NORSTAT Non-Contact Safety Switches User Manual

MECHAN

Installation Guide : SCU-1 & HE Safety Switches

Keep this guide for future reference

This information is designed to help suitably qualied

personnel install and operate Mechan Safety equipment.

Before using this product, read this guide thoroughly along

with any relevant European and/or National standards e.g.

Machinery Directive 2006/42/EC and it’s amendments,

Provision and Use of Work Equipment Regulations.

Further information can be obtained from Mechan Controls

Description

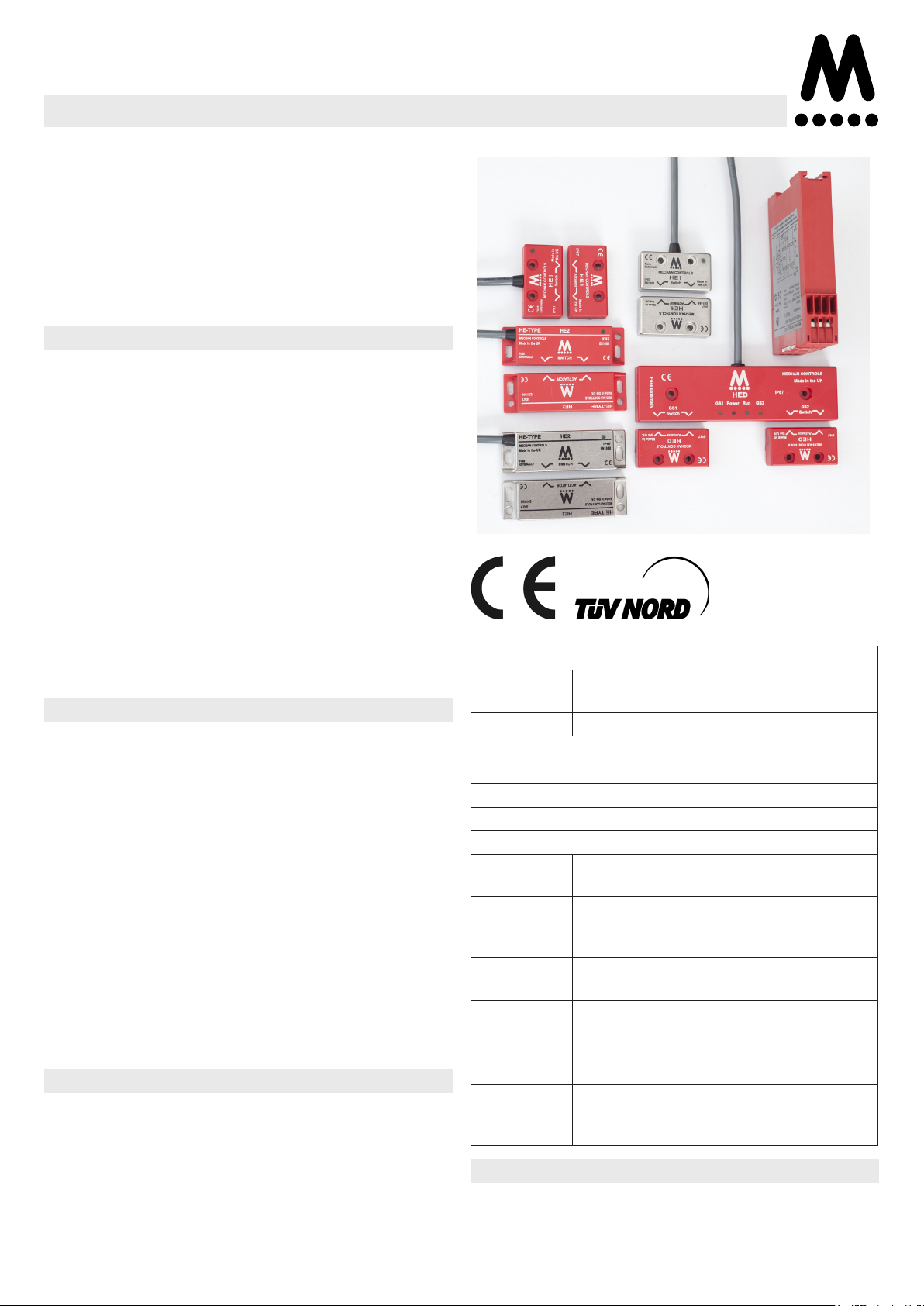

Mechan HE safety switches are magnetically coded, solid

state non-contact safety switches for use in machine guarding applications.

Non-contact operation makes the HE switches easy to

install and tolerant to misalignment. The solid state design

is even more tolerant to shock and vibration, and provides

single point switching which makes for a simpler and more

reliable machine guard interlock.

The additional security of the coded magnetic operation

along with fully sealed IP67 rating make these switches

ideal for use in wet or dusty and harsh environments.

The HE safety switches have been designed to connect to

the SCU-1 Safety Control Unit. When installed correctly, up

to 30 switches can be installed in series.

Operation

The HE safety switch has 2 x N/O + 1 N/C bi-directional

solid state outputs along with built in LED(s) for indication.

When installed on a machine guard, power is applied, and

the switch and actuator are within the specied operating

range, the N/O Outputs will be closed, the N/C Output will

be open. When the actuator moves out of the operating

range, the N/O Outputs will open, the N/C Output will close.

(See page 3 for LED Indication.)

The HE safety switch and actuator have an 7mm switching

distance and can approach each other from most angles.

When the switch is closed the targets on the printed face of

the switch must be aligned.

To avoid physical damage, do not use the switch and actuator as a stop, leave a 1-2 mm gap for best operation and

tolerance to machine guard vibration.

Applications

Interlocked guards where additional security required.

Door locking is not required.

Harsh environments where vibration, water or dust are

problems.

Food and Beverage packing/lling systems

Dairy Pharmaceutical Paper Industry

Can Forming and Filling, (Aluminium, Steel, Plastic)

Semi conductor Manufacture/Assembly.

CAT 4

SIL 3 PLe

APPROVALS

CE Complies with all relevant sections of the

CE marking directive

TUV CAT 4 SIL 3 PLe

EUROPEAN DIRECTIVES

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/EC

EUROPEAN STANDARDS

EN ISO

13849-1

EN ISO

62061

EN 60204 Safety of Machinery

EN

60947-5-1

EN 1088 Interlocking devices associated with

EN

60947-5-3

Declaration of Conformity

See back page for declaration of conformity.

Safety of Machinery

Safety related parts of control systems

Safety of Machinery - Functional safety

of safety related electrical, electronic and

programmable electronic control systems

Electrical equipment for machines

Low voltage switch gear and control gear

guards

Safety of Machinery

Specication for low voltage switchgear

and control gear

NORSTAT INC. 300 Roundhill Dr. Rockaway, NJ 07866 Tel: 973-586-2500 Fax: 973-586-1590 www.norstat.com

SAFETY CONTROL UNIT

1

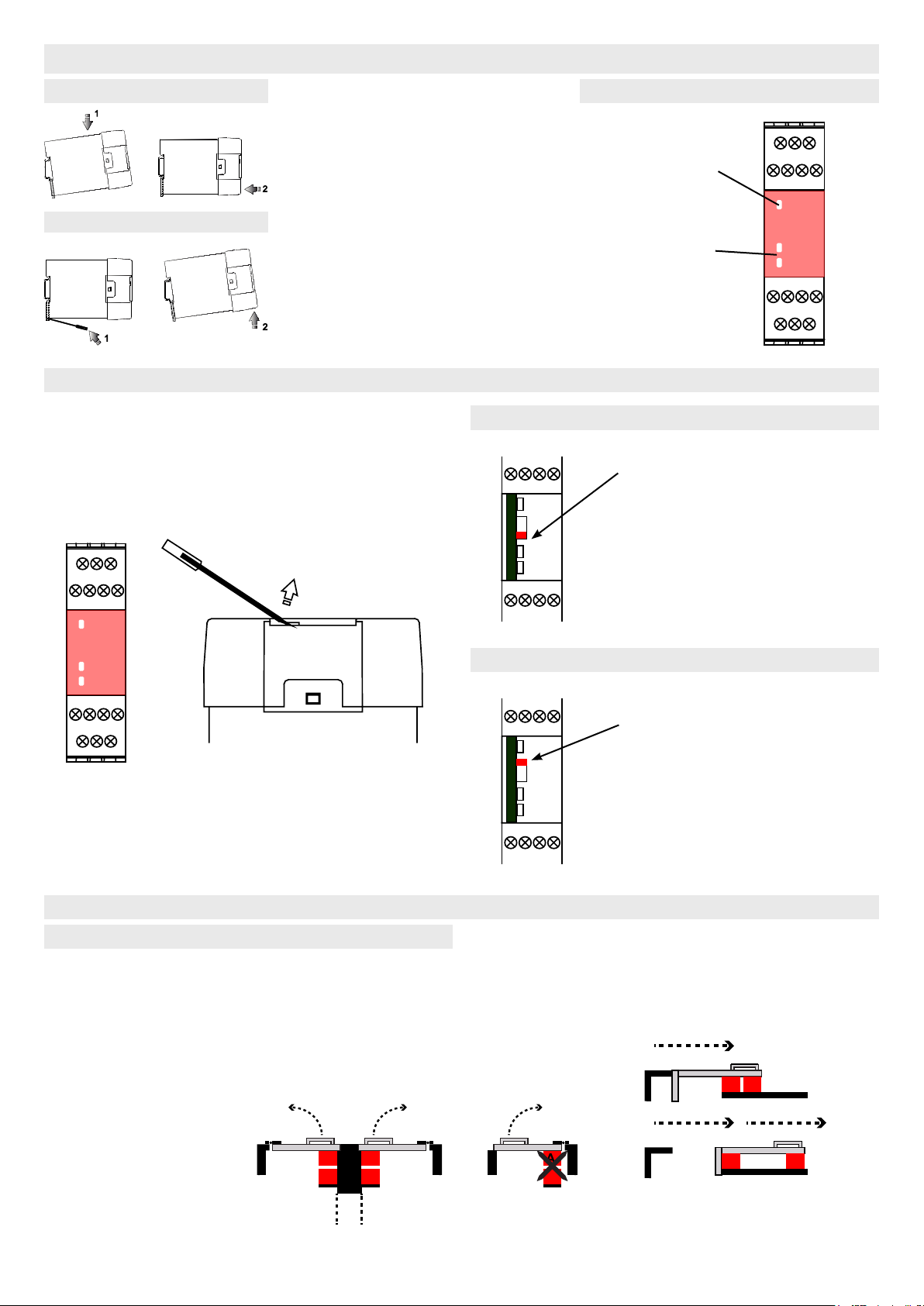

Mounting on 35mm DIN Rail

The control modules are designed to be mounted in an IP55

(minimum) control cabinet.

The modules clip on to standard

35 mm symmetric DIN-Rail

2

Removal from 35mm DIN Rail

To remove the modules, gently

lever out the DIN clip with a

small screwdriver as shown (1).

Tilt the unit in the direction (2)

and slip the unit off the DIN Rail

1

2

CONTROL UNIT RESET

To remove lid, use small screwdriver in the lid recess as

shown and prise gently upwards.

Indication

POWER

When power is

connected, the red

LED will be

illuminated

OUTPUT

When K1 & K2 are

illuminated green,

the outputs 13/14

& 23/24 will be

closed and 31/32

will open.

Manual Reset

Internal switch is set to the

LOWER position

Circuit X1/X2 requires a

momentary N/O button to

initialise reset.

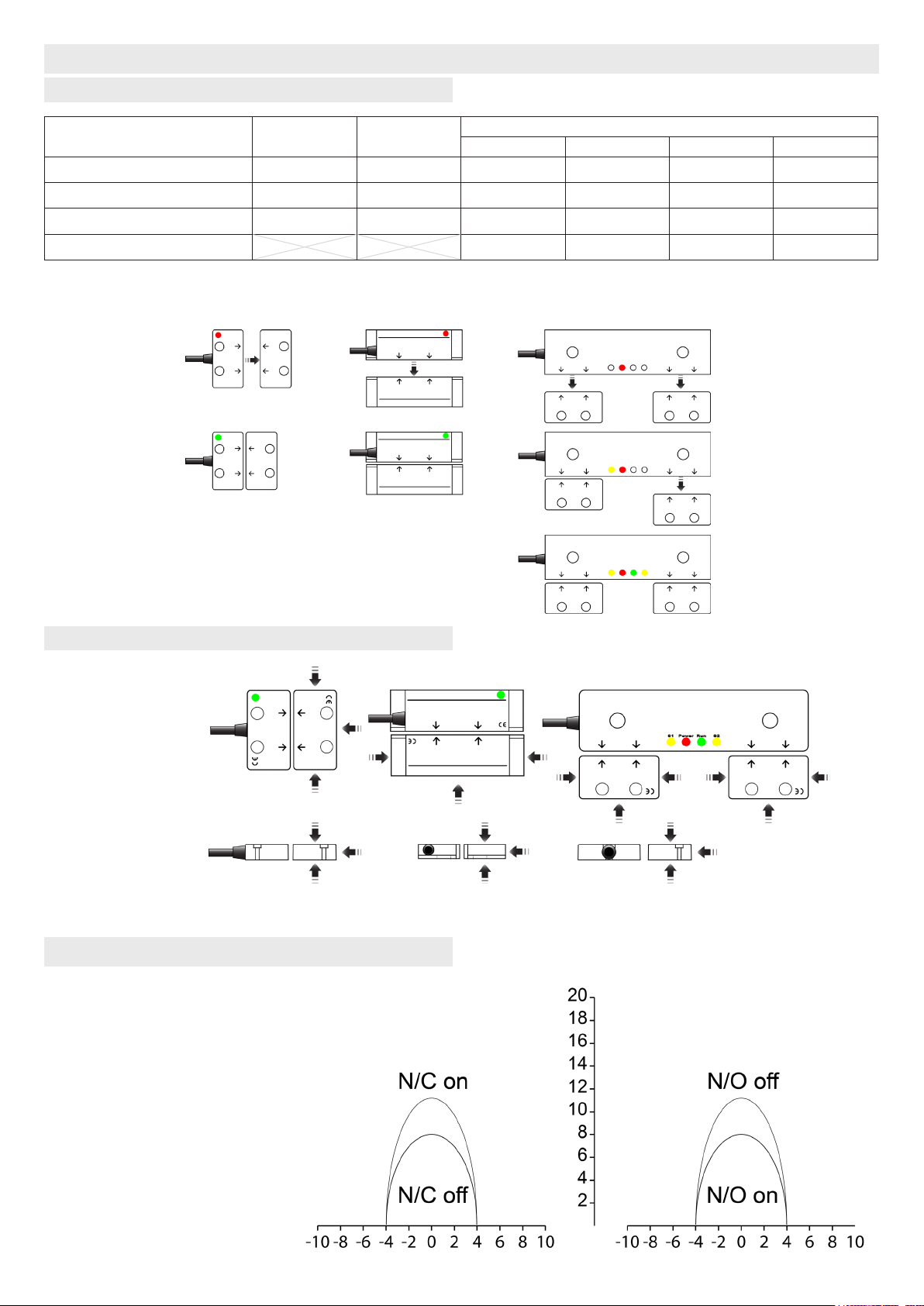

SAFETY SWITCHES

Mounting the Safety Switches

Do not use

safety switches

as a stop.

1 mm separation

when closed

provides the best

results.

Minimum separation 50mm

between adjacent switches.

Automatic Reset

DO NOT mount

on hinged side of

the guard.

Internal switch is set to the

UPPER position

Circuit X1/X2 requires a link.

NOTE: Closed contacts on

K3 & K4 can still be monitored

EN1088 :

Hide the actuator where

possible.

ASSS

A

A

NORSTAT INC. 300 Roundhill Dr. Rockaway, NJ 07866 Tel: 973-586-2500 Fax: 973-586-1590 www.norstat.com

Minimum Gap

50

mm

A

S

AS

SAFETY SWITCHES

Indication

HE1 HE2

HED

GS1 Power Run GS2

Power Off Off Off Off Off Off Off

Power On Gate(s) Open Red Red Off Red Off Off

Power On Gate Closed Green Green Yellow Red Off Off

Power On Gate 1 and 2 Closed Yellow Red Green Yellow

HE1 HE1-SS, HE2 & HE2-SS HED

Operation

The HE Safety

switches are extremely versatile

and can approach

each other from any

angle without false

tripping.

When the guard is

closed the targets

on the printed face

of the switch and

actuator must be

aligned.

Switching Characteristics

The chart shows the

switching points in

millimetres.

NORSTAT INC. 300 Roundhill Dr. Rockaway, NJ 07866 Tel: 973-586-2500 Fax: 973-586-1590 www.norstat.com

Loading...

Loading...