Page 1

STEAM

DISTRIBUTORS

ASD / BSD / CSD

Steam Distribution

Installation Manual

IMPORTANT: Read and save this guide for future

reference. This guide to be left with equipment owner.

1506117-B

Page 2

Table Of Contents

INSTALLATION .....................................1

RECEIVING & UNPACKING EQUIPMENT .....................1

PRE-INSTALLATION.................................1

STEAM LINE INSTALLATION ............................1

GUIDELINES ...................................1

CONDENSATE RETURN GUIDELINES FOR MAIN STEAM LINES ..........2

DISTRIBUTOR MOUNTING...............................3

VERTICAL AIRFLOW ..................................4

HORIZONTAL AIRFLOW ................................5

VERTICAL AIRFLOW ..................................6

DISTRIBUTOR MOUNTING - HORIZONTAL & VERTICAL FLOW ...........7

DISTRIBUTOR MOUNTING...............................7

EXPLODED VIEW ....................................8

Page 3

INSTALLATION

Chart #1

Steam Line Material

RECEIVING & UNPACKING EQUIPMENT

1. Check packing slip to ensure ALL material

has been delivered.

2. All material shortages are to be reported to

Walter Meier (NORTEC) within 48 hours

from receipt of goods. Walter Meier

(NORTEC) assumes no responsibility for

any material shortages beyond this period.

3. Inspect shipping boxes for damage and

note on shipping waybill accordingly.

4. After unpacking, inspect equipment for

damage and if damage is found, notify the

shipper promptly.

5. All NORTEC products are shipped on an

F.O.B. factory basis. Any and all damage,

breakage or loss claims are to be made

directly to the shipping company.

6. Each distributor is provided with: installation

manual, one hose cuff, and two hose

clamps.

PRE-INSTALLATION CHECK

1. Ensure the total capacity of the humidifier is

not higher than the allowable maximum

steam capacity of the distributors used.

ASD 10: 22 lbs/hr (8 kg/hr)

ASD: 25 lbs/hr (9 kg/hr)

BSD: 35 lbs/hr (13 kg/hr)

CSD: 115 lbs/hr (45 kg/hr)

STEAM LINE INSTALLATION

Short run

< 10 feet

Steam

Hose

üü ü

Copper Tube Stainless

Steel Tube

(3 m)

Long run

> 10 feet

üü

(3m)

DI/RO

water

ü

4. Consult the following pages for step by step

distributor installation starting with Figure

#1.

5. Consult the charts below for steam and

condensate sizing guidelines when using

steam distributors.

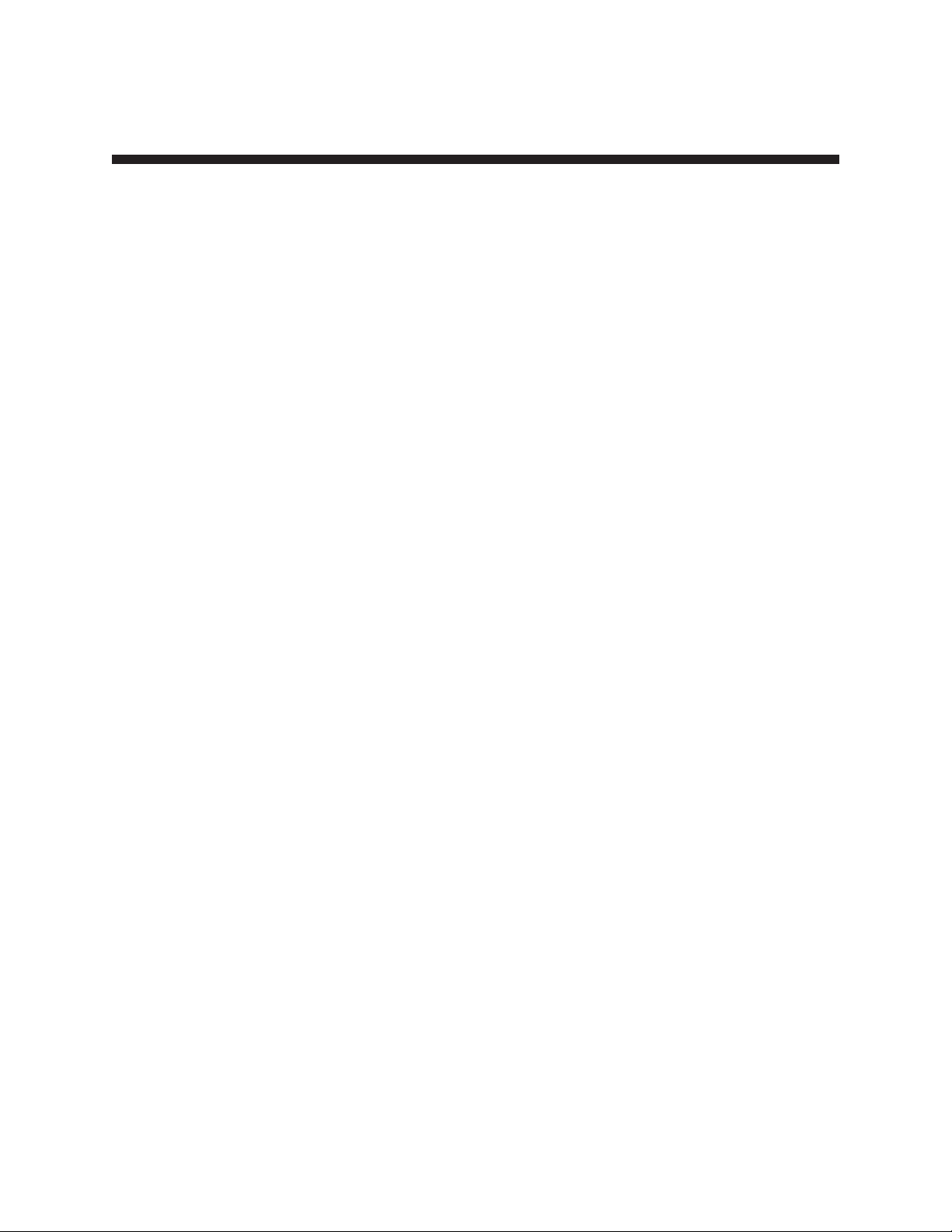

Chart #2

Recommended material and size for steam run

Load Steam Run

lb/hr kg/hr ft m

0-30 0-13 0-10 0-3

0-30 0-13 10 + 3 +

0-30 0-13 0-10 0-3

0-30 0-13 10 + 3 +

Steam

Line

Material

Copper

tube

Copper

tube

Stainless

Steel tube

Stainless

Steel tube

Steam Line

Description

3/4" MED-L Tubing

(7/8" O.D.)

1” MED-L Tubing

(1 1/8" O.D.)

7/8” tube x

0.049” thick.

1 1/8” tube x 0.049”

thick.

GUIDELINES

1. Nortec steam hose should only be used on

short steam runs below 10 feet.

2. Ensure that no condensate produced in the

steam line will remain trapped. Steam

naturally flows upward and condensate

naturally flows downward.

3. See material recommended for use in the

chart below. To eliminate the metal

corrosion, Nortec does not recommend the

use of steel piping.

30-100 13-45 0-20 0-6

30-100 13-45 20 + 6 +

30-100 13-45 0-20 0-6

30-100 13-45 20 + 6 +

Please note that options shown in a bold-italic font requires

that reducers be used at both ends. These extra large sizes are to

allow for better condensation removal in long steam runs. These

sizes will not permit you to use hose coupling to connect your

self to either humidifier or distributors.

Copper

tube

Copper

tube

Stainless

Steel tube

Stainless

Steel tube

1½”MED-LTubing

2” MED-L Tubing

-1-

(1 5/8" O.D.)

(2 1/8" O.D.)

1 ¾” tube x

0.065” thick.

2” tube x

0.065” thick.

Page 4

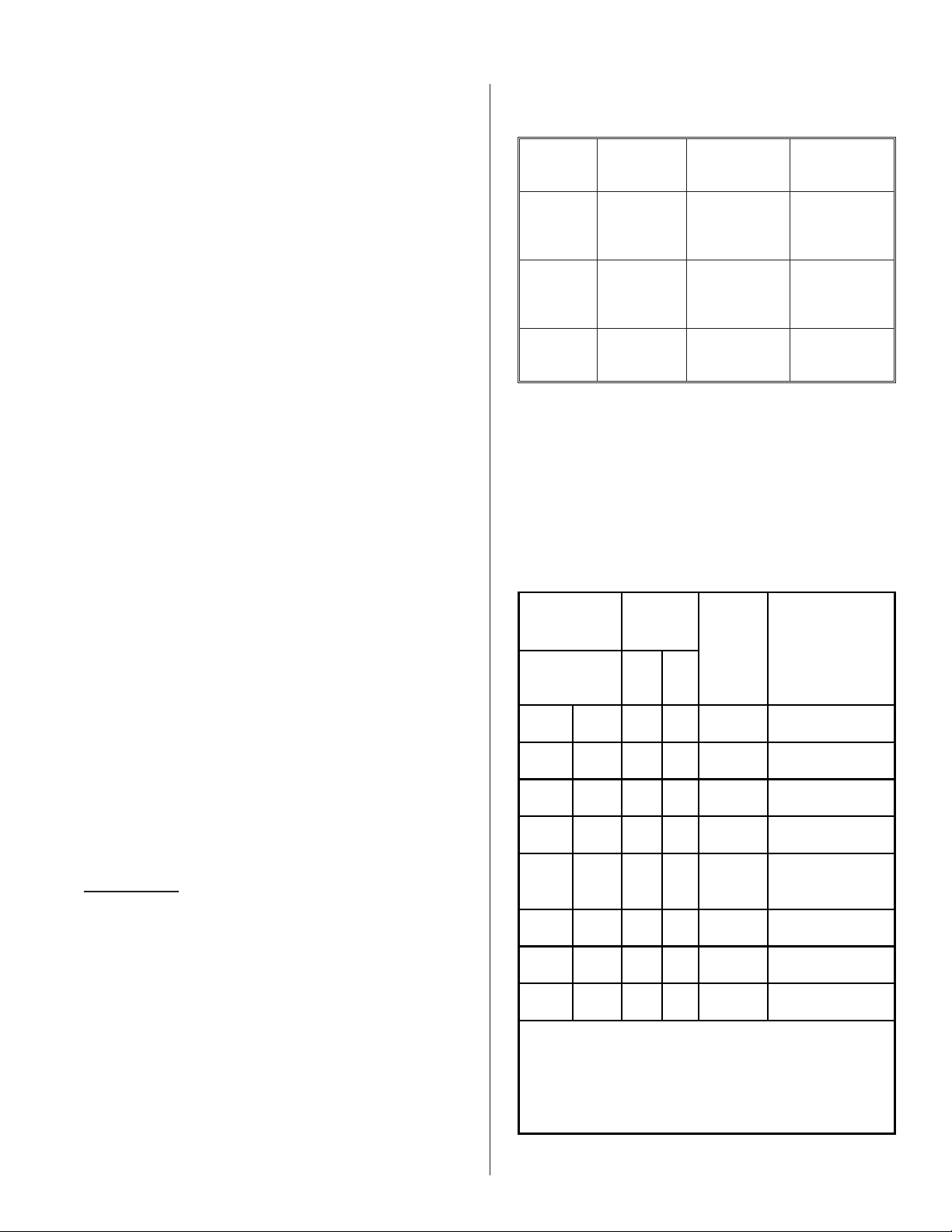

Chart #3

Recommended Condensate line at distributor(s)

Dispersion

Method

1 x Steam

distributor

3 x Steam

Distributor*

*When using more than one distributor, the condensate line

should be trapped before joined together.

Condensate

Hose

3/8" Nortec

1328840

3/8" Nortec

1328840

Copper tube

1/4" MED-L

Tubing

(3/8" O.D.)

1/2" MED-L

Tubing

(7/8" O.D.)

Stainless Steel

tube

3/8” tube

0.049” thick.

5/8” tube

0.049" thick

CONDENSATE RETURN GUIDELINES FOR

MAIN STEAM LINES

1. Use vertical condensate leg of distributor

only. Do not over-tighten clamp.

2. Drip stations on steam mains must be

located at all low points in the system, at

each elevation change and or directional

change.

6. Vertical drop of the drip station should be

1.5 times the diameter of the steam main

but no less then 12”.

7. At the bottom of this drip station is where

the “p-trap” is installed. It is to be 2” larger

then the duct static duct pressure.

8. All distributors must be individually trapped.

3. Horizontal runs of steam must have a 2”

rise per foot (10º) when flow is going

upwards from drip station and the steam

run is to fall ½” per foot (2º) when flow is

going downwards to drip station.

4. In a horizontal run of the steam main, drip

stations must be located at regular intervals

of 20 feet.

5. The drip station itself is a section of piping

connected to the bottom of the main. A full

size tee must be used to create a drip

station to allow the condensate to fall in the

drip station.

Figure #1

Drain Tee

Full Size

Drain Tee

-2-

Page 5

g

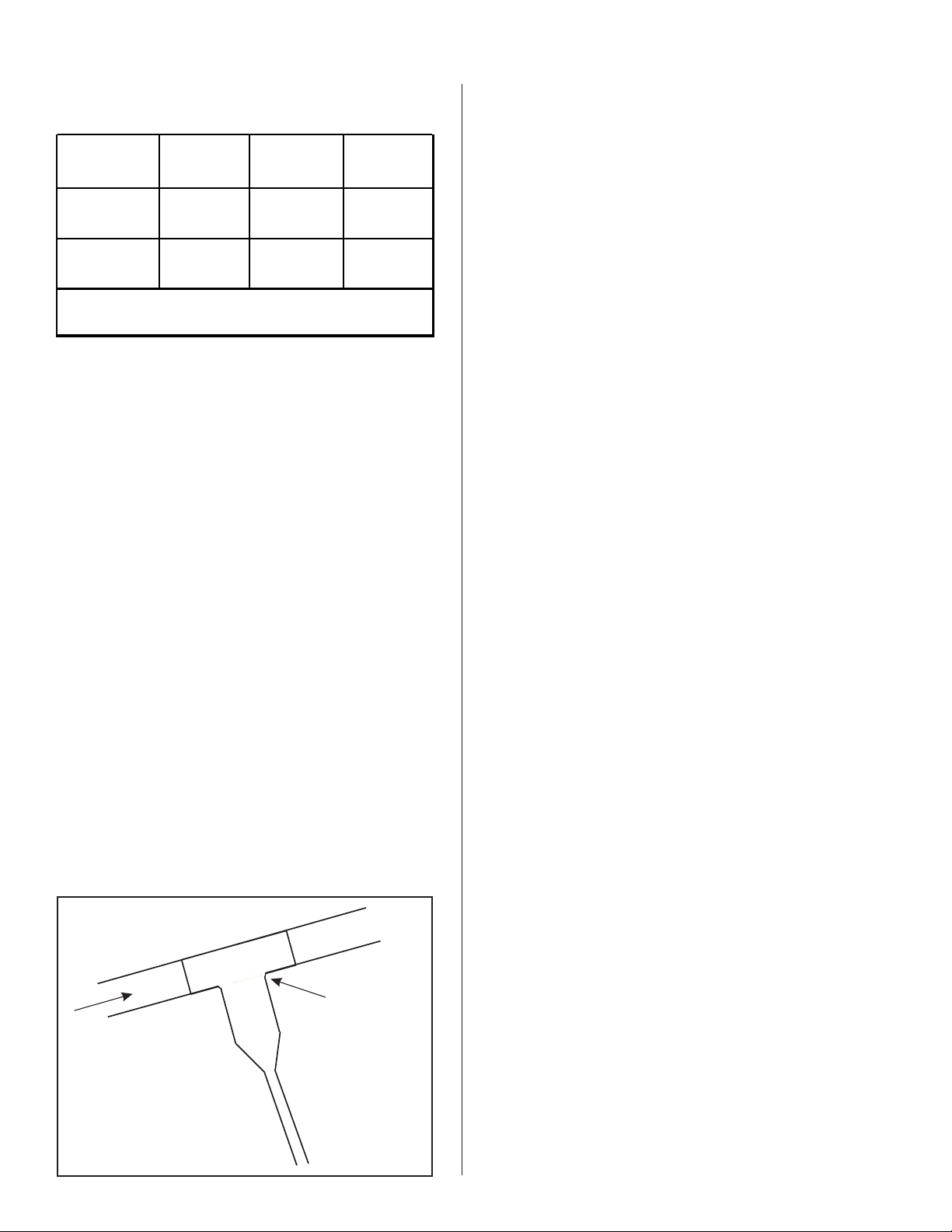

Figure #2

Distributor Mounting

A

HORIZONTAL FLOW

Use vertical

condensate leg

only.

To be 2” (50mm) longer

then duct static pressure

or minimum.

GO TO

Use vertical

condensate leg

only.

To be 2” (50mm) longer

then duct static pressure

or minimum.

min.

Use vertical

condensate leg

only.

100

m

”

6

VERTICAL FLOW

min. 2º min. 10º

)

m

.

m

n

i

0

m

0

R

min. 10º

”min.(914mm)

12

m

m

0

5

1

(

n

i

m

”

6

3

(

”

2

1

)

12” (300 mm)

Nortec

Use vertical

condensate leg

only.

m

”

6

Humidifier

NHB, NHP, NHMC,

RESDELUX ONLY

C1

min. 2º min. 10º

)

m

m

0

0

3

(

”

2

1

min. 10º

”min.(914mm)

12

)

m

m

0

5

1

(

n

i

m

”

6

Nortec

Humidifiers

All Models

)

m

m

0

.

0

n

i

min. 20 %

Nortec Humidifiers

All Models

%

”min.(914mm)

12

)

m

m

0

5

1

(

n

i

n

i

m

”

6

3

(

Rm

(

12” (300 mm)

min. 10ºmin. 2º

”

2

1

0

5

1

12” (300 mm)

)

m

m

Use vertical

condensate leg

only.

GO TO

Use vertical

condensate leg

only.

min. 20 %

(

n

i

m

”

6

0

5

1

(

n

i

m

”

6

min. 2º min. 10º

min. 10º

”min.(914mm)

12

)

m

m

0

5

1

(

n

i

B

min. 10º

”min.(914mm)

12

)

m

m

0

5

1

min. 10º

”min.(914mm)

12

)

m

m

)

m

.

m

n

i

0

m

0

R

3

(

”

2

1

Nortec

Humidifier

NHB, NHP, NHMC,

RESDELUX ONLY

min. 10ºmin. 2º

)

.

m

n

i

m

m

0

0

R

3

”(

2

1

Nortec

Humidifiers

All Models

)

m

m

0

0

.

3

(

n

i

”

2

1

Rm

Nortec Humidifiers

All Models

m

0

5

1

(

n

i

m

”

6

12” (300 mm)

12” (300 mm)

min. 10ºmin. 2º

12” (300 mm)

)

m

GO TO

C1 B

GO TO

For long steam runs, condensate trap with full size tee, must

be used every 20 feet to eliminate condensate. Follow same

rulesasabovefortraphei

ht.

-3-

Page 6

Figure #3

Vertical Airflow

B

Always align distributor holes so that steam is discharged

upwards to ensure condensate will remain in the distributor.

1

1x

2

+45º

-45º

3

GO TO

C2

-4-

Page 7

Figure #4

Horizontal Airflow

C1

Always align distributor holes so that steam is discharged

upwards to ensure condensate will remain in the distributor.

Template provided

81-...

41-...

6

1

m

m

m

m

3

4

8

1

.

.

.

6

1

.

.

.

/

4

1

.

.

.

m

m

6

.

3

H

¿

X

by Nortec in box.

61-...

81-

61-... / 41-...

...

3.6 mm

¿

XMin. HMin.

ASD

3” (76mm)

BSD

4” (102mm)

CSD

5” (127mm) 14” (356mm)

10” (254 mm)

ASD ø 1.7" (43 mm)

BSD ø 1.7" (43 mm)

CSD ø 2.4" (61 mm)

8” (203mm)

2/5H

2/5H

1/5H

A

A

B

2/3H

H

1/3H

H

5”m in.

AB

ASD: 5” 3”

BSD: 6” 4”

CSD: 9” 5”

GO TO

-5-

D

Page 8

Figure #5

Vertical Airflow

C2

Always align distributor holes so that steam is discharged

upwards to ensure condensate will remain in the distributor.

1/3W

W

2/3W

Min. W = 8” (203 mm)

GO TO

D

1/3W1/3W

H

1/3W

1/3W

WARNING:

·

These installation guidelines apply for duct velocities under 2000 ft/min (610 m/min), please consult factory

for higher velocities.

·

Please make sure no obstacles (elbow, filter, or diffuser) are located after the distributor in the direction of the

airflow closer than the absorption distance calculated for your application.

·

Unless you know the exact absorption distance required for the steam absorption into the air stream, the

distributor should be located at least 8-10 ft (2-3 m) away from any obstacle it may condense on (elbow,

diffuser, filter, etc.).

-6-

Page 9

Figure #6

t

Distributor Mounting - Horizontal & Vertical Flow

D

#10 Scre w

Use self tapping sc rews.

Mount

Level

GO TO

Distributor Mounting

E

Figure #7

E

5/16”

5/16” unc

Mandatory for Distributors longer than 36” (915mm).

-7-

Support Bracke

by Others

Page 10

ASD & BSD

1506162- Distributor End Cap Assembly

CSD

1506164 - Distributor End Cap Assembly

Distributor Core

ASD & BSD

1506161- Distributor Inlet Assembly

CSD

1506163 - Distributor Inlet Assembly

Exploded Views

December 18, 2002

-8-

Page 11

LIMITED WARRANTY

Walter Meier Inc. and/or Walter Meier Ltd. (hereinafter collectively referred to as

THE COMPANY), warrant for a period of one year from date of shipment, that THE

COMPANY’s manufactured and assembled products, not otherwise expressly

warranted, are free from defects in material and workmanship. No warranty is made

against corrosion, deterioration, or suitability of substituted materials used as a result of

compliance with government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to

furnishing replacement parts to the customer, F.O.B. THE COMPANY’s factory,

providing the defective part(s) is returned freight prepaid by the customer. Parts used

for repairs are warranted for the balance of the term of the warranty on the original

humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or

implied by law. No liability whatsoever shall be attached to THE COMPANY until said

products have been paid for in full and then said liability shall be limited to the original

purchase price for the product. Any further warranty must be in writing, signed by an

officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of Walter Meier’s

manufacture, such as controls, humidistats, pumps, etc. is limited to the warranty of the

original equipment manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment

is installed in strict accordance with a copy of the catalog and installation manual in

effect at the date of purchase and by a contractor approved by THE COMPANY to

install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for

consequential damage or damage resulting directly from misapplication, incorrect sizing

or lack of proper maintenance of the equipment.

THE COMPANY retains the right to change the design, specification and

performance criteria of its products without notice or obligation.

Page 12

Walter Meier (Climate USA) Inc.

826 Proctor Avenue, Ogdensburg, New York 13669

Walter Meier (Climate Canada) Ltd.

2740 Fenton Road, Ottawa, Ontario K1T3T7

Tel: 866 NORTEC 1 Fax: 613 822 7964

nortec@humidity.com www.humidity.com

PRINTED IN CANADA

Loading...

Loading...