Glass Break Detector 2GIG-GB1-345

Operating Instructions

This is the 2GIG-GB1-345 Glass Break Detector.

Installation/Mounting & Programming Guidelines

To setup the glass break detector:

1. Hold the 2GIG-GB1-345 Glass Break Detector unit upside down and twist the

base counter clockwise to remove it.

2. Install recommended batteries making sure to observe the correct polarity.

3. Wait 5 seconds for the power up delay.

4. Enter the programming mode for a wireless device on the alarm panel.

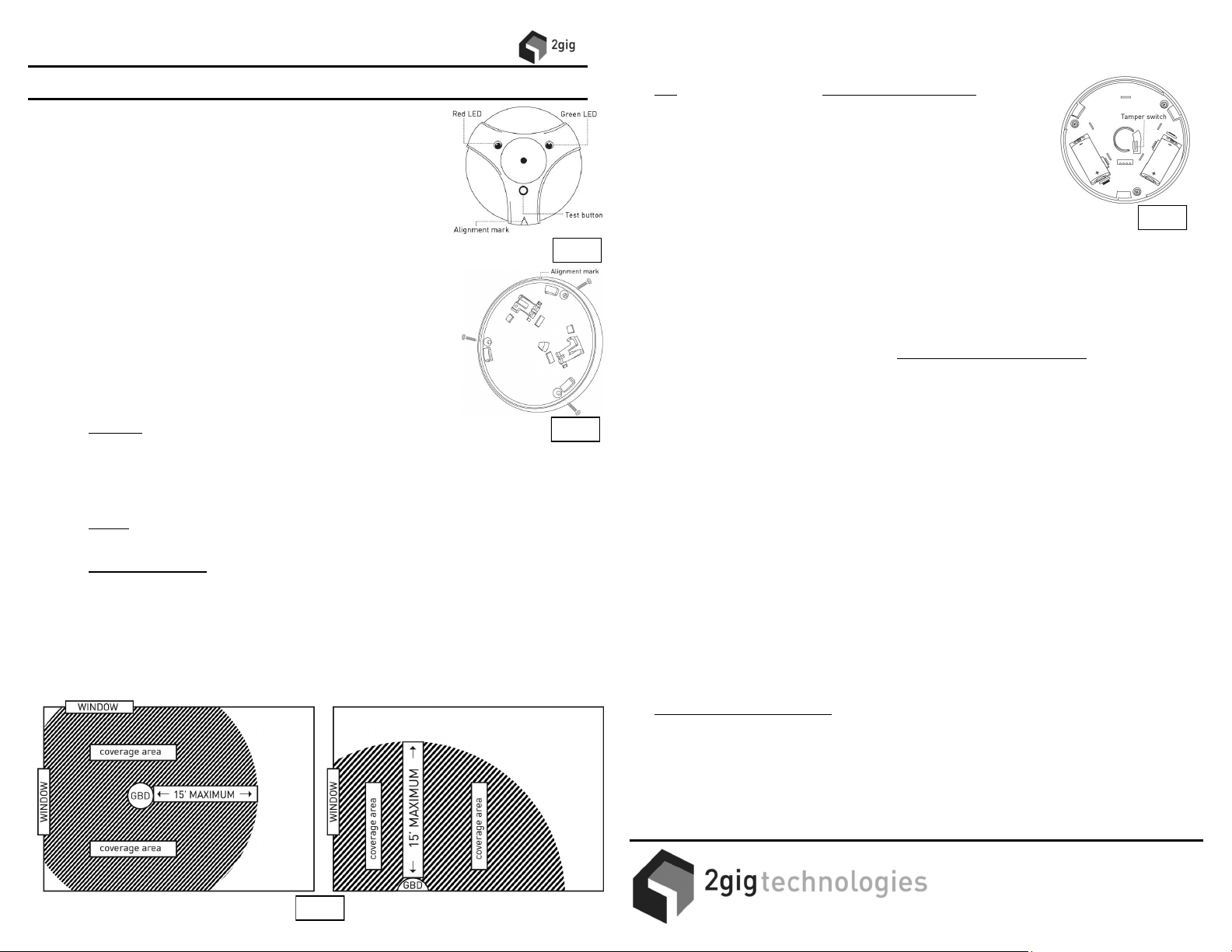

5. Enroll the Glass Break Detector by pressing and holding the tamper switch for 2

seconds (see

To Mount the glass break detector:

Figure 4

).

1. Place the Glass Break Detector base on the opposite wall or adjacent wall to the

window being protected.

2. Affix the base to the desired location utilizing the 3 long mounting screws with

anchors that are supplied. NOTE: For wall mounting the test button should be

oriented down nearest the floor.

3. When attaching the detector to the base, match the alignment marks and twist

clockwise. If batteries are not present, the red tabs must be held away from the

detector.

Testing

Walk Test

1. Push the test button for 2 seconds and then release it. You will now be in audio test mode for the

next 90 seconds (see

Figure 1

).

2. Activate a glass break simulator in the area of the window or windows that you are attempting to protect

with the glass break detector. The Glass Break Detector should first acknowledge the detection of a thud

sound by illuminating the green LED and then illuminate the red LED when the unit detects the crash

portion of the glass breaking sound (see

RF Test

Figure 1

).

Push and hold the test button for 5 seconds and then release it. The Glass Break Detector will continue to send

RF transmissions for 90 seconds (see

Program Single Stage

Figure 1

).

By default the Glass Break Detector is a two stage sensor, requiring first a thud sound followed by a crash sound

to trigger a glass break detection. To program the Glass Break Detector to require only a crash sound to trigger

a glass break detection, perform the following:

1. Push the Test Button for 10 seconds and then release it. The Red LED will light while the button is pressed.

The Green LED will blink three times to indicate that the Glass Break Detector has been reprogrammed for

Single Stage operation.

2. The Glass Break Detector will remain in Single Stage operation until a power cycle occurs (battery is removed for at least 20 seconds then re-installed).

Figure 1

Figure 2

Glass Type/Thickness

Minimum size for all glass types is 11” x 11” (28 cm x 28 cm) square; glass must be framed in the wall of the

room or mounted in a barrier of 36” (.9 m) minimum width.

Type Minimum to Maximum Thickness

Plate 1/8 in. to 1/4 in. (3.2 mm to 6.4 mm)

Tempered 1/8 in. to 1/4 in. (3.2 mm to 6.4 mm)

Laminated† 1/8 in. to 1/4 in. (3.2 mm to 6.4 mm)

Wired 1/4 in. to 1/4 in. (6.4 mm to 6.4 mm)

Coated‡ 1/8 in. to 1/4 in. (3.2 mm to 6.4 mm)

Sealed Insulating† 1/8 in. to 1/4 in. (3.2 mm to 6.4 mm)

† Laminated and sealed insulating glass types are protected only if both plates of glass are broken.

‡ For glass coated on the inner surface with 3M Scotchtint™ type RE35NEARL or Hardglass Security Film, reduce

effective range to 15 ft. (4.6 m) max.

Battery Installation & Replacement

Remove the cover by twisting counterclockwise. Use only the recommended replacement batteries (see

observe the polarity.

WARNING! The polarity of the battery must be observed, as shown (See

batteries may result in heat generation, explosion or fire, which may lead to personal injuries. Replace only with the

same or equivalent type of battery as recommended by the manufacturer. (see

Batteries must not be recharged, disassembled or disposed of in fire. Disposal of used batteries must be made in accor-

dance with the waste recovery and recycling regulations in your area.

Keep away from small children. If batteries are swallowed, promptly see a doctor.

California Only: This Perchlorate warning applies only to Manganese Dioxide Lithium cells sold or distributed ONLY in California,

USA. Perchlorate Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

Figure 4

). Improper handling of lithium

Specifications

Specifications

)

Figure 4

). Be sure to

Specifications

Wireless Signal Range 700 ft., open air, with 2GIG Wireless Alarm Control Panel

Code Outputs Alarm; Alarm Restore; Tamper; Tamper Restore; Supervisory; Low Battery

Transmitter Frequency 345.000 MHz (crystal controlled)

Transmitter Frequency Tolerance ± 10 kHz

Transmitter Bandwidth 24 kHz

Modulation Type Amplitude Shift Keying—On/Off Keying (ASK-OOK)

Unique ID Codes Over one (1) million different code combinations

Supervisory Interval 70 minutes

Peak Field Strength Typical 50,000 uV/m at 3m

Sensor Type Selectable: (1) single microphone, dual stage thud, and crash (default); (2) single stage

crash only

Mounting Height 7 ft. (2.13 m) Minimum to 10 ft. (3.05 m) Maximum

Sensor Range 15 ft. (4.57 m)

Maximum Horizontal Sensing Angle 360°

Dimensions (DxH) 4.55 x 1.9 in. (11.56 x 4.83 cm)

Weight (including battery & bracket) 5.1 oz. (144.6 g)

Housing Material ABS plastic

Color White

Operating Temperature 32° to 120°F (0° to 49°C)

Relative Humidity 5-95% Non-Condensing

Battery (included, not installed) Two (2) Panasonic CR123A, 3 VDC, 1550 mAh or equivalent Lithium cylindrical batteries

Battery Life 5 years

Regulatory Listing(s) ETL, FCC Part 15, Industry Canada

Approved Glass Break Simulator Intellisense FG-701

Warranty* Two (2) years

Included Accessories Three (3) Phillip’s head screws, three (3) plastic wall anchors

FCC COMPLIANCE STATEMENT*

This device complies with FCC Rules and Regulations as Part 15 devices, as well as Industry Canada Rules and Regulations.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Note: Changes or modifications to the device may void FCC compliance.

FCC ID: WDQ-GB1345

Industry Canada ID: 7794A-GB1345

*For more warranty and compliance information, visit our website (www.2gig.com).

Technical Support:

1-866-670-1591

www.2gig.com

Figure 3

05/19/09

©2009

Loading...

Loading...