Page 1

GS

Series

Gas Steam

Humidifiers

Designed for air handling

systems and for areas

requiring individual

humidification control

™

Page 2

commercial offices

schools and universities

museums

printing

laboratories

libraries

manufacturing plants

NORTEC GS Series – the next

generation of gas steam humidifiers.

AxAir NORTEC specializes in the design and production

of superior humidification systems. It’s all we do!

Our future depends on our ability to understand the

needs of all our customers. We create the most

appropriate solutions to their specific needs in the

most efficient way. To this end, we draw upon our

extensive experience to develop an ever-growing

range of products that will provide our customers with

maximum reliability, minimum maintenance and a

choice of energy sources.

The NORTEC GS Series product line is no exception.

Every unit has a built-in modular stainless steel heat

exchanger – its flat surfaces ensure easy cleaning

and its proven design ensures reliable operation in all

water conditions. The control system is powered by

a 120V or 208-240V single phase electrical supply.

Each humidifier is built to operate with a normal

potable cold water source, RO (reverse osmosis), or

DI (De-mineralized) water as a standard. GS Series

products are manufactured in Nortec’s ISO 9001-2001

registered facility. Your AxAir NORTEC representative

can provide details.

2

Page 3

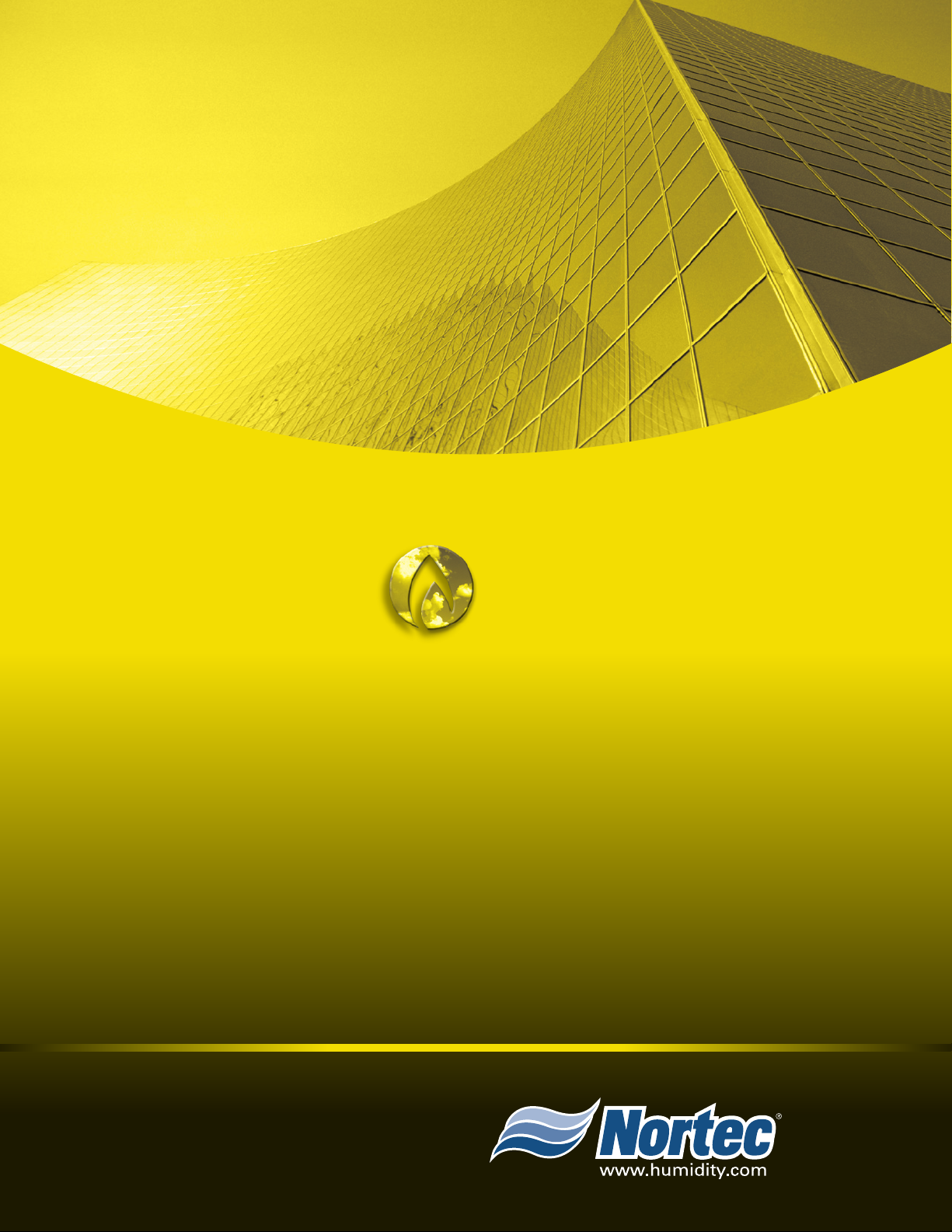

Economy

$/year

Operating costs based an electric cost of $0.08 per kWh, natural gas cost

$0.75 per therm, full output for 2,000 hours per season. Efficiency of

electric unit is 97% and efficiency of gas unit is 82%. Costs do not include

electric peak demand charges.

Annual

savings

with gas

$

3,658

0

1000

2000

3000

4000

5000

6000

Electric

$

5,443

Gas

$

1,784

Annual Operating Cost of

Natural Gas Humidifier vs Electric Humidifier

100 lbs/hr (45 kg/hr)

NORTEC GS Series Gas Steam humidifiers

provide clean steam humidification at an

economical operating cost. Units are packaged

in a powder coated cabinet for zero clearance

space requirement while offering high efficiency

output. They can be controlled from either a local

humidistat, from the central building management

system or multiple units can be staged together.

The combustion system utilizes a modulating

forced draft combustion air blower, a negative

pressure regulator gas valve and a 100% premix

burner. On a call for humidity, the combustion

air blower starts creating a negative pressure

across the valve orifice located at the air inlet.

The hot surface ignitor then energizes. The gas

valve opens and the regulated gas/air mixture is

forced through the burner ports and is ignited.

operating advantages

Easy Maintenance

The compact stainless steel heat exchanger has

large flat surfaces to minimize scale buildup

in the humidifier tank. Scale tends to fall off

the exchanger wall to the bottom of the tank,

maintaining efficient heat transfer to the water and

extending the intervals between cleanings. The

smooth stainless steel surface of the tank and

removeable heat exchanger are easily cleaned and

maintained.

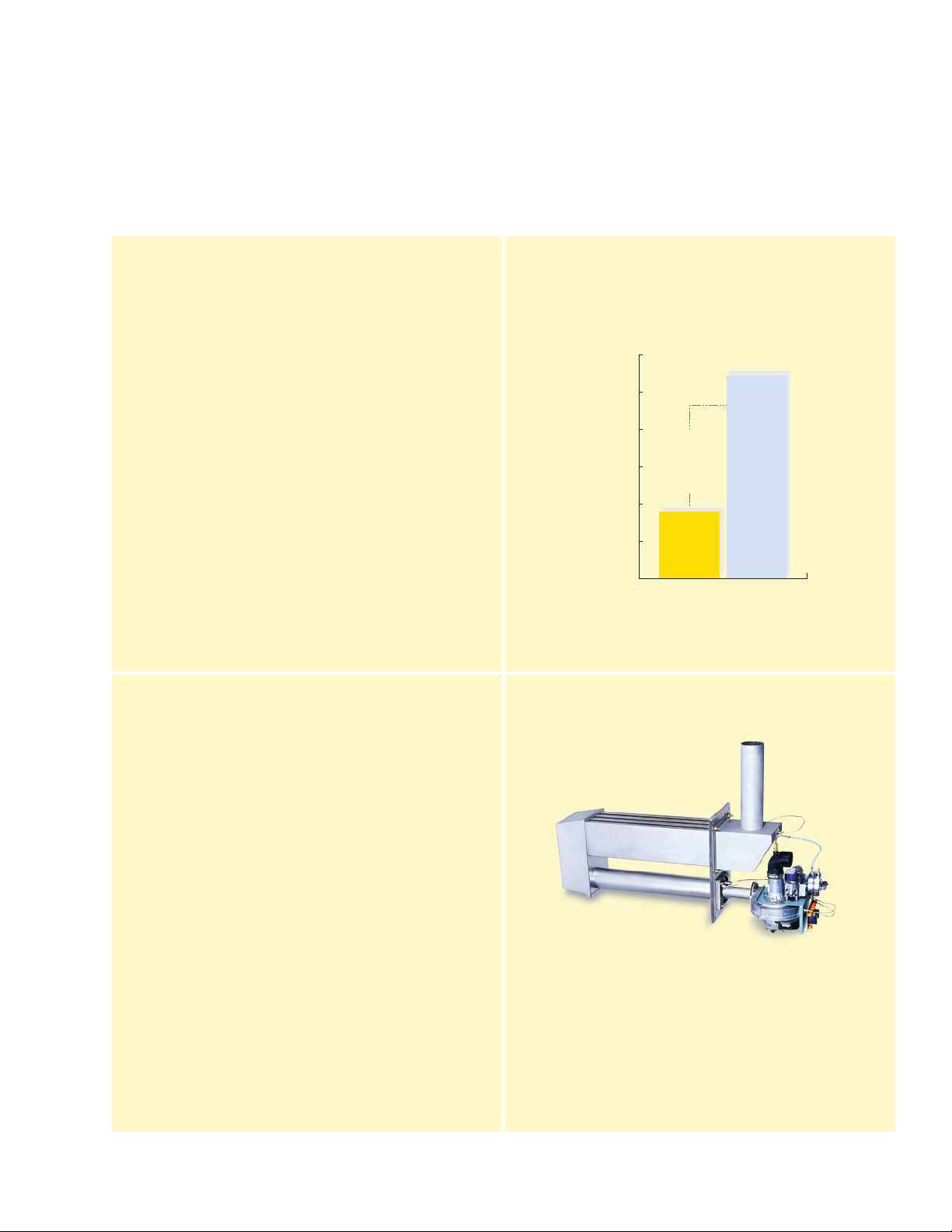

The GS SERIES compact heat exchanger design

provides a minimum footprint area where space

requirement is an issue.

Compact removeable heat exchanger.

105 lbs/hr of clean steam.

3

Page 4

technology

The new generation of GS Series Gas Steam humidifiers gives you more than economical operation. It’s the most versatile

gas humidifier available in the industry. When natural gas or propane is your preferred energy choice, the new GS Series gives

you the options!!! This new humidifier employs a state of the art controller giving networking capability to your engineer and

superior interconnection capabilities. It provides venting and steam distribution flexibility to contractor allowing fast and easy

installation in retrofit or new applications. The integrated troubleshooting guide, smart drain water tempering and pre-cleaning

sequence ensures fast servicing and efficient operation in all conditions.

Low emission gas appliance

▶

Capacity up to 630 lbs/hr with a single unit

▶

Nortec Total Controller

▶

Modbus host protocol

•

Easy to use scroll down menus

•

Stagged modulation of up to 10 units

•

Advanced scale management system with

▶

pre-cleaning sequence

Heavy-duty drain pump for scale removal

▶

Full modulation to 25 lbs/hr (11 kg/hr)

▶

for all capacities

GSTC 100

GS

Series

Gas Steam

Humidifiers

Produces clean, uncontaminated steam

▶

Multiple venting options for easy installation

▶

All components suitable for RO/DI water

▶

Compact flat surface heat exchanger

▶

Internal water tempering for drain water cooling

▶

360º gas burner technology

▶

All service connection outside the cabinet ready

▶

for field connection

Fully insulated tank for efficient operation

▶

™

GS OUTDOOR

ENCLOSURE

4

Page 5

GSTC

The GSTC has a built-in microcomputer with a full size

display that provides instantaneous updating of all

operating parameters. The unit accepts a modulation

control signal from a BAS var ying its output to

meet capacity demand. Models feature a capacity

adjustment of output down to 25 lbs/hr.

The GSP uses status lamps on the front to provide

operating diagnostics. The GSP model can accept a

modulating control signal from building management

systems.

GSP

Features Comparison

Steam Capacity adjustment

Full size alphanumeric display and keypad

Total Controller with Modbus host protocol

Transducer signal acceptance

Individual component diagnostic capability

Keypad set-point adjustment(humidity)

Display of relative humidity

Low and high relative humidity alarms

Adjustable drain with no call for humidity

Keep warm feature

Networking capability up to 10 units

Pre-cleaning sequence

Troubleshooting Guide

Self diagnostic capabilities

Fault history

Smart drain water cooling

On/off cycling prevention

Full tank blowdown capability via timer or external trigger

Board mounted display for fault and demand indication

Parameter change through jumper settings

Remote fault indication

Single or Dual modulation signal acceptance

Industry standard modulation signal acceptance

Time to next maintenance alarm

Internal Drain water cooler

System demand indication

Output display

Precise five level water level indication

Status indicator lamps

Backlit display

B or BH venting options

BH stack vent (outdoor only)

Large Side tank cleaning port

Top access cleaning (300, 400, 500 & 600 lb models)

Single water connections

Turn-down ratio from maximum output to 25lbs/hr(11kg/hr)

Time proportioning below 25lbs/hr(11kg/hr)

120V or 208-240V power supply

Freeze protection

Integral enclosure (outdoor only)

Nortec Links Building Management System capable using BACnet

or LonWorks N2 protocols

Nortec OnLine for web based monitoring and control

Sealed combustion / Direct vent

Floor stand

Distribution Systems

Short Absorption Manifold SAM-e

Steam distributor

Blower pack

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

• •

not req.

keypad

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

•

• •

• •

• •

• •

• •

• •

• •

•

º º

º

º º

º º

º º

º º

º º

GSTC

GSP

•

•

•

= standard

= optional

º

5

Page 6

options

Steam Distributor

Systems

Nortec offers flexible steam distribution choices

to satisfy a wide range of requirements:

Stainless Steel Steam Distributors to

•

distribute atmospheric steam into ducts.

Independant Blower Packs for in space

•

applications (remote mounted).

SAM-e Short Absorption Manifold for use

•

in air handlers or ducts where short steam

absorption distance is critical.

Atmospheric steam distributor

Blower pack

SAM-e Short Absorption Manifold

NORTEC LINKS

NORTEC Links offers monitoring and control

allowing humidifier(s) to communicate to your

Building Management System (BMS). The

controller is factory installed and is located

internally to the humidifier. Simply specify at

time of order what operating protocol you are

using – BACnet IP, BACnet MSTP, LonWorks or

Jonhson N2.

NORTEC OnLine

NORTEC OnLine is a remote interactive

communication package that allows satellite

contacts to monitor, maintain and control

a humidification center from any location

worldwide using standard internet connections.

This advanced software shows graphic

representations of the humidifier and its key

parameters (up to 75 functions).

Customer

www.nortecOnLine.com

Communication through the internet or email.

NORTEC Humidifier

NORTEC Technical Services

6

Page 7

technical data

SPECIFICATION GS 100 GS 200 GS 300 GS 400 GS 500 GS 600

Capacity: lbs/hr

Capacity: kg/hr

Input BTU/hr max

Input kJ/hr max

Flue Emissions Low CO (<10ppm) and NOx (<40ppm)

Unit rated Amps

Voltage/Phase

Unit rated Amps

Voltage/Phase

25-105 25-210 25-315 25-420 25-525 25-630

11-47 11-95 11-143 11-191 11-238 11-286

140,000 280,000 420,000 560,000 700,000 840,000

41 82 124 165 206 247

4 6 8 10 12 14

120V/1 120V/1 120V/1 120V/1 120V/1 120V/1

2 3 4 5 6 7

208-240/1 208-240/1 208-240/1 208-240/1 208-240/1 208-240/1

INSTALLATION FEATURES & REQUIREMENTS

Single point cabinet door fastening for easy removal.

Choice of venting comes standard allowing greater installation flexibility,

B or BH venting.

Cabinet and insulation allows mounting to combustible surfaces for

minimum space requirement.

Exclusive full size cleanout port for fast and easy servicing.

Floor stand optional for GS indoor units.

All service connections exterior to the humidifier ready for field

connections.

120, 208-240V single phase power supply.

Steam outlet configuration ready for duct distributor, remote mounted

blower pack or Short absorption manifold connection.

7

Page 8

U.S.A.

Certificate No. 002419

AxAir Nortec Inc.

826 Proctor Avenue

Ogdensburg, NY 13669

CANADA

AxAir Nortec Ltd.

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

FAX: 613.822.7964

EMAIL: nortec@humidity.com

WEBSITE: www.humidity.com

www.norteconline.com

www.nortecparts.com

U.S. Patent 5,816,496

Canadian Patent 2,203,332

Form 07-289

electric steam — atomizing nozzles — high pressure nozzles — steam injection — steam exchange — gas steam

Printed in Canada Printed on Recycled Paper

Loading...

Loading...