Nortec Condair ES MKII-300, Condair ES MKII-400, Condair ES MKII-500, Condair ES MKII-600, Condair ES MKII-700 Installation And Maintenance Manual

...

/,

ec

WHEN

YOU

NEED

HUMIDITY

INSTALLATION AND

MAINTENANC'E MANUAL

E~

~

LISTED

~

L

jl

HUMIDIFIER

,

&,e

~

E65185

....

~

NORTEC

INDUSTRIES

INC.

P.O.

9021:

698, BrIdge

Plala

..

~burg,

New

YOf1c,

1:3669

PhOl"llt

(315)

425·1:255

ES

MK

II

SERIES

HUMIDIFIERS'

NORJEC

AIR

CONDITIONING

INDUSTRIES

LTD.

2760

Fenton Road,

Bo)C

949

R.R.

5, Ottawa, Ont.

K1G

3Na

PhQI18

(613) 82NJ335 TeJex 053·3552

" ,

"ll""

",

I.

n

ec

Installation

Inat~uetien9

for

CondnuOWl

~~P:0J-f

132-']3)..

if

- .

..

...

Z

CI

M'

A-

Il}

.•

1,0

..-

11~-,\1'l..>

-

_,

),

1.

~

~

3>

l. ( .....

/:-

5"

V

~c.

I

3l~

-=t~

'l.S -- 0 -

,a

\/:1)

l..

~)

Connect

other

end

of

hatness

tQ

BBven

pOint

~B~~tal

Gt~lp

as

follows -see

fiS-

2

Blue

on

terminal

2

5)

Muunt and

con~a~t

Humldist~t

to

thE 1

point

terminal

8t~lp

~s

per

U,.

~

RECeiVING

EQUIPMENt

~

/lGCklng

$lIp to

eMUm

ALL

material h85 been

genvlind.

2.

All

mateflal

shoftage~

are

to

be

reported to the

f$Ctul}' _11hlo

48

hours from receipt

01

good$.

IIIORTEC aSsume9

no

responsibility

for

any

material

shorta9OS

beyond

."Is

pertod.

3.

.

Inspect.

shipping crale(s) for damage

anCi

nole on

. shipping waybill accordingly.

4.

5.

Aftef'

uncratlng,

inspect

unit

for

demage

and If

~

ie

found,

nollfy

the shipper promptly.

AU

NORTEC PRODUCTS ARE SHIPPED ON

AN

F.O.B. FACTORY BASIS. ANY

"NO

ALL

DAMAGE,

S,.EAKAGE OR

lOSS

CLAIMS ARE TO BE MADE

DIRECTLY

TO

THE

SHIPPING

COMPANY.

PRE·INSTAl.LATION

CHECKPOINTS

1.

ConflMllhat

the "Ollltg8 afld pha$e

of

th4il

un

It

cor·

tespond$ with available voltage and phase.

t

Enwm

that th&

(U"::!

l11atn

breaker

15

of

liufllclst1t

size

to

handle

th~

mallimum

fuse rallng

iI9

IndlcatlHd

on

the

8pecHtcatJon

labat.

....

OT01

t-i'1lH

WATI'.ft

.

u;:va..

--,.......~~

I!IIDICATOR

"

LIGHT

,_·./.V.RGE

. ::' ,S!O£

ACCE:SS

.

'<'.

• :ro!t EllS'"

..

::.'!It4STALLATION

:.:'j

. '-,

WiTH

··

...

utO-AOAPmIE-·

CONtROL

1

MOUNTING

PROCEDURE

1. LccatlOf\

C)f

linit

should

be as close

to

and

b$low

ste.tun di5tdbu!or location ~ poulble.

2.

Prov~de

a Illlnhn!.lm cfeamnclil

of

24"

(600 mAl}

to

the

rlght of the l:nlt and a minimum

cf

30"

(750

mm)

if' front

of

ttoe

unIt, Refer to Diagram 1.

INSTALLATION CtEAMNCEIi

I/II///ILI

3.

!f possible, avoid locat:ng humidifier more than

35

iS$t from - steam distributor location.

At

this

distance, flet

O~lpiJ~

will

be

approximately i!8%

of

unit

capacity.

as

a JesuIt

of

cond4m3ation

I()$$e!il.

Refll.

to

Chart 1

and

to

steam

ilose

sectiOf\ .

UNIT

CAPACltv

CORRECTION

fACTORS

DlS1ANce

Qf

Sl'E4!i4

UN'"

O,STRlUlHOR

fROM

Cl\tllNU

cp.PI'cnY

COIIRECflOIll

((0

METUIS

FAClOR

010.

1!)

G

to

4.6

1.00

15

to

20

4.6

to

0.1

.

0.97

21

to

26

i

I

6.4 tQ

7.~

0.94

Xl

ttl

3'l

8.2

10

10.1

0.00

CtilaAT1

UNIT CAPACITY

COA~ECTt0f4

FACYORS

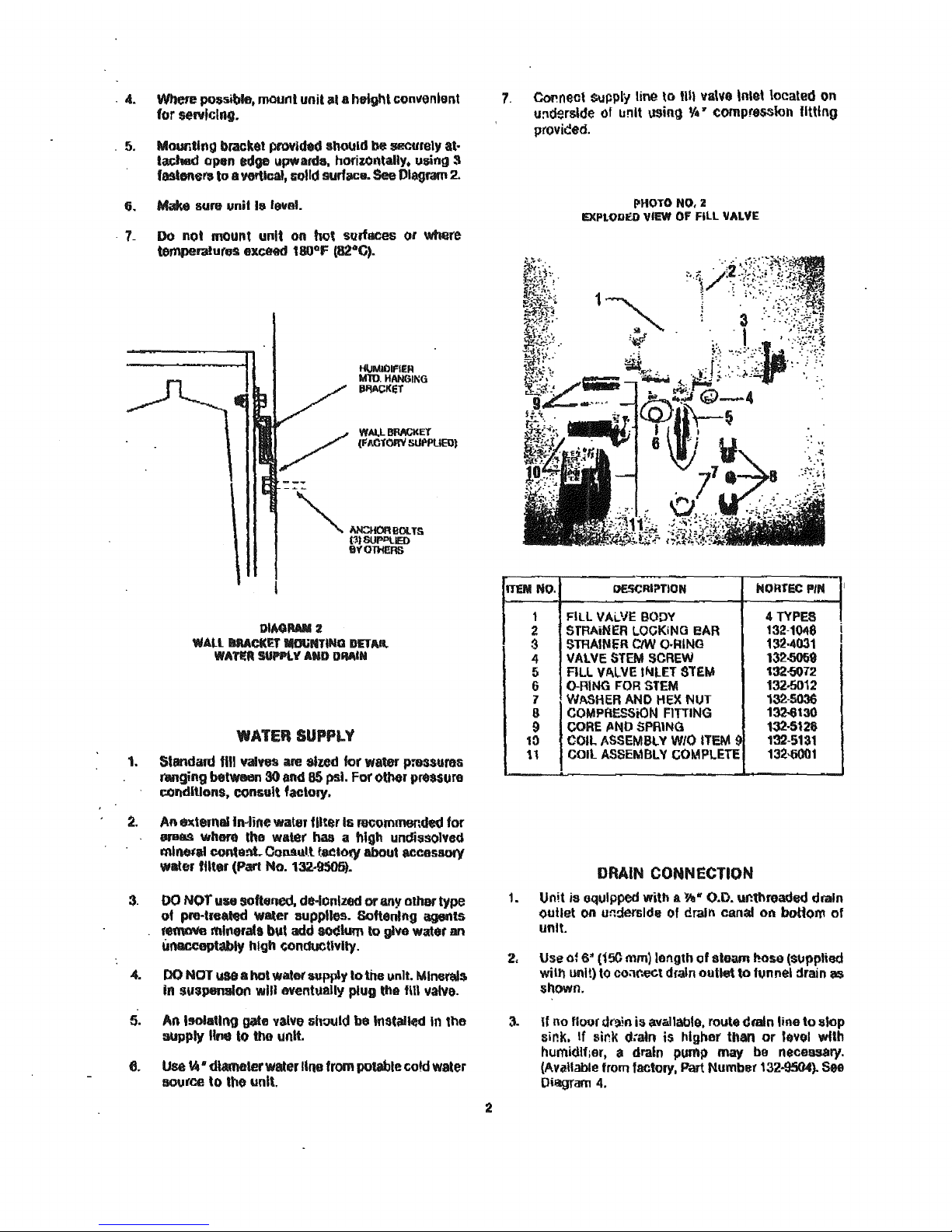

· 4.

Where

possible.

moont

unit

al a hvlght

conllenhmt

for 5efll'C!nt.

·

5.

Mour.ting bracket provided

shOUld

be

securely at·

tachod

Qpatn

ttdge ulW'ards. horizor.taily.

using

3

fsmener'3

to 8

vertlcat,

solid

M/ilCII.

See

Diagram

2.

6.

Make

SYnJ

unit

Is

1$1101.

·

7-

DO

not

mQunt

unit

on

twt

surfaces

Of

wlwre

temperatuiVS excHd 180

Q

F t82

411

C).

1.

2.

3.

4-

5.

6.

DlAGMII2

WAI.lllflACKEf

(FAC1()Jf\l

SUf'PtlB)l

WAlL

I'mAdCU

MOONTlNO

DIETM

\flAm

SUPPllf AND

DIWN

WATER

SUPPa..

y

Standard

fll!

valves

are

sized

101'

water prnuuros

ranging betwMn

30

and

85

psi.

FOI'

other

p!1$$Sure

eol'Jdltlons, consult factoI)'.

An

ext

....

altn-line

water

filter

Is

moommended

for

~

",hero

the

water

has

a high undissolved

mlnf#al conteM.-

Consult

f.aeIO~

about

accesmxy

WIMer

ttlter

(Part

No.

132-9506).

00

NOT

UR

sofiE/fled, de-lorl\l$d

or

any Olher type

of

pm-tre.

water lSupplles. Softening agents

~

millerats

blat

add

soelum

to give water an

unacceptably

high

(;onduetlvlty.

00

NOl

UN

a

hI::It

water supply

to

the unit. Minerals

In SUIJpumloo

will

eventually plug the till

valve.

An

IsoaatlRg gate valve

should

be

Install~

11'1

the

aupply

II""

to the unlt.

Use

14

•

dlm'neaer

water

line

from

potable

cold

water

source

to

the

unit.

2

7.

Coi>nect

supply

line

\0

Ull

va\~e

inlet

located

on

u:t~rslde

of

lI!'1lt

using

1flI7

eompr~lon

fitting

provi<!ed.

ITeM

No.

PHOTO

NO,

2

EXP1.0DED

ViEW

OF

Fill

VAL"[

DE$CRI~TION

i'40nrEC

PIN

I

1

FilL

VALVE

BODY

4

TYPES

1

2

STRAiNER

LOCKiNG

eAR

132-10118

3

STRAINER

CiW

Q.f;lING

132-4031

I

4

VAlVE

STEM SCREW

132-5069

5

ALL

VALVE

If\,Ilt:T

SlEM

132-5012

6

O-RING

rOR

STEM

132-5012

1

WASHER

AND

HEX

NUT

132-5036

8

COMPRESSiON

FITTING

13C6t30

9

CORE

~ND

SPRING 132·5126

10

COIL

ASSEMBLY

W/O

ITEM

9

132-5131

11

COil

ASSEMBLY

COMPlETE

132-6001

DRAIN CONNECTION

1.

Unit

is

oqulpped

with

a l'II" O.D. ur.threadsd drain

outlet

on

u~derslde

of drain canal

on

boUom

of

unit.

2,

Use

ol

6"

(150

mm)

length

cf

sWam oose ($\lpplied

will'!

unit)

to

ooar.eGt drain

outlet

to

funnel

drain as

shown.

3.

If no

floor

d(~;n

is

avt.lIablo. route dmtn line

to

slop

sil'1k.

If

sink

d:a1n

is higher than

or

level wfth

humidifier,

ill

drain pump may be neceasary.

(AvC!lIabie

from factoI)', Part Number

132·9504}.

See

Oillgfam 4.

r!".-

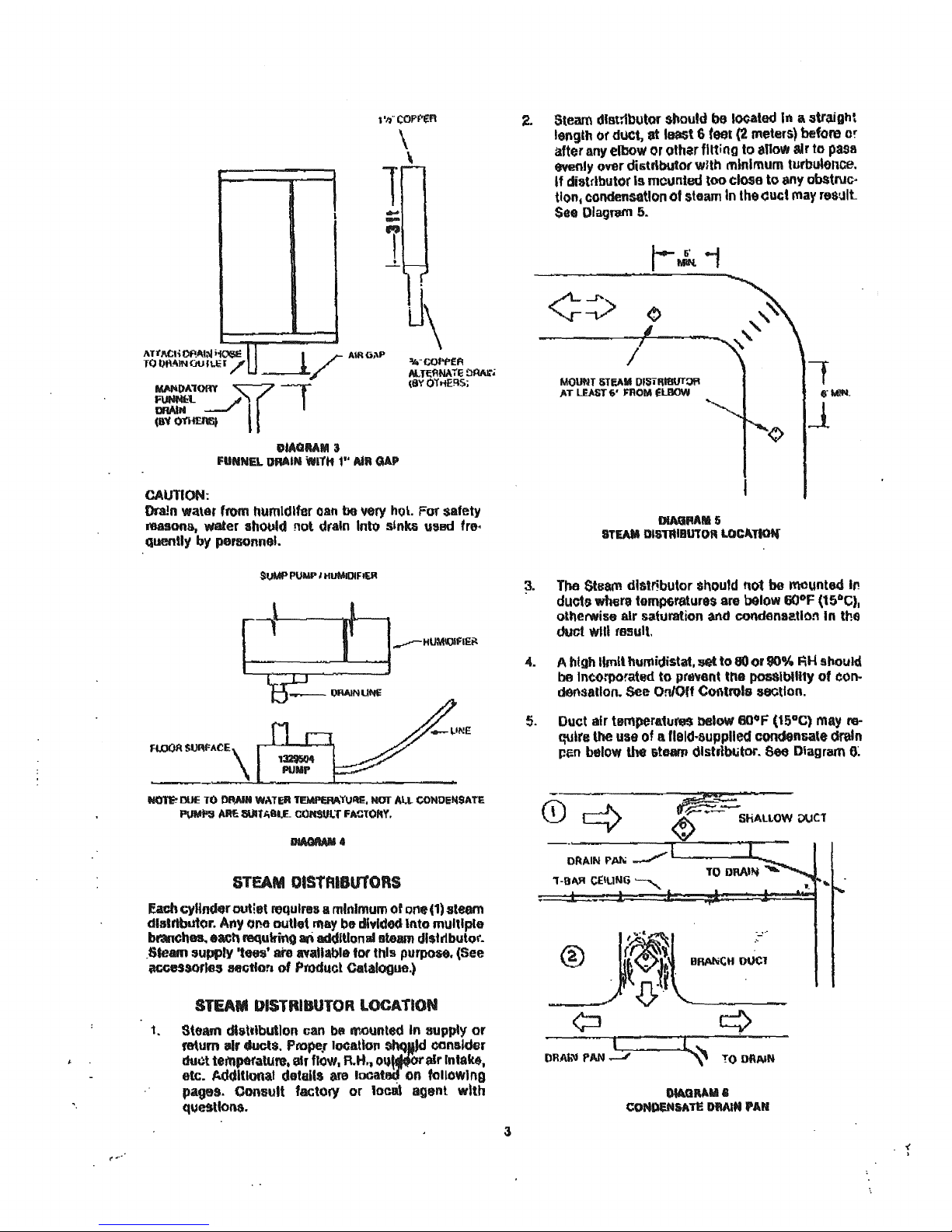

CAUTION;

1

-

.....

i

"",

..

coPf'EA

ALTI;~NAr~

OM!:'.

(BY

OltiEHS;

Oraln

water

from

humldlfer

Clln

be

WJry

hQl.

For

:safety

masons, water should !lot dfaln Into sinks

usE!d

fro<

quenlly by personnel.

~

OUE

TO

MAIN

WATER

TEMI'£HA'I'U~.

NOT

AI.i.-

CONDEt4SATE

P\Jtaff'9

AM

SUlTA8lJ:_

CONSUlT

F~TOhY,

STEAM

DISTRIBUTORS

Each

cyR""r

out;,. requires a minimum

Of

orle

(1)

steam

dlslrtbutor.

/Iotly

Ol'\e

outlet

I1\IIIY

be divlded

Into

multiple

branch-.

eaeh

mqulring

an

addltloniil BtNm dl$trlbutor •

.

Steam

!!JupplY

'tees'

am

available

for

this

purpose, (See

i\CGflSQfIes

secdon

01

Product Catalogue.)

STEAM

DISTRIBUTOR

LOCATION

1. Stoam distributIon

can

bl' mounted In supply

or

t'8\um

air

Wets.

Propel

location;!

oonalder

duCt teMperature. air

flow,

A.M.,

o,,~

air Intak&,

etc.

Additional

details

are

local

.

on

fallowing

pages. Commit factory

or

local agent wIth

questlona.

3

2. Steam distributor should

be

l()¢alad

In

Ii

straight

length

of

dUCt,

at

least 6

teal

(2

meters)

before or

after any elbow or othar fitting

to

3"01"

air

to

pass

evenly over distrlbutOf with

minimum

tl.lrbu*ence.

If

distributor

Is

mounted

too

close

to

!:iny obatruc-

tlon,

condensation

of

steam

In

lhe(luct

may

result

See

DlagnJiTI

5.

MOlmT

IiTI:AM

D'S"i~I8UTOtl

AT

lIlAST

t;'

mOM

f;UIOW

DIAG"ARIII5

STEAM

DISTRIBUlOR

LOCAnot4"

t

(I"

WIN.

1

3.

The

$team dlstrlbutor

shou1d

110t

be mounted In

ducts

wOOrtI

tell1fJ6ratures

are

below

60°F

(U;."·C).

otherwise

air s ..

duration

3I\d COIldensation

In

tht'l

duct WIll rosull,

4.

5.

A high

limit

humidistat. '*

to

80

Of

90% RH should

be

Incorporated

to

pr."ent

ttl"

posalbility

of

eon-

dMsllUon. See OnlOff Controls section.

Duct

air tempera.1uM

lHdow

60°F

(15°C)

may

m-

q\Jlrs

the

use of a fleld·supplled condensate

dn,ljn

p~n

bttlow the steam olstrlblitor.

See

Diagram

6~

-(

>

2.

8~

packs

aI'tl

available

Integr3liy-mO'.mted

with

the

twumldifi8f

Qnit

(blIlit-oll blower pack,

see

ptlC~to

,4)

Of

de~h8d

units

fiefd-plped

and

wired

to

the

humidifier

IJMt

(remote

mounted blower

pack,.

see

Photo 5).

3.

AU

modela

of bIoWItf'

packs

tor lhe MK.II Seril3$

Jwmldiflera

conalst

of

a

It"1

cabinet

containing

III

atoM!

distl1bt.tt1oo

manijoW.

steam

aupply

and

COt'\-

denNte

drainage

flttlng8, blow.,r fan 8fIti trans-

former

~ed

from

prtmaty voltage

and

secon-

dary fuM protection.

. .

4. . AU

bl(Wller

p.aeks

are

wlllld

(by

factolY

If

built

on,

by

othelIlf

~a

mo~nted)

to the

load

side of

the

, prlmary

conlactor

80

as

to

oporat(l

Slrm;ltaneouslv

"Ith

the humidifier.

.

6.

,Blower

_Its

equipped with optional air-proving

iIIwitdl (132,9204) at'8

equipped

with

an

additional

cootactor built Ittto the blower r»ek cabinet. With

.

this

#Cft$8Cry.

the

blowr

fan must operata before

the hutnldifter

wlli

generate

steam.

.

6.

FCefflote

m~ted

bluwef

packs

GC4ulppec:!

with too

optional 132C04 air proving switch require field

"'ring

~

the

primafy volt_ge terminal blocks

IIIII'Id

the

low-voltage CCntl"oIlermlnai

!trips;

one

of

each

too4*

In

the humldtfl9l"

&fl13

the blower pe.ck

cablMt.

Refer

to

wiring

d~

supplied with unit

on

Ins~

of

plumbing access door.

1.

ReId

wkiflg

of

remote blower packs

mu

at

cooform

. to

rudfonal

and

10GaI

el8Cttlcai

codes,

8.

nm

esa.50

and

ES8-100

mooal blower pack

.-robly

Is

unique

to

thi$

$ize

humidifier. Both the

buUt-on

and

the

remota

mounted models consist

of

II

ateet

cabtnil

containing a steam distributor

manifold, steam 3upply and

cOf1denaate

drainage

flttlng8.

buU1·ln

propeaer fan and 0.25

amp

fuse

protaclloti.

9.

ES8-5OI100

blower

packs

am

~Iahle

In

110Y

built-

on

132·9400,

110V

remote mounted

132.9410,

8

20B-240V

built-oo 132·9401. 206-240V remote

mounted

~32-9411.

ES8unlt$

are

tmlilabl9ln

other

voitages bot require separate

pOWefSUPPIy

forth.

blower

pook.

PHOto

Ii

ESe

W. BUILT

ON

8.P.

MOUNTING

AND

CONNECTIONS

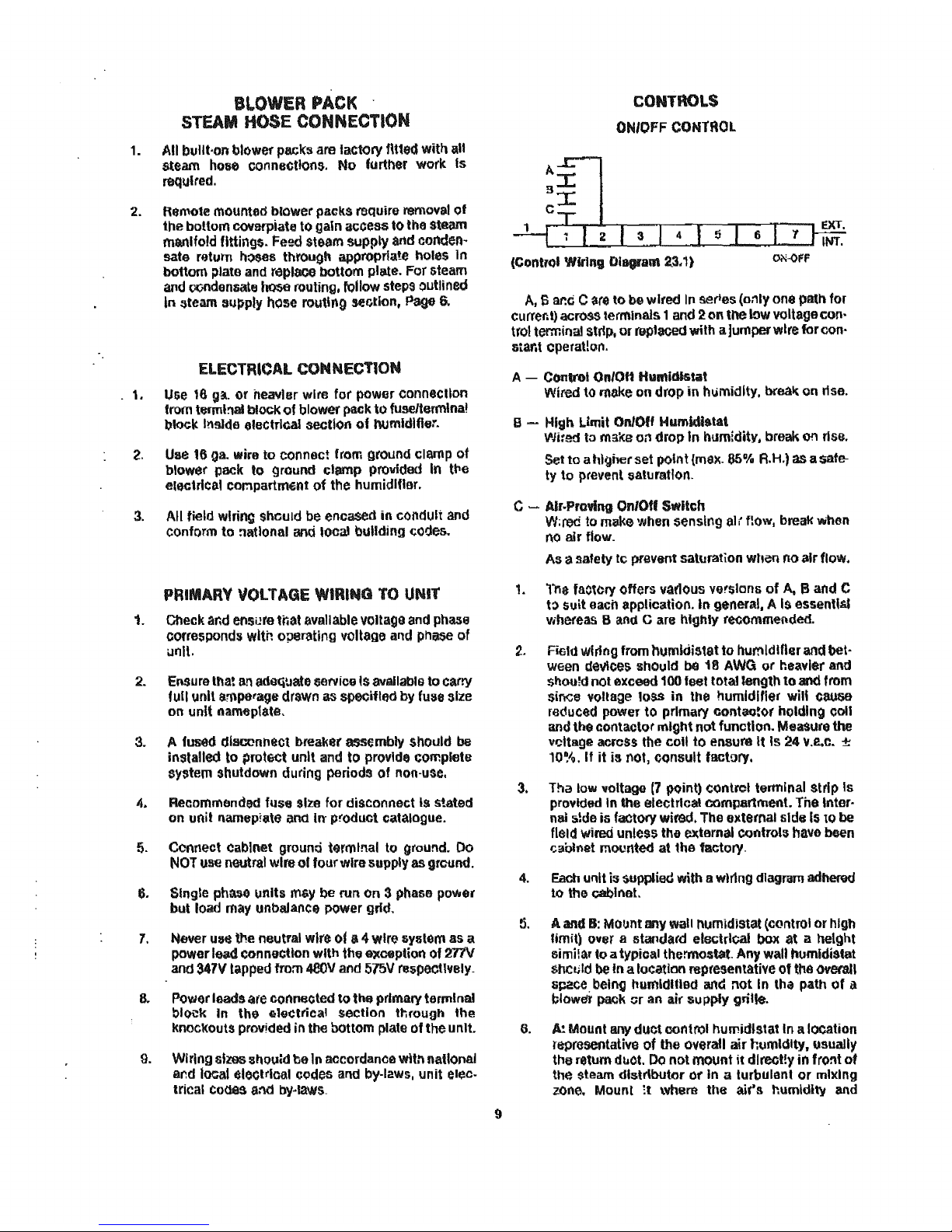

1.

Refer to Chart 2 for ceiling cleara..,oo (to top

01

unit)

required for

each

model

unit. Dimens!oos appfy to

both

btJllt.-ol'\

end

remote-ffiQunted

'1en'dons

of

blower

pacl<s.

UNIT

MeDEL

ES8-50

ESB·100

ES

MKU·2{)O

ES

MKI!·300

ES

MK!I·400

ES

MKII-600

ES

MI<II-600

E5

MKII-600

ES MKlI«lO

ES

MKII-700

ES

MKII-700

E$

MKII-OOO

es

MKU4lOO

NO.

Of

M\N.

CEILING

CAPACITY

BLOWER

CLEARANCE

LBSlMR

PACKS

INOHES

(MM)

S 1 18 (450)

10 1

18

(450)

10 1

18

(450)

17 1

'8

(450)

~

1

18

(450)

60 1

36(900)

60

2"

18

(450)

90 1 48 (1200)

90

2'

24

(600)

120 2" 36

(900)

120

4"

18

(450)

180

2'

48 (1200)

180

4'

24

{600}

'Remota

mounted

rrlO/'Jf;I

only.

CHARf2

2.

Mounl remote blower pack(s)

us~"g

sUpPlied

bracKsl(s)

with

ceiling

cleariinC$ ali recommended

II'

Chart

2.

BLOWER

PACK

.

STEAM

HOSE

CONNECTION

1. All built-on blower

pack~

are

lactory

HUed

with

all

steam hose connections.

No

further

work.

Is

required.

2. Remote mounted

blower

packs require removal

of

the

bottol'll

COV9rpiate

to

gain access

to

the

Stilian1

manifold fltting$.

Fe!i!d

steam

supply

and

conden-

sate f9tum hoses through appropriate holes

In

bottom

plata and

replace

bottom

plattt. For steam

and ()(';n(lensate

hose

rouling, follow steps outlined

In

l)team

8uJ)ply

hose

routl1\9

section, !'age

6.

ELECTRICAL

CONNECT10N

. 1. Use 16

ga.

or

heavier wire

for

power

connecllon

from

tt.WJI1I!Ul1

block

of

blower pack

to

fuseltenTIlna!

block

It'lsJde

electrical

section

of

numldlfler.

2.

Use 16

gao

wiro

to

connect from ground clarop

of

blower

paek

to

ground clamp provided In tl'le

eltlCtrical

cOr.lpartrmont

of

the humidifier.

3.

All field

wiring

shoUld

be

encased

in

conduit

and

COnform

to

:1atlonal

and

lOCal

building

codes.

PRIMARY

VOLTAGE

WIRING

TO

UNIT

1.

Check

and

et'Isure

that

available

VQltago

and

phase

corresponds

with

operating voltage and

ph~

of

iJolt.

2. Ensure tl'lat

an

adequate eef\lice Is aviidlable

to

Cat!Y

full unit

amperage

drawn

as

specified

by

fusa

size

on unit nameplate,

3.

A fused disccnnect

breaker

~mbly should be

installed to

protGCt

unit

and

to provide corr.pl8te

system shutdown during periods

of

non·use.

4.

Recommended fuse size

for

disconnect

1$

stated

on

unit

nameplate and

1ft

product

catalogue.

5.

COOTlect

cabloet

grounti terminal to ground. Do

NOT use neutral wire

of

fQurwlre supply as ground.

6.

Single pha5e

lInlts

INiY be

run

On

3 phase power

but

load may unbalaoce power grid.

1.

Never use the neutral wlre

of

a 4

wlr~

system as a

power lead connection

with

thu

exC41ptiOll

of

'E7V

and

347\1

tapped

from 480V and 575V !'el.'pootlvely.

8.

PoW$r

leads are connected

to

thliJ

primary terminal

blQi!k In

the

electrical

section

through

the

knocl<outs provided in the

bottom

plate

of

the

unit.

9.

Wiring

sims

shouid

be

In accordance vrith national

and

loc;a\

eleotrlcal codes

arm

by·laws,

unit

elec.

trical

Co<S$S

aM

by-laws.

9

CONTROLS

ON/OFF

CONTROL

(ContfC)1

Wiring

D100ram

2.3,1)

A,

6

a~c

C

are

to

be

wired In series (o:'Ily

one

path for

cu

rrer;

t)

acrQS.S

terminals 1

and

2 on

tM

low

voltage con·

trol terminal strlp. or replaced

wlth

a jumper wire for con-

&tar.t cperat!on.

A - Control On/OH th,midlsta1

Wired to make

on

drop

in

humidity. breal( on rise.

S - High

L.lmit

OnlOff

Humidistat

Wired

ta

make

0;'1

drop

In humidity, break on rise.

Set

to

a higher set point (max.

85

1

/0

A.H.)

as

a safe-

ty

to

prevent

~aturatlon.

c

~

Alr.Proving OnlOff 5wttch

1.

2.

3.

4.

t'

:.I.

6.

W:red to make wh8n sensing

alt

flow,

break

1Aihen

no air flow.

As

a safety

Ie

prevent saturation when

no

air

flow.

Tne

factery offers vat10us versions

of

A, B

and

C

t:>

suit

eaen applicatioo.

In

general. A

1$

essentlsJ

whereas B anti C are

highly

recomm~{\ded.

Field

wiring

from

humidistat to humidifier

and

bet-

ween de'l\ces should be 18 AWG

Qr

heavier and

sl"too!d

not

exceed 100

188t

total

length

to

all<!

from

SiflGS

vQJtage

loSS

in

tile

humidifier

will

CIlUOO

re(juced power

to

primary

contaotof

holding

coil

and the contacto(

might

not

function.

Measure

the

v~ltage

acrcss

the

coli

to

ensure It 1524 '1.2.0. ±

10%.

If

it

is

not, Consult factory.

Tha low voltage

17

point)

contrel

terminal

strip

Is

provided In the electrical compartment.

Tne

Inter·

nal 5!de

is

factory wired. The oxternal sldu Is

to

be

field wired unless the extern31

CCJntrol~

have

been

r..llblMt r.loonted at the factory.

Each unit is supplied

wUh

a wiring diagram

adhered

to

the cabinet.

A

and

B:

MOl)nt

any

wall Ill.lmidJstat (cQntrol

or

high

limit) over a standard

electrical

box

at a height

similar

to

a typical thermostat.

Any

wall

humidistat

ShCtjld

be

In

a location mptcsentative of

tM

overall

space bell\{j

humidified

and

not

In

th.

path

of

il

blower pack

or

an air su pply grille.

A!

Mount any

duct

control

humidistat

In

a location

r~reseotativa

of

the o\lerall

air

humidity. usually

the

retum duot.

Do

not

mount

it

dlroot!y

in

frollt

of

the

$team

distributor

Of

In a turbulent

or

mixing

u>oe.

Mounl

;1

where

the

ai(s

humldltv

and

Loading...

Loading...