Page 1

Important: Read and save these instructions. This guide to be left with equipment owner.

BACnet®,

LONWORKS®

Supplemental

Installation and

Operation Manual

Using BACnet or LonWorks with

Nortec Humidifiers. Includes

installation, operation

maintenance and troubleshooting

information.

2574199 –A| 24 October 2013

Page 2

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Thank you for choosing Nortec.

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nortec Humidity Ltd. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of Nortec Humidity Ltd., except to the extent required for installation or maintenance of

recipient’s equipment.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or the

use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2013, Nortec Humidity Ltd. All rights reserved

BACnet® is a registered trademark of ASHRAE.

LONWORKS® is a registered trademark of Echelon Corporation.

BACnet & LONWORKS Supplemental Install Manual | 2

Page 3

Contents

Introduction 2

Requirements 2

NH-EL Wiring Connections 3

BACnet MS/TP 3

BACnet IP 4

Addressing and Communication 8

BACnet Communication Set-up 8

Control Signal Setting 9

Control Mapping 10

Options (Lonworks, BTL Certified

BACnet) 14

Field Retrofit Installation 14

Addressing and Communication 17

Control Signal Setting 17

Controller Set-up 18

BTL Certified BACnet specific :

Changing Unit Addressing 18

Changing Baud Rate (BACnet MSTP Only) 19

BACnet Pics and Bibs 19

LonWorks Variables 19

Troubleshooting 22

APPENDIX A 24

APPENDIX B 26

Warranty 30

Page 4

Page 5

CAUTION: Servicing

CAUTION: Electrical

CAUTION: Installation

Disconnect main power before any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

Nortec Humidity Ltd does not accept any liability for installations of humidity

equipment installed by unqualified personnel or the use of

parts/components/equipment that are not authorized or approved by Nortec

Humidity Ltd.

All electrical work should be done according to local and national electrical code.

Electrical connection to be performed by a licensed electrician.

Do not mount Humidifier on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat.

Page 6

Introduction

Nortec Humidifiers equipped with the Integrated Controller (touch screen) can readily connect to

BACnet Master Slave Token Passing (BACnet MS/TP) and Internet Protocol (BACnet IP) building

management systems (BMS) right out of the box. This document describes how to connect

these humidifiers to such a network and defines the parameters that may be monitored. This

document also describes the additional options that can be purchased when interfacing with

LonWorks or BTL certified BACnet. Contact the factory for more information on other protocols

not listed in this manual.

Requirements

All NH-EL humidifiers are capable of Modbus, BACnet MS/TP and BACnet IP connectivity right

out of the box and require no additional hardware to interface with these BMS. For Modbus

specific details, consult Nortec Modbus Manual 2560599-C.

LonWorks and BTL certified BACnet systems require additional optional hardware – see Options

(Lonworks, BTL Certified BACnet) for more details.

Please note: to use the BTL certified BACnet or Lonworks protocols, the jumper J7 must NOT be

on. When the jumper J7 is on, the controller will enable the native Modbus protocol available

on BMS communication port.

BACnet & LONWORKS Supplemental Install Manual | 2

Page 7

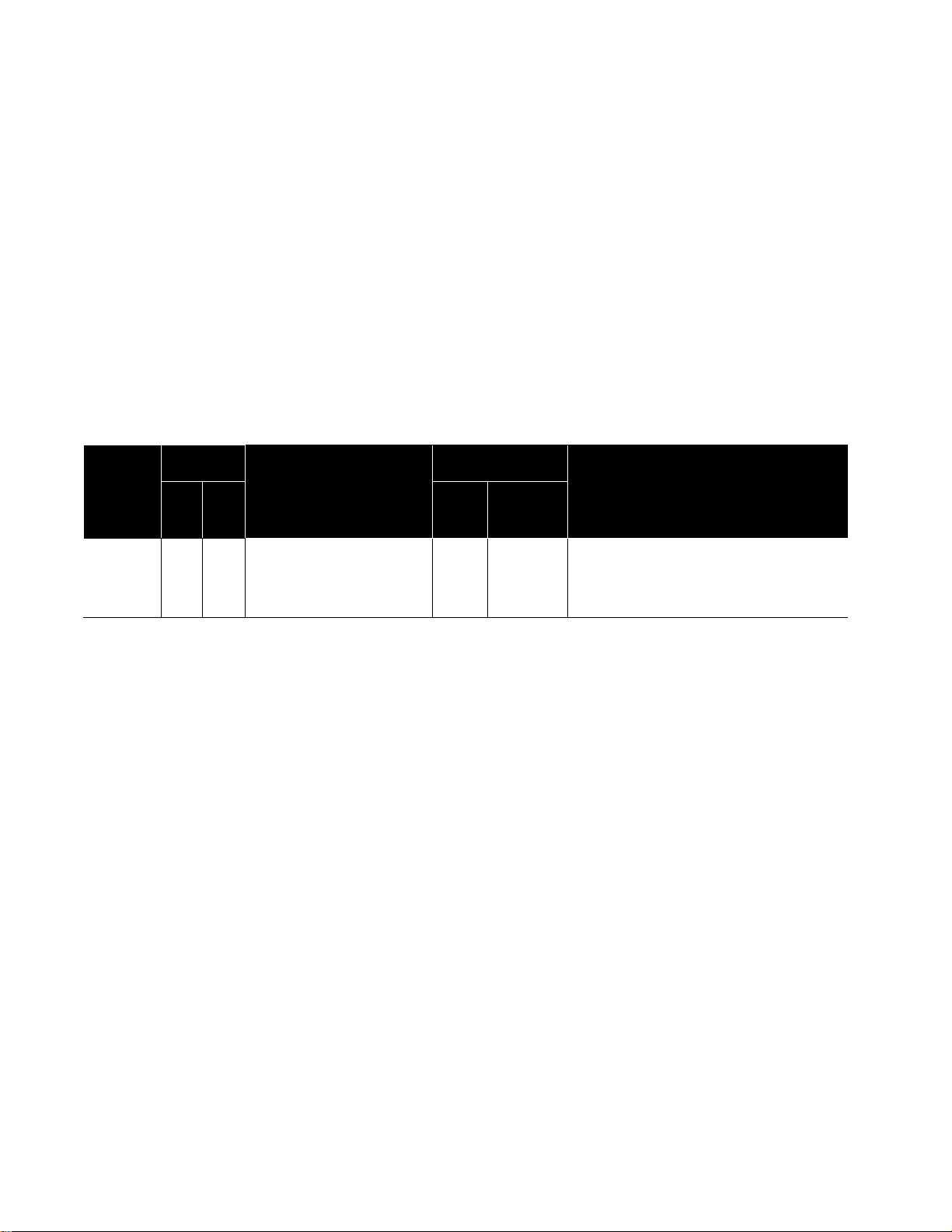

NH-EL Wiring Connections

Signal

Type

Polarity

Recommended Cable

Address

Maximum Recommended Distance

from NORTEC Humidifier

A

B

Node

ID

Device

Instance

EIA-485,

2-wire

Net - Net

+

18-24 AWG Shielded,

Twisted Pair

120 Impedance

79*

1001*

2300 ft at 9.6 kbps

2000 ft at 38.4 kbps

Using the correct wiring between the humidifier and the BACnet network is important to ensure

reliable communications and reduce the impact of electrical interference.

BACnet MS/TP

For BACnet MSTP networks, the recommended wire type is 18 -24 AWG, shielded twisted pair

wire with 120 Ohm characteristic impedance. Ensuring the correct shield terminations is

necessary to prevent electrical interference. The wire shield should be terminated at either the

humidifier or the BACnet system, but not both. This allows induced current to “drain”; if the

shield is terminated at both ends it will function as a conductor and can actually increase

electrical interference. To minimize signal loss a wire run should not exceed 2000 feet at 38.4

kbps.

Table 1: BACnet MS/TP Parameters

*Default, may vary for multi-unit orders.

3 | BACnet & LONWORKS Supplemental Install Manual

Page 8

BACnet IP

Signal Type

BACnet IP

Recommended Cable

Address

Maximum

Recommended Distance

from NORTEC Humidifier

Transmission

Mode

Port

Node

ID

Device

Instance

LAN

Standard

UDP

47808

Category 5 Ethernet

Cable (CAT 5 or better)

with RJ-45 termination

79*

12*

Depends on cable

manufacturer, refer to

BMS Supplier for

recommendations

For BACnet IP networks, the recommended wire type is standard Category 5 Ethernet Cable

(CAT 5) with RJ-45 terminations (Category 5E and category 6 cable are also acceptable). Refer

to the BMS supplier for maximum recommended lengths of CAT5 cable.

Table 2: BACnet IP Parameters

*Default, may vary for multi-unit orders.

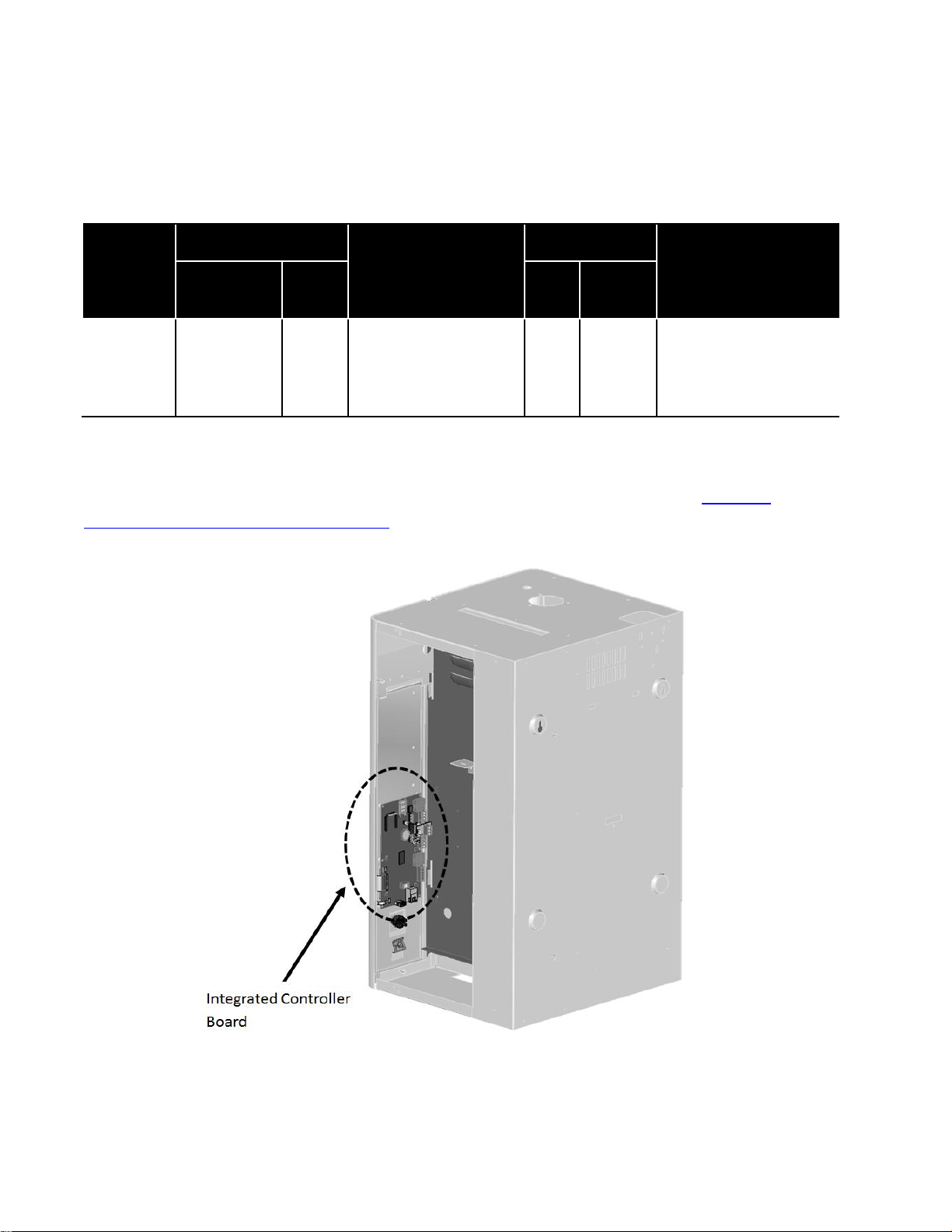

Wiring connections are made directly to the integrated controller circuit board. Figure 1:

Location of Integrated Controller Board shows the location of the board inside the NH-EL.

Figure 1: Location of Integrated Controller Board

BACnet & LONWORKS Supplemental Install Manual | 4

Page 9

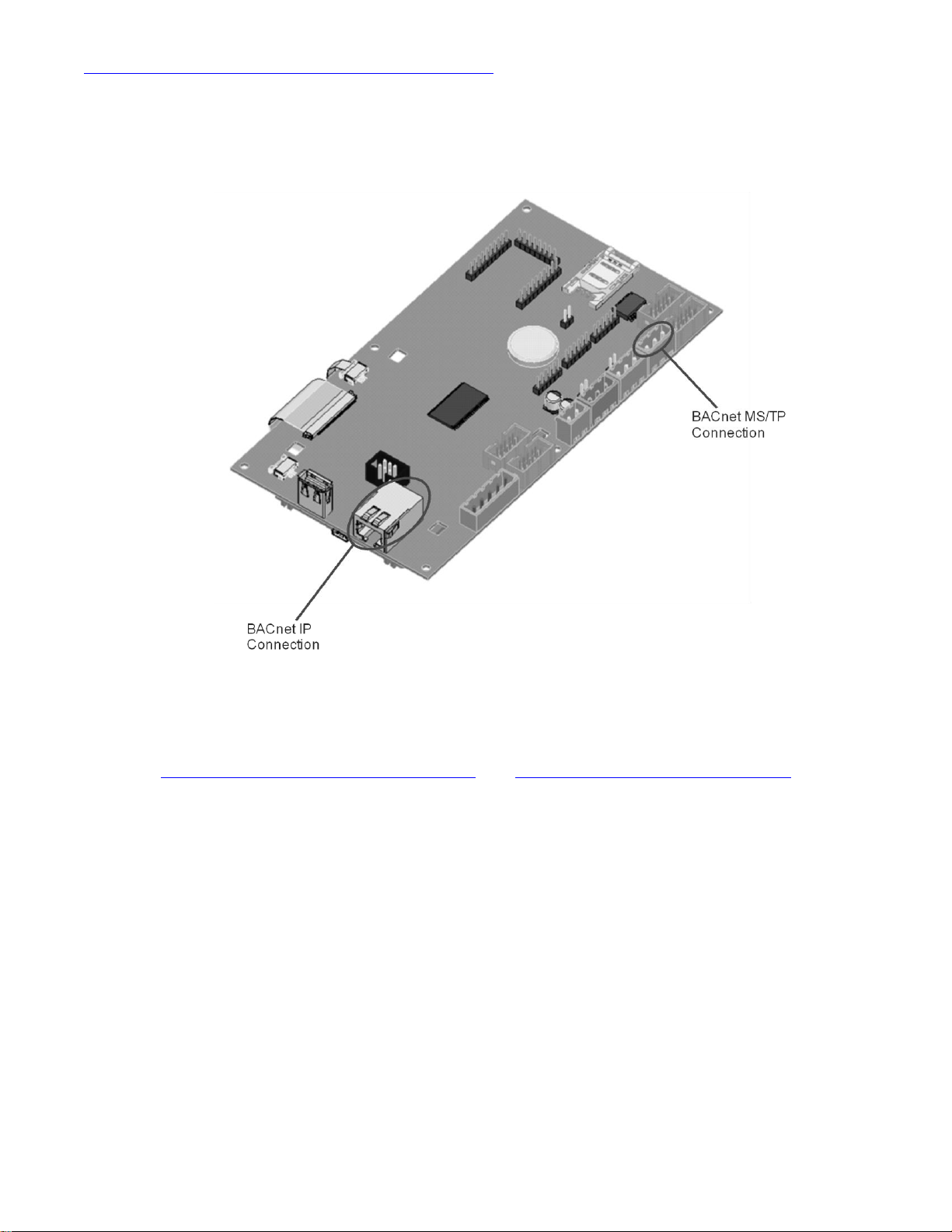

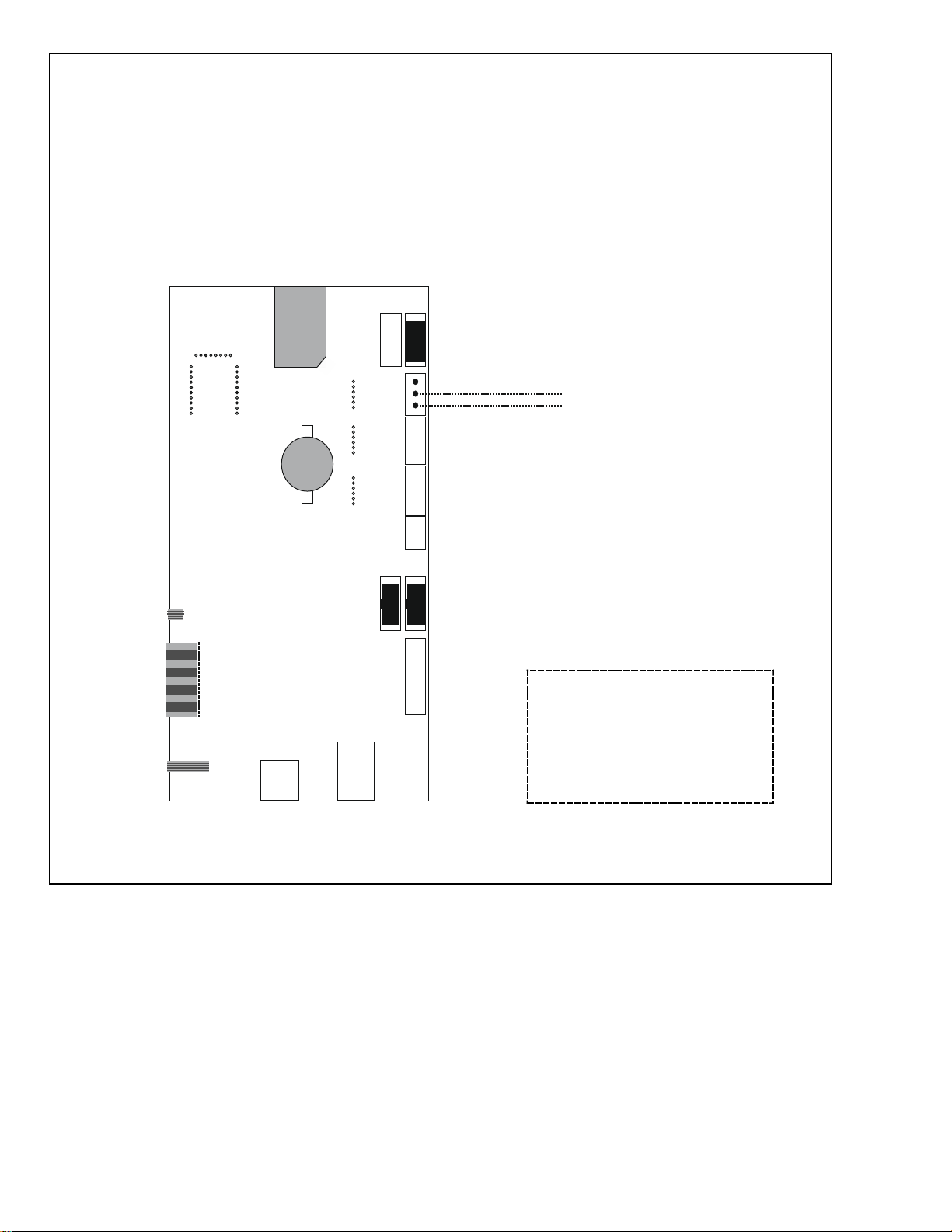

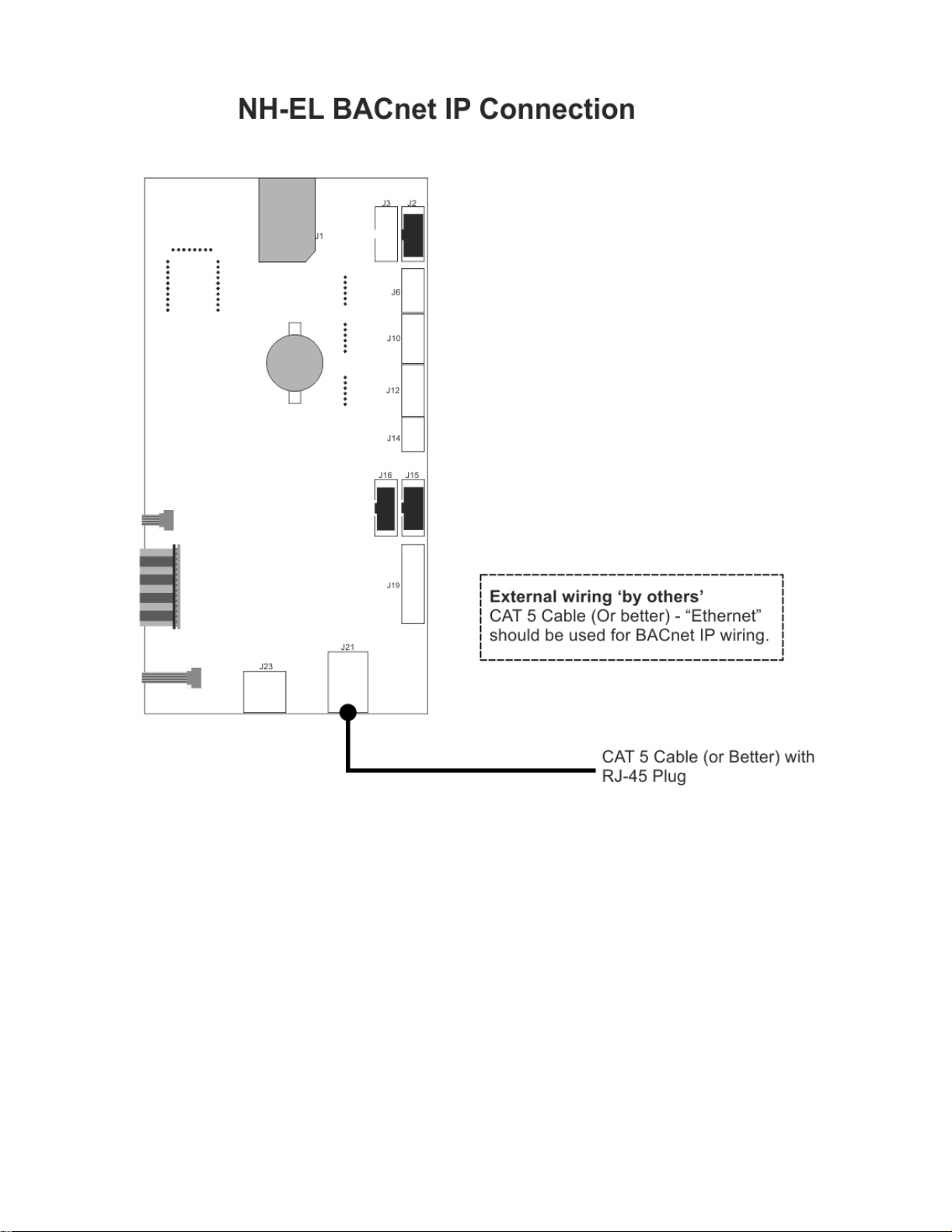

Figure 2: BACnet MS/TP and IP Connection Location show where the physical connections will

be made in order to interface with one of these BMS protocols. For information on Optional

protocols, such as Lonworks or BTL certified BACnet, please see Options (Lonworks, BTL

certified) for details.

Figure 2: BACnet MS/TP and IP Connection Location

Refer to , Figure 3: BACnet MS/TP Wiring Diagram and Figure 4: BACnet IP Wiring Diagram for

instructions on making wiring connections for each respective protocol.

5 | BACnet & LONWORKS Supplemental Install Manual

Page 10

J15

J1

J2J3

J6

J10

J12

J14

J19

J21

J23

J16

BACnet MS/TP Port

NET

NET

COMMON

(-)

()+

NH-EL BACnet MS/TP Connection

External wiring ‘by others’

RS-485 cable recommended:

-18-24 AWG stranded

-Twisted pair, Shielded

-120 Ohm impedance

-Terminate shield at one end only

Figure 3: BACnet MS/TP Wiring Diagram

BACnet & LONWORKS Supplemental Install Manual | 6

Page 11

Figure 4: BACnet IP Wiring Diagram

7 | BACnet & LONWORKS Supplemental Install Manual

Page 12

Addressing and Communication

BACnet IP

BACnet MSTP

Default IP addressing

IP Type: DHCP

IP: 192.168.168.243

Subnet: 255.255.255.000

Gateway: 192.168.168.101

N/A

Default BACnet Address

(MAC address)

79

79

Default BACnet Node ID

(Device Instance)

12

1001

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the BACnet interface.

BACnet Communication Set-up

The following table demonstrates the default addressing found on the NH-EL:

Table 3: BACnet Specific Defaults

Locating the IP addressing in the NH-EL is summarized as follows:

Main Menu > 0335 > Configuration > Comms. Menu > Network Parameters >

Note: By default, the NH-EL will have BACnet disabled. To enable BACnet, select BACnet IP or

BACnet MSTP under BACnet Parameters. Select the respective protocol and confirm the

selection by pressing the Check Mark button. This action is summarized as follows:

Main Menu > 0335 > Configuration > Comms. Menu > BACnet Parameters >

Once BACnet is enabled, addressing can be modified as desired.

Locating the BACnet Address (MAC address) in the NH-EL is summarized as follows:

Main Menu > 0335 > Configuration > Comms. Menu > BACnet Parameters > BACnet MSTP

address

Locating the BACnet Node ID (Device Instance) in the NH-EL is summarized as follows:

Main Menu > 0335 > Configuration > Comms. Menu > BACnet Parameters > Node ID

BACnet & LONWORKS Supplemental Install Manual | 8

Page 13

Control Signal Setting

Source

Analog: Use hardwired control signal

BACnet/IP: Write control signal through BACnet/IP interface

BACnet/MS: Write control signal through BACnet/MS interface

Control Mode

Demand: Use a demand control signal

RH P: Use a sensor value and proportional

RH PI: Use a sensor value and proportional-integral control band

Control Channels

Single: Use a single channel control signal

Dual: Use a dual channel control signal

By default the humidifier is configured to operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its BACnet interface.

*Note: the Humidifier Security loop will still need to be enabled for humidifier to run.

To adjust this setting:

1 Press the Menu icon on the lower left corner of the status screen, to access the menu.

2 When prompted for a password, enter 0335 using the number pad. Press the Check Mark

icon to confirm.

3 Select the Configuration menu.

4 Select the Control Settings menu. The following settings can be adjusted:

Table 4: Control Signal Parameters

Note: Refer to the CONTROL SETTING section of the NH-EL Installation and Operation Manual

for more information on the above settings.

5 Press Back repeatedly to return to the home screen when complete.

This procedure is summarized below:

Main Menu > 0335 > Configuration > Control Settings >

Source: Analog, BACnet/IP, BACnet/MS,

Control Mode: Demand, RH P, or RH PI

Control Channels: Single or Dual

9 | BACnet & LONWORKS Supplemental Install Manual

Page 14

Control Mapping

Parameter

Name

Description

BACnet

ID

Format

Range

Unit

R/W

Details

Dinput_A1

Write RH or

Demand signal

value to control

channel 1 for

cylinder A

10044

Integer

0 - 100

%

Write

Requires BACnet to be enabled.

For most common configurations,

this is the primary control signal

Dinput_A2

Write RH or

Demand signal

value to control

channel 2 for

cylinder A

10045

Integer

0 - 100

%

Write

Requires BACnet to be enabled.

Dinput_B1

Write RH or

Demand signal

value to control

channel 1 for

cylinder B

10046

Integer

0 - 100

%

Write

Requires BACnet to be enabled.

Only applies to NH-EL-150 and

NH-EL-200 with dual channel

control enabled

Dinput_B2

Write RH or

Demand signal

value to control

channel 2 for

cylinder B

10047

Integer

0 - 100

%

Write

Requires BACnet to be enabled.

Only applies to NH-EL-150 and

NH-EL-200 with cylinders dual

channel control enabled and

cylinders in independent

operation mode

Manual_

Capcity_A

Sets a manual

capacity limit

restriction for

cylinder A

10008

Integer

0 - 100

%

Write

Limits output to percentage of

total cylinder capacity (for single

cylinder) or for cylinder A (NH-EL150 and NH-EL-200 models only)

Manual_

Capcity_B

Sets a manual

capacity limit

restriction for

cylinder B (if

present)

10027

Integer

0 - 100

%

Write

Limits output to percentage

capacity for cylinder B (NH-EL150 and NH-EL-200 models only)

BMS_

Timeout

BMS timeout

for Modbus and

BACnet

10043

Integer

0 - 300

s

Write

It is recommend to not change

the value from the factory default

(300)

Remote_

Disable

Remotely

disable steam

production for

the unit

25

Integer

0 or 1

-

Write

0 = Idle/Humidify

1 = Disabled

SP_Chan_

A1

Writes the

desired space

setpoint for

control channel

1 for cylinder A

10010

Integer

0 - 95

%

Write

Use only when Control Mode (14)

is set to RHp or RHpi

Use only when sending RH values

to Dinput_A1.

For most common configurations

this is the primary space

setpoint.

Table 5: BACnet Object Definition List

BACnet & LONWORKS Supplemental Install Manual | 10

Page 15

SP_Chan_

A2

Writes the

desired space

setpoint for

control channel

2 for cylinder A

10013

Integer

10 - 95

%

Write

Use only when sending RH value

to Dinput_A2 with dual channel

control enabled

SP_Chan_

B1

Writes the

desired space

setpoint for

control channel

1 for cylinder B

10016

Integer

0 - 95

%

Write

Use only with NH-EL-150 and NHEL-200 models when sending RH

value to Dinput_B1 and cylinders

are in independent operation

mode

SP_Chan_

B2

Writes the

desired space

setpoint for

control channel

2 for cylinder B

10019

Integer

10 - 95

%

Write

Use only with NH-EL-150 and NHEL-200 models when sending RH

value to Dinput_B2 with dual

channel control enabled and

cylinders are in independent

operation mode

Signal_

Source

Selects signal

source to

control unit

13

Integer

0 - 4

-

Write

0 = Analog

1 = Modbus

2 = BACnet/IP

3 = BACnet/MS

4 = LonWorks

Control_M

ode

Selects method

to control unit

14

Integer

1 - 3

-

Write

1 = Demand

2 = RH P

3 = RH PI

Control_

Channel

Selects method

to control

channels

15

Integer

0 - 1

-

Write

0 = Single Channel

1 = Dual Channel

Input_A1

Displays

channel 1

demand for

cylinder A

10001

Integer

0 - 100

%

Read

Displays channel 1

demand/sensed RH as a

percentage of cylinder capacity

for cylinder A

Input_A2

Displays

channel 2

demand for

cylinder A

10002

Integer

0 - 100

%

Read

Displays channel 2

demand/sensed RH as a

percentage of cylinder capacity

for cylinder A

Input_B1

Displays

channel 1

demand for

cylinder B

10003

Integer

0 - 100

%

Read

Displays channel 1

demand/sensed RH as a

percentage of cylinder capacity

for cylinder B (NH-EL-150 and

NH-EL-200 models only)

Input_B2

Displays

channel 2

demand for

cylinder B

10004

Integer

0 - 100

%

Read

Displays channel 2

demand/sensed RH as a

percentage of cylinder capacity

for cylinder B (NH-EL-150 and

NH-EL-200 models only)

Blower_

Pack_A

Reads the

status of the

blower pack for

cylinder A

4

Integer

0 or 1

-

Read

0 = Open

1 = Closed

11 | BACnet & LONWORKS Supplemental Install Manual

Page 16

Blower_

Pack_B

Reads the

status of the

blower pack for

cylinder B

6

Integer

0 or 1

-

Read

0 = Open

1 = Closed

Fan_

Activate_A

Indicates if air

handle or

furnace is

activated for

cylinder A

1

Integer

0 or 1

-

Read

0 = Not Activated

1 = Activated

Fan_

Activate_B

Indicates if air

handle or

furnace is

activated for

cylinder B

2

Integer

0 or 1

-

Read

0 = Not Activated

1 = Activated

Do_Fault_

A

Reads the

status of a fault

on the unit

69

Integer

0 or 1

-

Read

0 = No Fault

1 = Fault

Do_

Service_A

Reads the

status of a

service request

on the unit

67

Integer

0 or 1

-

Read

0 = No Service Required

1 = Service Required

Humidifier

_

Status_A

Reads the

status of the

unit for cylinder

A

36

Integer

0 - 9

-

Read

0 = Humidifying

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

9 = Fault

10 = blower pack

Humidifier

_

Status_B

Reads the

status of the

unit for cylinder

A

57

Integer

0 - 9

-

Read

0 = Humidifying

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

9 = Fault

10 = blower pack

BACnet & LONWORKS Supplemental Install Manual | 12

Page 17

System_

Demand_A

Reads the

demand for

cylinder A

10057

Integer

0 –

100

%

Read

Demand Mode:

Summation of Input_A1 and

Input_A2

RH Mode:

PID calculation

System_

Demand_

B

Reads the

demand for

cylinder B

10058

Integer

0 –

100

%

Read

Demand Mode:

Summation of Input_B1 and

Input_B2

RH Mode:

PID calculation

Safety_

Loop_A

Reads the

status of the

safety loop for

cylinder A

3

Integer

0 or 1

-

Read

0 = Open

1 = Closed

Safety_

Loop_B

Reads the

status of the

safety loop for

cylinder B

5

Integer

0 or 1

-

Read

0 = Open

1 = Closed

Run_Time

_A

Reads

operating time

for cylinder A

10060

Integer

0 5000

Hrs

Read

Displays the total time cylinder A

has been running since last reset

Run_Time

_B

Reads

operating time

for cylinder B

10079

Integer

0 5000

Hrs

Read

Displays the total time cylinder B

has been running since last reset

Weighted_

Hours_A

Reads the

weighted time

for cylinder A

10061

Integer

0 5000

Hrs

Read

An equated run time based on

Run_Time_A x

System_Demand_A

Weighted_

Hours_B

Reads the

weighted time

for cylinder B

10080

Integer

0 5000

Hrs

Read

An equated run time based on

Run_Time_B x

System_Demand_B

13 | BACnet & LONWORKS Supplemental Install Manual

Page 18

Part

Number

Kit Name

Kit Description

2574194

Lonworks, NH-EL

Factory installed option for Echelon’s LonWorks

protocol

2574193

BACnet MSTP, BTL Certified, NH-EL

Factory installed option for BTL approved protocol for

BACnet MSTP

2574192

BACnet IP, BTL Certified, NH-EL

Factory installed option for BTL approved protocol for

BACnet IP

Part

Number

Kit Name

Kit Description

2574197

Lonworks, NH-EL , Retrofit

Field install option for Echelon’s LonWorks protocol

2574196

BACnet MSTP, BTL , NH-EL Retrofit

Field install option for BTL approved protocol for BACnet

MSTP

2574195

BACnet IP, BTL, NH-EL Retrofit

Field install option for BTL approved protocol for BACnet

IP

1

Options (Lonworks, BTL Certified BACnet)

Nortec offers additional protocol options that may be purchased if required. Both field and

factory installed versions are available and include Lonworks and BTL® (BACnet Testing Lab)1

certified BACnet. See Table #6 and Table #7 for specific part numbers and details.

Table 6: Optional Factory Installed Part Numbers

Table 7: Optional Field Install Part Numbers

Field Retrofit Installation

The kits consist of a single interface card that is mounted on the rear side of the integrated

controller. Care should be taken with installation the optional unit in the field. Users will need to

install the interface card onto the pins as shown in Figure 5: Mounting Location and Figure 6:

Pin Alignment. Figure 8: BACnet Specific Port and Figure 9: LonWorks Specific Port display the

location of each port for the respective protocol.

BTL is a registered trademark of BACnet International (BI)

BACnet & LONWORKS Supplemental Install Manual | 14

Page 19

Figure 5: Mounting Location

Figure 6: Pin Alignment

15 | BACnet & LONWORKS Supplemental Install Manual

Page 20

Figure 7: Installation complete

Figure 8: BACnet Specific Ports

Figure 9: LonWorks Specific Port

BACnet & LONWORKS Supplemental Install Manual | 16

Page 21

Addressing and Communication

Source

Analog: Use hardwired control signal

Modbus: Write control signal through BTL Certified BACnet Option

LonWorks: Write control signal through LonWorks Option

Control Mode

Demand: Use a demand control signal

RH P: Use a sensor value and proportional

RH PI: Use a sensor value and proportional-integral control band

Control Channels

Single: Use a single channel control signal

Dual: Use a dual channel control signal

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the interface. The initial step is to configure the Control settings to

ensure the humidifier points to the installed option.

Control Signal Setting

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Optional interface.

To adjust this setting:

1 Press the Menu icon on the lower left corner of the screen, to access the menu.

2 When prompted for a password, enter 0335 using the number pad. Press the Check Mark

icon to confirm.

3 Select the Configuration menu.

4 Select the Control Settings menu. The following settings can be adjusted:

Table 8: BTL / Lonworks Control Signal Parameters

Note: Refer to the CONTROL SETTING section of the NH-EL Installation and Operation Manual

for more information on the above settings.

5 Press Back repeatedly to return to the home screen when complete.

This procedure is summarized below:

Main Menu > 0335 > Configuration > Control Settings >

Source: Analog, Modbus, LonWorks

Control Mode: Demand, RH P, or RH PI

Control Channels: Single or Dual

17 | BACnet & LONWORKS Supplemental Install Manual

Page 22

Controller Set-up

The BACnet BTL or LonWorks options utilize an additional hardware component. Protocol

configuration is completed at the factory, prior to final testing. It may be necessary to configure

the address parameters in the field.

BACnet IP systems will require a static IP address to communicate on the network.

BACnet MS/TP systems require both a device instance and a baud rate to be set.

LonWorks systems automatically detect network address parameters and do not require

configuration.

BTL Certified BACnet specific : Changing Unit Addressing

The BTL Certified BACnet options utilize an additional hardware component for translation. For

address changes in either BACnet MS/TP or BACnet IP, the device instance and BACnet MAC

address can be modified easily using the dip switches shown in Figure 10: Dipswitches on BTL

Certified BACnet.

Figure 10: Dipswitches on BTL Certified BACnet

These switches allow you to set a binary value between 1 and 127 inclusive. The methodology

for converting numbers to binary is presented in Appendix A. To set the device instance to a

value outside of this range, a specific web browser tool may be used to make IP and address

modifications in the field, Contact Nortec Technical Services for further detail.

Take care when adjusting switches to ensure the settings are entered as intended. Common

settings are tabulated in Appendix A. After an address change has been made, the humidifier

must be power cycled for the change to take effect.

BACnet & LONWORKS Supplemental Install Manual | 18

Page 23

Changing Baud Rate (BACnet MSTP Only)

The baud rate for communications can also be changed through the respective dip switches.

By adjusting the settings according to Appendix A, the baud rate can be changed. For best

results it is recommended to set the baud rate to Auto (BACnet MSTP only), 9600, 19200, or

38400. Communication performance varies with building automation system manufacturer

and some experimentation with other baud rates may be required to obtain the best

performance. The Auto setting is currently only supported for BACnet MSTP networks.

BACnet Pics and Bibs

The Protocol Implementation Conformance Statement or “PICS” describes the BACnet

capabilities of a particular BACnet implementation. It is a written document, created by the

manufacturer of a device, which identifies the particular options specified by BACnet that are

implemented in the device.

BACnet Interoperability Building Blocks (BIBBs) describe a list of services a BACnet device

provides. The main areas that the building blocks are concerned with include: data sharing,

trends, schedules, device and system management. BIBBs help specify the interoperability

capabilities of a BACnet device. Please contact the factory to obtain a PICS statement or BIBBs

profile.

LonWorks Variables

LonWorks uses the identical set of variables/points as BACnet. For a detailed list of the

variables, please see Appendix B.

To facilitate the integration of a LonWorks unit within a network, it may be desirable to obtain an

External Interface File (XIF). Files of type .xif are used to convey the resources, specific objects

and data types which a LonWorks device possesses. The .xif file allows a network integrator to

simulate the presence of a networked humidifier even if it is not yet physically connected to the

network. In fact, if the integrator has the .xif files of all network devices, a complete system

could be simulated and configured off-line. Once the configuration is done, the integrator's

software tool can be connected to the actual system and the configuration information can be

downloaded.

The XIF file can be retrieved directly from the Optional Interface Card. A Windows based laptop

and an Ethernet cable (CAT 5 or better) are required for this process. This process requires the

“Remote User Interface” software tool from Fieldserver. It is available by visiting

http://fieldserver.com/techsupport/utility/utility.php and downloading the “Utility” software:

19 | BACnet & LONWORKS Supplemental Install Manual

Page 24

Figure 11: Software Retrieval

Once this software has been installed, use the following procedure:

1. Locate desired humidifier. Ensure unit is powered on and remove the panel on the Front

side of the humidifier. Locate the Integrated Controller Board inside of the unit.

2. Connect one end of the CAT5 cable into the Ethernet port on the Optional Interface Card

directly.

3. Connect other end of CAT5 cable to the Ethernet port on the laptop.

4. Run the “Remote User Interface” utility by double clicking the shortcut on your desktop (or

Start>Programs>Fieldserver Utilities>Remote User Interface)

5. The program should automatically recognize connected humidifier and bring you to the

“Main Menu”. If it does not, contact Nortec Technical Services at the number on the back

cover of this manual.

6. Type “u” for upload.

7. Type “o” for other. (A warning will appear, press any key to continue.)

8. Type “r” for remote.

BACnet & LONWORKS Supplemental Install Manual | 20

Page 25

9. Enter “fserver.xif”’ and hit the ‘enter’ key.

10. Type “u” to initiate upload from the humidifier to the laptop.

11. The .xif file will be saved in the folder “Configuration File Folder” located at

Start>Programs>Fieldserver Utilities>Configuration File Folder.

12. Type ‘q’ twice to exit out of the program

13. Locate file in Configuration File Folder and change name to corresponding humidifier, (ex,

“fserverH1.xif” for Humidifier 1)

14. Repeat this procedure for humidifiers changing the name of the .xif once saved to

correspond with the tag of the appropriate humidifier.

21 | BACnet & LONWORKS Supplemental Install Manual

Page 26

Troubleshooting

Problem

Resolutions

Cannot see/change

set

object/parameter

from BMS

Check control type. Demand type controls use internal algorithms to

generate a signal telling the humidifier to operate at a certain output

percentage. These of controls do not report the detected humidity

level or set point to the humidifier. As a result the set point and

space humidity levels cannot be monitored through the humidifier

when using demand controls.

Sensor ("transducer") type controls report a sensed humidity value to

the humidifier. The set point is configured at the humidifier and the

humidifier uses internal algorithms to determine the output

percentage. Since the humidifier knows both the set point and

humidity level, these values may be monitored through the

humidifier.

Cannot establish

communication.

Check communication parameters. Nortec humidifiers are capable

of BACnet MSTP and IP communication. LonWorks and BTL certified

BACnet based systems require an interface card to translate the

information, See Options for respective part numbers.

Verify Hardware connections from BMS to humidifier as per the

installation chapter.

Confirm that the protocol has been activated in the humidifier

software: main menu>0335>configuration>Comms menu>

BACnet MSTP Specific:

Check baud rate . Modifying bps may be necessary for some BMS

networks.

Ensure BACnet Workstation/BAS can handle BACnet slave devices

Cannot read data

from

object/parameter

Carefully ensure that addresses are mapped correctly. A single

incorrect address may cause loss of communication or faults for an

entire chain of humidifiers.

Check data type, some network controllers default to integer or

binary values depending on variable type.

Only some

objects/parameters

report data.

Check the baud rate being used on the BMS network. Use of faster

baud rates may assist.

Check the polling rate being used. High polling rates can interrupt

responses from the previous poll of data causing incomplete data

transfer. A recommended polling rate is once per minute.

Humidifier will not

respond to set

point/sensor

values/ demand

values written over

BACnet/LonWorks.

Check that humidifier is configured for automation system.

Refer to the "Control Signal Settings" section for your humidifier

model.

If the setting is "Analog" the humidifier will look for a control signal on

the low voltage terminal strip only.

Table 9: General Troubleshooting

BACnet & LONWORKS Supplemental Install Manual | 22

Page 27

Humidifier will not

respond to

hardwired controls.

Check that humidifier is configured for "Analog" control. Refer to the

"Control Signal Settings" section for your humidifier model. If the

setting is "BACnet" or other, the humidifier will look for a control

value to be written over that medium.

Intermittent

Communications

Check wire type and run length. Wire type should be 18 – 24 AWG,

shielded twisted pair wire with 120 ohm characteristic impedance.

Chains should generally not exceed 2000 feet total length.

Look for wire runs in close proximity to equipment generating

significant electrical noise (such as VFD's, medical equipment, X-ray

machinery, servers, etc).

Check that wire shield is terminated at one end only. Terminations

at both ends cause shield to conduct electricity and can generate

noise.

Confirm correct polarity of conductors at each device. This problem

can be the result of Net+ and Net- terminals being crossed.

Check BACnet Device Instance, LonWorks addressing for conflicts

with any device. Each device on the network must have a unique

address. Devices (humidifiers or otherwise) cannot share addresses.

Invalid data

Check BACnet/LonWorks addresses for conflicts. Each device on the

network must have a unique address. Devices (humidifiers or

otherwise) cannot share addresses.

More variables or

additional

information is

required from the

humidifier.

Contact Nortec Technical Services for additional support.

BACnet MSTP:

Cannot pass data to

controller.

Humidifier does not

pass token

Isolate chain and try only Humidifier.

Embedded BACnet MSTP functions as a slave device and cannot be

setup as a Master. Ensure BACnet Workstation/BAS can handle

BACnet slave devices. If not possible, consider the BTL option for

BACnet MSTP if problem persists. BTL option for BACnet MSTP will

function as a Master device.

23 | BACnet & LONWORKS Supplemental Install Manual

Page 28

APPENDIX A

Switch

A8

A7

A6

A5

A4

A3

A2

A1

Setting

Off

On

Off

Off

On

On

On

Off

Binary 0 1 0 0 1 1 1 0

Exponential Meaning

27 x 0

26 x 1

25 x 0

24 x 0

23 x 1

22 x 1

21 x 1

20 x 0

Simplified Meaning

128 x 0

64 x 1

32 x 0

16 x 0

8 x 1

4 x 1

2 x 1

1 x 0

Numerical Meaning

0

64 0 0 8 4 2 0

Result

64 + 8 + 4 + 2 = 78

Value

A8

A7

A6

A5

A4

A3

A2

A1

0 (Auto)*

Off

Off

Off

Off

Off

Off

Off

Off 1 Off

Off

Off

Off

Off

Off

Off

On

10

Off

Off

Off

Off

On

Off

On

Off

25

Off

Off

Off

On

On

Off

Off

On

40

Off

Off

On

Off

On

Off

Off

Off

50

Off

Off

On

On

Off

Off

On

Off

75

Off

On

Off

Off

On

Off

On

On

78

Off

On

Off

Off

On

On

On

Off

100

Off

On

On

Off

Off

Off

On

Off

125

Off

On

On

On

On

On

Off

On

127

Off

On

On

On

On

On

On

On

Table 10: Converting Numbers to Binary

Table 11: Common Settings for Addressing - BTL BACnet MSTP

* Auto uses the value in the configuration file.

BACnet & LONWORKS Supplemental Install Manual | 24

Page 29

Table 12: Common Settings – Baud rate BTL BACnet MS/TP

Setting

B4

B3

B2

B1

Auto*

Off

Off

Off

Off

110

Off

Off

Off

On

300

Off

Off

On

Off

600

Off

Off

On

On

1200

Off

On

Off

Off

2400

Off

On

Off

On

4800

Off

On

On

Off

9600

Off

On

On

On

19200

On

Off

Off

Off

20833

On

Off

Off

On

28800

On

Off

On

Off

38400

On

Off

On

On

57600

On

On

Off

Off

76800

On

On

Off

On

115200

On

On

On

Off

* Auto baud is only supported for BACnet MSTP

25 | BACnet & LONWORKS Supplemental Install Manual

Page 30

APPENDIX B

Parameter Name

Description

SNVT

#

SNVT

Range

NV

Index

R/W

Details

nviDRHDem_A1

Write RH or

Demand signal

value to control

channel 1 for

cylinder A

81

Lev_percent

0 - 100

23

W

Requires LonWorks

to be enabled.

For most common

configurations, this

is the primary

control signal

nviDRHDem_A2

Write RH or

Demand signal

value to control

channel 2 for

cylinder A

81

Lev_percent

0 - 100

24

W

Requires LonWorks

to be enabled.

nviDRHDem_B1

Write RH or

Demand signal

value to control

channel 1 for

cylinder B

81

Lev_percent

0 - 100

33

W

Requires LonWorks

to be enabled.

Only applies to NHEL-150 and NH-EL200 with dual

channel control

enabled

nviDRHDem_B2

Write RH or

Demand signal

value to control

channel 2 for

cylinder B

81

Lev_percent

0 - 100

34

W

Requires LonWorks

to be enabled.

Only applies to NHEL-150 and NH-EL200 with cylinders

dual channel

control enabled and

cylinders in

independent

operation mode

nviManCapacity_A

Sets a manual

capacity limit

restriction for

cylinder A

81

Lev_percent

0 - 100

15

W

Limits output to

percentage of total

cylinder capacity

(for single cylinder)

or for cylinder A

(NH-EL-150 and

NH-EL-200 models

only)

nviManCapacity_B

Sets a manual

capacity limit

restriction for

cylinder B (if

present)

81

Lev_percent

0 - 100

30

W

Limits output to

percentage capacity

for cylinder B (NHEL-150 and NH-EL200 models only)

nviBMStimeout

BMS timeout

for Modbus and

BACnet

107

SNVT_time_

sec

0 - 300

5

W

It is recommend to

not change the

value from the

factory default

(300)

nviDisable

Remotely disable

steam production

for the unit

95

Switch

0 or 1

44

W

0 = Idle/Humidify

1 = Disabled

Table 13: Parameters

BACnet & LONWORKS Supplemental Install Manual | 26

Page 31

nviSetPoint_A1

Writes the desired

space setpoint for

control channel 1

for cylinder A

81

Lev_percent

0 - 95

21

W

Use only when

sending RH values

to Dinput_A1.

Use only when

nviCtrlMode (3) is

set to RHp or RHpi

For most common

configurations this

is the primary space

setpoint

nviSetPoint_A2

Writes the desired

space setpoint for

control channel 2

for cylinder A

81

Lev_percent

10 - 95

22

W

Use only when

sending RH value to

Dinput_A2 with dual

channel control

enabled

nviSetPoint_B1

Writes the desired

space setpoint for

control channel 1

for cylinder B

81

Lev_percent

0 - 95

36

W

Use only with NHEL-150 and NH-EL200 models when

sending RH value to

Dinput_B1 and

cylinders are in

independent

operation mode

nviSetPoint_B2

Writes the desired

space setpoint for

control channel 2

for cylinder B

81

Lev_percent

10 - 95

37

W

Use only with NHEL-150 and NH-EL200 models when

sending RH value to

Dinput_B2 with

dual channel

control enabled and

cylinders are in

independent

operation mode

nviSigSource

Selects signal

source to control

unit

81

Lev_percent

0 - 4

2

W

0 = Analog

1 = Modbus

2 = BACnet/IP

3 = BACnet/MS

4 = LonWorks

nviCtrlMode

Selects method to

control unit

81

Lev_percent

1 - 3

3

W

1 = Demand

2 = RH P

3 = RH PI

nviCtrlChannel

Selects method to

control channels

81

Lev_percent

0 - 1

4

W

0 = Single Channel

1 = Dual Channel

nvoRHDem_A1

Displays channel 1

demand for

cylinder A

81

Lev_percent

0 - 100

12

R

Displays channel 1

demand/sensed RH

as a percentage of

cylinder capacity for

cylinder A

nvoRHDem_A2

Displays channel 2

demand for

cylinder A

81

Lev_percent

0 - 100

13

R

Displays channel 2

demand/sensed RH

as a percentage of

cylinder capacity for

cylinder A

nvoRHDem_B1

Displays channel 1

demand for

cylinder B

81

Lev_percent

0 - 100

27

R

Displays channel 1

demand/sensed RH

as a percentage of

cylinder capacity for

cylinder B (NH-EL150 and NH-EL-200

models only)

27 | BACnet & LONWORKS Supplemental Install Manual

Page 32

nvoRHDem_B2

Displays channel 2

demand for

cylinder B

81

Lev_percent

0 - 100

28

R

Displays channel 2

demand/sensed RH

as a percentage of

cylinder capacity for

cylinder B (NH-EL150 and NH-EL-200

models only)

nvoBlowerAct_A

Reads the status

of the blower pack

for cylinder A

95

Switch

0 or 1

46

R

0 = Open

1 = Closed

nvoBlowerAct_B

Reads the status

of the blower pack

for cylinder B

95

Switch

0 or 1

49

R

0 = Open

1 = Closed

nvoFanAct_A

Indicates if air

handle or furnace

is activated for

cylinder A

95

Switch

0 or 1

47

R

0 = Not Activated

1 = Activated

nvoFanAct_B

Indicates if air

handle or furnace

is activated for

cylinder B

95

Switch

0 or 1

50

R

0 = Not Activated

1 = Activated

nvoFault

Reads the status

of a fault on the

unit

95

Switch

0 or 1

42

R

0 = No Fault

1 = Fault

nvoService

Reads the status

of a service

request on the unit

95

Switch

0 or 1

41

R

0 = No Service

Required

1 = Service

Required

nvoStatusCylA

Reads the status

of the unit for

cylinder A

81

Lev_percent

0 - 9

1

R

0 = Humidifying

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

9 = Fault

10 = blower pack

nvoStatusCylB

Reads the status

of the unit for

cylinder B

95

Switch

0 - 9

N/A

R

0 = Humidifying

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

9 = Fault

10 = blower pack

nvoSysDem_A

Reads the demand

for cylinder A

81

Lev_percent

0 –

100

14

R

Demand Mode:

Summation of

Input_A1 and

Input_A2

RH Mode:

PID calculation

BACnet & LONWORKS Supplemental Install Manual | 28

Page 33

nvoSysDem_B

Reads the demand

for cylinder B

81

Lev_percent

0 –

100

29

R

Demand Mode:

Summation of

Input_B1 and

Input_B2

RH Mode:

PID calculation

nvoSecurity_A

Reads the status

of the safety loop

for cylinder A

95

Switch

0 or 1

45

R

0 = Open

1 = Closed

nvoSecurity_B

Reads the status

of the safety loop

for cylinder B

95

Switch

0 or 1

48

R

0 = Open

1 = Closed

nvoHourOpt_A

Reads operating

time for cylinder A

124

SNVT_time_

hour

0 -

5000

10

R

Displays the total

time (hrs) cylinder A

has been running

since last reset

nvoHourOpt_B

Reads operating

time for cylinder B

124

SNVT_time_

hour

0 -

5000

25

R

Displays the total

time (hrs) cylinder B

has been running

since last reset

nvoHourWeight_A

Reads the

weighted time for

cylinder A

124

SNVT_time_

hour

0 -

5000

11

R

An equated run

time (hrs) based on

Run_Time_A x

System_Demand_A

nvoHourWeight_B

Reads the

weighted time for

cylinder B

124

SNVT_time_

hour

0 -

5000

26

R

An equated run

time (hrs) based on

Run_Time_B x

System_Demand_B

29 | BACnet & LONWORKS Supplemental Install Manual

Page 34

Warranty

Nortec Humidity Inc. and/or Nortec Humidity Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of two years after installation or 30 months from

manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s manufactured and

assembled products, not otherwise expressly warranted (with the exception of the cylinder), are

free from defects in material and workmanship. No warranty is made against corrosion,

deterioration, or suitability of substituted materials used as a result of compliance with

government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the defective

part(s) is returned freight prepaid by the customer. Parts used for repairs are warranted for the

balance of the term of the warranty on the original humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or implied by law. No

liability whatsoever shall be attached to THE COMPANY until said products have been paid for in

full and then said liability shall be limited to the original purchase price for the product. Any

further warranty must be in writing, signed by an officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of the companies manufacture, such as

controls, humidistats, pumps, etc. is limited to the warranty of the original equipment

manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment is installed in

strict accordance with a copy of the catalog and installation manual in effect at the date of

purchase and by a contractor approved by THE COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for consequential

damage or damage resulting directly from misapplication, incorrect sizing or lack of proper

maintenance of the equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for damage resulting

from freezing of the humidifier, supply lines, drain lines, or steam distribution systems.

THE COMPANY retains the right to change the design, specification and performance criteria of

its products without notice or obligation.

BACnet & LONWORKS Supplemental Install Manual | 30

Page 35

Page 36

U.S.A.

826 Proctor Avenue

Ogdensburg, NY 13669

CANADA

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

FAX: 613.822.7964

EMAIL: nortec@humidity.com

WEBSITE: www.humidity.com

Loading...

Loading...