Page 1

|

Fabius

°-

CE

Drager

A

medical

Dräger

and

Siemens

Company

Emergency

Care

Perioperetive

Care

Critical

Care

Inhalation

Software

Instructions

ae

Care:

Home

Anesthesia

4.n

for

Я

Use

Because

Machine

you

6816

Page 2

Contents

Contents

For

Your

Safety

and

that

of

Your

Patients

intendedÜse........................

Safety

Features

Copyright,

Typicai

Components

Fabius

Configurations

Anesthesia

Compact

SemiOpenAdapter.................................

Magill

A-Cone

Dräger-Vapor®

Vapor

Dräger-Vapor®

Selectatec®

Airway

Ventilation

User

Rotary

Displays...............

Warning

Screen

Mode

Ventilation

Function

Setting

Calibrating

Calibrating

Menu

Configuration

Language

Gas

Preparation

Caution

Gas

Cylinders

Cylinders

Electrical

Eguipotential

Attaching

Preparing

Fitting

Breathing

Fitting

Fitting

Fiting

Inserting

Fitting

Fabius

Inhalation

Breathing

Switch

Interlock

Monitor

interface

Control し に に に

Tones

Display

Selection

Alarm

Display

Compensation

During

supply

the

the

the

the

the

the

..

Trademark,

.............,.....,.,,..,....,4...,..

Ventilator

Breathing

.,.....,...,,...,......,....,4........

and

.....,,..,,....,,,....,...,,.

Parameter

Buttons

Limits

the

The

Button

Menu

Selection

............

...........

with

Threaded

with

Pin-index

Supply

Bonding

Manual

the

Ventilator

CO2

System

Inspiratory

Expiratory

Pressuredimiting

Flow

Waste

and

Disclaimer

Configurations

Anesthesia

......

....

System

Cireuit

.....,..,,,...,....,,,....,..,,,....,

Anesthetic

System

.........,....,........,,.....

......................,..

Machine

.........,,...,.....,.....

............,,...,,..,.......

Agent

Vaporizer

ーー

with

Control

Monitor

.......,...,.,......,.........,....,

Configuration

Buttons

Units

Operating

に に に に し に に

トト に レト

1.100

.......

Buttons

.....,.........,.....

Concept

レト

eee

Oxygen

Sensor

Flow

Sensor

.....

...

Menu

Setting

Transport

.

.......,...,,....,,...,

...

...........,........,......

Menu

....,........,......,

Connectors

Mounting

...........,......,,...,....,,,...,

..........

Ventilation

Absorber

Gas

on

..................,,..............

Valve

Valve

Sensor

............,...............

Outlet

....,.......,,,.....

Bag

.

the

Compact

.......

Valve

.

Port

.............,,,..,..

..............

er

Notices

トッ レト ト レート

............

.

.

トト

トー

ρ

レー て て

νοκ

..5

..

.

.

..

…

ων

..

..

..

Connecting

4

Fitting

Connecting

5

Connecting

Connecting

5

Connecting

Connect

6

ConnectingiheO2Sensor...........................

Installing

10

CompactBreathingSystem..........................

Anesthetic

10

Scavenger

10

Semi-open

10

A-Cone

10

Installation

11

Removing

11

InstallingtiheCO2>Absorber..........................

12

Additional

12

Operation

Nitrogen

13

Adjusting

SettingtiheVapor......................

Ventilation

Semi-open

Spontaneous

Manual

Automatic

Pressure

Using

A-Cone

OzFlush

ReplacingCO2Absorbent...........................

Replacing

Shut-down

Switch

(Dráger-Vapor“)

ClosetheMeteringValves

Switch

Disconnect

De-pressurizing

Switch

Remove

Fault - Cause — Remedy

Dismantling

Dismaniling

for

26

26

27

27

Cleaning

Dismantling

DismantlingtheExpiratoyValve

Dismantling

Dismantling

Dismantiing

the

Compact

Microbial

Switch 上 に に に に に

Ventilation

the

Lever

Off

off

Off

the

Filters

the

Breathing

the

02

the

Pressure

the

Flow

the

Magill

Anesthetic

Gas

Scavenging

System

Compact

of

the

Semi-OpenAdapter

the

Semi-Open

Equipment

......................

Wash-out

the

Fresh

Modes

Compact

Breathing

Ventilation

limited

ventilation

Magill

Breathing

Selection

..............

Used

Absorbent

.......,.....,.....,....,,....,....,.,..

the

Anesthetic

ручке

anesthesia

the

Fresh-gas

the

the

Control

O2

Sensor......,.,....,,...,,,...,,....

Down

the

Compact

に に レー レレ に トー

the

Inspiratory

the

Flow

the

Pressure-imiting

the

Absorbent

Breathing

..............

Hoses

Sensor

Capsule

Sensor

Sensor

inhalation

Gas

Scavenging

System

Connections

Breathing

に に に に に に

Adaptor

..........,...,,,.........,....

(when

Required)

Gas

Composition

with

the

Compact

Breathing

...........,....,.....,.,...,

..................................

...,.............,...,,...,,....

System

..........

System

..

...................

.....................

......

Device

AGS

for

the

System

レレ

レー

and

2.

System

.........,...........,....

. .

............

ーー

.

Hose

to

..............

................

ドッ

トド

.................

elele

..................

.................

6.0

and

................

(Compact

Agent

...........................

ventilator

Supply

Anesthesia

Unit

..........................,

...........,......,....,......,..

Breathing

トト

Valve

Sensor

..............,,....,....

Canister

System)

Vaporizer

.......................

.....................

Machine

.

System

トト トト

レッ

トット

.

......................

Valve

...................

the

トー

ee

..........

ттт

ーー ス いい

ュー

レト

ここ

...

..

.

...

ーー

...

・

-

27

28

28

29

29

30

31

32

32

33

33

33

34

35

36

37

37

37

37

38

38

39

40

41

42

43

43

44

44

45

47

49

ΠΠ:

Page 3

Conients

Minimum

Magil!

Dismantling

Disinfecting/Cleaning

Wipe

Flow

of

Anesthesia

Breathing

Device

Parts

of

Disinfecting

.........................

........

the

Ventilator

..............................

............,.,,,....

DisinfectingandCleaning...........................

Automatic

Sterilzind

Checking

Maintenance

Disposal

What'swhat

Compact

Compact

TechnicalData....................................

DiagramS

Compact

Semi-Open

Gas

Cleaning/Disinfecting

エレ

に に に に に に トト

Readiness

intervals

.,,..,...,..,.,,,.......,,,,.,..,.,,,,,,.,

for

..............................

................

Breathing

Breathing

Breathing

Compact

Delivery

Unit

System,

System,

System

Breathing

(3-Gas

version)

Machine

に に に トー

トト

Operation

0

Front

Back

........

System

トレ

レレ

レト ト トト

...................

eee

...

.....,,.,.......,...,

. .

.....................

..............

レット

レト て トト

こてこて

eneree

・

.

50

50

51

51

52

52

52

53

53

56

62

62

63

64

Âbbreviations

Used

..................,,.,.,,,.,,....

DailyPre-UseCheckforFabius

Index

sise.

......................

65

66

71

Page 4

For

Your

Safety

For

Your

Patients

and

that

Safety

of

Your

and

Patients

that

of

Your

Strictly

Any

observation

The

Maintenance

The

service

We

Only

Observe

Accessories

Do

(86

and/or

be

iramediately

cracks,

foliow

use

of

the

of

apparatus

Observe

equipment

Repair

carried

DrägerService

maintenance.

Even

result

parts

may corrode

the

used}

apparatus

personnel

and

general

out by

recommend

authentic

chapter

not

use

accessory

06

304,

revision

reusable

sterilized)

increased

of

various

(e.g.

disinfectant

if

deformation,

and

the

the

Instructions

apparatus

these

is

only

Instructions

must

trained

that a service

and

Drager

accessories

factors

material).

external

requires

instructions.

to

be

for

be

inspected

at

six

month

overhaul

service

that

all

repairs

spare

"Maintenance

parts

index

00).

have a limited

the

service

when

residues

Such

signs

discoloration,

for

Use

full

used

for

Use

of

and

intervals.

of

the

apparatus

personnel.

contract

also

parts

may

Intervals".

other

than

(e.g.

parts

useful

life

reduced

handling

left

behind

parts

of

wear

peeling,

understanding

purposes

the

which

must

become

specified

supplementary

serviced

be

be

be

those

life,

and

by

may

obtained

carried

out

used

for

in

the

can

be

Wear

and

considerably

conditioning such

after

autoclaving

be

replaced

evident,

etc.

and

strict

here.

trained

only

be

with

by

them.

order

list

cleaned

tear

as

such

Liability

The

irrevocably

that

employed

used

Drager

non-compliance

The

delivery

recommendations

Dräger

may

a

as

for

proper

liability

for

transferred

the

apparatus

or

authorized

in a manner

cannot

warranty

and

of

Drager

Medical

function

the

proper

is

serviced

not

conforming

be

held

with

the

liability

are

likewise

given

AG & Co.

or

damage

function

to

the

by

DragerService

responsible

recommendations

provisions

above,

KG

owner

or

repaired

to

not

of

the

or

its

for

of

modified

apparatus

operator

by

personnel

or

if

the

intended

damage

given

the

terms

by

is

to

the

apparatus

use

caused

above.

of

sale

the

extent

noi

is

by

and

Not

for

Use

in

This

apparatus

areas

where

combustible

occur,

Safe

connection

Electrical

these

consultations

connections

Instructions

with

Areas

is

neither

with

for

the

of

Explosion

approved

or

explosive

other

electrical

to

equipment

Use

should

respective

Hazard

nor

certified

gas

mixtures

equipment

which

is

not

only

be

made

manufacturers

for

use

in

are

likely

listed

in

following

or

an

expert.

to

Page 5

intended

Use

Intended

Fabius

is

continuous

of

at

Jeast 5 kg.

Fabius

is

Use

an

inhalation

fresh

intended

gas

for

rooms.

It

may

be

used

with

O2,

gas

pipeline

Fabius

providing

The

following

©

Automatic

©

Pressure

@

Manual

©

Spontaneous

The

Fabius

electronically

pressure

centration

According

Modules - Particular

the

volume

additionally

with

the

As

per

Special

concentrations

EN

740

available

Fresh

anesthetic

Do

not

ether,

system

or

can

be

equipped

fresh gas

decoupling,

ventilation

Ventilation

limited

ventilation

Ventilation

Breathing

can

be

equipped

controlled

(Paw),

the

volume

(FiO2).

to

EN

740

(V)

and

the

monitored

ventilator.

EN

740

(Anesthetic

Reguirements),

of

COz

reguires

for

gas

that a manual

emergenoy

enrichment

vaporizer.

use

readily

flammable

cyclopropane,

Requirements)

anesthesia

flow

for

patients

use

in

operating,

N20,

and

AIR

by

externally

with a compact

PEEP,

options

are

((PPV),

(IPPV/PLV),

(MAN),

(SPONT).

with

an

ventilator,

(V)

which

and

(Anaesthesia

oxygen

concentration

in

the

case

of a Fabius

Workstations

additional

and

monitoring

anesthetic

ventilation

use,

is

provided

etc.

by

anesthetic

machine

with

with a body

induction

supplied

mounted

by a medical

gas

breathing

and

pressure

available:

electrically

the

inspiratory

operated

monitors

Workstations

the

airway

pressure

(FiO2)

not

and

their

of

the

agent

is

reguired.

bag

must

the

Dráger-Vapor“

agents

weight

and

recovery

cylinders.

system,

limitation.

and

the

airway

oxygen

con-

and

Their

(Paw),

must

be

eguipped

Modules

be

such

as

Safety

@

Monitoring

©

Automatic

©

integrated

{control

21

Burns

ventilation

electrical

breathing

Caution: Do

tomography

endangering

Caution:

10

meters

malfunctions

endangering

Copyright,

Copyright

Copyright

of

this

transcribed,

means,

recording,

—

Registered

1 1 1

DrägerService®

Fabius?

Dráger

Drágersorb?

are

—

Selectatec?

is a registered

Features

O2

S-ORC = Sensitive

device

vol.%).

may

occur

tubes

surgery

tubes

not

equipment.

the

Do

not

from

in

the

Trademark,

by

Drager

publication

or

stored

electronic

without

trade

Vapor“

registered

trade

trade

of P,

V,

FiO2

shortage

to

ensure

if

antistatic

are

used

equipment.

are not

recommended.

use

Fabius

Malfunctions

patient.

use

mobile

the

machine.

electrical

medical

patient.

Medical,

may

be

in a retrieval

or

mechanical,

written

marks

800

Plus

marks

mark

alarm

and

Oxygen

minimum

or

electrically

in

combination

Therefore,

in

the

environment

phones

within a distance

Mobile

phones

equipment,

and

Disclaimer

Inc.

All

reproduced,

system

including

permission

of

Drager

of

Datex-Ohmeda.

N2O

cut-off

Ratio

O2

concentration

conductive

with

high-frequency

these

types

of

may

result,

can

thereby

rights

reserved,

transmitted,

in

any

photocopying

of

Drager

Medical

AG & Co.

Controller

of

of

NVR

thereby

of

cause

Notices

No

part

form

or

by

and

Medical,

inc.

KG.

any

Page 6

Typical

Fabius

Configurations

Typical

General

The

Fabius

consisting

components

requirements

Versions

2-gas

3-gas

Optionally

two

cylinder

Wall

breathing

holder).

Fabius

Description

Inhalation

of a basic

and

version:

version:

available

connections:

mounted

system

Anesthesia

gas-delivery

configuration

of

various

with

Fabius

with

(2-gas

Configurations

Machine

module

designs

anesthesia

02,

N20

O2,

N20,

O2,

N20

single

vaporizer

version),

(illustrated

is a modular

with a variety

to

meet

delivery

applications.

Air

and

with

system

of

the

Magill

vaporizer

Wall

mounted

compact

(3-gas

version).

Alternatively:

Fabius

breathing

mounted

with

system,

on

dual

vaporizers,

ventilator,

CE

trolley (not

and

control

illustrated).

box

00137440

00237440

Page 7

Wall

mounted

compact

and

PM

Fabius

breathing

8050

gas

with dual

system,

monitor

vaporizers,

ventilator,

(3-gas

version).

control

box,

Typical

Fabius

Configurations

CON

Alternatively:

5

Pin

index

Magill

mounted

trolley

breathing

on

mounted

system

CE

trolley (not

Fabius

(2-gas

with

single

version).

illustrated).

vaporizer

and

00337440

Fabius

00437440

Page 8

Typical

Fabius

Configurations

Pin

index

trolley

breathing

mounted

system,

Fabius

ventilator,

and

with

dual

vaporizers,

control box

(3-gas

compact

version).

a

а

©

00637440

Pin

index

compact

and

PM

trolley

mounted

breathing

8050

gas

Fabius

system,

monitor

with

dual

ventilator,

(8-gas

control

version).

vaporizers,

box,

00627440

Page 9

Typical

Fabius

Configurations

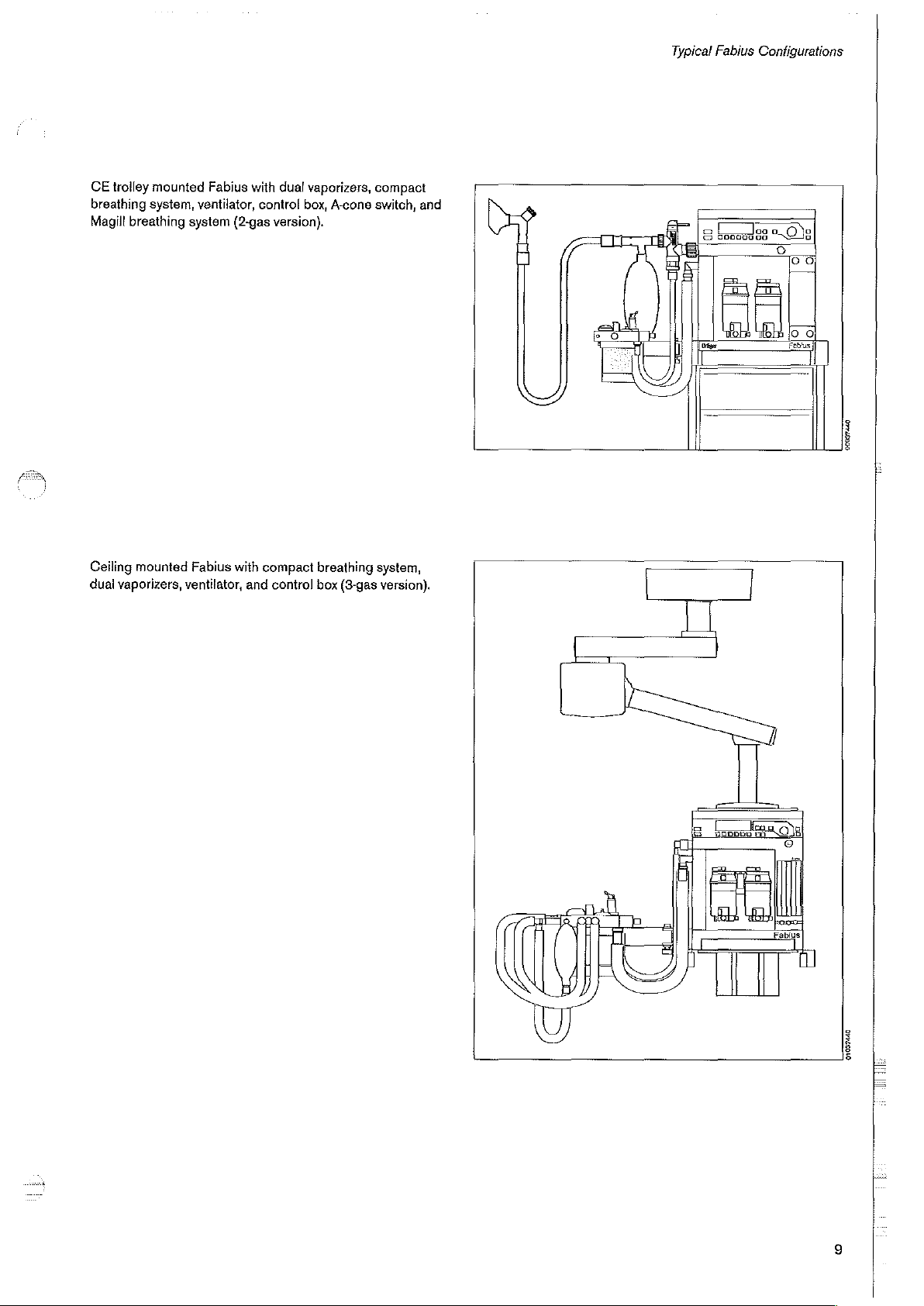

CE

trolley

breathing

Magill

breathing

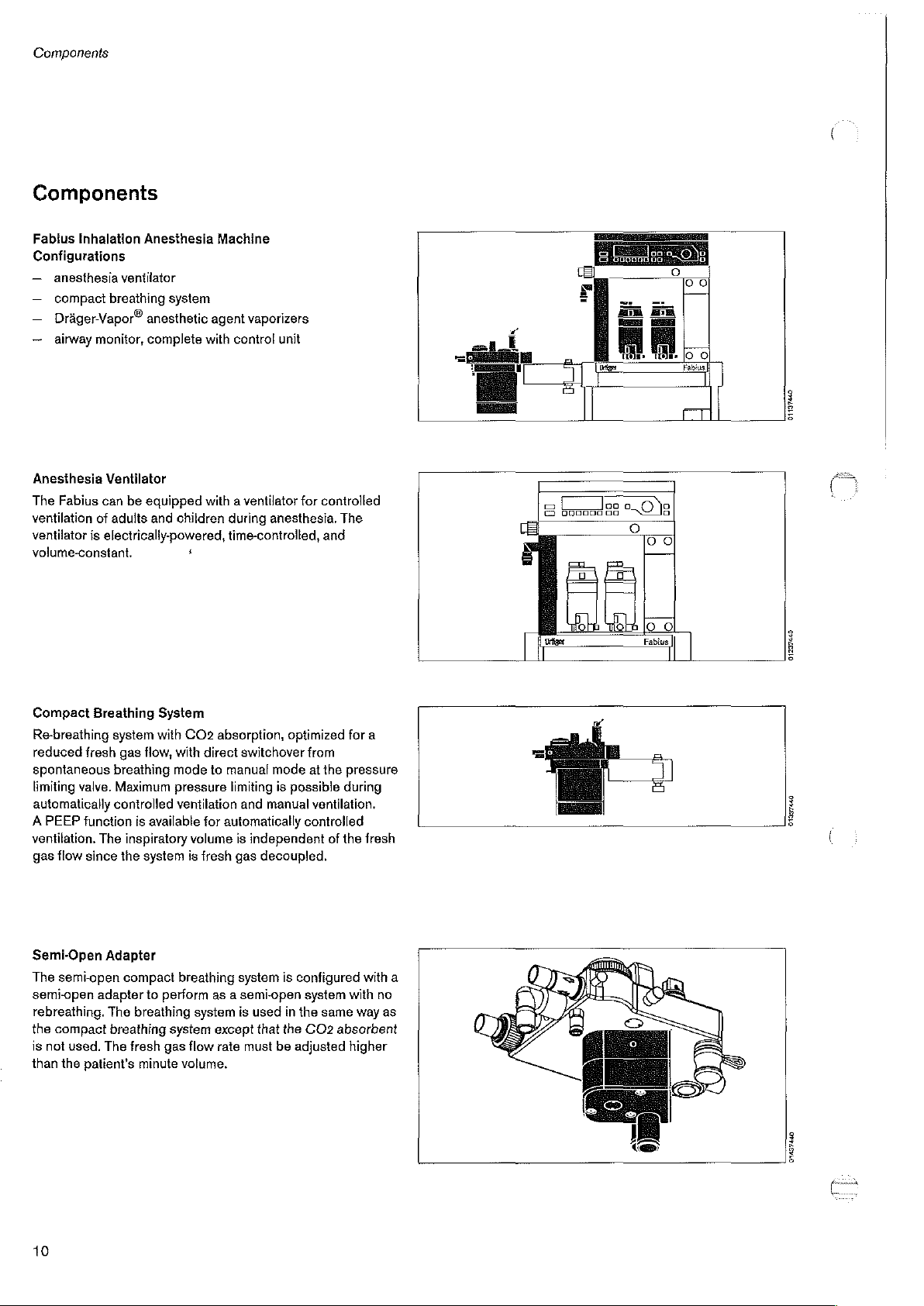

Ceiling

mounted

dual

vaporizers,

mounted

system,

system

ventilator,

Fabius

ventilator,

(2-gas

Fabius

with

and

with

dual

control

version).

compact

control box

vaporizers,

box,

A-cone

breathing

(3-gas

compact

switch,

and

system,

version).

8

booed

88

0%

00037440

01037440

Page 10

Components

Components

Fabius

Inhalation

Configurations

—

anesthesia

—

compact

一

DrágerVapor?

ー

airway

Anesthesia

The

Fabius

ventilation

ventilator

volume-constant.

ventilator

breathing

monitor,

Ventilator

can

of

adults

is

electrically-powered,

Anesthesia

system

anesthetic

complete

be

equipped

and

Machine

agent

vaporizers

with

control

with a ventilator

children

during

time-controlled,

s

unit

for

controlled

anesthesia.

The

and

Eroi

=

[=

(ee

Ha

ER

圖

m | Че.

—

5

бо

abius

био

01237440

Compact

Re-breathing

reduced

spontaneous

limiting

automatically

A

PEEP

ventilation.

gas

Semi-Open

The

semi-open

rebreathing.

the

is

than

fresh

valve.

function

flow

since

semi-open

compact

not

used.

the

patient’s

Breathing

system

breathing

controlled

The

Adapter

adapter

The

breathing

The

System

with

gas

flow,

with

mode

Maximum

inspiratory

the

compact

pressure

ventilation

is

available

system

to

perform

breathing

system

fresh

gas

minute

CO2

absorption,

direct

to

manual

limiting

for

automatically

volume

is

fresh

gas

breathing

as a semi-open

system

except

flow

rate

volume.

optimized

switchover

mode

is

possible

and

manual

is

independent

decoupled.

system

is

is

used

in

that

the

must

be

adjusted

for

from

at

the

pressure

during

ventilation.

controlled

of

the

configured

system

with

the

same

way

CO2

absorbent

higher

a

fresh

with

no

as

a

01997440

A

01437440

10

Page 11

Magill

Breathing

The

Magill

used

in

combination

instead

of a semi-closed

breathing

02

monitoring.

Circuit

system

Circuit

is a semi-open

with a semi-closed

breathing

makes

no

breathing

allowances

breathing

system.

for

system

and

system

The

Magill

pressure

or

can

Components

be

or

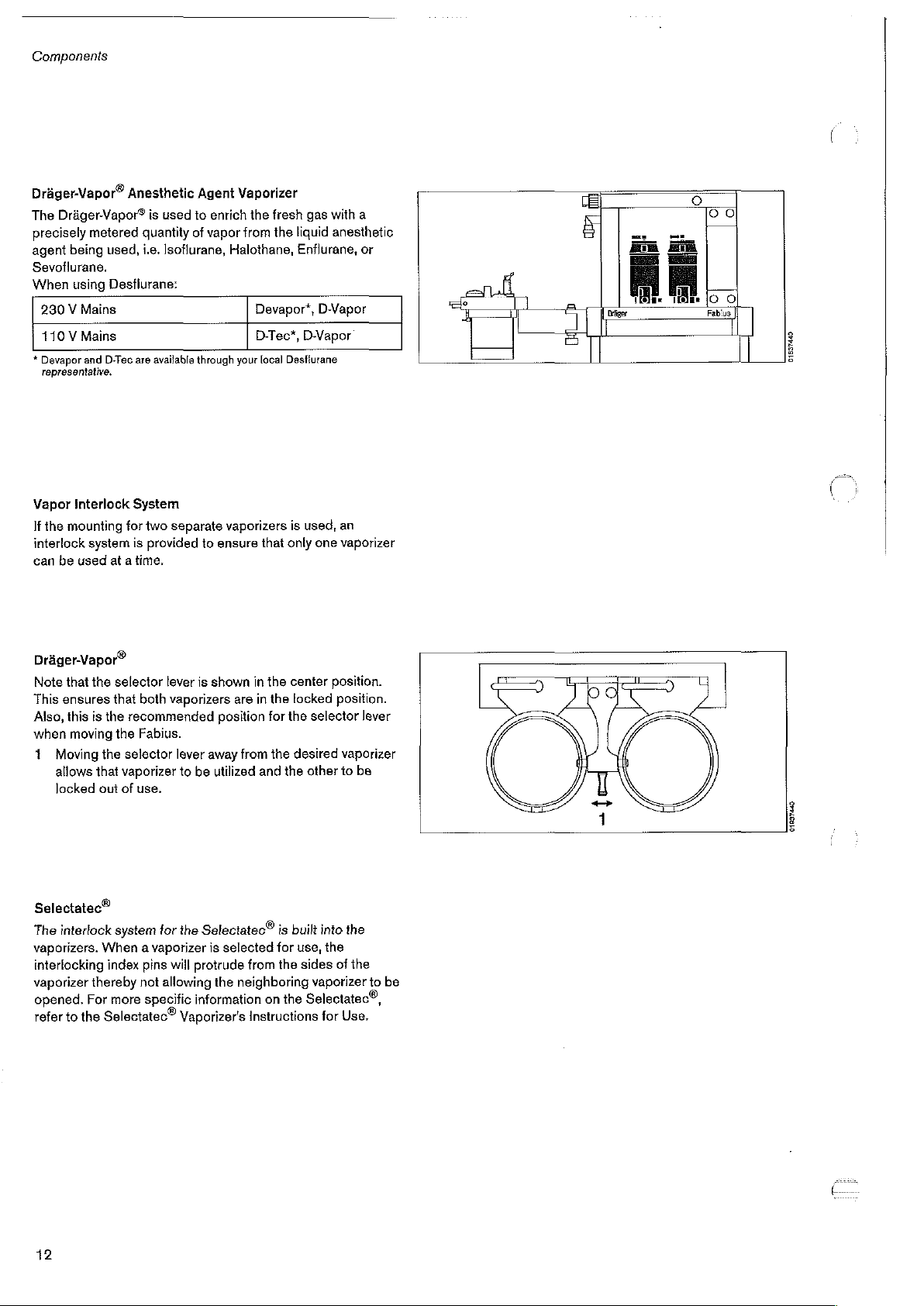

A-Cone

The

A-Cone

gas

flow

without

flow

is

accomplished

A-cone

a

spring

the

right-hand

spring

loaded

gas

flow

Switch

switch

between

changing

switch,

to

loaded

or

feature

to

the

breathing

provides a means

two

separate

fresh-gas

the

switch

the

hose

by

moving

desired

that

has a positive

lefthand

ensures

circuit

for

patient

breathing

connections.

the

lever,

flow

position.

side

of

the

positive

sealing

selected.

switching

circuits

Switching

located

A-cone

This

set

position

on

lever

switch,

for

the

the

fresh

top

of

controls

in

either

This

fresh

the

the

01637440

01787440

11

Page 12

Components

Drdger-Vapor®

The

Dr&ger-Vapor®

precisely

agent

Sevoflurane.

When

230V

110 V Mains

*

Devapor

representative.

Vapor

If

interlock

can

being

the

mounting

be

metered

using

Mains

and

Interlock

system

used

Anesthetic

is

used

quantity

used,

i.e.

Isotiurane,

Desflurane:

D-Tec

are

available

System

for

two

separate

is

provided

at a time.

Agent

to

enrich

of

vapor

through

to

ensure

Vaporizer

the

fresh

gas

with

a

from

the

liquid

anesthetic

Halothane,

your

vaporizers

Enflurane,

Devapor*,

D-Tec*,

local

that

DVapor

D-Vapor

Desflurane

is

used,

only

one

or

an

vaporizer

E

δ

E

=

Fem

ES

n)

ome

A

Es

圖

ο

So

rable

|

g

Е

Dräger-Vapor®

Note

that

the

This

ensures

Also,

this

is

when

moving

1

Moving

allows

that

locked

out

Selectatec®

The

interlock

vaporizers.

interlocking

vaporizer

opened.

refer

to

the

thereby

For

selector

that

the

the

the

system

When a vaporizer

index

more

Selectatec®

lever

both

vaporizers

recommended

Fabius.

selector

vaporizer

of

lever

use.

for

pins

will

not

allowing

specific

to

the

Vaporizer's

is

away

be

Selectatec®

is

protrude

information

shown

in

are

in

position

from

utilized

selected

from

the

neighboring

Instructions

the

center

the

locked

for

the

the

desired

and

the

is

built

for

use,

the

on

the

Selectatec®,

position.

position.

selector

vaporizer

other

to

into

the

the

sides

of

vaporizer

for

Use.

lever

be

the

to

be

TT

pa

-a

II

01807620

42

Page 13

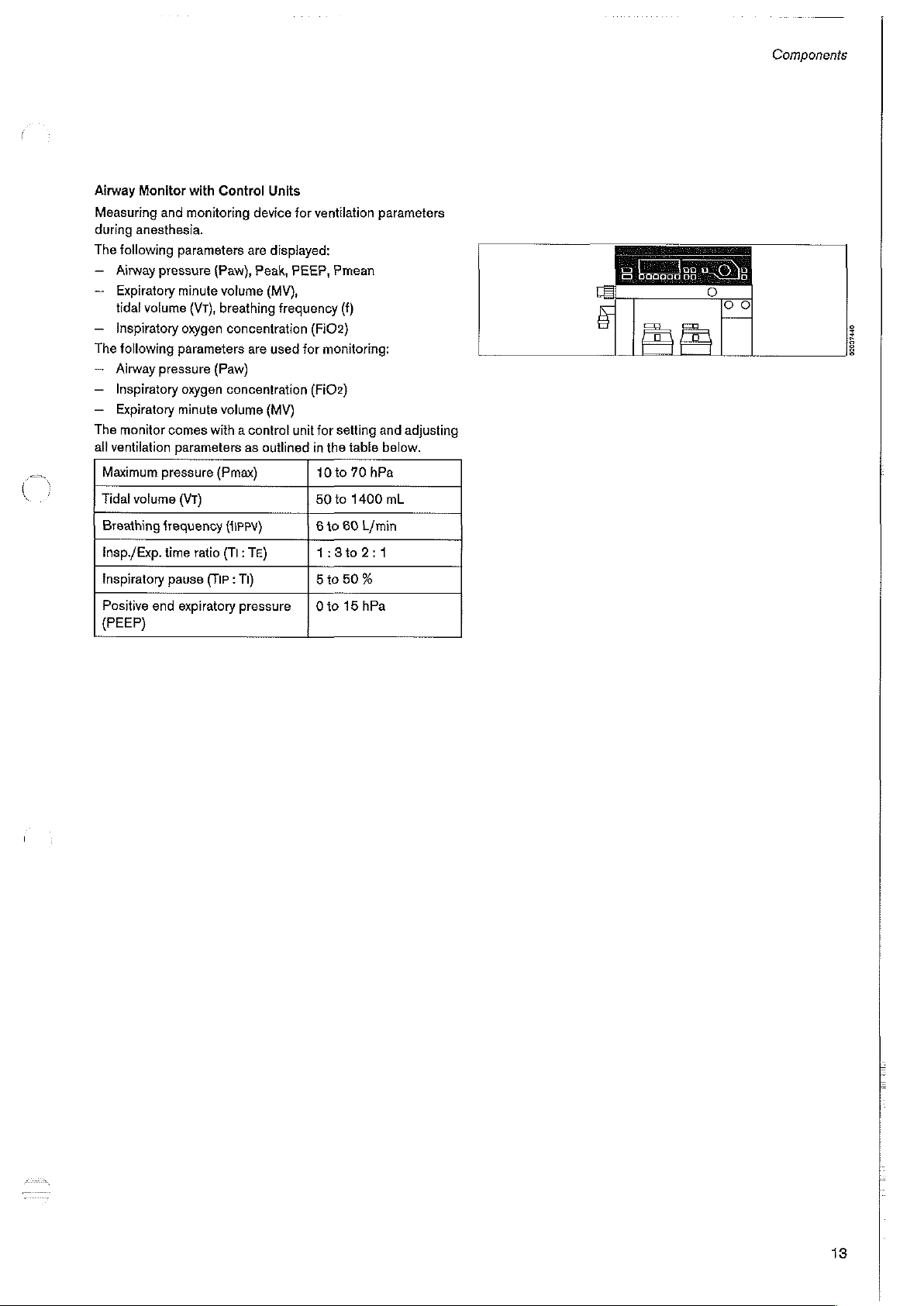

Airway

Monitor

Measuring

during

anesthesia.

The

following

—

Airway

—

Expiratory

tidal

volume

ー

Inspiratory

The

following

~

Airway

—_

Inspiratory

—

Expiratory

The

monitor

all

ventilation

Maximum

Tidal

volume

Breathing

Insp./Exp.

Inspiratory

Positive

(PEEP)

end

with

and

monitoring

parameters

pressure

minute

(V1),

oxygen

parameters

pressure

oxygen

minute

comes

with a control

parameters

pressure

(VT)

frequency

time

ratio

pause

(TIP : Tl)

expiratory

Control

(Paw),

volume

breathing

(Paw)

volume

(Pmax)

Units

device

are

displayed:

Peak,

(MV),

frequency

concentration

are

used

concentration

(MV)

as

outlined

{ИРРУ\)

(T1:

TE)

pressure | Oto

for

ventilation

PEEP,

Pmean

(FiO2)

for

monitoring:

(FiO2)

unit

for

setting

in

the

10

to

50

to

8

to

1:3t02:1

5

to

(f)

table

70

1400

60

L/min

50

%

15

hPa

parameters

and

adjusting

below.

hPa

mL

Componenis

02037840

13

TNT

Page 14

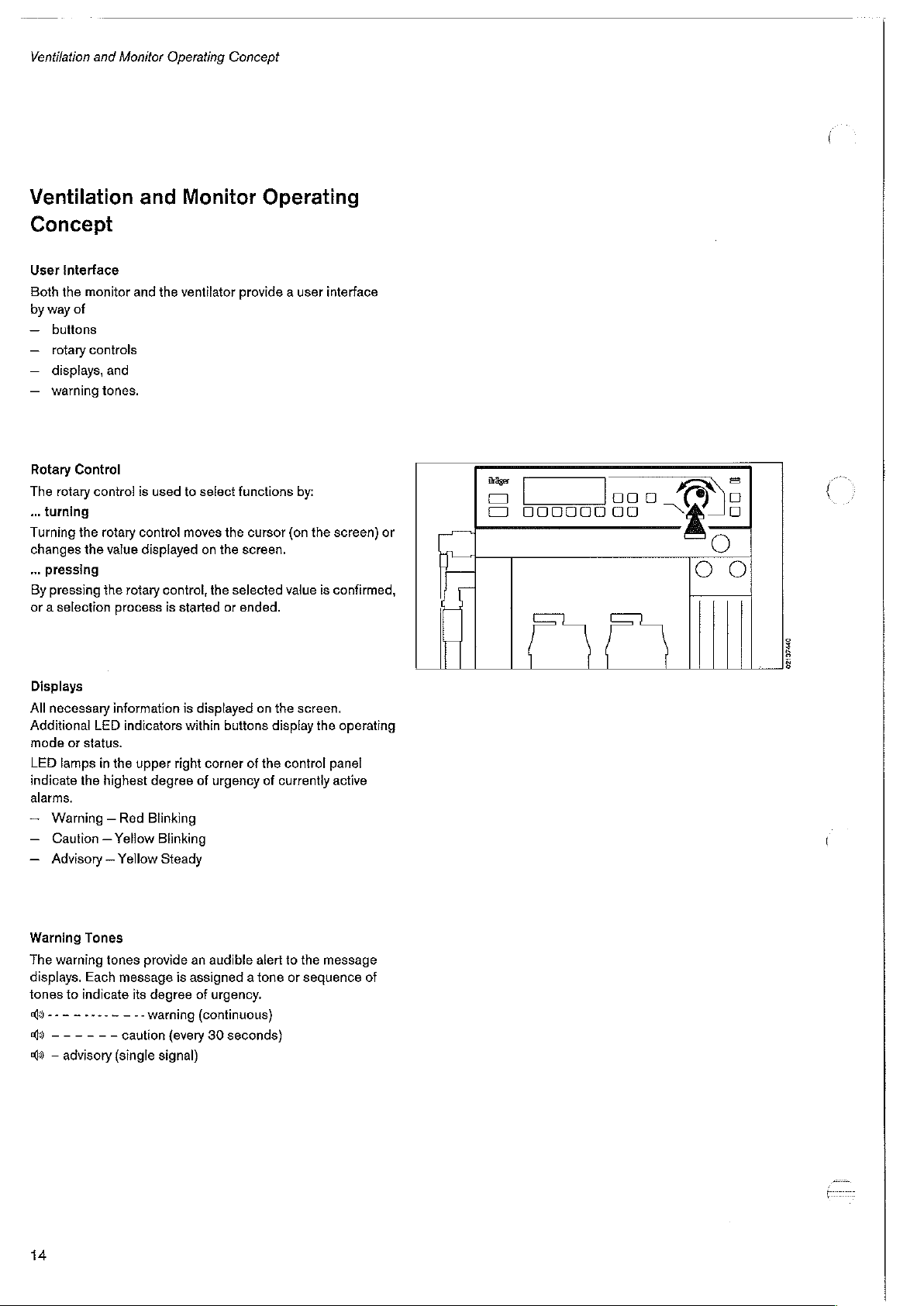

Ventilation

and

Monitor

Ventilation

Concept

User

Interface

Both

the

monitor

by

way

of

—

buttons

—

rotary

—

displays,

—

warning

Rotary Control

The

rotary

«

turning

Turning

changes

…

By

or a selection

the

the

pressing

pressing

and

controls

and

tones.

conirol

rotary

value

the

rotary

process

Operating

and

Monitor

the

ventilator

is

used

to

control

moves

displayed

control,

is

started

Concept

Operating

provide a user interface

select

the

on the

the

selected

or

functions

cursor

screen.

ended.

by:

(on

value

the

screen)

is

confirmed,

or

Sager

に

コ

O

000000

900

ロロ

II

O

ο

ο

Displays

All

necessary

Additional

mode

LED

indicate

alarms.

—

—

—

Warning

The

displays.

tones

a)

)

$ — advisory

LED

or

status.

lamps

in

the

highest

Warning — Red

Caution — Yellow

Advisory — Yellow

Tones

warning

-- - ~----~

------

Each

to

indicate

tones

information

indicators

the

upper

message

its

—--

warning

caution

(single signal}

is

within

right

degree

Blinking

Blinking

Steady

provide

is

assigned a tone

degree

{every

displayed

of

an

of

(continuous}

buttons

corner

of

urgency

audible

urgency.

30

seconds)

on

the

display

the

control

of

currentiy

alert

to

or

screen.

the

operating

panel

active

the

message

sequence

of

Il

02137440

14

Page 15

Ventilation

and

Monitor

Operating

Concept

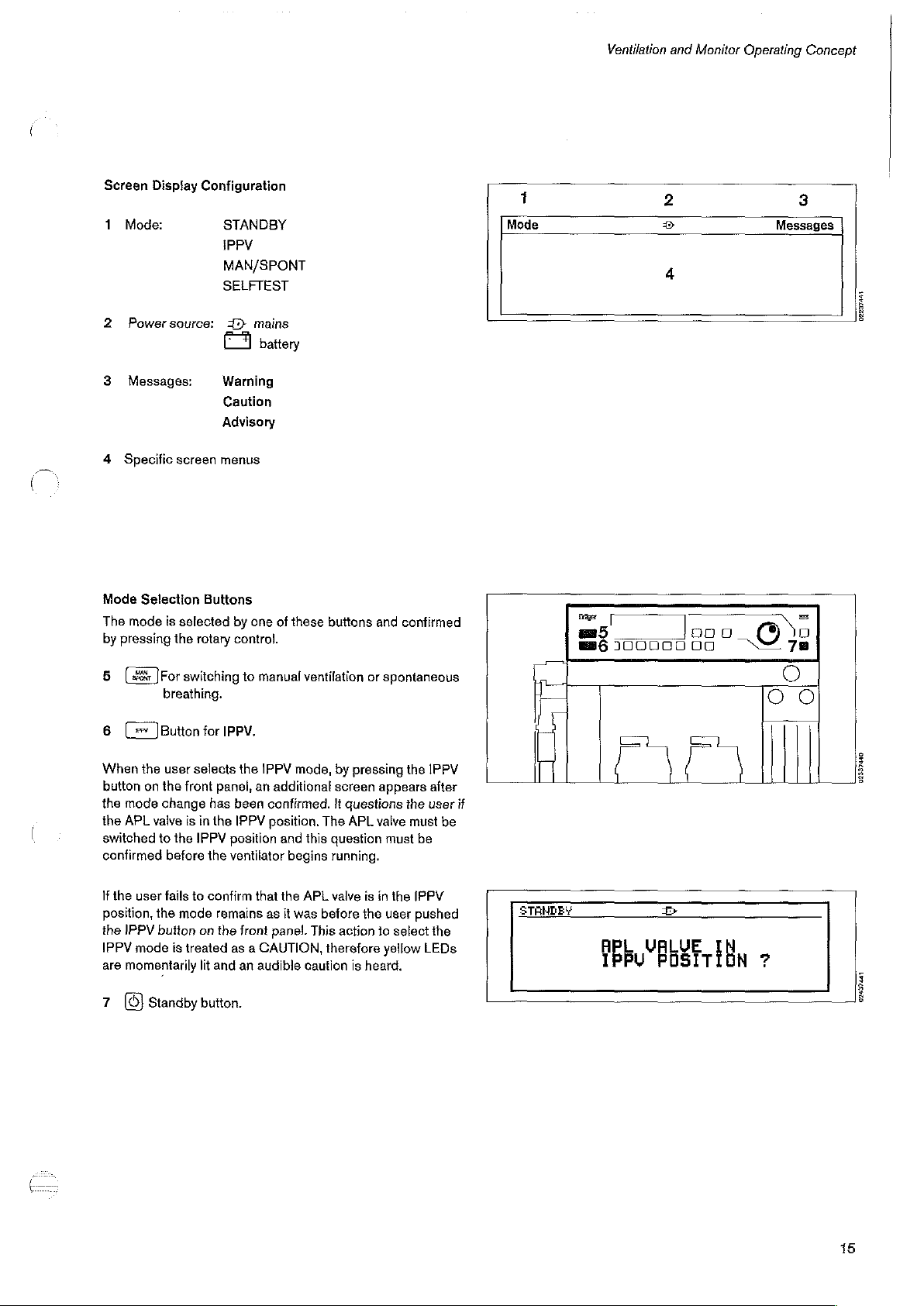

Screen

1

2

3

4

Mode

The

by

5

6

Display

Mode:

Powersource:

Messages:

Specific

Selection

mode

pressing

[48%

]For

(=

]Button

Configuration

STANDBY

IPPV

MAN/SPONT

SELFTEST

1)

Warning

Caution

Advisory

screen

menus

Buttons

is

selected

the

rotary

switching

breathing.

for

IPPV.

mains

battery

by

one

of

control.

to

manual

these

buttons

ventilation

and

confirmed

or

spontaneous

Mode

1

Dee

æ5

86

100000

2

4

000

00

©

Messages

E

3

|

0223744

|

When

the

user

button

on

the

the

mode

change

the

APL

valve

switched

confirmed

If

position,

the

IPPV

are

7

to

the

user

fails

the

IPPV

button

mode

momentarily

Standby

selects

front

is

in

the

IPPV

before

to

mode

on

is

treated

lit

button.

the

panel,

an

has

been

the

IPPV

position

the

ventilator

confirm

that

remains

the

front

as a CAUTION,

and

an

audible

IPPV

mode,

additional

confirmed.

position.

as

panel.

and

this

begins

the

APL

it

was

caution

The

before

This

by

pressing

screen

appears

it

questions

APL

valve

question must

running.

valve

is

in

the

the

user

action

to

select

therefore

is

heard.

yellow

the

IPPV

after

the

user

must

be

IPPV

pushed

the

LEDs

be

if

STAHDEY

IPBU

CI)

tr

POSTTĚDN

>

02337440

02439441

15

Page 16

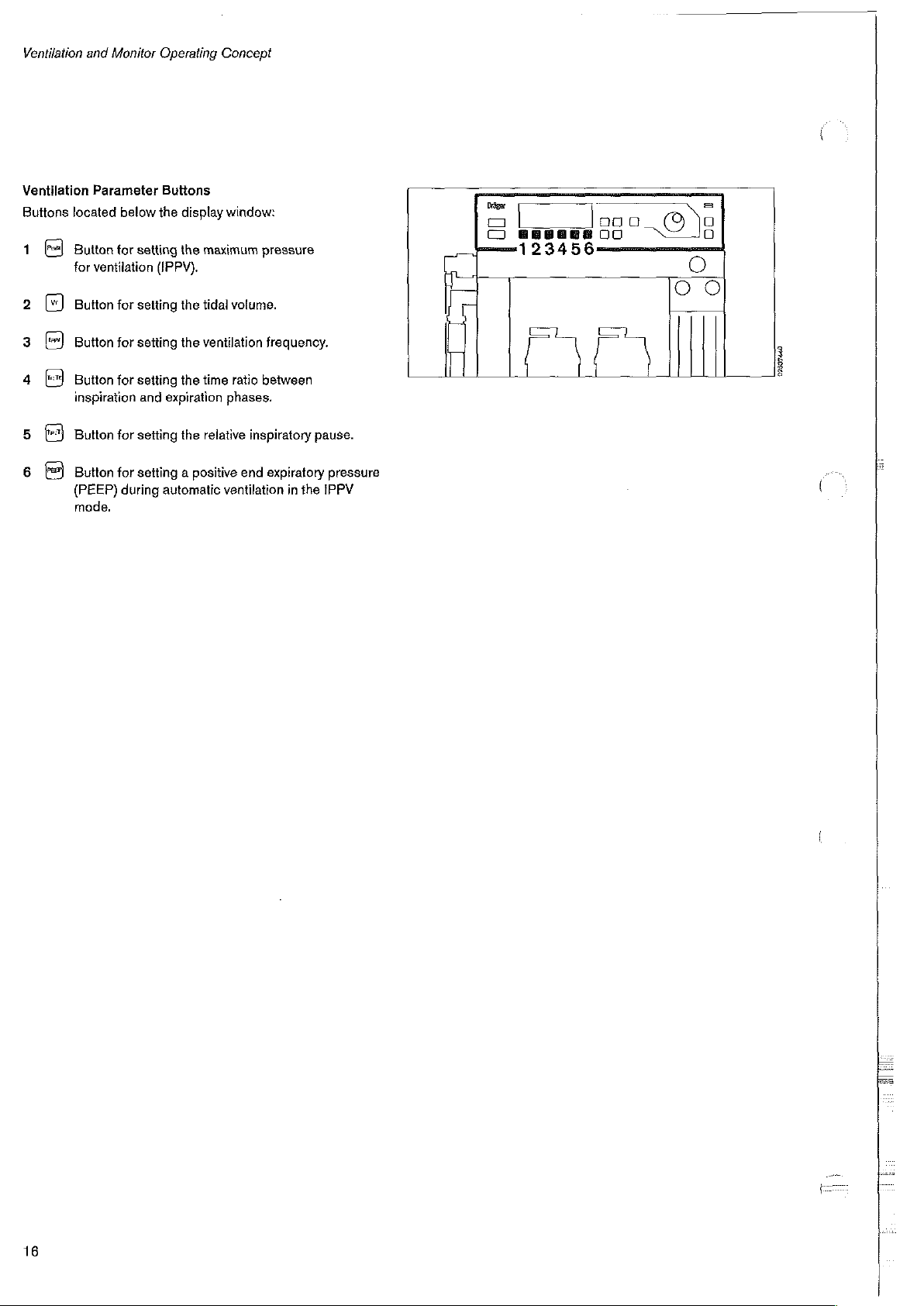

Ventilation

and

Monitor

Operating

Concept

Ventilation

Buttons

1

5

6

located

Button

for

Button

Button

Button

inspiration

Button

Button

(PEEP)

mode.

Parameter

ventilation

Buttons

below

the

for

setting

(IPPV).

for

setting

for

setting

for

setting

and

for

setting

for

setting a positive

during

automatic

display

window:

the

maximum

the

tidal

the

ventilation

the

time

expiration

the

relative

phases.

ventilation

pressure

volume.

freguency.

ratio

between

inspiratory

end

expiratory

in

pause.

the

IPPV

pressure

πα

|

=

|

Doo

ロロ

1

>

=

Q

개

(

16

Page 17

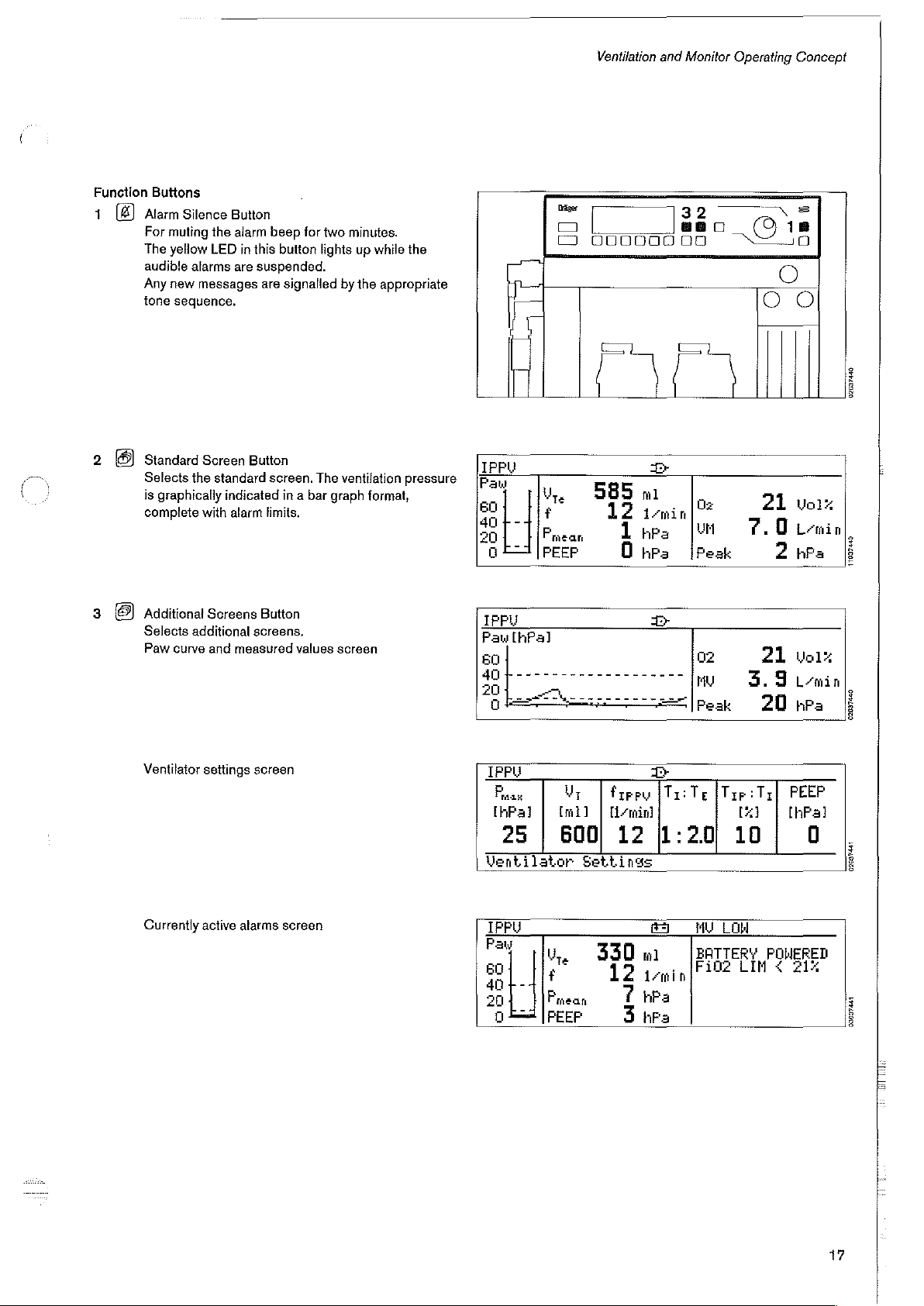

Function

1

Alarm

The

audible

Any

tone

Standard

Selects

is

complete

Buttons

Silence

For

muting

yellow

alarms

new

messages

sequence.

Screen

the

graphically

with

Button

the

alarm

LED

in

this

are

suspended.

Button

standard

indicated

alarm

beep

button

are

signalled

screen.

in a bar

limits.

for

two

lights

The

by

graph

minutes.

up

while

the

the

appropriate

ventilation

pressure

format,

IPPU

Paw

so)

401-41

20

1

İle”

Fran

a

器

O

Ventilation

000000008

5

1

O

т

ismin

hPa

hpa

585

and

Monitor

88

0

[=

|

μή

[Peak

Operating

0

18

21

7.0

ㆍ

2

Concept

vox

1

Lemin

hPa

02037440

11937440

3

Additional

8

Selects

Paw

Ventilator

Currently

Screens

additional

curve

and

settings

active

Button

screens.

measured

screen

alarms

screen

values

screen

IPPU

[hPa]

Pau

IPPU

|

Pau

[hPa]

25 | 600!

|

Mentilator

TFPu

Pay

ent

an

20

n

Mr.

[ml]

|

Settings

Le

L-

f

Paean = È

4IFEEF

|

330

B

>

¡Tao

#zrey

[min]

12

1:20

#3

m . [Fine

ismin

hPa

hs

02

ryu

Peak

Te

МУТОН

BATTERY

3.9

:Tz|

{Typ

Lx]

10

LIM < 21%

Vol:

21

min

hPa

20

PEEP

[hPal

0

POHERED

02097480

02099447

03097441

17

TA

Page 18

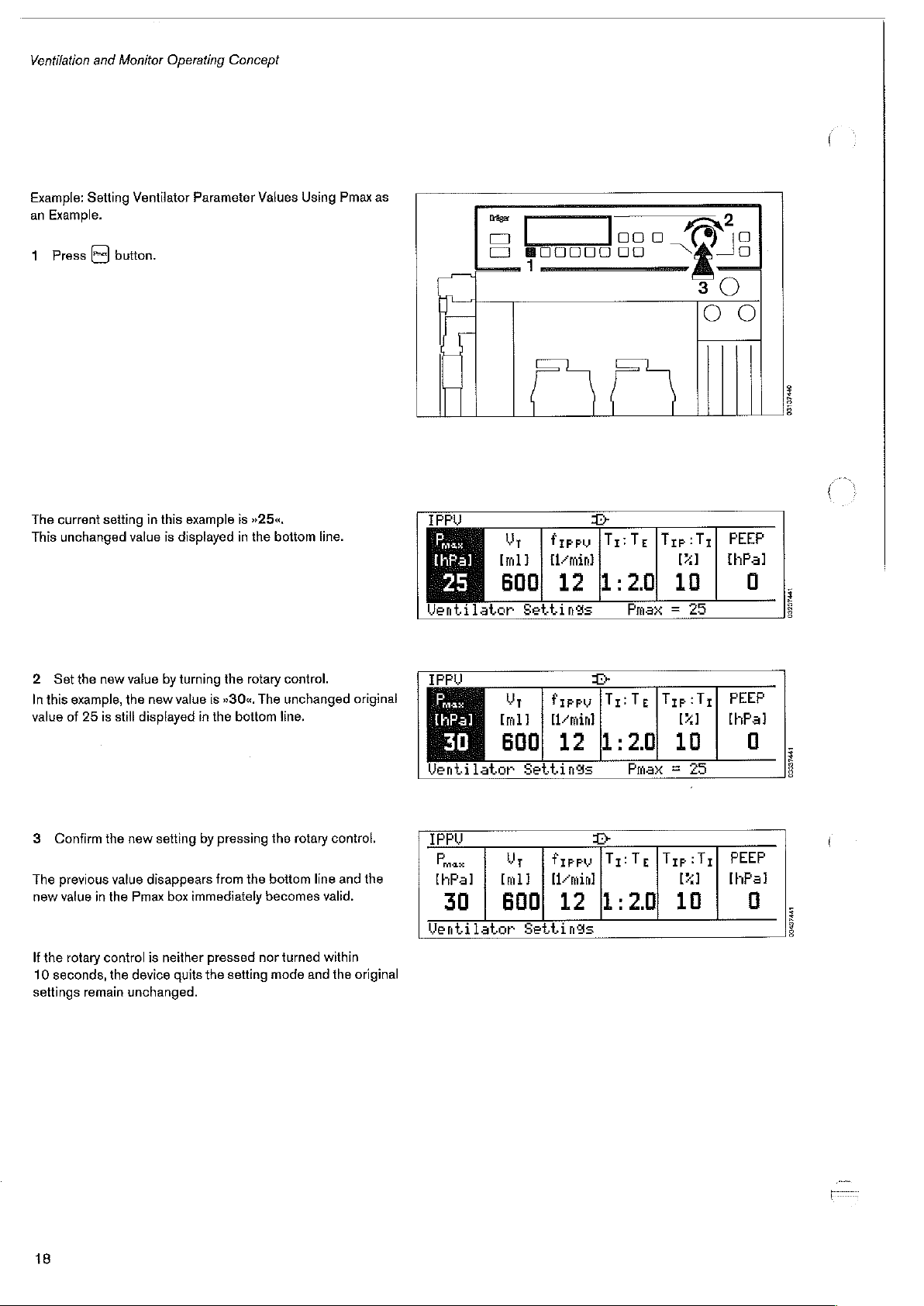

Ventilation

Example:

an

1

The

This

and

Setting

Example.

Press

current

unchanged

Monitor

Ventilator

button.

setting

value

Operating

in

this

is

displayed

Concept

Parameter

example

is

»25«.

in

the

Values

bottom

Using

line.

Pmax

as

Ventilator

Bager

O

DI

00000

Fiera

Amin]

12

Settings

noo

06

ロロ

T+

Ta:

1:20

0

_&—1

Te

[Τρ

:Ττ

[1]

10

Prax = 25

a

30

OO

Il

PEER

[hPa]

03137440

0

09227431

2

Set

the

In

this

example,

value

of

3

Confirm

The

previous

new

value

If

the

rotary

10

seconds,

settings

new

25

is

still

the

value

in

the

control

the

remain

value

by

turning

the

new

value

displayed

new

setting

disappears

Pmax

box

is

neither

device

quits

unchanged.

the

rotary

is

»30«.

The

in

the

bottom

by

pressing

from

the

immediately

pressed

the

nor

setting

control.

unchanged

line.

the

rotary

bottom

becomes

turned

mode

and

control.

line

and

valid.

within

the

original

the

original

НЫ

[hPa]

Ventilator

IPPU

Fax:

[hFal | [ml] | [min]

Ventilator

30 | 600)

Settings

Ут | Pree

Settings

Pirro

[min]

12

12

T

Tr:

1:20

T+

[Tri

1:

2.0

Te

[Trp:Tr|

[X]

10

Prax = 25

Te | Trp:

Tr}

[x]

10

PEEP

[hPa]

PEEP

[hPa]

0

03937441

0

09437441

18

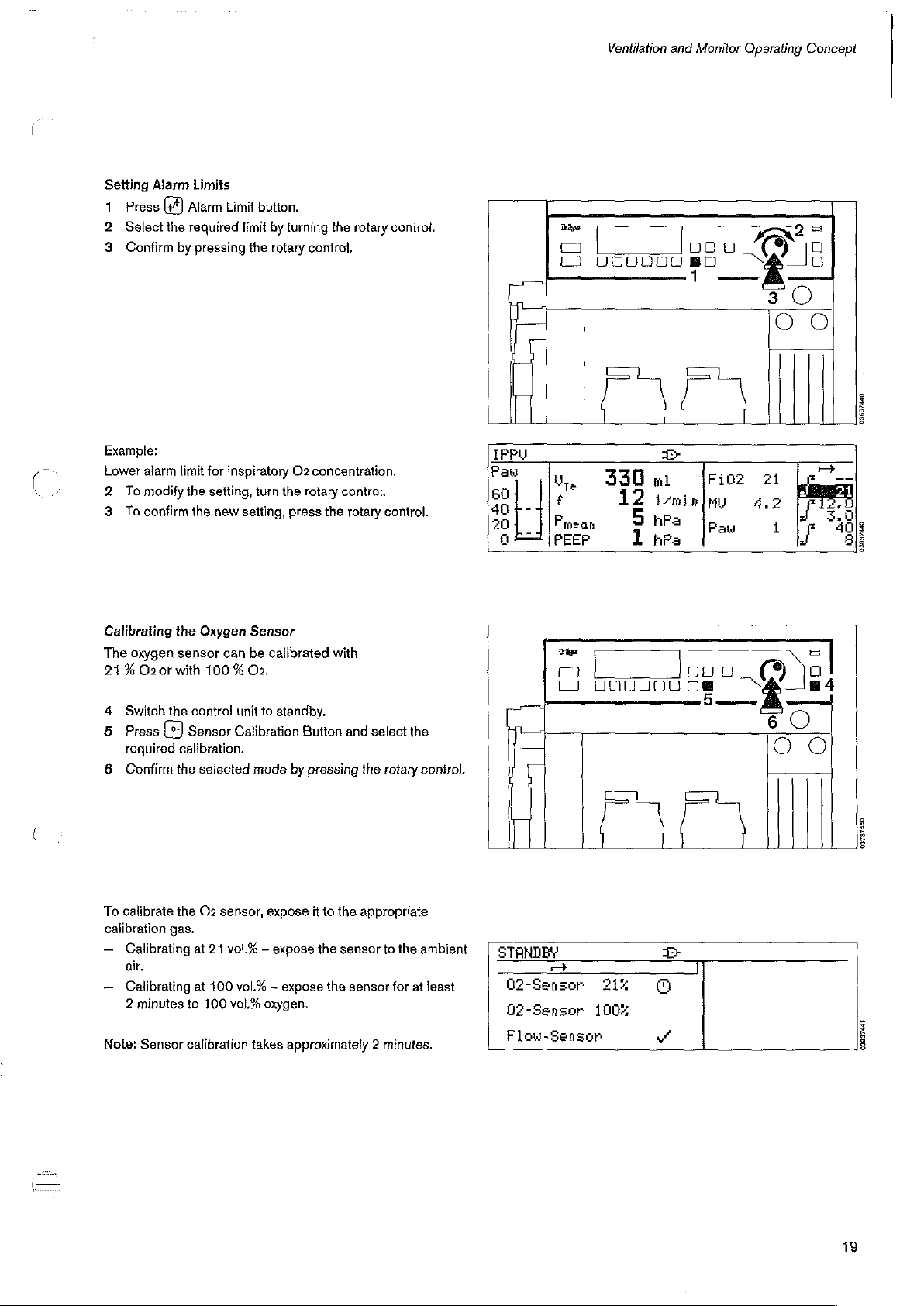

Page 19

Ventilation

and

Monitor

Operating

Concept

Setting

1.

2

3

Alarm

Press

[+]

Select

the

Confirm

Limits

Alarm

required

by

pressing

Limit

button.

limit

the

by

turning

rotary

the

rotary

control,

control.

Dés

O

σα

090000

口 口 口

BO

Fe

<Q

So

3

==

D

〇

ο ο

la,

#

Fmeas

PEEP

Trigo

0

O

330m

|

UO0NDOCO

12

i-min

5

hPa Paw

1

hPa

|

>

[rioz

HU

O

ao

5

Example:

Lower

alarm

limit

for

inspiratory

X

2

To

modify

3

To

confirm

Calibrating

The

21%

4

Switch

5

Press

required

6

Confirm

the

oxygen sensor

O2

or

with

the

the

setting,

the

new

setting,

Oxygen

can

100 % O2.

contro!

unit

Sensor

Calibration

calibration.

the

selected

O2

turn

the

press

Sensor

be

calibrated

io

standby.

mode

by

concentration.

rotary

control.

the

rotary

control.

with

Button

and

select

pressing

the

rotary

the

control.

IPPU

Pav

21

4,2

1

(9

6

ο ο

jal

O

03537440

03897440

To

calibrate

calibration

ー

ー

Note:

gas.

Calibrating

air.

Calibrating

2

minutes

Sensor

the

O2

sensor,

at

21

vol.% — expose

at

100

vol.% — expose

to

100

vol.%

calibration

expose

it

to

the

appropriate

the

sensor

the

sensor

oxygen.

takes

approximately 2 minutes.

to

the

for

ambient

at

least

STANDBY

02-Sensor

D2-Sensor

Flou-Sensor

다

aix

1

údy

09037441

19

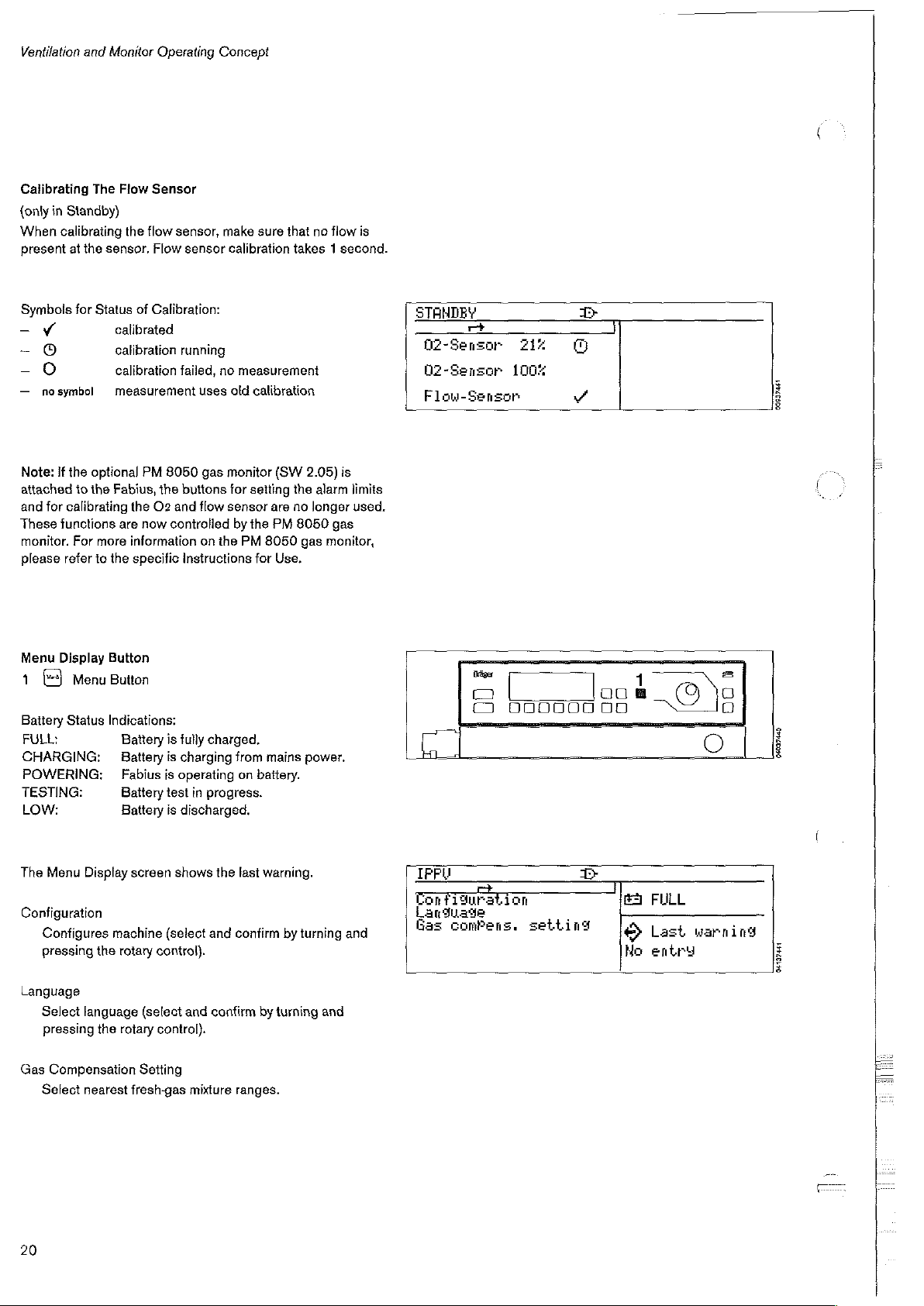

Page 20

Ventilation

and

Monitor

Operating

Concept

Calibrating

{only

in

Standby)

When

calibrating

present

Symbols

ー

-

-

—

Note:

attached

and

These

monitor.

please

at

the

for

ザ

0

0

nosymbol

if

the

optional

to

the

for

calibrating

functions

For

refer

The

Flow

Sensor

the

flow

sensor.

Status

more

to

Flow

of

Calibration:

calibrated

calibration

calibration

measurement

PM

Fabius,

the

the

O2

are

now

information

the

specific

sensor,

failed,

8050

and

controlled

make

sensor

running

no

uses

old

gas

monitor

buttons

flow

sensor

on

the

Instructions

sure

that

calibration

measurement

for

by

PM

takes 1 second.

calibration

(SW

2.05)

setting

the

are

no

the

PM

8050

8050

gas

for

Use.

no

flow

is

alarm

longer

gas

monitor,

is

limits

used.

STANDEY

+

D2-Senzor

Q2-Sensor

Flow-Sensor

212

100%

om

vč

ση

Menu

Display

1

6-3

Battery

FULL:

CHARGING:

POWERING: _ Fabius

TESTING:

Low:

The

Menu

Configuration

Configures

pressing

Language

Select

pressing

Gas

Compensation

Select

Menu

Status

Display

the

language

the

nearest

Button

Button

Indications:

Battery

Battery

Battery

Battery

screen

machine

rotary

(select

rotary

Setting

fresh-gas

is

fully

charged.

is

charging

is

operating

test

in

progress.

is

discharged.

shows

(select

and

control}.

and

confirm

control).

mixture

from

on battery.

the

last

warning.

confirm

by

ranges.

mains power.

by

turning

turning

and

and

Pes

DI

O

IPPU

Configuration

Laru

zde

Gas

comPens.

|

000000

oo

look.

.

setting

T+

00

83

E

©

Ho

17

FULL

Last

entry

D

©

0

warning

N

DO

64027420

04137551

20

Page 21

Ventilation

and

Monitor

Operating

Concept

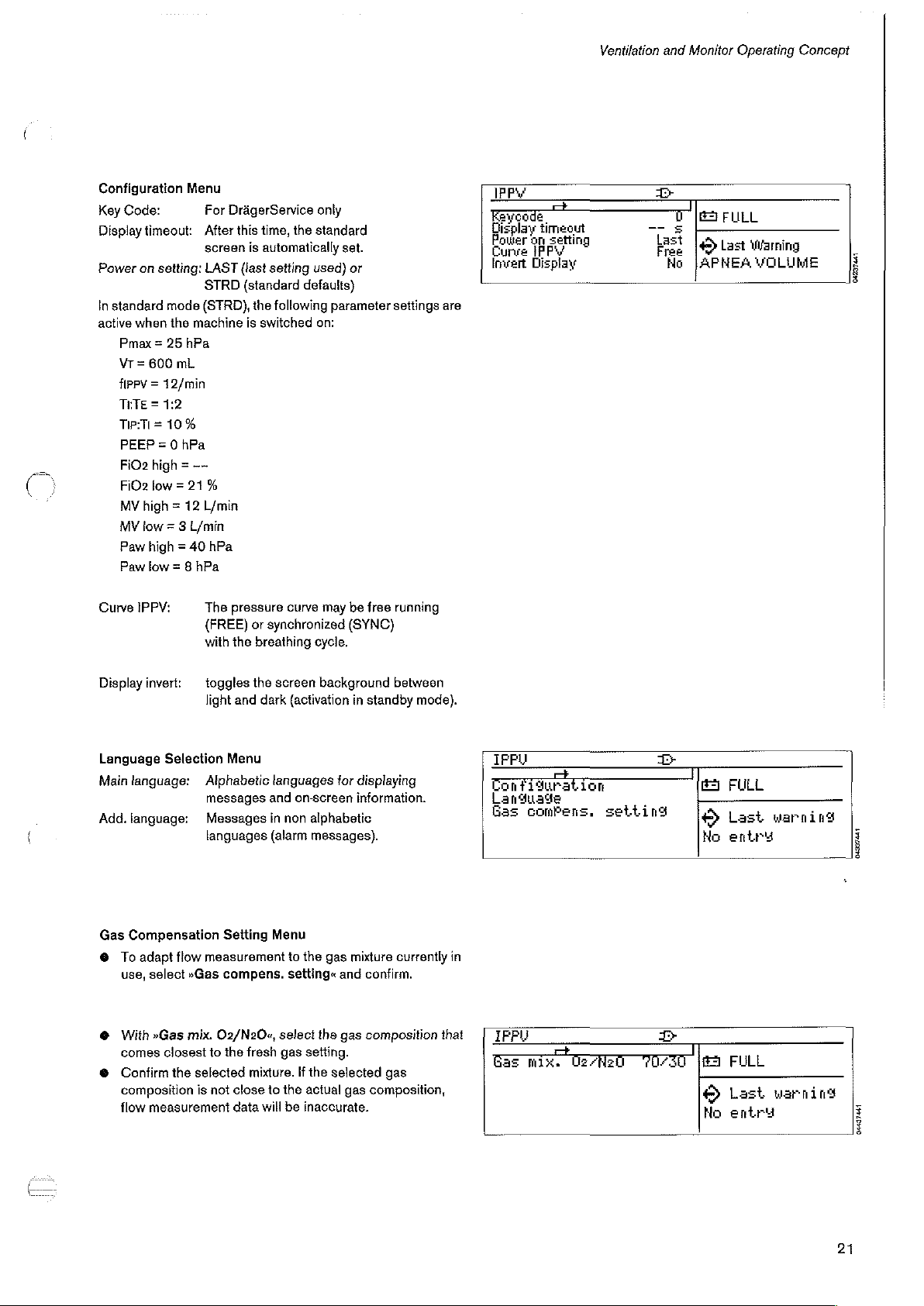

Configuration

Key

Code:

Display

timeout:

Power

on

setting:

In

standard

active

Pmax = 25

VT = 600

flppv = 12/min

ТЕТЕ = 1:2

TipiTi=

PEEP = 0

FiO2

FiO2

MV

MV

Paw

Paw

Curve

mode

when

the

10%

high = ——

low=

high = 12

tow = 3

high = 40

low

IPPV:

Menu

machine

hPa

mL

hPa

21%

L/min

= 8

hPa

For

DrägerService

After

this

time,

screen

is

automatically

LAST

(last

STRD

(standard

(STRD),

L/min

The

(FREE)

with

hPa

pressure

the

the

is

switched

or

breathing

only

the

standard

set.

setting

used)

defaults)

following

synchronized

on:

curve

cycle.

parameter

may

or

be

free

(SYNC)

settings

running

are

IPP

eycode

Display

timeout

peer

ap

Invert

Display

se

seria

Er

n

ES

5

test

[tact

No

JAPNEA

FU

FULL

+

waning

VOLUME

|

È

8

Display

Language

Main

Add.

Gas

©

e

e

invert:

language:

language:

Compensation

To

adapt

use,

select

With

comes

Confirm

composition

flow

measurement

Selection

flow

»Gas

»Gas

mix.

closest

the

selected

is

toggles

light

Alphabetic

measurement

the

and

dark

Menu

messages

Messages

languages

Setting

compens.

D2/N20«,

to

the

fresh

mixture.

not

close

data

will

screen

languages

and

in

(alarm

Menu

to

background

(activation

tor

on-screen

non

alphabetic

messages).

to

the

gas

setting«

select

the

gas

setting.

If

the

selected

the

actual

be

inaccurate.

between

in

standby

displaying

information.

mixture

currently

and

confirm.

gas

composition

gas

gas

composition,

mode).

in

that

IFPU

Configuration

Language

Gas

comPens,

IPP

as

mix.

setting

Üz”fiz

©

BI

-一

<>

©

Ho

E

©

No

FULL

Last

entry

FULL

Last

entry

warning

i

é

warning

04437441

.

D

E

21

Page 22

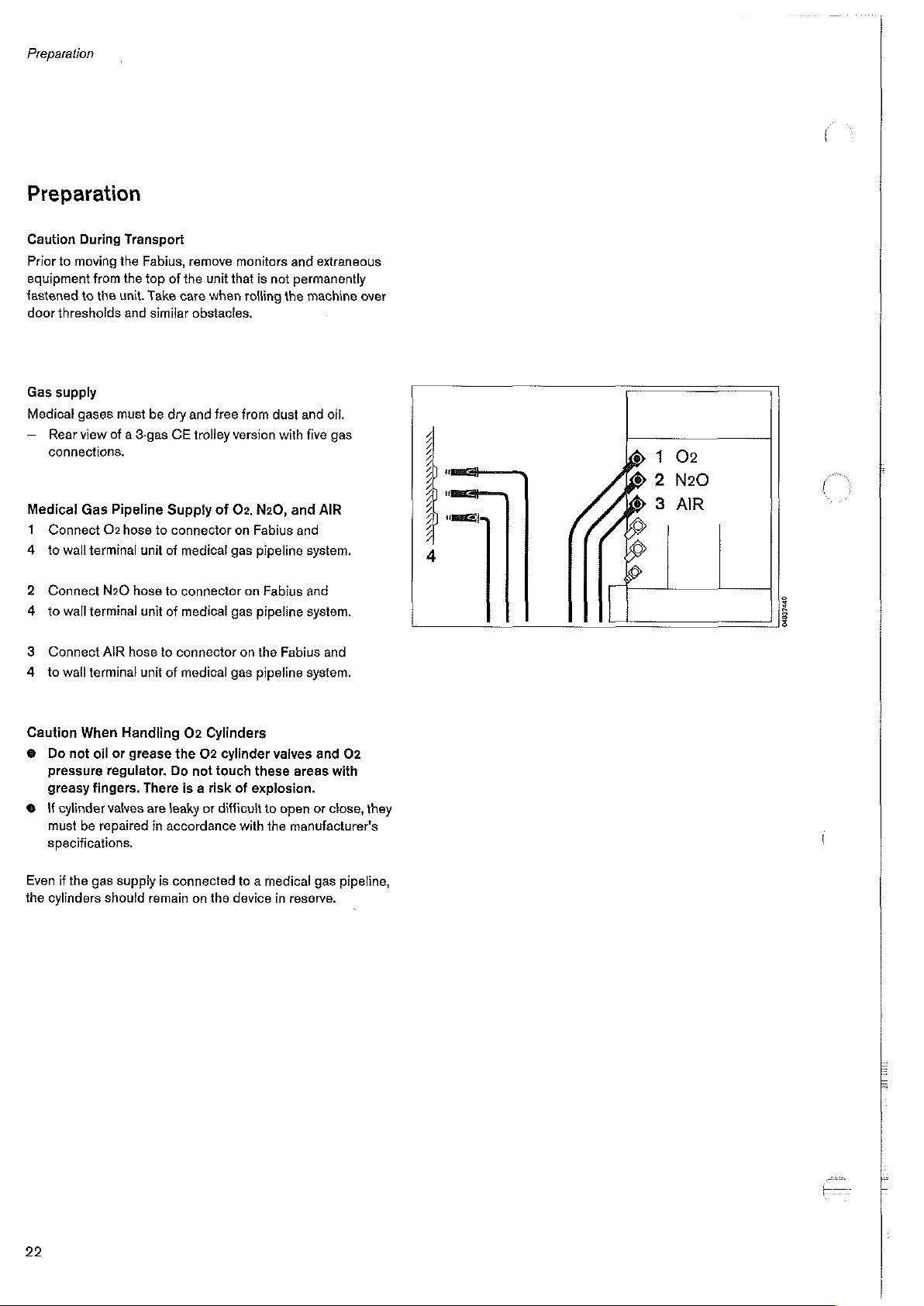

Preparation

Preparation

Caution

Prior

equipment

fastened

door

Gas

Medical

—

Medical

1.

4

2

4

3.

4

During

to

moving

to

thresholds

supply

gases

Rear

view

connections.

Conneot

to

wall

Connect

to

wall

Connect

to

wall

Transport

the

from

the

the

unit.

and

must

of a 3-gas

Gas

Pipeline

O2

hose

terminal

N2O

terminal

AIR

terminal

Fabius,

top

Take

similar

be

to

unit

hose

unit

hose

unit

remove

of

the

unit

care

obstacles.

dry

and

CE

trolley

Supply

connector

of

medical

to

connector

of

medical

to

connector

of

medical

that

when

free

of

gas

gas

gas

monitors

is

not

rolling

from

dust

version

with

O2,

N20,

on

Fabius

pipeline

on

Fabius

pipeline

on

the

pipeline

and

extraneous

permanently

the

machine

and

oil.

five

gas

and

AIR

and

system.

and

system.

Fabius

and

system.

over

©

1

02

ASS

SSAA

A

2

N20

(©

0

3

AIR

O O

04037480

Caution

©

©

Even

the

When

Do

not

oil

pressure

greasy

fingers.

{f

cylinder

must

be

repaired

specifications.

if

the

gas

cylinders

Handling

or

grease

regulator.

There

valves

are

in

accordance

supply

is

should

remain

O2

Cylinders

the

O2 cylinder

Do

not

touch

is a risk

leaky

or

difficult

connected

on

the

valves

these

areas

of

explosion.

io

open

with

the

manufacturer's

to a medical

device

in

reserve.

and

O2

with

or

close,

gas

pipeline,

they

22

Page 23

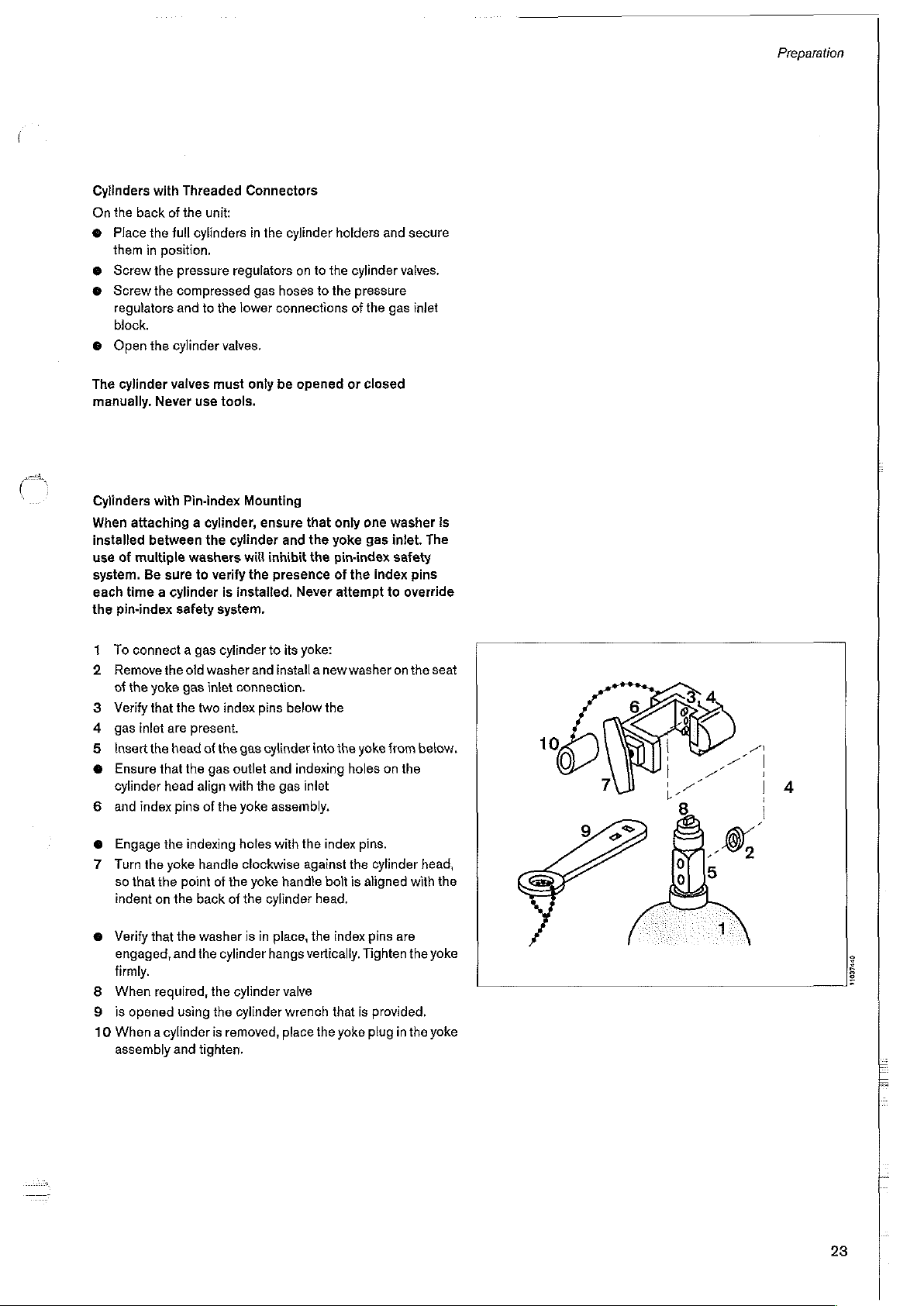

Preparation

Cylinders

On

@

@

e

©

The

manually.

Cylinders

When

installed

use

system.

each

the

1

N

ea bw

6

with

the

back

of

Place

the

full

them

in

position.

Screw

the

Screw

the

compressed

regulators

block.

Open

cylinder

of

time a cylinder

pin-index

To

Remove

of

the

Verify

gas

Insert

Ensure

cylinder

and

and

the

cylinder

vaives

Never

with

attaching a cylinder,

between

multiple

Be

sure

safety

connect a gas

the old

yoke

that

the

inlet

are

the

head

that the

head

index

pins

Threaded

the

unit:

cylinders

pressure

to

the

valves.

must

use

tools.

Pin-index

the

washers

to

verify

is

system.

cylinder

washer

gas

intet

two

index

present.

of

the

gas

align

with

of

the

Connectors

in

the

cylinder

regulators

gas

hoses

lower

connections

only

be

Mounting

ensure

cylinder

outlet

and

will

inhibit

the

presence

installed.

to

its

and

install a newwasher

connection.

pins

below

gas

cylinder

and

the

gas

yoke

assembly.

holders

on

to

the

to

the

opened

that

only

the

yoke

the

pin-index

of

Never

attempt

yoke:

the

into

the

indexing

inlet

and

cylinder

pressure

of

the

gas

or

closed

one

washer

gas

inlet.

safety

the

index

to

on

yoke from

holes

on

secure

valves.

inlet

is

The

pins

override

the

seat

below.

the

Engage

7

Turn

so that

indent

©

Verify

engaged,

firmly.

8

When

9

is

10

When a cylinder

assembly

the

the

the

on

that

required,

opened

yoke

indexing

handle

point

the

back

the

washer

and

the

using

and

tighten.

holes

clockwise

of

the

yoke

of

the

is

cylinder

the

cylinder

the

cylinder

is

removed,

with

the

handle

cylinder

in

place,

hangs

valve

wrench

place

index

pins.

against

the

cylinder

bolt

is

aligned

head.

the

index

pins

vertically.

the

that

yoke

Tighten

is

provided.

plug

with

are

the

in

the

head,

the

yoke

yoke

31837440

23

Page 24

Preparation

Electrical

Fabius

127

socket!

@

1

Equipotential

For

Troltey-mounted

2

e

Supply

can

be

operated

V.

Observe

Push

Switch

the

machine.

intra-cranial

Use

cable

Connect

equipotential

power

on

the

the

the label

plug

Bonding

and

ref,

at

mains

beside

into

main

machine.

anesthesia

83

terminal

bonding

The

intra-cardiac

01

349

on the

point

voltages

the

mains

supply

on/off

operations

machines:

cable.

back

of

in

the

from

voltage

socket.

switch

is

the

trolley

operating

100 V to

input

on

the

rear

to

an

room.

of

Bi

1

(mL)

ev

¥

“fr?

©

B

mx

05037450

Pin

Index

version

05197440

06237440

24

Page 25

Preparation

Attaching

e.g.,

Resutator

©

Hang

right.

Preparing

Use

only

disinfected/sterilized

Swing

a

Unlock

@

remove

ON

Insert

Fit

the

BPN

lock

both

+

Swing

Manual

2000

the

fully

the

Ventilator

out the

the

clasps

the

cover.

the

diaphragm.

cover

and

locking

the

ventilator

Ventilation

for

emergency

prepared

ventilator

and

door.

to

screws.

unit

back

Bag

ventilation

tested

bag

components.

into

position.

on

the

rail

at

the

000

OOO)

Fabius

05997440

Ventilator

A

Over

pressure

B

Additional

Safety

air

Feature

valve

valve

06457440

25

Page 26

Preparation

Fitting

the

Breathing

©

Fill

the

recommends

@

Tighten

compact

©

Ensure

deposited

Such

Fitting

the

1

Place

2

Fit

the

3

Tighten

CO2

Absorber

System

absorber

the

the

absorber

breathing

that

no

CO2

between

dust

and

particles

Inspiratory

the

valve

disc

inspection

the

retaining

with

fresh

use

of

by

system.

absorbent

the

Valve

in

the

cap

(with

nut

on

the

Compact

CO2

absorbent.

Dragersorb®

turning

it

to

dust/particles

gaskets

and

can

cause

valve

seat.

port).

securely.

800

the

right

the

sealing

leaks

Drager

Plus.

in

the

into

the

have

been

surfaces.

system.

06537440

Fitting

4

Place

5

Fit

the

6

Tighten

Fitting

7

Tighten

the

Only

use a valve

the

Expiratory

the

valve

disc

inspection

the

the

Pressure-limiting

the

retaining

cap.

retaining

pressure-limiting

nut.

marked

Valve

in

the

nut

with

valve

seat.

securely.

Valve

valve

securely

"SPONT/IPPV"

into

and

place

"MAN".

with

05637440

26

08737440

Page 27

Preparation

Inserting

1

Unscrew

2

Insert

flow.

Fitting

the

3

Screw

system

Connecting

@

The

sealing

must

be

@

Only

hand-tighten

tools.

€

Slightly

system.

4

Fit

the

anesthesia

©

Tighten

the

Flow

and

the

flow

Waste

the

waste

from

underneath.

the

Compact

rings

undamaged

loosen

compact

machine.

the

knurled

Sensor

remove

sensor,

Gas

Outlet

gas

on

the

and

the

the

knurled

breathing

screw.

the

expiration

observing

Port

port

into

Breathing

threaded

clean.

threaded

screw

system

port.

the

indicated

the

compact

System

and

conical

connectors.

on

the

compact

to

the

pin

direction

breathing

connectors

Do

not

use

breathing

on

the

.

of

05837440

05937440

5

Screw

breathing

6

Screw

compact

7

Plug

expiration

the

fresh

system.

the

ventilation

breathing

the

control

valve

gas

system.

hose

and

hose

to

hose

to

to

the

the

connection

the

Fabius

the

ventilator

connection

port

and

to

and

port

on the

the

compact

to

the

on

the

ventilator.

95097440

27

Page 28

Preparation

Fitting

Microbial

@

Push

the

expiratory

Dismantling

@

Squeeze

pull

the

filter

Condensation

filters,

making

Carefully

Observe

filter.

Connecting

Note:

@

©

—

@

monitor

the

Take

care

When

connecting

breathing

reinforcement.

torn

loose,

Breathing

kink,

thereby

Before

each

Filters

microbial

port,

instructions:

at

specific

the

not

hoses

hoses

filters

until

they

the

points

marked

off

the

port.

may

increase

breathing

the

airway

Instructions

Breathing

to

damage

and

by

the

Otherwise,

e.g.

at

the

end-sleeve.

with

damaged

interrupting

use,

check

more

disconnecting,

into

the

noticeably

"PRESS"

the

flow

difficult.

pressure.

for

Hoses

the

breathing

end

sleeve,

the

spiral

spiral

breathing.

the

breathing

inspiratory

click

resistance

Use

not by

reinforcement

port

into

and

simultaneously

for

the

microbial

hoses.

always

the

reinforcement

hoses

for

and

place.

of

the

hold

the

spiral

may

damage.

can

be

00137440

1

Push a patient

cone

and

2

Connect

3

Connect

hose

via

4

Connect

breathing

the

expiratory

both

the

manual

the

double

the

bag

system.

breathing

patient

breathing

breathing

port.

hose

to

hose

cone

the

on

to

or

on

hoses

bag

elbow

both

to

the

to

the

port

the

microbial

to

the

Y-piece.

bag

on

the

inspiratory

filters.

breathing

compact

06207440

06337440

28

Page 29

Preparation

Connecting

1

Push

the

and

2

plug

in

Connecting

3

Press

socket

until

it

the

O2

O2

sensor

the

connector

the

Pressure

the

probe

on

the

underside

engages.

Sensor

into

of

the

Capsule

the

port

on

the

back

Sensor

pressure

of

the

of

the

of

the

measuring

compact

inspiratory

control

breathing

line

valve,

unit.

into

system

the

96437440

4

Connect

bacterial

the

the

filter

control

hose

and

unit.

of

the

plug

pressure

it

firmly

measuring

into

the

port

line

on

to

the

the

back

of

08597440

29

Page 30

Preparation

Connecting

1

Push

the

the

flow

Please

the

Flow

measuring

sensor

note

the

Sensor

hoses

on

and

at

the

back

connections

to

the

of

the

are

different.

connection

unit.

ports

on

00037440

30

Page 31

Preparation

Connect

For

use

Screw

må

Connect

Connect

ON

Plug

Connect

Aah

Connect

connector.

For

use

@

Remove

@

Use

@

Plug

the

Magill

with

mask:

Magill

breathing

breathing

ISO

mask

mask

sampling

with

tube:

ISO

mask

ISO

connector.

connector

Inhalation

connector

bag.

hose E (110

connector

io

ISO

mask

hose

connector.

for

tracheal

Device

onto

the

into

breathing

connector.

for

monitoring

tube

freshgas

cm).

to

into

ISO

outlet.

hose.

the

Magill

connector.

00037440

Caution:

The

the

Magill

Fabius

Circuit

shall

ventilator,

not

be

connected

to

11737440

31

Page 32

Preparation

Connecting

inserting a new

Unscrew

1

Remove

e

a

2

Insert

conductor

Screw

installing

Compact

Connect

Compact

scavenging

A

compact

the

the

the

disinfected

the

the

Anesthetic

Breathing

the

Breathing

second

breathing

O2

Sensor

O2

sensor

screw

new

sensor

sensor

capsule

transfer

against

screw

cap

System

transfer

line

or

in

Gas

hose

capsule:

cap

from

capsule

capsule.

the

housing,

the

contacts

on

firmly

Scavenging

hose

System

an

anesthetic

is

required

system.

to

and

the

in

by

the

sensor

from

its

with

the

housing.

hand.

Hose

waste

to

the

agent

for

housing.

packaging,

the

ring-shaped

to

the

gas

port

of

anesthetic

filter.

the

Semi-open

or

the

gas

use

N

wk

07037440

|

07137440

32

Page 33

Preparation

Anesthetic

1

Oufput

2

Connection

outlet

3

Flow

indicator.

between

4

Connection

For

more

detailed

to

the

specific

Scavenger

Semi-open

Both

exhaust

5

one

on

6

the

other

must

be

connected

Remove

the

Gas

Scavenging

connection

to

scavenger

port.

During

the

upper

for

Semi-open

information

Instructions

System

Compact

ports

the

semi-open

on

the

existing

System

from

the

system

use,

the

and

lower

breathing

on

for

Use.

Connections

Breathing

adapter

Compact

to

scavenger

the

Breathing

AGS

AGS

scavenging

from

Fabius

flow

indicator

marks

on

system.

the

scavenging

for

the

System

and

System

scavenger.

plug

if

necessary,

system.

waste

must

the

tube.

system,

housing

be

gas

refer

17097440

A-Cone

7

The

the

the

8

The

alternate

9

The

the

the

Switch

A-Cone

conical

Fabius.

horizontal

lower

Compact

Fabius.

switch

fitting.

breathing

vertical

or

is

connected

it

must

port

of

the

system.

port

of

Semi-open

be

mounted

A-Cane

the

A-Cone

Compact

to

the

parallel

switch

switch

breathing

fresh

gas

to

is

connected

is

connected

outlet

the

front

to

system

via

of

the

to

on

07337440

σαι

lago

00060000

a

0)

O

ay

“ble

[o_o

Fabius

t=

33

07437440

Page 34

Preparation

Installation

Disconnect

Disconnect

Close

all

Remove

Compact

Remove

Noo

Remove

Loosen

Breathing

Gently

lift

a

firm

surface.

surface

Remove

washers

breathing

Ensure

that

mount,

Store

this

absorbent

of

the

Semi-Open

the

the

Fabius

gas

cylinders

all

hoses,

Breathing

the

APL

the

absorbent

the

locking

System

the

breathing

It

such

as a towel

the

three

that

hold

system

all

"O"

mount

canister.

Fabius

from

from

(if

sensors,

System.

valve.

canister

screw

to

the

mounting

system

is

recommended

to

mounting

the

canister

housing.

rings

are

assembly,

Adapter

the

mains

power

the

central

applicable).

and

control

and

store

that

secures

stud.

and

place

that

it

prevent

marring

screws

(M 5 x

mount

removed

hardware,

to

with

and

supply.

pipeline

the

be

lines

from

properly.

Compact

upside

placed

of

the

16

mm)

the

compact

the

canister

"O"

rings

gas

supply.

the

down

on

on a soft

unit.

and

with

the

07537440

34

0763740

Page 35

Preparation

Prepare

Ensure

~

These

the

not

Place

and

secure

the

These

and

first

belleville

be

these

Place

the

Connect

Install

Connect

pipeline

the

that

"O" rings

"O"

rings

interchangeable.

the

with

adapter.

screws

four

followed

installed

screws.

the

Fabius

the

gas

semi-open

the

"O"

rings

are

from

the

adapter

belleville

style

semi-open

all

APL

Fabius

the

three

each

by

the

washer

by

opposing

and

secure

hoses,

valve.

supply.

onto

come

washers.

sensors,

to

the

adapter.

are

provided

compact

the

compact

screws

with a flat

The

flat

washer.

is a curved

each

adapter

the

locking

and

mains

in

the

proper

with

the

canister

breathing

provided

washer

belleville

Please

spring

other.

Do

back

on

the

screw.

contro)

powers

supply, and

position.

adapter.

mount,

(M 5 x

80

and

washers

note

that

washer

not

over

mounting

lines.

Do

not

use

as

they

are

assembly

mm)

with

go

on

the

and

must

tighten

pole

central

of

07737440

Removing

Installing

Disconnect

Disconnect

Close

Remove

Compact

Remove

Loosen

Breathing

Gently

a

firm

Itis

recommended

as a towel

Remove

washers

to

the

the

Semi-Open

the

CO2

the

the

all

gas

cylinders

all

hoses,

Breathing

the

APL

the

locking

System

lift

the

breathing

surface.

to

prevent

the

three

that

hold

compact

Adaptor

Absorber

Fabius

from

Fabius

from

(if

sensors,

System.

valve.

screw

to

the

mounting

system

that

it

marring

mounting

the

semi-open

breathing

and

the

mains

the

central

applicable).

and

contro!

that

secures

stud.

and

place

be

placed

on a soft

of

the

unit.

screws

(M 5 x

breathing

system

housing.

power

supply.

pipeline

lines

the

upside

gas

from

Compact

surface

80