Page 1

NH Electrode

Steam Humidifiers

Installation,

Operation, and

Maintenance Guide

IMPORTANT: Read and save these instructions. This

guide to be left with equipment owner.

Form #03-172 1506262

Page 2

Table Of Contents

INSTALLATION 1

RECEIVING & UNPACKING EQUIPMENT ................................1

PRE-INSTALLATION CHECKPOINT ...................................1

BASIC HUMIDIFIER CONFIGURATION..................................1

LOCATION & MOUNTING .........................................2

HUMIDIFIERS ...............................................2

BLOWER PACKS .............................................2

STEAM DISTRIBUTORS..........................................3

PLUMBING .................................................3

WATER SUPPLY LINE...........................................3

DRAIN LINE ................................................3

STEAM LINE AND CONDENSATE RETURN LINE ............................4

ACCESSORIES - FILL CUP EXTENSION KIT(S) .............................4

ELECTRICAL................................................4

PRIMARY VOLTAGE SUPPLY WIRING TO HUMIDIFIER ........................4

LOW VOLTAGE CONTROL WIRING ...................................5

On-Off Controls.............................................5

CONTROL INSTALLATION ........................................5

OPTIONAL MODULATION (CONTINUOUS CONTROLS) ........................5

OPTIONAL MODULATION (CONTINUOUS CONTROL) PACKAGES BY NORTEC ...........7

OPERATION 7

INTRODUCTION ..............................................7

LAYOUT AND FUNCTION .........................................7

NHMC OPERATION ............................................8

START-UP SELF TEST ..........................................8

USER LEVEL................................................9

INFORMING THE USER ..........................................9

SELF-HELP ................................................9

SYSTEM MESSAGES ...........................................9

REMOTE INDICATION...........................................9

DOUBLE UNIT OPERATION .......................................9

NHB/NHP OPERATION ..........................................9

END OF CYLINDER LIFE .........................................9

MANUAL CAPACITY ADJUSTMENT...................................10

OTHER POTENTIOMETERS.......................................10

DETECTING WATER SUPPLY DEFICIENCY ..............................10

REMOTE INDICATION ..........................................10

DOUBLE UNIT OPERATION .......................................10

BLOWER PACK OPERATION ......................................10

Page 3

MAINTENANCE 10

WHEN TO REPLACE THE STEAM CYLINDER .............................10

HOW TO REMOVE THE STEAM CYLINDER ..............................13

MANDATORY CLEANING OF THE DRAIN VALVE ...........................13

HOW TO INSTALL THE REPLACEMENT CYLINDER ..........................14

BUILT ON AND REMOTE MOUNTED BLOWER PACKS (BOBP’S / RMBP’S) .............15

TROUBLESHOOTING 15

STARTING POINT ............................................15

USING THE WIRING DIAGRAM .....................................21

TERMS USED ..............................................22

WIRING DIAGRAM ..........................................23-25

PRE START-UP CHECKLIST ......................................26

START-UP CHECKLIST AND QUICK REFERENCE...........................27

MAINTENANCE CHECKLIST .....................................28-29

REPLACEMENT PARTS .......................................30-35

Page 4

INSTALLATION

pply

3. Report any discrepancy immediately.

RECEIVING & UNPACKING EQUIPMENT

1. Check packing slip to ensure ALL material has

been delivered.

2. All material shortages are to be reported to

NORTEC within 48 hours from receipt of goods.

NORTEC assumes no responsibility for any

material shortages beyond this period.

3. Inspect shipping boxes for damage and note on

shipping waybill accordingly.

4. After unpacking, inspect equipment for damage

and if damage is found, notify the shipper

promptly.

5. All NORTEC products are shipped on an F.O.B.

factory basis. Any and all damage, breakage or

loss claims are to be made directly to the shipping

company.

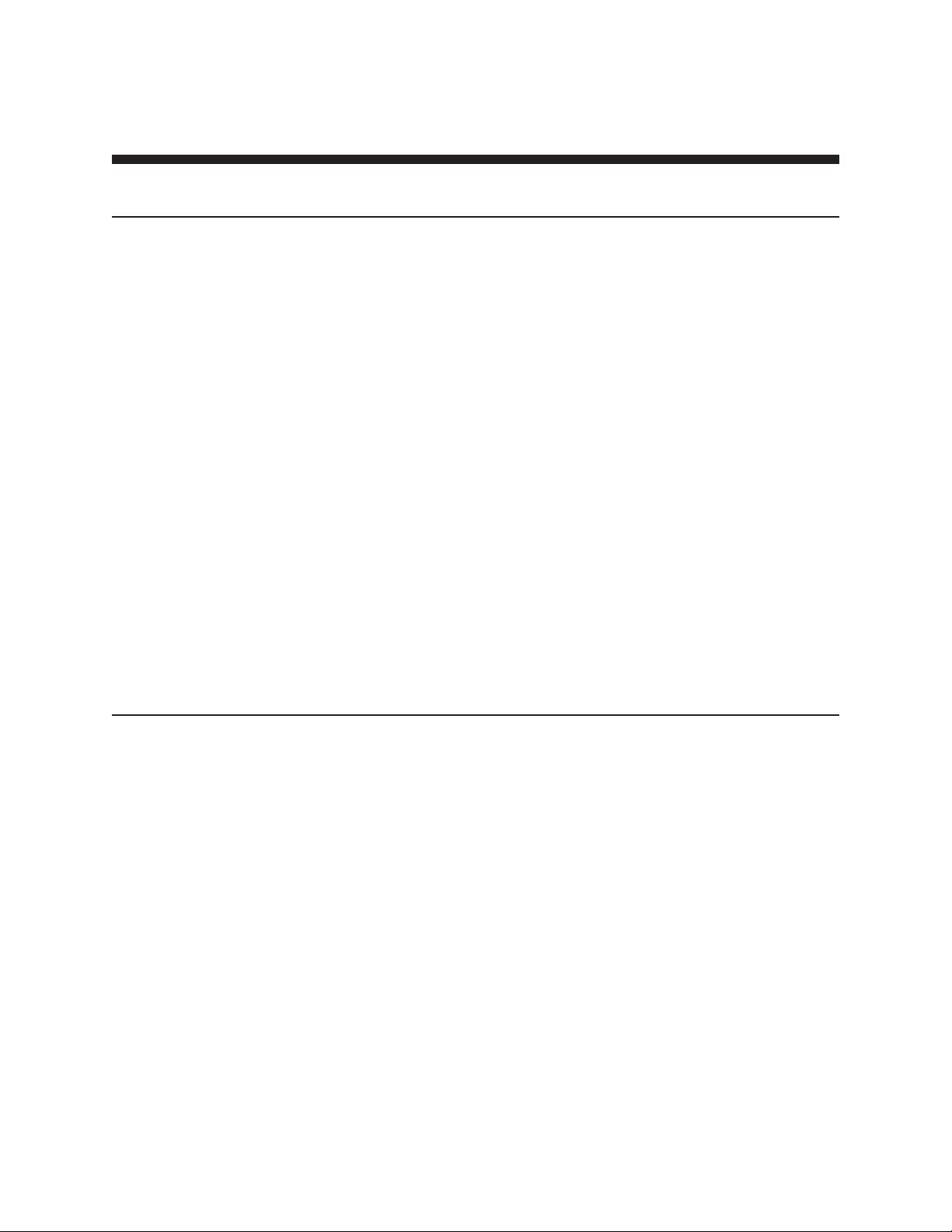

PRE-INSTALLATION CHECKPOINT

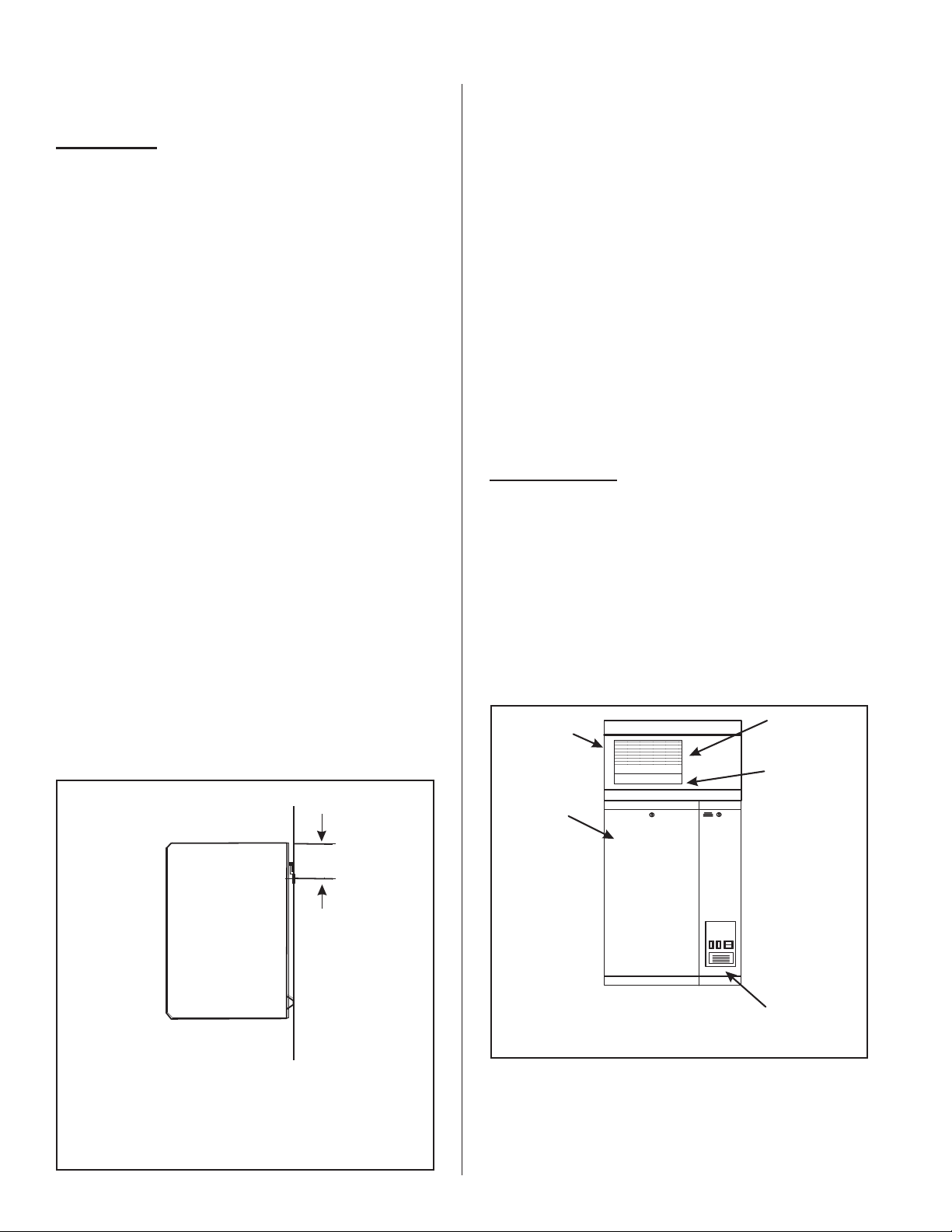

1. Ensure that available voltage and phase

corresponds with humidifier voltage and phase as

indicated on humidifier’s nameplate label (see

Figure #1).

2. Ensure that the dedicated external disconnect is of

sufficient size to handle the rated amps as

indicated on the nameplate label. Refer to local

codes.

BASIC HUMIDIFIER CONFIGURATION

NORTEC humidifier models NHMC, NHP and

NHB share a modular sheet metal cabinet. Each unit

has a right side electrical compartment. Each

electrical compartment has a hinge-down front door

which is removable from any partially or fully opened

position. Each electrical compartment has a

screw-mounted right side cover which can also be

removed for ease of electrical connection. For safety,

the door when closed keeps the side cover from being

removed.

Single units have a plumbing compartment

attached to the left side of the electrical. Double units

have a second plumbing compartment. Each

plumbing compartment has a hinge-down front door

which is not intended to be removed. For safety, the

door must be closed in order to engage the shared

lock. To avoid any danger, never operate the

humidifier with a door off. For safety, each door when

closed engages its own safety interlock switch. All

switches must be engaged before the unit will operate.

To open the doors, unlock key, lift door up slightly

and pull top of door forward. Door will hinge 180

degrees and hang straight down. To remove door,

swing door parallel to floor. Then lift up slightly and

out. To reinstall door, hold parallel to floor and insert

hinge pins at bottom.

Condensate

Return

Figure #1

NH Series Humidifier

Steam

Outlet

Drain

Nameplate

Label

Water

Su

Power And

Control

Wiring

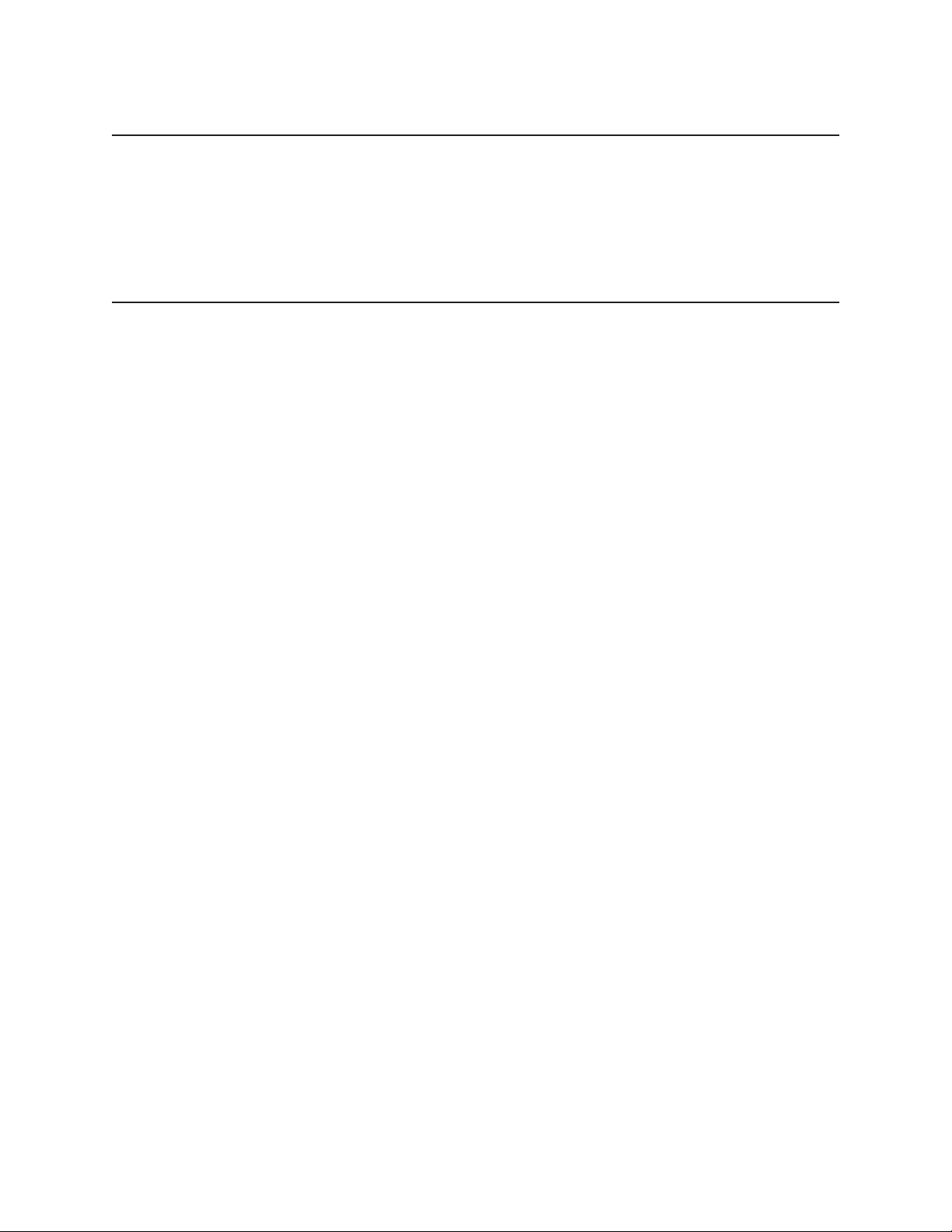

Clearance Requirements

WALL

WITHOUT BLOWER PACK

TOP VIEW

NOTE: LOCAL AND NATIONAL

CODES MAY DEVIATE. PLEASE

CONSULT APPLICABLE CODES

FOR CLEARANCE REQUIREMENTS

IN ALL CASES.

Figure #2

MIN. 36"

FRONTAL

CLEARANCE.

MIN. 36"SIDE

CLEARANCE

RECOMMENDED.

SEE NOTE.

-1-

Page 5

LOCATION & MOUNTING

g

HUMIDIFIERS

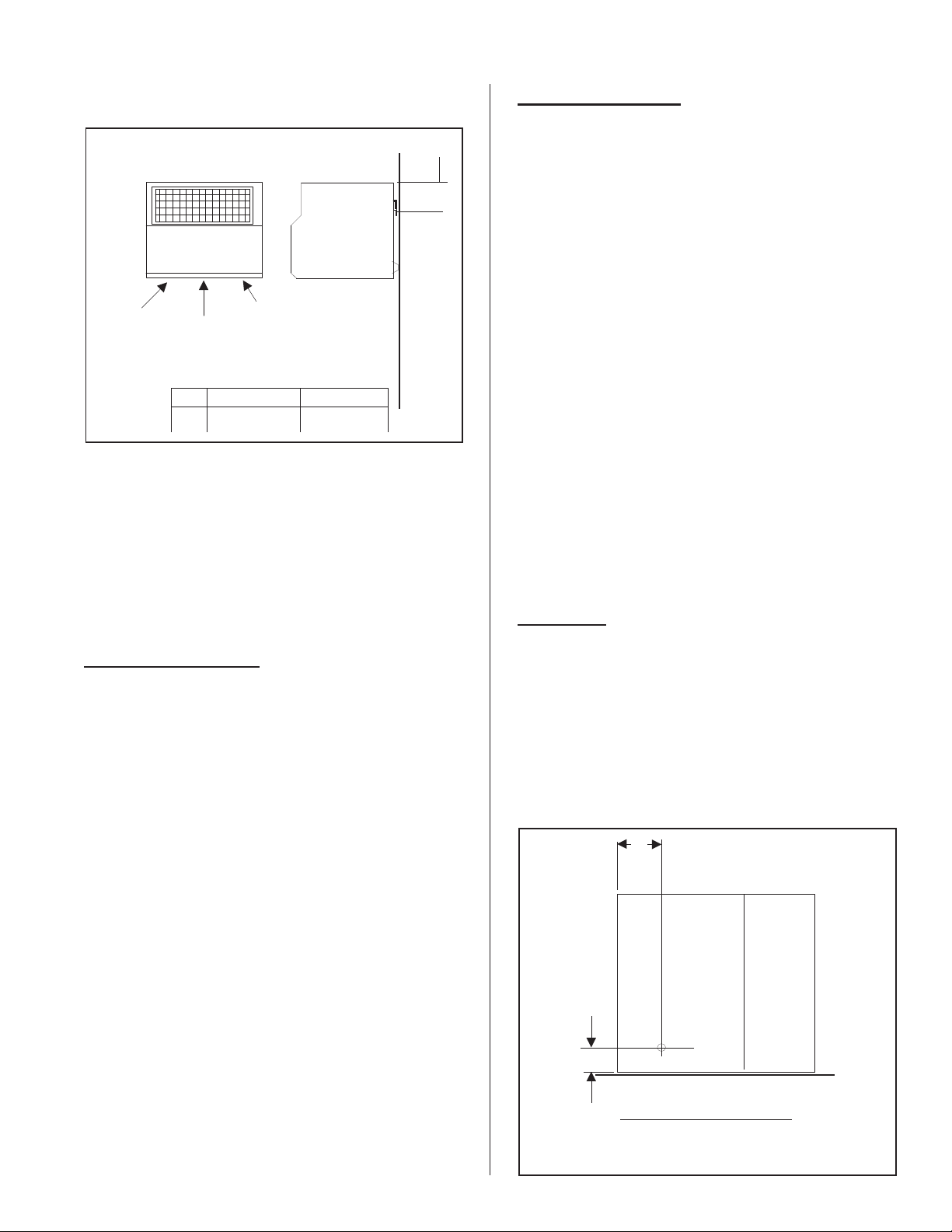

NH Series humidifiers are designed to mount on a

suitable wall or vertical surface. Do not sit on floor due

to clearances required for plumbing, electrical, and

control entrances. The clearance dimensions shown

in this manual are for reference only and are the

minimum required for maintenance of the humidifier.

Local and National Codes should be consulted prior to

final location and installation of the humidifier.

NORTEC can not accept responsibility for installation

code violations.

1. Location of the humidifier should be below and as

close as possible to the steam distributor location

as possible.

2. For front and side clearance requirements (for

access during installation, maintenance and

troubleshooting), see Figure #2.

3. If possible, DO NOT locate humidifier any further

than absolutely necessary from steam distributor

location, as net output will be reduced as a result

of heat loss through steam hose (see Engineering

Manual, Form -163D). Also, increased static

pressure may necessitate using an accessory fill

cup extension kit.

4. Where possible, mount humidifier at a height

convenient for servicing.

5. Wall mounting bracket provided should be

securely attached horizontally and open edge

upwards, using field-supplied fasteners. Use a

minimum of 3 - #12 x 3" long wood screws, or

Figure #3

Wall Bracket Mounting Detail

WALL

Wall

better, into a vertical structural surface. If any

spacer material is used between the bracket and

the structural material such as drywall, increase

fastener length accordingly. In addition, install a

minimum of 2 field supplied fasteners in the holes

provided in the back of the unit to prevent the unit

from being bumped off the wall bracket. See

Figure #3.

6. Make sure humidifier is level.

7. DO NOT mount humidifier on hot surfaces.

8. If humidifiers are mounted on roof, a

thermostatically ventilated weatherproof cabinet by

others should be used. Consult factory.

9. DO NOT mount humidifiers in an area where

freezing may occur. Use an accessory Low

Temperature Protection Kit, if necessary.

10. DO NOT mount humidifiers on vibrating surface.

Consult factory.

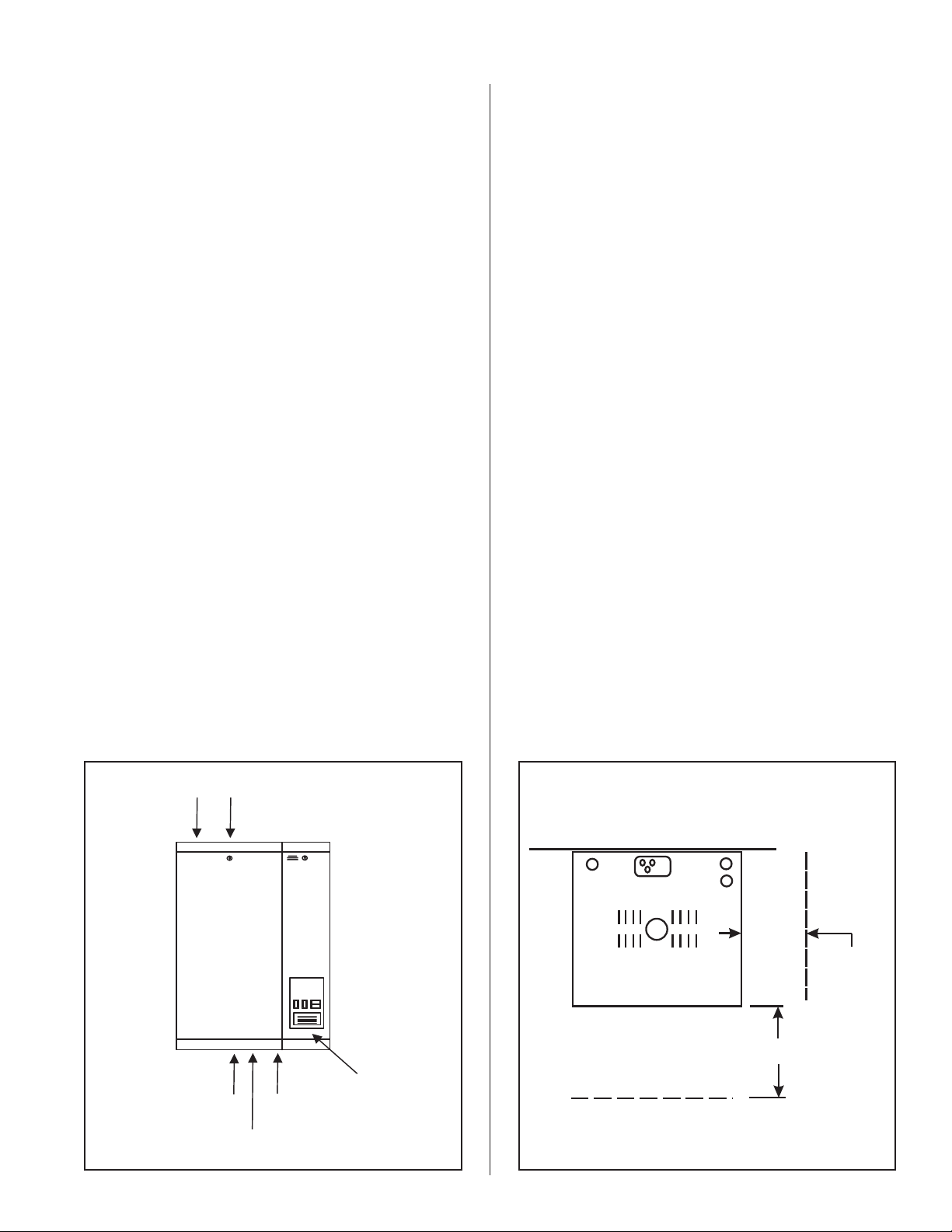

BLOWER PACKS

1. Blower packs are an optional accessory used to

directly distribute steam to localized areas (such

as computer rooms) or in structures that do not

have a built-in air distribution system.

2. Blower packs are available integrally-mounted on

humidifier (built-on blower pack, BOBP, see Figure

#4) or detached and field-piped and wired to

humidifier (remote mounted blower pack RMBP,

see Figure #5).

Figure #4

Built On Blower Pack (BOBP)

Optional

Built-On

Blower Pack

Single

Circuit

Humidifier

Built-In

Supply Air

Grille

Built-In Steam

Distributor

Fasten wall bracket

FASTEN WALL BRACKET

(FACTORY SUPPLIED) TO

(Factory supplied) to

WALL USING ANCHOR BOLTS

wall using field supplied

(3) SUPPLIED BY OTHERS

fasteners.

005-030

7.7 (19.6cm)

050-200

7.7 (19.6cm)A

7.7”

A

(19.6 cm)

3. All NH Series blower packs consist of a steel

cabinet containing: blower/motor powered by

voltage directly from the humidifier, fuse, relay,

speed select switch (in NH-050 and larger),

stainless steel steam distributor, supply air grille

with adjustable louvers, and built-in manual reset

-2-

Power And

Control

Wirin

Page 6

Wall

Figure #5

)

Remote Mounted Blower Packs (RMBP)

Side

050-100

3.2" (8.0cm)

Condensate

Front

Steam

A

Power and control

wiring from humidifier

005-030

3.2" (8.0cm)

safety thermostat to turn off the humidifier if the

blower pack gets overheated. Control thermostat,

mounted on the steam distributor, starts the fan

when steam is generated. When supply voltage

differs from voltage required to run blower motor,

blower pack will contain a proper transformer. All

blower packs provide intake air filters.

For installation details about the blower pack,

please refer to the blower pack installation manual

located in the blower pack box (Form #XX-239).

WATER SUPPLY LINE

1. Humidifier is intended to operate on potable (cold)

tap water.

2. If the raw water is very hard, NORTEC can

A

provide longer cylinder life on softened water.

However, softened water is more conductive and

more corrosive. Some hardware and/or software

changes may be required, at time of order or in the

field. Consult factory.

3. If RO or DI is available, blending may increase

cylinder life. Consult factory.

4. DO NOT use a hot water supply to humidifier.

Minerals will adhere more easily to surfaces and

the fill valve’s small flow regulating orifice and

could become plugged.

5. Standard fill valves are sized for water pressure

ranging from 30 to 80 psig (ideally 55 to 60 psig).

For other pressures, consult factory. This

pressure should be measured at the humidifier if

the water pressure is suspect.

6. ALWAYS supply and install a shut off valve in the

water supply line dedicated to the humidifier to

facilitate servicing. Use ½" OD copper to within 4

feet of the humidifier. Reduce copper to 3/8" OD

and connect to the factory-supplied 3/8" olive

compression fitting under the humidifier.

DRAIN LINE

STEAM DISTRIBUTORS

1. Steam distributors are used in ducts or air

handling units, and are made of stainless steel.

2. Steam distributors can be in vertical or downflow

applications.

3. Proper location should consider: air temperature,

relative humidity before the distributor, air velocity,

dimensions of the location, amount of steam

introduced into the duct, downstream obstructions,

and surfaces vulnerable.

4. For installation details, please refer to steam

distributor installation manual located in the

distributor box (Form #XX-231).

5. For calculating absorption distances, refer to

H.E.L.P. Software or steam distribution and

absorption distances engineering manul (Form

#XX-232).

PLUMBING

All water supply and drain line connections

should be installed in accordance with local

plumbing codes.

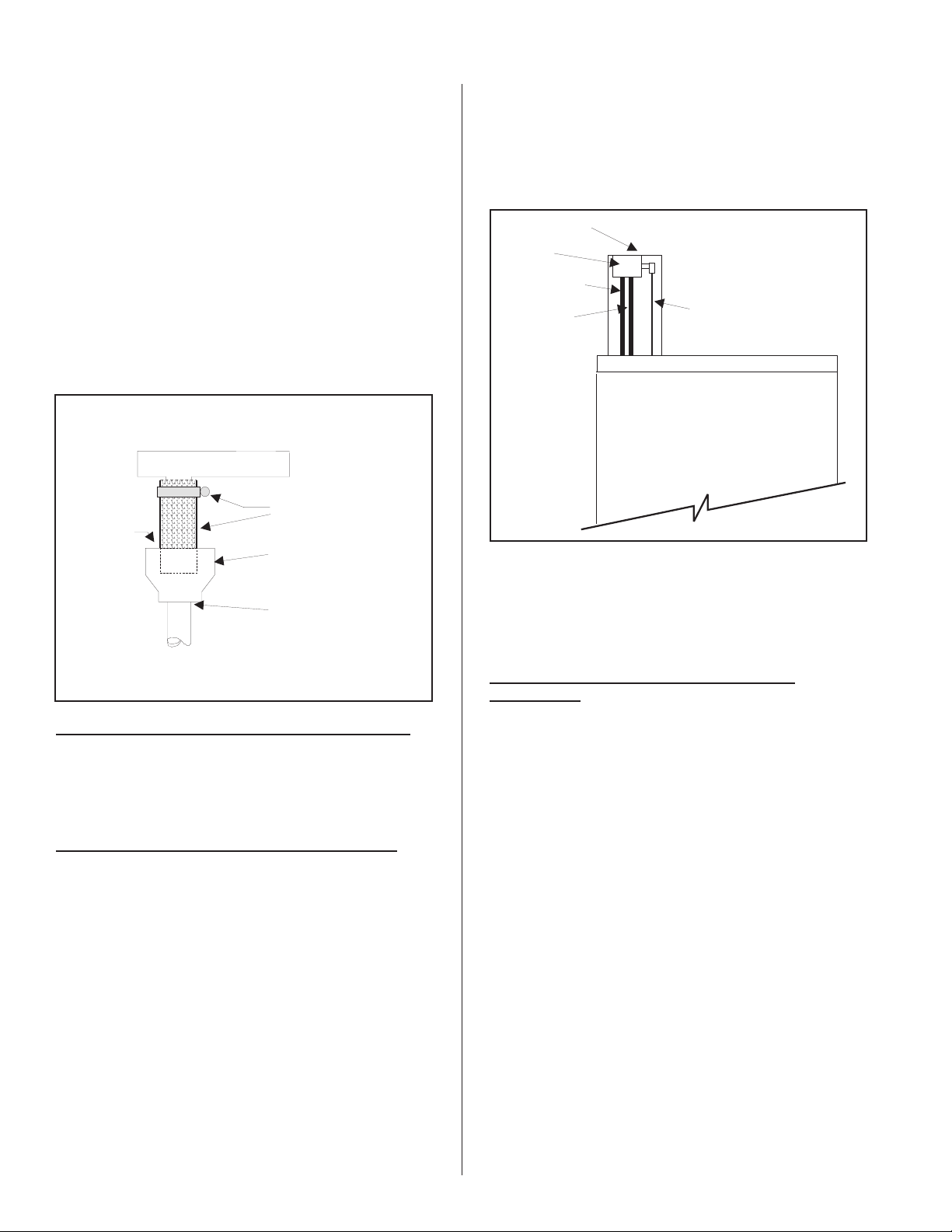

1. Humidifier is equipped with a 7/8" O.D. unthreaded

drain outlet on underside of drain canal on bottom

of the humidifier (see Figure #6). A field-supplied

funnel (see Figure #7) is recommended. It will

prevent backup in the drain pan and in the cylinder

due to partially blocked or badly installed drain

lines. This prevents rusting of the drain pan and

arcing due to over-concentration. The drain canal

Figure #6

Drain Line Connection

A

B

Model

005 -030

050 -100

150 -200 Left

150 -200 Right

Bottom View

Ain.(mm)

1.0 (25)

2.2 (55)

2.2 (55)

2.2 (55)

B in.(mm)

5.0 (127)

6.2 (158)

6.2 (158)

19.6(498

Wall

-3-

Page 7

has been improved to prevent backup despite long

e

A

or gently sloped drain lines but it can not

compensate for flat or uphill runs.

2. The drain line should not end in a sink used

frequently by personnel, or where plumbing codes

prohibit it. Route to a floor drain or equivalent for

safety reasons, since drain water from humidifier

can be very hot.

3. Keep drain lines as short as possible. Keep drain

lines sloped down, not level and not up since

low spots in drain lines will accumulate

sediment and cause backup. The drain line

should be 7/8" O.D. copper pipe or larger. Do not

use plastic pipe for drain lines. Consult factory.

Figure #7

Drain Connection

ClampAnd

1.5” I.D.Hose

ir Gap

NOTE: Steam hose should not reach bottom of the funnel.

Factory Supplied

Stainlesssteel Reducer To

ServeAs Funnel

Drain (ByOthers)

2" O.D. StainlessSteel Pipe

Or 2" I.D.DI Compatible Hos

(Not Supplied)

4. To increase allowable water column (allowable

positive static pressure) an accessory Fill Cup

Extension Kit is available from NORTEC. See

Figure #8.

Figure #8

Fill Cup Extension Kit to Overcome Static Pressure

Fill Cup Bracket

Fill Cup

Overflow Hose

Fill Hose To

Cylinder

Hose From FillValve

5. Water column requirements are even higher duct

static pressure when distributor’s steam outlets

are faced with downflow duct applications.

ELECTRICAL

PRIMARY VOLTAGE SUPPLY WIRING TO

HUMIDIFIER

STEAM LINE AND CONDENSATE RETURN LINE

1. Check and ensure that available voltage and

phase corresponds with operating voltage and

1. Refer to the installation manual of the steam

distribution system used in your application.

phase of humidifier as indicated on the humidifier

nameplate label (see Figure #1).

Steam Distribution - Form #XX-231, SAM-e - Form

#XX-249, Blower Pack - Form #XX-239.

2. Ensure that an adequate power supply is available

to carry full humidifier amperage drawn as

ACCESSORIES - FILL CUP EXTENSION KIT(S)

1. The NH Series humidifier is an electrode

humidifier. It produces steam at atmospheric

pressure. Pressure head must develop to push

steam through supply line and into air duct.

2. Combined resistance of duct positive static

pressure and steam line resistance creates a

small pressure head in steam cylinder. Total

amount of positive static pressure head is

reflected directly by water column differential that

develops between water in the fill cup hose

feeding cylinder and water level in cylinder.

3. Standard dimensions of humidifier limit static that

can be tolerated before water will be pushed high

enough to spill over into overflow tube in fill cup

assembly.

specified by rated amps on the humidifier

nameplate label refer to local codes.

3. A dedicated external disconnect must be installed.

Do not exceed the maximum circuit protection

amps as indicated on the nameplate label.

4. Optional internal primary fuses are not intended to

substitute for external fuses. Internal primary

fuses are a factory added option (when specified)

to protect internal primary wires individually.

5. Connect ground wire to cabinet ground clamp. Do

not use neutral wire of four wire supply as ground.

6. Single phase humidifiers may be run on three

phase power, but load may unbalance power grid.

7. External wiring sizes must be in accordance with

NEC and/or CEC and existing local electrical

codes and by-laws.

-4-

Page 8

LOW VOLTAGE CONTROL WIRING

On-Off Controls

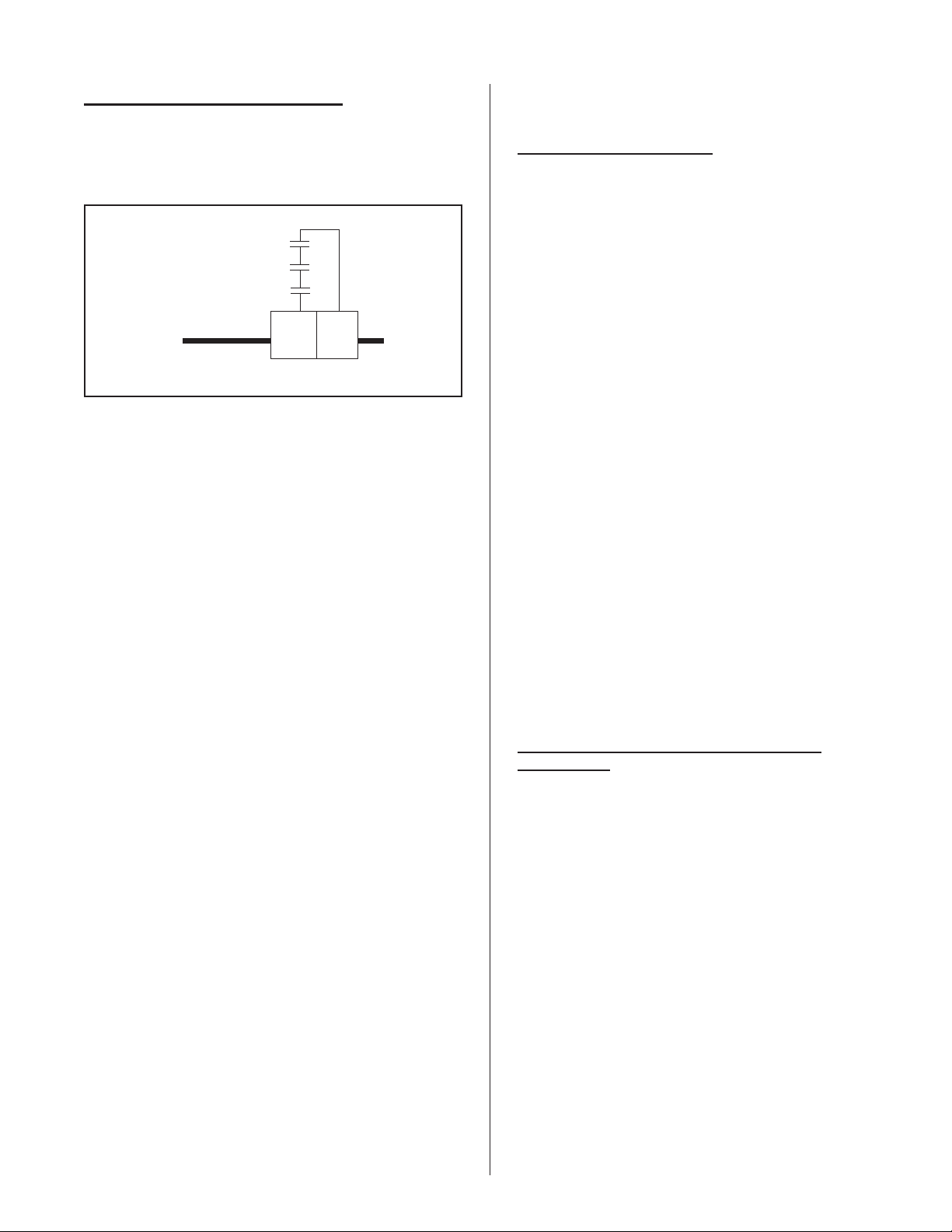

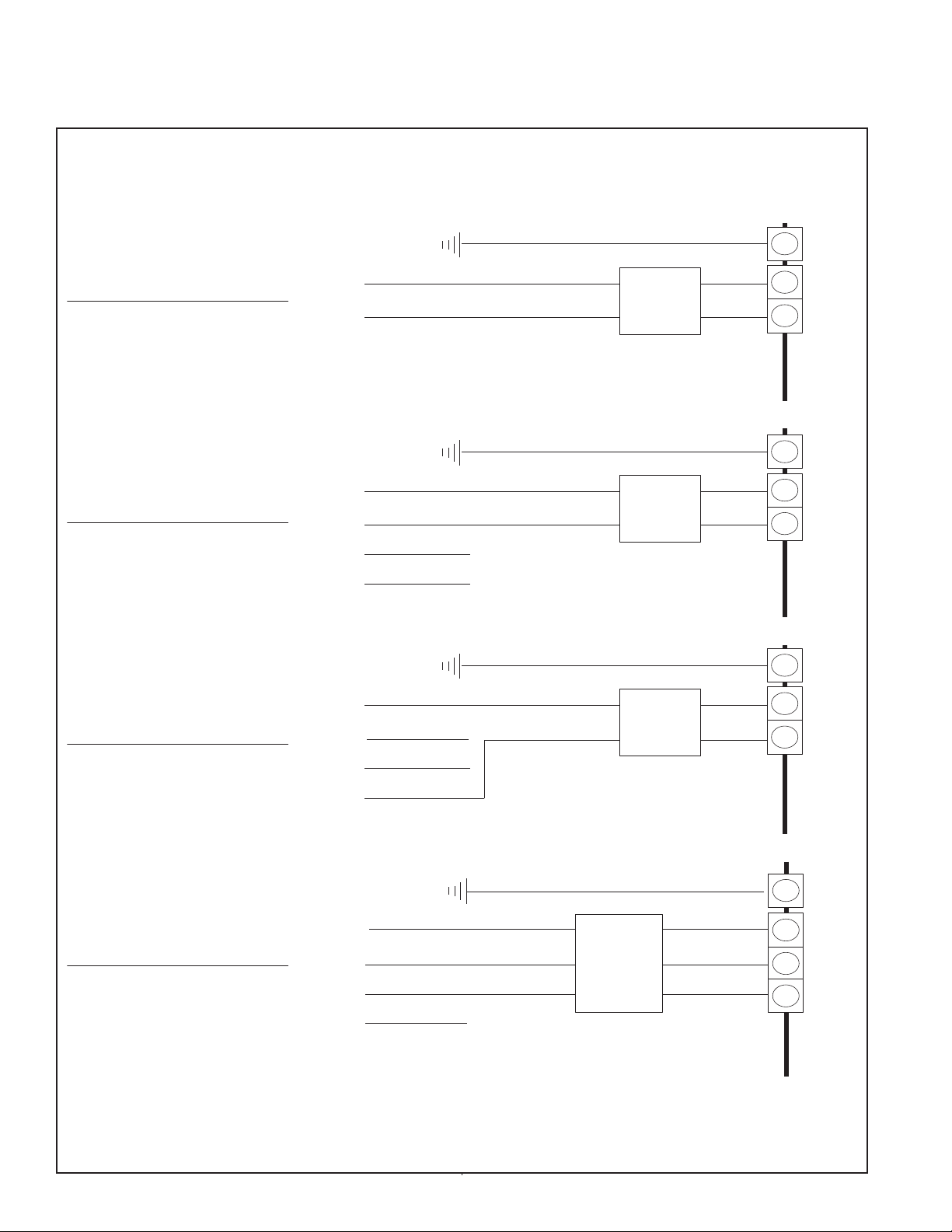

Figure #9

External Wiring of On/Off Controls

A

B

C

4. Each humidifier is supplied with a wiring diagram

inside.

CONTROL INSTALLATION

1. Mount any wall humidistat (control or high limit)

over standard electrical box at height similar to

typical thermostat. Any wall humidistat should

be in location representative of overall space

being humidified and not in path of blower pack or

air supply grille. Do not mount on a outside wall

where temperature fluctuation can affect control

response.

EXTERNAL

810

INTERNAL

Controls are available from NORTEC as

accessories. If controls were not ordered with

humidifier, they must be purchased supplied by others.

The following information is relevant to all controls,

factory supplied or otherwise.

A, B and C (described below) are to be wired in

series (only one path for current) across terminals 8

and 10 on the low voltage control terminal strip, or

replaced with a jumper wire for constant operation.

Caution: this is the “hot” wire from the 24V control

transformer; it will blow the 3A fuse if any control field

wiring touches ground metal.

A - Wall or Duct Mounted Control On/Off

Humidistat: Wired to make on drop in humidity, break

on rise to setpoint. Set to desired % RH. Can be a

make/break set of contacts from a Building Automation

System.

B - Duct Mounted Safety High Limit On/Off

Humidistat (if used): Wired to make on drop in

humidity, break on rise to safety setpoint. Set to

approximately 85% RH as a safety to help prevent

saturation and wetting in the duct.

C - Duct Mounted Safety Air-Proving On/Off

Switch (if used): Wired to make when sensing air

flow, break when no air flow. Used as a safety to

prevent saturation when no air flow.

1. NORTEC offers various versions of A, B and C to

suit each application. In general, A is essential,

whereas B and C are highly recommended in

ducted applications.

2. Field wiring from humidistat to humidifier and

between devices should be 18 AWG or heavier

and kept as short as possible.

3. Low voltage control terminal strips are provided in

the electrical compartment. Internal sides are

factory wired. External sides are to be field wired.

2. Mount duct humidistat in location representative

of overall air humidity, usually return duct. Do not

mount it directly in front of steam distributor or in

turbulent or mixing zone. Mount it where air’s

humidity and temperature are uniform and

representative of spaces being humidified.

3. Mount duct high limit humidistat downstream of

steam distributors far enough that, under normal

humidity and air flow conditions, steam will have

been fully absorbed (typically at least 10 feet). It

must be located to sense high humidity only when

uniform and representative air is over-humidified

or approaching saturation.

4. Mount duct air-proving switch so that it is able to

sense air flow or lack of it. Wire it to make when

air flow is sensed and break when air flow fails.

5. Check operation of all on/off controls before

starting humidifier.

6. Calibration of controls (on/off or modulation) in the

field may be necessary due to shipping and

handling. Verify humidistat accuracy before

commissioning system.

OPTIONAL MODULATION (CONTINUOUS

CONTROLS)

1. Read on/off controls section first since it is

necessary to all control systems.

2. Virtually any modulation (continuous control)

external hardware by others (as long as it has

%RH setpoint circuitry) may be interfaced with

pre-specified factory-configured NHMC/NHP

Series pc board via the control terminal strip. The

NHB can be used with on-off control only. Use

shielded cables for modulation circuits.

3. Modulation (continuous control) by others for use

with NHMC/NHP Series humidifiers involves one

of several control wiring diagrams. In all cases,

modulating signal interfaces through control

terminal strip to main pc board inside humidifier.

4. The modulation signal must increase from

minimum toward maximum as sensed RH (actual

RH) drops below desired RH (%RH setpoint). In

response, humidifier’s steam output will increase

from minimum toward maximum. When

humidifier’s steam output (lbs/hr) matches

humidification load (lbs/hr), modulation signal will

stabilize.

-5-

Page 9

l

l

l

(ACTUAL)

Figure #10

Primary Voltage Supply Wiring

PRIMARY (LINE) VOLTAGE WIRING TO UNITVOLTAGE

(BY OTHERS)

L1

L2

- Single Phase Unit.

- Single Phase Supply.

- Required Voltage Between L1 And L2.

- Load Balanced.

L1

L2

L3

Neutral

L1

L2

L3

Neutral

Ground

Ground

- Single Phase Unit.

- 3 Phase Supply.

- Required Voltage Between L1 And L2.

- Load Will Be Unbalanced.

Ground

- Single Phase Unit.

- 3 Phase Supply.

- Required Voltage Between L1 And Neutral.

- Load Will Be Unbalanced.

Ground Wire

Dedicated

Disconnect

Ground Wire

Dedicated

Disconnect

Ground Wire

Dedicated

Disconnect

Circuit

Breaker

Or

Circuit

Breaker

Or

Circuit

Breaker

Or

Ground

Leg

2 Pole

Termina

Block

E

I

X

N

T

T

Ground

Leg

2 Pole

Termina

Block

E

I

X

N

T

T

Ground

Leg

2 Pole

Termina

Block

E

I

X

N

T

T

Ground Wire

L1

L2

L3

Neutral

Ground

Dedicated

Circuit

Breaker

Or

Disconnect

- 3 Phase Unit.

- 3 Phase Supply.

- Required Voltage Between Any Two Legs.

- Load Will Be Balanced.

NOTE: VoltageAt TerminalBlockMust Be InAccordance WithSpec.Label.

All Wiring ToBeInAccordance With Existing NationalAnd LocalElectrical Codes.

-6-

Ground

Leg

3 Pole

Terminal

Block

E

I

X

N

T

T

Page 10

5. Field-wiring connections for modulation control are

to be made to external side of terminals 26, 28, 30

and 32 on humidifier’s control terminal strip.

Always refer to the external control’s wiring

diagram factory supplied with each NORTEC

modulation control option.

6. Varying dc Voltage Modulation Signal Powered

by Others: NHMC/NHP Series humidifier can be

factory configured to accept the following vdc

signals: 0-3 vdc, 0-10 vdc, 0-16 vdc, 0-20 vdc, 1-5

vdc or 2-10 vdc. Wire according to NORTEC

supplied external wiring diagram that comes with

each modulation option. To share the signal with

more than one humidifier, wire in parallel to each

humidifier. If a different signal is desired consult

factory.

7. Varying dc milliAmp (mA) Modulation Signal

Powered by Others: NHMC/NHP Series

humidifier can be factory-configured to accept a

standard dc mA signal, if pre-specified. Wire

according to NORTEC supplied external wiring

diagram that comes with each modulation option.

Choose from 0-20 dc mA or 4-20 dc mA. To share

the signal with more than one humidifier consult

factory.

8.

Varying Resistance (W) Modulation by Others:

NHMC/NHP Series humidifiers can be factory

configured to power a 3-wire varying resistance

modulation humidistat by others, if pre-specified.

Wire according to NORTEC supplied external

wiring diagram that comes with each modulation

option. Choose from 0-135W, 0-500W or up to

0-1000W. To share the signal with more than one

humidifier consult factory.

pre-selected when ordering the option. NORTEC

offers several packages for NHMC/NHP Series

humidifiers. Wire according to NORTEC supplied

external wiring that comes with each optional

modulation package.

3. Optional modulation packages without modulating

safety high limit can use on-off safety high limit.

Refer to on-off controls section.

4. All versions can use on-off safety air proving

switch. Refer to on-off controls section.

OPERATION

INTRODUCTION

The NORTEC NH Series humidifier is a

completely new design based on up-to-date

technology. The NHB is designed to provide clean

steam humidification at an economical price. It utilizes

NORTEC’s patented electronic Auto-Adaptive internal

control system for high efficiency, low waste of water

and electricity.

The NHP and NHMC utilize NORTEC’s patented

P+I Auto-Adaptive control for greater control of the

space humidity. Both the NHP and NHMC use a

micro-computer control system for greater flexibility.

The NHMC has a liquid crystal display (LCD) to

indicate system messages, display RH and

temperature. The NHMC can accept dual modulation

signals and is NORTEC’s most advanced model.

OPTIONAL MODULATION (CONTINUOUS

CONTROL) PACKAGES BY NORTEC

1. Modulation (continuous control) “packages” are

offered as accessories by NORTEC. Power

supply comes from inside NHMC/NHP Series

humidifiers.

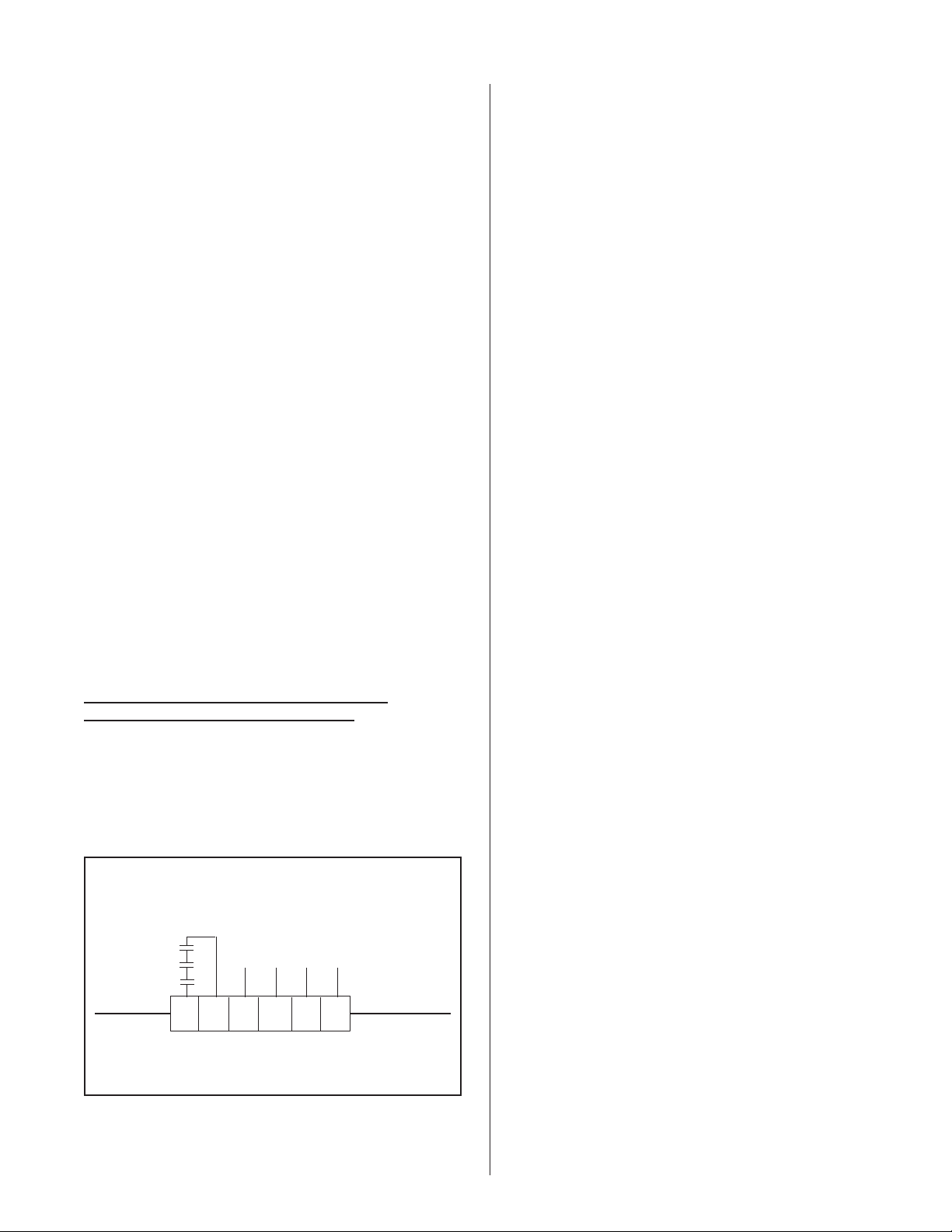

Figure #11

Generalized Modulation Wiring

VariesWith Each

Modulation Option

See NORTECSupplied

External Wiring Diagram

_

y

z

+

NHMC/NHP

External

Internal

A

B

C

810 32 30 28 26

2. NORTEC provides the humidity set point circuitry

and sensor(s) for wall or duct mounting or both

(only applies to NHMC. NHP is only capable of

single channel continuous control modulating) as

LAYOUT AND FUNCTION

The NH Series humidifiers consist of a plumbing

and an electric compartment. In every case there is at

least one steam distributor (SD) for installation in air

ducts or blower packs (built on: BOBP, remote

mounted: RMBP) for direct space humidification.

Water enters the steam cylinder through the

bottom via the drain valve from the fill cup assembly

when the 24 volt fill valve solenoid is energized. When

water submerges the electrodes, the minerals in the

water conduct current that heats the water and

produces sterile steam for distribution into the air. The

minerals in the water remain in the cylinder which is

periodically drained to maintain optimum performance

and cylinder life.

Primary electric power is applied to the electrodes

in the steam cylinder when the on/off switch is pushed

on and all controls options are calling. A primary to 24

volt stepdown transformer provides power to the

contactor holding coil(s) via the main control board.

The humidifier’s operating status is reported to the

user by the green and yellow indicator lights on the

front of the unit as shown in following table.

-7-

Page 11

SIGNAL LIGHT STATUS

NHMC OPERATION

YELLOW GREEN

OFF OFF Off

OFF ON Normal operation

ON ON Replace cylinder or normal

startup operation

ON OFF Operation fault

The prerequisites for getting power and water into

the steam cylinder are as follows:

on/off/drain switch must be switched on

-

control circuit 8-10 must be made

-

modulation humidistat, if present, must be calling

-

control circuit 82-83 must be made

-

control circuit 84-85 must be made

-

cabinet mounted humidistat, if present, must be

calling

- door interlock switch must be made (interlock switch

can be pulled out to operate unit)

START-UP SELF TEST

Observe the LCD display when the on/off/drain

switch is first pushed on. The microcomputer pc board

will check the system components, display in words

what it is doing and provide a message if any faults

are found. The start-up self-test sequence will be

displayed as follows:

LCD EXPLANATION/COMMENTS

(WHAT YOU READ)

CONDAIRMATIC MC Note the V number. It tells you

the EPROM version.

NORTEC V2...

CONDAIRMATIC MC Note the model type. Ensure

NHMC (model type) compatibility

with spec label (name plate).

Can be reconfigured if

necessary.

SYSTEM TEST Test begins.

LAMP GREEN Observe green signal light on

LAMP YELLOW Observe yellow signal light on

Most water does not contain enough conductivity

for full boil on initial start-up. Units will need to

concentrate the water over a time period (hours to

days). During this process both lights are on.

CONTACT RELAY 1 Provides 24 VAC to 61-20 and

DRAIN VALVE Observe 24 volt solenoid

INLET VALVE Observe 24 volt solenoid

CONTACTOR Observe 24 volt coil activated

CONTACT RELAY 2 Provides 24 VAC to 63-36 and

CONTACT RELAY 3 Provides 24 VAC to 62-40 and

INTERNAL TEST Completion of self test.

LAMP

GREEN-YELLOW

INTERNAL TEST

external optional yellow lamp at

control strip to simulate a fault.

activated on drain valve.

activated on fill valve.

on contactor OR fan activated on

blower pack if present.

external optional red lamp at

control strip to simulate cylinder

spent.

external optional green lamp at

control strip.

Observe green and yellow

lamps pulse on together as sign

that all passed.

-8-

STEAM OUTPUT

INTERNAL TEST

sensor, the LCD will read “MAXIMAL LEVEL”.

NOTE: If cylinder water reaches the full cylinder

Begins normal operation and

displays lbs/hr.

Page 12

USER LEVEL

REMOTE INDICATION

The keypad has four keys: MENU, é , ê,

ENTER.

Each time the user presses the menu key, the

microcomputer will display on the LCD the next

operating parameter on the menu. The basic display

will read:

Steam output (lbs/hr)

-

Capacity demand

-

Limited capacity

-

Control signal y

-

The display loops back to the top of the menu the

next time the user presses the menu key. As

NORTEC software updates are incorporated, new

parameters will automatically be added to the menu.

INFORMING THE USER

The microcomputer continually monitors the

operating status and informs the user in four ways.

The first (signal light status), second (optional external

lamps tied to the control strip) and third (operating

parameters displayed on the alphanumeric LCD

display) have been discussed. The fourth way is to

interrupt the LCD and display a system message. It

only does this as a last resort.

SELF-HELP

The microcomputer applies corrective actions

whenever its self-diagnostics identifies a problem that

it is able to correct by itself. If the corrective action is

not successful then it displays a system message. If

the corrective action requires a service person, then

the microcomputer’s only resort is to stop the unit and

display a system message. The unit never stops

unless it has to.

After three days of no call from either the on/off

controls or the modulating controls, the drain valve is

automatically activated long enough to drain all water

from the steam cylinder. This NORTEC exclusive

feature will prolong the life of the cylinder.

SYSTEM MESSAGES

Alphanumeric system messages will appear on

the LCD display any time the microcomputer decides

the user must be informed. The microcomputer does

not stop the unit for all system messages. (See the

Troubleshooting Section in this manual)

The NHMC is always internally wired to provide 24

VAC to the terminal strip for optional external remote

indication. Up to 100 milliamps is available at each of

three terminal pairs (61-20, 62-40, 63-36) for activating

yellow, green and red lamps ordered as options from

NORTEC or for powering field-supplied resistive loads

such as lamps.

DOUBLE UNIT OPERATION

Turn both switches on. During start-up self test

both sides respond to the self test together. Watch for

the lamps to light and the drain, fill and contactor to

energize as described on page 15. The LCD,

however, only indicates the left circuit [1].

After the self test, the LCD will display the steam

output for the left side [1] and both sides will operate

normally.

To alternate between parameters for the left side

[1] and parameters for the right side [2], press the

Enter key.

Use the MENU key to see other parameters

besides steam output. To display steam total output

for both sides press the enter key until [S] is displayed.

When a fault occurs on the right side of the double

unit, both sets of lamps (and remote relays) will come

on indicating that a fault has occurred. The left

[master] will display its own faults.

The LCD will indicate which fault has occurred and

on which side of the unit, [1] or [2]. The side not

faulted will continue to operate as usual.

Display is not available for the right side [2] if the

left side is switched off.

NHB/NHP OPERATION

END OF CYLINDER LIFE

When the cylinder is used up and water level can

no longer stabilize below full cylinder (due to fully

coated electrodes), the yellow light will come back on,

in addition to the green light. The disposable cylinder

must be replaced.

Although “both lights on” is the same signal at

start-up as it is at end of cylinder life, the age of the

cylinder enables the user to know when “both lights

on” is indicating end of cylinder life. It is wise to keep

a new replacement cylinder on hand to avoid

downtime when it becomes time to change the

disposable cylinder. (See Troubleshooting section.)

-9-

Page 13

MANUAL CAPACITY ADJUSTMENT

The NHB humidifier is rated in lbs/hr of steam

output capacity. Set to 100%, it will operate at full

output until the humidistat has sensed that the

humidity has reached setpoint. Then it will stop the

humidifier by breaking control circuit 8-10.

If the humidifier is oversized, the humidistat will be

quickly satisfied and stop the humidifier. As humidity

level drops the humidistat calls again. It is quickly

satisfied and stops again. The resultant short-cycling

is easily overcome.

A manual capacity adjustment potentiometer

(“pot”) is provided on the NHB main pc board for that

purpose. It is marked “Sx%” and is adjustable from 20

to 100% of rating.

The NHP humidifier, utilizing modulation control,

does not have the same problems of oversizing. It

reacts to the modulation signal and varies its capacity

automatically. However, if you wish to turn down the

capacity, the NHP has the same manual capacity

adjustment potentiometer (“pot”) that the NHB has.

OTHER POTENTIOMETERS

On the NHP, the optional output indication meter

will steadily increase until the meter reads maximum

output. Maximum output depends on the manual

capacity setting of the unit and/or the continuous

control demand.

The NHB/NHP has built in diagnostic capabilities

and will shutdown for the following reasons:

No current (similar to NHMC Error Message 5).

-

Excess current (similar to NHMC Error Message 1).

-

Change cylinder/end of life (similar to NHMC Error

-

Message). NHB will shutdown on this fault.

In all cases, when an error is detected, there will

be 24 VAC potential (100 mA max.) available at

terminals 20 and 61 of the internal external white

terminal strip.

BLOWER PACK OPERATION

Blower packs are equipped with a control

thermostat mounted on the steam distributor. As soon

as humidifier generates steam, the contact is closed

and the fan is started. When steam is no longer being

generated, the fan cuts out with a delay.

Do not adjust any other potentiometers (“pots”) on

the pc board(s). They are factory-set and not meant to

be user-set.

DETECTING WATER SUPPLY DEFICIENCY

Knowing how long it normally takes to fill each size

steam cylinder, each humidifier’s pc board is factory

configured to an acceptable maximum filling time

(using jumpers). If it is filling too slowly, when the time

expires the electronics stops the humidifier. To

indicate this, the green light goes out and the yellow

light goes on.

REMOTE INDICATION

Every NHB/NHP comes factory wired to provide

24 VAC (100 mA max.) at 61-20 on the control

terminal strip. The user can connect an indicator

externally to 61-20. It will automatically be activated

any time the yellow light is on. It will therefore be

activated whenever the humidifier shuts off due to

excess current or water deficiency. It is also normal

for it to be activated on start-up.

DOUBLE UNIT OPERATION

Turn both switches on. If there is a demand for

humidity, the green status lamp will indicate that the

circuit is operating.

If blower packs get overheated (malfunction of the

air circulation), the manual reset safety thermostat

interrupts the steam generation. To reset, switch off

the humidifier and wait until the steam distributor cools

down. Then remove left-hand side intake air filter and,

using a screwdriver, press the reset button (marked

with a red dot) inside the blower packs.

Units are equipped with speed select switch. The

switch is located on the right-hand side of the blower,

inside the blower pack. To access the switch, remove

right-hand side intake air filter.

To avoid condensation on the cabinet parts, run

blower pack on high speed when humidifier delivers 75

lbs/hr or 100 lbs/hr of steam.

MAINTENANCE

WARNING! The plumbing and electrical

compartments contain high voltage components and

wiring. The access door(s) is equipped with a lock.

Access should be limited to authorized personnel only.

WHEN TO REPLACE THE STEAM

CYLINDER

The steam cylinder is disposable and must be

replaced at end of cylinder life. Cylinder life is

-10-

Page 14

dependent on water supply conditions and humidifier

(

)

usage. Failure to replace the cylinder at the end of

cylinder life may result in unit damage. NORTEC is

not responsible for any damages resulting from, or

attributable to, the failure to replace a used cylinder

(see Manufacturer’s Warranty). There are many

indications, each of which signifies the end of cylinder

life.

NHMC

1. After a period of operation (not on initial start-up),

the water level will approach the top of the

cylinder. (Life varies from 500 to 2000 operating

hours, as illustrated in Figure #12.)

Figure #12

Water Conditions vs. Cylinder Life

Capacity Adjustment Setting

100% 50% 25%

30

20

10

Grains of Hardness

500

400

200

3

CaCO mg/L (ppm)

6. The three (3) messages that will appear in

sequence are “MAXIMAL LEVEL”, then

“CYLINDER SPENT”, and finally “CYL. LIFESPAN

END”. The yellow unit status lamp will be on

during all three.

7. The green unit status lamp, primary contactor and

steam output will stop at “CYL. LIFESPAN END”.

This distinguishes it from “MAXIMAL LEVEL” and

“CYLINDER SPENT”.

8. Each of these three (3) messages has a unique

combination of responses at the terminal strip for

remote indication. These unique combinations

distinguish them from each other and from any

other system message.

9. At “MAXIMAL LEVEL” remote yellow-green-red

are OFF-ON-OFF. (Note that “MAXIMAL LEVEL”

will also appear at unit start-up.)

10. At “CYLINDER SPENT” remote yellow-green-red

are OFF-ON-ON. In other words, the red comes

on as the cylinder ages from “MAXIMAL LEVEL”

to “CYLINDER SPENT”. This gives the user

ample warning (remote red on) to replace the

cylinder before the NHMC shuts itself down.

11. At “CYL. LIFESPAN END” remote

yellow-green-red are ON-OFF-ON. In other

words, the remote green goes off and the remote

yellow comes on in addition to the red if

“CYLINDER SPENT” remains unchanged for

approximately three (3) days.

5

500 1000 2000 4000 8000

Cylinder Life Expectancy

average operatinghours

100

2. There will be reduced output in spite of a 100%

capacity setting and/or an unsatisfied demand

from the humidistat for more humidity. This is

evident by monitoring the unit’s output on the LCD

(liquid crystal display) with up to two lines of

continually updated alphanumeric information for

the user.

3. Each NHMC humidifier has an internal

micro-computer that can detect end of cylinder life.

If the cylinder is not changed, the humidifier will

automatically shut down.

4. The unit’s yellow status lamp is activated anytime

there is a system message sent to the LCD where

two lines of alphanumeric information await the

user. System messages are explained in greater

detail later in this manual. Three (3) different

messages will appear, in sequence, as the

cylinder goes from new to spent to needing

replacement.

5. The NHMC is pre-programmed to inform the user

of the cylinder’s status. It is important to

understand the significance of the unit’s system

messages, status lamps and 24VAC circuits for

remote indication. Figure #2 summarizes these

messages and responses.

12. The NHMC is always internally wired to provide

24VAC to the terminal strip for optional external

remote indication. Up to 100 mA is available at

each of three terminal pairs (61-20, 62-40 and

63-36) for activating yellow, green and red optional

external remote indicators, respectively. Any or all

of these remote indicators can be utilized. They

can be field-supplied resistive 24 VAC loads such

as lamps or ordered as options from NORTEC.

NHB/NHP

1. There will be reduced output in spite of a 100%

capacity setting and/or an unsatisfied call from the

on/off humidistat for more humidity. The NHP has

an output display where you will observe that the

capacity of the unit is decreasing.

2. Each NHB/NHP humidifier has a yellow status

lamp, a green status lamp, and a relay for remote

indication. Double units (models NH 150-200)

have two of each.

3. The yellow and green status lamps are long-life

LED’s (light emitting diodes) not incandescent

lamps.

4. The yellow and green status lamps are to be

viewed as a pair. This way, they convey four

-11-

Page 15

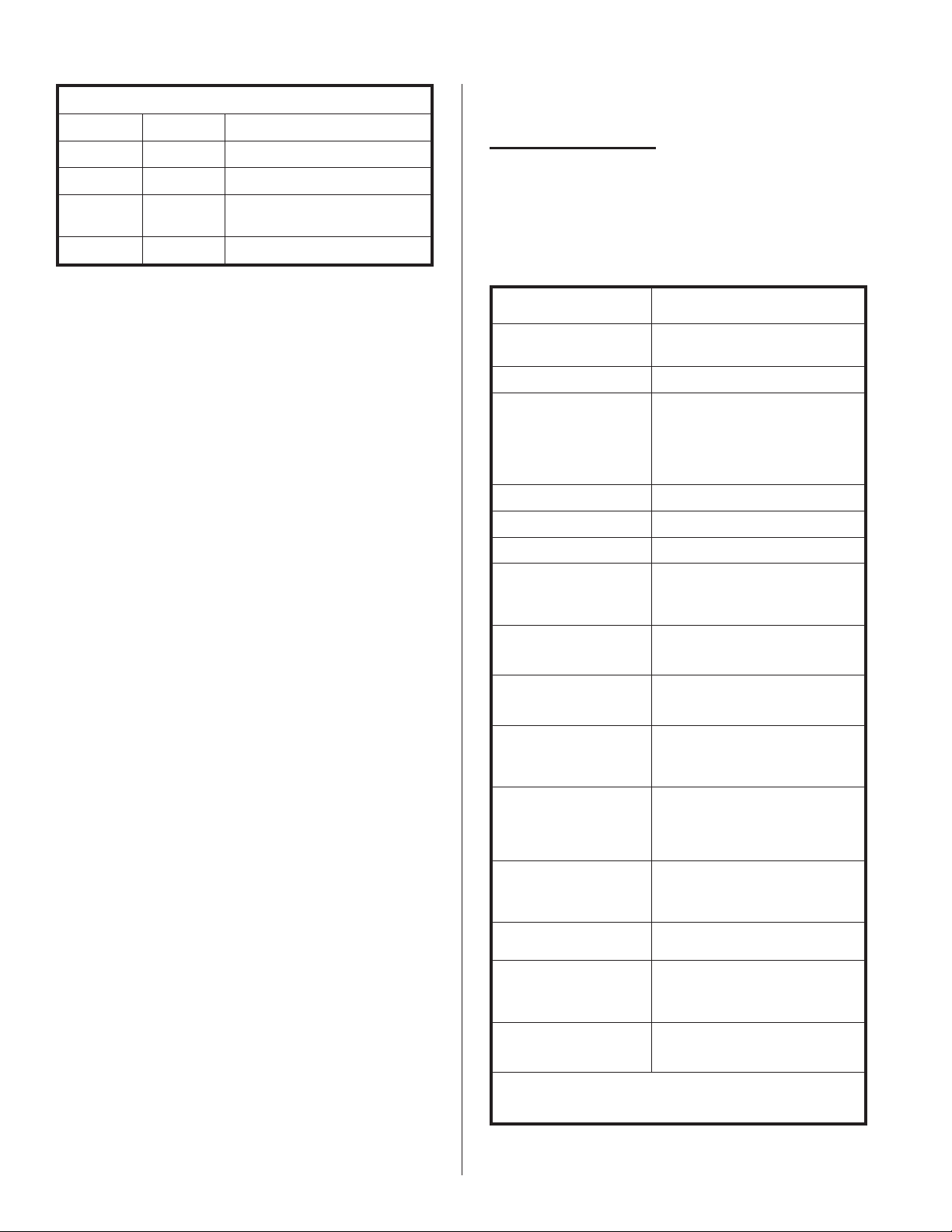

SYSTEM MESSAGE

DISPLAYED ON LCD

Figure #13

System Messages and Responses (EPROM : 2.XXN)

NHMC

UNIT STATUS LAMPS REMOTE INDICATION (24 VAC TO:)

UNIT

CONTACTOR YELLOW GREEN

61-20

“YELLOW”

62-40

“GREEN”

63-36

“RED”

Maximal Level

Excess Current / Error 1

No Current / Error 2*

Max. Filling Time / Error 3

Cylinder Spent / Error 4

No Current / Error 5

Output Too Low / Error 6

Electronic / Error 7

Phase Interrupt / Error 8

Cyl. Lifespan End / Error 9

* When No Current/Error 2 is displayed, display will change to show Maximal Level and will alternate back and forth.

SYSTEM FAULTS* UNIT CONTACTOR YELLOW GREEN “YELLOW” 61-20

ON ON ON OFF ON OFF

OFF ON OFF ON OFF OFF

OFF ON OFF ON OFF OFF

OFF ON OFF ON OFF OFF

ON ON ON OFF ON ON

OFF ON OFF ON OFF OFF

OFF ON OFF ON OFF OFF

OFF ON OFF ON OFF OFF

ON ON OFF OFF OFF OFF

OFF ON OFF ON OFF ON

NHP

UNIT STATUS LAMPS REMOTE INDICATION

(24 VAC TO:)

Maximal Level

Excess Current

No Current

Max. Filling Time

Cylinder Spent

No Current

Output Too Low

Electronic

Phase Interrupt

Cyl. Lifespan End

-

Remote indication 61-20 “yellow” means humidifier has shutdown and one of several system messages is showing.

The exception is on the NHP when No Current or Output Too Low is the fault, 61-20 “yellow” will be off, but the yellow

light on the NHP will be on.

-

Remote indication 62-40 “green” means contactor is on; humidifier is operating.

-

Remote indication 63-36 “red” means cylinder is spent; replacement is necessary.

OFF ON OFF ON

OFF ON OFF OFF

OFF ON OFF ON

ON FLASHING ON OFF

OFF ON OFF OFF

OFF ON OFF OFF

N/A N/A N/A N/A

N/A N/A N/A N/A

OFF FLASHING OFF ON

*NOTE: NHP does not display actual message or error.

See NHMC Chart above for details

-12-

Page 16

messages, instead of two, as summarized in

g

A

Figure #14.

5. Once drained, open

the main electrical disconnect

during the entire cylinder change operation.

Figure #14

YELLOW GREEN

OFF OFF

OFF ON

ON ON

ON OFF

Off

Normal operation

Replace cylinder or normal

start-up operation

Operation fault

5. When both the yellow and the green status lamps

are on, the water level is detected as being at the

top of the cylinder. This is normal on start-up, but

as the contained water concentrates, the water will

stabilize at a lower water level and the yellow lamp

will be off.

6. When the cylinder is fully used, the water level will

have returned to the top of the cylinder. Since

there is no longer any clean electrode surface

available at end-of-cylinder-life, the required steam

output rate can no longer be maintained.

7. At this stage, the yellow lamp flashes and the

green lamp is on, telling the user that the cylinder

is reaching the end of its life and will need to be

replaced shortly. The humidifier continues to

operate.

8. The NHB relay for remote indication is not

intended to indicate end-of-cylinder-life. It is

intended to indicate other detected faults

explained later in this manual.

6. Open plumbing door.

7. Cylinder plugs are attached to the primary voltage

cylinder wires. (The plugs remain attached to the

wires unless they have to be replaced due to

damage.) The plugs are press-fitted over the

electrode pins protruding from the top of the

cylinder. Remove cylinder plugs from cylinder by

pulling vertically.

8. Using slot screwdriver, loosen the steam hose

clamp(s) and pull steam hose off the cylinder

vertically.

9. Using a small slotted screwdriver, depress tab on

the re-usable tie wrap, if present, around the

middle of the cylinder. This will loosen the tie

wrap to come apart for re-use later on.

10. Cylinder is now ready to be lifted out of the unit.

CAUTION: Cylinder and any undrained water

might still be HOT.

MANDATORY CLEANING OF THE DRAIN

VALVE

Always clean the drain valve before installing a

new cylinder since the valve port may be as dirty as

the used cylinder.

1. Remove used cylinder as previously described.

NORTEC does not recommend the use of any

acid solutions to clean the used cylinder. Always

replace a used cylinder.

9. The NHP at end of cylinder life will not operate,

the yellow lamp will “flash

”, and the green lamp will

be “off”.

HOW TO REMOVE THE STEAM CYLINDER

1. (It is advisable to keep a spare cylinder in stock

throughout the humidification season.) When

ordering a replacement steam cylinder, always

quote the three or five digit model number on the

label applied to the cylinder or quote the unit’s

serial number, model and voltage located on the

spec label (nameplate).

2. Turn off water supply to unit.

3. The used cylinder must be drained completely

before removal. If the water has just been boiling,

allow it to cool before draining. Push the

ON/OFF/DRAIN switch to the MANUAL DRAIN

position. Leave it in this position just long enough

to drain the cylinder (usually less than 10

minutes).

4. When completely drained, push the main

ON/OFF/DRAIN switch back to the OFF position.

Figure #15

Reassembly of the Drain Valve and Fill Valve

ctuator

Male Slip-on

Connection Tabs

Holdin

Sleeve

Coil

Plunger

Spring

2. Note that ring terminal for drain valve green

ground wire is sandwiched between drain valve

body and drain pan.

3. Remove two screws securing drain valve body to

drain pan. Disconnect the two slip-on terminals

from the two tabs on the (24VAC) drain valve coil.

4. Remove hose clip and hose connection from drain

valve body.

5. Drain valve assembly is now free to be taken to a

sink for disassembly and cleaning.

-13-

Page 17

6. Remove snap-fit red cap from coil assembly and

slide coil off the actuator.

7. Loosen actuator with wrench and unscrew from

plastic valve body.

8. Clean the exposed core and spring and plastic

drain valve port.

9. Important: Tapered end of spring must be

installed toward the solenoid. Reassemble,

tighten actuator 1/4-turn past hand-tight.

Figure #16

Cylinder Plug Installation

Cylinder Plug Installation Instruction

Cylinder Plug Installation Instruction

For Part # 135-4012 (R, Y, or B)

for Part # 135-4012 (R,Y or B)

0.50"

10 ga Wire

10 GA Wire

0.50

Cylinder p lug

Cylinder Plug

10. Clean out the end of the hose, then reconnect it to

the drain valve body with the clamp.

11. Fit mounting screws through drain valve body, one

through ring terminal on green ground wire.

12. WARNING: To prevent the possibility of electrical

shock the green ground wire must be reinstalled

before power is restored.

13. Push the two slip-on terminals back onto the two

tabs on the coil. The terminals, although not

identical, are reversible.

HOW TO INSTALL THE REPLACEMENT

CYLINDER

1. Reverse procedure should be followed to install

new cylinder. Main disconnect is to be left open

until cylinder is completely installed and

reconnected.

2. Ensure that cylinder is secured properly by the

re-usable tie wrap and mounting brackets within

the unit.

3. The cylinder plug wires are color-coded in

accordance with colored dots beside the electrode

pins on top of the cylinder.

4. This color-coding must be adhered to when

replacing cylinder plugs on pins.

5. With cylinders having six primary voltage

plugs

, it should be noted that there are two of each

color.

cylinder

Hex (Allen)

5/64 (2m m)

Hex (Allen)

5/64" (2 mm)

12/08/94

EXTENDED SHUTDOWN

Before disconnecting power to the humidifier for a

period of extended shutdown, ALWAYS DRAIN the

cylinder first. Otherwise, the electrodes are subject to

harmful corrosion which drastically shortens cylinder

life. Do NOT leave the switch in the DRAIN position

indefinitely as the drain coil could burn out. Leave the

switch in the OFF position and “open” the main

external fused disconnect to stop power to the

humidifier. Close the shut off valve in the water supply

line feeding the humidifier. Lock the cabinet door(s) to

prevent unauthorized tampering. All doors are factory

supplied with keyed locks. DO NOT LEAVE KEY IN

LOCK. ACCESS SHOULD BE LIMITED TO

AUTHORIZED PERSONNEL ONLY.

As long as the NHMC is powered, it will

automatically drain the cylinder when there has not

been a call for humidity for an extended period of time.

The cylinder will remain empty until there is a call for

humidity at which time the fill valve will open and refill

the cylinder. The unit will go through its normal

stabilization process for optimum operation.

6. Care must be taken so that cylinder leads of the

same color

are always directly opposite each other

as indicated by the dot formation on the top of the

cylinder.

7. The white cylinder plug on all units is for the

sensor electrode which always goes on the single

pin surrounded by a plastic shoulder.

8. Ensure that cylinder plugs fit snugly on the pins.

9. If cylinder plugs become loose, it is best to obtain

a new replacement plug. Consult factory.

Figure #17

Where To Oil

Oil Here

-14-

Page 18

This feature will reduce the possibility of corrosion

of the electrodes and the possible accumulation of

algae and bacteria growing in the cylinder.

malfunction due to foaming. These are just some

examples of what can go wrong if the fill and drain

rates are not maintained.

BUILT ON AND REMOTE MOUNTED

BLOWER PACKS (BOBP’s / RMBP’s)

FAN MOTOR OILING: The blower pack fan motor

requires occasional oiling of motor bearings. To do

this, open up the blower pack top and oil the motor

with ten drops of SAE-20 grade motor oil. Refer to

Figure #6 for oiling slots. It is important to oil the fan

motor every four months to preserve long life and to

maintain the fan’s warranty. It is not necessary to

disassemble the fan/motor assembly. The exploded

view is for visual purposes only.

TROUBLESHOOTING

PLEASE READ THIS SECTION BEFORE

REFERENCING SPECIFIC DIAGNOSTIC

MESSAGES.

1. Ensure the installation detail conforms with the

recommendations contained in the Installation

Manual, Form #XX-161.

2. Understanding the Principle of Operation is an

asset when troubleshooting. This information is

readily available from your local representative.

3. When contacting your local representative or

NORTEC, for troubleshooting assistance, please

ensure the serial number has been obtained for

reference purposes.

4. Whenever the troubleshooting steps indicate a

problem with the main pc-board, first check all

connections at the main pcb (including the ribbon

cable connections at the center of the main pcb)

before ordering replacements.

STARTING POINT

Fill rates of suspect units should be checked.

Open the disconnect to cut off all power in the

humidifier before reaching inside. One of the 24VAC

wires to each primary voltage contactor holding coil

(some models have two contactors per cylinder)

should be temporarily disconnected for this test. This

way, no boiling occurs during the test so as not to

detract from the fill rate. Fill rates should measure

nominally at 1" to 1-1/2" of vertical rise in water level in

the cylinder in one minute.

If filling too quickly, check for excessively high

supply water pressure (over 80 psig). If water

pressure is correct, verify fill valve body orifice (consult

factory). If filling too slowly, look to probable causes

described under Error 3 later in this manual. Check

rate with steam line disconnected.

Manual drain rates of suspect units should be

checked using Figure #18 as reference times.

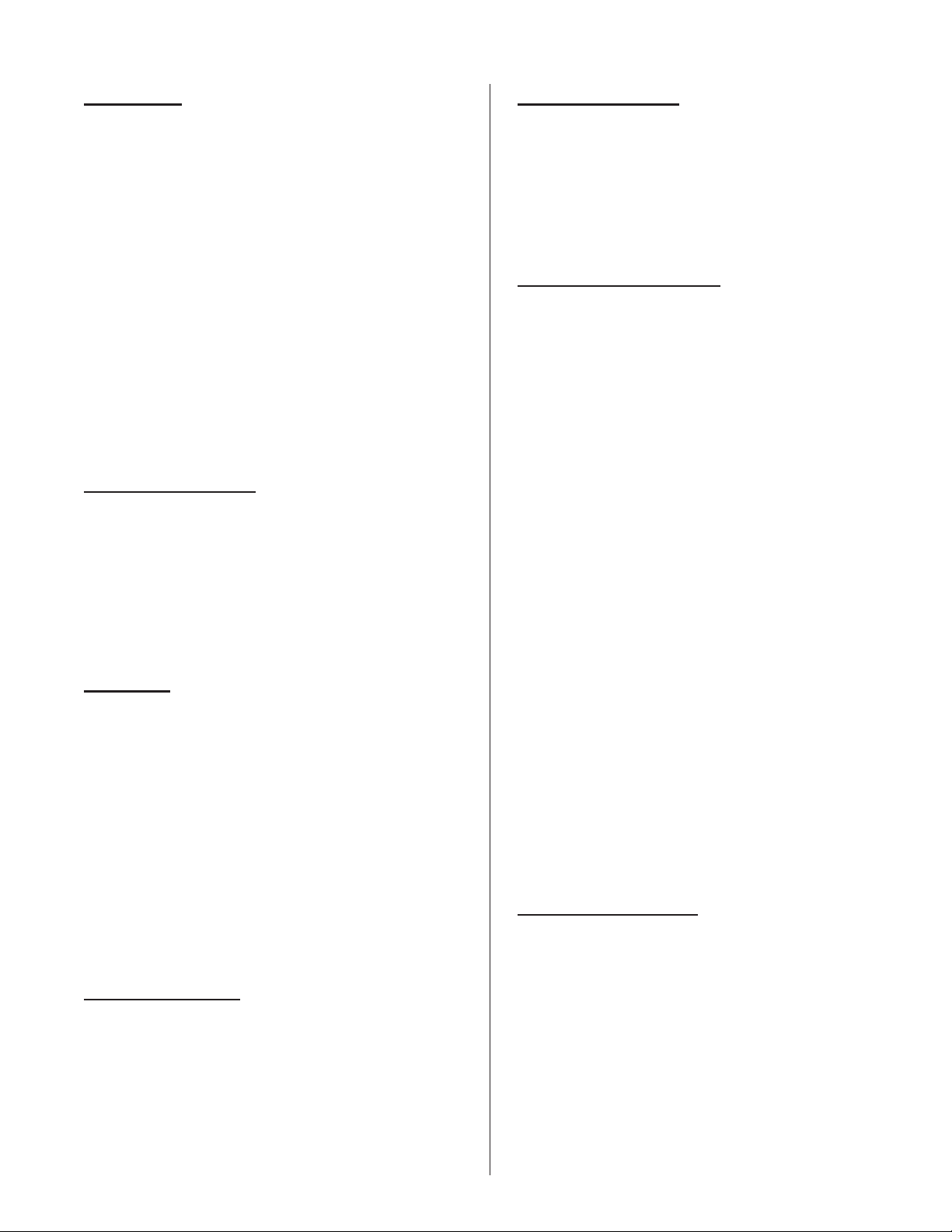

Figure #18

Manual Drain Times

CYL. SIZE

(SERIES)

500/600 2 minutes and 52 seconds ± 10 sec.

400 1 minute and 20 seconds ± 5 sec.

300 43 seconds ± 2 sec.

200 25 seconds ± 1 sec.

PROPER TIME (sec) TO DRAIN MANUALLY

FROM SEAM TO EMPTY

BEIGE BODY DRAIN VALVE

If nothing is working, check for 24 VAC output

from the stepdown transformer (see wiring diagram).

If there is no 24 VAC output, the transformer might

have been damaged if external controls were installed

and/or connected with the field-supplied fused

disconnect on. If this is the case, the transformer must

be replaced.

The conductivity of the water within the cylinder

must be controlled, in order for the humidifier to

function properly. The fill and drain rates must be

maintained. Filling too quickly can cause over-amping

and automatic shutdown or blown fuses. Filling too

slowly can cause insufficient steam output and

humidity levels. Water supply pressure should be

between 30 and 80 psig, ideally 55 to 60 psig.

Draining too slowly can cause over-concentration and

If time measurements are longer, repeat with

external drain disconnected (and draining into a pail)

to know if external drain is impeding flow.

Clogged strainer and/or clogged drain valve will

cause shortened cylinder life. But start by determining

what caused the strainer and/or drain valve to clog in

the first place.

Do not assume that if strainer and/or drain valve

are clogged that they are to blame. If the external

drain has been impeding flow, then waste

accumulates, resulting in a clogged strainer and/or

clogged drain which, in turn, results in shortened

cylinder life.

-15-

Page 19

Clean the drain valve; start with a fresh cylinder.

Then measure the manual drain time with and without

the external drain connected. Is the external drain

impeding flow? NORTEC recommends an open

external drain line. See Form #XX-161.

NHMC/NHP

The self-diagnostic system built into the NHMC is

continually checking the status of the electrical circuits

to the fill valve, drain valve, primary voltage contactor,

high water sensor and steam cylinder. The modulating

signals from external humidistats and reduced manual

capacity settings are taken into consideration. When

problem symptoms are found, the NHMC/NHP will

take self-corrective actions, if applicable. It will, if

necessary, respond by shutting itself down.

The NHMC/NHP communicates its findings to the

user by way of the unit’s status lamps and signals sent

to the terminal strip for optional external remote

indication. Even more directly, the NHMC has an

alphanumeric system message to the user via the

LCD (liquid crystal display).

de-energizing the contactor momentarily while it

drains.

Probable Cause(s):

1. Cylinder water is over-concentrated (too

conductive) due to restricted drain, short-cycling

by controls, supply water not within acceptable

limits (too conductive), improper fill rate, incorrect

cylinder being used.

2. Water level too high due to leaking fill valve,

excess condensate return from steam line.

Corrective Action:

1. Note water level.

2. Manually drain cylinder while checking drain rate

(refer to Figure #7 for proper drain times). If too

slow correct cause.

3. Turn unit back on and check the fill rate (1 - 1-1/2

inches per minute)

4. Once RH% set point is attained, monitor cycle

time.

All of this is summarized for each system message

in the following easy-to-follow format.

NHMC/NHP Explanation of System Messages and

Responses —- EPROM : 2.XXN

1. Maximal Level (Shown on NHMC LCD display

only)

Symptom(s) Diagnosed:

Water has reached the

top of the cylinder and activated the high water

sensor circuit. This is not an error or fault

diagnostic. Note: This is normal on start-up and

at end of cylinder life before Error 4 shows.

Probable Cause(s):

Normal on startup with a

new cylinder or a cylinder that has been

completely drained because of an extensive off

period. Can last for several hours until the water

in the cylinder has concentrated or the electrodes

can no longer provide rated capacity (or adjusted

capacity). Water level automatically rises to seek

out fresh electrode surface to meet the demand.

Unit Takes Self-Corrective Action:

Yes. It stops

the fill valve to prevent overfilling.

2. Excess Current - Error 1

Symptom(s) Diagnosed:

Current drawn on

monitored primary lead to cylinder has reached or

exceeded 125% of its rated amps. The unit will

have tried to self-correct prior to system shutdown

by draining water from the cylinder or

Response:

See Figure #2, NHMC/NHP System

Messages

3. No Current - Error 2

Symptom(s) Diagnosed:

Full cylinder (MAXIMAL

LEVEL) detected with no current draw sensed by

the electronics on monitored primary lead to

cylinder.

Probable Cause(s):

1. No current being drawn, specifically on the

monitored primary lead to the cylinder, or the

actual current not being sensed.

2. False detection of a full cylinder (water level within

inches of cylinder top) due to foaming,

wiring/connection problem, circuit board failure.

Corrective Action:

Check water level in cylinder.

1. If full (within 4" of top) disconnect white sensor

plug on cylinder, reset unit and check monitored

primary lead to cylinder for current with amp

clamp. If current present, determine why main

PCB does not sense the current. If no current,

present determine cause of primary voltage

interruption.

2. If not full disconnect white sensor plug on cylinder,

reset unit. If error 2 does not reoccur within two

minutes, cylinder was likely foaming and should be

flushed. If error 2 does reoccur within two

minutes, there is a problem with the high water

sensor PCB. If error 2 occurs with the high water

sensor PCB disconnected, there is a problem with

the main PCB.

-16-

Page 20

Response: See Figure #2, NHMC/NHP System

Messages

4. Max. Filling Time - Error 3

Symptom(s) Diagnosed:

Time dependent.

Neither Maximal Level (full cylinder) is detected,

nor is there enough current drawn to meet

capacity demand. Current monitored on primary

lead to cylinder is greater than zero and not

decreasing. The unit will have tried to self-correct

prior to system shutdown by pulse activating the

drain valve to possibly clear any debris holding the

drain valve open.

Probable Cause(s):

1. Steam line restriction causing back pressure.

displayed and the fill valve does not energize (green

LED must be illuminated), the main PCB is defective.

If Maximal level is displayed, a problem exists with

the cylinder or the high water sensor PCB. A voltage

of 85 VAC or greater across the orange wires of the

high water PCB ( one orange wire terminates at the

white sensor plug attached to the soldered pin of the

cylinder, the other terminates at one of the contactor

connections) will signal a full cylinder (Maximal

Level) to the main pcb. If this voltage does exist, the

problem is with the high water PCB, if not, the

problem is within the cylinder (can be caused by

cylinder being past end of life.

5. If not full, drain cylinder, reset unit, and check the

fill rate (refer to Figure #2 ). If the fill rate is

correct, back pressure is the likely cause and

should be rechecked.

2. Improper fill rate.

3. Leaking drain valve

4. Full cylinder not detected.

Unit Takes Self-Corrective Action:

Yes. It

pulse-activates the drain valve to possibly clear

any dirt. It retests. If the symptoms persist after

two attempts, it then responds as shown in Figure

#2.

Corrective Action:

1. Check for water leaking from drain. If present,

correct the drain valve deficiency (check for debris

holding drain coil plunges open).

2. Ensure the steam line, from the cylinder outlet to

the steam distributor (duct or blower pack), is

properly installed, to ensure back pressure is not

the case.

3. Check water level in cylinder.

4. If full reset unit and ensure there is a demand for

steam (the green LED on unit door will stay

illuminated. Maximal Level should be indicated on

the LCD display and both green and yellow LED is

on the unit door illuminate almost immediately. If

Maximal Level is not indicated, a problem exists

with the high water sensor circuitry.

a) Check wiring of the high water sensor PCB

(refer to unit wiring diagram).

Response:

See Figure #2, NHMC/NHP System

Messages.

5. Cylinder Spent - Error 4

Symptom(s) Diagnosed: Water level stays high,

cycling on and off Maximal Level (full cylinder),

without an increase in output/amp draw or

reaching demand.

Probable Cause(s):

1. Cylinder has reached end of life due to insulative

mineral coating on electrodes.

2. New cylinder start up with low incoming water

conductivity.

Corrective Action:

1. If the cylinder is not new, replace the cylinder

immediately. Within approximately three days, the

unit will shut itself down on Error 9 resulting in no

output instead of reduced output.

2. If the cylinder is new, the electronics will

differentiate cylinder spent from new cylinder start

up and the displayed error will discontinue without

a shutdown on Error 9.

Response:

See Figure #2, NHMC/NHP System

Messages.

6. No Current - Error 5

b) Check for amperage on all wires at the

cylinder, with an amp probe (amp clamp). If

amperage is not detected on all wires,

correct primary wiring deficiency. If

amperage is detected on all wires, proceed

to next step.

c) Place a jumper across 42 and 48 of main

PCB for five seconds. If Maximal Level is not

-17-

Symptom(s) Diagnosed:

Time dependent. No

current sensed by the electronics on the monitored

primary lead to the cylinder. The unit will have

tried to self correct prior to system shutdown by

pulse activating the drain valve, to possibly clear

any debris holding the drain valve open.

Probable Cause(s):

Page 21

1. No current being drawn on the monitored primary

lead to the cylinder, or the actual current is not

being sensed.

2. Water does not reach the electronics due to a

restricted water supply line or due to a constantly

open/leaking drain valve preventing a water level

increase.

3. High duct static pressure blowing back into the fill

cup (via steam line, empty cylinder) diverting the

fill cup water to the overflow.

c) If 24 VAC is not present, then check for 24

VAC across 6 and 14 on the PCB.

d) If 24 VAC is not present across 6 and 14 of

the PCB, then the problem is with the main

PCB.

e) If 24 VAC is present across 6 and 14 of the

PCB, then check for a break in the circuit to

the fill valve.

Unit Takes Self-Corrective Action:

Yes. It

pulse-activates the drain valve to possibly clear

any dirt holding the seal open. It re-tests. If

symptoms persist after two attempts, it then

responds as shown in Figure #2.

Corrective Action:

1. Check the water level in the cylinder.

2. If there is water in the cylinder (1/5 of a full

cylinder or more) check monitored primary lead to

the cylinder for current with an amp clamp.

a) If current is present with zero output

indicated on the display, the problem is with

the main PCB.

b) If no current is present determine the cause

of the primary voltage interruption.

3. If there is little or not water in the cylinder turn the

unit off and disconnect the steam line at the

cylinder. Reset the unit and monitor filling.

a) If unit fills and Error 5 does not reoccur, the

problem was likely caused by air flow through

the fill system and can be permanently

corrected by installing a U trap on the fill line

between the fill cup and the drain valve body.

Response:

See Figure #2, NHMC/NHP System

Messages.

7. Output Too Low - Error 6

Symptom(s) Diagnosed:

Time dependent.

Neither Maximal Level (full cylinder) is detected,

nor is there enough current drawn to meet

capacity demand. Current monitored on primary

lead to cylinder greater than zero but decreasing.

Unit Takes Self-Corrective Action:

Yes. It

pulse-activates the drain valve to possibly clear

any dirt holding the seal open. It re-tests. If

symptoms persist after two attempts, it then

responds as shown in Figure #2.

Probable Cause(s):

Corrective Action:

Response:

See Figure #2, NHMC/NHP System

Refer to Error 3.

Refer to Error 3.

Messages.

8. Electronic - Error 7 (NHMC only)

Symptom(s) Diagnosed:

The electronics of the

main PCB have diagnosed the main PCB as

defective.

b) If unit does not fill, then turn the unit off and

clean and check the drain valve (refer to

section on Mandatory Cleaning of the Drain

Valve in this manual) to ensure that there are

no obstructions or leaks in the drain valve

preventing it from holding water in the

cylinder, and check water inlet for

obstructions.

4. Turn unit back on and see if it will fill.

a) If unit still does not fill, then with the unit

turned on, check for 24 VAC across the fill

valve (there must be a call for humidity).

b) If 24 VAC is present, then the problem is with

the fill valve.

Probable Cause(s):

1. A spike in the primary power supply to the

humidifier, either high (surge) or low (brown out),

causing the electronics to experience a logic

glitch.

2. A problem with the main PCB.

Corrective Action:

1. Reset humidifier and monitor display. If Error 7

reoccurs within one minute of resetting the unit,

the problem is with the main PCB. If Error 7 is not

repeated, the primary power to the unit is suspect.

Response:

See Figure #2, NHMC System

Messages.

-18-

Page 22

9. Phase Interrupt - Error 8 (NHMC only)

NHB

Symptom(s) Diagnosed:

The 24 VAC to the main

PCB, across terminals 44 and 46 is interrupted.

Probable Cause(s):

a) A wiring problem leading to an interruption of

the 24 VAC to terminals 44 and 46 of the

main PCB.

b) A problem with the main PCB.

Corrective Action:

1. With the unit switched on, measure across

terminals 44 and 46 of the main PCB for 24 VAC.

If not present, find the cause of interruption. If

present, the problem is with the main PCB.

Response:

See Figure #2, NHMC System

Messages

10. Cyl. Lifespan End - Error 9

Symptom(s) Diagnosed:

The criteria for

diagnosing Cylinder Spent - Error 4 has expired

and cylinder has not been replaced. Humidifier

has shut down to avoid unsafe operation.

Probable Cause(s):

Refer to Error 4.

The NHB checks the status of the electrical

circuits to the fill valve, drain valve, primary voltage

contactor, high water sensor and steam cylinder. The

manual capacity setting, if reduced, is taken into

consideration. When problem symptoms are found,

the NHB will, if necessary, respond by shutting itself

down.

The NHB communicates its findings to the user by

way of the unit’s status lamps and a 24 Vac (maximum

100 mA maximum) signal sent to the terminal strip for

optional external remote indication.

The signal for remote indication comes in

response to the following symptoms. In each case,

the NHB shuts itself down. The green status lamp

goes off, but the yellow status lamp (and remote fault

relay) remain on.

NHB Explanation of Automatic Shutdowns

1. Excess Current

Symptom(s) Diagnosed:

Current in steam

cylinder increases beyond the fill off and

emergency drain on triggers. Current reaches

150% of FLA (i.e. 134% of fill off rated amps; i.e.

134% of amps on spec. label) for 1 second.

Corrective Action:

Response:

See Figure #2, NHMC/NHP System

Refer to Error 4.

Messages.

Troubleshooting Dual Cylinder Units

Double units, NHMC-150 and 200, are two circuits

in one cabinet sharing one LCD display. A ribbon

cable between the RS232 ports links the two circuits.

The left circuit is the master. [1] on the display means

left side. [2] on the display means right side.

Refer to double unit operation on in the NHMC

Installation and Operation Manual.

When a fault occurs on the right side of a double

unit, both sets of lamps (and remote relays) will come

on indicating that a fault has occurred. The left side

(master) will display its own faults as well.

The LCD will indicate which fault has occurred and

on which side of the unit, [1] or [2]. The side not

faulted will continue to operate as usual.

The side which has shut down on fault can be

treated as a single circuit using the same

troubleshooting guidelines as previously described.

Probable Cause(s):

Blocked drain due to blocked

cylinder strainer or blocked drain valve or blocked

external drain line. No power to drain valve at

emergency drain on trigger. Power remains on fill

valve at fill off trigger. Wrong steam cylinder (too

conductive). Wrong fill valve (orifice too big).

Wrong supply voltage (too high). Supply water too

conductive. Contained water too conductive.

100% softened supply water is often too

conductive. Measure conductivity and report