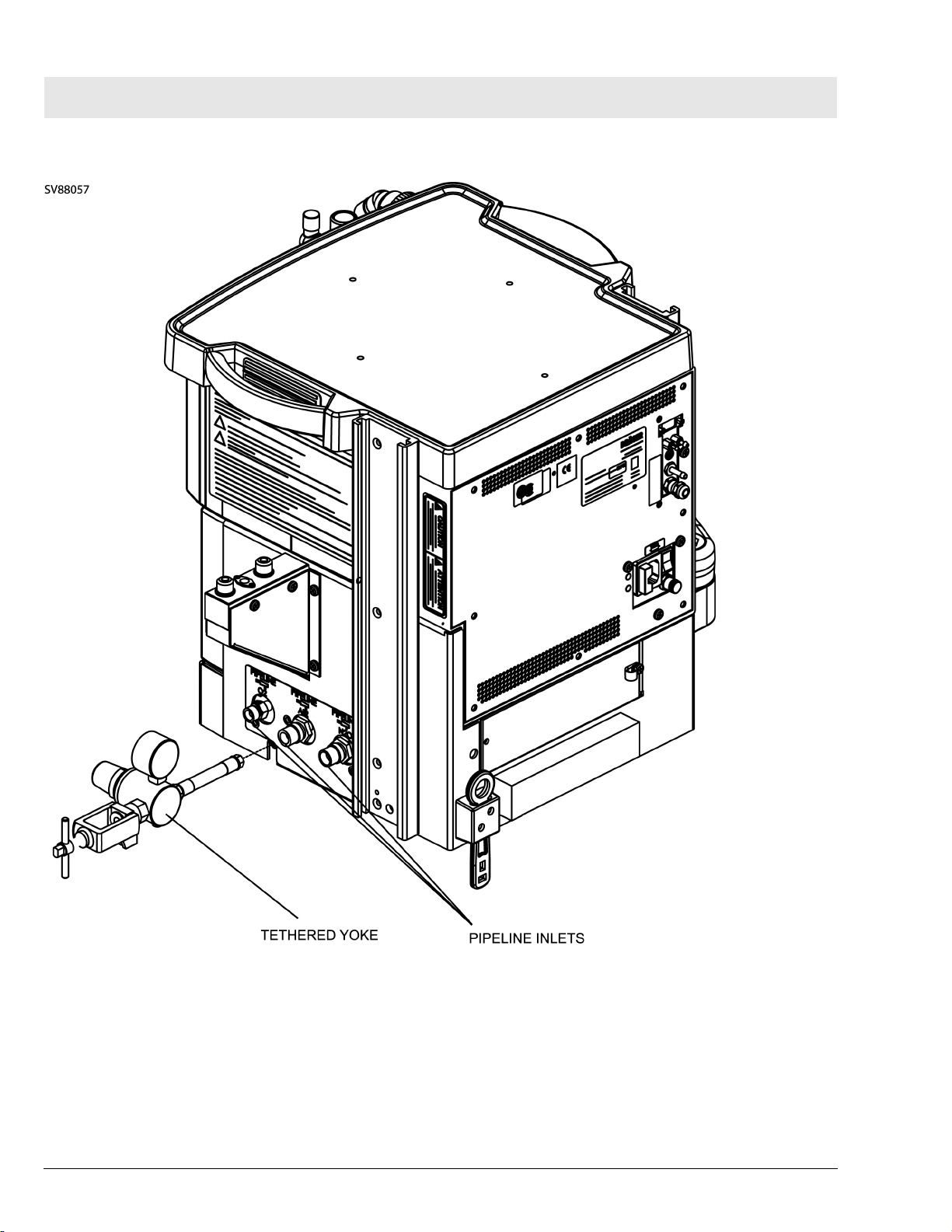

Figure 4 Side View - Gas Pipeline Inlets and Tethered Yoke - Wall Mount Configuration

12

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 19

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 5 Back/Side View - Gas Pipeline and Cylinder Hose Connections - Trolley Mount Configuration

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

13

Page 20

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

2 Fabius Tiro Function

Diagram

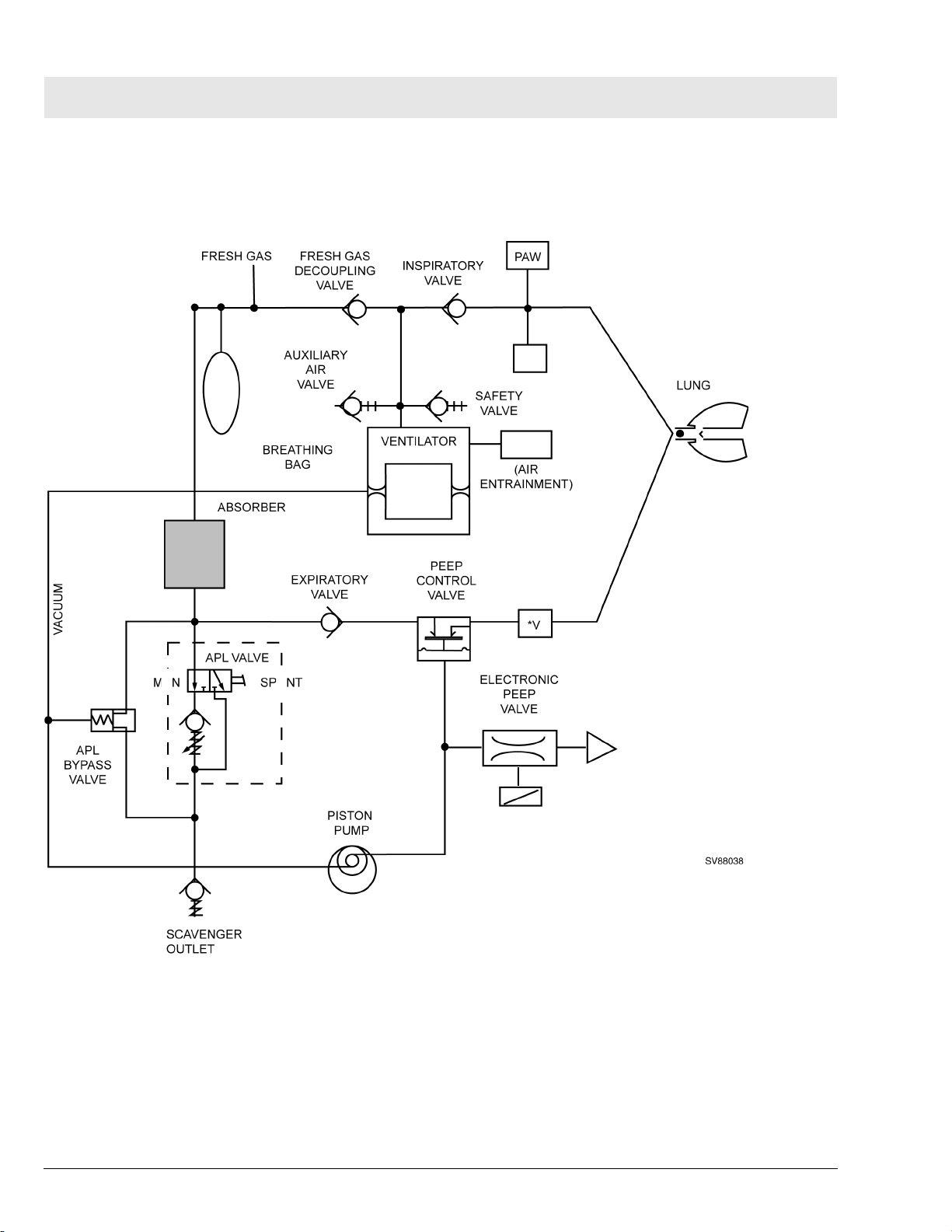

Figure 6 Functional Diagram of Fabius Tiro - Typical for Breathing System P/N 4116398 or 4117529

14

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 21

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

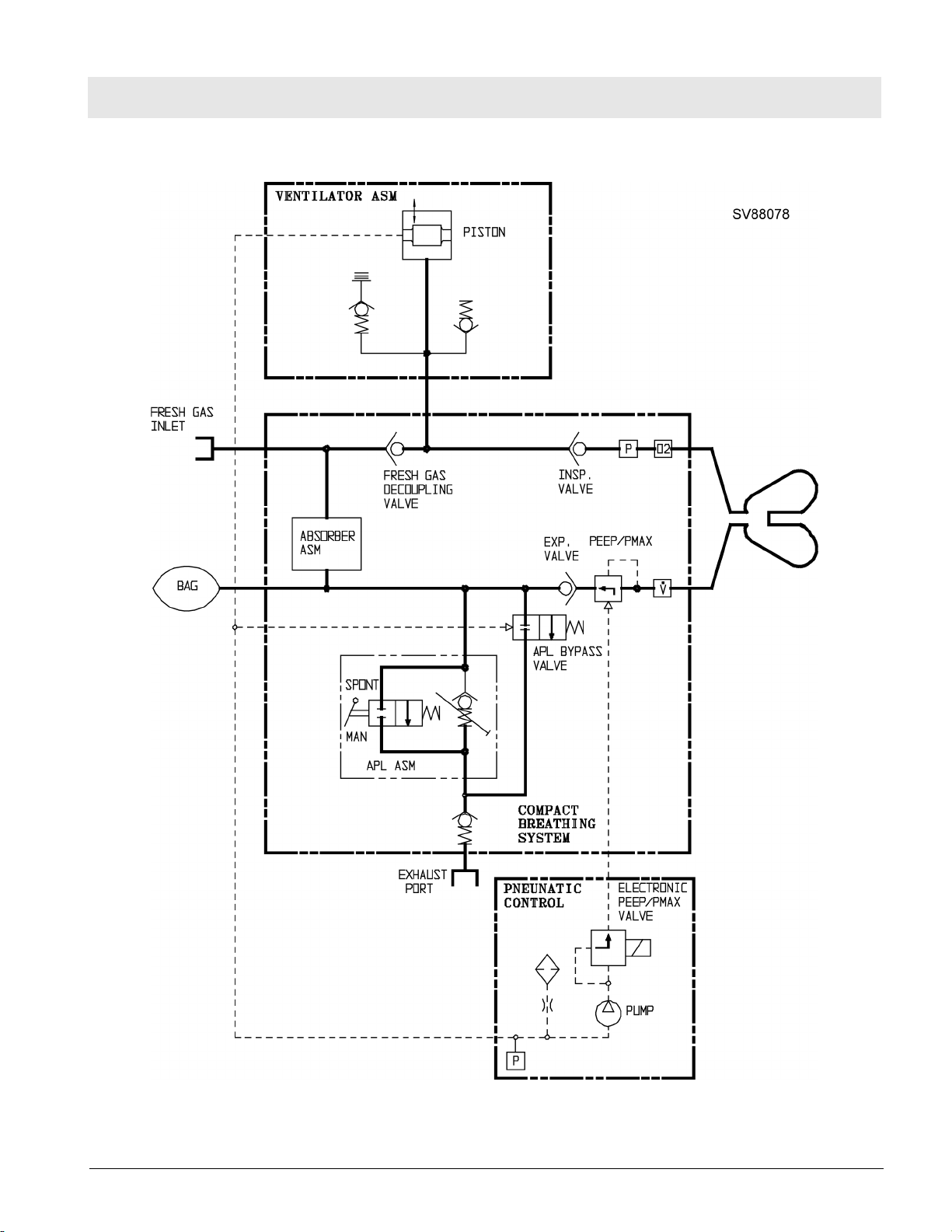

Figure 7 Function Diagram of Fabius Tiro - Typical for Breathing System P/N 4118378 or 4118379

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

15

Page 22

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

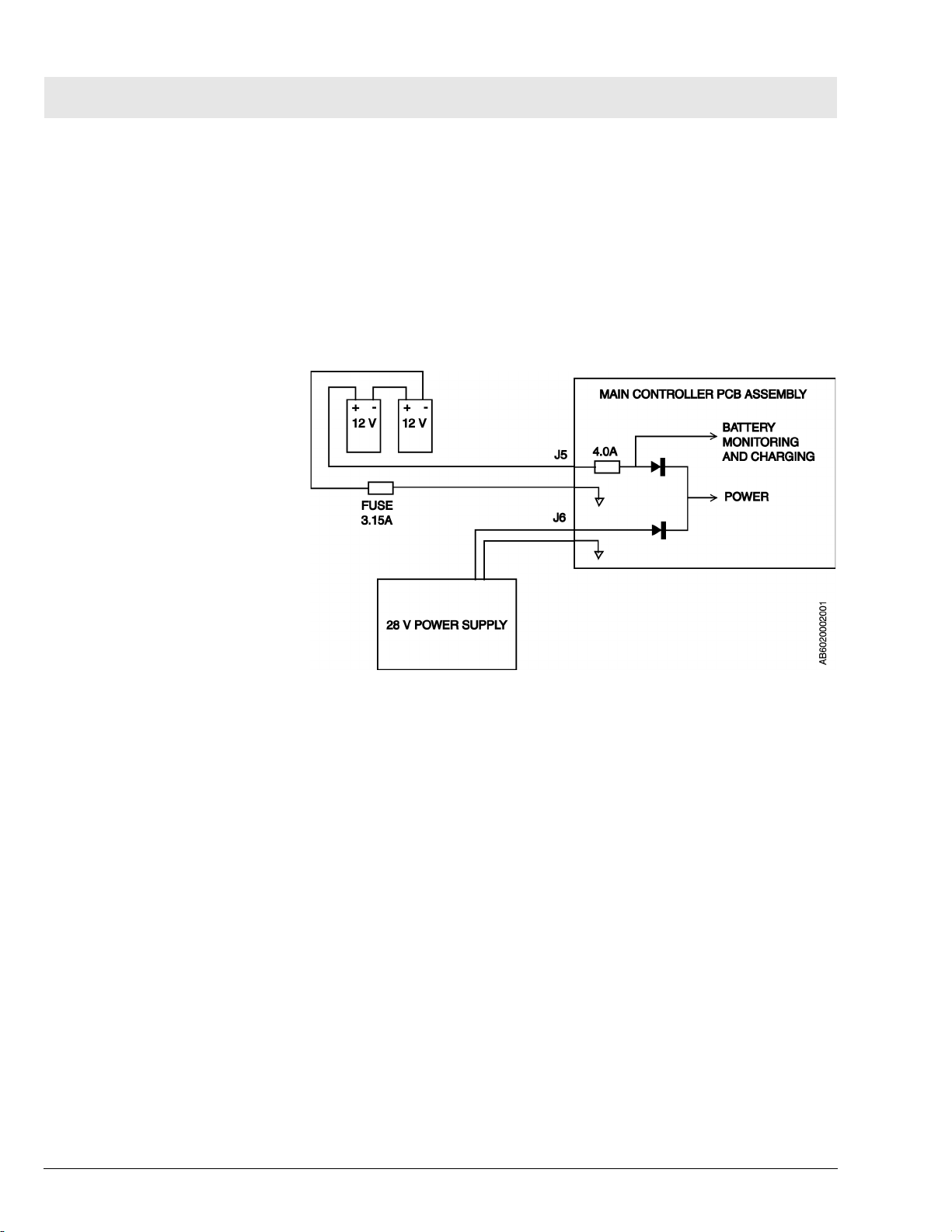

3 Battery Backup Fabius Tiro backup power is provided by two series-connected 12 V

rechargeable batteries. These batteries remain on charge as long as the

machine is plugged into an active AC outlet. Should power to the main controller PCB assembly fail while the machine is in operation, the batteries will

allow the machine to continue operating for a minimum of 45 minutes, provided the batteries are fully charged.

The batteries are located within the controller housing and are accessible by

opening the ventilator compartment. The 3.15A battery fuse is located on the

power entry panel at the back of the machine.

Figure 8 Battery Backup Arrangement

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

16

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 23

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

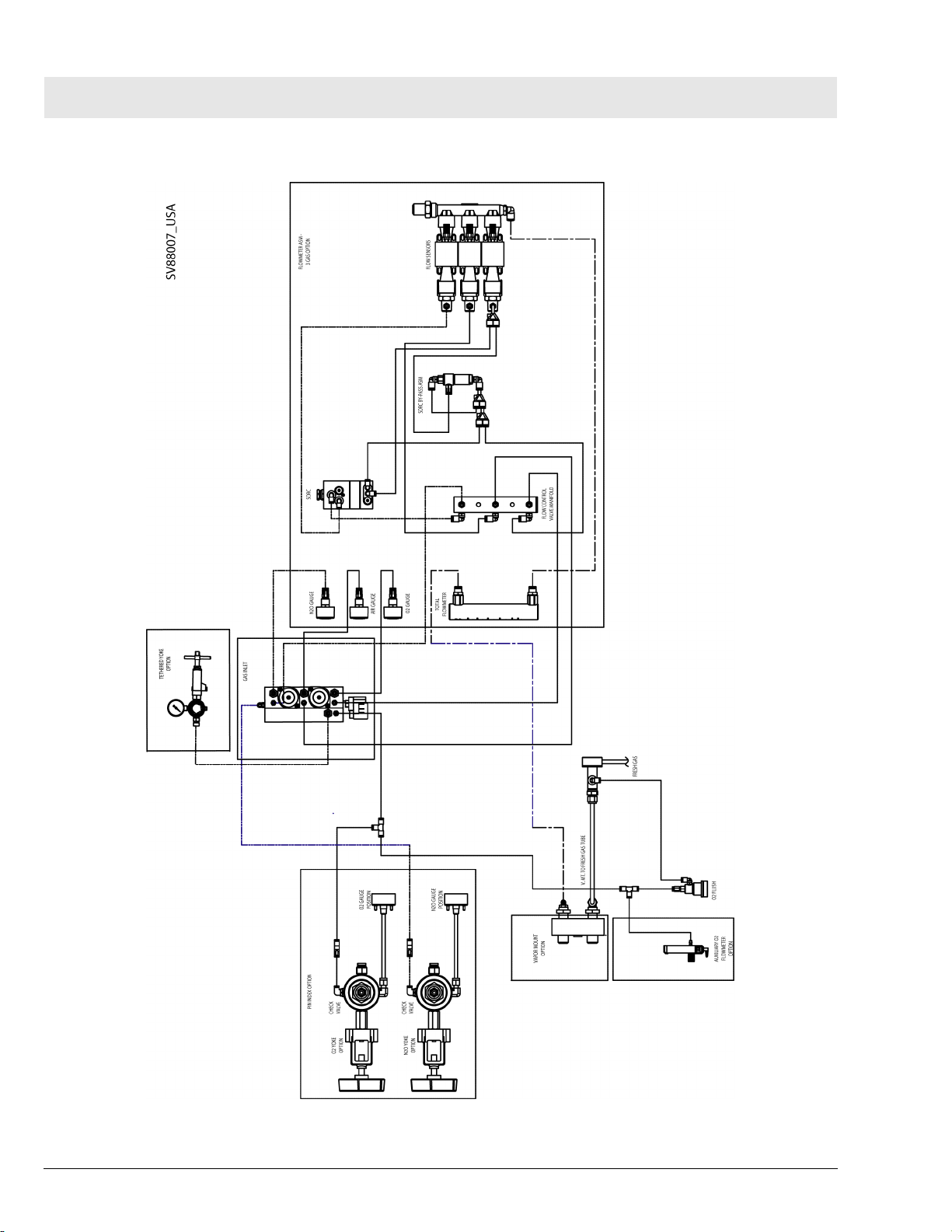

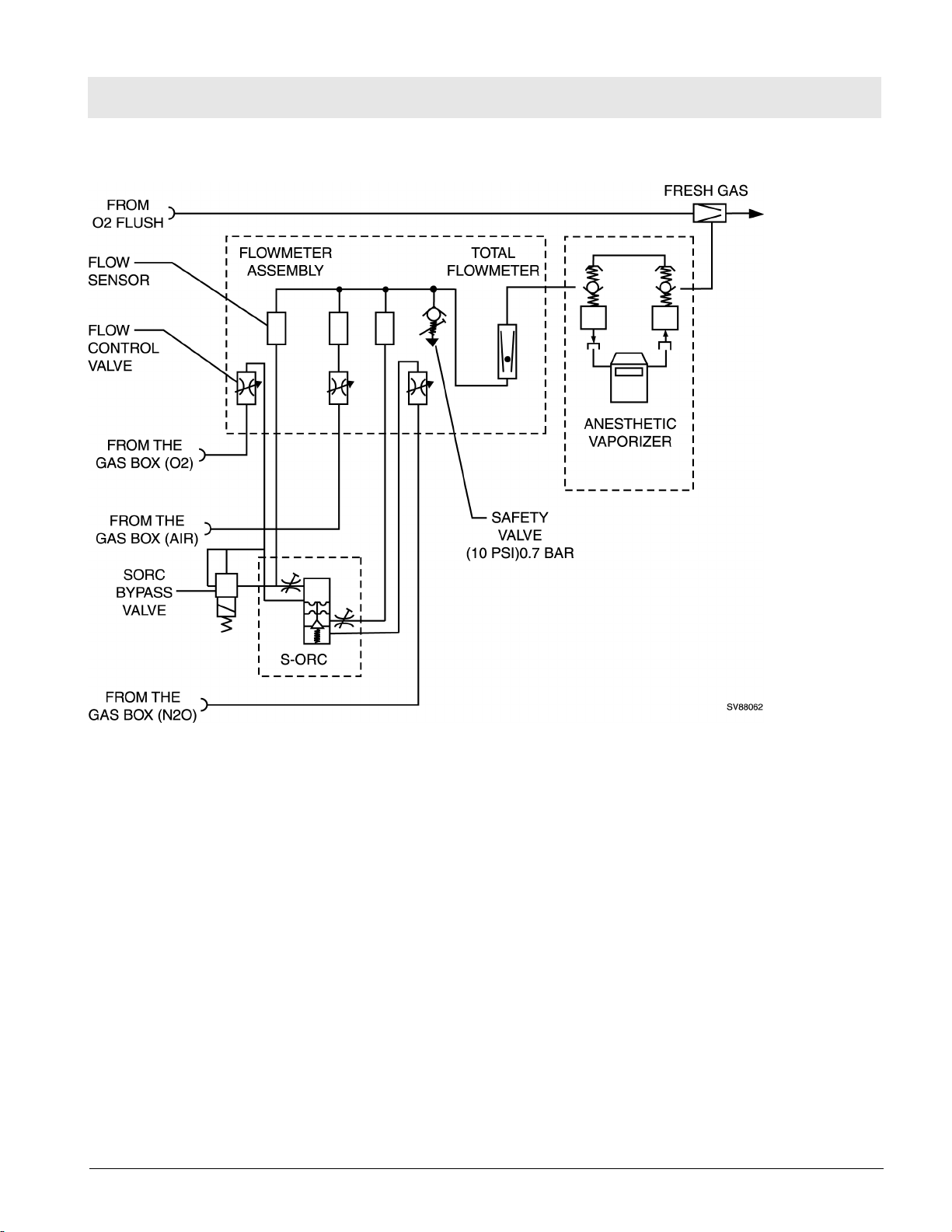

4 Fabius Tiro Piping

Diagram

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

17

Page 24

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 9 Fabius Tiro 3-Gas Piping Diagram

18

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

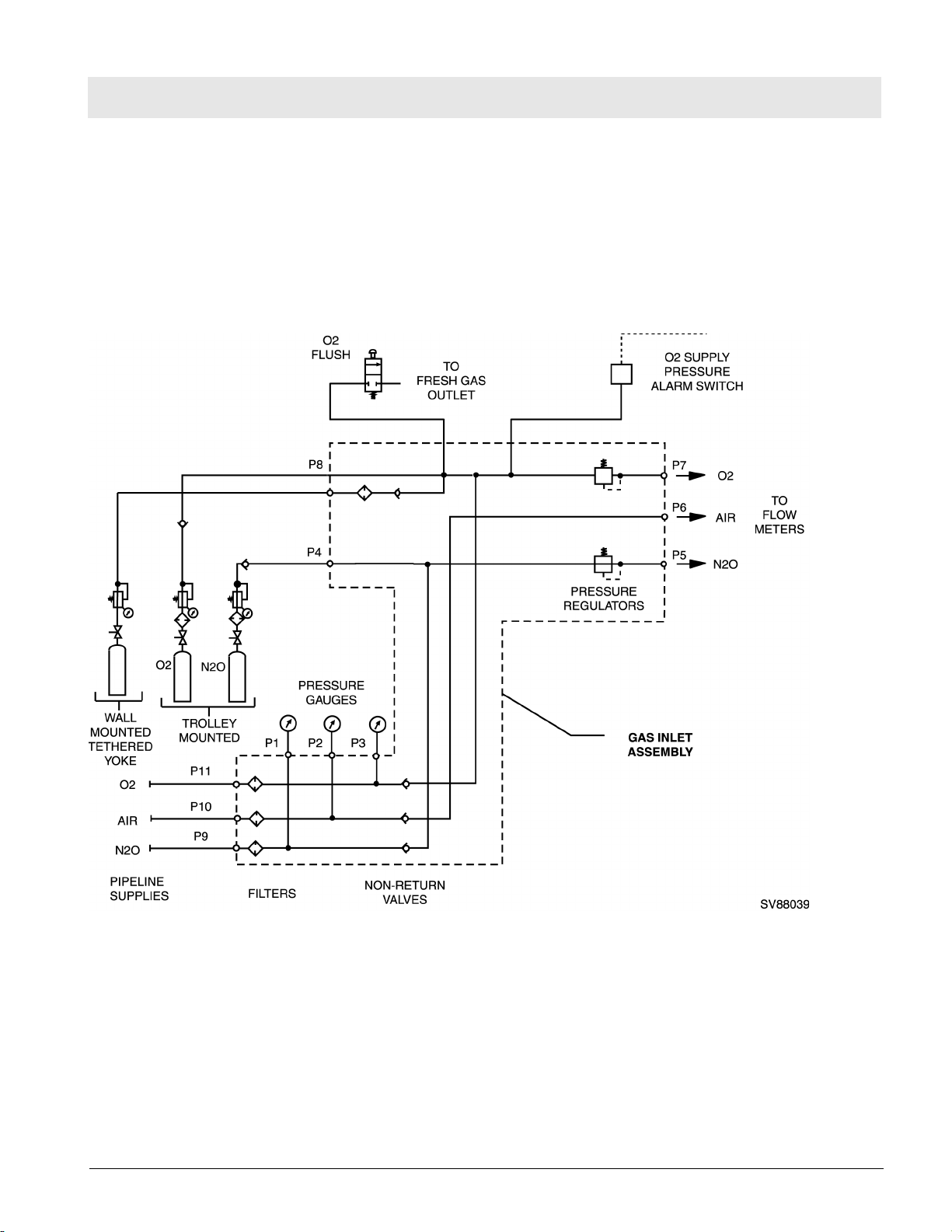

5 Function Descrip-

tion of Gas Box

The supply gases flow through the filters and non-return valves in the gas

inlet assembly. Pipeline supply pressures are indicated on gauges located on

the flowmeter assembly. Cylinder pressure gauges are located on the base

machine assembly. The pressures of O2 and N2O delivered to the flowmeter

assembly are set by regulators on the gas inlet assembly.

Should the O2 supply fail or its pressure decrease below a certain limit, the

O2 supply pressure alarm switch signals an alarm.

Figure 10 Gas Box Functional Diagram (Part 1 of 2)

If the O2 flush button is pressed, oxygen is delivered to the fresh gas outlet.

The fresh-gas ejector prevents the fresh gas from flowing back into the anesthetic vaporizer. This avoids an increase in the anesthetic gas concentration.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

19

Page 26

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

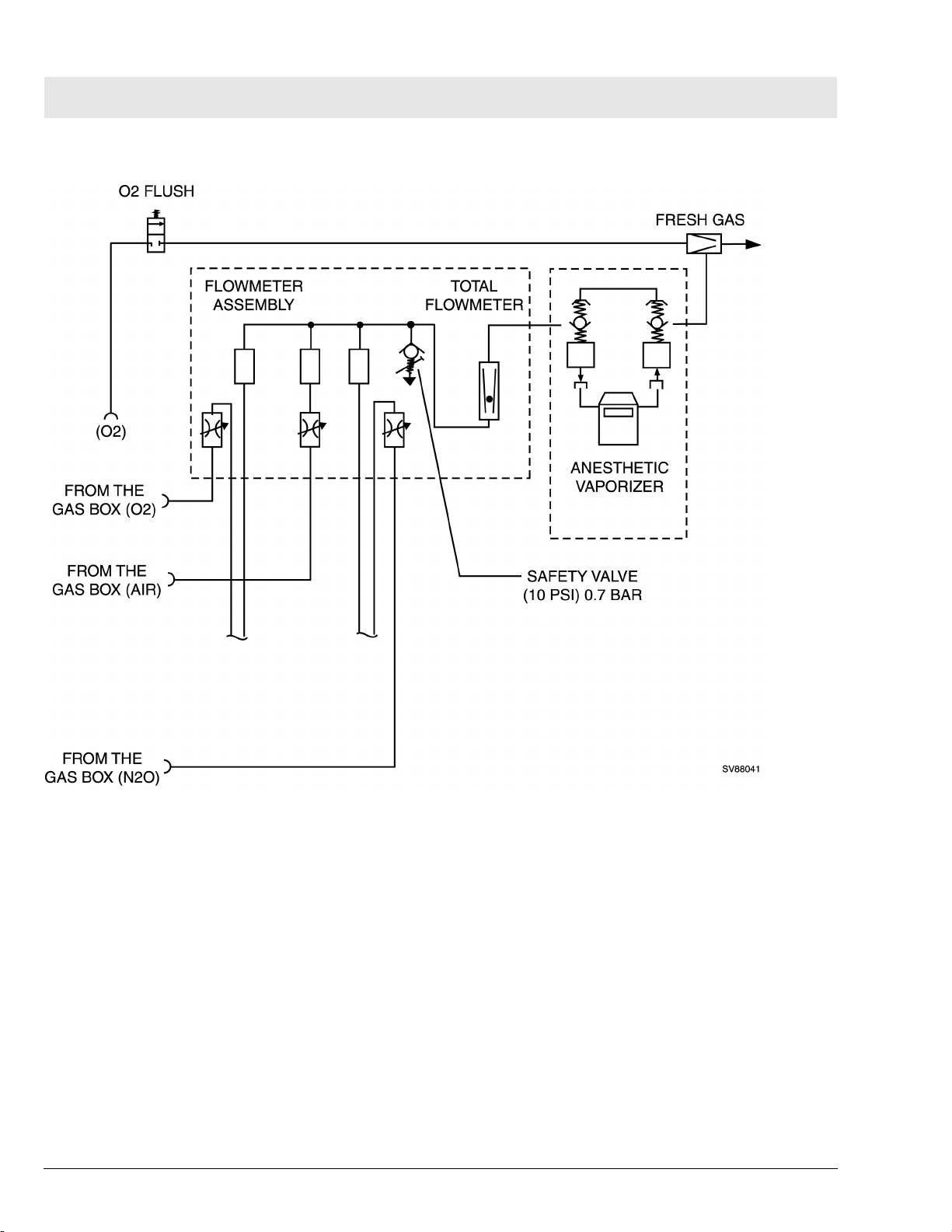

Figure 11 Gas Box Functional Diagram (Part 2 of 2)

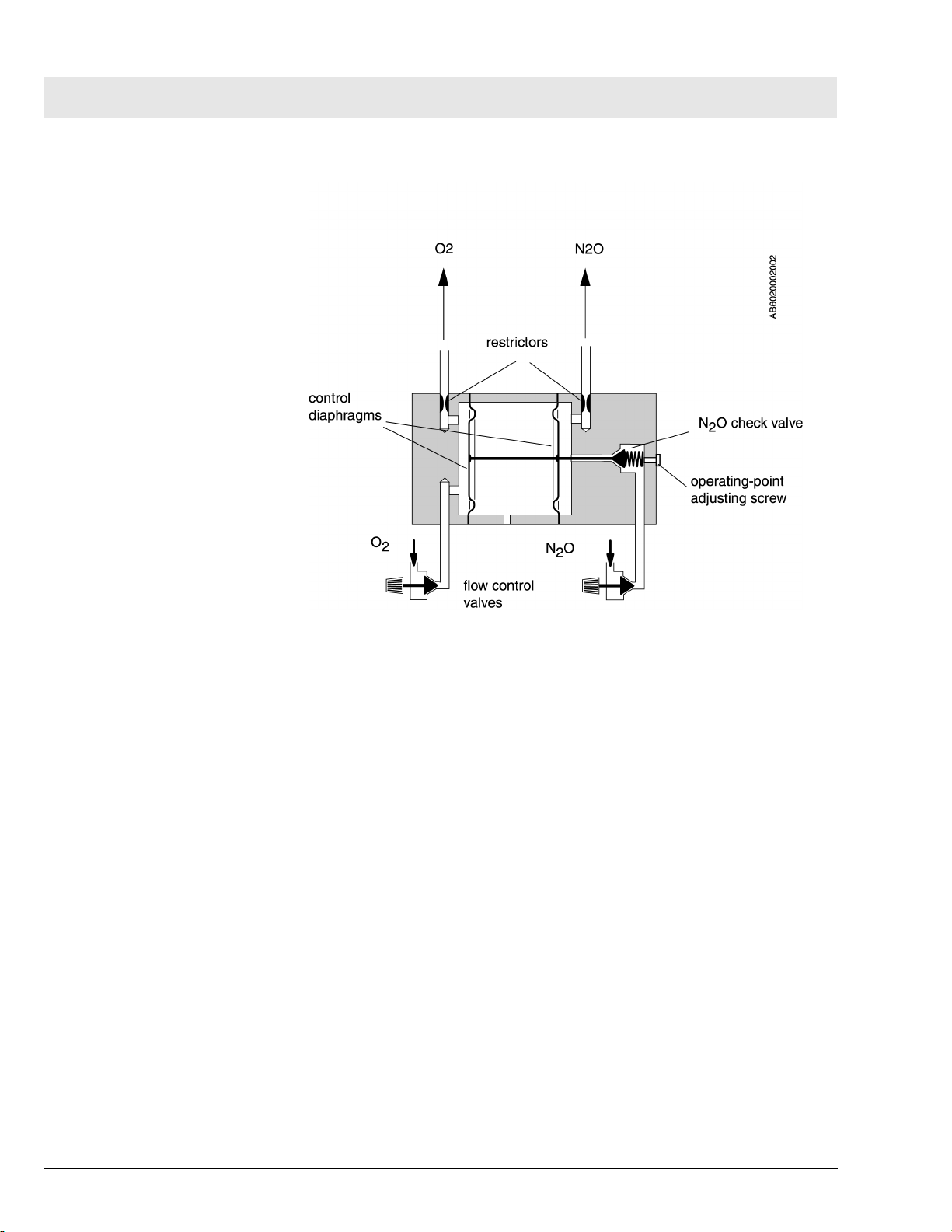

6 SORC (Sensitive

Oxygen Ratio Controller)

20

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

The SORC is a control element that functions like an N2O shut-off device and

ensures a vital O2 concentration in the fresh gas. In the event of an O2 shortage, the SORC limits the N2O flow such that the O2 concentration in the

fresh gas does not decrease below 23 vol.%.

If the O2 flow control valve is closed or if the O2 flow is lower than or equal to

200 mL/min, the SORC interrupts the N2O flow.

N2O can be added when the O2 flow is approx. 300 mL/min. In this case, the

SORC also prevents O2 concentrations below 23 vol.%.

The SORC bypass allows O2 to bypass the restrictor in the SORC when O2

flows above 10 L/min. are needed.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 27

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 12 SORC Functional Diagram (Part 1 of 2)

The flow control valves are used to adjust the O2 and N2O flows.

Restrictors located at the outlets of the SORC generate back-pressures.

These back-pressures exert a force on the control diaphragms of the SORC.

The O2 back-pressure opens the SORC. The N2O back-pressure closes the

SORC. The pressure ratio at the control diaphragm affects the N2O flow.

The restrictors and the spring tension are dimensioned such that a minimum

concentration of 23 vol.% O2 is always ensured. The maximum O2 flow is

approx. 12 L/min.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

21

Page 28

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

7 Compact Breathing

System, Cosy II

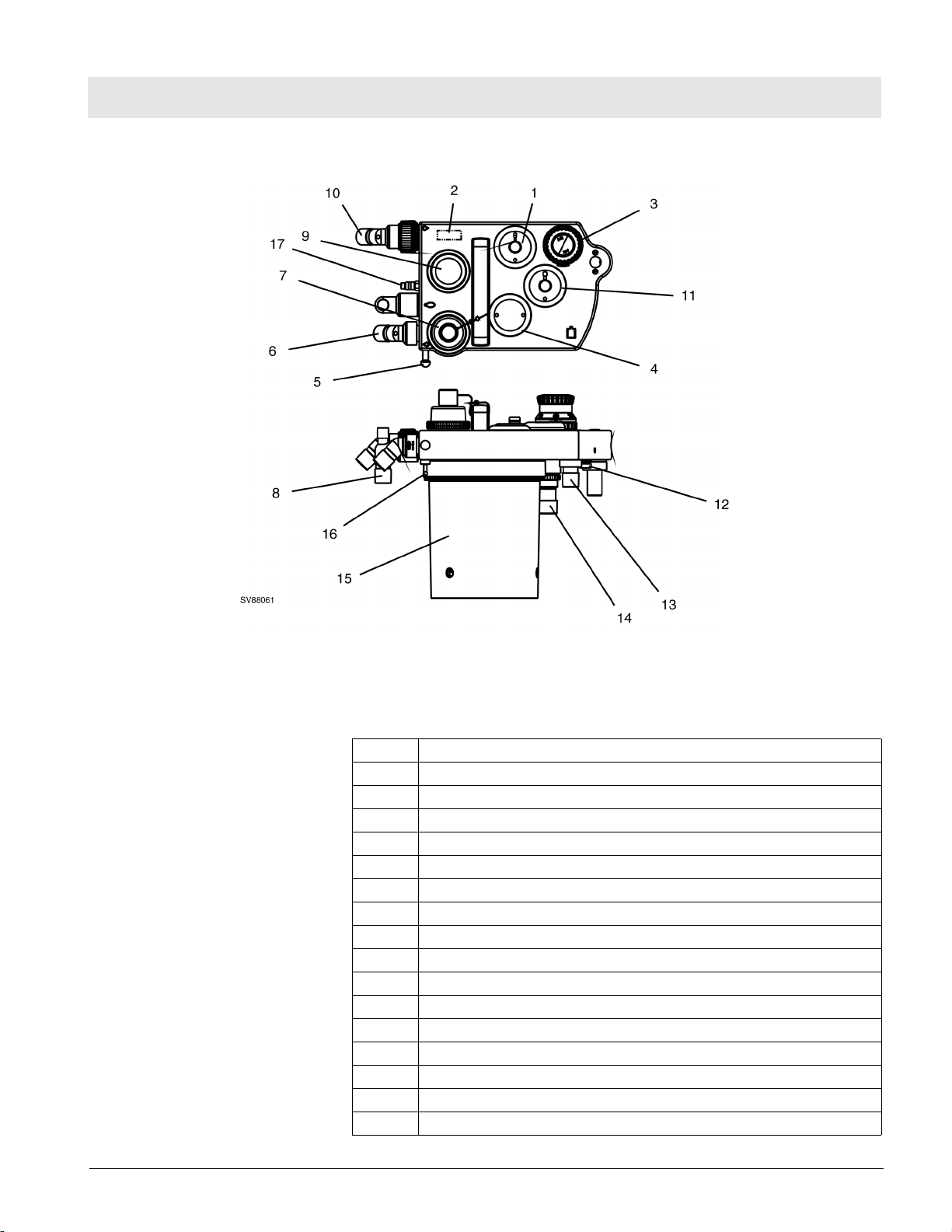

Figure 13SORC Functional Diagram (Part 2 of 2)

The Cosy II compact breathing system allows various modes of patient ventilation: manual and spontaneous breathing, volume controlled, and pressure

controlled.

In the "MAN" position, the compact breathing system is closed to atmosphere. This position is used for manual ventilation of the patient. The APL

valve opening pressure can be adjusted from 5 to 70 cmH2O.

In the "SPONT" position the APL valve is open to atmosphere. This position

is used for spontaneous patient breathing.

The pressure limit (Pmax) can also be adjusted (through front panel interface)

during volume control from 15 cmH2O to 70 cmH2O using the control box

and the PEEP/Pmax valve.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

22

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 14 Compact Breathing System, Cosy II - Typical for P/N 4116398 or 4117529

Table 1 Key, Figure 14

1 PEEP/Pmax valve

2 Flow sensor (Spirolog)

3 MAN/SPONT-APL Valve

4 Fresh-gas decoupling valve

5 Breathing bag hook

6 Inspiratory port

7 Inspiratory valve and O2 sensor port

8 Breathing bag terminal and Y-piece plug

9 Expiratory valve

10 Expiratory port

11 APL Bypass valve

12 Fresh-gas port

13 Ventilator port

14 Anesthetic gas scavenging port

15 Absorber

16 Pressure sensor connector

17 Exhaust port, anesthetic monitor return (non-U.S. systems only)

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

23

Page 30

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

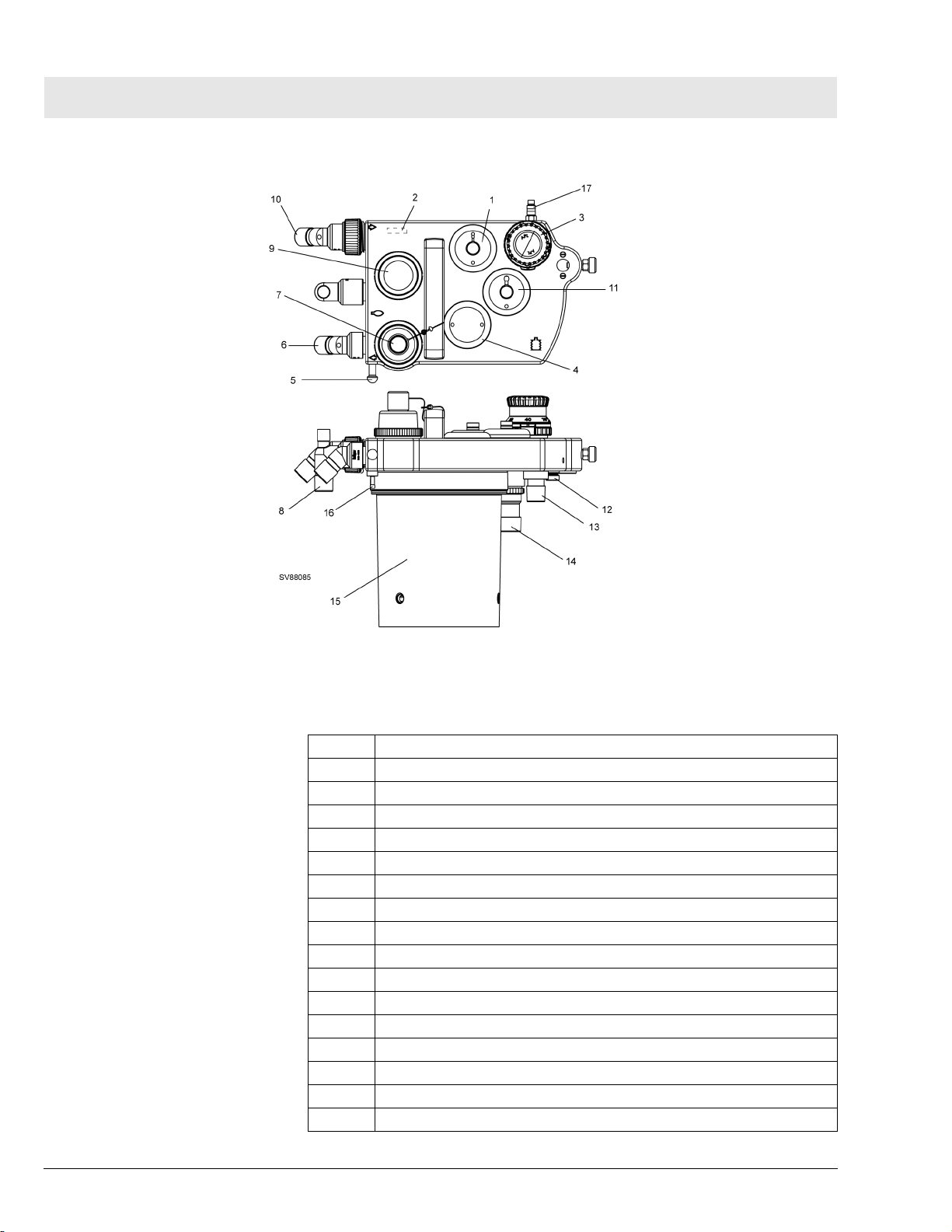

Figure 15 Compact Breathing System, Cosy II - Typical for P/N 4118378 or 4118379

Table 2 Key, Figure 15

1 PEEP/Pmax valve

2 Flow sensor (Spirolog)

3 MAN/SPONT-APL Valve

4 Fresh-gas decoupling valve

5 Breathing bag hook

6 Inspiratory port

7 Inspiratory valve and O2 sensor port

8 Breathing bag terminal and Y-piece plug

9 Expiratory valve

10 Expiratory port

11 APL Bypass valve

12 Fresh-gas port

13 Ventilator port

14 Anesthetic gas scavenging port

15 Absorber

16 Pressure sensor connector

17 Exhaust port, anesthetic monitor return (non-U.S. systems only)

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

24

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 31

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

7.1 Manual Ventilation Manual Ventilation: General

During manual ventilation, the APL valve is set to the "MAN" position. The

patient system safety valve is activated. The piston of the ventilator is in the

upper end position in order to reduce the volume of the ventilator.

Manual Ventilation: Inspiration

During inspiration, expiratory valve remains closed. When the clinician compresses the breathing bag the gas mixture (expiratory gas and fresh gas)

flows through the fresh-gas decoupling valve, the inspiratory valve, the O2

sensor, the inspiratory hose, and the Y-piece into the patient’s lung. The pressure sensor measures the airway pressure. The APL valve limits the ventilation pressure. Any excess amount of the gas mixture flows through the APL

valve and the non-return valve to the anesthetic gas scavenging system.

Figure 16 Manual Ventilation (Inspiration) - Typical for Breathing System P/N 4116398 or 4117529

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

25

Page 32

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 17 Manual Ventilation (Inspiration) - Typical for Breathing System P/N 4118378 or 4118379

Manual Ventilation: Expiration - Typical for Breathing System P/N 4116398 or

4117529

During expiration, the inspiratory valve remains closed and thus prevents the

expiratory gas from flowing back into the inspiratory branch.

After releasing the breathing bag, the expiratory gas from the lung flows

through the expiratory hose, the flow sensor, the PEEP/Pmax valve, the expiratory valve, and through the absorber into the breathing bag. At the same

time, new fresh gas flows into the breathing bag.

26

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 18 Manual Ventilation (Expiration) - Typical for Breathing System P/N 4116398 or 4117529

Manual Ventilation: Expiration - Typical for Breathing System P/N 4118378 or

4118379

During expiration, the inspiratory valve remains closed and thus prevents the

expiratory gas from flowing back into the inspiratory branch.

After releasing the breathing bag, the expiratory gas from the lung flows

through the expiratory hose, the flow sensor, the PEEP Pmax valve, the expiratory valve, onto the breathing bag and through the absorber. At the same

time, new fresh gas flows into the breathing bag.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

27

Page 34

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 19 Manual Ventilation (Expiration) - Typical for Breathing System P/N 4118378 or 4118379

7.2 Spontaneous

Spontaneous Breathing: General

Breathing

A prerequisite for spontaneous breathing is that the patient is supplied with a

sufficient amount of fresh gas. The APL valve selector must be set to the

"SPONT" position. No pressure builds up in the compact breathing system.

Spontaneous Breathing: Inspiration

During inspiration, the expiratory valve remains closed thus preventing

rebreathing of expiratory gas containing CO2.

28

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 35

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

The patient inhales the gas mixture (expiratory gas and fresh gas) from the

breathing bag. The gas mixture flows through the fresh-gas decoupling valve,

the inspiratory valve, the O2 sensor, the inspiratory hose, and through the Ypiece into the lung. The pressure sensor measures the airway pressure.

Figure 20 Spontaneous Breathing (Inspiration) - Typical for Breathing System P/N 4116398 or 4117529

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

29

Page 36

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 21 Spontaneous Breathing (Inspiration) - Typical for Breathing System P/N 4118378 or 4118379

Spontaneous Breathing: Expiration - Typical for Breathing System P/N

4116398 or 4117529

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The APL valve is open, regardless of its pressure setting.

The expiratory gas flows from the lung through the expiratory hose, the flow

sensor, the PEEP control valve, the expiratory valve, and through the

absorber into the breathing bag. At the same time, new fresh gas flows into

the breathing bag.

30

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

When the breathing bag is full, any excess gas mixture flows through the

non-return valve into the anesthetic gas scavenging system.

Figure 22 Spontaneous Breathing (Expiration) - Typical for Breathing System P/N 4116398 or 4117529

The CO2 is scrubbed from the expiratory gas by the soda lime contained in

the absorber. The fresh gas replaces the anesthetic and oxygen taken up by

the patient.

Spontaneous Breathing: Expiration - Typical for Breathing System P/N

4118378 or 4118379

During expiration, the inspiratory valve remains closed thus preventing the

expiratory gas from flowing back into the inspiratory branch.

The APL valve is open, regardless of its pressure setting.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

31

Page 38

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

The expiratory gas flows from the lung through the expiratory hose, the flow

sensor, the PEEP control valve, the expiratory valve, the breathing bag, and

through the absorber. At the same time, new fresh gas flows into the breathing bag.

When the breathing bag is full, any excess gas mixture flows through the

non-return valve into the anesthetic gas scavenging system.

Figure 23 Spontaneous Breathing (Expiration) - Typical for Breathing System P/N 4118378 or 4118379

7.3 Volume/Pressure

Volume Control Mode: General

Mode Ventilation

A prerequisite for volume control is that the patient is supplied with a sufficient

amount of fresh gas.

The APL bypass valve opens in volume mode, allowing excess gas to be

vented to the scavenging system regardless of the MAN-SPONT valve setting.

32

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 39

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

The safety valve of the patient system makes sure that no pressures greater

than 75 cmH2O build up in the system.

During ventilation, the pressure limit (Pmax) can be adjusted on the control

box.

Volume/Pressure Control Mode: Inspiration

During inspiration, the PEEP/Pmax valve remains closed. The control pressure present at the PEEP/Pmax valve varies with the set pressure limit

(Pmax).

The pressure generated by the ventilator’s piston closes the fresh-gas decoupling valve. The gas mixture (expiratory gas and fresh gas) flows through the

inspiratory valve, the O2 sensor, the inspiratory hose, and through the Ypiece into the lung. The pressure sensor measures the airway pressure. The

ventilation pressure cannot exceed the pressure limit (Pmax) set on the control box because the PEEP/Pmax valve opens. The fresh gas then fills the

breathing bag.

Any excess fresh gas flows through the open APL bypass valve, and through

the non-return valve into the anesthetic gas scavenging system.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

33

Page 40

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 24 Volume Control Ventilation (Inspiration) - Typical for Breathing System P/N 4116398 or 4117529

34

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 41

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 25 Volume Control Ventilation (Inspiration) - Typical for Breathing System P/N 4118378 or 4118379

Volume/Pressure Control Mode: Expiration

During expiration, the inspiratory valve remains closed thus preventing

rebreathing into the inspiratory branch.

The expiratory gas from the lung flows through the expiratory hose, the flow

sensor, the PEEP/Pmax valve, the expiratory valve, and through the absorber

back into the breathing bag mixing with fresh gas also flowing into the breathing bag.

The ventilator’s piston moves back drawing the gas mixture needed for the

next inspiration into the piston space.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

35

Page 42

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Any excess fresh-gas flows through the APL bypass valve, and through the

non-return valve into the anesthetic gas scavenging system.

Figure 26 Volume Control Ventilation (Expiration) - Typical for Breathing System P/N 4116398 or 4117529

36

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 27 Volume Control Ventilation (Expiration) - Typical for Breathing System P/N 4118378 or 4118379

7.4 Cosy II Absorber The absorber canister is filled with fresh soda lime. The soda lime scrubs

CO2 from the respiratory expired gas.

Expired soda lime changes its color. The soda lime must be replaced when

two thirds of the soda lime in the absorber canister is discolored.

8 Ventilator The ventilator is located in a swing-out compartment at the left side of the

Fabius Tiro. A hose terminal is provided on the left side of the compartment

for connection to the breathing system. Fresh gas is delivered to the patient

by a piston that is driven by a motor and ball-screw arrangement. A sight window on the compartment allows the operator to verify movement of the piston.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

37

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Two diaphragms (upper and lower) comprise a bag-type rolling seal that surrounds the piston. Vacuum from the pneumatic assembly (described in a later

paragraph) is provided between the outside of the seal and the cylinder, to

ensure proper operation of the seal during piston movement.

During inspiration the ventilator delivers fresh gas at a given volume, pressure and frequency. These parameters are set at the control panel. Refer to

the Operatorís Manual for details on ventilator settings, displays and controls.

During expiration, the bag-type rolling seal fills with expired gas from the

patient and with fresh gas stored in the breathing bag.

Power for the ventilator motor is distributed from the control PCB. A position

sensor on the ventilator signals the control PCB when the piston reaches its

lower limit. An incremental encoder on the motor shaft determines the number of revolutions and provides piston travel information to the control PCB.

Ventilator pressure is monitored by a transducer on the control PCB. Should

the negative pressure relief valve on the patient assembly open, a Fresh Gas

Low alarm is displayed if enabled via service mode.

The ventilator pressure transducer is the same type as the one used for measuring airway pressure. A hose connects the transducerís positive pressure

port to a hose barb located on the top cover of the ventilator. The purpose of

this transducer is to allow the software to sense when a condition exists that

would cause the ventilator negative pressure relief valve to open. The threshold used by the software for this condition is -8 mbar. In normal use the primary cause for this condition is an insufficient amount of reserve gas in the

breathing bag. The operator is alerted when this condition exists, with a

medium priority FRESH GAS LOW alarm. This alarm may be disabled via

service mode.

The ventilator assembly is illustrated on Figure 28.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

38

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 45

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 28 Ventilator (piston shown in down position)

The top of the ventilator assembly (patient system) contains two valves:

8.1 High Pressure Safety Valve

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

If the pressure limit control fails, the patient system high pressure safety valve

limits the gas pressure. This valve is set to open at approximately 75 cmH2O.

39

Page 46

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 29 Sectional View of the Safety Valve

8.2 Negative Pressure Relief Valve

Figure 30 Sectional View of the Negative Pressure Relief Valve

The negative pressure relief valve allows the patient to spontaneously

breathe ambient air should the medical gas supply and/or Fabius Tiro fail.

The opening pressure of this valve is -8 mbar.

9 Pneumatic System The pneumatic assembly provides pressure for the PEEP valve control, and

also provides vacuum for the ventilator bag-type rolling seals and the APL

bypass valve control.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

40

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 47

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 31 Pneumatic Control System Schematic

9.1 PEEP/Pmax Valve Control

9.2 APL Bypass Valve Control

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

When the Fabius Tiro is operating in the automatic mode, the pump on the

pneumatic assembly is running, and the electronic PEEP valve receives a

signal from the main control PCB. The amount of current supplied to the coil

of the electronic PEEP valve is proportional to the PEEP value set by the

operator, and controls the position of the diaphragm within the electronic

PEEP valve. This then determines the control pressure applied to the proportional PEEP valve in the breathing system, which maintains the desired

amount of PEEP during patient expiration. The V1 reservoir smooths out

pressure variations caused by the pump. See Figure 29.

When the Fabius Tiro is operating in the automatic mode, the pneumatic

assembly provides a vacuum signal to hold open the APL bypass valve in the

breathing system. The V2 reservoir and filter provide noise damping, and the

variable restrictor is used to set the vacuum level in the range of -150 to -240

cmH2O.

41

Page 48

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

When the machine is operating in the Manual mode, the pump on the pneumatic assembly (and the ventilator) is stopped, and the spring-loaded APL

bypass valve in the breathing system closes, directing exhaled gas through

the APL valve.

42

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 49

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

10 Electronic Block

Diagram

Figure 32 Electronic Block Diagram

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

43

Page 50

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

11 Control PCB The control PCB provides the following functions in the Fabius Tiro:

11.1 Flowmeter Receives flow rate data from the N2O, Air, and O2 flow sensors and provides

fresh gas display information for these gases.

11.2 Patient Interface Receives information from the oxygen sensor and processes it for display.

Receives flow information from the Spirolog sensor and processes it for display.

Converts airway breathing pressure to an electrical signal and processes it

for display.

11.3 Ventilator Provides ventilator motor drive, receives ventilator piston position and move-

ment information. Provides ventilator pressure information.

11.4 Front Panel Func-

Provides power for the display panel and LED table lamp.

tions

Provides video signals to the display.

Receives information from the keypad and rotary encoder for making display

and operating selections, setting alarm limits, and service functions.

11.5 Pneumatic Assem-

Provides power to the pump on the pneumatic assembly.

bly Control

Provides control signal to the electronic PEEP valve on the pneumatic

assembly in response to operator setting.

Monitors pump vacuum to stabilize PEEP control.

11.6 Serial Port Interface Provides isolated port for connecting external monitors and downloading soft-

ware.

11.7 Battery Provides charging current for battery and monitors state of battery charge.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

44

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 51

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Figure 33 Controller Functional Block Diagram

12 Control Panel

Assembly

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

The control panel assembly consists of a 320 x 240 pixel graphical display, a

table lamp with six LEDs, a membrane keypad, rotary encoder and speaker.

45

Page 52

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Data and power for the display comes from the main controller PCB via a 20conductor ribbon cable. The keypad interface is connected to the main controller PCB by a 30-conductor ribbon cable. A block diagram of the control

panel assembly is shown in Figure 34.

Figure 34 Control Panel Block Diagram

An illustration of the control panel is shown in Figure 35.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Figure 35 Fabius Tiro Control Panel (Main Service Screen Illustrated)

46

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 53

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

Descriptions of the numbered items in Figure 35 are given in the Tabl e 3.

Table 3 Fabius Tiro Control Panel Key for Figure 35

ITEM FUNCTION

1 Selects volume controlled ventilation mode. Refer to Operator’s Manual

2 Select pressure controlled ventilator mode. Refer to Operator’s Manual

3 Reserved for future use

4 Reserved for future use

5 Controls table lamp: Off/On

6 Places ventilator in Man Spont mode. Refer to Operator’s Manual

7 Soft Keys: active the corresponding function that appears on screen above the key

8 For setting alarm limits. Refer to Operator’s Manual

9 Setup Key: activates sub-screens for monitoring functions. Refer to Operator’s Manual

10 Home key: returns display to main screen shown before standby

11 Rotary control: moves the cursor on the screen; confirms selection when pressed

12 Alarm Status Indicators: Flashing Red: Warning; Flashing Yellow: Caution; Solid Yellow: Advi-

sory

13 Alarm Silence key: silences all active alarms for two minutes

14 Power ON indicator: lighted when machine is plugged into an active AC outlet

15 Returns unit to Standby mode

13 FiO2 Measurement The O2 sensor measures the fraction of inspired O2 (FiO2) in the respiratory

gas.

The O2 sensor contains an alkaline electrolyte, a lead anode, two gold cathodes, and a Teflon membrane. The spatial separation of the two gold cathodes allows a voltage comparison to be made as explained below.

The O2 sensor is an electrochemical cell that generates a voltage from the

ion current.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

47

Page 54

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 36 O2 Sensor

14 Respiratory Flow

Measurement

The O2 to be measured diffuses through the Teflon membrane, reacts at the

gold cathodes (negative polarity) and forms lead oxide and water at the lead

anode (positive polarity). During this chemical process, a voltage is generated which is proportional to the O2 partial pressure.

The internal resistance of the cell is determined by the surface area of the

gold cathodes, the O2 diffusion velocity, the distance between the gold cathodes and the lead anode. This resistance is approximately 700 ohms.

The chemical process is temperature-sensitive. Therefore temperature-sensitive resistors are connected in parallel with the O2 sensor. These resistors

and the internal resistance of the O2 sensor correct the measuring voltage.

Because two cathodes used in the O2 sensor cell, two different voltages are

generated. These voltages are compared with each other. If their difference

exceeds a certain value, the machine prompts the operator to check the cell.

If the O2 sensor fails, the control box will indicate an error on the graphics

display.

The flow sensor functions according to the constant temperature hot-wire

anemometer principle. Respiratory gas flows past a thin platinum wire. This

platinum wire (A) is located in a measuring tube and is electrically heated.

The platinum wire is held at a constant temperature. Gas flow removes heat

from the hot wire. The higher the gas flow rate, the greater the heat removal.

The amount of electrical current needed to maintain a constant platinum wire

temperature is thus proportional to the gas flow rate.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

48

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

Page 55

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Function Description Fabius Tiro

A second platinum wire (B) in the measuring tube is used to compensate for

interferences from different gases present in the respiratory gas. The heat

removed from the second platinum wire is measured during inspiration when

the gas flow is zero.

The different gases present in the respiratory gas have a different thermal

conductivity. The amount of heat removed from the second platinum wire is

thus an indicator of respiratory gas composition.

Internal calibration tables for O2/N2O mixtures, Air and 100% O2 are used to

linearize the measured flow.

Figure 37 Respiratory Flow Sensor

15 Gas Flow Rate Mea-

surement

The gas flow sensors operate on the principle of specific heat for individual

gases. In each sensor, as the gas flows through a heated chamber the gas

molecules carry away a certain amount of heat relative to the specific heat

index for that gas.

A known amount of electrical current is required to maintain the temperature

in the heated chamber. The higher the gas flow rate, the more heat is

removed from the chamber and more current is required to maintain the temperature in the chamber. This current is then scaled and displayed as liters

per minute flow rate for each gas.

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

49

Page 56

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Function Description

Figure 38 Flow Sensor Details

Figure 39 Flow of Gases through Sensors

16 Vaporizer Refer to separate technical documentation of the anesthetic vaporizer.

50

Dräger Medical AG & Co. KGaA 6020.002 Revision B Released

All rights reserved. Copyright reserved.

F6020002_Function_Description_USA.fm 17.06.04

Page 57

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

ELECTROMAGNETIC TESTING AND

COMPLIANCE

51

Page 58

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

52

Page 59

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Electromagnetic Testing and Compliance

1 Electromagnetic

Testing and Compliance

The following CAUTIONS and WARNINGS are applicable to the Fabius Tiro

Anesthesia Machine:

CAUTION

Do not use Fabius Tiro in the environment of NMR tomography equipment. Malfunctions may result, thereby endangering the patient.

CAUTION

The use of portable and mobile radio frequency communications

equipment can affect medical electrical equipment. Do not use mobile

phones within a distance of 10 meters from the machine. Mobile

phones can cause malfunctions in electrical medical equipment,

thereby endangering the patient and the operator.

WARNING

No third-party components shall be attached to the anesthesia

machine, ventilator, or breathing system (except for certain approved

exceptions). For more information, contact your local Authorized Service Organization or DrägerService at:

DrägerService

Draeger Medical, Inc.

3122 Commerce Drive

Telford, PA 18969

Tel:(215) 721-5402

(800) 543-5047

Fax:(215) 721-5784

CAUTION

Although the Fabius Tiro is designed to minimize the effects of ambient radio-frequency interference, machine functions may be

adversely affected by the operation of electrosurgical equipment or

short wave or microwave diathermy equipment in the vicinity.

CAUTION

Communications with external equipment may be temporarily

affected by electromagnetic interference due to the use of electrosurgical equipment.

Tables 1 through 4 contained in this section are provided for informational

purposes and general guidance, as required by IEC 60601-1-2:2001, Medical

Electrical Equipment, Part 1-2, General Requirements for Safety - Collateral

Standard: Electromagnetic Compatibility.

2 Guidance and manu-

facturer’s declaration-electromagnetic

All rights reserved. Copyright reserved.

L6020002_EMC.fm 17.06.04

Dräger Medical Systems, Inc. 6020.002 Revision B Released

emissions

The Fabius Tiro is intended for use in the electromagnetic environment specified below. The customer or the user of the Fabius Tiro should assure that it

is used in such an environment.

53

Page 60

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Electromagnetic Testing and Compliance Fabius Tiro

Table 1 Electromagnetic Emissions

Emissions test Compliance level Recommendations

3 Guidance and manu-

facturer’s declaration-electromagnetic

immunity

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/flicker emissions

IEC 61000-3-3

The Fabius Tiro is intended for use in the electromagnetic environment specified below. The customer or the user of the Fabius Tiro should assure that it

is used in such an environment.

Table 2 Electromagnetic Immunity

Group 1 The Fabius Tiro uses RF energy

only for its internal function.

Therefore, its RF emissions are

very low and are not likely to

cause any interference in nearby

electronic equipment.

Class B The Fabius Tiro is suitable for

use in all establishments, except

Complies

Complies

NMR environments, including

domestic establishments and

those directly connected to the

public low-voltage power supply

network that supplies buildings

used for domestic purposes.

Immunity test IEC 60601 test

level

Electrostatic discharge (ESD)

IEC61000-4-2

Electrical fast

Transient/burst

IEC61000-4-4

Surge

IEC61000-4-5

+/-6 kV contact

+/-8 kV air

+/-2 kV for power

supply lines

+/-1 kV for

input/output lines

+/-1 kV differential mode

+/-2 kV common

mode

Compliance

level

Complies Floors should be

Complies Mains power quality

Complies Mains power quality

Recommendations

wood, concrete, or

ceramic tile. If floors

are covered with

synthetic material,

the relative humidity

should be at least

30%.

should be that of a

typical commercial or

hospital environment.

should be that of a

typical commercial or

hospital environment.

L6020002_EMC.fm 17.06.04

All rights reserved. Copyright reserved.

54

Dräger Medical Systems, Inc. 6020.002 Revision B Released

Page 61

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Electromagnetic Testing and Compliance

Immunity test IEC 60601 test

level

Voltage dips,

short interruptions, and voltage variations on

power supply

input lines

IEC 61000-4-11

Power frequency

(50/60 Hz) magnetic field

IEC61000-4-8

<5% Ut

(>95% dip in Ut)

for 0.5 cycle

40% Ut

(60% dip in Ut)

for 5 cycles

70% Ut

(30% dip in Ut)

for 25 cycles

<5% VT

(>95% dip in Ut)

for 5 seconds

3 A/m Complies Power frequency

Compliance

level

Complies Mains power quality

Recommendations

should be that of a

typical commercial or

hospital environment. The Fabius

Tiro provides battery

back-up in the event

of a power failure.

magnetic fields

should be at levels

characteristic of a

typical location in a

typical commercial or

hospital environment.

NOTE

Ut is the a.c. mains voltage prior to application of the test level.

4 Guidance and manu-

facturer’s declaration-electromagnetic

The Fabius Tiro is intended for use in the electromagnetic environment specified below. The customer or the user of the Fabius Tiro should assure that it

is used in such an environment.

immunity

Table 3 Electromagnetic Immunity

Immunity

test

All rights reserved. Copyright reserved.

L6020002_EMC.fm 17.06.04

IEC 60601

test level

Compliance

level

Electromagnetic environ-

ment-guidance

Portable and mobile RF communications equipment

should be used no closer to

any part of the Fabius Tiro,

including cables, than the

recommended separation

distance calculated from the

equation applicable to the frequency of the transmitter.

Dräger Medical Systems, Inc. 6020.002 Revision B Released

55

Page 62

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Electromagnetic Testing and Compliance Fabius Tiro

Immunity

test

Conducted

RF

IEC61000-46

Radiated RF

IEC61000-43

IEC 60601

test level

3 Vrms

150 kHz to

80 MHz outside ISM

bands (ref.

NOTE A)

10 Vrms

150 kHz to

80 MHz in

ISM bands

(Ref. NOTE

A)

10 V/m

80 MHz to

2.5 GHz

Compliance

level

[V1] V

Complies

[V2] V

Complies

[E1] V/m

Complies

Electromagnetic environ-

ment-guidance

Recommended separation

distance

d=[3.5/V1]vP

d=[12/V2]vP

d=[12/E1]vP 80 MHz to

800 MHz

d=[23/E1]vP 800 MHz to

2.5 GHz

where P is the maximum output power rating of the transmitter in watts (W) according

to the transmitter manufacturer and d is the recommended separation distance

in meters (m) (Ref. NOTE B).

Field strengths from fixed RF

transmitters, as determined

by an electromagnetic site

survey (ref. NOTE C), should

be less than the compliance

level in each frequency range

(Ref. NOTE D).

Interference may occur in the

vicinity of equipment marked

with the following symbol:

((e»)

NOTE

At 80 MHz and 800 MHz, the higher frequency range applies.

56

Dräger Medical Systems, Inc. 6020.002 Revision B Released

L6020002_EMC.fm 17.06.04

All rights reserved. Copyright reserved.

Page 63

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Electromagnetic Testing and Compliance

NOTE

These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects, and

people.

NOTE A

The ISM (industrial, scientific, and medical) bands between 150 kHz and

80 MHz are 6.765 MHz to 6.795 MHz; 13.553 MHz to 13.567 MHz;

26.957 MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz.

NOTE B

The compliance levels in the ISM frequency bands between 150 kHz and

80 MHz and in the frequency range 80 MHz to 2.5 GHz are intended to

decrease the likelihood that mobile/portable communications equipment

could cause interference if it is inadvertently brought into patient areas. For

this reason, an additional factor of 10/3 is used in calculating the recommended separation distance for transmitters in these frequency ranges.

5 Recommended sep-

aration distances

between portable

and mobile RF communications equipment and the Fabius

Tiro

NOTE C

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and

FM radio broadcast, and TV broadcast cannot be predicted theoretically

with accuracy. To assess the electromagnetic environment due to fixed RF

transmitters, an electromagnetic site survey should be considered. If the

measured field strength in the location in which the Fabius Tiro is used

exceeds the applicable RF compliance level above, the Fabius Tiro should

be observed to verify normal operation. If abnormal performance is

observed, additional measures may be necessary, such as re-orienting or

relocating the Fabius Tiro.

NOTE D

Over the frequency range 150 kHz to 80 MHz, field strengths should be

less than 1 V/m.

The Fabius Tiro is intended for use in an electromagnetic environment in

which radiated RF disturbances are controlled. The customer or the user of

the Fabius Tiro can help prevent electromagnetic interference by maintaining

a minimum distance between portable and mobile RF communications equipment (transmitters) and the Fabius Tiro as recommended below, according to

the maximum output power of the communications equipment.

Table 4 Distance Recommendations between RF Communications

All rights reserved. Copyright reserved.

L6020002_EMC.fm 17.06.04

Dräger Medical Systems, Inc. 6020.002 Revision B Released

57

Page 64

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Electromagnetic Testing and Compliance Fabius Tiro

Equipment and the Fabius Tiro

Rated maximum output

Separation distance according to frequency of transmit-

ter (meters)

power of

transmitter

W(atts)

150 kHz to

80 MHz outside ISM

bands

150 kHz to

80 MHz in

ISM bands

d=[12/E1]vP

80 MHz to

800 MHz

d=[12/E1]vP

800 MHz to

2.5 GHz

d=[23/E1]vP

d=[3.5/V1] vP

0.01 0.116 0.120 0.120 0.230

0.1 0.368 0.379 0.379 0.727

1 1.166 1.200 1.200 2.300

10 3.689 3.794 3.794 7.273

100 11.66 12.000 12.000 23.000

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be determined using the

equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the

transmitter manufacturer.

NOTE

At 80 MHz and 800 MHz, the separation distance for the higher frequency

range applies.

NOTE

The ISM (industrial, scientific, and medical) bands between 150 kHz and

80 MHz are 6.765 MHz to 6.795 MHz; 13.553 MHz to 13.567 MHz; 26.957

MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz.

NOTE

An additional factor of 10/3 is used in calculating the recommended separation distance for transmitters in the ISM frequency bands between 150

kHz and 80 MHz and in the frequency range 80 MHz to 2.5 GHz to

decrease the likelihood that mobile/portable communications equipment

could cause interference if it is inadvertently brought into patient areas.

L6020002_EMC.fm 17.06.04

All rights reserved. Copyright reserved.

58

Dräger Medical Systems, Inc. 6020.002 Revision B Released

Page 65

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Fabius Tiro Electromagnetic Testing and Compliance

NOTE

These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects, and

people.

All rights reserved. Copyright reserved.

L6020002_EMC.fm 17.06.04

Dräger Medical Systems, Inc. 6020.002 Revision B Released

59

Page 66

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Electromagnetic Testing and Compliance Fabius Tiro

60

Dräger Medical Systems, Inc. 6020.002 Revision B Released

L6020002_EMC.fm 17.06.04

All rights reserved. Copyright reserved.

Page 67