2GIG-SMKT2-345

L

I

S

T

D

WIRELESS PHOTOELECTRIC

SMOKE ALARM

Installation

Instructions

R

I

CM

Temperature

Sensor

Test/Silence

button

LED

Sounder vent

Temperature

sensor

388 West Center Street

Orem, UT 84057

Technical Support 866-670-1591

www.2gig.com

DESCRIPTION

The 2GIG-SMKT2-345 is a photoelectric smoke alarm with a built-in transmitter

designed for use with the 2GIG-CNTRL-345 security system. When smoke is

detected, the alarm sounds a loud local alarm. Twenty seconds after the local

alarm sounds, the built-in transmitter sends a digitally coded wireless signal to

the Control Panel. The wireless signal will be repeated every 20 seconds as

long as smoke is still present.

In addition to the photoelectric detector, the unit contains an integrated fi xed

135° temperature and rate-of-rise heat sensor that will send an alarm signal

based on temperature detected.

BUILT-IN WIRELESS TRANSMITTER

The smoke alarm can send three different wireless signals to the alarm Control

Panel: alarm, low battery, and status.

Every hour, the smoke alarm sends a status transmission to the Control Panel.

The hourly signal updates the Control Panel with the smoke alarm’s condition.

By monitoring status transmissions, the Control Panel can determine that the

smoke alarm is still operational in the installation and if it has a low battery.

The Control Panel must be programmed to the transmitter’s serial

number before system testing and operation. Refer to the Control Panel’s

instructions for details on programming.

INSTALLATION

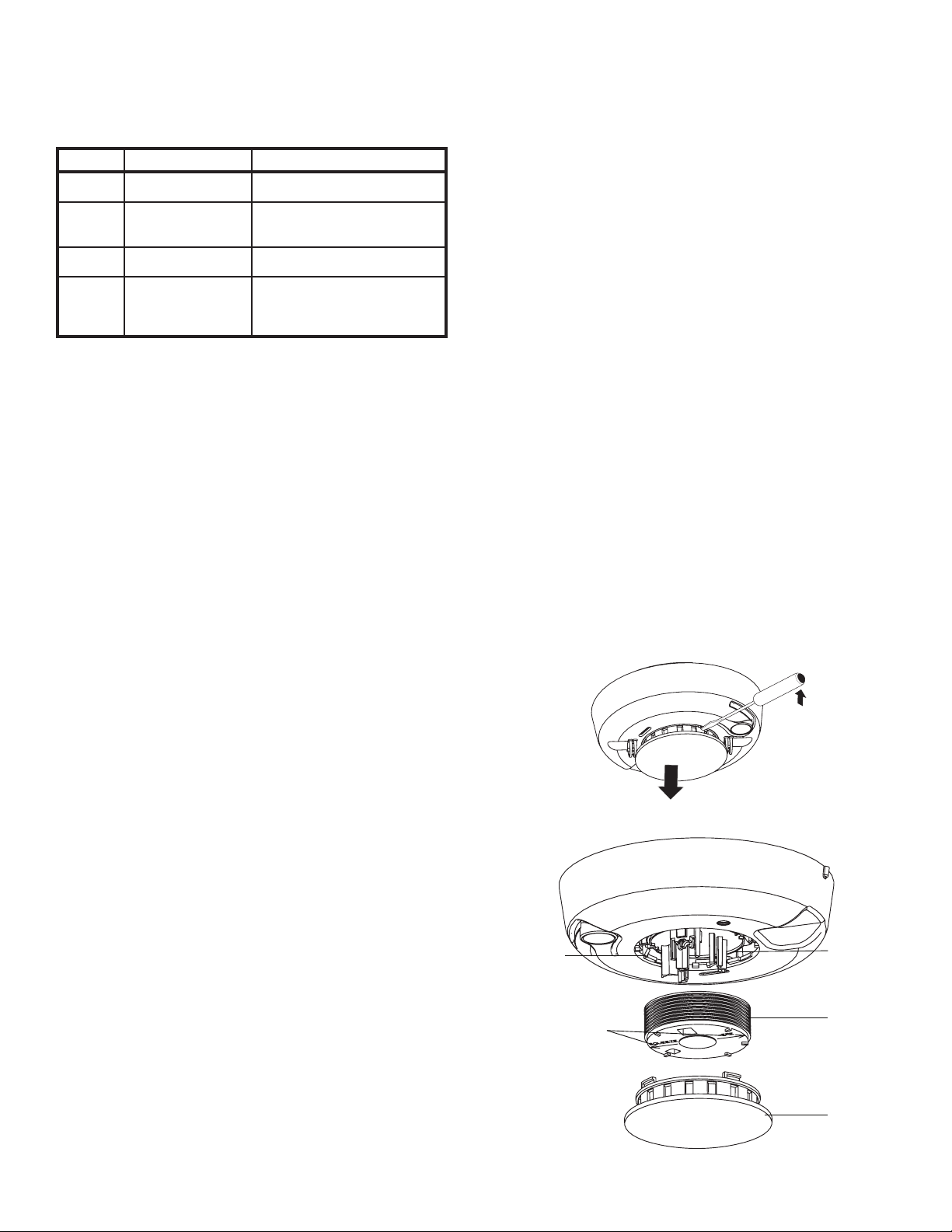

1. Slide the battery compartment cover away from the unit to unsnap it and

lift it off. See Figure 2.

2. Observing proper polarity, insert the two 3V lithium batteries supplied into

the alarm battery compartment and replace the battery cover.

3. Remove the red plastic dust cover from the unit.

4. Refer to Page 3 for selecting a proper location for the smoke alarm.

5. Using the two screws and anchors provided, mount the base.

6. Attach the unit to the base as follows:

• Line up the raised alignment tab on the lip of the unit with the alignment

arrow on the base. See Figure 3.

• Insert the unit into the base and turn clockwise approximately 15

degrees. It should snap fi rmly into place.

• IMPORTANT: The unit cannot be attached to the base if no batteries

are installed.

PROGRAM SMOKE ALARM INTO THE CONTROL PANEL

Before testing the smoke alarm, the internal wireless transmitter must be

programmed into the Control Panel.

1. Refer to the Control Panel’s instructions to prepare the receiver to accept

the smoke alarm’s serial number.

2. Press the smoke alarm’s TEST/SILENCE button for 4 seconds. The

smoke alarm will perform a sounder test, a sensitivity test, and send a

test signal to the Control Panel.

3. Verify that the signal was received by the Control Panel and that the

sensor was entered into the system.

4. Exit Control Panel programming before testing the smoke alarm.

Figure 1. Smoke Alarm Features

Battery

compartment

Figure 2. Battery Compartment

Alignment tab

Alignment arrow

Figure 3. Smoke Alarm-to-Base Alignment

SMOKE TEST

Units should be tested in place annually using one of the following methods:

A. Use Smoke! in a can® and follow directions on the can.

B. Hold a smoldering punk or cotton wick close to the unit and gently direct

the smoke into the smoke entry openings for 20 seconds or until an alarm

is indicated.

The smoke alarm LED should stay on and the sounder should emit a temporal

three pattern, and an alarm should be indicated at the Control Panel. Disarm

the system to reset the Control Panel alarm. Be sure to extinguish the

smoke source after testing!

SILENCE THE ALARM

Press the TEST/SILENCE button to silence the sounder during an alarm. After

a few minutes, the sounder and alarm resume if smoke is still present.

1

SENSITIVITY TEST

1. Press and hold the TEST/SILENCE button for 4 seconds. Once the test

starts, the smoke alarm LED fl ashes 1 to 9 times.

2. Count the number of LED fl ashes and use the following table to determine

if any action is necessary.

FLASHES INDICATION ACTION

0-1

2-3

4-7

Unserviceable

hardware fault

Unit is becoming

insensitive

Unit is within normal

sensitivity range

Reset and rerun sensitivity test. If

the error persists, replace the unit.

Clean and reset the unit. Rerun

sensitivity test. If the error persists,

replace the unit.

No action required

Verify that the optical chamber is

8-9

Unit is becoming too

sensitive

snapped down securely. Clean

the unit and replace the optical

chamber.

After the LED fl ashes, if the sensitivity is within limits and all other tests pass,

the unit goes into alarm and resets after 7 seconds. If the sensitivity is not

within limits, or an unserviceable hardware fault has been detected, the unit

LED extinguishes until the unit is serviced.

LED FUNCTIONS

Flashing — Flashes every 9 seconds to indicate normal operation.

On — Detects smoke

Off — Trouble or maintenance is required.

WHEN TO REPLACE THE BATTERIES

When the batteries are low, the unit extinguishes its LED and chirps every 45

seconds until the batteries are replaced. The low battery trouble chirps can be

silenced for 24 hours by pressing the TEST/SILENCE button. Battery life is a

minimum of one year, and varies depending on how often the unit is tested.

REPLACING THE BATTERIES

Use only 3V lithium batteries listed on the battery compartment cover.

1. Remove the unit from the mounting base, grasp the unit and turn it

counterclockwise approximately 15 degrees.

2. Slide the battery compartment cover away from the smoke alarm to

unsnap it and lift it off. See Figure 2.

3. Remove the batteries and dispose of them properly.

4. Observing correct polarity, insert two new 3V lithium batteries into the

battery compartment and replace the cover.

5. Reattach the unit to the mounting base. See Installation, Step 6.

6. Test the system.

CLEANING

Clean the cover with a dry or damp (water) cloth as needed to keep it free

from dust and dirt.

When necessary, clean the interior and replace the optical chamber (part

number ??????) as follows:

1. To remove the unit from the mounting base, grasp the unit and turn it

counterclockwise approximately 15 degrees.

2. Remove the batteries.

3. Slide a fl at-blade screwdriver in the slot on the alarm cap and gently push

the handle down to pry the alarm cap up and off. See Figure 4.

4. Squeeze the optical chamber where indicated and pull it up and away

from the optical base and discard. See Figure 5.

5. Blow out or use a soft-bristled brush to remove all dust and dirt from the

optical base.

6. Line the new smoke chamber up with the optical base by lining up the

arrows on the optical chamber to the latches on the optical base. Ensure

that the LED cavity in the optical chamber is above the LED and snap the

optical chamber down into place.

7. To replace the alarm cap as follows:

• Line the alarm cap up with the unit.

• Insert the alarm cap into the unit and turn clockwise approximately 15

degrees. It should snap fi rmly into place.

2

8. Observing proper polarity, replace the batteries and the battery

compartment cover.

9. Reattach the unit to its mounting base. See Installation, Step 6.

10. Test the unit sensitivity.

MAINTENANCE

The units are designed for easy fi eld service and maintenance. When installed

and used properly, they require minimal maintenance.

The unit should be tested weekly.

When a unit requires maintenance, it extinguishes its LED and stops sending

supervisory signals to the alarm Control Panel.

If the Control Panel indicates supervisory trouble for the smoke alarm, perform

the sensitivity test and follow the recommended actions.

SPECIFICATIONS

Voltage 3VDC

Typical average standby current 35µA

Typical test current 2mA

Typical alarm current 70mA

Battery type 3V lithium, Duracell® 123, Panasonic

CR123A, Sanyo® 123A

Low battery threshold 2.70V causes low battery signal

Sounder 85dBa at 10’ temporal pattern

Low battery beep rate 1 every 45 sec.

Sensitivity 2.2% ± 1.3% / ft.

Operating temperature 40°-100°F (4.4°-37.8°C)

Operating humidity range 0-95% non-condensing

Color White

Alarm dimensions 5.6” x 2.4” (14.2 cm x 6.1cm)

Base dimensions 5.4” x 0.46” (13.7 cm x 1.17cm)

Drift compensation adjustment 0.5% / ft. max.

Heat detector specifications

Rate-of-rise 15°F/min>105°F

(8.3°C/min>40.6°C

Fixed 135°F ± 5°F (57.2°C ± 2.8°C)

Listings ETL, UL217, CSFM

Figure 4. Removing the Smoke Alarm Cap

Smoke

chamber

latch

Alignment

arrows

Optical base

Optical

chamber

Alarm Cap

Figure 5. Smoke Alarm Parts

®

SELECTING A LOCATION

Selecting a suitable location is critical to the operation of smoke alarms. This

equipment should be installed in accordance with National Fire Protection

Association’s (NFPA) Standard 72 (see Figure 6).

A-11-8.3a Where to Locate the Required Smoke Alarms in Existing

Construction.

The major threat from fi re in a family living unit occurs at night when everyone

is asleep. The principal threat to persons in sleeping areas comes from fi res in

the remainder of the unit. Therefore, a smoke alarm(s) is best located between

the bedroom areas and the rest of the unit. In units with only one bedroom area

on one fl oor, the smoke alarm(s) should be located as shown in Figure 6A.

In family living units with more than one bedroom area or with more than one

fl oor, more than one smoke alarm is required, as shown in Figure 6B.

In addition to smoke alarms outside of the sleeping areas, the installation of

a smoke alarm on each additional story of the family living unit, including the

basement, is required. These installations are shown in Figure 6C. The living

area smoke alarm should be installed in the living room or near the stairway

to the upper level, or in both locations. The basement smoke alarm should be

installed in close proximity to the stairway leading to the fl oor above. Where

installed on an open-joisted ceiling, the alarm should be placed on the bottom

of the joists. The alarm should be positioned relative to the stairway to intercept

smoke coming from a fi re in the basement before smoke enters the stairway.

Where to Locate the Required Smoke Alarms in New Construction.

All of the smoke alarms specifi ed for existing construction are required and, in

addition, a smoke alarm is required in each bedroom.

Are More Smoke Alarms Desirable?

The required number of smoke alarms might not provide reliable early warning

protection for those areas separated by a door from the areas protected by the

required smoke alarms. For this reason, it is recommended that the householder

consider the use of additional smoke alarms for those areas for increased

protection. The additional areas include the basement, bedrooms, dining

room, furnace room, utility room, and hallways not protected by the required

smoke alarms. The installation of smoke alarms in kitchens, attics (fi nished

or unfi nished), or garages is not normally recommended, as these locations

occasionally experience conditions that can result in improper operation.

Since regulations pertaining to smoke alarm/detector installation vary from

state to state, contact the authority having jurisdiction (AHJ). Where public

safety is primary, the AHJ may be fedral, state, local, or other regional

department or individual such as a fi re chief, fi re marshal, chief of a fi re

prevention bureau, labor or health department, building offi cial, electrical

inspector, or others having statutory authority. For insurance purposes, an

insurance inspection department, rating bureau, or other insurance company

representative may be the AHJ. In some cases, the property owner or their

designated agent assumes the role of the AHJ. At government installations,

the commanding offi cer or department offi cial may be the AHJ.

In addition to NFPA 72, use the following location guidelines to optimize

performance and reduce the chance of false alarms from the alarm:

• Locate ceiling-mounted smoke alarms in he center of a room or hallway

at least 4 inches (10cm) from any walls or partitions.

• Locate wall-mounted smoke alarms so the top of the alarm is 4 to 12

inches (10 to 31cm) below the ceiling.

• Locate in a suitable environment as follows:

• Temperature between 40°F (4.4°C) and 100°F (37.8°C)

• Humidity between 0 and 95% non-condensing

• Locate away from air conditioners, heating registers, and any other

ventilation source that may interfere with smoke entering the alarm.

• Mount smoke alarms on a fi rm permanent surface.

• Locate away from large metallic objects to reduce shielding of the

wireless transmitter’s signal.

Smoke alarms are not to be used with detector guards unless the

combination has been evaluated and found suitable for that purpose.

A

B

IMPORTANT: Regulations pertaining to

smoke alarm installations vary from

state to state. For more information,

contact your local fire department or

local authority having jurisdiction.

Figure 6. Smoke Alarm Placement

Indicates additional smoke alarms

required for new construction

C

3

WARNING! LIMITATIONS OF SMOKE ALARMS

Wireless smoke alarms are very reliable, but may not work under all conditions.

No fi re alarm provides total protection of life or property. Smoke alarms are not

a substitute for life insurance.

Smoke alarms require a source of power to work. This smoke alarm will

not operate and the alarm will not sound if batteries are dead or not installed

properly.

Smoke alarms may not be heard. A sound sleeper or someone who has

taken drugs or alcohol may not awaken if the alarm is installed outside a

bedroom. Closed or partially closed doors and distance can block sound. This

alarm is not designed for the hearing impaired.

Smoke alarms may not always activate and provide warning early

enough. Smoke alarms only activate when enough smoke reaches the alarm.

If a fi re starts in a chimney, wall, roof, on the other side of closed doors, or on

a different level of the property, enough smoke may not reach the alarm for it

to alarm.

Smoke alarms are a signifi cant help in reducing loss, injury and even death.

However, no matter how good a detection device is, nothing works perfectly

under every circumstance and we must warn you that you cannot expect a

smoke alarm to ensure that you will never suffer any damage or injury.

Current studies have shown smoke alarms may not awaken all sleeping

individuals. It is the responsibility of individuals in the household that are

capable of assisting others to provide assistance to those who may not be

awakened by the alarm sound, or to those who may be incapable of safely

evacuating the area unassisted.

FIRE PREVENTION AND ESCAPE

The purpose of an early warning smoke alarm is to detect the presence of fi re

in its early stages and sound an alarm giving the occupants time to exit the

premises safely.

AVOID FIRE HAZARDS

No detection device can protect life in all situations. Therefore, safeguards

should be taken to avoid potentially dangerous situations as follows:

• Do not smoke in bed.

• Do not leave children home alone.

• Never clean with fl ammable liquids such as gasoline.

• Properly store materials. Use general good housekeeping techniques

to keep your home neat and tidy. A cluttered basement, attic, or other

storage area is an open invitation to fi re.

• Use combustible materials and electrical appliances carefully and only

for their intended uses. Do not overload electrical outlets

• Do not store explosive and/or fast burning materials in your home.

• Even after proper precautions have been taken, fi res can start. Be

prepared.

IN CASE OF FIRE

In the event of a fi re:

• Leave immediately. Don’t stop to pack or search for valuables.

• In heavy smoke, hold your breath and stay low, crawl if necessary. The

clearest air is usually near the fl oor.

• If you have to go through a closed door, carefully feel the door and door

knob to see if undue heat is present. If they seem cool, brace your foot

against the bottom of the door with your hip against the door and one

hand against the top edge. Open it slightly. If a rush of hot air is felt, slam

the door quickly and latch it. Unvented fi re tends to build up considerable

pressure. Be sure all members of the household realize and understand

this danger.

• Use your neighbor’s phone or a street fi re alarm box to call the fi re

department. The job of extinguishing the fi re should be left to the

professionals.

BE PREPARED

Practice the following steps to prepare you and your family in the event of a fi re:

• Perform fi re drills regularly. Use them to assure recognition of an alarm

signal.

• Draw a fl oor plan and show two exits from each room. It is important

that children be instructed carefully, because they tend to hide in times

of crisis.

• Establish one meeting place outside the home. Insist that everyone

meet there during an alarm. This will eliminate the tragedy of someone

reentering the house for a missing member who is actually safe.

• If you have children and/or physically challenged people residing in your

household, use window decals to help emergency personnel identify the

sleeping quarters of these individuals.

WARNING

Smoke alarms CANNOT provide warnings for fi res resulting from

explosions, smoking in bed or other furniture, ignition of fl ammable

liquids, vapors and gases, children playing with matches or lighters.

LIMITED WARRANTY

This 2GIG Technologies product is warranted against defects in material

and workmanship for two (2) years. This warranty extends only to

wholesale customers who buy direct from 2GIG Technologies or through

2GIG Technologies’ normal distribution channels. 2GIG Technologies does

not warrant this product to consumers. Consumers should inquire from

their selling dealer as to the nature of the dealer’s warranty, if any. There

are no obligations or liabilities on the part of 2GIG Technologies for

consequential damages arising out of or in connection with use or

performance of this product or other indirect damages with respect

to loss of property, revenue, or profi t, or cost of removal, installation,

or reinstallation. All implied warranties, including implied warranties for

merchantability and implied warranties for fi tness, are valid only until the

warranty expires. This 2GIG Technologies Warranty is in lieu of all other

warranties express or implied.

SERVICING INFORMATION:

All products returned for warranty service require a Return Product

Authorization Number (RPA#). Contact 2GIG Technologies at 1-866-670-1591

for an RPA# and other important details.

For additional warranty and compliance information, visit our Web site at:

www.2gig.com

IMPORTANT!!!

Radio controls provide a reliable communications link and fi ll an important

need in portable wireless signaling. However, there are some limitations which

must be observed.

• For U.S. installations only: The radios are required to comply with FCC

Rules and Regulations as Part 15 devices. As such, they have limited

transmitter power and therefore limited range.

• A receiver cannot respond to more than one transmitted signal at a time

and may be blocked by radio signals that occur on or near their operating

frequencies, regardless of code settings.

• Changes or modifi cations to the device may void FCC compliance.

• Infrequently used radio links should be tested regularly to protect against

undetected interference or fault.

• A general knowledge of radio and its vagaries should be gained prior

to acting as a wholesale distributor or dealer, and these facts should be

communicated to the ultimate users.

FCC COMPLIANCE

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference

that may cause undesired operation.

Copyright © 2010 230723 X1

4

Loading...

Loading...