Nortec GS 100, GS 200, GS 300, GS 400, GS 500 Maintenance Manual

...

GS Series

Gas Steam Humidifier

Installation,

User & Maintenance

Guide

IMPORTANT: Read and save this guide for future reference. This

guide to be left with equipment owner.

Form #07-287

150-6222

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any telephone in your

building.

Immediately call your gas supplier from a neighbor’s telephone.

Follow the gas supplier’s instructions. If you can not reach your gas

supplier, call the fire department.

UNIT OPERATING RANGES:

Max. Ambient Temperature 104ºF (40ºC).

Min. Ambient Temperature 41ºF (5ºC).

Max. Relative Humidity (RH) non-condensing 95% RH.

Min. Relative Humidity (RH) non-condensing 5% RH.

WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Refer to this manual. For

assistance or additional information consult a qualified installer, service

agency, or the gas supplier.

WARNING:

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss

of life.

IMPORTANT:

Read and save this guide for future reference. This guide to be left with

equipment owner.

Table Of Contents

GENERAL 1

- WARNING ................................................1

- DELIVERY ................................................1

- RECEIVING & UNPACKING EQUIPMENT................................1

- GENERAL SPECIFICATIONS ......................................1

- MODEL DESIGNATION .........................................1

MODEL SPECIFICATION 2

GS INDOOR INSTALLATION 3

- LOCATING AND MOUNTING ......................................4

- GAS PIPING ...............................................5

- COMBUSTION AIR REQUIREMENTS ..................................6

- DIRECT VENT GUIDELINES.......................................6

- EXHAUST VENTING ...........................................7

- ADDITIONAL REQUIREMENTS WHEN VENTING THROUGH A SIDEWALL .............11

- ELECTRICAL ..............................................12

- PRIMARY WIRING ...........................................13

- LOW VOLTAGE CONTROL WIRING .................................14

- CONTROL INSTALLATION .......................................15

- PLUMBING ...............................................15

- FILL WATER SUPPLY LINE ......................................15

- DRAIN LINE ...............................................15

- AUX DRAIN PORT ...........................................16

-STEAM LINES AND CONDENSATE LINE ...............................16

GS OUTDOOR INSTALLATION 16

- MOUNTING ...............................................16

-TYPICAL GSTC OUTDOOR INSTALLATION ..............................17

- ROOF CURB DIMENSIONS ......................................18

- GAS PIPING...............................................19

- EXHAUST VENTING ..........................................20

- ELECTRICAL INSTALLATION .....................................20

- FILL WATER SUPPLY LINE ......................................21

- DRAIN LINE ...............................................21

- AUXILIARY DRAIN ...........................................21

- STEAM LINES..............................................22

PRINCIPLE OF OPERATION 22

- COMBUSTION .............................................22

- WATER MANAGEMENT ........................................22

- START UP PROCEDURE .......................................23

- FILLING THE SYSTEM .........................................23

- TESTING THE IGNITION SAFETY SHUT-OFF.............................23

- STARTING THE HUMIDIFIER .....................................24

- TAKING OUT OF OPERATION .....................................24

- INSTALLATION CHECKLIST ......................................25

- SCALE MANAGEMENT .........................................27

- WATER QUALITY ............................................27

- FAULT CONDITIONS ..........................................28

MAINTENANCE 28

- DRAINING THE TANK .........................................28

- MANDATORY MAINTENANCE SCHEDULE ..............................29

- CLEANING THE TANK .........................................30

- SERVICING THE UNIT .........................................31

- SERVICE CHECKS ...........................................31

- COMPONENTS REPLACEMENT....................................32

-Hot Surface Igniter and Flame Sensor Replacement ........................32

-Burner Removal and Installation ...................................32

-Removal and Installation of the Combustion Blower.........................33

-Gas Valve Replacement .......................................33

-Air Switch Replacement .......................................34

-Float Chamber Replacement ....................................34

-Transformer Replacement ......................................35

-Fill Valve Replacement .......................................35

-Drain Pump Replacement ......................................36

-Fill Box Replacement ........................................36

-Removal of the Heat Exchanger ...................................37

- DIP SWITCH SETTINGS ........................................38

- SOFTWARE FLOW CHART ......................................39

- FAULT AND WARNING LIST ......................................60

- EXPLODED VIEW INTERNAL COMPONENTS SPARE PARTS ....................63

- EXPLODED VIEW INDOOR CABINETRY SPARE PARTS.......................65

- EXPLODED VIEW OUTDOOR CABINETRY SPARE PARTS .....................67

- GS QUICK REFERENCE ........................................71

GENERAL

N

C

This installation guide has been designed to

provide assistance when installing, mounting, and

commissioning a GS Series humidifier. Actual on site

application may vary. Consult Technical Services or

your local NORTEC representative.

WARNING

Improper installation, adjustment, alteration,

·

service, maintenance, or use can cause carbon

monoxide poisoning, an explosion, fire, electrical

shock, or other conditions which may cause

personal injury or property damage. Consult a

qualified installer, service agency, local gas

supplier, or your distributor or branch for

information or assistance. The qualified installer

or agency must use only factory authorized and

listed kits or accessories when modifying this

product. A failure to follow this warning can

cause electrical shock, fire, personal injury, or

death.

· Should overheating occur, or the gas fail to shut

off, shut off the manual gas valve to the appliance

before shutting off the electrical supply.

· Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas

control which has been under water.

DELIVERY

The standard delivery includes:

RECEIVING & UNPACKING EQUIPMENT

Check packing slip to ensure ALL material has

·

been delivered.

All material shortages are to be reported to

·

NORTEC within 48 hours from receipt of goods.

NORTEC assumes no responsibility for any

material shortages beyond this period.

Inspect shipping boxes for damage and note on

·

shipping waybill accordingly.

After unpacking, inspect equipment for damage

·

and if damage is found, notify the shipper

promptly.

All NORTEC products are shipped on an F.O.B.

·

factory basis. Any and all damage, breakage or

loss claims are to be made directly to the

shipping company.

GENERAL SPECIFICATIONS

The NORTEC GS Series humidifier is a

completely new patented design based on leading

edge technology. The GS is designed to provide clean

steam humidification at an economical price.

The GS Series humidifiers are designed

exclusively for humidification in ventilation systems or

direct room humidification. Any other type of

application, without the written consent of Nortec or

your Nortec agent, is considered as not conforming

with the intended purposes. The manufacturer/

supplier can not be made liable for any damages

resulting from improper use.

·

Gas Steam humidifier equipped with desired

options.

·

In a bag you will find:

- Manuals.

- Adapter fittings for water connection.

- Steamhose for steam outlet with clamps.

- Hose and clamps for drain connection.

·

The GS Indoor Series offers an optional

telescopic stand mounted inside the unit legs.

Stand cross bracing are shipped with the unit.

·

The GS Outdoor Series comes with all required

venting to be installed on site.

·

Desired accessories ordered.

MODEL DESIGNATION

The unit specification label indicates the model of

gas humidifier according to the following chart:

GS 100 N DV

TC

PRODUCT LINE

(Gas Steam Humidifier)

TC = Total Controller

c/w KEYPAD

P = Economical

Humidifier size (lbs/hr)

FUEL

= NATURAL GAS

P = PROPANE GAS

DIRECT VENT

OPTION

OUTDOOR MODEL

100

200

300

400

500

600

-1-

O

MODEL SPECIFICATION

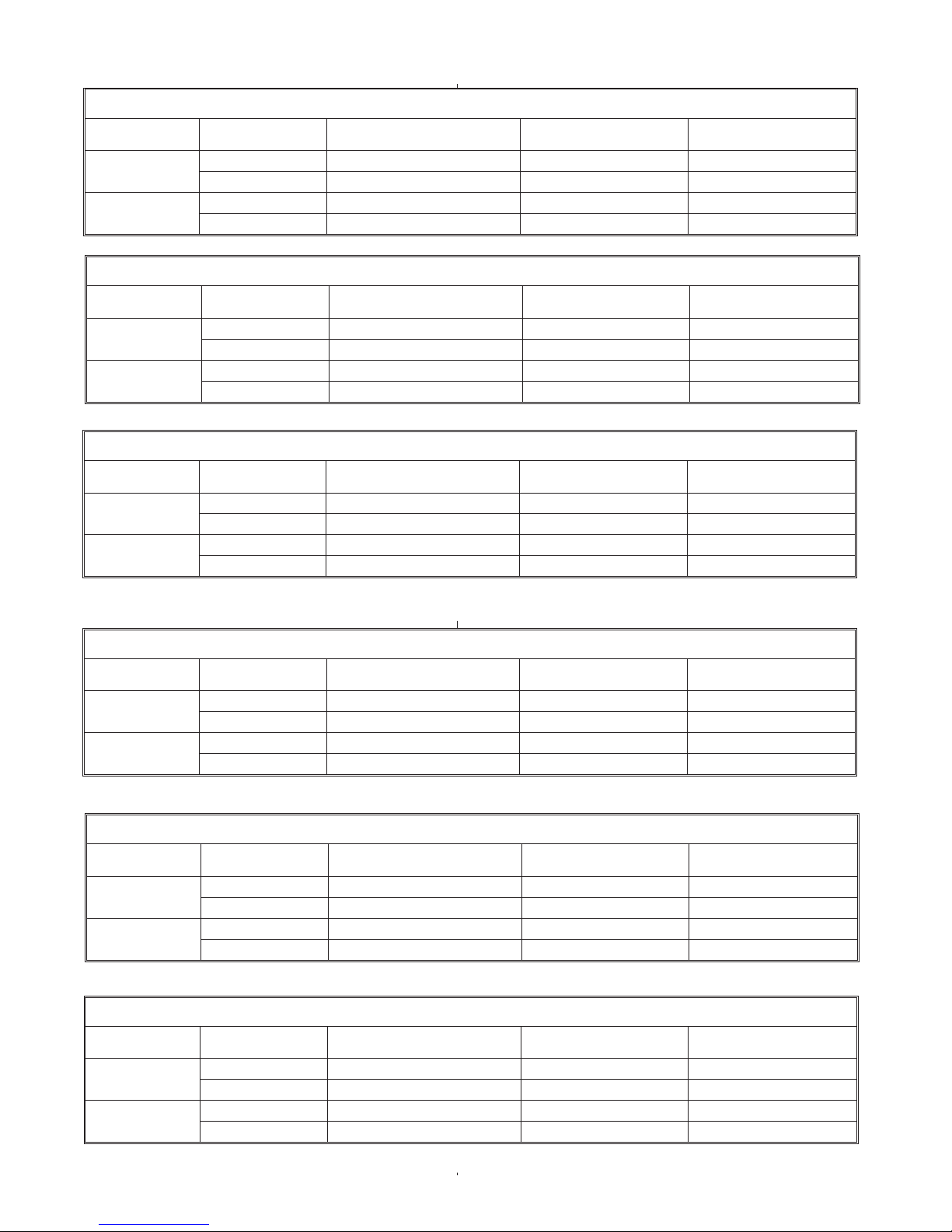

MODEL GS 100 SPECIFICATIONS

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 140,000 105 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 140,000 105 -0.35

MIN 50,000 25 -0.35

MODEL GS 200 SPECIFICATIONS

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 280,000 210 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 280,000 210 -0.35

MIN 50,000 25 -0.35

MODEL GS 300 SPECIFICATIONS

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 420,000 315 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 420,000 315 -0.35

MIN 50,000 25 -0.35

MODEL GS 400 SPECIFICATIONS

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 560,000 420 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 560,000 420 -0.35

MIN 50,000 25 -0.35

MODEL GS 500 SPECIFICATIONS

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 700,000 525 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 700,000 525 -0.35

MIN 50,000 25 -0.35

FUEL BLOWER SPEED INPUT (BTUH)* STEAM CAPACITY (LBS/HR) MANIFOLD PRESS. IN W.C.

NATURAL GAS MAX 840,000 630 -0.05

MIN 45,000 25 -0.05

PROPANE MAX 840,000 630 -0.35

MIN 50,000 25 -0.35

MODEL GS 600 SPECIFICATIONS

-2-

l

HIGH ALTITUDE

- A derate in input exists for installations at higher altitudes. For Canadian models, an automatic

10% derate applies to installations from 2000-4500 feet. For U.S. Models, refer to the chart below for high altitude

derate information.

FOR U.S. MODELS ONLY

Altitude Derate %

Feet Meters

0-2000 0-610 0

2001-3000 610-915 8

3001-4000 915-1220 12

4001-4500 1220-1370 16

4501-higher 1370-higher Contact Factory

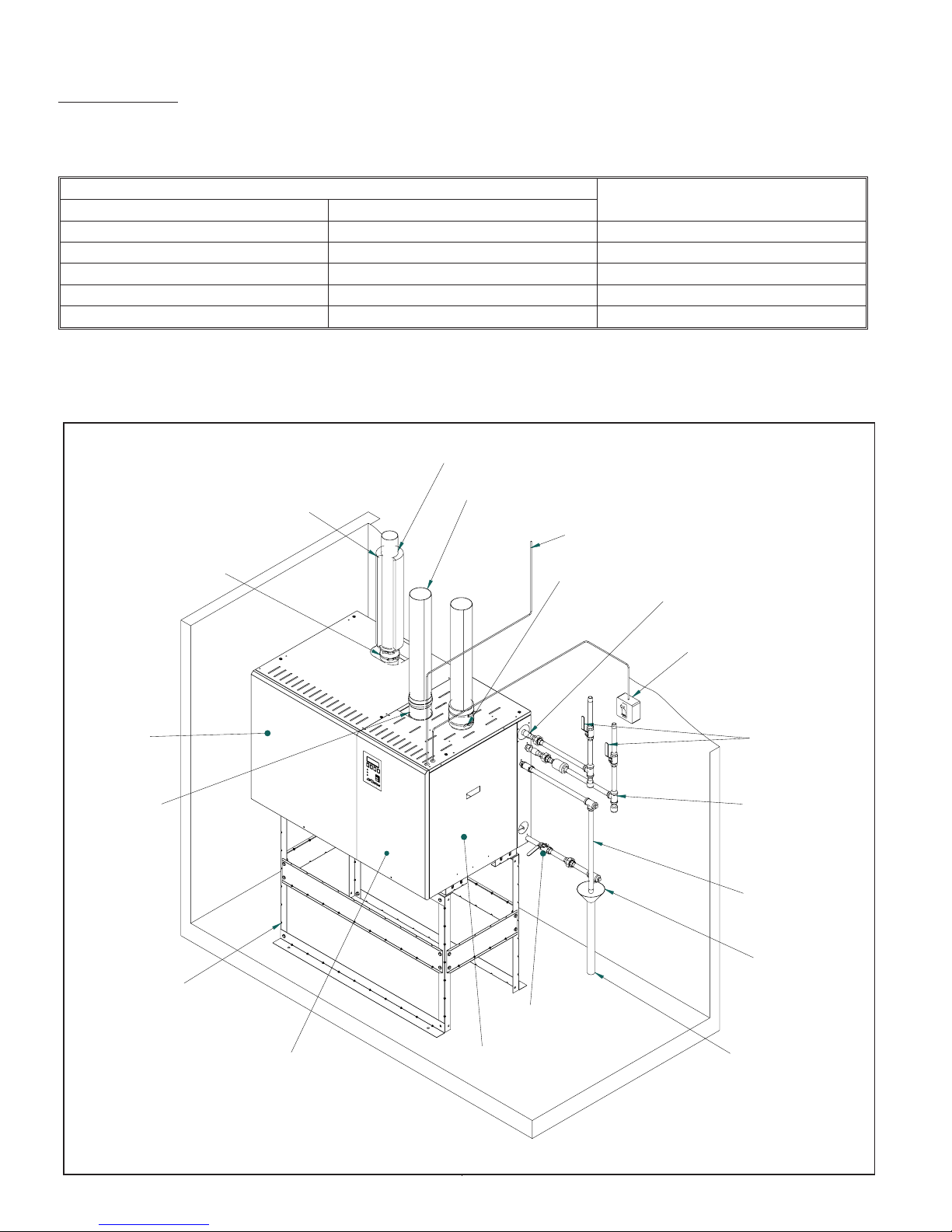

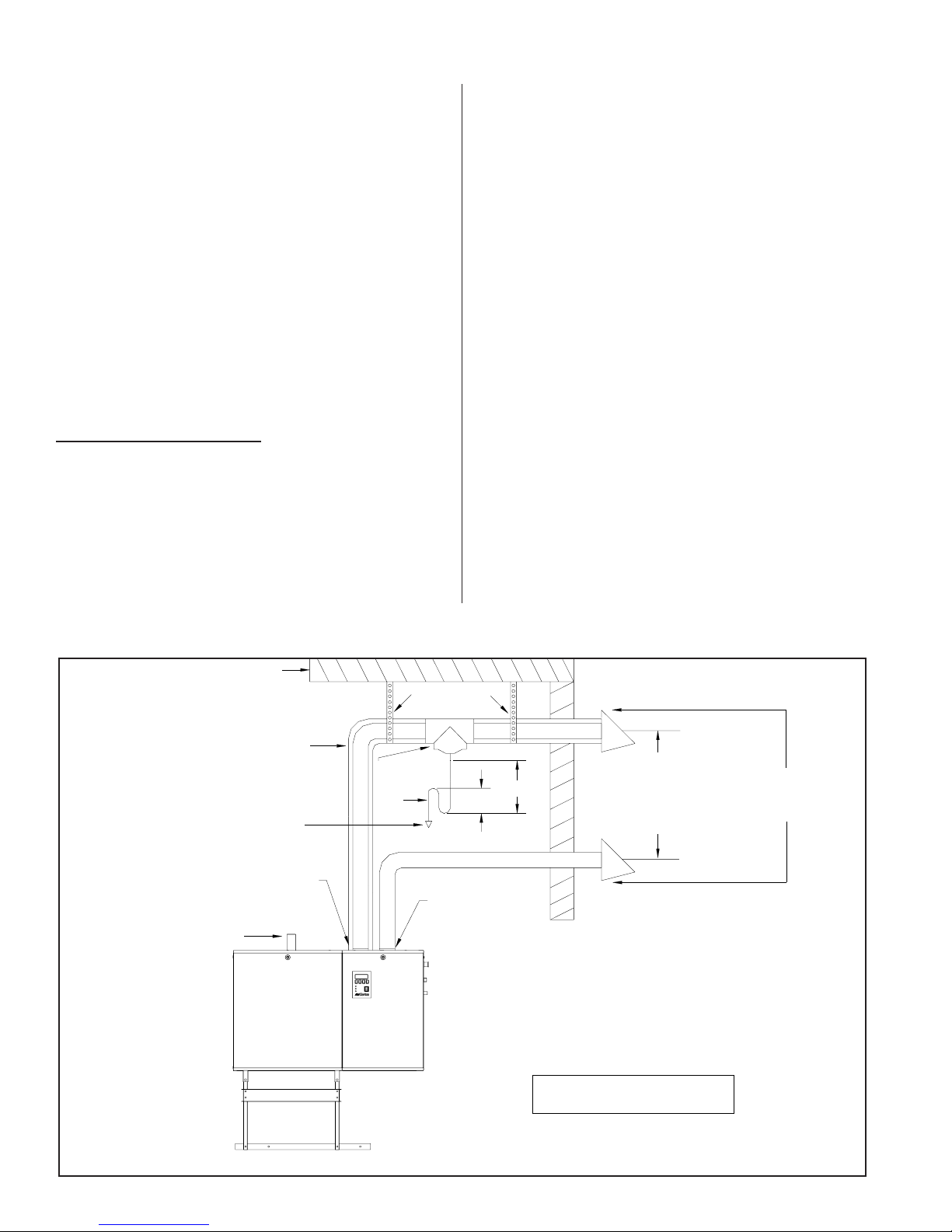

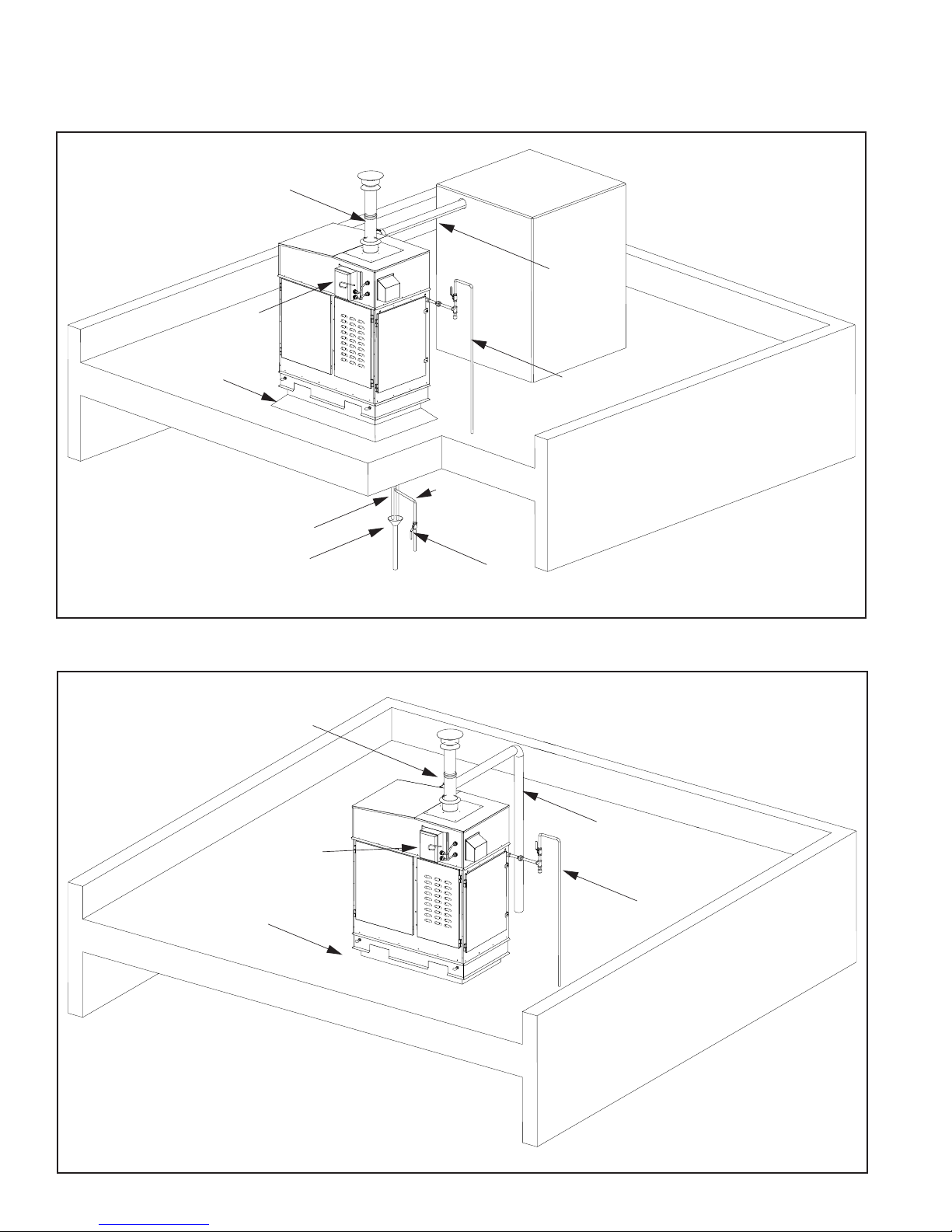

Figure #1

Typical Installation (Indoor)

Steamline

Clean Out

Access Door

Exhaust Outlet

Snap on Installation

Steam Outlet

B or BH Venting Type

Control Wiring

Optional

Direct Vent

Gas Line

Connection

Main Power Disconnect

Shut Off

Fresh Water

Fill Line

3/4"min 30-80 psi

Drain

Optional Stand

Service Access

Door (Electrical)

Service Access Door

(Mechanical)

-3-

Air Gap with Funne

Auxiliary Drain

To Drain

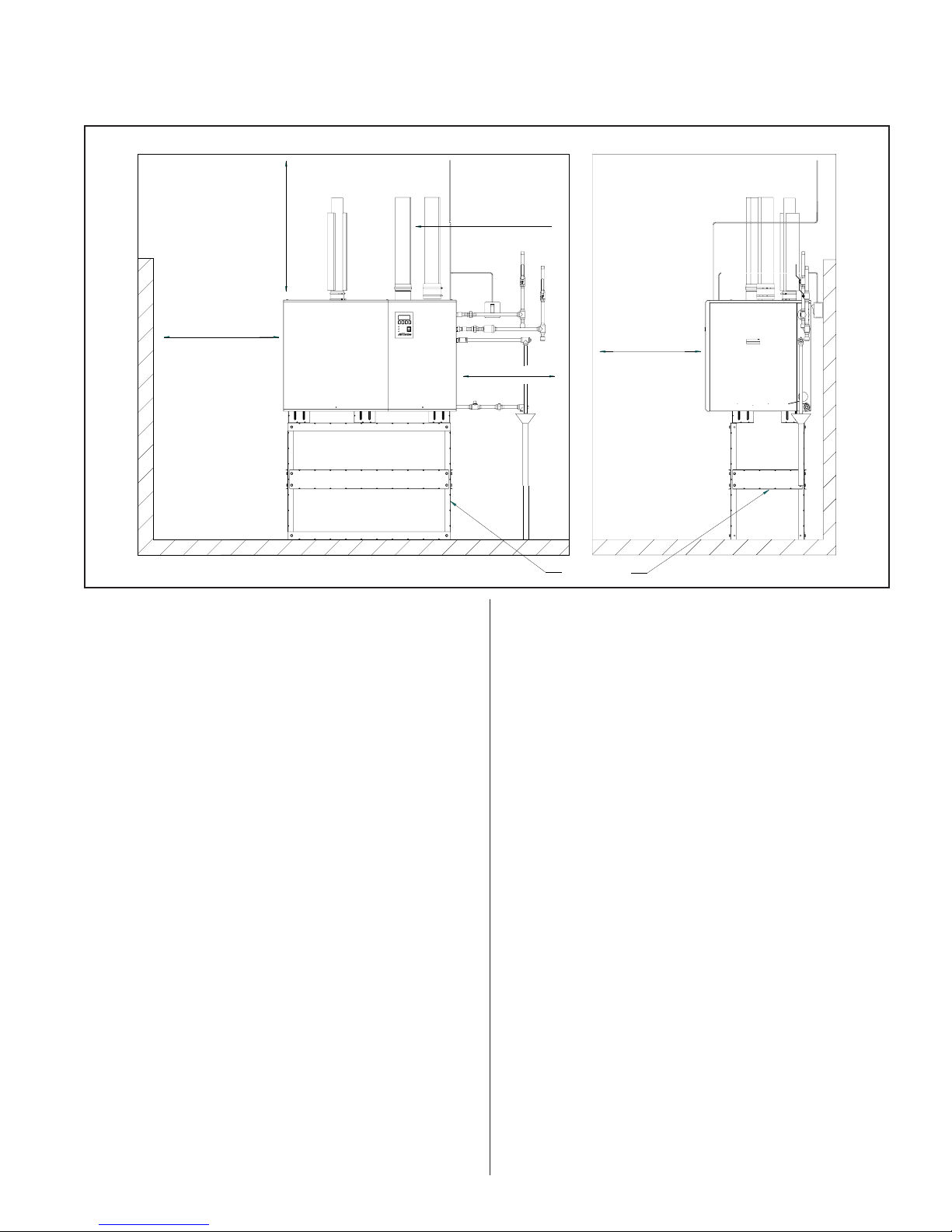

Figure #2

Clearance Requirements

Minimum

36" (91.5 cm)

Left

36" (91.5 cm)

Required only for

GSTC/GSP

500/600

Side Clearance

Minimum

4" (10.2 cm) to vent pipe

Right

30" (76.2 cm)

Optional Stand

Front Clearance

Front

30" (76.2 cm)

INDOOR INSTALLATION

The installation must conform with local building

codes or, in the absence of local codes, with the ANSI

Z223.1, National Fuel Gas Code, and/or CAN/CGA

B149 Installation Codes. Refer to the Gas Piping

section of this manual.

LOCATING AND MOUNTING

GS Series humidifiers are designed for floor

mounting or on a GS Stand (optional). The clearance

dimensions shown in this manual are for reference

only and are the minimum required for maintenance of

the humidifier. Local and National Codes should be

consulted prior to final location and installation of the

humidifier. NORTEC cannot accept responsibility for

installation code violations.

Figure #1 shows a typical installation with all

required connections to the GS Humidifier. Careful

consideration should be given to all of these

connections when choosing a location for the

humidifier.

· Ambient temperature location for humidifier:

41ºF - 104ºF (5ºC - 40ºC).

· Relative humidity location for humidifiers:

5% rh - 80% rh.

·

All GS humidifiers are rated for the clearance to

shown in Figure #2.

·

Location of the steam distributor should be

minimum of 36” above the humidifier.

·

DO NOT locate humidifier any further than

absolutely necessary from steam distributor

location. Net output will be reduced as a result of

heat loss through steam line. Also, increased

static pressure (over 12" W.C.) will result in hot

water going down the drain. Consult factory if this

situation occurs.

·

Where possible, mount humidifier at a height

convenient for servicing.

·

Make sure the humidifier is mounted level.

WARNING: During installation cover the

humidifier to prevent any dust or other

contaminants from entering the cabinets when

activities such as drilling are taking place.

-4-

·

DO NOT mount humidifier on hot surfaces.

·

The humidifier must be installed so that all

electrical components are protected from

exposure to water.

DO NOT mount humidifiers in an area where

·

freezing may occur.

If humidifiers are mounted on a roof, a properly

·

ventilated, temperature controlled, (above

freezing), weatherproof enclosure must be used.

DO NOT mount humidifiers on vibrating surface.

·

Consult factory.

The humidifier shall not be installed directly on

·

carpeting, tile or other combustible material other

than wood flooring.

The gas inlet pipe size to the appliance is:

½” NPT for GS 100

¾” NPT for GS 200

1” NPT for GS 300 / 400

1 ¼” NPT for GS 500 / 600

Provide an adequate size gas supply line.

In all installations, a certified manual shut off

valve, located outside the cabinet, must be installed.

When black iron gas pipe is used, a sediment trap

must be located ahead of the humidifier gas controls.

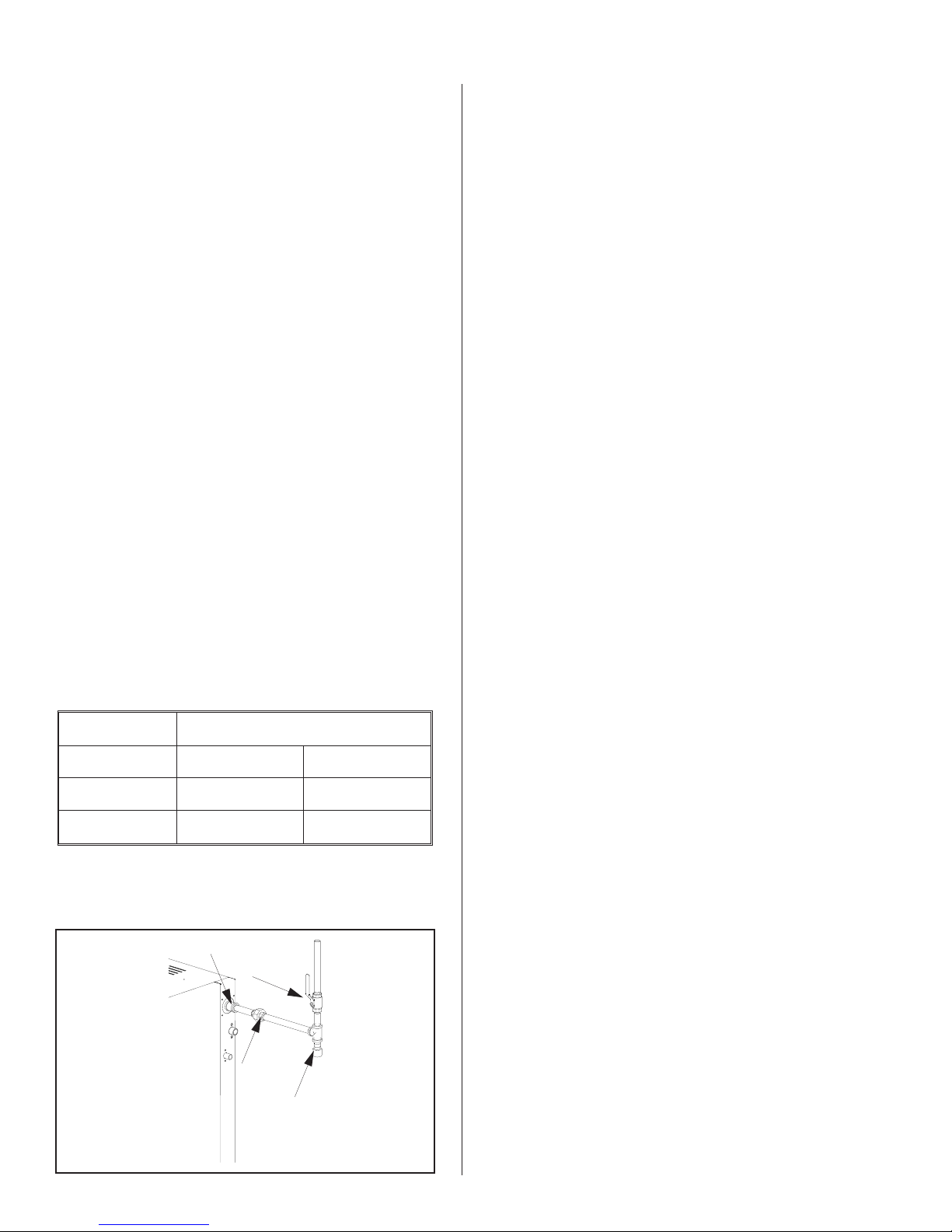

See Figure #3.

Some insulating materials may be combustible.

·

Prior to installing this appliance examine the area

for insulating material. If this appliance is

installed in an insulated space, it must be kept

free and clear of insulating materials. If insulation

is added after the appliance is installed, it will be

necessary to examine the area again.

GAS PIPING

Installation of piping must be in accordance with

local codes, and ANSI Z233.1, “National Fuel Gas

Code,” in the United States or CAN/CGA-B149

Installation Codes in Canada.

The following table indicates the maximum and

minimum allowable gas pressures for the Gas

Humidifier.

INCHES W.C.

GAS MIN. MAX.

Natural 4.5 9.0

Leak test all gas connections external to the

humidifier, using a commercial soap solution made to

detect leaks. Bubbles indicate gas leakage. Seal all

leaks before placing the humidifier in operation.

WARNING: Never use an open flame to check for

gas leaks. If a leak does exist, a fire or explosion

could occur, resulting in damage, injury or death.

The appliance must be isolated from the gas

supply piping system by closing its individual manual

shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or

greater than 14” w.c. (3.5 kPa).

Dissipate test pressure from the gas supply line

before re-opening the manual shut off valve to the

appliance.

NOTES: (See pg 19 for additional Gas Piping

information)

·

Failure to follow this procedure may damage the

gas valve. Over pressured gas valves are not

covered by warranty.

Propane 9.0 13.0

Figure #3

Gas Connection

Inlet coupling supplied

Shut-off Gas Valve

(by others)

Union

(by others)

Sediment Trap

(by others)

·

DO NOT use Teflon tape on gas line pipe

threads. A flexible sealant suitable for use with

Natural Gas and Propane Gas is recommended.

·

Plan gas supply piping so it will not interfere with

removal of gas valves or blower assemblies and

front or side service doors.

·

All gas piping should be adequately supported to

prevent any strain on inlet piping.

The gas valve is provided with pressure taps to

measure gas pressure upstream and downstream,

(manifold pressure). The minimum gas pressure

shown is for the purpose of input adjustment.

A 1/8" NPT plugged tapping, accessible for test

gage connection, must be installed immediately

-5-

upstream of the gas supply connection to the

appliance.

recommended that the supply air line is insulated and

an in line heat is added. Consult factory.

COMBUSTION AIR REQUIREMENTS

Provide for adequate combustion and ventilation

air in accordance with Sections 8.3, Air for Combustion

and Ventilation, of the National Fuel Gas Code, ANSI

Z223.1, or Sections 7.2, 7.3, 7.4 of CAN/CGA B149

Installation Codes, or applicable provisions of the local

building codes.

The required free area of supply air opening is:

13 in. sq. (8,387 mm

23 in. sq. (14,839 mm

35 in. Sq. (22,581 mm

47 in. Sq. (30,323 mm

59 in. Sq. (38,064 mm

71 in. Sq. ( 45,806 mm

Cabinet top and bottom contain air openings to

provide combustion air to the forced draft blower. DO

NOT BLOCK THESE OPENINGS.

Excessive exposure to contaminated combustion

air will result in safety and performance related

problems. Known contaminates include halogens,

ammonia, and chlorides, excessive dust, lime or dirt.

Excessive exposure of electronics to the contaminants

will also result in performance related problems.

Contact NORTEC Technical Services if you have any

questions. If contaminants exist, isolate the unit from

the contaminated space.

2

), for GS 100

2

), for GS 200

2

), for GS 300

2

), for GS 400

2

), for GS 500

2

), for GS 600

Attach the air supply line to the manifold using a

hose clamp or hose coupling if required. See Figure

#4.

WARNING: Air supply line should not obstruct

any services going to the humidifier front and

right side cabinet panels.

WARNING: BH Type venting must be used in

a direct vent application.

The air intake terminal and the flue gas terminal

must end at an outside location. See Figure #5.

Air Piping Insulated

(by others)

Hose Coupling

(by others)

Air Intake Connection

DIRECT VENT GUIDELINES

Installation of the combustion air supply line must

be carried out by adequately qualified personnel. All

local regulations relating to the provision of air supply

systems must be observed and adhered to.

The maximum pipe length for the air supply line

and exhaust is equivalent to 70’ (21m). The vent pipe

diameter must be maintained over the overall length of

the vent.

All air piping must be listed type for direct vent

application with sealed joints and seams, such as Z

flex.

The air supply line should be approximately as

long as the flue gas venting and must be supported at

every 5 ft. (1.5 m) and additionally at every pipe bend.

The air supply line must be installed with air

supply terminals provided.

At low temperatures, water condensation can form

on the outside of the pipe. To prevent this, it is

Figure #5

Direct Vent Side Wall Requirements

Exhaust terminal with

opening vertical.

Intake terminal with

opening vertical.

4ft-6ft

(1.2 m - 1.83 m)

Keep 6“ (15.2 cm)

away from sidewall.

-6-

Location of air intake and flue gas terminal must

g

comply with all local and national regulations.

EXHAUST VENTING

The GSTC and GSP are classed category I and III

fan assisted gas appliances. This allows two methods

of venting. Listed below are instructions for both

venting systems, followed by specific requirements for

each system.

Review the requirements for both category I and III

installations and select the venting method best suited

for the installation.

Category III class must be used in direct vent

applications.

GENERAL REQUIREMENTS

The vent systems shall be listed to UL or UL/CSA

·

standard and meet the installation requirements

of the National Fuel code in the USA ( ANSI

Z223.1) and the Canadian Standards

CAN/CGA.B149 Installation Codes. Any local

jurisdictions reflecting changes to the above

codes should be observed.

In applying the codes, reference should be given

·

to the venting manufactures instructions, the

serving gas supplier regulations, and the specific

instructions provided in this manual.

This appliance must be installed to comply with

·

national regulations and codes. A qualified

technician, competent with these codes and the

local requirements of the jurisdiction must carry

out the installation.

Proper removal of combustion gases must be

·

assured, and building materials must be

protected from degradation by flue gases.

Never mix venting types. (B to BH or visa versa.)

·

Never use two different manufacturer’s

equipment for the same chimney.

All vent runs should be as direct as possible with

·

no more than 6 elbows in the system.

Maintain an upward slope of ¼” per ft on all

·

horizontal vent pipe runs.

· This gas humidifier may not be used in

conjunction with a power venter or draft inducer.

Horizontal Venting Using a Direct Vent Application Using BH Type Only

Wall

BH type vent using double wall vent

with all joints being air and water tight.

Reference local and/or national codes

before installation of the vent

Condensate tee and trap must

be installed. Take the condensate

to a floor drain or a condensate pump

Exhaust venting outlet

Steam

Outlet

Hangers straps

Condensate

Tee

Trap

Figure #6

3” Min

Direct vent

Inlet

2ftMin

Exhaust venting must

be min.4 ft, max.6 ft

in distance apart from

the fresh air intake

for direct venting

Terminations

supplied with

unit

Note: These are

BH type double wall with double

wall connectors required.

uidelines only. Follow the local and/or national codes inyour respective area.

-7-

Figure #7

Vertical Venting Application Using B or BH Venting

UL Listed Cap

Required

Flashing

B or BH type vent using double wall vent

with double wall connectors is required.

Reference local and/or national codes

before installation of the vent.

Horizontal run

1/4"rise per ft

4" minimum air

space required

Exhaust venting

outlet

Steam Outlet

Side Wall Venting Application Using BH Type Only

Wall

BH type vent using double wall vent

with all joints being air and water tight.

Reference local and/ or national

codes before installing vent

Trap

3” Min.

Condensate tee and

trap must be installed.

Take the condensate to

a floor drain or a

condensate pump.

Figure # 8

Hangers Straps

Condensate tee

required

2 FT Min

B type double wall vent with

double wall connectors required

for category I appliances.

Limitations on horizontal

distance when venting with B

vent

BH type double wall vent with

double wall connectors required

and all joints are to be air and

water tight. BH vent is a category

III appliances

Nortec vent terminal

Exhaust venting outlet

Steam Outlet

Note: These are guidelines only, follow the local and/or national codes in your respective area.

Condensate

Te e

Trap

2 ft Min.

3” Min.

Condensate tee and trap

must be installed. Take

the condensate to a floor

drain or a condensate

pump.

BH type double wall vent with double wall

connectors is required for category III appliances

-8-

Exhaust venting

Steam Outlet

Co-venting Application Using B Vent Only

B type double wall vent

with double wall

connectors is required for

category I, serving two or

more gas appliances.

outlet

Condensate

Te e

Figure # 9

UL Listed Cap

Required

Condensate tee and trap

must be installed. Take

the condensate to a floor

drain or a condensate pump.

Trap

Note: These are guidelines only. Follow local and/ or national codes in your respective area.

· For any vent lengths over 20 feet long, insulate

the vent pipe to reduce the amount of condensate

that could form in the flue gases.

· When the venting passes through a cold area, or

location that has large amounts of air passing

over the venting, it should be insulated to prevent

condensation from forming inside the venting.

· Vent pipe passing through walls, floors, and

ceilings, must be installed with the proper

clearances from combustible materials, and

venting manufactures fire stop equipment.

· The venting shall not pass through any circulation

air duct or plenum.

WARNING: Provide a screen or barrier to prevent

personal injury in areas where personnel may come

into contact with hot vent pipes.

· A drip “T” or flue box condensate port should be

used for condensate removal. When a

condensate drain is used it will be necessary to

install a trap to prevent flue gases from escaping.

Category I gas appliance uses

B type venting. Follow local

and/or national codes for

venting installation.

Install a trap with a minimum 12” standing

water column.

· Prior to activating the appliance, ensure that the

trap is filled with water and that the drain

terminates in accordance with local plumbing

codes.

· Never vent into a unlined masonry or concrete

chimney.

· Chimney or vent should extend at least 3’ (1 m)

above a roof and at least 2’ (.6 m) above any

ridge within 10’ (3 m) of the chimney. Local codes

apply.

· Install venting so as to prevent accumulation of

condensate and have a means for condensate

removal.

· Plastic, PVC, CPVC and HTPV special gas vents

are not approved for use with this appliance.

· The vent must terminate at a sufficient height

above the roof to prevent blockage by expected

snowfall.

-9 -

Vent pipe must be secured with hangers or pipe

e

·

straps

All horizontal runs must be adequately supported

·

with hangers or straps to prevent sagging.

Installation as a Category I Appliance

The GS series humidifiers have a fan-assisted

·

combustion which operates with a non-positive

vent static pressure when installed with the

appropriate vent diameter.

Category I appliances must be vented vertically

·

or nearly vertical. (See Figure #7 & #9)

This category appliance is restricted to vertical

·

venting installations with limits placed on

horizontal lengths and vent diameters. Refer to

the tables in local and/or national codes. No

sidewall termination is accepted.

Vent piping must be UL or UL/CSA listed type B

·

or B-W.

Recommended B-Venting Manufacturers

Vent connectors shall not be connected into any

·

portion of a mechanical draft system operating

under positive pressure.

Use only double wall (aluminum inner wall) B

·

vent. Single wall venting can not be used due to

the increased wet time in the lining. If the vent

connector attaches to a lined masonry chimney,

the chimney must be sized and installed

according to the provisions of the National Fuel

Gas Code or Canadian CAN/CGA.B149

standards.

An approved venting manufacturers termination

·

cap for the stack outlet must be used.

The maximum flue temperature is 400 degrees F.

·

Normal operating range is 360 to 380 degrees F.

When the category I installation is selected it may

·

be commonly vented with other listed gas fire

appliances. Total input rates of all appliances will

determine the vent size the chimney must be

sized and installed according to the provisions of

the National Fuel Gas Code or Canadian

CAN/CGA.B149 standards.

1. Simpson Dura-Vent

2. Selkirk Canada Corporation

3. American Metal Products

4. Metal-Fab Inc.

·

The vent pipe exiting the humidifier is sized for

Category III installations. A field supplied adapter

is required to increase the pipe immediately at

the exit of the humidifier. The vent pipe must be

expanded to the minimum sizes listed below for

each model, increasing as code requires.

GS 100 4” minimum diameter

GS 200 5”

GS 300/400 7”

GS 500/600 8”

·

The termination at the humidifier is a MALE

connection. Standard venting hook-ups require a

female path. It is highly recommended that a

female to female adapter be assembled onto the

humidifier to establish the proper venting

sequence. Consult with the venting manufacturer

for proper hook up.

· A maximum of 4 gas appliances may be common

vented on the same floor. Multiple story common

venting is not recommended.

· Refer to the vent manufacturers instructions for

proper clearances to combustibles.

Figure #10

Exhaust Connection

Female to Femal

Adapter

(by others)

-10-

This appliance should not be connected to a

·

chimney flue servicing a separate appliance

designed to burn solid fuel. Never connect this

humidifier to a chimney servicing a fireplace.

This venting category cannot be used in direct

·

vent applications.

Installation as a Category III Appliance

This venting system can be installed horizontally

·

or vertically and can terminate on a rooftop or

sidewall provided the NFGC (Nation Fuel Gas

Code) and CAN/CGA- B149 codes are followed.

The venting manufacturer instructions must also

be followed. See Figure # 6,#7 & #8.

WARNING: Provide a screen or barrier to prevent

personal injury in areas where inadvertent personnel

contact with vent pipe can occur.

A minimum equivalent vent length of 7 feet must

·

be connected to the humidifier. Vent lengths

must not exceed 100’ (30 m). Each 90° elbow

is equivalent to 10’ and each 45° elbow equals 5'.

The vent run should be as direct as possible with

no more than 6 elbows in the system.

Diret vent applications, length of vent should not

·

exceed 70” in equivalent length.

ADDITIONAL REQUIREMENTS WHEN VENTING

THROUGH A SIDEWALL

This venting must be used in all direct vent

·

applications.

This category installation may not be common

·

vented with any other natural draft gas appliance

or power assist appliance. The humidifier cannot

share a chimney flue servicing an appliance

designed to burn solid fuel.

· Venting must be UL or UL/CSA listed, tested to

ULC-5636 Standard. Venting may be BH or L

vent. Special gas vent shall be listed and installed

in accordance with the terms of the special gas

vent listing and the manufacture’s instructions.

The special instructions listed below should be

followed as well.

·

All joints must be sealed using high temperature

RTV silicone.

BH Vent Manufacturers

1. Flex-L International

For sidewall venting, locate the humidifier as close

as possible to the wall being used.

Locate the vent terminal at least three feet above

any forced air inlet located within ten feet; or at least

four feet below, four feet horizontally from, or one foot

above any door, window, or gravity air inlet into any

building.

A minimum horizontal clearance of four feet from

electric meters, gas meters, regulator and relief

equipment is required.

For sidewall vent terminations, the humidifier must

be installed with the certified vent terminal that can be

purchased from Nortec.

GS 100 3” Nortec P/N 1502321

GS 200 4” Nortec P/N 1502322

GS 300/400 5” Nortec P/N 1507320

GS 500/600 6” Nortec P/N 1507321

2. Fas-N Seal

3. Heat-Fab Inc.

4. Z Flex

·

The gas humidifier is supplied with the following

exhaust outlets.

GS 100 3”

GS 200 4”

GS 300/400 5”

GS 500/600 6”

·

The venting must remain the same diameter

throughout the installation.

Locate the vent terminal at least seven feet above

grade when it is adjacent to public walkways.

Locate the bottom of the vent terminal at least

twelve inches above grade or ground, or normally

expected snow accumulation level. The snow level

may be higher on walls exposed to prevailing winds.

Avoid areas where local experience indicates that

condensate drip may cause problems such as above

planters, patios, or over public walkways, or over an

area where condensate or vapor could create a

nuisance or hazard, or could be detrimental to the

operation of regulators, relief valves, or other

equipment. Refer to the vent manufacturer's

installation instructions.

-11-

The vent terminal must be installed in the same

atmospheric pressure zone as the combustion air inlet

of the humidifier. If this is not possible (as in cases of

positive or negative room pressures) the humidifier

should be installed with the direct vent option.

ELECTRICAL

PRIMARY WIRING

Field wiring from humidistat to humidifier and

between devices should be shielded 18 AWG or

heavier and kept as short as possible.

Controls are available from NORTEC as

accessories and can be ordered with the humidifier.

Controls by others may also be used as long as they

meet the criteria noted below. The following is a

summary of the common types of controls that may be

used with NORTEC Gas Humidifiers.

All work concerning the electrical installation

must be performed by qualified personnel.

WARNING: The electrical parts inside the

humidifier are very sensitive to electrostatic discharge.

Appropriate measures against electrostatic discharge

(ESD protection) must be taken when carrying out

installation work.

The humidifier should only be connected to

·

primary power (mains power) after all installation

work has been completed.

· An external disconnect switch must be installed

close to the unit to allow for power interruption

during servicing and/or maintenance.

· Humidifiers require field wiring to primary voltage

terminal blocks. Power requirement must be

120V or 208-240 Vac, 15A separately fused

circuit, single phase. Use only copper wire with a

minimum 70 °C (158 °F) temperature rating.

Wiring can be fed through a 7/8" hole on the

bottom or the top of the control compartment.

See Figure #1.

·

When installed, the appliance must be electrically

grounded in accordance with local codes or, in

the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, and/or the CSA

C22.1 Electrical Code, if an external electrical

source is utilized.

·

External wiring sizes must be in accordance with

NEC and/or CEC and existing local electrical

codes and by-laws.

Wall or Duct Mounted Control On/Off

Humidistat: Wired to make on drop in humidity,

break on rise to setpoint. Set to desired RH. Can

be a make/break set of contacts from a Building

Automation System.

Duct Mounted Safety High Limit On/Off

Humidistat: Wired to make on drop in humidity,

break on rise to safety setpoint. Set to

approximately 85% RH as a safety to prevent

saturation and wetting in the duct. Highly

recommended for ducted applications.

Duct Mounted Safety Air Proving On/Off Switch:

Wired to make when sensing air flow, break when no

air flow. Used as a safety to prevent saturation when

there is no air flow. Highly recommended for ducted

applications.

Wall or Duct Mounted Modulating Humidistat:

Provides a modulating signal to the unit that

represents the output (up to 100%) required from the

humidifier. Signal type can be changed in the field via

dip switch settings on the logic control board.

All GS models may be configured for either single

or dual channel modulation. Control signals can be

0-10 VDC or 0-20 mA (0-5 VDC, 1-5 VDC, 4-20 mA

and 2-10 VDC are also available). The unit must be

ordered from the factory for the desired signal type

and number of channels. When configured for

2-channel modulation the humidifier will generate

steam only if both channels indicate a demand. If both

channels are demanding steam the humidifier will

satisfy the lower demand signal.

LOW VOLTAGE CONTROL WIRING

All GS models require at least one type of input

control signal for unit operation. Refer to the sections

below that detail the types of controls that can be used

with each model.

Low voltage control terminal strips are provided in

the electrical compartment. Internal sides are factory

wired. External sides are to be field wired. Refer to

the specific control-wiring diagram supplied with each

unit.

-12-

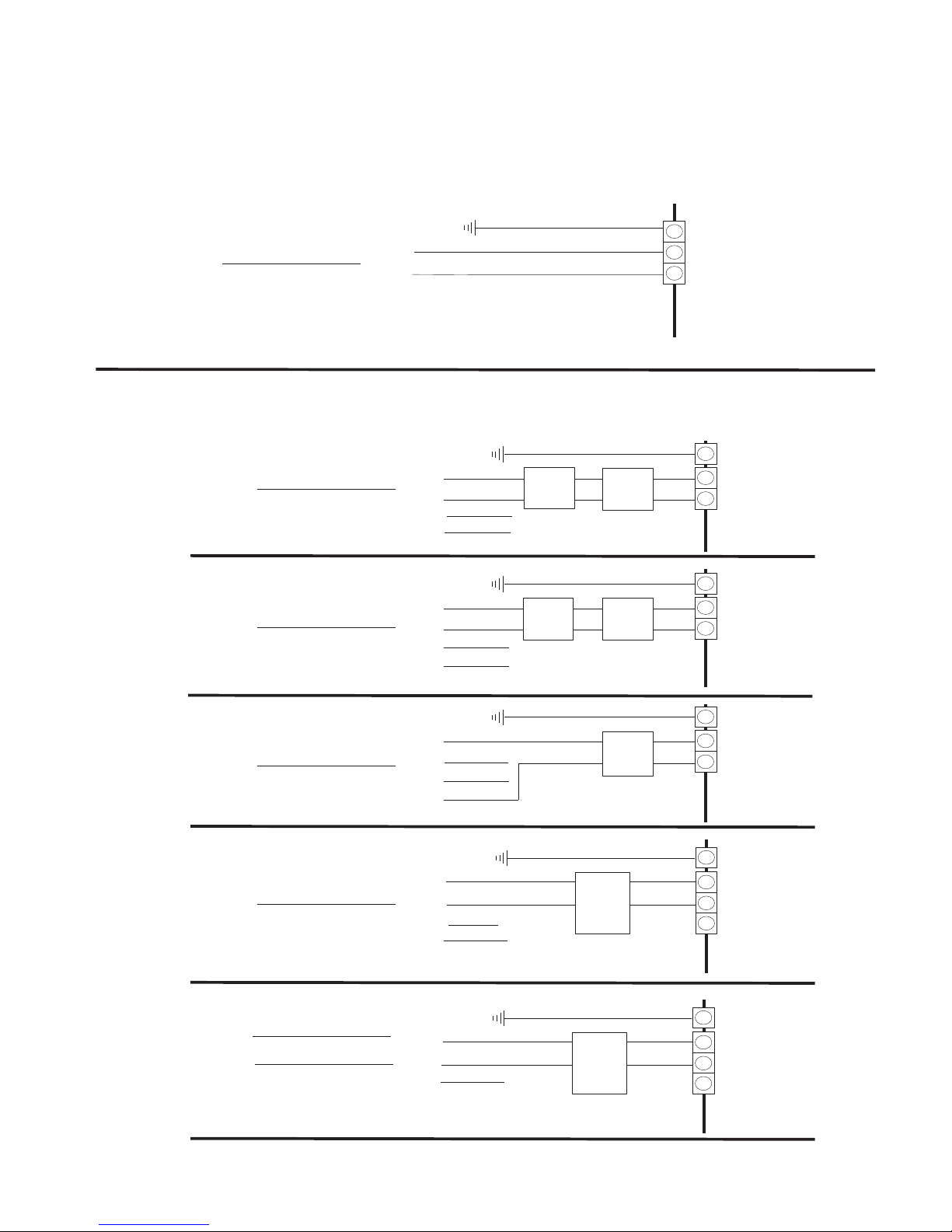

NOTE: VoltageAt TerminalBlock MustBe InAccordance With Spec.Label.

A

ll Wiring ToBeInAccordance With Existing NationalAndLocalElectricalCodes.

PRIMARY120V 1 phase line voltage wiring to unit

120V/1ph

VOLTAGE

(ACTUAL)

600V/3ph

460V/3ph

Ground Wire

E

X

N

T

T

L1

Neutral

Ground

Note:

- 120V/ 1phase Supply.

- 120V/1phase betweenhot andneutral.

- 240V/1phase betweentwo 120V/1phsupply.

PRIMARY208-240V 1 phase line voltagewiring to unit

L1

L2

L3

Neutral

L1

L2

L3

Neutral

(BY OTHERS)

Ground

Transformer

600V/208V

Note:

- 600V/3 Phase Supply.

- 600V/1ph betweenany twohot leg.

- 347V/1ph betweenhot andneutral.

Ground

Stepdown

Transformer

460V/208V

Note:

- 460V/3 Phase Supply.

- 460V/1ph betweenany twohot leg.

- 277V/1ph betweenhot andneutral.

Stepdown

byothers

byothers

Ground Wire

Ground Wire

Dedicated

Circuit

Breaker

Or

Disconnect

Dedicated

Circuit

Breaker

Or

Disconnect

I

Ground

Leg

2 Pole

Terminal

Block

E

X

T

E

X

T

L1

Neutral

Ground

Leg

2 Pole

Terminal

Block

I

N

T

Ground

Leg

2 Pole

Terminal

Block

I

N

T

380V/3ph

208V/3ph

120V/1ph

120V/1ph

L1

L2

L3

Neutral

L1

L2

L3

Neutral

L1

L2

Neutral

Ground

Note:

- 380V/3 Phase Supply.

- 380V/1 phasebetween twohot legs.

- 220V/1 phasebetween hotand neutral.

Ground

Note:

- 208V/3 Phase Supply.

- 208V/1 phasebetween twohot legs.

- 120V/1 phasebetween hotand neutral.

Ground

Note:

- 120V/ 1phase Supply.

- 120V/1phase betweenhot andneutral.

- 240V/1phase betweentwo 120V/1phsupply.

Ground Wire

Ground Wire

Dedicated

Circuit

Breaker

Or

Disconnect

Ground Wire

Dedicated

Circuit

Breaker

Or

Disconnect

Dedicated

Circuit

Breaker

Or

Disconnect

Ground

Leg

2 Pole

Terminal

Block

E

I

X

N

T

T

Ground

Leg

3 Pole

Terminal

Block

E

I

X

N

T

T

Ground

Leg

3 Pole

Terminal

Block

E

I

X

N

T

T

-13-

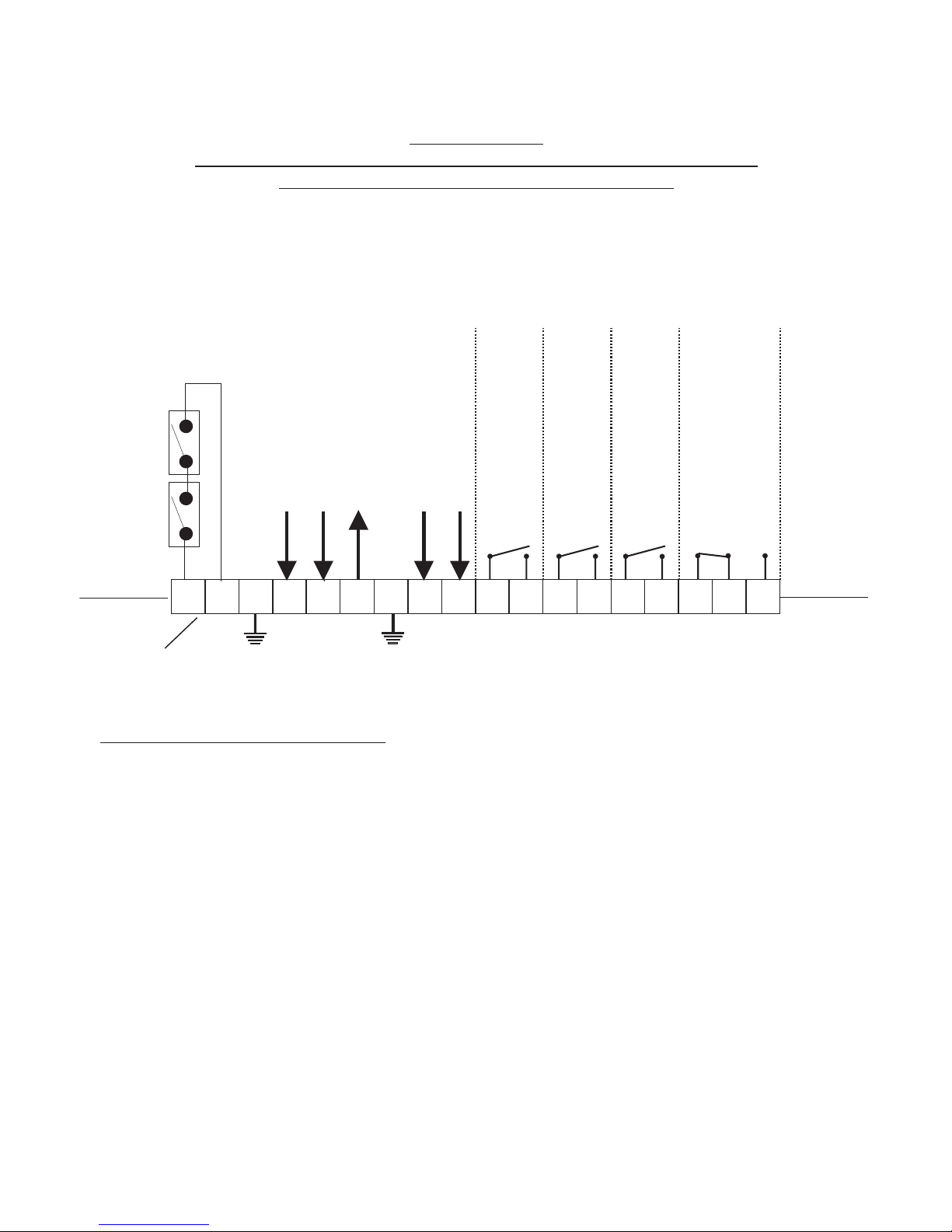

GS SERIES

EXTERNAL CONTROLS WIRING CONNECTIONS

LOW VOLTAGE TERMINAL STRIP

NOTE: This is a wiring diagram only. For specific wiring instructions, it is necessary to refer

to the wiring diagram which is supplied with each unit.

WARNING: Failure to wire the controller in accordance with the wiring diagram that was supplied

with the unit could permanently damage the GSTC/GSP board. Such errors will void the unit warranty.

Security Loop

EXTERNAL

INTERNAL

NOTE: If no On/Off Control is used then a field jumper

must be connected across terminals 1 and 2 in order

for the humidifier to operate.

1

generic

2

3

Modulation Input Signal “A"

Modulation Input Signal “B”

5

4

++

6

10 Vdc output

7

enable (24 Vac)

Full Tank Blow Down (FTBD)

8

9

Safety Interrupt (24 Vac)

COM

10

Humidifier “ON”

N.O.

1211

Humidifier “ACTIVE”

COM

13

N.O.

14

COM

Humidifier “SERVICE”

N.O.

16

N.O.

17

Humidifier “FAULT”

COM

N.C.

EXTERNAL

1815

INTERNAL

Low Voltage Terminal Strip

1 & 2: Wire all on/off controls and safeties between these two terminals. If not used, jumper1&2forthe

unit to operate.

4: Modulating input to humidifier “A”.

5: Modulating input to humidifier “B”.

6: 10 Vdc output.

8: When 24 Vac input received, the unit will initialize a full tank blowdown.

9: Safety interrupt (24 Vac).

10 & 11: Remote indication connection for humidifier “on” status indication.

12 & 13: Remote indication connection for humidifier “active” status.

14 & 15: Remote indication connection for service required indication.

16 & 17 & 18: Remote indication connection for fault indication.

-14-

CONTROL INSTALLATION

f

Mount any wall humidistat (control or high limit)

·

over standard electrical box at height similar to

typical thermostat. Any wall humidistat should be

in location representative of overall space being

humidified and not in path of blower pack or air

supply grille. Do not mount on an outside wall

where temperature fluctuations can affect control

response.

Mount duct humidistat in location representative

·

of overall air humidity, usually in return duct. Do

not mount it directly in front of steam distributor or

in turbulent or mixing zone. Mount humidistat

where air's humidity and temperature are uniform

and representative of spaces being humidified.

Mount duct high limit humidistat downstream of

·

steam distributors far enough that, under normal

humidity and air flow conditions, steam will have

been fully absorbed (typically at least 10 feet). It

must be located to sense high humidity only

when uniform and representative air is

over-humidified or approaching saturation.

· Mount duct air-proving switch so that it is able to

sense air flow or lack of it. Wire it to make when

air flow is sensed and break when air flow fails.

· Check operation of all on/off controls before

starting humidifier.

·

Calibration of controls (on/off or modulation) in

the field may be necessary due to shipping and

handling. Verify humidistat accuracy before

commissioning system.

PLUMBING

NOTE: All water supply and drain line

connections should be installed in accordance with

local plumbing codes.

FILL WATER SUPPLY LINE

It is recommended to have a faucet installed

·

close to the humidifier to allow quick filling of the

system on initial start up. This can also be very

useful for mandatory cleaning of the unit.

ALWAYS supply and install a shut off valve and

·

union in the water supply line dedicated to the

humidifier to facilitate servicing.

If water hammer occurs, install a shock arrester

·

on the fill water line just before the inlet to the fill

valve. Water hammer will damage the fill valve.

A 1” air gap is designed into the fill system of the

·

GS humidifier. Some local plumbing codes may

still require the installation of a double check

valve on the fill line to the humidifier to prevent

contamination of the supply water system. Verify

with local codes and install if necessary.

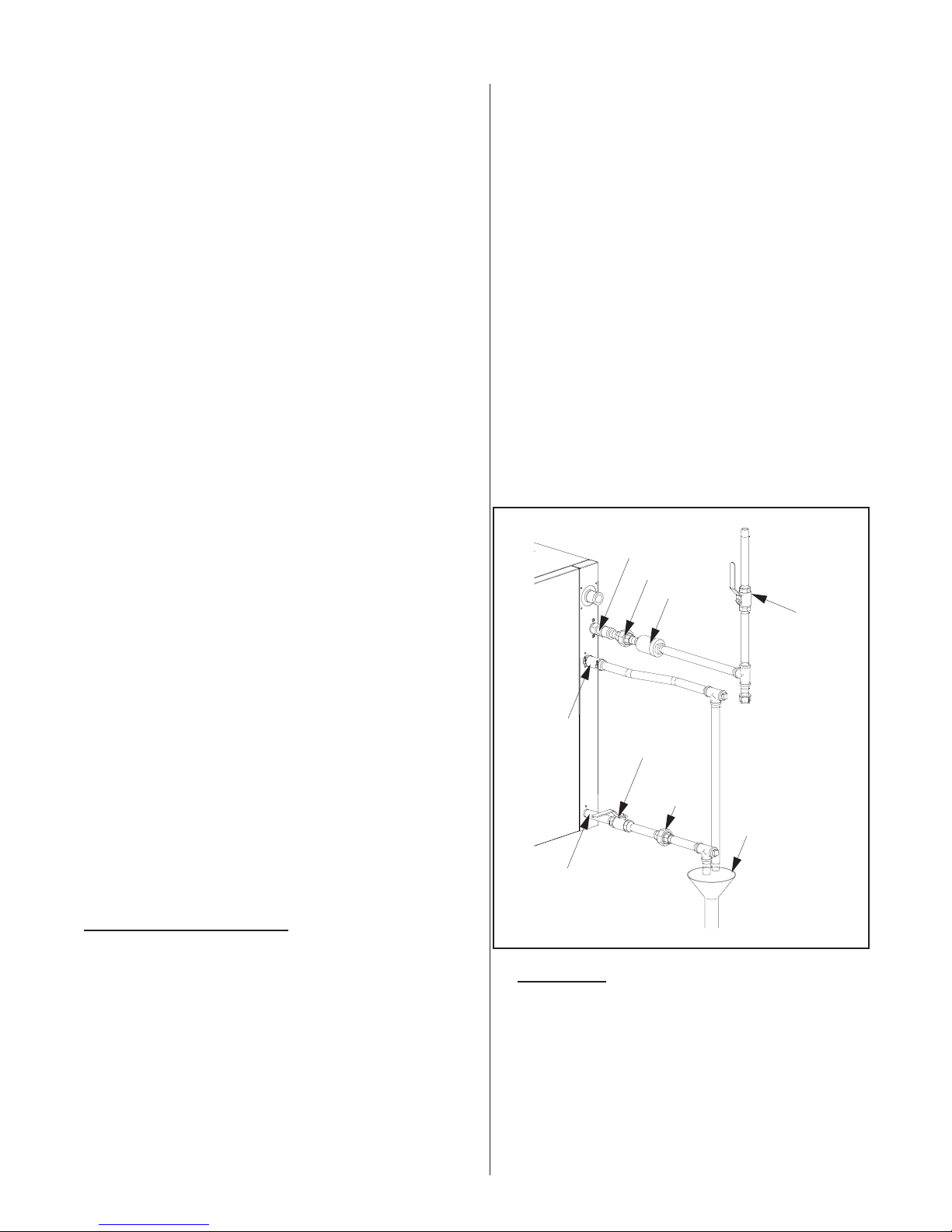

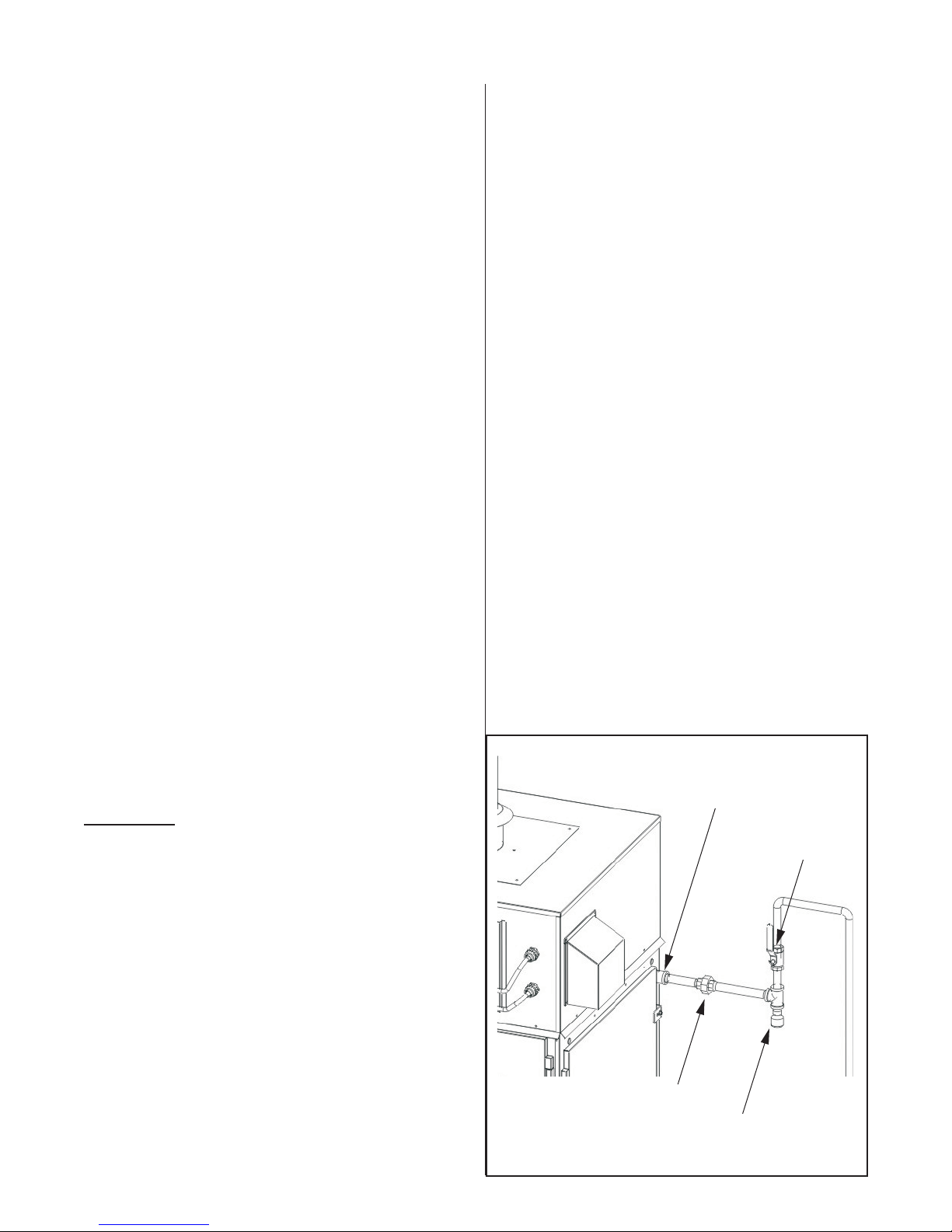

Plumbing Connections

1/2” NPT Water Supply

(by Nortec)

3/4” O.D.

Drain

(Hose clamp by Nortec)

1/2” NPT Female

Auxiliary Drain

Figure # 11

Union

(by others)

Check Valve

(by others,

if required)

Manual

Shut-off

(by others)

Union

(by others)

Manual Shut-of

(by others)

Funnel with

Air Gap (by others)

·

Each unit is supplied with an adapter for the fill

valve (½”NPT ). Fill rate 10 l/min all unit sizes.

Size of piping is a minimum ½” copper,

recommend ¾” up to within 4 feet of unit.

·

Standard fill valves are sized for water pressure

ranging from 30 to 80 psig (ideally 55 to 60 psig).

For other pressures, consult factory. This

pressure should be measured at the humidifier if

the water pressure is suspect.

-15-

DRAIN LINE

·

The humidifier is equipped with a ¾”O.D.

Unthread ed drain outlet connection on the side

of the humidifier. A vacuum break valve is

installed internal to the unit on the drain line. The

drain water line must be piped to a drain funnel to

provide an air gap before connection to the

building drainage system.

The drain line should not end in a sink used

·

frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or

equivalent for safety reasons. Internal drain water

tempering will ensure a maximum of 140ºF

(60ºC) exiting water temperature.

Never install PVC piping as a drain line material.

·

Always use material suitable for with-standing

140ºF (60ºC).

Keep drain lines as short as possible. Keep drain

·

lines sloped down, not level and not up since low

spots in drain lines will accumulate sediment and

cause backup. The drain line should be 1-1.5"

O.D. or larger. Consult local codes.

When the drain pump is activated, the tank drains

·

at a rate of 7-8 gal/min (18-20 l/min).

AUX DRAIN PORT

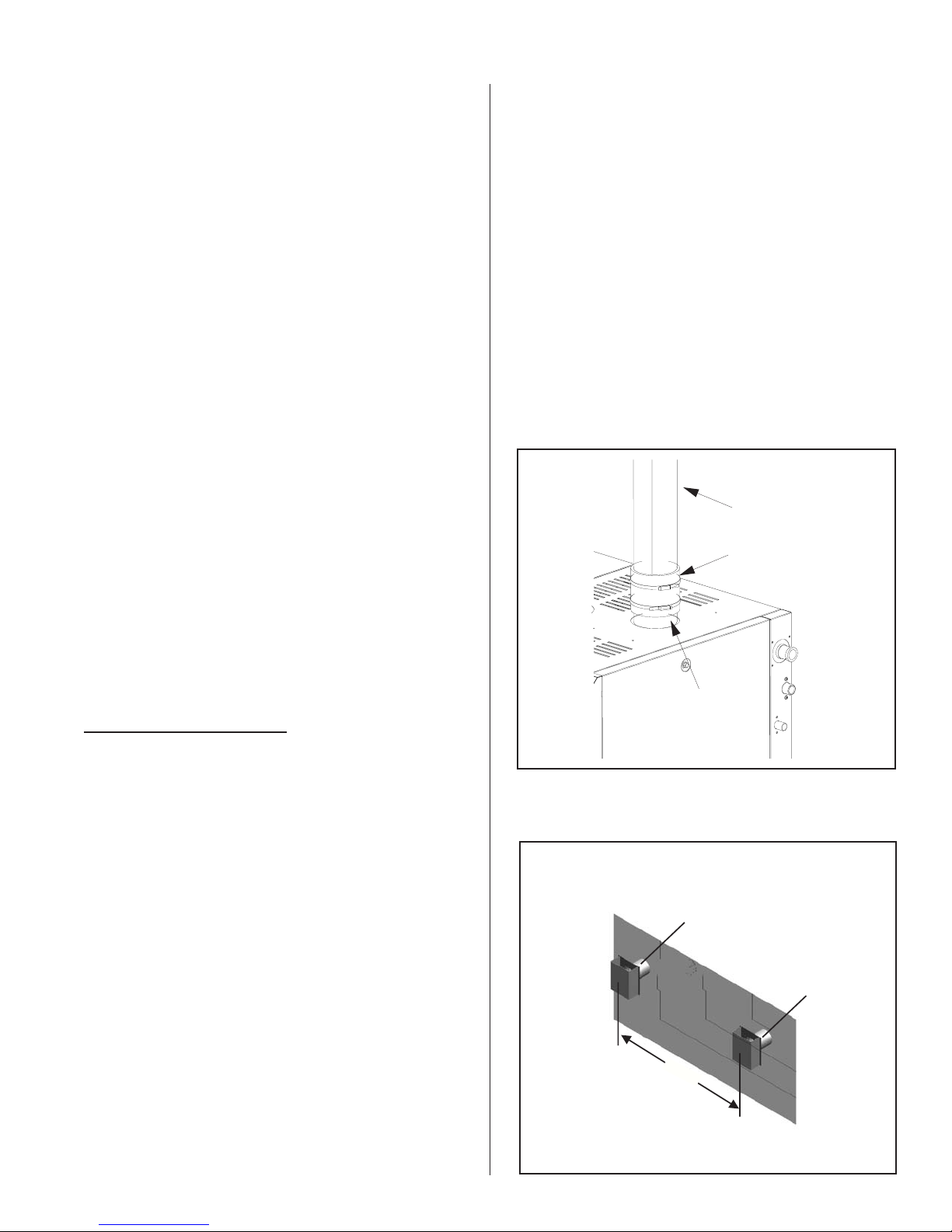

Figure #12

Steam Line Connection

Steam Line

Snap on Insulation

Hose cuffs &

clamps supplied

An auxiliary drain port is also provided on the

·

side of the humidifier. It can be used to manually

drain the unit, if required. The unit is shipped

with this connection plugged. It is recommended

to install a shut off valve on this line (see Figure

#11).

· The auxiliary drain port is used when the freeze

protection option is required. Install a shut off

valve on this line and pipe to the drain funnel (see

Figure #11). The manual shut off valve must

always be in the open position when the unit is

operating but can be closed for servicing of the

unit.

STEAM LINES AND CONDENSATE LINE

·

Steam hoses and clamps are provided with the

GS humidifier for connection to the steam lines.

Refer to Figure #12 for connection details.

·

For steam line installation between the humidifier

and distribution system, consult the distribution

system installation manual. Steam Distributor

Installation Manual - Form #XX-231 and SAM-e

Short Absorption Manifold - Form #XX-249.

·

The GS series of Gas-Steam humidifiers can

develop steam pressures up to 12”w.c. to

overcome duct and steam line pressures. An

enclosed trap on the drain line prevents steam

from going to drain. Duct pressures above 12”

will cause steam to exits through the drain line.

Consult factory.

GS Outdoor Installation

GS Outdoor units are CSA certified for outdoor

installation and come complete with exhaust venting

and internal ventilation (cooling) for the electronics.

Optional heaters for freeze protection in cold climates

are available.

All installations must conform with local building

codes or, in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1 in the United

States or CAN/CGA B149 Installation codes in

Canada. NORTEC can not accept responsibility for

installation code violations.

MOUNTING

·

Typical rooftop installations are shown in Figure

#13 & #14.

·

The GS Outdoor unit comes standard with

cutouts in the base to allow for lifting by a forklift.

When lifting by this method, ensure that the forks

extend across the entire base to prevent tipping

or damage to the unit.

·

The enclosure also comes complete with four (4)

removable lifting lugs fastened to the base. All

four lugs must be utilized if moving the unit in this

manner. Protect the cabinet from damage from

the lifting cables/chains during lifting. The lifting

lugs should be removed from the base once the

unit has been correctly positioned on the curb

mounting.

-16-

·

See Figure #15 for clearance details.

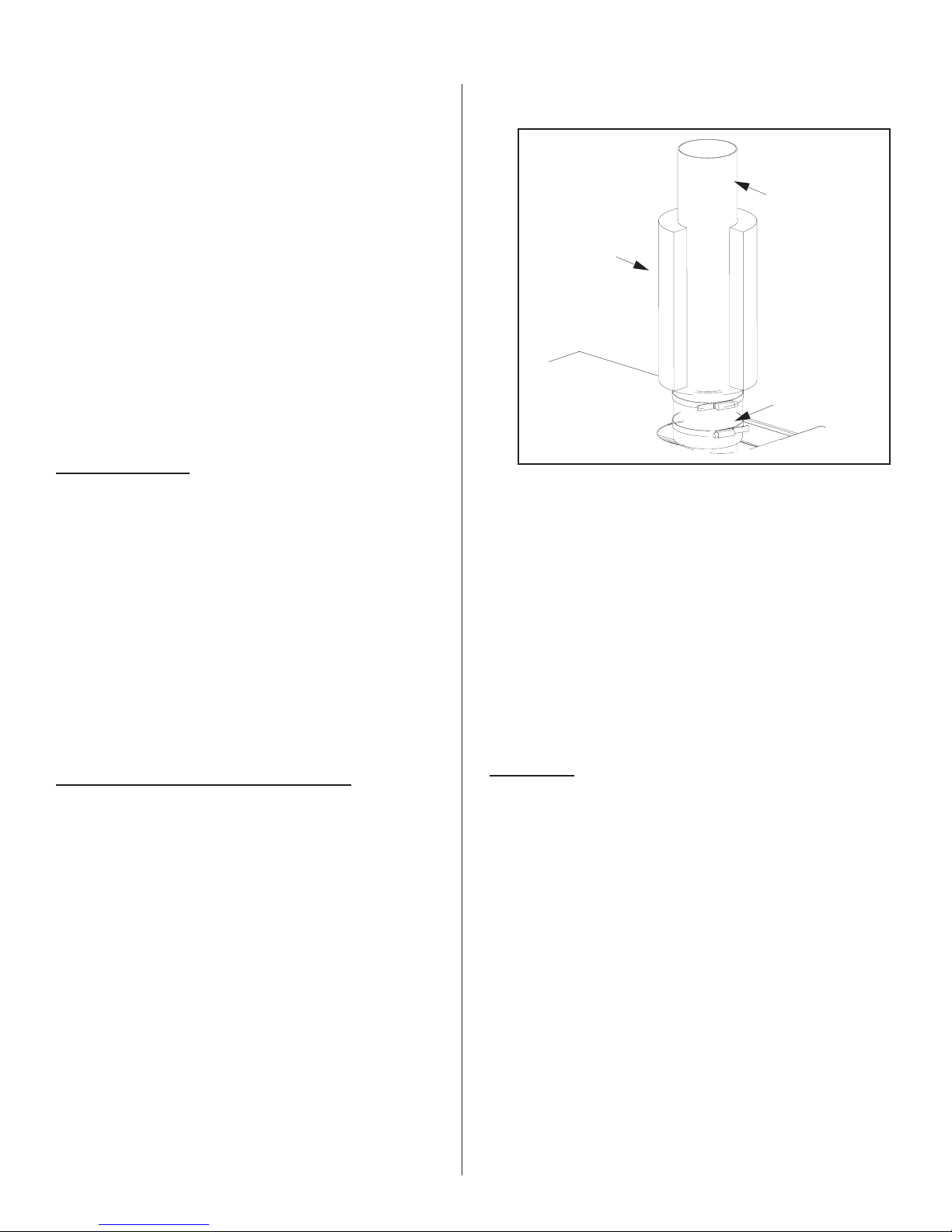

Figure # 13

GSTC Outdoor Typical Installation Rooftop

Electrical

Disconnect

(By others)

Roof Curb

(By others)

BH Vent

(By Nortec)

Drain

Lines

Funnel

With Air Gap

AHU

Insulated

Steam Line

(By others)

Gas Line with

Manual Shut-off

(By others)

Water

Supply

Manual

Shut-off

Roof Curb

(By others)

BH Vent

(By Nortec)

Electrical

Disconnect

(By others)

Figure # 14

GS Outdoor Typical Installation Rooftop

Insulated

Steam Line

(By others)

Gas Line with

Manual

Shut-off

-17-

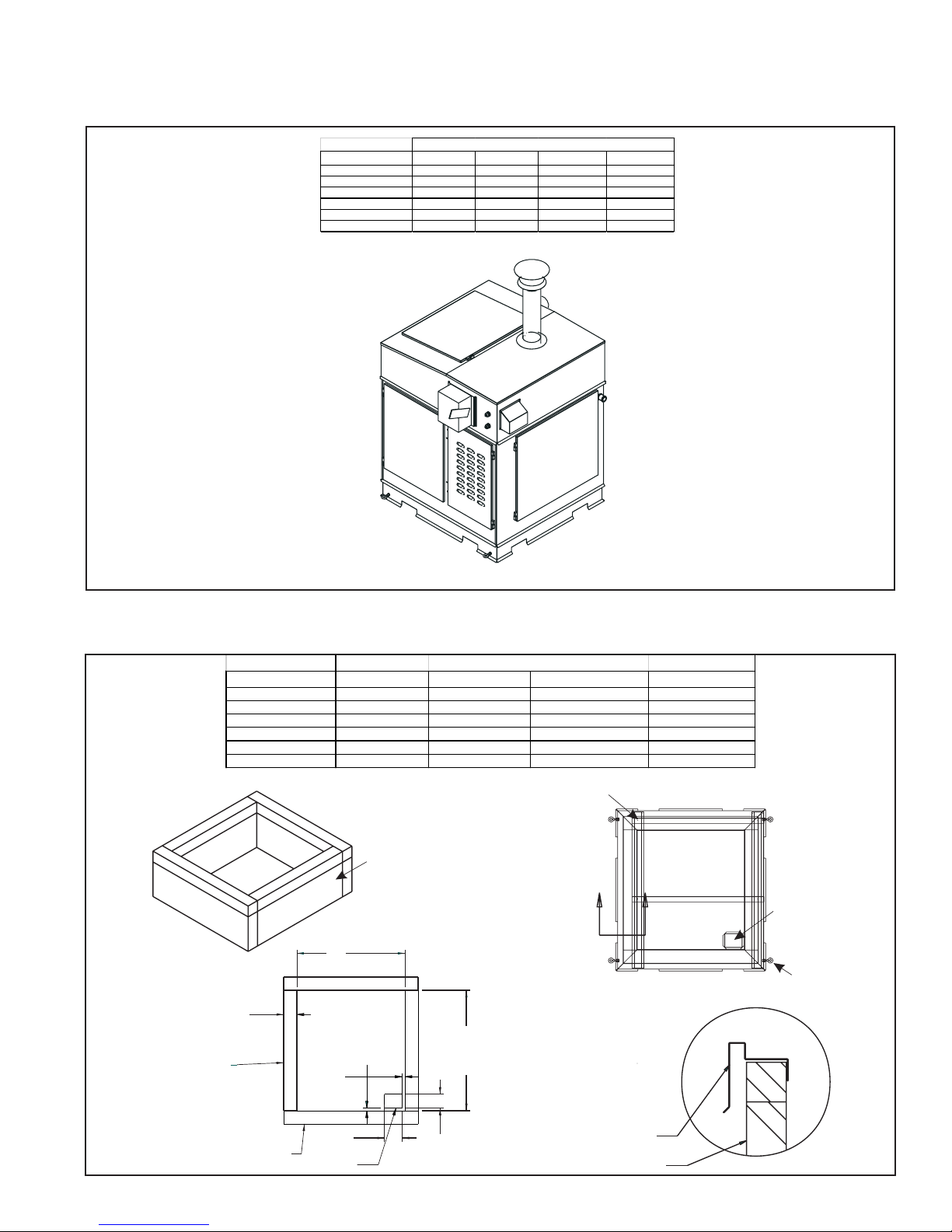

Figure # 15

GSTC Outdoor Clearance

Model Front Left Right Back

GSTC Outdoor 100 30" (76cm ) 0 40" (101.6 c m) 6" (15.25 c m)

GSTC Outdoor 200 30" (76cm ) 0 40" (101.6 c m) 6" (15.25 c m)

GSTC Outdoor 300 30" (76cm ) 30" (76cm ) 40" (101.6 c m) 6" (15.25 c m)

GSTC Outdoor 400 30" (76cm ) 30" (76cm ) 40" (101.6 c m) 6" (15.25 c m)

GSTC Outdoor 500 30" (76cm ) 30" (76cm ) 40" (101.6 c m) 6" (15.25 c m)

GSTC Outdoor 600 30" (76cm ) 30" (76cm ) 40" (101.6 c m) 6" (15.25 c m)

Minimum Required Clearances

TOP

Left

FRONT

RIGHT

3 3/4”

(9.5cm)

ELECTRICAL SIDE

Figure # 16

Roof Curb Dimensions

Roof Curb Dimensions

Model Dimension A Curb Height Shipping We ight Operating Weight

GSTC Outdoor 100 8.63" (27.91cm ) 15" (38.1cm) Min. 400 lbs (181 k g) 556 lbs (252 kg)

GSTC Outdoor 200 15.06" (38.25cm ) 15" (38.1cm) Min. 500 lbs (227 kg) 744 lbs (338 kg)

GSTC Outdoor 300 30.63" (77.8cm ) 15" (38.1c m) Min. 700 lbs (318 kg) 1185 lbs (539 k g)

GSTC Outdoor 400 30.63" (77.8cm ) 15" (38.1c m) Min. 745 lbs (339 kg) 1210 lbs (550 k g)

GSTC Outdoor 500 46.25" (117.5cm ) 15" (38.1cm) Min. 800 lbs (363 kg) 1505 lbs (684 kg)

GSTC Outdoor 600 46.25" (117.5cm ) 15" (38.1cm) Min. 844 lbs (384 kg) 1525 lbs (693 kg)

Roof Curb

by Others

AA

A

SECTION A-A

MAX.

34 1/8”

(86.6cm)

3/4”

(1.90cm)

11/16”

(1.8cm)

Pipe

Chase

Lifting

Hooks

BURNER SIDE

(15.24cm)

PIPE CHASE

6.0”

ROOF

5.0”

(12.7cm)

-18-

BASE FRAME

ELEMENT

CURB

The integral base of the GS Outdoor model is

e

·

designed to mount on a curb. The curb must be

built to structurally support the entire weight of

the humidifier when in operation. Required curb

dimensions are given in Figure #16 .

Ensure that the humidifier is mounted level.

·

The pan in the bottom of all outdoor models has

·

a pipe chase for routing of services into the

humidifier from below.

It is not necessary to make the hole in the roof

·

the same size as the curb. The curb drawing

shows the location and size of the pipe chase

required. The pipe chase should be sealed when

the installation is complete to ensure positive or

negative pressure from the building.

The panels of the outdoor model have louvers to

·

provide ventilation for the electronics and air for

the combustion process. Locate the unit so that

louvered panels are a minimum of 10 ft from any

mechanical exhaust outlet.

· When mounted on the curb, the lowest air intake

louvers must be a minimum of 12” above any

surface where snow or ice could accumulate. In

areas where normal snow accumulation is

higher, mount the unit accordingly.

· Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of the humidifier.

·

The humidifier may be installed directly on

combustible flooring or, in the U.S., on wood

flooring or Class A, Class B or Class C roof

covering materials.

Gas lines are to be routed to the outside

·

connection on the right side near the back of the

unit. The installation of a sediment trap and a

certified manual shut-off valve are required

outside of the unit. The gas piping must not block

access to or prevent opening of the right side

service door. Refer to Figure #17 for details.

Nortec recommends that each Gas Fired

·

Humidifier has it’s own regulator installed in line to

the unit. Th operating Natural Gas pressure

supplied for the GS units must be in the range of

5-9 “ of Water Column and propane version

10-14” of Water Column.

Over pressure protection devices shall be

·

provided to prevent the pressure in the piping

system from exceeding that value that would

cause unsafe operation of any connected and

properly adjusted Gas utilization equipment. See

Figure #18

If the system has a pressure that is higher than

·

the max working pressure of our humidifier, then

an Over pressure protection system is required. If

there is an Over pressure protection device

installed, it MUST consist of 2 devices in series.

(A pressure regulator plus one other device) Both

these devices must be able to work on their own

without damaging any downstream piping or

appliance, and the only way the downstream

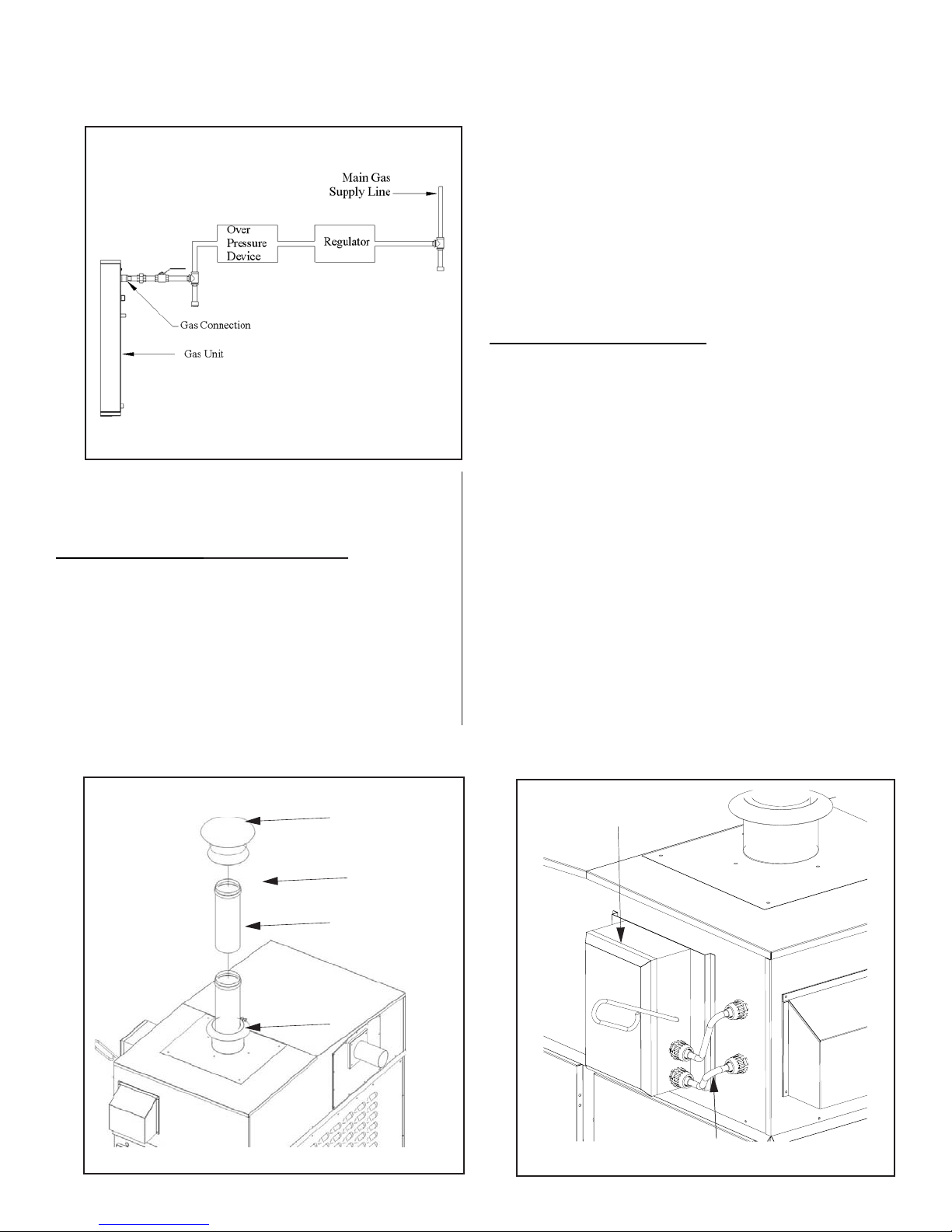

Figure #17

Gas Piping

Inlet coupling supplied

GAS PIPING

·

Installation of piping must be in accordance with

local codes, and the National Fuel Gas Code

ANSI Z223.1 in the United States or

CAN/CGA-B149 Installation Codes in Canada.

·

Refer to the indoor gas piping installation

guidelines for gas line sizes, pressures, leak

testing procedures, and safety instructions.

Shut-off Gas Valv

(by others)

Union

(by others)

Sediment Trap

(by others)

-19-

(By

)

d

Figure #18

GasPiping

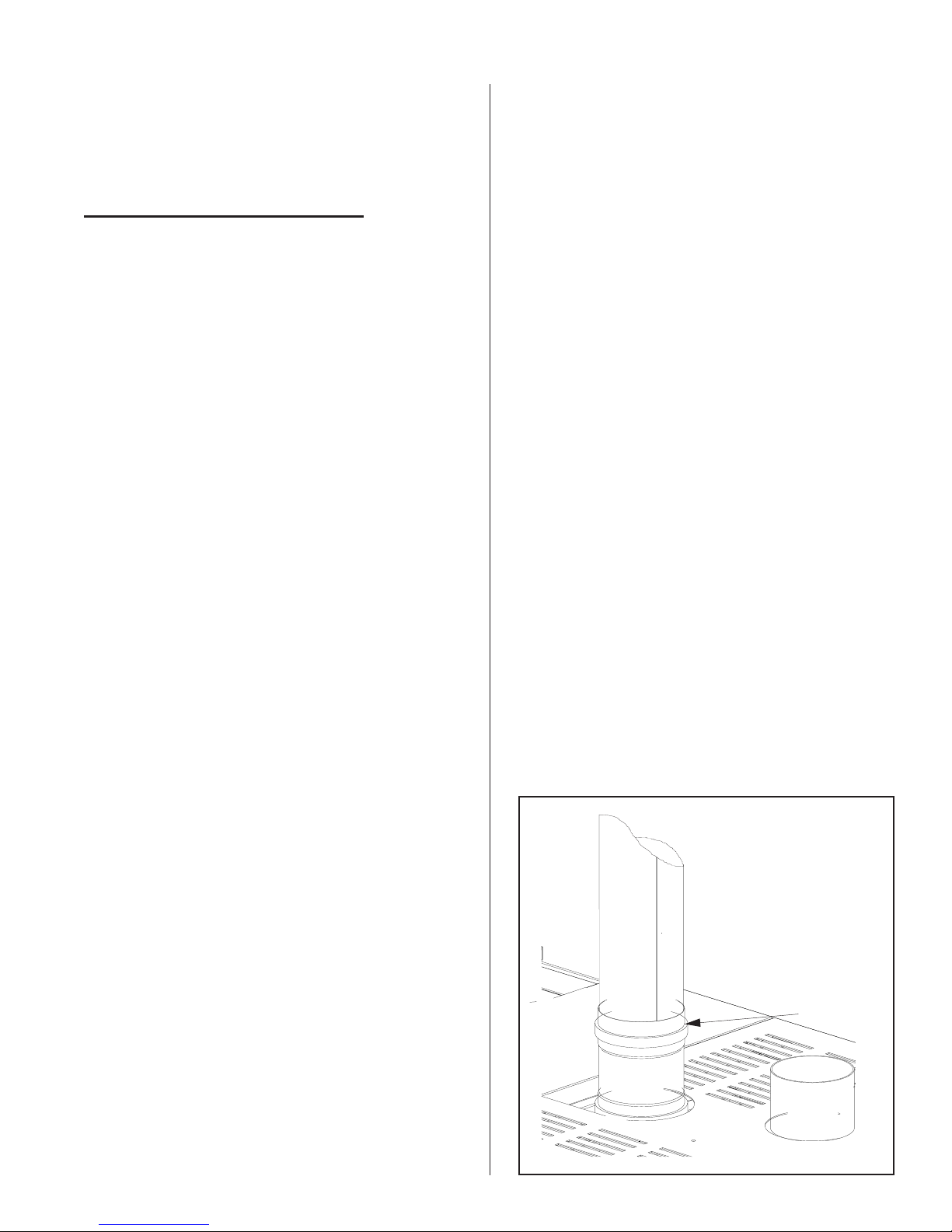

Each vent length and the rain cap have a built-in

·

mechanical locking band and gasket. Simply

push together each component to the stop bead,

which provides an air & water-tight seal. Then

tighten the integrated locking band on each

component to complete the installation of the

exhaust venting.

The rain cap must extend at least 2 feet above

·

any ridge within 10 feet of the unit. The exhaust

venting can be extended using additional vent

lengths purchased from Nortec.

ELECTRICAL INSTALLATION

Power and control wiring is to be routed into the

·

humidifier through the pipe chase in the base pan

of the outdoor models located in the burner area.

Installation details for primary and low voltage

·

control wiring are the same as for indoor units.

system can be damaged is by the failure of both

devices.

EXHAUST VENTING

- OUTDOOR UNITS

· All required exhaust venting is provided with each

GS Outdoor model, by Nortec, including rain cap

and storm collar. All venting components

external to the unit are shipped with the unit and

must be installed on site. Refer to Figure #19 for

venting components.

Figure #19

Exhaust - Outdoor Units

Rain Cap

All Venting provide

by Nortec

Extension Pipe

A field supplied NEMA rated weatherproof

·

disconnect switch must be mounted external to

the GS Outdoor unit to allow for power

interruption during servicing and/or maintenance.

A mounting plate, located on the front of each

outdoor model above the electrical access door,

is available for mounting of the disconnect switch.

Two electrical conduits are provided for routing

the primary wiring to the disconnect switch and

then back inside the enclosure to the main power

terminal strip. See Figure #20 for details.

Figure #20

Electrical Box

Disconnect box

(By others)

Storm Collar

Primary wiring

others

-20-

Loading...

Loading...