Page 1

INSTALLATION MANUAL

Electrode Steam Humidifier

Nortec EL Series

2582302_C_EN_1611

Humidication and Evaporative Cooling

IMPORTANT! Read and save these instructions. This manual to be left with the equipment.

Page 2

Thank you for choosing Nortec

Installation date (DD/MM/YYYY):

Commissioning date (DD/MM/YYYY):

Site:

Model:

Serial number:

Manufacturer

Nortec Humidity Ltd.

2740 Fenton Road, Ottawa, ON, Canada K1T 3T7

Tel. 1.866.NORTEC1, Fax 613.822.7964

nortec@humidity.com, www.humidity.com

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nortec Humidity Ltd. Neither this document, nor the information contained herein shall be reproduced, used, or disclosed to others without the written

authorization of Nortec Humidity Ltd., except to the extent required for installation, operation or maintenance of

the customer's equipment.

Liability Notice

Nortec Humidity Ltd. does not accept any liability due to incorrect installation, maintenance or operation of the

equipment, or due to the use of parts/components/equipment that are not authorized by Nortec Humidity Ltd.

Copyright Notice

Copyright 2016, Nortec Humidity Ltd, All rights reserved.

Technical modication rights reserved.

Page 3

iiiContents

Nortec EL

2582302_C_EN_1611

Contents

1 Introduction 1

1.1 Before You Start! 1

1.2 General 1

2 For Your Safety 3

3 Receiving and Storage 5

3.1 Inspection 5

3.2 Storage and Transportation 5

4 Product Overview 7

4.1 General Description 7

4.2 Models Overview 8

4.3 Model Designation 8

4.4 Options 9

4.5 Accessories 10

5 Installation 11

5.1 General 11

5.2 Installation Overview 12

5.2.1 Typical Installation for Duct Humidication 12

5.2.2 Typical Installation for Direct Room Humidication 14

5.3 Site Requirements 15

5.4 Mounting the Humidier 16

5.4.1 Location and Clearances 16

5.4.2 Standard Mounting 18

5.4.3 Mounting Using Optional Mounting Bar 20

5.4.4 Mounting to OSHPD Seismic Requirements 22

5.4.5 Mounting Checklist 24

5.5 Steam Line Connections 24

5.5.1 Steam Distribution Using the Air Handling Unit 24

5.5.2 Steam Distribution Using the Blower Pack 24

5.5.2.1 Placement of Humidier 24

5.5.2.2 Remote-Mounted Blower Pack 25

5.5.3 Best Practices for Installing Steam and Condensate Lines 26

5.5.3.1 Common Steam and Condensate Line Installation Mistakes 34

5.5.4 Steam Connections Checklist 35

5.6 Water Connections 36

5.6.1 Water Connections Overview 36

5.6.2 Water Connection Requirements 38

5.6.3 Water Connections Checklist 38

5.7 Humidity Control Systems 39

5.7.1 Control Device Locations 39

5.7.2 Permissible Control Signal Inputs 39

Page 4

iv Contents

2582302_C_EN_1611 Nortec EL

5.8 Electrical Connections 40

5.8.1 General 40

5.8.2 Wiring Diagrams 41

5.8.2.1 Nortec EL Steam Humidier, Steam Cylinder A 41

5.8.2.2 Nortec EL Steam Humidier, Steam Cylinder B (Large Units Only) 43

5.8.3 External Connections 44

5.8.3.1 3-Phase Power Supply Connection 44

5.8.3.2 Single-Phase Power Supply Connection 45

5.8.3.3 External Safety Chain 46

5.8.3.4 Modulating Demand or Humidity Signal 47

5.8.3.5 Ohmic Humidity Controller (Passive) 48

5.8.3.6 24V On/Off Humidistat 49

5.8.3.7 External On/Off Input 49

5.8.3.8 Dual Steam Cylinders Control Wiring 50

5.8.3.9 Remote Relay PCB Connections 51

5.8.3.10 Accessory Relay PCB Connections 52

5.8.3.11 Modbus Connection 53

5.8.4 Connecting Multiple Units Using Linkup 54

5.8.5 Maximum External Fuse 55

5.8.6 Electrical Connections Checklist 57

6 ProductSpecications 59

6.1 Weights 59

6.2 Dimensions 60

A Appendix i

A.1 Installation Checklist i

B Appendix iii

B.1 Commissioning Checklist iii

B.1.1 Pre-Start-Up Checklist iii

B.1.2 Performance Checklist vi

Page 5

1Introduction

Nortec EL

2582302_C_EN_1611

1 Introduction

1.1 Before You Start!

Thank you for purchasing the Nortec EL steam humidier.

The Nortec EL steam humidier incorporates the latest technical advances and meets all recognized

safety standards. Never-the-less, improper use of the Nortec EL steam humidier may result in danger

to the user or third parties, and/or damage to property.

To ensure safe, proper and economical operation of the Nortec EL steam humidier, observe and comply

with all information and safety instructions contained in this manual, as well as all relevant documentation of components of the installed humidication system.

If you have additional questions, contact your local Nortec representative. They will be glad to assist you.

1.2 General

Limitations

The subject of this manual is the Nortec EL steam humidier. The various options and accessories

may only be described in-so-far as is necessary for proper installation and operation of the equipment.

Additional information on available options and accessories can be obtained in the instructions that are

supplied with them.

This manual is restricted to the installation of the Nortec EL steam humidier, and is intended for well

trained personnel who are suitably qualied for their respective tasks.

Symbols Used in This Manual

CAUTION!

The word "CAUTION" in conjunction with the general caution symbol is used to provide safety

instructions that, if neglected, may cause damage and/or malfunction of the unit or damage to

property.

WARNING!

The word "WARNING" in conjunction with the general warning symbol is used to provide safety

instructions that, if neglected, may cause injury to personnel. Other specic warning symbols may

also be used in place of the general symbol.

DANGER!

The word "DANGER" in conjunction with the general danger symbol is used to provide safety

instructions that, if neglected, may cause severe injury to personnel or even death. Other specic

danger symbols may also be used in place of the general symbol.

Page 6

2 Introduction

2582302_C_EN_1611 Nortec EL

Other Related Publications

This installation manual is supplemented by other publications such as the operation and maintenance

manual, spare parts list, etc., which are included in the delivery of the equipment. Where necessary,

appropriate cross-references to these publications have been added in this manual.

Storage of Manual

Keep this manual in a place where it is safe and readily accessible. If the equipment is moved to another

location, make sure that the manual is passed on to the new user.

If the manual is lost or misplaced, contact your local Nortec representative for a replacement copy.

.

Page 7

3For Your Safety

Nortec EL

2582302_C_EN_1611

2 For Your Safety

General

Every person who is tasked with the installation of the Nortec EL steam humidier must read and understand this manual before performing any work. Knowing and understanding the contents of the installation manual and the operation and maintenance manual is a basic requirement for protecting personnel

against any kind of danger, preventing faulty operation, and operating the unit safely and correctly.

All labels, signs and marking applied to the Nortec EL steam humidier must be observed and kept in

a readable state.

PersonnelQualications

All procedures described in this manual must only be performed by personnel who are adequately qualied, well trained and are authorized by the customer.

For safety and warranty reasons, any activity beyond the scope of this manual must only be performed

by qualied personnel authorized by Nortec.

All personnel working with the Nortec EL steam humidier must be familiar with, and comply with the

appropriate regulations on workplace safety and prevention of accidents.

Intended Use

The Nortec EL steam humidier is intended exclusively for air humidication using a Nortec-approved

steam distributor or blower pack within specied operating conditions (refer to the Operation and

Maintenance Manual for details). Any other type of application, without the express written consent of

Nortec, is considered to be not conforming to its intended purpose, and may lead to dangerous operation and will void the warranty.

In order to operate the equipment in the intended manner all information contained in this manual, in

particular the safety instructions, must be observed closely.

DangersthatmayarisefromtheNortecELsteamhumidier:

DANGER!

Risk of electric shock!

The NortecELsteamhumidierismainspowered.Livepartsmaybeexposedwhenthedoor

panels are removed. Touching live parts may cause severe injury or even death.

Prevention: The Nortec EL steam humidier must be connected to the mains only after all installa-

tion work has been completed, checked for correct workmanship, and the door panels are installed

and fastened securely.

WARNING!

Risk of severe burns from exposure to hot steam vapors!

The Nortec EL steam humidier uses hot steam vapors for humidication. Bare skin exposed to hot

steam vapors can result in severe burns.

Prevention: Avoid contact with hot steam. Or, wear appropriate personal protective equipment

when working near steam vapors.

Page 8

4 For Your Safety

2582302_C_EN_1611 Nortec EL

Preventing Unsafe Operation

All personnel working with the Nortec EL steam humidier must immediately report to the customer any

alterations to the unit that may affect safety, and securethehumidieragainstaccidentalpower-up.

ModicationstotheUnitProhibited

Modicationsarenotpermitted on the Nortec EL steam humidier without the express written consent

of Nortec.

Page 9

5Receiving and Storage

Nortec EL

2582302_C_EN_1611

3 Receiving and Storage

3.1 Inspection

After receiving the shipment, inspect the goods as follows:

– Inspect the shipping boxes for damage.

Report any shipping box damages to the shipping company without delay.

– Check the goods against the packing slip to ensure that all items have been delivered.

Report any shortages to your Nortec representative within 48 hours of receipt of the goods. Nortec

does not assume responsibilities for any shortages beyond this period.

– Unpack the parts/components and check for any damage.

If parts/components are damaged, notify the shipping company immediately.

– Verify the model type on the rating label to ensure that it is suitable for your installation. Refer to

Figure 3 on page 9.

3.2 Storage and Transportation

Storage

Store the Nortec EL steam humidier in its original packaging inside a protected area that meets the

following requirements until it is installed, or if it needs to be stored for an extended period of time:

– Room temperature: 41 to 104 °F (5 to 40 °C)

– Room humidity: 10 to 75% RH

Transportation

For optimum protection always transport the unit and components in their original packaging, and use

appropriate lifting/transporting devices.

Packaging

Keep the original packaging of the unit/components for later use.

If the packaging needs to be disposed off, observe local regulations on waste disposal. Recycle packaging where possible.

Page 10

6 Receiving and Storage

2582302_C_EN_1611 Nortec EL

This page intentionally left blank

Page 11

7Product Overview

Nortec EL

2582302_C_EN_1611

4 Product Overview

4.1 General Description

The Nortec EL steam humidier is an advanced electrode steam humidier with state-of-the-art features.

It has an integrated controller which not only controls the humidier, but also allows the humidier to be

connected to a building automation system, or an off-line computer, so it can be controlled and monitored remotely.

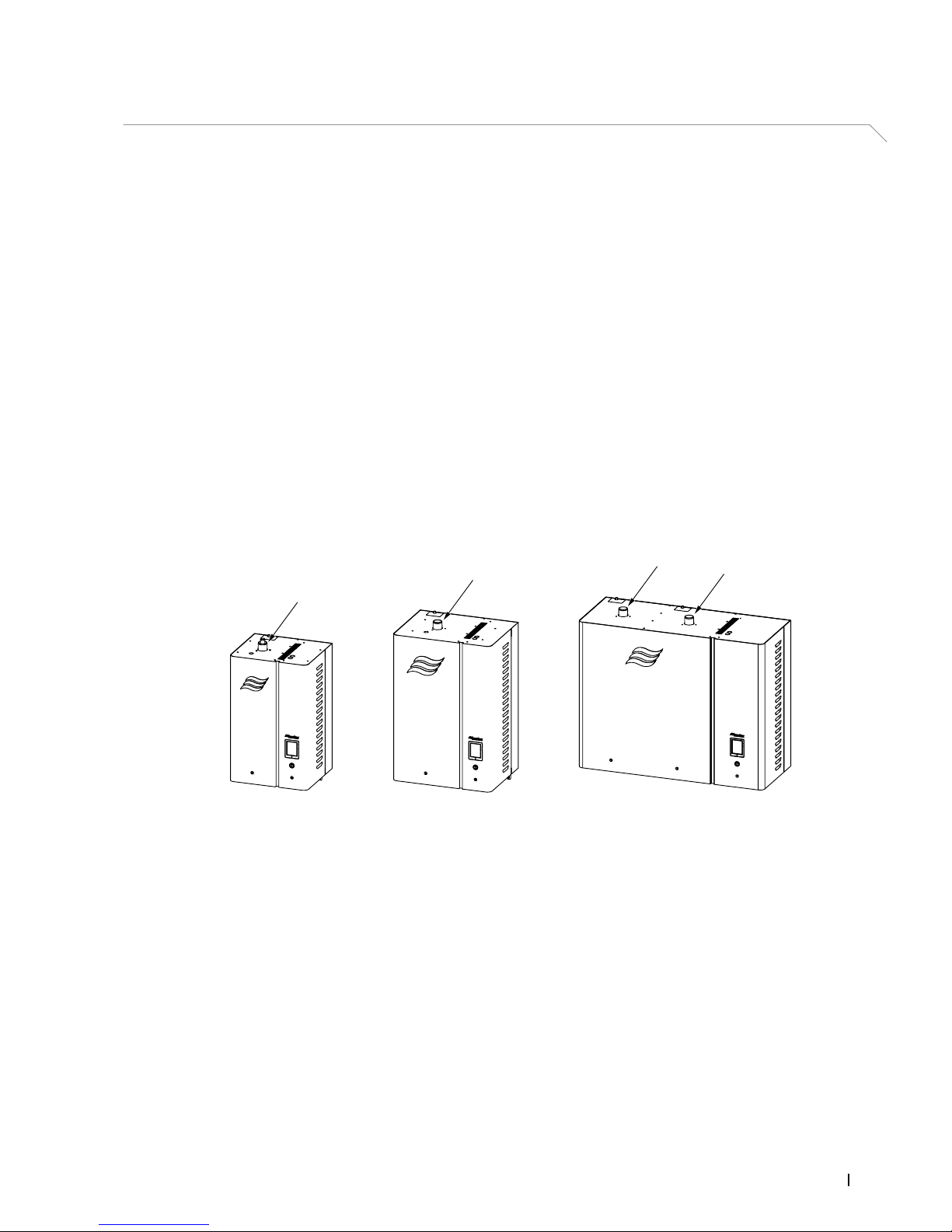

The Nortec EL steam humidier comes in three different housing sizes depending on the steam capacity. Refer to Figure 1. These units can range from 5 lb/h (2.2 kg/h) to 200 lb/h (91 kg/h) – refer to "Models

Overview" on page 8. Models with steam capacity up to 100 lb/h (45 kg/h) can also be ordered with a

built-on blower pack. The large models, with steam capacity from 150 lb/h (68 kg/h) to 200 lb/h (91 kg/h),

are equipped with dual steam cylinders – each with its own dedicated driver board.

The dedicated driver boards in the large models allow the steam cylinders to be congured to operate in

series, in parallel or independent mode. Two separate sets of control signals are needed for independent mode of operation. In series mode, the output capacity of steam cylinder "A" is congured to 0-50%

of humidier demand, and steam cylinder "B" to 50-100% of humidier demand. In parallel mode, the

output capacity of each steam cylinder is congured to 0-100% of humidier demand.

In addition, up to six integrated controllers (for a maximum of 12 steam cylinders) can be set up in a

"main-extension" conguration using Nortec's Linkup system to satisfy large humidication needs.

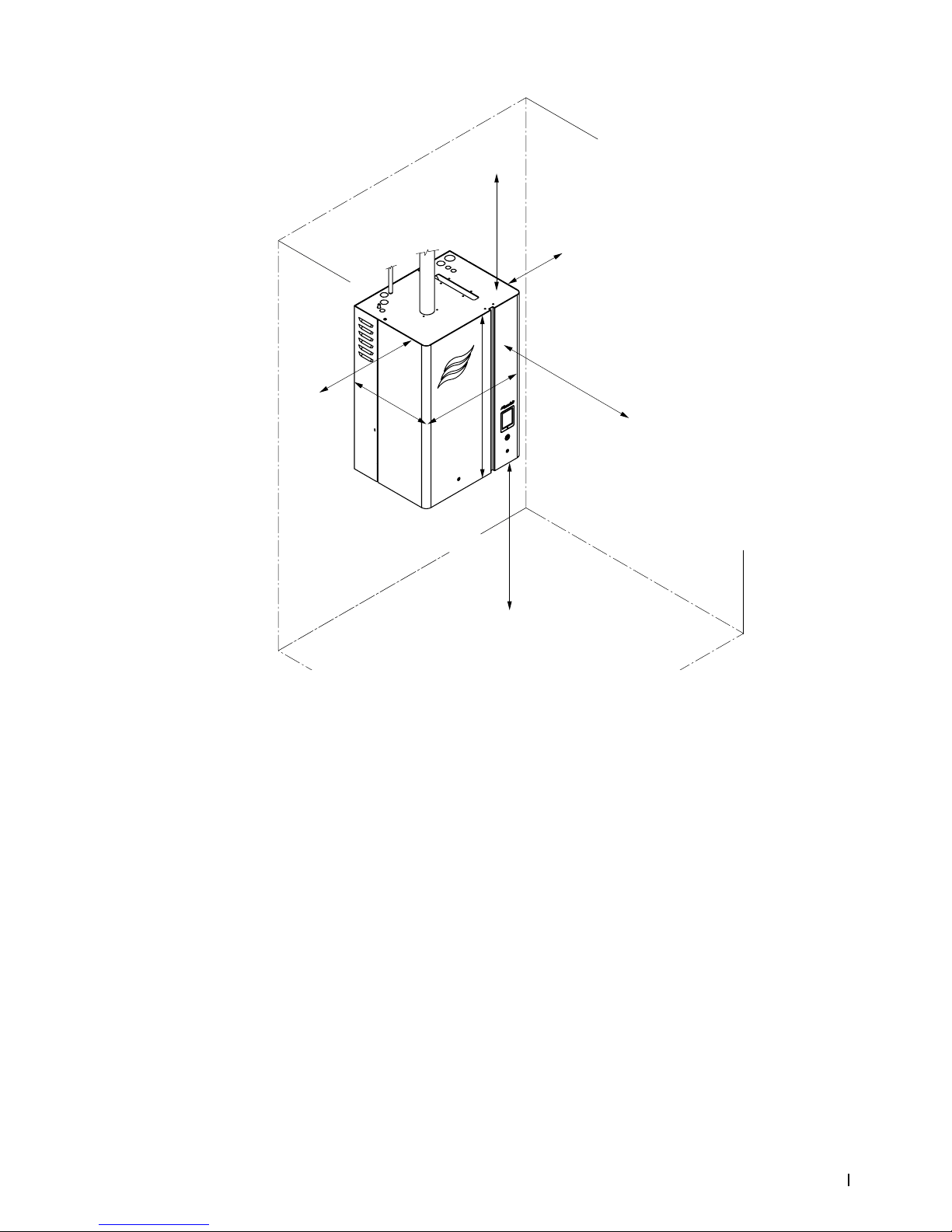

Figure 1:

1

2

3

4

Nortec EL Steam Humidier Model Sizes

1 Small model, steam cylinder "A" only

2 Medium model, steam cylinder "A" only

3 Large model, steam cylinder "B"

4 Large model, steam cylinder "A"

Page 12

8 Product Overview

2582302_C_EN_1611 Nortec EL

4.2 Models Overview

The Nortec EL steam humidier is available in different sizes (S, M and L) with different heating voltages

and steam capacities as shown in Table 1 below.

Table 1: Nortec EL Steam Humidier Models

Housing

Size

Nortec EL

Model

110-

120V/1~

208V/1~

220-

240V/1~

277V/1~

380-

415V/1~

440-

480V/1~

550-

600V/1~

208V/3~

220-

240V/3~

380V/3~

440-

480V/3~

550-

600V/3~

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

lb/h

(kg/h)

S 005 5

(2.2)

– – – – – – – – – – –

010 – 10

(4.5)10(4.5)10(4.5)10(4.5)10(4.5)10(4.5)

– – – – –

020 – 20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

20

(9)

030 – – – – – – 30

(13.6)30(13.6)30(13.6)30(13.6)30(13.6)

M 050 – – – – – – 50

(22.7)50(22.7)50(22.7)50(22.7)50(22.7)

075 – – – – – – 75

(34)75(34)75(34)75(34)75(34)

100 – – – – – – 90

(41)

100

(45)

100

(45)

100

(45)

100

(45)

L 150* – – – – – – 150

(68)

150

(68)

150

(68)

150

(68)

150

(68)

200* – – – – – – 180

(82)

200

(91)

200

(91)

200

(91)

200

(91)

* These models have two steam cylinders.

4.3 Model Designation

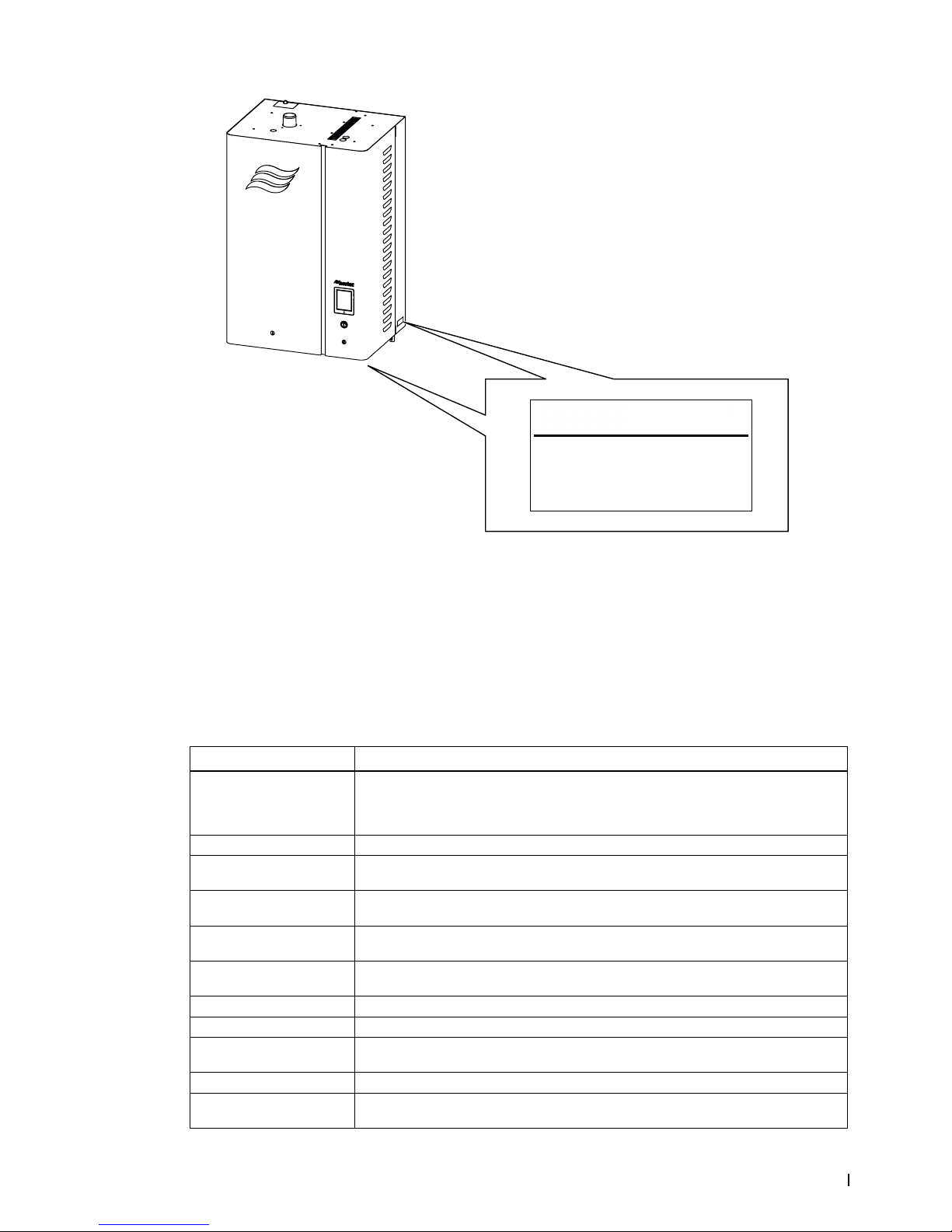

The specication label on the side (and the underside) of the Nortec EL steam humidier shows its model

number, serial number and ratings – refer to Figure 3 on page 9. The breakdown of the model number

is shown in Figure 2. For other details of the specication label refer to the Operation and Maintenance

Manual.

Figure 2:

Nortec EL 100 400V/3~Space

Product series:

Steam capacity (lb/h):

Model:

Blank = Duct

Space = with Blower Pack

RMBP = with power for remote-mounted Blower Pack

Heating voltage and phase:

Model Breakdown

Page 13

9Product Overview

Nortec EL

2582302_C_EN_1611

Figure 3:

Circuit Protection

MADE IN CANADA

HUMIDIFIER

LISTED

205X

MODEL:

VOLTS:

AMPS:

KW:

MAX:

XXXXXXXXXXXXXXXXXXXXXXXX

S/N:

XXXXXXX

XXXXXXXXXXXX

PHASE:

XXXX

HZ:

XXXXXX

XXXXX

XXXXXXXXX

XXX

DATE:

XXXXXXXXX

XXXXXXXX B

AMPS

Nortec EL Steam Humidier Specication Label

4.4 Options

Table 2 shows the list of options for the Nortec EL steam humidier. Contact your Nortec representative

for details.

Table 2: Nortec EL Options

Option Application

Mounting bar Provides two mounting bars which t into each other for wall mounting. One bar is fastened

to the humidier, the other bar is fastened to the wall. The unit can be hung onto the wall by

engaging the two mounting bars. Note: The unit can also be wall mounted (without this option) using the keyhole cutouts on the back of the humidier housing.

Mounting rack Stand-alone rack for mounting the Nortec EL steam humidier.

Remote fault indication PCB

(printed circuit board)

Printed circuit board with relay contacts for connecting remote status displays for “Unit On”,

“Steam”, “Error” and “Service”.

Accessory relay PCB

(printed circuit board)

Printed circuit board with relay contacts for connecting other accessories such as fans and

supply water ushing valves.

Internal primary fusing Optional internal fuse for heating voltage power supply. Only available as a factory-installed

option. Note: This is not a substitute for a dedicated external disconnect switch.

Fill cup extension Kit for extending the ll cup so the humidier can accommodate backpressure of up to

10 in H20 (2.49 kPa).

Extreme drain water cooling Kit for cooling drain water to less than 120°F (49°C) before it is discharged into the drain.

Foam detection kit Kit for extending the ability of the humidier to handle a wider range of water supply quality.

BACnet MSTP BTL PCB to provide BTL certied BACnet MSTP. This option also enables full Master functionality

when using BACnet MSTP.

BACnet IP BTL PCB to provide BTL certied BACnet IP.

LonWorks board Supplementary board to connect the Nortec EL to a building management system using

LonWorks.

Page 14

10 Product Overview

2582302_C_EN_1611 Nortec EL

Option Application

Remote blower pack power

kit

When a remote blower pack is being installed with the humidier, this option provides a

transformer, fusing, and a terminal block inside the humidier to provide power to the remote

blower pack. Without this option, a separate 110-120V supply must be provided for the

remote blower pack.

4.5 Accessories

Table 3 shows the list of accessories for the Nortec EL steam humidier. Contact your Nortec representative

for details. To install and operate the accessories, refer to the instructions supplied with the accessories.

Table 3: Nortec EL Accessories

Accessory Application

Steam distributor Steam distribution system for use in an air duct.

SAM-e steam distribution

manifold

Steam distribution system for use in an air duct where reduced absorption distance is required.

Blower pack, built-on or

remote

For direct room humidication or use in conditioned spaces without a built-in air distribution

system. The EL Space model has a blower pack mounted directly, the EL RMBP model has

power for a remote-mounted blower pack (blower pack ordered as an accessory).

Digital or analog control

humidistat with either On/Off

or modulating operation

Input device used to meter the output of the humidier based on the sensed relative humidity.

The humidistat can be installed in the conditioned space that is being humidied, or within

the duct.

Digital RH transducer Input device used to communicate the relative humidity in a conditioned space or a duct to

the humidier.

Digital or analog high limit

humidistat with either On/Off

or modulating operation

Input device used to limit the output of the humidier by either shutting it down or throttling it

down when the humidity in the duct approaches the high limit.

Air proving switch Input device to ensure that humidication only occurs when air is moving through the duct.

Outdoor temperature sensor Input device used to communicate the outdoor temperature to the humidistat so that it can

lower the setpoint value during cold weather to prevent condensation on exterior windows/

surfaces.

Page 15

11Installation

Nortec EL

2582302_C_EN_1611

5 Installation

5.1 General

Strictly observe and perform all installation tasks including the mounting of the unit and connection of

the water, steam and power supplies as described in this manual.

Observe and comply with all local and national codes dealing with water, steam and electrical installations.

Nortec does not accept any liability for installation of humidication equipment by unqualied personnel,

or the use of equipment/parts that are not authorized by Nortec.

PersonnelQualications

All installation work must be performed only by licensed personnel authorized by the customer. It is the

customer’s responsibility to verify qualications of the personnel.

Safety

Observe the following safety precautions:

DANGER!

Risk of electric shock!

The Nortechumidierismainspowered.Livepartsmaybeexposedwhenthedoorpanels

are open. Touching live parts may cause severe injury or even death.

Prevention: The Nortec humidier must be connected to the mains only after all installation work

has been completed, checked for correct workmanship, and the door panels are closed and fastened securely.

CAUTION!

Risk of damage to internal components from electrostatic discharge (ESD)!

Theelectroniccomponentsinsidethehumidieraresensitivetoelectrostaticdischarge

(ESD).

Prevention: Take appropriate measures to protect the electronic components inside the unit against

damage caused by electrostatic discharge (ESD). Refer to ANSI/ESD-S20.20.

Page 16

12 Installation

2582302_C_EN_1611 Nortec EL

5.2 Installation Overview

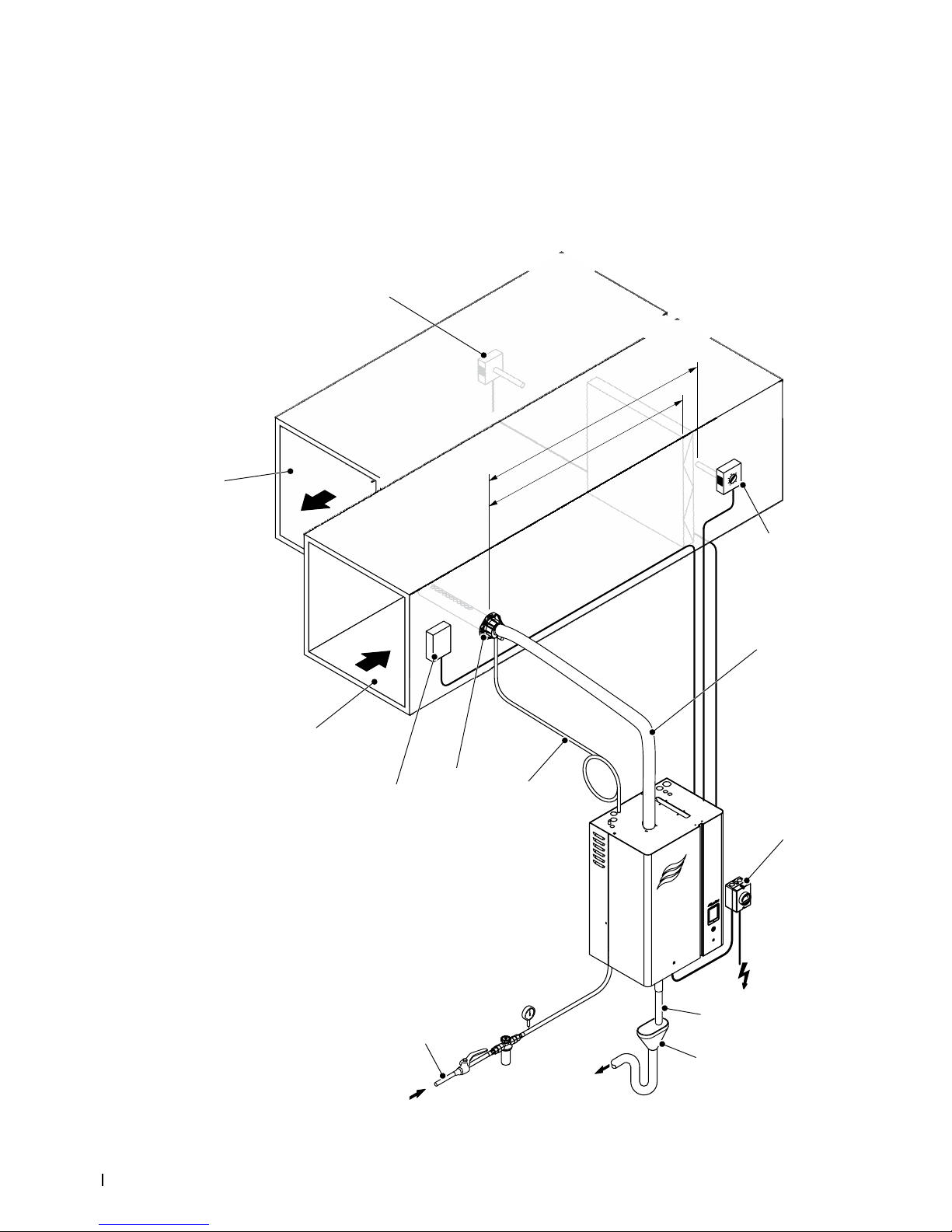

The Nortec EL humidier can use a steam distributor to distribute steam through air ducts – refer to

Figure 4. The humidier can also use a blower pack to distribute steam directly into a conditioned space

– refer to Figure 5 on page 14.

5.2.1 TypicalInstallationforDuctHumidication

Figure 4:

min. 10 ft (3m)

B or min. 8-10 ft (2.4-3m)

n

1, 2

4

5

6

7

8

9

10

12

13

2, 3

11

Typical Installation for Duct Humidication

Page 17

13Installation

Nortec EL

2582302_C_EN_1611

Legend:

1 High limit On/Off humidistat (external safety chain)

2 Humidity sensor or modulating humidistat (used for control of space in return duct, or high limit in supply duct)

3 On/Off humidistat (used for humidity control)

4 Steam line (see Note 1 below)

5 Electrical disconnect, high voltage supply

6 Drain line (see Note 2 below)

7 Air gap with optional trap (see Note 3 below)

8 Water supply (see Note 4 below)

9 Condensate line (see Note 5 below)

10 Steam distributor (see Note 6 below)

11 Air proving switch (external safety chain)

12 Supply air duct

13 Return air duct

Note1: The steam line should be as short as possible – the maximum length varies depending on unit

capacity and material used (refer to Table 6 on page 28). The steam line should have adequate upslope

(minimum 10°) /downslope (minimum 2°), without restrictions and with a condensate trap at the lowest

point. Steam traps are required every 15 ft (5 m) for long runs. The steam line must rise a minimum of

12 in (30 cm) straight up before running to the steam distributor. The minimum bend radius for steam

hose is 12 in (30 cm), or 5× the internal diameter for rigid pipes. Refer to Table 6 on page 28 for steam

line recommendations.

Note2: The drain line should have a minimum internal diameter of 7/8 in (22 mm), with a constant

minimum downslope of 1 in/48 in (1.2°) to the funnel, and must not touch the sides or bottom of funnel.

Note3: The air gap and trap should be located to the left of the humidier, as shown. A 2-1/2 in to 7/8 in

(63.5 mm to 22 mm) reducer is ideal (Nortec option P/N 2522172). The hose must not touch the bottom

of the funnel.

Note4: Water supply should be potable drinking water, with conductivity of 150-1200 micro-siemens/

cm (0-12 gpg). The water supply line should have a minimum diameter of 1/2 in (13 mm) with a shutoff

valve. An optional 5 μm lter is also recommended. Water temperature should be 34-104°F (1-40°C).

Pressure should be surge-free and regulated to 30-80 psig (207-550 kPa).

Note5: Condensate drain line from the steam distributor should have a constant minimum downslope

of 1 in/48 in (1.2°), with no restrictions and a minimum trap height of 8 in (200 mm). The trap should be

located a minimum of 12 in (30 cm) below the steam distributor.

Note6: The distance from the steam distributor to any obstruction or transition in the duct should be

equal to the calculated absorption distance B

n

or a minimum of 8-10 ft (2.4-3 m) if Bn is not known. For

details refer to the installation manual for the relevant steam distribution system. The absorption distance

can be obtained using Nortec HELP. The steam distributor capacity must equal or exceed the maximum

capacity of the humidier.

Page 18

14 Installation

2582302_C_EN_1611 Nortec EL

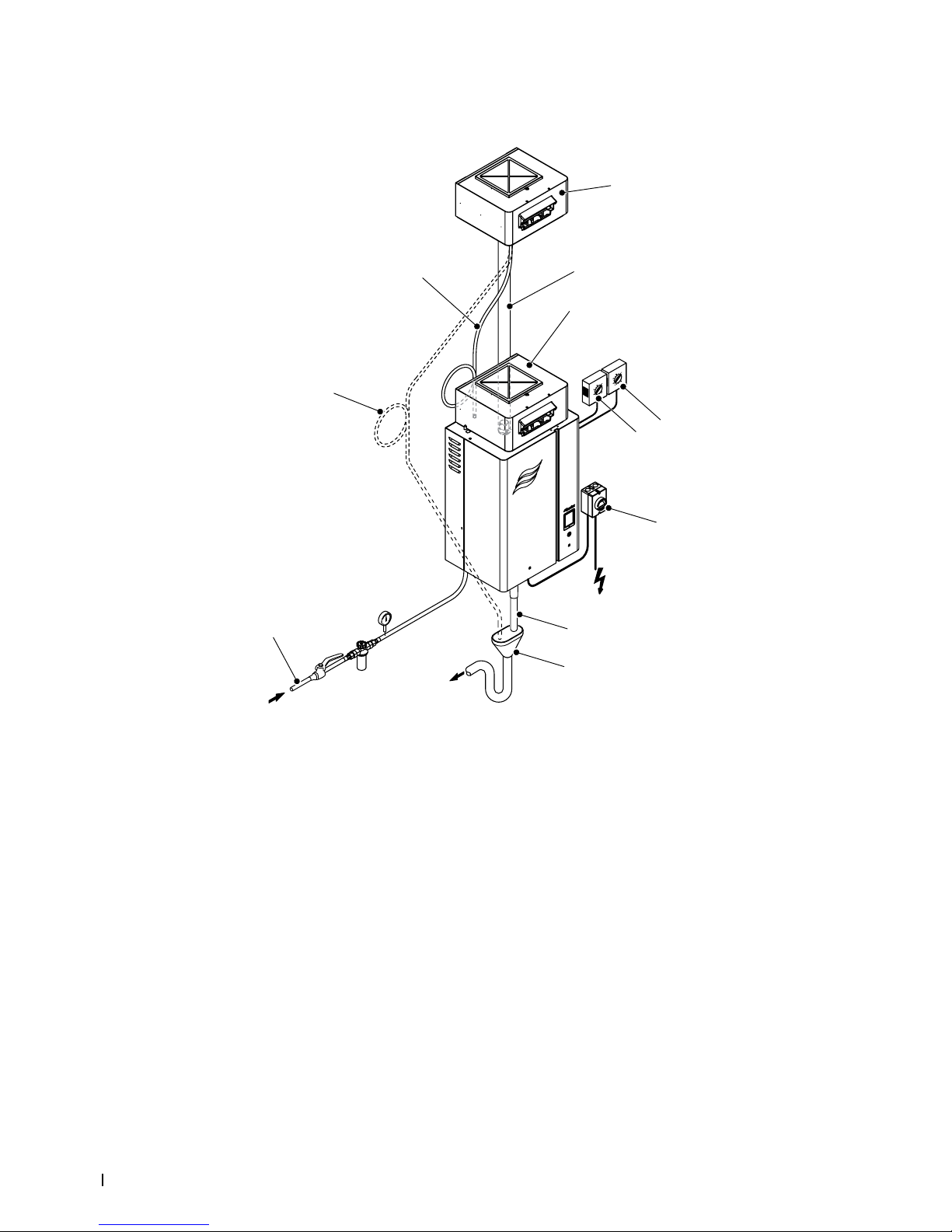

5.2.2 TypicalInstallationforDirectRoomHumidication

Figure 5:

1

2

3

4

5, 6

7

8

9

10

11

12

Typical Installation for Direct Room Humidication

1 Blower pack, remote-mounted

2 Steam line (see Note 1 below)

3 Blower pack, built-on

4 High level On/Off humidistat (external safety chain)

5 Humidity sensor or humidistat (used for control of space humidity or high limit)

6 On/Off humidity control

7 Electrical disconnect, high voltage supply

8 Drain line (see Note 2 below)

9 Air gap with optional trap (see Note 3 below)

10 Water supply (see Note 4 below)

11 Condensate drain line (routed to oor drain, see Note 5 below)

12 Condensate drain connection through ll cup to steam cylinder (for remote blower pack)

Note1: The steam line should be as short as possible – the maximum length varies depending on unit

capacity and material used (refer to Table 6 on page 28). The steam line should have adequate upslope

(minimum 10°) /downslope (minimum 2°), without restrictions and with a condensate trap at the lowest

point. Steam traps are required every 15 ft (5 m) for long runs. The steam line must rise a minimum of

12 in (30 cm) straight up before running to the steam distributor. The minimum bend radius for steam

hose is 12 in (30 cm), or 5× the internal diameter for rigid pipes. Refer to Table 6 on page 28 for steam

line recommendations.

Page 19

15Installation

Nortec EL

2582302_C_EN_1611

Note2: The drain line should have a minimum internal diameter of 7/8 in (22 mm), with a constant minimum downslope of 1 in/48 in (1.2°) to the funnel, and must not touch the side or bottom of the funnel.

Note3: The air gap and trap should be located to the left of the humidier, as shown. A 2-1/2 in to 7/8 in

(63.5 mm to 22 mm) reducer is ideal (Nortec option P/N 2522172). The hose must not touch the bottom

of the funnel.

Note4: Water supply should be potable drinking water, with conductivity of 150-1200 micro-siemens/

cm (0-12 gpg). The water supply line should have a minimum diameter of 1/2 in (13 mm) with a shutoff

valve. An optional 5 μm lter is also recommended. Water temperature should be 34-104°F (1-40°C).

Pressure should be surge-free and regulated to 30-80 psig (207-550 kPa).

Note5: For remote-mounted blower pack, the condensate line can be routed to either an external drain

or to the ll cup of the humidier. The condensate drain line from the blower pack should have a constant

minimum downslope of 1 in/48 in (1.2°), with no restrictions and a minimum trap height of 8 in (200 mm).

The trap should be located a minimum of 12 in (30 cm) below the condensate port on the blower pack.

5.3 Site Requirements

In preparation for installation of the Nortec EL steam humidier, make sure that the following site requirements are satised. Report any discrepancies to the site engineer.

SteamandCondensateLines:

When choosing the location of the humidier, install it as close as possible to the steam distributor

to minimize heat loss through the steam line.

When possible, install the humidier below the steam distributor. Make sure that the selected loca-

tion permits proper routing of steam and condensate lines as described in "Best Practices for Installing

Steam and Condensate Lines" on page 26.

Mounting

Allow adequate clearances around the humidier for ease of maintenance. Although the

Nortec EL steam humidier requires no side clearance, Nortec recommends minimum clearances

of 6 in (150 mm) on the side. A 24 in (610 mm) clearance between the humidier and the ground is

required. Observe all local and national installation codes. Nortec is not responsible for any installation code violations.

Do not mount the humidier on hot surfaces, or surfaces that can freeze, or near vibrating compo-

nents, or on the oor. In addition, the mounting surface must be able to withstand temperatures of

140-158°F (60-70°C) that can be generated during operation of the humidier.

The humidier should be mounted on a wall or other suitable surface that offers a sufciently high

load-bearing capacity. Refer to Table 15 on page 59 for operating weights.

The Nortec EL steam humidier should be installed in a drip-proof location within buildings, where

the ambient temperature is 41-104°F (5-40°C) and the relative humidity is 5-95% (non-condensing).

Water Supply

The water supply to the humidier must be cold potable drinking water, and not reverse osmosis

(RO) or deionized (DI) water. The water quality requirements are listed in Table 4 below.

Table 4: Water Quality Requirements

Conductivity

(μS/cm)

Hardness

(gpg)

Silica

(ppm)

Alkalinity

(pH)

150-1200* 0-12 0-4 7-7.5

0-3 4-14

* Default humidier conguration supports approximately 330-670 μS/cm.

The water supply should have a minimum ow rate of 0.9 gpm (3.3 L/min), and should be pressure

regulated to 30-80 psig (207-550 kPa), with spike pressure limited to 120 psig (827 kPa).

The water supply should be ltered to 5 μm (optional, but recommended).

Page 20

16 Installation

2582302_C_EN_1611 Nortec EL

Water temperature should be 34-104°F (1-40°C).

The diameter of the water supply piping should be minimum 1/2 in (13 mm), and must have a 1/2 in

NPT female end.

The water supply line should be made of copper, stainless steel or plastic certied for drinking water

systems.

A shutoff valve and a union tting must be supplied in the water supply line for ease of maintenance.

The water supply should be free of additives such as corrosion inhibitors, disinfectants, etc., which

may affect the performance of the humidier. If using softened or partially softened water, contact

your Nortec representative for assistance.

Drainage

The humidier should be connected to a dedicated building drain (recommended) with a minimum

drainage rate of 2.3 gal/min (8.7 L/min) per steam cylinder. For safety reasons, drain water from the

humidier should not empty into a sink used by personnel. The drain line must allow free and easy

draining. A restricted drain can cause water in the humidier to over-concentrate and result in poor

operation, or cause water to back up at the air gap funnel.

The building drain pipe should be made of either copper or stainless steel (minimum DIN 1.4301)

so it can handle drain water temperatures up to 212 °F (100 °C).

The space in which the humidier is to be installed should have a oor drain. However, if a oor drain

is not available, a leakage monitoring device must be installed (by others) to permit interruption of

the water supply in case of a leakage.

Power Supply

The power supply to the humidier should be adequate to match the full voltage and current draw

shown on the specication label of the humidier.

The power supply must have an external dedicated fused disconnect switch. The fusing must not

exceed the maximum circuit protection indicated on the specication label. Refer to Figure 3 on page 9.

5.4 MountingtheHumidier

Refer to "Site Requirements" on page 15 for the location and mounting requirements for the

Nortec EL steam humidier.

5.4.1 Location and Clearances

The location of the humidier depends largely on the steam distribution system. For the required minimum

clearances for a Nortec EL steam humidier with a built-on blower pack refer to "Placement of Humidier" on

page 24; or refer to the blower pack manual for a remote-mounted blower pack.

For all other steam distribution systems refer to Figure 6. The clearance dimensions shown are for reference only, and are suggested clearances for ease of maintenance. Consult local and national installation

codes. Nortec does not accept responsibility for violations of the installation codes.

Page 21

17Installation

Nortec EL

2582302_C_EN_1611

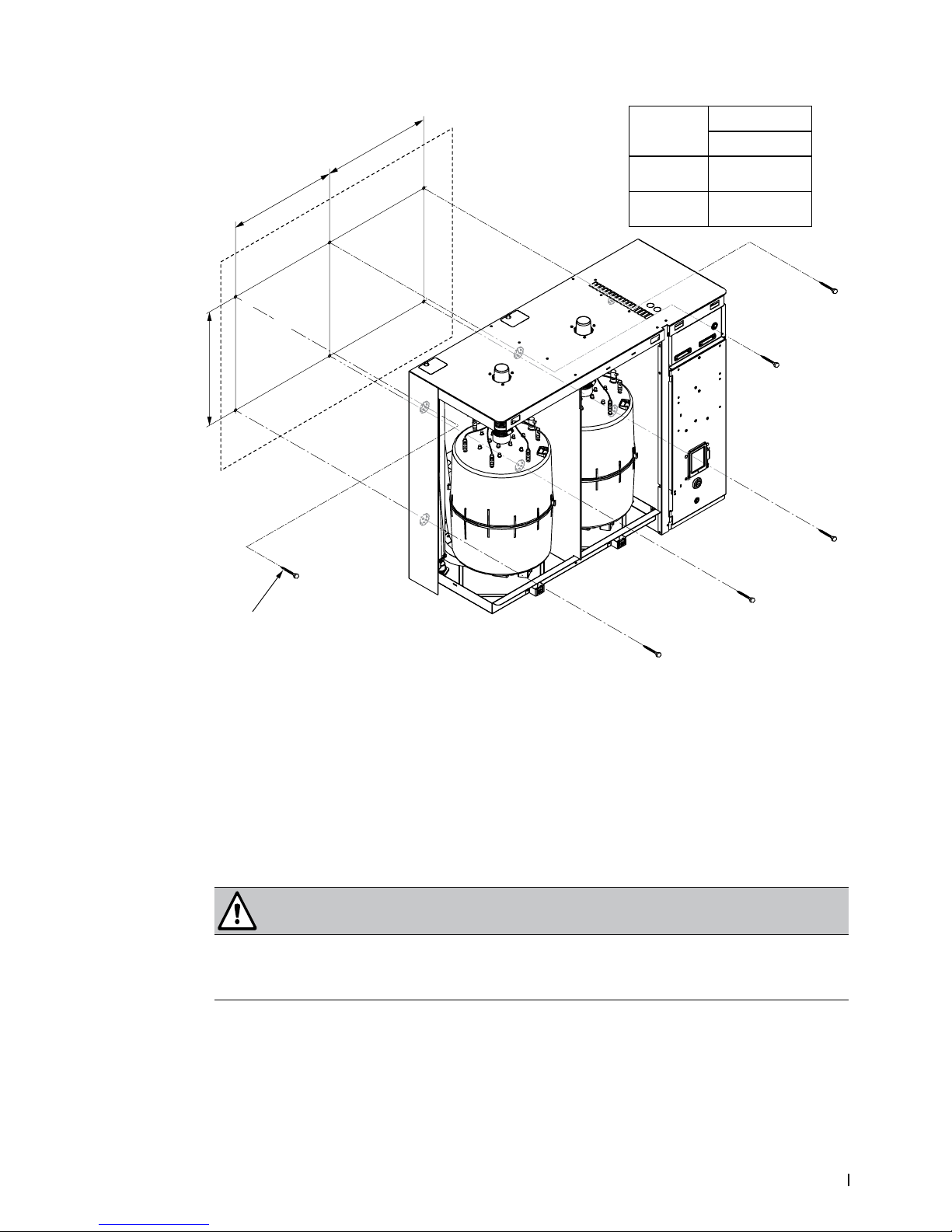

Figure 6:

W

D

H

0 in

(0 mm)

min. 24 in

(610 mm)

min. 12 in

(300 mm)

min. 36 in

(915 mm)

0 in

(0 mm)

Nortec EL Humidier Suggested Clearances

Page 22

18 Installation

2582302_C_EN_1611 Nortec EL

5.4.2 Standard Mounting

Locate the Nortec EL humidier according to "Location and Clearances" on page 16, and install it on the

mounting surface as follows:

1. Locate 2×4 wooden studs or equivalent support in the mounting surface, and mark the attachment

points “A” and “B” at the desired position with the help of a level. For small or medium housing refer

to Figure 7. For large housing refer to Figure 8 on page 19.

Figure 7:

A

A

B

B

X

Y

1

Standard Mounting, Small or Medium Housing

1 Lag bolt, 1/4×2 in (×4)

Dimension

Housing Size

Small Medium

X 12.0 in

(305 mm)

16.0 in

(406 mm)

Y 17.56 in

(446 mm)

20.71 in

(526 mm)

Page 23

19Installation

Nortec EL

2582302_C_EN_1611

Figure 8:

X

A

A

A

B

B

B

X

Y

1

Standard Mounting, Large Housing

1 Lag bolt, 1/4×2 in (×6)

2. Install 1/4×2 in lag bolts (supplied by others) at attachment points "A". Use longer screws if going

through drywall or other structural material into the mounting surface. Allow the heads of the screws to

extend 0.25 in (5 mm) from the mounting surface so that the humidier can be installed on the bolts.

3. Remove the door panels from the humidier.

WARNING!

Heavy object – risk of injury!

Thesmallhumidierweighs45lb(20kg),andthelargehumidierweights120lb(54kg).

Prevention: Use an appropriate lifting device, or request assistance to raise the humidier into

position.

4. Carefully raise and install the humidier onto the installed lag bolts.

5. Align the humidier with the help of a level, then tighten the lag bolts.

6. Install additional lag bolts (supplied by others) into the mounting surface at attachment points “B”,

and fasten securely.

7. Reinstall the door panels, and fasten them securely.

Dimension

Housing Size

Large

X 16.0 in

(406 mm)

Y 16.75 in

(426 mm)

Page 24

20 Installation

2582302_C_EN_1611 Nortec EL

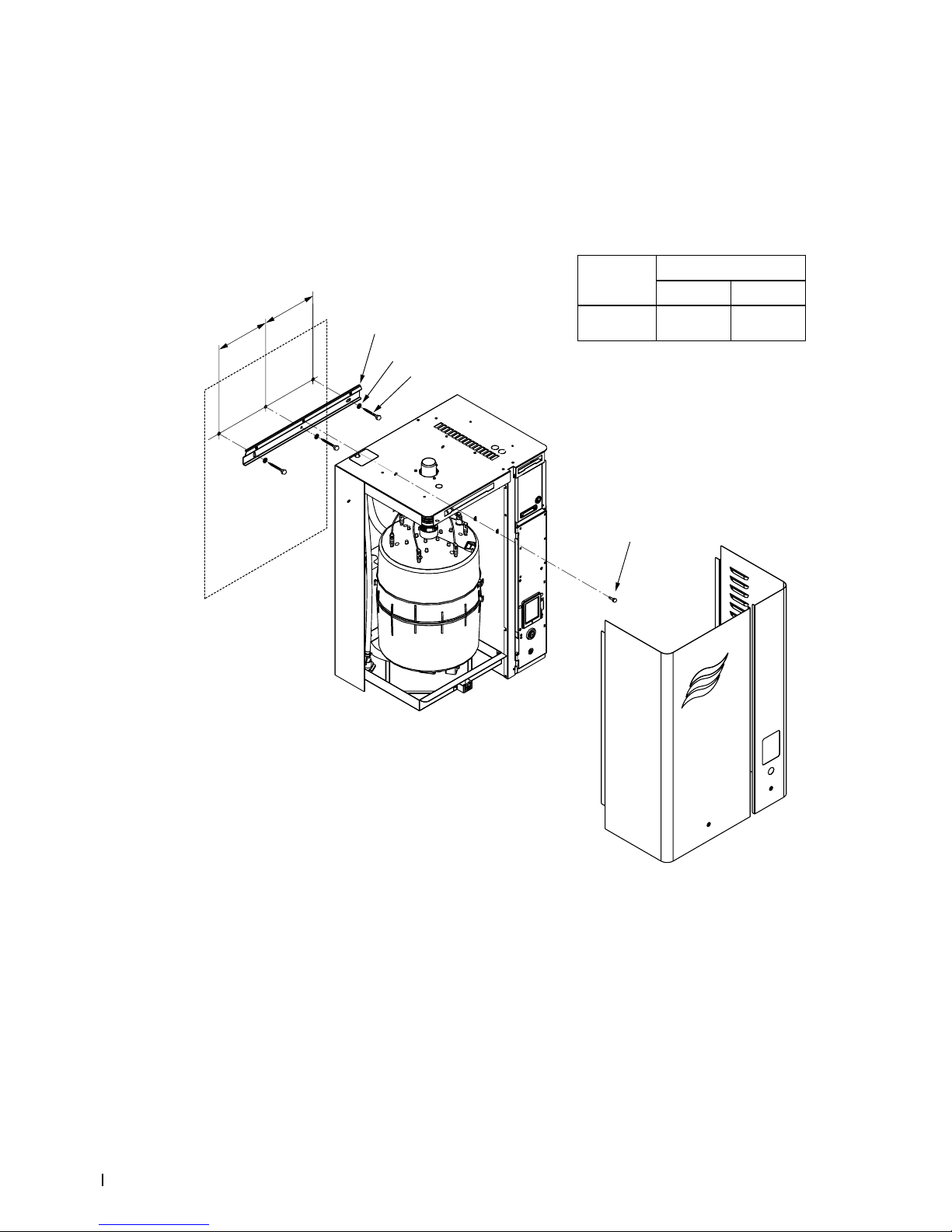

5.4.3 Mounting Using Optional Mounting Bar

Locate the Nortec EL humidier according to "Location and Clearances" on page 16, and install it on the

mounting surface as follows using the optional mounting bar. Mounting bars are a factory-installed option.

If ordered, the corresponding bars and bumpers will be riveted/installed to the housing at the factory.

1. Locate 2×4 wooden studs or equivalent support in the mounting surface, and mark the attachment

points “A” at the desired position with the help of a level. For small or medium housing refer to Figure 9.

For large housing refer to Figure 10 on page 21.

Figure 9:

X

A

A

A

X

1

2

3

4

Optional Mounting, Small or Medium Housing

1 Mounting bar

2 Flat washer (×3)

3 Lag bolt, 1/4×2 in (×3)

4 Screw, M6×10 (×1), supplied

Dimension

Housing Size

Small Medium

X 6.0 in

(152 mm)

8.0 in

(203 mm)

Page 25

21Installation

Nortec EL

2582302_C_EN_1611

Figure 10:

X

A

X

A

A

1

2

3

4

Optional Mounting, Large Housing

1 Mounting bar

2 Flat washer (×3)

3 Lag bolt, 1/4×2 in (×3)

4 Screw, M6×10 (×1), supplied

2. Align the holes in the mounting bar with the marks for the attachment points "A", and install the

mounting bar on the mounting surface with 1/4×2 in lag bolts and at washers (supplied by others).

Use longer bolts if going through drywall or other structural material into the mounting surface. Level

the mounting bar before tightening the lag bolts.

3. Remove the door panels from the humidier.

WARNING!

Heavy object – risk of injury!

Thesmallhumidierweighs45lb(20kg),andthelargehumidierweights120lb(54kg).

Prevention: Use an appropriate lifting device, or request assistance to raise the humidier into

position.

4. Carefully raise the humidier into position, and hang it on the mounting bar.

5. Secure the humidier to the mounting bar with the M6×10 screw (supplied), and fasten securely.

6. Reinstall the door panels, and fasten them securely.

Dimension

Housing Size

Large

X 16.0 in

(406 mm)

Page 26

22 Installation

2582302_C_EN_1611 Nortec EL

5.4.4 Mounting to OSHPD Seismic Requirements

The Nortec EL is certied to OSHPD seismic requirements in its standard conguration (reference OSP0225-10); no additional kits are required. The humidier must be mounted as per the instructions in this

section in order to fulll the seismic requirements.

Locate the Nortec EL humidier according to "Location and Clearances" on page 16, and secure it to doublelayered 3/4 in (20 mm) thick plywood (or equivalent) as follows:

1. Secure the double-layered 3/4 in (20 mm) plywood sheets to the selected mounting surface.

2. Mark the attachment points “A” and "B" at the desired position on the plywood sheets (or equivalent)

with the help of a level. For small or medium housing refer to Figure 11. For large housing refer to

Figure 12 on page 23.

3. Install 3/8×2 in grade B5 (or equivalent) lag bolts and at washers (supplied by others) at attachment

points "A". Allow the heads of the screws to extend 0.25 in (5 mm) from the mounting surface so that

the humidier can be installed on the bolts.

Figure 11:

A

A

B

B

X

Y

2

3

1

Optional Seismic Mounting, Small or Medium Housing

1 Lag bolt, 3/8×2 in, grade B5 (×4)

2 Flat washer (×4)

3 3/4 in (20 mm) double-layer plywood sheet (or equivalent)

Dimension

Housing Size

Small Medium

X 12.0 in

(305 mm)

16.0 in

(406 mm)

Y 17.56 in

(446 mm)

20.71 in

(526 mm)

Page 27

23Installation

Nortec EL

2582302_C_EN_1611

Figure 12:

X

A

A

A

B

B

B

X

Y

1

2

3

Optional Seismic Mounting, Large Housing

1 Lag bolt, 3/8×2 in, grade B5 (×6)

2 Flat washer (×6)

3 3/4 in (20 mm) double-layer plywood sheet (or equivalent)

4. Remove the door panels from the humidier.

5. Enlarge the mounting holes in the rear of the cabinet to accommodate the 3/8×2 in lag bolts.

WARNING!

Heavy object – risk of injury!

Thesmallhumidierweighs45lb(20kg),andthelargehumidierweights120lb(54kg).

Prevention: Use an appropriate lifting device, or request assistance to raise the humidier into

position.

6. Carefully raise and install the humidier onto the installed lag bolts.

7. Align the humidier with the help of a level, then tighten the lag bolts.

8. Install additional grade B5 (or equivalent) lag bolts and at washers (supplied by others) into the

plywood sheet (or equivalent) at attachment points “B”, and fasten securely.

9. Reinstall the door panels, and fasten them securely.

Dimension

Housing Size

Large

X 16.0 in

(406 mm)

Y 16.75 in

(426 mm)

Page 28

24 Installation

2582302_C_EN_1611 Nortec EL

5.4.5 Mounting Checklist

Check the following to ensure that the humidier has been mounted correctly:

Unit installed in the correct location (according to "Location and Clearances" on page 16)?

Mounting surface stable, and capable of supporting the full operating weight of the humidier?

Unit level?

Unit fastened securely?

5.5 Steam Line Connections

Steam generated by the Nortec EL humidier is not pressurized, but is delivered at atmospheric pressure.

It can be distributed directly into a conditioned space with a built-on or remote-mounted blower pack, or into

an AHU (air handling unit) using Nortec steam distributors or Nortec SAM-e steam distribution manifold.

Read "Best Practices for Installing Steam and Condensate Lines" on page 26 before installing steam lines.

5.5.1 Steam Distribution Using the Air Handling Unit

For placement of the steam distributor or SAM-e steam distribution manifold in the air handling unit, as

well as best practices and installation procedures, refer to their installation manuals.

5.5.2 Steam Distribution Using the Blower Pack

5.5.2.1 PlacementofHumidier

Figure 13 on page 25 and Table 5 show the minimum clearances required for installation of a

Nortec EL steam humidier with a built-on Nortec blower pack.

Table 5: Minimum Clearances

Blower Pack

Capacity

5 lb/h

(2.3 kg/h)

10 lb/h

(4.5 kg/h)

20 lb/h

(9kg/h)

30 lb/h

(13.6 kg/h)

50 lb/h

(22.7 kg/h)

75 lb/h

(34.0 kg/h)

100 lb/h

(45.4 kg/h)

Low Speed

Dimension "A" (minimum), Low speed 9 in

(0.23 m)

18 in

(0.46 m)

75 in

(1.91 m)

86 in

(2.19 m)

174 in

(4.42 m)

189 in

(4.81 m)

248 in

(6.3 m)

Dimension "B" (minimum), Low speed 12 in

(0.31 m)

48 in

(1.22 m)

84 in

(2.14 m)

High Speed

Dimension "A" (minimum), High speed 6 in

(0.16 m)

60 in

(1.53 m)

71 in

(1.81 m)

132 in

(3.36 in)

153 in

(3.89 m)

218 in

(5.54 m)

Dimension "B" (minimum), High speed 12 in

(0.31 m)

Dimension "C" (minimum) 90 in

(2.3 m)

Dimension "D" (suggested) 12 in

(0.31 m)

30 in

(0.77 m)

Note:

The values in Table 5 are based on the following nominal conditions: 72°F (22˚C), 40% RH.

Blower pack should not be installed near cold surfaces or where dew point may be reached.

Higher humidity or lower room temperature (compared to nominal conditions stated above) will require increased clearances.

Page 29

25Installation

Nortec EL

2582302_C_EN_1611

Figure 13: Clearance Requirements for

B

C

D

D

A

Nortec EL Humidier with Built-on Blower Pack

5.5.2.2 Remote-MountedBlowerPack

For the installation requirements and installation procedure for the remote-mounted blower pack, refer

to the blower pack manual.

Page 30

26 Installation

2582302_C_EN_1611 Nortec EL

5.5.3 Best Practices for Installing Steam and Condensate Lines

Nortec recommends that you observe the following best practices for installing atmospheric steam lines

and condensate lines. Refer to Figure 16, Figure 17, Figure 18 and Figure 19 for installation examples.

Steam Lines

– Use rigid steam pipes made of copper (MED Type-L) or stainless steel (minimum DIN 1.4301) ex-

clusively, and use steam hoses for short distances only. Use original steam and condensate hoses

from your local Nortec representative. Steam and condensate lines made of any other materials

may adversely affect the operation of the unit, and will void the warranty. Refer to Table 6 on page 28

for details.

WARNING!

Excessive backpressure can result in serious injury or damage to equipment!

Excessive backpressure in the steam line may affect the proper functioning of the humidier,

and may also cause unexpected release of hot steam vapors. Bare skin exposed to the hot

steam vapours can result in severe burns.

Prevention: Minimize the length of the steam line and the number of bends, as the backpressure

can rise approximately 0.12 in H2O for every foot (100 Pa for every meter) of steam line, and

every 90° elbow.

– The length of the steam line should be kept as short as possible – refer to Table 6 on page 28 for

details. Avoid 90° bends, or use long radius elbows. Minimum bend radius is 12 in (300 mm) for

steam hoses, and 5× the internal diameter for rigid steam pipes. Exceeding the maximum length

can affect performance of the unit and may void the warranty. Backpressure in the line combined

with duct static pressure must not exceed 5.5 in H2O (1.37 kPa) and 10 in H2O (2.49 kPa) with the

optional ll cup extension.

Note: With oversized steam lines the maximum length can be extended. Use Nortec steam hose

for short distances only. When calculating the total equivalent length, refer also to Table 7 on page 28

for equivalent length of common ttings.

IMPORTANT! When determining the length and routing of steam lines, allowances must be

made for thermal expansion. If a steam hose is used, allowances must be made for shrinkage

in the length of the hose due to aging.

– Do not decrease the diameter of the steam line, as it increases the backpressure in the line and

also allows condensation of the steam. If that is unavoidable, install a Nortec steam line reducer at

the connection to the steam distributor only, and install a condensate line just before the restriction.

Contact your local Nortec representative for details of the reducer.

– If necessary, increase the diameter of the steam line on the downslope and install a condensate

trap at the lowest point.

– Do not combine steam lines except at the steam distributor. Use a Nortec adaptor specically de-

signed for that purpose, and only if the humidier steam cylinders operate in parallel.

– If using blower packs with large Nortec EL humidiers, do not connect the output from both steam

cylinder to a single blower pack. Each blower pack has a maximum capacity of 100 lb/h (45 kg/h).

– The steam line from the humidier must lead straight upwards for a minimum of 12 in (300 mm)

before continuing on to the steam distribution system.

– The steam line must have a constant minimum upslope of 2 in/12 in (10°), or a constant minimum

downslope of 1/2 in/12 in (2°), as shown in Figure 14 on page 27.

– Use short lengths of steam hose to connect the steam line to the humidier or steam distributor.

Secure the steam hoses with clamps.

Page 31

27Installation

Nortec EL

2582302_C_EN_1611

CAUTION!

Do not over-tighten the hose clamp on the steam hose. Maximum torque for 7/8 in (22 mm)

clamps is 12 in·lbs (135 N·cm), and 16 in·lbs (180 N·cm) for 1-3/4 in (45 mm) clamps.

Figure 14:

10

o

2

o

12 in

(300 mm)

2 in

(50 mm)

12 in

(300 mm)

½ in

(12 mm)

Minimum Upslope Minimum Downslope

Steam Line Slope

– To minimize formation of condensation and maximize efciency, the steam lines made of rigid pipes

(copper or stainless steel) must be insulated with a minimum of 1 in (25 mm) of pipe insulation over

its entire length.

– The weight of the steam line must be supported so there is no load on the humidier.

WARNING!

Risk of severe burns from exposure to hot steam vapours!

Restrictions in the cross-section of the steam line will cause excessive backpressure in the

steam cylinder when the unit is operating, which may cause unexpected release of hot steam

vapors. Bare skin exposed to the hot steam vapours can result in severe burns.

Prevention: Observe the following:

• Upon completion of the installation, purge the steam line to remove any contaminants and

installation materials.

• If using a steam hose make sure there are no kinks in the hose. A heated hose is more likely

to kink.

• To prevent condensate pockets, the steam line must not sag. If necessary, support the steam

line with pipe clamps, trough, or wall brackets, and install a condensate drain at the lowest

point in the steam line.

• Do not install a shutoff valve (e.g. a manually operated shutoff valve, solenoid valve, etc.) in

the steam line.

Page 32

28 Installation

2582302_C_EN_1611 Nortec EL

Table 6: Steam Line Recommendations

Model

Steam Line Over-sizedSteamLine**

Steam

Losses***

Maximum

Equivalent

Length

MED-L

Copper

Pipe

Diameter

Stainless Steel

(min. DIN 1.4301)

Pipe Diameter

Maximum

Equivalent

Length

MED-L

Copper

Pipe

Diameter

Stainless Steel

(min DIN 1.4301)

Pipe Diameter

EL005 7 ft

(2 m)

3/4 in

(20 mm)

7/8 in

× 0.049 wall

(22 mm

× 1.25 mm wall)

14 ft

(4 m)

1 in

(25 mm)

1-1/8 in

× 0.049 wall

(29 mm

× 1.25 mm wall)

0.06 lb/h/ft

(0.09 kg/h/m)

EL010 12 ft

(3.5 m)

24 ft

(7 m)

EL020 17 ft

(5 m)

34 ft

(10 m)

EL030 22 ft

(6.5 m)

44 ft

(13 m)

EL050 43 ft

(13 m)

1-1/2 in

(40 mm)

1-3/4 in

× 0.065 wall

(45 mm

× 1.65 mm

wall)

86 ft

(26 m)

2 in

(50 mm)

2 in

× 0.065 wall

(50 mm

× 1.65 mm

wall)

0.11 lb/h/ft

(0.18 kg/h/m)

EL075

EL100

47 ft

(14 m)

94 ft

(28 m)

EL150*

EL200*

50 ft

(15 m)

1-1/2 in

(40 mm)

1-3/4 in

× 0.065 wall

(45 mm

× 1.65 mm wall)

100 ft

(30 m)

2 in

(50 mm)

2 in

× 0.065 wall

(50 mm

× 1.65 mm

wall)

Nortec Steam Hose

EL005-

EL030

10 ft

(3 m)

P/N 1328810 – 7/8 in (22 mm) 0.1 lb/h/ft

(0.15 kg/h/m)

EL050-

EL200

10 ft

(3 m)

P/N 1328820 – 1-3/4 in (45 mm) 0.15 lb/h/ft

(0.22 kg/h/m)

Notes:

* Use a single steam line for each steam cylinder. Do not combine lines except at a distributor, and only if using the humidiers in parallel.

** The over-sized lines may require a reducer at the humidier and the steam distributor.

*** Based on 1 in (25 mm) insulated copper pipe.

Table 7: Approximate Equivalent Length of Atmospheric Steam Line Fittings

Nominal

Tube Size

in (mm)

Standard90°

Elbow

ft (m)

45°Elbow

ft (m)

Side-outlet

Tee

ft (m)

0.75-0.875

(19-22)

2 (0.6) 1 (0.3) 4 (1.2)

1.5-1.75

(38-45)

3.5 (1.1) 1.75 (0.5) 7 (2.1)

3 (76) 5 (1.5) 2.5 (0.8) 11 (3.4)

4 (102) 8 (2.4) 4 (1.2) 15 (4.6)

Page 33

29Installation

Nortec EL

2582302_C_EN_1611

Condensate Lines

– The condensate drain line from the steam distributor must have a constant minimum downslope of

1 in/48 in (1.2°), with a minimum trap height of 8 in (200 mm), and may be connected to the ll cup

port on the top of the humidier, or to the building oor drain with condensate cooler as required. The

condensate trap must be at least 12 in (300 mm) below the condensate port on the steam distribution system or the "T" connector in the steam line. Refer to Figure 15.

Figure 15:

10

o

2

o

12 in

(300 mm)

2 in

(50 mm)

12 in

(300 mm)

½ in

(12 mm)

Minimum Upslope Minimum Downslope

Condensate Drain Lines

WARNING!

Riskofsevereburnsfromhotuidsorsteam!

The condensate lines may be lled with hot uids or steam. Bare skin in contact with hot uids

or steam can result in severe burns.

Prevention: Never plumb the condensate lines to empty into a sink used by personnel. Always

connect the lines to a drain according to applicable national and local plumbing codes.

– Condensate lines must also be installed at all low points and at vertical transitions in the steam

line. The condensate drain lines should always connect to full-size "T" connectors in the steam line.

Install full-size "T" connectors for condensate drain lines at all transitions from vertical to horizontal.

– For a steam line that is longer than 15 ft (4.5 m) up to the maximum recommended length, install

condensate lines and traps at regular intervals. The maximum distance between the condensate

traps for long runs is 15 ft (4.5 m).

– Use 3/8 in (9.5 mm) Nortec condensate hose, or 3/8 in (9.5 mm) stainless steel pipe or 1/4 in (6.5 mm)

copper pipe for traps in the condensate lines.

– Make sure that the condensate lines allow proper ow.

– Do not over-tighten the hose clamps on the condensate lines.

IMPORTANT! Before starting up the unit, prime the traps in the condensate lines with water.

Page 34

30 Installation

2582302_C_EN_1611 Nortec EL

Figure 16:

A

B

C

D

Installation Example – Steam Distributor 20 in (500 mm) Above Humidier

A Steam line must run minimum 12 in (300 mm) vertically before continuing on to the steam distributor.

B All condensate traps must be minimum 12 in (300 mm) below the condensate outlet on the steam distributor, and condensate lines

must have a constant minimum downslope of 1 in/48 in (1.2°).

C The steam line must not exceed the length specied in Table 6 on page 28. The minimum bend radius is 12 in (300 mm) for a steam

hose, or 5× the internal diameter for rigid steam pipes.

D All condensate traps must have a minimum height of 8 in (200 mm).

Page 35

31Installation

Nortec EL

2582302_C_EN_1611

Figure 17:

B

D

D

C

F

A

A

B

B

C

D

C

E

Installation Example – Steam Distributor Less Than 20 in (500 mm) Above Humidier

A Steam line must run minimum 12 in (300 mm) vertically before continuing on to the steam distributor.

B All condensate traps must be minimum 12 in (300 mm) below the condensate outlet on the steam distributor or the steam line.

C The steam line must not exceed the length specied in Table 6 on page 28. The minimum bend radius is 12 in (300 mm) for a steam

hose, or 5× the internal diameter for rigid steam pipes.

D All condensate traps must have a minimum height of 8 in (200 mm).

E Obstacle

F Condensate line must connect into a full-size "T" connector installed at the lowest point in the steam line.

Page 36

32 Installation

2582302_C_EN_1611 Nortec EL

Figure 18:

B

D

C

A

E

Installation Example – Rigid Steam Pipe With Insulation

A Steam line must run minimum 12 in (300 mm) vertically before continuing on to the steam distributor.

B All condensate traps must be minimum 12 in (300 mm) below the condensate outlet on the steam distributor, and condensate lines

must have a constant minimum downslope of 1 in/48 in (1.2°).

C The steam line must not exceed the length specied in Table 6 on page 28. The minimum bend radius is 12 in (300 mm) for a steam

hose, or 5× the internal diameter for rigid steam pipes.

D All condensate traps must have a minimum height of 8 in (200 mm).

E Steam line must have a minimum of 1 in (25 mm) of pipe insulation over its entire length.

Page 37

33Installation

Nortec EL

2582302_C_EN_1611

Figure 19:

A

A

B

C

E

D

Installation Example – Remote-Mounted Blower Pack

A Steam line must run minimum 12 in (300 mm) vertically before continuing on to the blower pack.

B All condensate traps must be minimum 12 in (300 mm) below the condensate outlet on the blower pack.

C The steam line must not exceed the length specied in Table 6 on page 28. The minimum bend radius is 12 in (300 mm) for a steam

hose, or 5× the internal diameter for rigid steam pipes.

D All condensate traps must have a minimum height of 8 in (200 mm).

E Steam line must have upslope (minimum 10°) /downslope (minimum 2°), and condensate line must constant minimum downslope of

1 in/48 in (1.2°).

Page 38

34 Installation

2582302_C_EN_1611 Nortec EL

5.5.3.1 Common Steam and Condensate Line Installation Mistakes

Some common steam and condensate line installation mistakes are shown in Figure 20.

Figure 20:

7

1

2, 3

4

5

4, 6

7

2, 3

2

Common Steam and Condensate Line Installation Mistakes

1 The condensate trap is located less than the required minimum 12 in (300 mm) below the steam distributor.

2 The minimum bend radius of 12 in (300 mm) for the steam hose (or 5× the internal diameter for rigid pipes) is not maintained.

3 No condensate trap is installed at the vertical transition.

4 The minimum slope for steam and condensate lines is not maintained.

5 The steam line does not run straight up for the required minimum 12 in (300 mm) before continuing on to the steam distributor.

6 On long steam line runs, condensate traps are required every 15 ft (4.5 m), and must connect into full-size "T" connectors in the steam

line. A condensate trap must also be installed a minimum of 12 in (300 mm) below the steam line.

7 Steam lines must not merge or reduce in diameter except at the steam distributor (only through a Nortec adaptor), and must have a

condensate line just before the restriction.

Page 39

35Installation

Nortec EL

2582302_C_EN_1611

5.5.4 Steam Connections Checklist

Check the following to ensure that the steam connections for the humidier have been installed correctly:

Steam Line

Observed all best practices?

Steam line exceed maximum length specied in Table 6 on page 28?

Minimum bend radius of 12 in (300 mm) for steam hose, or 5× internal diameter for rigid pipes

maintained?

Steam line sized correctly?

Backpressure in the line combined with duct static pressure exceed 5.5 in H2O (1.37 kPa), or

10 in H2O (2.49 kPa) with the optional Fill Cup Extension?

Steam lines run straight up from the humidier steam outlet for at least 12 in (300 mm) before bend?

Steam line have a constant minimum upslope of 2 in/12 in (10°), or a constant minimum downslope

of 1/2 in/12 in (2°)?

Steam lines do not reduce in diameter except, if required, at the steam distributor, and condensate

line installed just before the restriction?

Steam lines do not merge except at the steam distributor through a Nortec adaptor?

Steam line does not sag or kink? Supported adequately? Any low points in line without condensate

trap?

If a steam hose is used, is it attached securely with clamps? Clamps secure without crushing steam

line?

Allowances for thermal expansion during operation, and shortening of the hose due to aging taken

into consideration?

Condensate Line

Local codes on drain water temperature requirements have been satised?

Condensate line from the steam distributor condensate port connected to the humidier ll cup port,

or the drain?

Condensate lines installed at all low points, and at vertical transitions in the steam line?

Condensate lines in the steam line always connect to full-size "T" connectors?

Condensate traps have a minimum loop height of 8 in (200 mm) and installed at least 12 in (300 mm)

below the "T" connector or steam distributor?

All condensate lines have a constant minimum downslope of 1 in/48 in (1.2°)?

Maximum distance between the condensate traps on long runs is 15 ft (4.5 m)?

Condensate traps primed with water?

Page 40

36 Installation

2582302_C_EN_1611 Nortec EL

5.6 Water Connections

Refer to "Site Requirements" on page 15 for the water supply and drain requirements.

Read "Water Connection Requirements" on page 38, and perform the water connections as shown in Figure 21

on page 36 and Figure 22 on page 37.

5.6.1 Water Connections Overview

Figure 21:

8

10

11

5

7

6

4

2

1

3

5

4

9

Water Supply and Drain Connections, Small and Medium Units

1 Drain canal (outlet un-threaded), 1-3/16 in (30 mm) O.D.

2 Hose clamp (supplied)

3 Flexible bent hose (supplied)

4 Drain line, minimum 7/8 in (22 mm) I.D. (not supplied)

5 Water supply line, minimum 1/2 in (13 mm) (not supplied)

6 Adaptor, 3/4 BSPP to 1/2 in NPT (supplied)

7 Fill valve (3/4 in BSPP plastic threads)

8 Air gap and optional trap (not supplied)

9 Shutoff valve (not supplied)

10 Filter, 5 μm (optional, but recommended)

11 Union tting (not supplied)

Page 41

37Installation

Nortec EL

2582302_C_EN_1611

Figure 22:

1

8

5

9

10

11

5

7

6

4

2

1

3

4

Water Supply and Drain Connections, Large Units

1 Drain canal (outlet un-threaded), 1-3/16 in (30 mm) O.D.

2 Hose clamp (supplied)

3 Flexible bent hose (supplied)

4 Drain line, minimum 7/8 in (22 mm) I.D. (not supplied)

5 Water supply line, minimum 1/2 in (13 mm) (not supplied)

6 Adaptor, 3/4 BSPP to 1/2 in NPT (supplied)

7 Fill valve (3/4 in BSPP plastic threads)

8 Air gap and optional trap (not supplied)

9 Shutoff valve (not supplied)

10 Filter, 5 μm (optional, but recommended)

11 Union tting (not supplied)

Page 42

38 Installation

2582302_C_EN_1611 Nortec EL

5.6.2 Water Connection Requirements

Water and drain connections must meet the following requirements:

– All water supply and drain connections are to be installed to local plumbing codes.

– For ease of maintenance, a water shutoff valve and union tting must be installed in the supply line

before the humidier.

– The water supply piping should have a minimum diameter of 1/2 in (13 mm), with a 1/2 in NPT female

end. The piping material should be made of copper, stainless steel or plastic certied for drinking

water systems.

CAUTION!

Risk of damage to the plastic threads!

Thethreadsonthellvalvearemadeofplastic.

Prevention: Hand-tighten the NPT adaptor to the ll valve.

– The (optional but recommended) water lter must be installed as close as possible to the humidier.

– The air gap funnel should have a minimum diameter of 2-1/2 in (64 mm).

– The air gap and optional trap should be located away from the control cabinet to keep any rising

steam from damaging the electrical components in the cabinet.

– The drain piping should have a minimum internal diameter of 7/8 in (22 mm).

– The exible bent hose exiting the humidier should be connected to a drain line with a minimum

internal diameter of 7/8 in (22 mm) and secured with clamps.

– The drain line should be as short as possible, and have a constant minimum downslope of 1 in/48 in

(1.2°) to the funnel without touching its sides or bottom. Use stainless steel or copper pipe to handle

temperatures up to 212°F (100°C).

– Drain lines from large humidiers with dual steam cylinders must empty into separate open air gap

funnels before connecting to the drain. Combined drain line minimum 1.5 in (38 mm) ID.

– Upon completion of installation, ush the water supply and drain lines to clear out any debris in the

lines. Check the strainer in the ll valve to ensure it is clear of all debris.

5.6.3 Water Connections Checklist

Check the following to ensure that the water connections for the humidier have been installed correctly:

Shutoff valve and union tting installed in supply line?

Water supply piping minimum 1/2 in (13 mm) diameter, and made of copper, stainless steel or plastic

certied for drinking water systems?

Optional 5 μm water lter installed in the supply line close to the humidier?

Water supply temperature 34-104°F (1-40°C)?

Water supply surge-free and pressure regulated to 30-80 psig (207-550 kPa)?

Leak-free water supply line?

Air gap funnel has a minimum diameter of 2-1/2 in (64 mm)?

Air gap funnel and any other drain located away from the control cabinet in the humidier?

Drain lines have a minimum internal diameter of 7/8 in (22 mm)?

Drain line have a constant minimum downslope of 1 in/48 in (1.2°) to funnel without touching its

sides or bottom?

Drain lines from large humidiers with dual steam cylinders empty into separate open air gap funnels

before connecting to the drain? Combined drain line minimum 1.5 in (38 mm) ID?

All debris ushed from supply and drain lines?

Page 43

39Installation

Nortec EL

2582302_C_EN_1611

5.7 Humidity Control Systems

5.7.1 Control Device Locations

The following schematic describes a potential system setup with respect to control devices. Refer to

Figure 23.

Figure 23:

φ

φ

max

φ

Δp

1

1

2

3

System Setup Schematic

1 On/Off humidistat, modulating humidistat, or humidity sensor

2 On/Off high limit humidistat, modulating humidistat, or humidity sensor

3 Air proving switch

Notes:

• Humidity sensors and humidistats (1) can be modulating or On/Off. Preferred location is in the return

duct, as the supply air is well mixed with the room air at this location. Avoid placing near discharge

diffuser, near doorways, in sunlight, or in airow “dead-zones”.

• Locate the high limit humidistat or humidity sensor (2) downstream of the humidier’s distributor so that

it can sense a duct that is over-humidied. Recommended setting is 85% RH. Locate it downstream

of the distributor – at least 5x the absorption distance away. If the absorption distance is not known,

locate it at least 10 feet (3 m) downstream from the distributor. Can be a humidistat (modulating or

On/Off), or a humidity sensor.

• Locate the air proving switch (3) in the same duct as the humidier’s distributor so that it can sense

air ow (or lack thereof).

5.7.2 Permissible Control Signal Inputs

Table 8 shows the different permissible control signal inputs the Nortec EL steam humidier can handle.

Table 8: Permissible Control Signal Inputs

Humidity Control with External Con-

troller Control Signals

Humidity Control with Internal PI

Controller Humidity Sensor Signals

DigitalInputs(viaModbus,

BACnet IP/MSTP slave)

0-5 VDC (potentiometer 135-10kΩ)

1-5 VDC

0-10 VDC

2-10 VDC

0-20 VDC

0-16 VDC

3.2-16 VDC

0-20 mA

4-20 mA

0-5 VDC (potentiometer 135-10kΩ)

1-5 VDC

0-10 VDC

2-10 VDC

0-20 VDC

0-16 VDC

3.2-16 VDC

0-20 mA

4-20 mA

Standard

BACnet IP, BACnet MSTP (slave),

Modbus

Optional

BACnet IP (BTL), BACnet MSTP (Mas-

ter, BTL), Lonworks

Humidistat (24 V On/Off)

Page 44

40 Installation

2582302_C_EN_1611 Nortec EL

5.8 Electrical Connections

Refer to the specication label in Figure 3 on page 9 for the electrical requirements.

Install the electrical connections according to the wiring diagram(s) (Figure 24 on page 41, and Figure 25

on page 43, as applicable) and the instructions for "External Connections" on page 44.

For connecting multiple Nortec EL humidiers, refer to "Connecting Multiple Units Using Linkup" on page 54.

5.8.1 General

Safety

The electrical installation work requires removal of the door panels in the humidier. Observe the

following safety precautions:

DANGER!

Risk of electric shock!

The Nortechumidierismainspowered.Livepartsmaybeexposedwhenthedoorpan-

els are open. Touching live parts may cause severe injury or even death.

Prevention: The Nortec humidier must be connected to the mains only after all installation

work has been completed, checked for correct workmanship, and the door panels are closed

and fastened securely.

CAUTION!

Electrostatic discharge (ESD)!

Theelectroniccomponentsinsidethehumidieraresensitivetoelectrostaticdischarge

(ESD).

Prevention: Take appropriate measures to protect the electronic components inside the unit

against damage caused by electrostatic discharge (ESD). Refer to ANSI/ESD-S20.20.

• All electrical installation work must be performed only by a licensed electrician authorized by the

customer. It is the customer’s responsibility to verify qualications of the personnel.

• The electrical installation must be performed according to the wiring diagrams in this manual,

the instructions in this section, as well as applicable national and local codes.

• All cables must lead into the unit, via appropriate cable glands or grommets, and be properly

supported.

• Make sure the cables are secured, and do not rub on any components or become a tripping hazard.

• Observe national and local codes for maximum cable length and required wire sizes for cables.

Page 45

41Installation

Nortec EL

2582302_C_EN_1611

5.8.2 Wiring Diagrams

5.8.2.1 NortecELSteamHumidier,SteamCylinderA

Figure 24:

PEPESC2SC1NL1

INLET

SPARE/DRAIN

CONTACT.

CONT. SIGN.

GNDINV+

24V

10V

CONT.

DRAIN INLET

L1FU

L1SW

N

LEVEL SENS.

MAIN SUPPLY

MODULE B

PEP1NP

LIM. SIGN.

GNDIN

F3 4AT

SPARE

SWITCH

L1SC NSWL1SC NSWL1SW NSWL1SW

F1 1AT

COMM

HB OK

JP3

JP1

LEVEL

LOW 24V GND

CURRENT SENSOR

SC OK

HWS

BLOWER

IN24V

ON/OFF

IN24V

SPARE1 SPARE2

T1

On/Off

Switch

1

2

3

4

Drain

Fill

D+GND D-

GND24V

D+GND D-

RS4852RS4851PWR IC

PRI

N.O. Blower Pack

Air Proving switch

24 VAC

Sec. Loop

GND

CH 1

CH 2

10 VDC

GND

1

2

3

4

5

6

7

9

8

J16

J15

JP11

JP8

JP4

JP7

DISPLAY

ACC

RFB

TD RD GND

5V

3.3V

COMM PORT

USB

DISPLAY

J22 LED

ETHERNET

SIM Card

Main unit

CR2032

BAT

+

GND

-

J10

J12

+

GND

-+

GND

-

J14

GND

24V

SW1

s

s

s

s

s

s

s

s

s

s

s

Primary

Fuse

Option

Main Contactors

K1

Main

Contactor

K1

Steam Cylinder

Steam Cylinder

Steam Cylinder

Broken lines 3-phase

6-wire unit

L1

T1

T2

T3

L2

L3

L1

T1

T2

L2

Cylinder with Dual Contactor

Cylinder with Single Contactor

R

R

R

R

Y

Y

YY

B

B

B

R

B

B

B

B

B

B

B

Y

Y

Y

Y

R

R

R

R

R

To Level Sensor

QC2

To Level Sensor

QC2

To Level Sensor

QC1

To Current Sensor

To Current Sensor

1

1

1

1

1

1

1

1

1

1

11

1

ModuleA(Three Phase)

Single Contactor

ModuleA(Three Phase)

Dual Contactor

Module A(Single Phase)

X0

X0

X0

L1L2

L1L2

L3

L1L2

L3

R

R

R

Y

B

BL

BL

BL

R

R

DriverA

Driver B

QC1

QC2

To transformer

(primary side)

To transformer

(primary side)

Transformer

X13

X14

X15

X8

X9

X12

X11

X7

X1

X2

X4

X5

X6

To Connector

X4

To Connector

X4

DRIVER

BOARD A

CONTROL BOARD

CYLINDER-A

B

To Level Sensor

QC1

L1

T1

T2

T3

L2

L3

L1

T1

T2

T3

L2

L3

Main

Contactor

K1

SEC

24 VAC

R

R

R

R

R

B

B

Y

R

Y

Y

B

B

R

B

R

YG GY

BGY

BR

GY

Y

G

R

B

J19

J21

J17

J18

J23

J6

J2J3

432121

Analog Out

F1

100mA

Sensor Supply

Max. 60mA

Unit ON

Steam Service

Error

Remote BoardFault (option)

1

2

3

4

5

6

7

8

9

10

432121

Analog Out

F1

100mA

Sensor Supply

Max. 60mA

FanA

Fan B

Flush B

FlushA

Accessory Board (option)

1

2

3

4

5

6

7

8

9

10

To Module B (double unit only)

A

To Terminal X1

in Module B

(double unit only)

B

C

To Terminal X14 in Driver Board B

(double unit only)

Wire Colors:

R Red

YYellow

B Black

BL Blue

BR Brown

GY Grey

G Green

O Orange

To Module B (double unit only)

A

NL

Blower Pack Power Supply

(for Space and RMBP units)208-600 V

110-120 VAC

+

1A

slow blow

R

R

G

RR

O

s

s

O

O

O

BP Loop

Wiring Diagram - Nortec EL Humidier, Steam Cylinder A (Module A)

Page 46

42 Installation

2582302_C_EN_1611 Nortec EL

Legend:

F1 Internal fuse, driver board (1A, slow-acting)

F3 Internal fuse, driver board (4A, slow-acting)

JP4 Jumper for activating the termination resistor for Modbus or BACnet MSTP network.

J6 Modbus connector (RS485 interface)

JP7 Jumper for activating Modbus or BACnet MSTP communication via connector J6.

JP8 Termination, Linkup system

J10 Linkup connector

K1 Main contactor, supply voltage

LV Low voltage terminal strip A

SW1 Rotary switch, module identication (Module A: 0)

X0 Terminal block, supply voltage

Page 47

43Installation

Nortec EL

2582302_C_EN_1611

5.8.2.2 NortecELSteamHumidier,SteamCylinderB(LargeUnitsOnly)

Figure 25 shows the wiring diagram for large humidiers with a second steam cylinder (usually referred