Page 1

ttttttttttttttttttttttttttttttttttttttttt

Modular DR5

Installer Guide

Page 2

Networking with

The Big Picture

Bits and pieces

Loop start trunks

Configuration requirements

E&M trunks

DID trunks

Benefits

Security

Unified dialing plan

Call handling with target lines

Customer Use

In the public network

In the private network

In the system

1

1

4

5

5

6

8

10

13

15

17

18

22

25

Installation

Module installation

Recommended layout

System hardware configuration

Mounting a module

installing the Feature Cartridge

Installing an Expansion Cartridge

Installing a Trunk Cartridge

Upgrading the Software Cartridge

Wiring

Cable routing in the cable trough

Connecting internal wiring

Connecting external lines

Connecting DS-30 cables

Emergency telephones

Connecting emergency telephones

Testing the emergency telephones

Installing

Wall-mounting a telephone

telephones

Telephones

29

31

34

36

38

41

42

44

46

48

48

49

50

52

53

53

54

55

55

56

Modular DR5 Installer Guide

Page 3

ii

Contents

Applying the button cap labels

default button assignments

Optional equipment

‘Auxiliary Ringer

External music source

Installing an external paging system

Power Bar installation

Power up the system

Telephone relocation and replacement

Automatic Telephone Relocation

Telephone replacement

Regulations

Specifications and wiring charts

Port numbering

Port number coding on the wiring charts

system numbering plan

KSU wiring charts

Station Module wiring chart

Loop Start or Cl Trunk Cartridge wiring chart

E&M or

Using the wiring chart

DID Trunk Cartridge wiring chart

Using the DID wiring chart

Trunk Cartridge wiring chart

58

59

63

63

64

65

66

67

68

68

69

71

75

79

79

79

82

85

86

87

87

91

91

Modular DR5 Installer Guide

Programming

Startup defaults

Configuration defaults 97

General administration defaults

Configuration overview

How programming is done

Reviewing programmed settings

Programming tools

Entering Configuration

Exiting Configuration

Configuration headings

95

97

102

108

108

108

110

111

111

112

Page 4

Contents

iii

Using the Overlay

The

Programming details

Data

Trunk lines and Target lines

Trunks

Target lines

Remote system access

Copying Trunk and Line data

Trunk data

Line data

Line Access

Call Handling

Miscellaneous

System Data

Set copy

Applying Set copy

Maintenance

Beginning a Maintenance session

System Version

Status

Examining Status

Module Status

Examining Module Status

Diagnostics

Running Diagnostics

System Test Log

Examining the System Test Log

System Administration Log

Examining the System Administration Log

Alarm codes

If you see an alarm code

Event messages

Dealing with event messages

Significant event messages

Complete list of event numbers

Maintenance records

Recording information

display buttons

114

115

116

117

117

118

121

122

124

125

131

134

139

143

151

155

157

159

160

161

163

164

170

176

177

180

180

183

183

185

185

190

190

190

193

195

195

Modular Installer Guide

Page 5

iv Contents

Version number record

System Test Log

System Administration Log record

Troubleshooting

Getting ready

Other troubleshooting tools

Types of problems

General troubleshooting procedure

Installation check

Testing the system

Checking the hardware

Problems with equipment

equipment trouble

Symptoms at the alarm telephone

Problems with lines

Auto-answer line rings at a telephone

Prime telephone gets misdialed calls

Selected line shows Not in service

Selected line pool shows No free lines

Problems with features

Problem descriptions

Network telephone trouble for remote users

Calling directly to

Calling through

Using remote features

Calling through to another system

Problems with optional equipment

Analog Terminal Adapter

Auxiliary ringer

Call Identification Interface

External paging

196

197

198

199

199

199

200

201

202

202

204

207

207

211

213

216

216

217

218

219

219

222

222

226

229

230

234

234

235

236

237

Glossary

Modular DR5 Installer Guide

239

Page 6

can now be part of a corporate telecommunications

network. You can connect

or to other

This chapter explains:

how components behave in a network,

how they benefit your business, and

how you can configure to achieve those benefits.

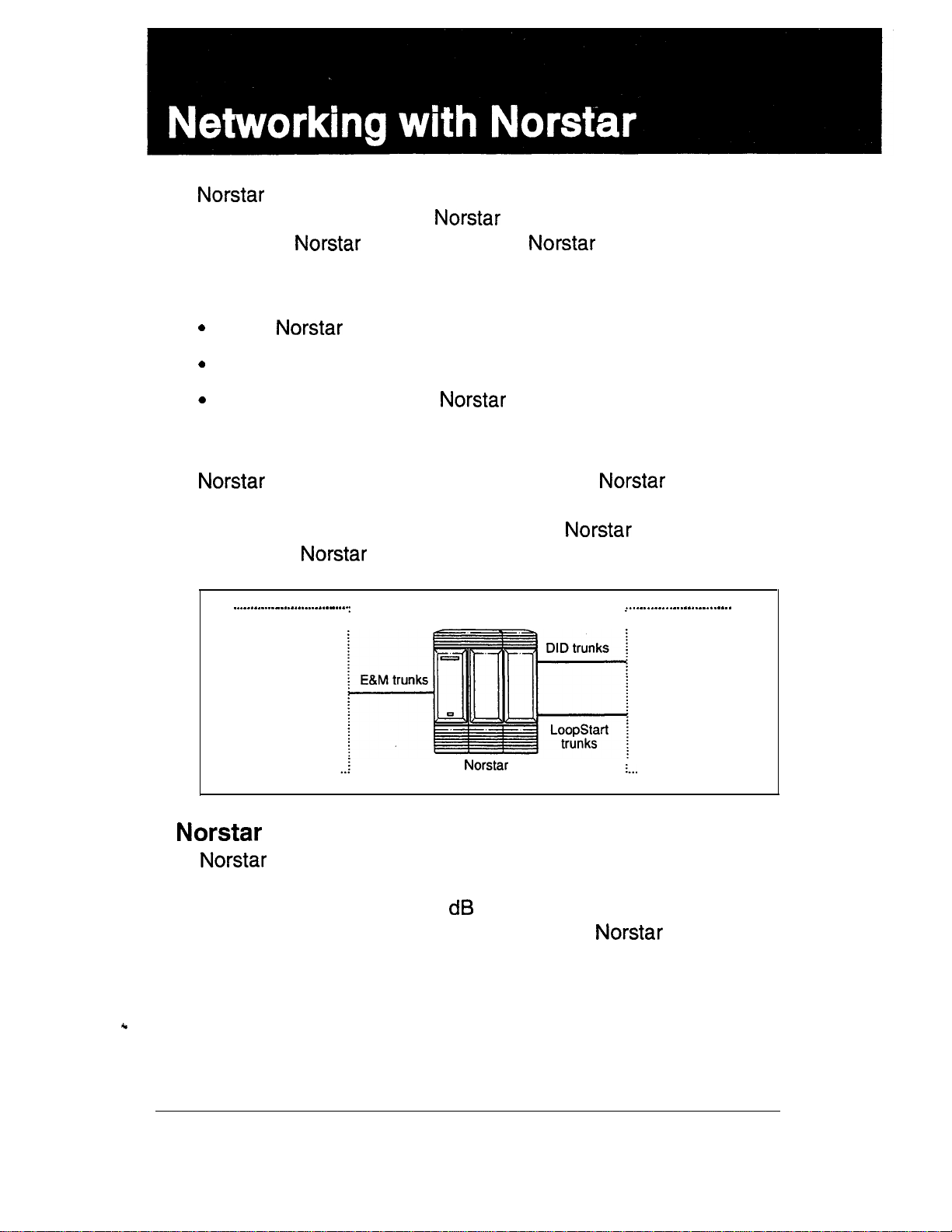

The Big Picture

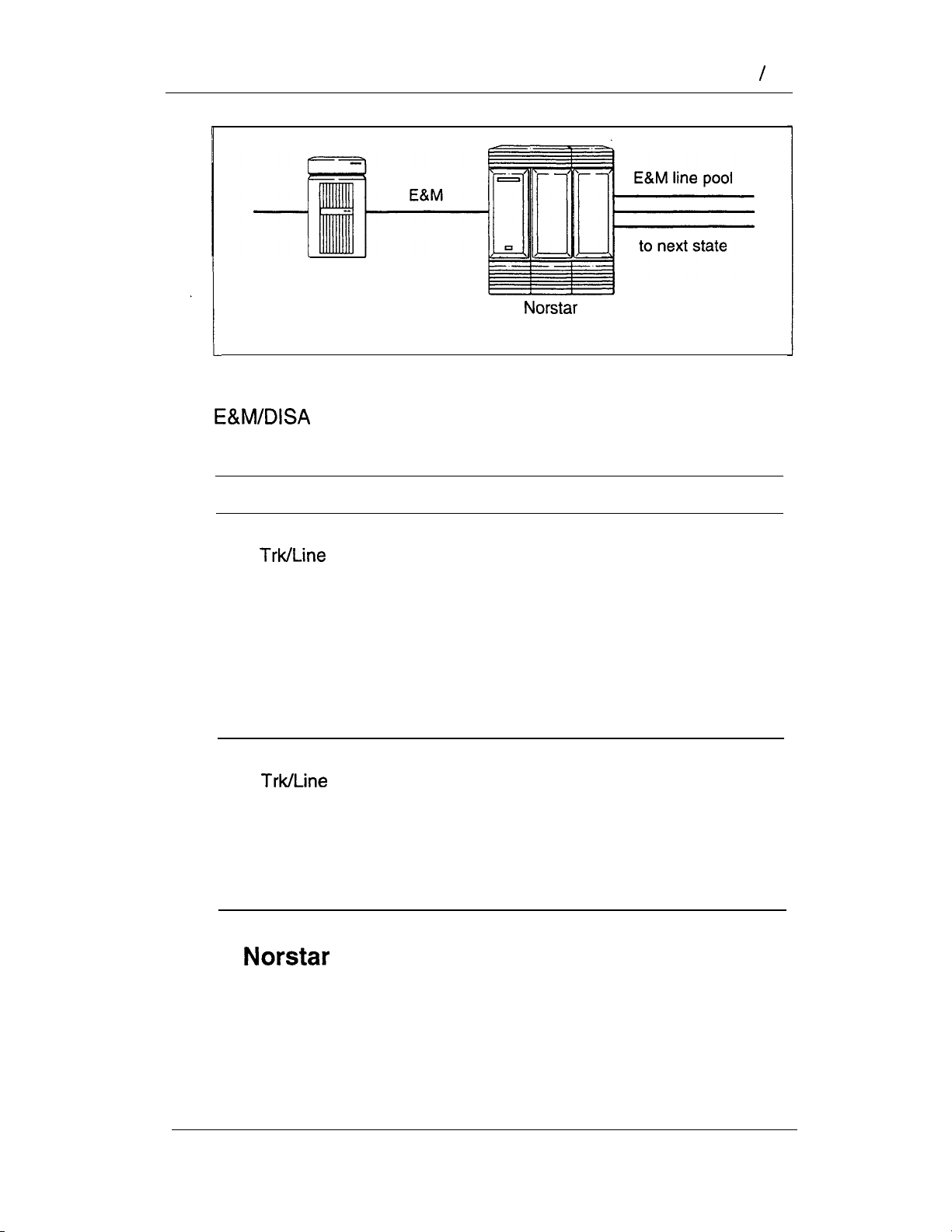

uses enhanced trunking to join other or customer

equipment in a private network. Authorized users can also

access tie-lines, Central Office lines, and

outside the

to an existing private network,

systems to form a network.

features from

system.

. . . Private network

Public network

as an OPX

can be used as an off premise extention (OPX) from a

PBX. In order to support this application, the OPX lines must be

engineered not to exceed 7

central office to the demarcation point at the

total loop loss from the serving

KSU.

Modular DR5 Installer Guide

Page 7

2 Networking with

Bits and pieces

The trunks and lines that uses make network access

possible. Target lines concentrate incoming calls on fewer trunks,

and three types of trunks provide the network access:

l

E&M trunks handle incoming and outgoing traffic between

the

DID trunks route incoming calls from the public network

directly to telephones within

l

loop start trunks handle incoming and outgoing calls between

and the public network.

Benefits

Security

provides the security that expanded access demands.

You can:

system and the private network.

without an attendant.

control remote access to tie-lines, Office lines, and

system features by setting up a specific Class of Service for

each type of caller,

l

restrict outgoing calls to certain telephone numbers or area

codes by applying dialing filters to lines and telephones, and

screen remote callers by configuring trunks to answer with

DISA, a system response that requires callers to enter a valid

password.

Unified dialing plan

When you link a number of systems into a network, you

can configure them so that the length of Directory Numbers

the line pools, and the line pool access codes are

consistent from one system to the next.

Call handling capabilities

In the system, the concentrated environment supports

call handling features on up to 184 lines, of which 80 are physical

trunks and 104 are target (virtual) lines.

Modular

Installer Guide

Page 8

Customer use

Callers in the public network can:

call directly to one or more telephones,

call into the system and select outgoing tie-lines to

access the private network,

call into the system and select outgoing Central

Office lines to access the public network, and

.

call into the system and use remote features.

Callers in the private network can:

call directly to one or more telephones,

l

call into the system and select outgoing tie-lines to

access other nodes in the private network,

call into the system and select outgoing Central

Office lines to access the public network, and

Networking with Not-star 3

call into the system and use remote features.

Callers in the

system can:

call directly to a specific telephone,

select outgoing tie-lines to access the private network,

select outgoing tie-lines to access features that are available

on the private network,

select outgoing Central Office lines to access the public

network, and

use all of the features.

Modular

Installer Guide

Page 9

4 Bits and Pieces

Bits and pieces

To understand the capabilities that are described later in this

chapter, you need to know how the trunks and lines behave in

the

system.

A trunk is a physical connection between the

the outside world. A line is a flexible communication path

between a

one-to-many relationship between trunks and lines.

What this means is that one trunk does not have to represent

one line, but can represent several lines. You achieve this in two

ways:

1. Auto-answer trunks

lines, you configure it as Auto-answer. The

answers calls and maps incoming digits onto numbers that

you define in programming. The numbers can access the

system, so that callers can then use selected features or call

out to another destination (calling through the system). The

numbers can also access target lines that appear on one or

more

2. Target lines

number of different target lines. These are virtual lines that

can appear on a

are incoming lines only, and cannot be selected for outgoing

calls. They are identified to the system by their number. Any

line with a number from 081 to 184 is a target line.

user and the outside world. This allows a

If you want one trunk to serve many

telephones.

incoming calls on one trunk can map onto a

telephone like any other line. They

system and

system

Of course, you can still have a one-to-one relationship between a

trunk and a line. In this case, you configure the trunk as

manual-answer.

You can read more on target lines in the Programming chapter.

To learn more about the types of trunks and the important

differences between auto-answer and manual-answer trunks,

read on.

Modular DR5 Installer Guide

Page 10

Loop start trunks

Loop start trunks give you incoming and outgoing access to the

public network. However, you would typically configure your

system with loop start trunks for outgoing calls and DID trunks for

incoming calls. Loop start trunks can be configured as

manual-answer or auto-answer.

When a call comes in on a manual-answer loop start trunk, it

alerts at all telephones with that line appearance.

When a call comes in on an auto-answer loop start trunk, you

hear a stuttered dial tone if the trunk is configured to answer with

DISA. Then you must use a DTMF telephone to enter a

Class of Service password.

When a call comes in on an auto-answer loop start trunk, you

hear the system dial tone if the trunk does not have DISA, or if

the Class of Service password is valid. Use a DTMF telephone to

enter a target line number, the DN, a line pool access

code, or a remote feature code.

Bits and Pieces 5

To place an outgoing call, select a loop start line by dialing a line

pool access code, pressing a line button on the telephone, or

pressing a memory button that has been programmed with a line

pool access, code.

Configuration ‘requirements

You need one Loop Start Trunk Cartridge or Cl Trunk Cartridge

for every four trunks beyond the eight that come with the Key

Service Unit. If you wish to configure your loop start lines as

auto-answer, the lines must have disconnect supervision. You

will also need one

start lines that you configure as auto-answer. An auto-answer

loop start trunk can give you the same kind of direct inward

dialing function as a DID trunk, but you will require

Trunk Cartridges to receive the incoming digits from the Central

Office.

Trunk Cartridge for every two loop

Modular DR5 installer Guide

Page 11

6 Bits and Pieces

You may configure a loop start line as the Prime line for a

telephone.

E&M trunks

An E&M trunk gives incoming and outgoing tie-line access from

other systems in the private network to the

trunks can be configured as manual-answer or auto-answer.

system. E&M

cartridges

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When a call comes in on a manual-answer E&M trunk, it alerts at

all telephones with that line appearance.

Modular

Installer Guide

Page 12

Bits and Pieces 7

When a call comes in on an auto-answer E&M trunk, you hear a

stuttered dial tone if the trunk is configured to answer with DISA.

Then you must use a DTMF telephone to enter a 6-digit Class of

Service password.

When a call that comes in on an auto-answer E&M Trunk, you

hear the system dial tone if the trunk does not have DISA, or if

the password is valid. Use a DTMF telephone to enter a target

line number, the DN (the number that will call for a Class of

Service password), a line pool access code, or a remote feature

code.

When a call comes in on an auto-answer E&M trunk from an

intelligent network, the system answers the call and

interprets the incoming digits:

l

If the digits map onto a target line, routes the call to

all

devices with an appearance of that line.

If the digits map onto the DN, you hear a stuttered dial

tone, and must use a DTMF telephone to enter a valid Class

of Service password to get the system dial tone.

If the digits map onto the Auto DN (the number for direct

system access), you hear the system dial tone, and can use

a DTMF telephone to enter a target line number, the

DN, a line pool access code, or a remote feature code.

To place an outgoing call, select an E&M trunk by dialing a line

pool access code, pressing a line button on the telephone, or

pressing a memory button that has been programmed with a line

pool access code.

Configuration requirements

In your configuration, one Trunk Cartridge is required

for every two E&M trunks. One

also required for every two DTMF receivers required for on

loop start trunks.

Trunk Cartridge is

You may configure an E&M trunk as the Prime line for a

telephone.

Modular DR5 Installer Guide

Page 13

8 and Pieces

DID trunks

DID trunks give you direct inward dialing (DID) from the public

network to the system. A typical application of these

trunks is to map incoming digits onto target line appearances

within the

auto-answer trunks.

system. DID trunks can operate only as

Target lines

084

I--

r

Central office

Modular DR5 Installer Guide

Page 14

Bits and Pieces 9

When a call comes in on a DID trunk, interprets the

incoming digits:

If the digits map onto a target line, routes the call to

all devices with an appearance of that line.

l

If the digits map onto the DN, you hear a stuttered dial

tone, after which you must use a DTMF telephone to enter a

valid Class of Service password to get the system dial tone.

If the digits map onto the Auto DN, or if the Class of Service

password is valid, you hear the system dial tone. Then you

can use a DTMF telephone to enter a target line number, a

line pool access code, or a remote feature code.

Configuration requirements

You need one DID trunk cartridge for every four DID trunks. Each

DID Trunk Cartridge has four DID trunks and four DTMF

receivers dedicated to those trunks.

You cannot configure a DID trunk as the Prime line for a

telephone.

Modular DR5 installer Guide

Page 15

10

Benefits

Benefits

Security

In the Capabilities section of Administration programming, there

are several ways of protecting your

unauthorized access.

Class of Service

Class of Service refers to the capabilities that provides to

users who access the system from the public or private network.

The Class of Service includes:

l

filters that restrict dialing on the line, and

an access package, which defines the set of line pools that

may be accessed and whether or not the user has access to

the paging feature.

system from

The Class of Service that is applied to an incoming

remote-access call is determined by:

the filters that you apply to the incoming trunk, or by

the Class of Service password that the caller used to gain

access to the

In cases where is not applied to incoming calls, the remote

caller can change the Class of Service by dialing the

and entering a Class of Service password.

To program Class of Service passwords, see Administration in

the Programming chapter.

system.

DN

Dialing filters

You can use dialing filters to restrict the numbers that may be

dialed on any external line within your

specify up to 100 dialing filters for the system. A dialing filter

consists of up to 48 restrictions and their associated exceptions.

system. You may

Modular

Installer Guide

Page 16

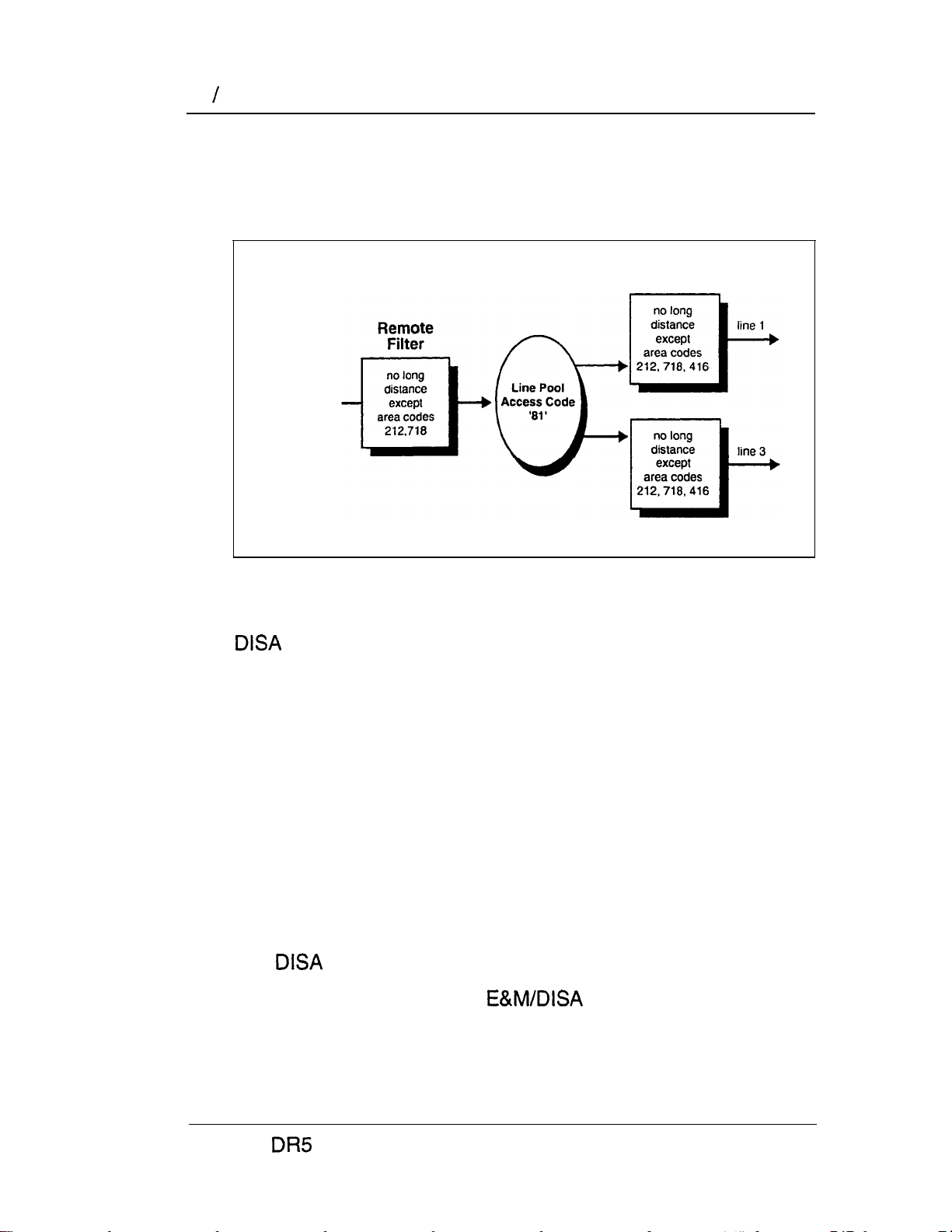

Benefits

11

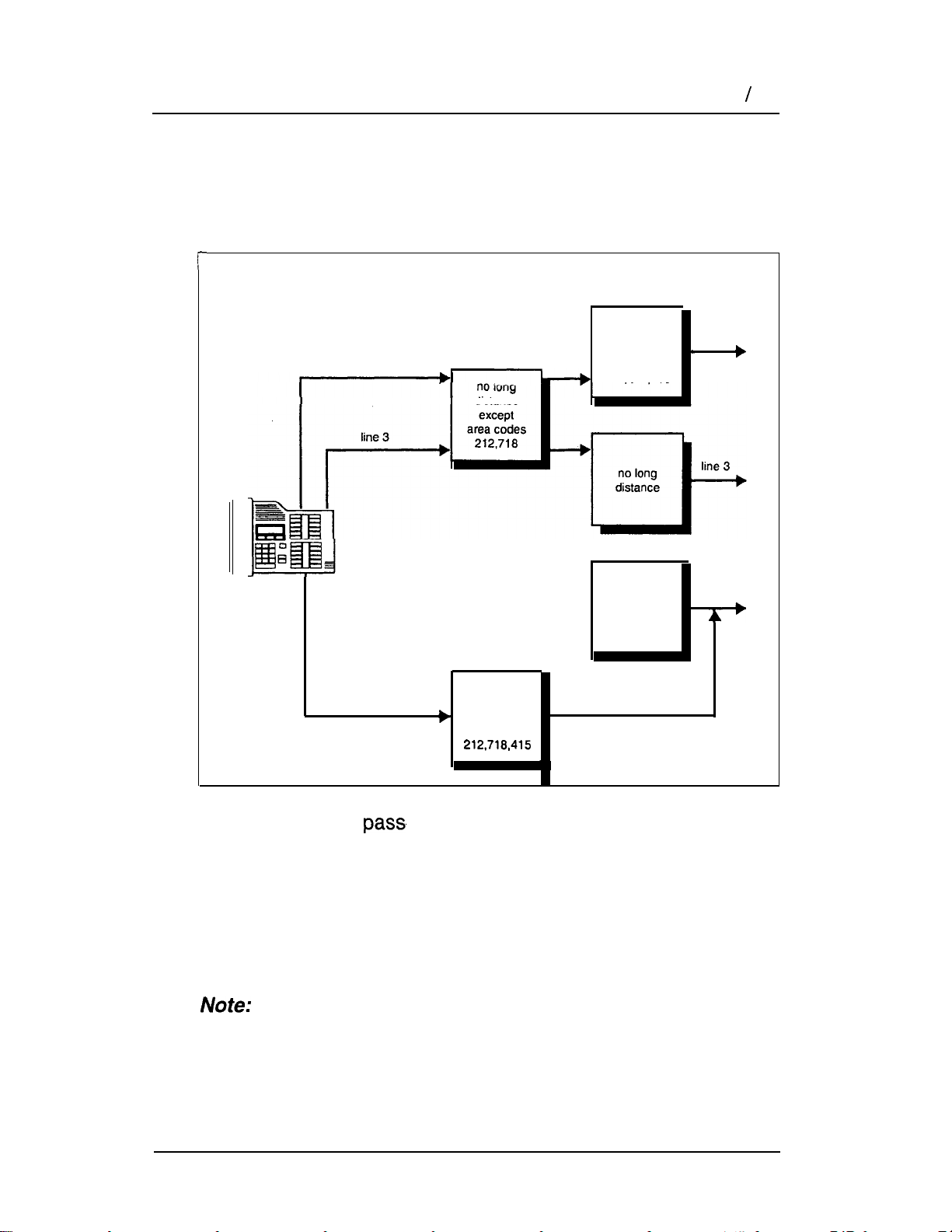

Dialing within the system

To restrict dialing within the system, you can apply dialing filters

to outgoing external lines (as line filters), to telephones (as set

filters), and to external lines on specific telephones (as line per

set filters).

Line

Filter

no long

line 1

Set

Filter

distance

distance

except area

codes 212.

718.214.713

line 1

1

no long

distance

line 5

Line per Set

Filter

no long

line 5

distance

except

area codes

Dialed digits must both the line filter and the set filter. The

line per set filter overrides the line filter and set filter.

In this diagram, a caller using line 1 could only dial long-distance

numbers to area codes 212 and 718. A caller using line 3 could

not dial any long-distance numbers. A caller using line 5 could

dial long-distance numbers to area codes 212, 718, and 415.

Set filters have no effect on the numbers that are dialed

on an E&M trunk.

Modular DR5 Installer Guide

Page 17

12 Benefits

Dialing outside the system

To restrict dialing outside the system (once a caller gains remote

access), you can apply dialing filters to incoming external lines

(as remote filters).

Remote

caller

Line

Filter

In this case, dialed digits must pass both the remote filter and the

line filter. A remote caller can override these filters by dialing the

DN and entering a Class of Service password.

For programming instructions, see the Programming chapter of

this Installer Guide.

Direct inward system access (DISA)

To control access from the public or private network, you can

configure auto-answer trunks to answer with DISA. Remote

callers hear a stuttered dial tone and must then enter a Class of

Service password that determines what they are allowed to do in

the system.

Auto-answer loop start and E&M trunks are configured to answer

with

Note;’

by default.

You must have one Trunk Cartridge for every

two auto-answer loop start trunks.

Modular

Installer Guide

Page 18

Benefits 13

DID trunks cannot be configured to answer with DISA. If you

want incoming DID calls to be answered with DISA, configure the

system with a

DN are then routed to a line that has DISA.

For programming instructions, see the Programming chapter of

this Installer Guide.

DN. incoming DID calls that map onto the

Unified dialing plan

The system does not support a coordinated dialing plan

for other systems in the network. However, if you are configuring

more than one Nor-star system in your network, you can make

access between the systems much easier with a unified dialing

plan.

Directory Numbers

Make sure that the length of your is the same for all the

systems.

Line pools

If the systems are close to each other geographically,

you can conserve resources by not duplicating access. For

example, system A has a line pool to New York, System B has a

line pool to Los Angeles, and system C has a line pool to Dallas.

A

Dallas.

user in system A calls system C to get the line pool to

Line pool access codes

To simplify access between systems, all line pools that

go to the same destination should have the same line pool

access code. For example, system A and system B both have a

line pool to London. You can configure both systems with the

same line pool access code for the Nashville line pool.

Modular Installer Guide

Page 19

14 Benefits

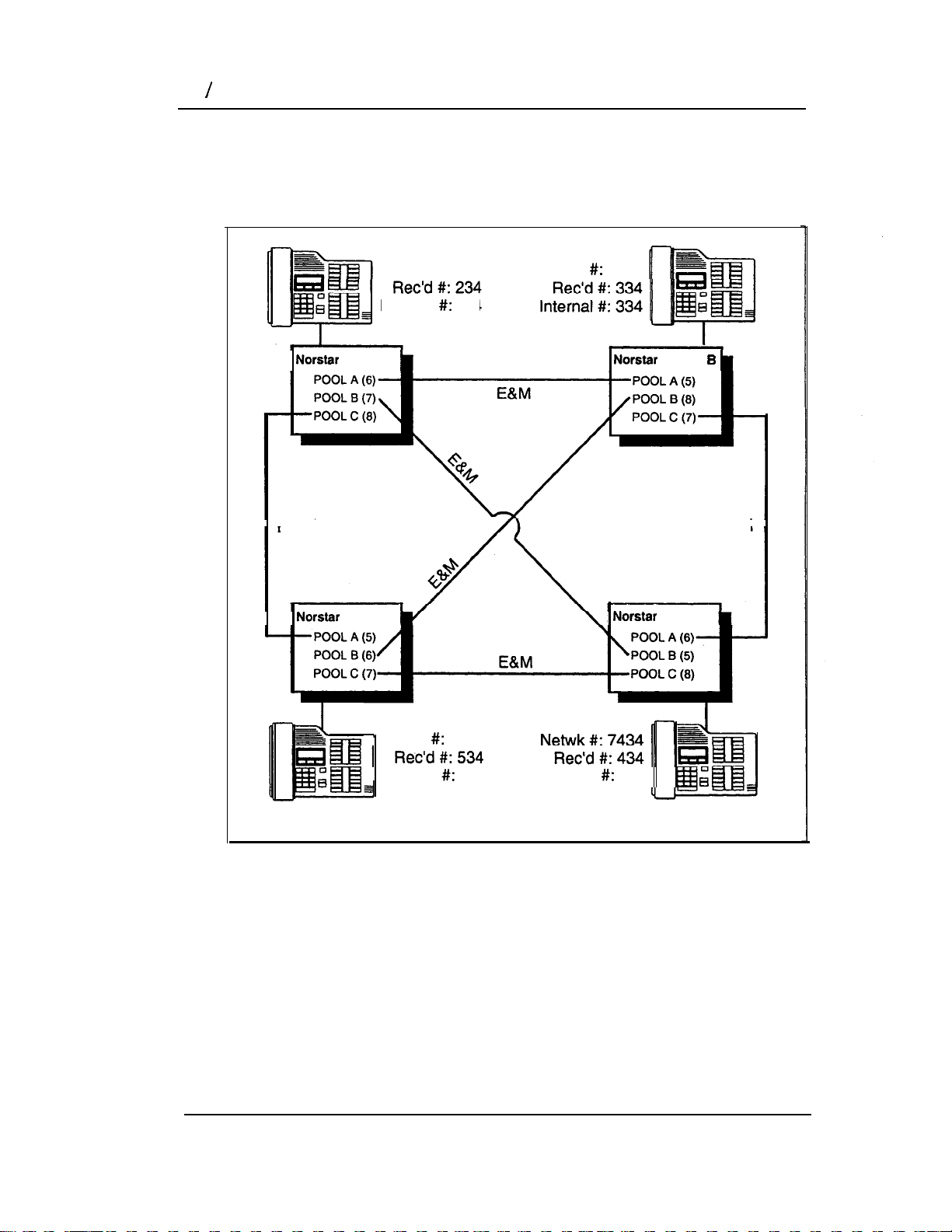

Unified dialing plan among four systems

A dialing plan similar to the one in the following figure will let you

create a company directory that includes the line pool access

codes.

E&M

Netwk #: 5234

Internal 234

System A

System D

Netwk

6334

System

E&M

System C

Netwk 8534

Internal

534

Internal

434

For instance, the person on System A at telephone 234 can

select an Intercom button and dial 7434.

This means that telephone 234 has dialed the line pool access

code of the trunk to System C, and will receive the dial tone of

System C. The digits 434 then map to the Received number 434,

and ring telephone 434 with an appearance of the associated

target line.

Modular DR5 Installer Guide

Page 20

Call handling with target lines

Having target lines with the system means that call

coverage is extended. All call handling features that apply to

regular lines also apply to target lines.

Here are some brief descriptions of features that apply to any line

appearance on a telephone. For complete information on

these features, see the Telephone features chapter of this

‘Installer Guide.

Auxiliary Ringing

If the system has an auxiliary ringer (a bell that is not part

of a telephone), the target line can be administered so that the

auxiliary ringer alerts in addition to the telephone ringer.

Callback

When an external call on a target line is transferred to a busy

telephone or not answered after a specified number of rings, the

call automatically rings at the Prime telephone for that line. The

display shows that the telephone was busy or that the call was

not answered.

Benefits 15

Camp on

Even when a telephone is busy, a call on a target line can be

routed to the telephone, where it waits in a queue until the

telephone is not busy.

Delayed Ring Transfer

Target line calls that go unanswered after a specified number of

rings can be routed to the Prime telephone if programmed to do

so in Configuration.

Held Line Reminder

When a target line call is placed on hold, the telephone gives two

reminder tones at periodic intervals until the call is taken off hold.

This happens only if Held reminder is activated during

Configuration programming.

Modular Installer Guide

Page 21

16 Benefits

Overflow Call Routing

If a call comes in for a target line that is busy, routes the

call to the Prime telephone for that target line. If you don’t assign

a Prime telephone for the target line or if a call cannot be

mapped onto a target line, the call will go to the Prime telephone

for the incoming trunk.

Prime Telephone Call Capture features

See the Prime Telephone User Card for details.

Privacy

When a user is on an external call and the Privacy

feature is turned on, no other

target line can join in on the call. If Privacy is turned off, another

person with the same line can press the line button to join your

conversation, forming a conference.

telephone with the same

Service Modes

When there are fewer people available to answer calls during

lunch hours, nights, or weekends, you can administer the system

so that target line calls ring at certain telephones.

Modular DR5 Installer Guide

Page 22

Customer Use 17

Customer Use

This section shows sample configurations for different types of

network access. Each example has four parts:

A scenario explains the caller’s goal and what is required to

achieve it.

A diagram shows the network configuration that supports the

l

application.

.

A list shows the

configuration.

Tables show the Configuration and Administration

l

programming required. Only those settings that are important

to network access are described here.

hardware required to support the

Modular Installer Guide

Page 23

18

Customer Use

In the public network

Call one or more telephones

Ms. Nelson is a bank customer who has a question for an

accountant. She dials the telephone number that maps onto

target line 083. All of the accountants’ telephones ring.

Ms. Nelson

Target line

083

Accountant

Accountant

(telephone 226)

Central office

Hardware:

any version of KSU, one Trunk Module, one DID

Trunk Cartridge.

Heading

1. Data

5. System Data

Parameter

Rec’d #

Line 009

Rec’d # length 4 (can be up to 7

Setting

4321 (for Line 083)

DID

digits, but must match

number of digits sent

by Central Office)

Modular Installer Guide

Page 24

Customer Use

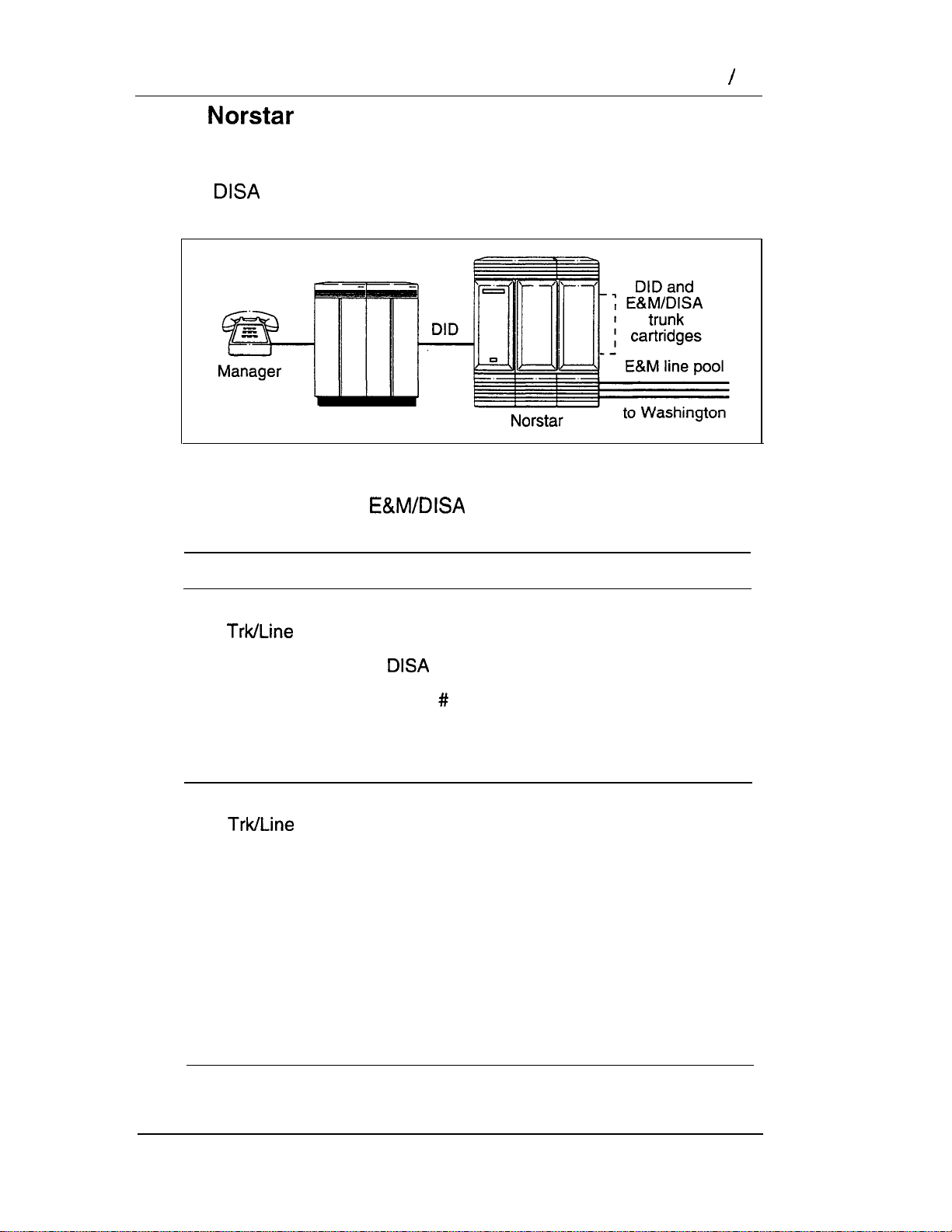

Call and select tie lines to a private network

A manager in Georgia wants to use the tie lines at headquarters

to call Washington. He dials a telephone number that maps onto

the

dials a line pool access code to select a tie line to Washington.

DN, enters a Class of Service (COS) password, then

Central office

19

Hardware:

any version of KSU, one Trunk Module, one DID

Trunk Cartridge, two Trunk Cartridges (for the three

trunks in the line pool to Washington).

Heading

Incoming trunk:

1.

4. Miscellaneous

5. System Data

Outgoing trunk:

1.

4. Miscellaneous

5. Capabilities

Data

Data

Parameter

Line 009

DN

Rec’d

Line 013

Line type

Line pool F

length

Setting

DID

5321

4 (can be up to 7

digits, but must match

number of digits sent

by Central Office)

E&M

Pool F

6 (up to 4 digits)

Define filters: Define

remote access pkgs.

Assign a dialing filter

to the line. Assign

COS passwords and

filters for each class

of service.

Modular DR5 Installer Guide

Page 25

20 Customer Use

Call and select lines to the public network

Gord wants to make a long-distance business call from home. To

avoid being charged, he dials the telephone number that maps

onto the Auto DN at work. After hearing the dial tone, Gord dials

a line pool access code to select a line to the public network. He

then dials the long-distance number.

r

Gord

at home

Business

client

Central office

Hardware:

any version of KSU, one Trunk Module, one DID

Trunk Cartridge.

DID

Line

Central office

Modular Installer Guide

Page 26

Customer Use 21

Heading

Incoming trunk:

1.

4. Miscellaneous

5. System Data

5. Capabilities

Outgoing trunk:

1.

Data

Data

Parameter Setting

Line 009

Auto DN

Rec’d # length

Line 001

Line type

DID

4321

4 (can be up to 7

digits, but must match

number of digits sent

by Central Office)

Define dialing filters.

Define remote access

packages. Assign a

remote filter and

remote package to

the line.

Loop

Pool A

4. Miscellaneous

5. Capabilities

Line pool A

1234

Assign a dialing filter

to the line.

Modular DR5 Installer Guide

Page 27

22 Customer Use

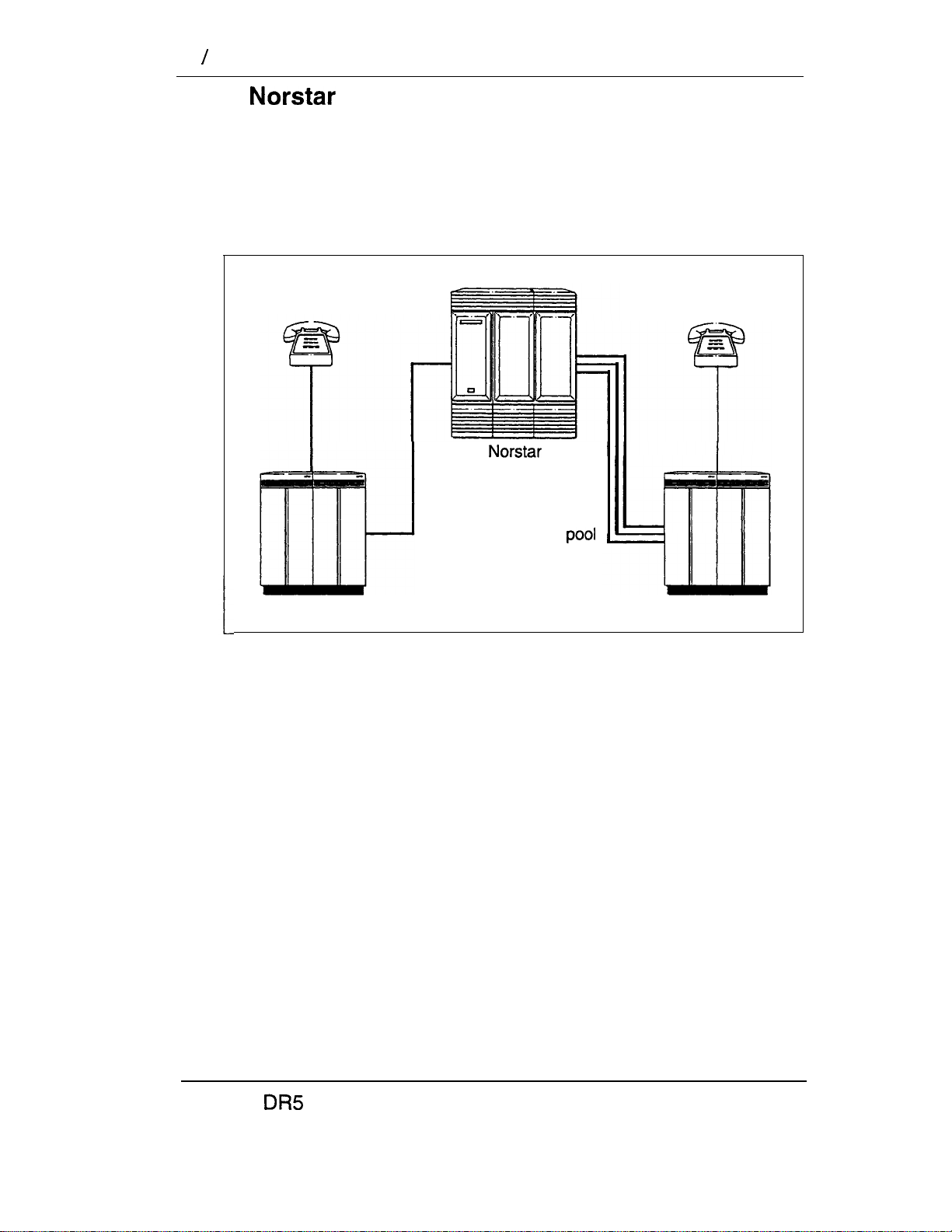

In the private network

Call one or more telephones

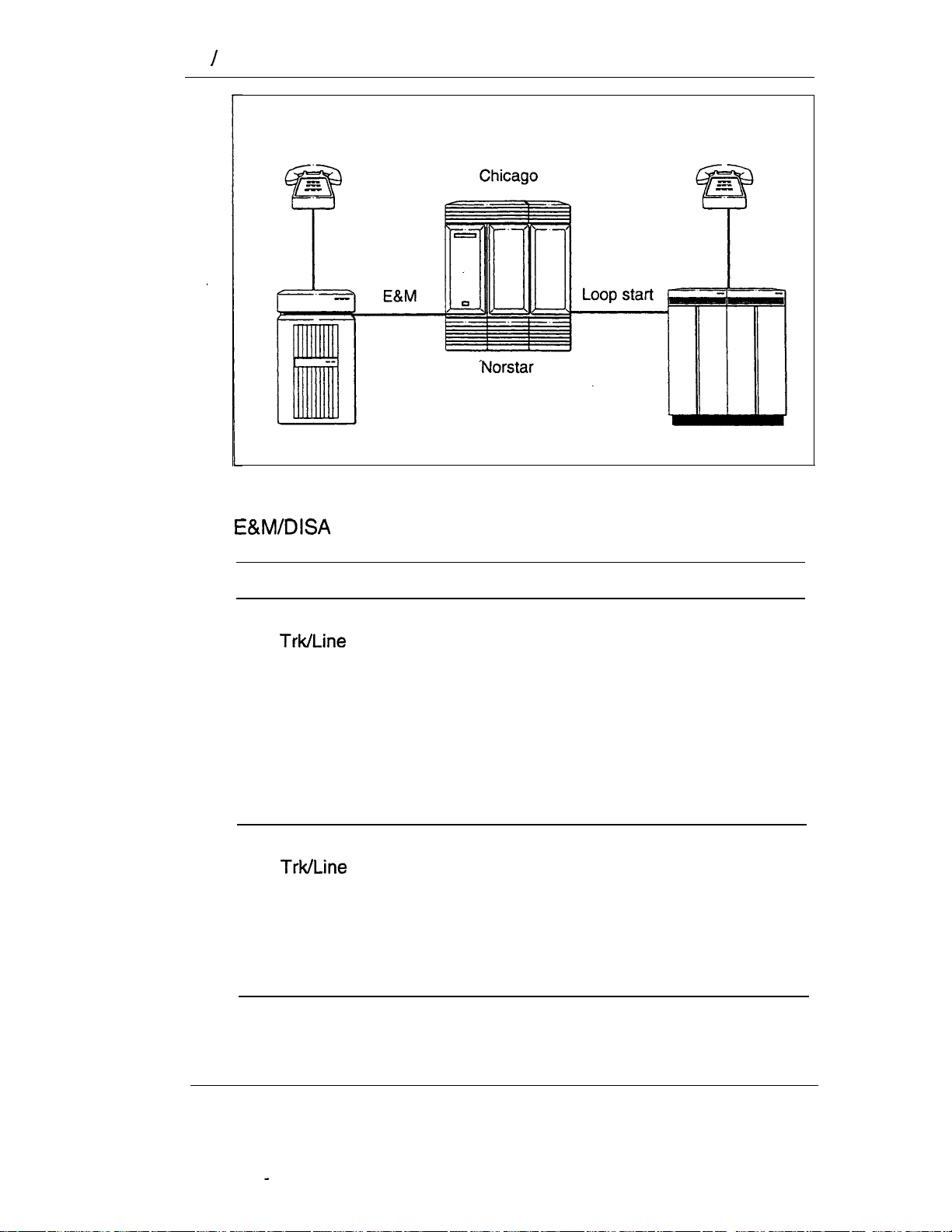

The production supervisor in Houston selects the less-expensive

company tie line to call the manager at the Administration office

in Dallas. Once the line is selected, the production supervisor

dials the digits that will map onto the target line of the manager in

Dallas.

target line

083

PBX in

Houston

Hardware

E&M

: any version of KSU, one Trunk Module, one

Trunk Cartridge.

Heading Parameter Setting

incoming trunk:

1. Data

5. System Data

Rec’d #

Line 009

Ans Mode

Rec’d # length 4 (can be up to 7

4321

083)

E&M

Auto

digits, but must match

number of digits sent

by Central Off ice)

Manager

in Dallas

(for target line

Call and select tie lines to other nodes in the

private network

At a branch office, Joan selects a tie line to the government office

downtown. After hearing the dial tone, she dials a line pool

access code to select another tie line to a government office in

the next town.

Modular Installer Guide

Page 28

Key system

Customer Use 23

Hardware:

any version of KSU, one Trunk Module, two

Trunk Cartridges (for the three lines in the line pool

and the one incoming line)

Heading

Incoming trunk:

1.

5. Capabilities

Outgoing trunk:

1.

4. Miscellaneous

Data

Data

Parameter

Line 009

Ans mode

Line 010

Line type

Line pool D

Setting

E&M

Auto

Define dialing filters.

Define remote access

packages. Assign a

remote line filter and

remote package to

the trunk.

E&M

Pool D

71 (up to 4 digits)

5. Capabilities

Assign a dialing filter

to the trunk.

Call and select lines to the public network

Liz needs to call long-distance to a client in Toronto. She selects

a tie-line to the branch office in Toronto. After hearing the dial

tone, she dials a line pool access code to select a line to the

public network. Then, she dials the client’s number as a local call.

Modular DR5 Installer Guide

.

Page 29

24 Customer Use

Liz in

Memphis

Key system

Hardware:

Client in

Toronto

Central office

any version of KSU, one Trunk Module, one

Trunk Cartridge.

Heading

Incoming trunk:

1.

5. Capabilities

Outgoing trunk:

1.

4. Miscellaneous

5. Capabilities

Data

Data

Parameter Setting

Line 009

Ans mode

Line 001

Line type

Line pool B

E&M

Auto

Define dialing filters.

Define remote access

packages. Assign a

remote filter and

remote package to

the trunk.

Loop

Pool B

73 (up to 4 digits)

Assign a dialing filter

to the line.

Modular DR5 Installer Guide

Page 30

Customer Use 25

In the system

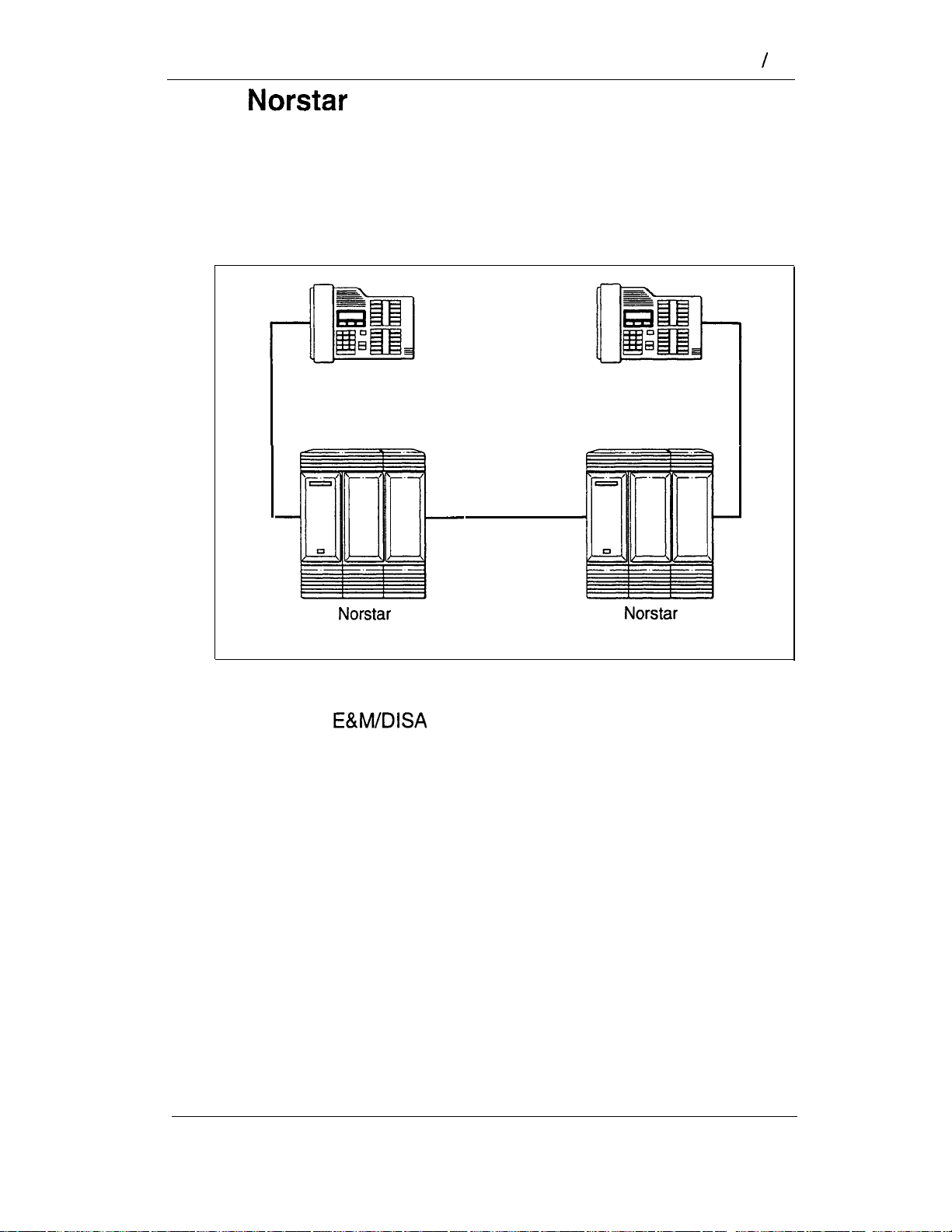

Select tie trunks to the private network

. For a confidential call, the Montana sales manager presses the

line button for a private E&M trunk to the Oregon office. This

automatically alerts at the line appearance on the telephone of

the Oregon sales manager.

Montana

Sales Manager

E&M

Hardware:

(for both systems) any version of KSU, one Trunk

Module, one Trunk Cartridge

Oregon

Sales Manager

Modular DR5 Installer Guide

Page 31

26 Customer Use

Heading

Outgoing trunk

(Montana):

Trunk Data

(Line 009)

Line Data

(Line 009)

Incoming trunk

(Oregon):

Trunk Data

(Line 009)

Parameter Setting

Line

Line type Private

Line

Ans mode

Line type

E&M

E&M

Manual

Private

Modular installer Guide

Page 32

A System Feature

Line Redirection feature

I””

target line

092

Branch office

I

I

Customer Use 27

line 3

,

incoming call

redirected

call

The branch office is receiving more calls than it can handle, so it

redirects one of its lines to the main office. All calls that come in

on target line 092 will be routed out on line 003 to the

office.

Whenever a call is redirected, the target line and outgoing line

will be busy for the duration of the call.

Hardware

: Version 2 or higher KSU, an Trunk

Cartridge if the incoming trunk is E&M, or a DID Trunk Cartridge

if the incoming trunk is DID.

Note:

Any line appearance on a telephone can be

selected as the incoming line to be redirected. A

target line can not be selected as the outgoing

line for redirection.

The incoming trunk must have disconnect

supervision.

Modular DR5 Installer Guide

Page 33

28 Customer Use

Program heading

Incoming trunk:

1.

5. System Data

Outgoing trunk:

1. Data

Data Line001

Trunk mode:Super

Ans mode:Auto

OR

Line 009:DID

OR

Line

Ans mode:Auto

Rec’d 1

(for target line 092)

Rec’d # length:4 (can be up to 7

digits, but must match number

of digits sent by Central Office)

Line 003: Loop

OR

Line01

Branch office set:

5. Capabilities

Allow redirect:\/

Modular DR5 Installer Guide

.

Page 34

Check the location where the system modules, the

telephones, and auxiliary equipment are to be installed. This

includes making sure sufficient space is available to install the

components.

Location requirements

Clean, dry, and well-ventilated

Temperature: to 50°C (32°F to 122°F)

Humidity: 5% to non-condensing

Location: at least 4 m (13.1 ft) from equipment such as

photocopiers, electrical motors, and other equipment that can

produce electromagnetic, radio frequency, and electrostatic

interference.

Electrical requirements

Non-switched outlet

ac outlet located not more than 1.5 m (4.9 ft) from the Key

Service Unit (KSU). The actual distance from the KSU to the

Power Bar may vary with additional Trunk and Station

Modules. Do not use an extension cord between the KSU

and the power bar.

For the 110 V system

Dedicated 110-V ac nominal, 15-A minimum

service with third wire ground.

the 220 V system

Dedicated to 240-V ac nominal,

10-A minimum service with third wire ground.

WARNING

The ac outlet must be equipped with a third wire ground

to avoid electromagnetic interference.

Modular Guide

Page 35

30 installation

Internal wiring requirements

All new or existing wiring for telephones must meet the

following specifications:

one twisted pair per telephone

a dc loop resistance less than 59

cable length (0.5 mm or 24 AWG) not to exceed 305 m

(1000 ft)

use of a Station Auxiliary Power Supply (SAPS) to

extend the loop up to 790 m if the cable is longer than 305 m

(1000 ft)

no bridge taps

Installers should also check the lightning protectors at

the cable entry point to the building with special attention

to the grounding. Any problems should be reported to

the telephone company in writing.

wiring should not leave the buildings as it is not

lightning-protected.

WARNING

telephone

Mounting requirements

If a smooth surface is not available, cut a backboard large

enough to accommodate the system modules and the distribution

block. The system module physical dimensions are listed in this

chapter.

Equipment ‘for mounting the modules

screwdriver, diagonal cutters, pliers, connecting tool, pencil,

level (optional)

four 1 long wood screws for the KSU and four for

each of the expansion modules

(1 %-in) long screws for the cable troughs

thick wooden backboard (if necessary)

Modular DR5 Installer Guide

Page 36

Module installation 31

Module installation

Key System Unit (KSU)

The Key Service Unit (KSU) is the hub of the Not-star System. It

can function on its own as a basic system (with up to 24

telephones and eight external lines). The system may also be

expanded with any combination of up to six Trunk Modules

and/or Station Modules.

LED

CO Lines connector

Feature cartridge (2 parts)

Cable clips

Stations connector

Expansion cartridge

cartridge shown)

Half-size

Cable trough

Modular DR5 Installer Guide

Page 37

32 Module installation

Trunk Module (TM)

The Trunk Module allows additional Trunk Cartridge installation.

This in turn allows more external lines to be connected to the

system. The Trunk Module has three slots in front for

inserting Trunk Cartridges. Each Trunk Module can add a

maximum of 12 external lines (four external lines per Trunk

Cartridge). Different types of Trunk Cartridges can be mixed in

one Trunk Module. When mixing Trunk Cartridges, use a

separate distribution block for each type of Trunk Cartridge.

Slot for Trunk cartridge

(face plate removed)

Protective faceplates

covering unused slots

LED

DS-30 port

Cable clip

connector

Trunk cartridge

Half-size

Cable trough

Modular Installer Guide

Page 38

Module installation 33

Station Module (SM)

The Station Module allows up to 16 additional telephones

to be connected to the system. A DS-30 cable connects each

Station Module to the KSU.

LED

DS-30 port

Cable clips

50-pin connector

Cable clips

Quarter-size

Cable trough

Modular DR5 Installer Guide

Page 39

34 Module installation

Recommended layout

The Key Service Unit (KSU), Trunk Modules (TM), and Station

Modules (SM) can be mounted in any order. Allow suitable wall

space for installing future Trunk and Station Modules.

S

r

dimensions

If possible, leave

enough room for

future expansion

TM SM

mm (15.5 in.)+

698 mm

Widths

L

Additional dimensions of KSU, TM SM

Dimension

KSU

TM

SM

Clearance

(front)

Modular DR5 Installer Guide

171

(6.7

346

(13.6

7.5

Kg

(16.6

mm

in)

mm

in)

lb)

4.3

Kg

(9.5 lb)

2.4

(5.3

Kg

lb)

Page 40

Module installation 35

Remember

Leave about 15 centimetres (6 inches) of space above the screw

holes of the mounting bracket. This allows room to slide the KSU,

Trunk Module and Station Module on and off the bracket and

provides space for venting the heat from the modules.

Bottom

Ensure there is at least 10 centimetres (4 inches) of space

between the bottom of the cable trough and the floor, or any

object that may block the flow of air from the bottom for cooling.

CAUTION

All modules must be mounted well above the floor to

prevent water damage.

Sides

Mount the distribution block on the left side of the KSU. Leave

enough room to mount additional Trunk Modules and Station

Modules on the right side.

Front

Leave enough room to allow the doors of the modules to open

and the cabling to run on the side.

Between modules

The space between two modules hung on the mounting brackets

is approximately

Note:

Refer to the illustration showing the system dimensions

mm in).

for additional module clearance requirements.

CAUTION

Mount the KSU vertically to avoid overheating.

Modular DR5 Installer Guide

Page 41

36 Module installation

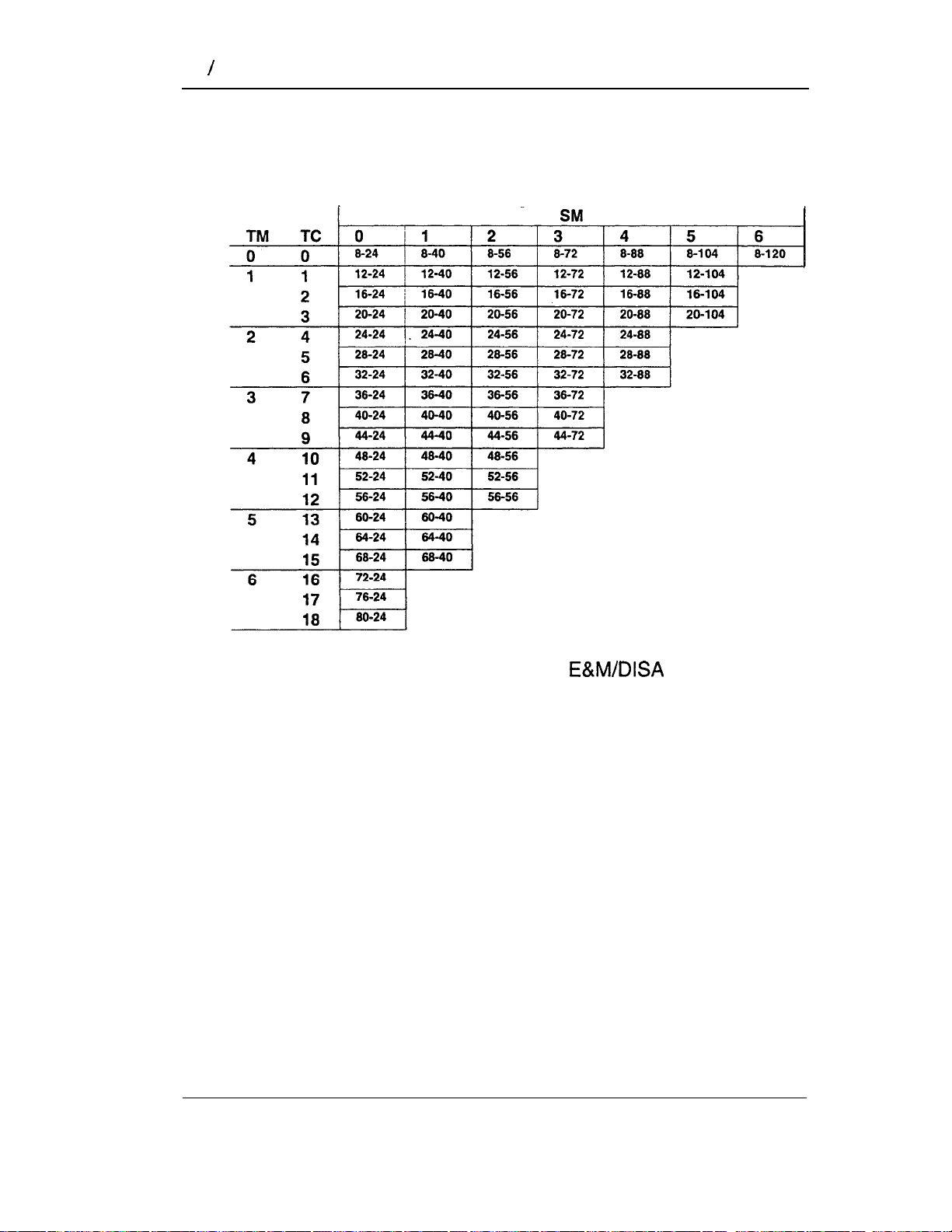

System hardware configuration

This chart shows combinations of Trunk Modules, Trunk

Cartridges, and Station Modules for expanding the system.

Possible line and station configurations

Note:

Number of physical lines shown is for Loop Start, DID,

and Cl Trunk Cartridges only.

Cartridges provide half the number of lines.

Trunk

Modular DR5 Installer Guide

Page 42

Module installation 37

How to read the hardware chart

To find the maximum number of lines and telephones for a

particular configuration of KSU, Trunk Module(s), and Station

Module(s):

1.

Find the number of Trunk Modules in the left column. The

column labeled “TC” gives the number of Trunk Cartridges.

2.

Find the number of Station Modules in the top row.

3.

Read across to the right from the Trunk Module column and

down from the Station Module row.

A pair of numbers indicates lines and telephones for that

combination of Trunk Modules and Station Modules. The left

number is the maximum number of external lines. The right

number is the maximum number of telephones.

Examples:

8-24

12-24 =

12-40 =

=

8 lines and 24 telephones (KSU without Trunk

Modules or Station Modules).

12 lines and 24 telephones (KSU lines and

telephones, plus one Trunk Module and one Trunk

Cartridge with 4 more lines, and no Station

Modules).

12 lines and 40 telephones (KSU lines and

telephones, plus one Trunk Module and one Trunk

Cartridge with 4 more lines, and one Station Module

with 16 more telephones).

Modular DR5 Installer Guide

Page 43

38 Module installation

Mounting a module

1.

Position metal mounting bracket(s) on the wall or on the

backboard. Fasten the brackets with

in) screws.

Hint:

2.

Slide the KSU, Trunk Module, or Station Module down onto

the mounting brackets. Line up with the notches on either

side of the mounting bracket as you slide the module onto

the mounting bracket(s). This facilitates accurate hanging.

3.

Slide the cable trough(s) up under the appropriate module(s).

The KSU requires two half-size cable troughs. A Trunk

Module uses one half-size cable trough, while an Station

Module uses a quarter-size cable trough.

Open each cable trough door and let the door swing open.

5.

Fasten the cable trough to the wall with long screws.

Each cable trough requires two screws through the holes

provided in the lower tray of the cable trough.

6.

Close the doors of the cable troughs.

Before positioning the mounting brackets, draw a line

using a level and a pencil. This will help align the

modules.

7.

Do

not

connect power at this point.

Installing the KSU mounting bracket

Modular Installer Guide

Page 44

Module installation 39

Installing the cable troughs

Modular DR5 Installer Guide

Page 45

40 Module installation

Trunk Module. and Station Module installed

Key Service Unit (KSU)

Feature

Expansion

cartridge

shown)

Note:

Station

Module

Cable trough

(l/2-size)

Cable trough

For clarity, the illustration shows a KSU, a Trunk Module,

and an Station Module without doors. The doors should

not be removed during installation or operation. Also

shown are the Feature, Expansion, and Trunk Cartridges

which are installed later.

Modular DR5 Installer Guide

Page 46

Module installation 41

Installing the Feature Cartridge

The Feature Cartridge is made up of a Software Cartridge and a

Data Cartridge. The Software Cartridge contains the system

programming. The Data Cartridge contains the data from

Configuration and Administration programming.

When there is a software upgrade, only the Software Cartridge,

and not the Data Cartridge, needs to be replaced.

CAUTION

Do not touch the printed circuit board inside the cartridge

casing. This is an electrostatic-sensitive device.

1.

Turn the KSU power OFF before installing or removing a

Feature Cartridge.

Make sure you are wearing a grounding strap when handling

cartridges.

3.

Insert the Software Cartridge into the Data Cartridge.

4.

Insert the Feature Cartridge assembly into the KSU.

Unassembled and

assembled Feature

Cartridges

Installing the Feature

Cartridge

Modular Installer Guide

Page 47

42 Module installation

Installing an Expansion Cartridge

The two-port Expansion Cartridge allows up to two additional

modules (Trunk Modules and/or Station Modules) to be

connected to the system. The six-port Expansion Cartridge

allows the connection of up to six additional Trunk or Station

Modules. This Cartridge fits into the right slot of the Key Service

Unit (KSU).

Two-port Expansion

cartridge

Six-port Expansion

cartridge

Modular Installer Guide

Page 48

Module installation 43

The procedures for installing the Two-port and Six-port

Expansion Cartridges are identical. (Refer to the Port Numbering

information in this Guide for changes to default internal number

length caused by installing an Expansion Cartridge.)

CAUTION

Do not touch the printed circuit board on the Expansion

,

1.

2.

Cartridge. This is an electrostatic-sensitive device.

Make sure that the KSU power is OFF before installing or

removing an Expansion Cartridge.

Remove the cover of the

Expansion Cartridge slot

in the KSU. Use a

screwdriver at the bottom

of the cartridge slot cover

to help detach the

cartridge slot cover from

the slot.

3.

Make sure you are wearing a grounding strap when handling

any cartridge.

4.

While holding the latches

open, insert the Expansion

Cartridge in the

appropriate slot and close

the latches at the same

time to align the cartridge

properly.

Modular Installer Guide

Page 49

44 Module installation

Installing a Trunk Cartridge

The Trunk Cartridge, when inserted in a Trunk Module, adds up

to four external lines to the

Trunk Cartridges can be installed in each Trunk Module.

There are four types of Trunk Cartridges:

the Loop Start Trunk Cartridge (4 lines)

the Trunk Cartridge (2 lines)

the DID Trunk Cartridge (4 lines)

l

the Cl Trunk Cartridge (4 lines)

The Loop Start Trunk Cartridge supports regular external lines.

The

network. The DID Trunk Cartridge supports direct inward dialing

on incoming external lines. The Cl Trunk Cartridge supports Call

Display features on external lines.

Trunk Cartridge connects to a private

system. A maximum of three

Trunk Cartridges

Loop Start

DID

Cl

Different Trunk Cartridges can be installed in one Trunk Module if

required for a particular installation. When mixing Trunk

Cartridges, use a separate distribution block for each type of

Trunk Cartridge.

Modular DR5 Installer Guide

Page 50

Module installation 45

The procedures for installing the different Trunk Cartridges are

identical. See the wiring charts in this Guide for details.

CAUTION

I

Do not touch the printed circuit board on the Trunk

Cartridge. This is an electrostatic-sensitive device.

1.

Make sure that the Trunk Module power is OFF before

installing or removing a Trunk Cartridge.

2. Remove the appropriate

cartridge slot cover of an

unused Trunk Cartridge slot

on the Trunk Module. Use a

screwdriver at the bottom of

the cartridge slot cover to

detach the cover from a

Trunk Cartridge slot.

The numbers on the cartridge slots indicate the order

that the cartridges should be installed. If an

or a DID Trunk Cartridge is installed in

slot 1, Emergency telephones cannot be supported.

3.

Make sure you are wearing a grounding strap when handling

cartridges.

4.

While holding the latches open,

insert the Trunk Cartridge in the

appropriate slot and close the

latches at the same time to

align the cartridge properly.

Modular DR5 Installer Guide

Page 51

46 Module installation

Upgrading the Software Cartridge

Before installing a Modular DR5 Cl Trunk Cartridge or Call

Identification Interface (CII), the KSU system Software Cartridge

must be upgraded to DR5.

There are two possible situations where a software upgrade is

necessary:

1.

upgrading from a DR2 Software Cartridge, or

2.

upgrading from either a DR3 or a DR4 Software Cartridge.

Upgrading from DR2

If you are upgrading from a DR2 Software Cartridge, you must

first upgrade to DR3 software.

When a DR3 Feature Cartridge is plugged into a DR2 KSU, an

automatic upgrade takes place. In order to allow remote

programming of the NVRAM and prevent the automatic upgrade,

the following should be done:

Insert the Cartridge into the Data Cartridge prior to

installing in the system.

Place the new DR3 Feature Cartridge assembly into a

2.

captive KSU with the appropriate Two-port or Six-port

Expansion Cartridge, and power up the system.

Perform the Administration programming appropriate for the

3.

customer’s site. This will maintain their DR2 programming.

Change the Time and Date (either the hour or minutes, or

4.

both). This sets a lock on the NVRAM data so that it cannot

be updated.

Power down the captive KSU, remove the DR3 Feature

5.

Cartridge and take it to the customer site. To return a DR3

Feature Cartridge to the state where an automatic upgrade

will occur, perform ** Startup on it while it is in the captive

KSU.

Modular DR5 Installer Guide

Page 52

Module installation 47

Continue with the following procedure to install the DR3 Feature

Cartridge assembly in the customer’s KSU.

1.

Make sure that the KSU power is OFF before installing or

removing the DR3 Feature Cartridge assembly.

2.

Make sure you are wearing a grounding strap when handling

a cartridge.

3.

Insert the DR3 Feature Cartridge assembly into the KSU.

Once you have completed the upgrade to DR3 you can continue

with the next procedure to upgrade from DR3 to DR5 software.

Upgrading from DR3 or DR4

1.

Ensure that there is no call activity by informing all

users that the system will briefly be out of operation.

Turn OFF the KSU power (unplug the power cord).

2.

While wearing a grounding strap, remove the Feature

3.

Cartridge from the KSU.

4.

Remove the Software Cartridge from the Data Cartridge.

Insert the new Software Cartridge into the Data Cartridge.

5.

Insert the new Feature Cartridge into the KSU.

6.

Turn ON the KSU power (plug in the power cord)-.

7.

Modular DR5 Installer Guide

Page 53

48 Wiring

Wiring

Cable routing in the cable trough

Cable troughs beneath the Trunk Module, and Station

Module hold the 25-pair cables, the DS-30 cables, the power

cord(s), and the Power Bar (if required).

The cable troughs have been designed to keep the ac power

cords and Power Bar separate from the connecting cables and to

allow ease of access. Place the cabling in the two shelves, as

described in the following chart and pages.

Upper shelf

Lower shelf

All cables and DS-30 cables:

Place

Place the DS-30 cables in the front.

All power cords and the Power Bar(s).

cables in the back.

WARNING

To avoid electrical shock, hazard to personnel, or

equipment.damage, observe the following precautions

when installing telephone equipment:

l

Never install telephone wiring during a lightning storm.

l

Never install telephone jacks in wet locations unless

the jack is specifically designed for wet locations.

l

Never touch non-insulated telephone wires or terminals

unless the telephone line has been disconnected at the

network interface.

Modular DR5 Installer Guide

Page 54

Connecting internal wiring

To connect the internal telephones, each KSU and Station

Module requires one

female 50-pin connector at one end. Enough 50-pin distribution

blocks are required to accommodate the internal wiring.

1.

Plug the co

into the station connector on the KSU or the

Station Module. (The connector is labeled

with an icon representing a telephone.)

2.

Route the cable(s) through the upper shelf of the cable

troughs to the distribution block.

Note: Route the cables straight out to one side of the cable

trough in a bundle. Use cable ties to secure them to

the wall and to support their weight.

3.

Connect the wires to the appropriate pins on the distribution

block. (Refer to the wiring charts in this Guide.)

nnector of a cable

(24-AWG) cable with a

Wiring 49

4.

Cross-connect the KSU and Station Module telephone wires

to the corresponding station pins on the distribution block.

(Refer to the wiring charts in this Guide.)

5.

Using a single pair of wires for each telephone, connect each

of the telephones according to the wiring charts.

Connecting to the KSU

Connecting to the Station

Module .

Modular DR5 Installer Guide

Page 55

50 Wiring

Connecting external lines

To connect the external lines and auxiliary equipment, each KSU

and Trunk Module requires one

terminated with a female 50-pin connector on one end. A

distribution block is required for each

1.

Plug the connector of a cable into the external

line connector on the KSU or the Trunk Module. (The

connector is labeled with an icon representing telephone

poles.)

2.

Route the cable(s) through the upper shelf of the cable

trough to the

block.

0.5mm (24-AWG) cable

cable.

Note:

3.

Cross-connect the external lines to the distribution block.

(Refer to the KSU and Trunk Module external line wiring

charts and wiring arrangement diagrams in this Guide.)

4.

Connect the auxiliary equipment lines to the distribution

block. (Refer to KSU and Trunk Module external line wiring

charts and wiring arrangement diagrams in this Guide.)

Note: Auxiliary equipment cannot be connected to the

Route the cables straight out to one side of the cable

trough in a bundle. Use cable ties to secure them to

the wall and to support their weight.

RJ-21 interface.

Modular DR5 Installer Guide

Page 56

Wiring 51

5.

Connect external lines to a standard RJ-21 interface:

Bring the external cable to the distribution block and use the

distribution block to cross-connect to the corresponding KSU

and Trunk Module external lines according to the KSU and

Trunk Module external line wiring charts and diagrams. Refer

to the following charts and illustrations in this Guide:

Wiring arrangement for KSU

Wiring arrangement for Trunk Module

KSU external lines and auxiliary equipment wiring

Loop Start/Cl Trunk Cartridge wiring chart

6.

Wire the auxiliary equipment lines separately. (Refer to the

KSU and Trunk Module external line wiring charts and

diagrams.)

Note: For the Trunk Module, the auxiliary equipment line is

an Emergency Telephone (ET).

Connecting the KSU

external lines

Connecting the Trunk

Module external lines

as an OPX

can be used as an off premise extension (OPX) from a

PBX. In order to support this application, the OPX lines must be

engineered not to exceed 7 total loop loss from the serving

central office to the demarcation point at the KSU.

,

Modular DR5 Installer Guide

Page 57

52 Wiring

Connecting DS-30 cables

Plug one end of the DS-30 cable into the DS-30 port on the

front of a Trunk Module or Station Module.

2.

Route the cable through the cable clips on the right side of

the Trunk Module or Station Module.

3.

Route the cable through the upper shelf of the cable trough

to the KSU and up through the cable clip to the Expansion

Cartridge.

4.

TM DS-30 into

the

port and work DOWN.

available

Plugging in a Trunk Module

DS-30 cable

Plug SM DS-30 into

the LOWEST available

port and work UP.

Plugging in a Station

Module DS-30 cable

Modular Installer Guide

Page 58

Emergency telephones 53

Emergency telephones

Emergency telephones (ET) are standard single-line

telephones that provide emergency service in case of power

failure or

The KSU has two emergency telephone connections. Each

Trunk Module has one emergency telephone connection.

Connecting emergency telephones

The procedure is the same for connecting emergency telephones

to the distribution block for a KSU or a Trunk Module.

Wire a modular jack or equivalent to each set of emergency

telephone pins on the distribution block for KSU or

Trunk Module external lines.

power to the system is disconnected.

The connections on the distribution block for emergency

telephones appear in the wiring charts in this Guide.

Note:

Connect a single-line telephone to the modular jack.

2.

The emergency telephone connections will not work

if there is an

the first slot of the Trunk Module.

or DID Trunk Cartridge in

Modular DR5 Installer Guide

.

Page 59

54 Emergency telephones

Testing the emergency telephones

The emergency telephones must be tested with the power OFF

at the KSU and Trunk Module.

Pick up the receiver of the emergency telephone.

2.

Listen for the dial tone.

If you hear a dial tone, both the emergency telephone and

the line are functioning properly.

If you hear no dial tone:

Verify that power to the KSU and Trunk Module(s) is

OFF.

Check that the external line and emergency telephone

connections have been made correctly.

Ensure that the emergency telephone is not faulty, by

connecting it directly to the external line and listening for

dial tone.

Verify that there is dial tone on lines 1 and 2 of the KSU

and on line 1 of the Trunk Module.

3.

If all previous steps have been verified and there is still no

dial tone at the emergency telephone, replace the KSU if the

emergency telephone is connected to the KSU, or replace

the Trunk Module if the emergency telephone is connected to

the Trunk Module.

Modular DR5 Installer Guide

Page 60

telephones

WARNING

telephones cannot be used as off-premise

extensions (OPX). For OPX applications, use the

Analog Terminal Adapter and a single line

telephone. (See the

Installing Telephones

Connect the receiver cord to the telephone modular jack

1.

indicated by the following symbol, then route the cord

through the appropriate cord guide in the base of the

telephone.

installation card for details.)

telephones 55

Connect the line cord to the telephone jack indicated by the

2.

following symbol, then route the cord through the appropriate

cord guide.

Plug the other end of the line cord into the modular jack

3.

wired from the distribution block.

When the telephone is connected to the KSU or Station

4.

Module, the telephone display and indicators flash briefly

while the telephone initializes (when the

powered up). The telephone is fully operational when the

display shows the default time and date.

For example:

Note:

If the telephone line is supported with auxiliary power,

the power source must be a Class 2 device that is UL

and CSA listed.

Jan 1

1:

System is

Modular Installer Guide

Page 61

56 Not-star telephones

Wall-mounting a telephone

telephones can be mounted on the wail.

1.

Remove the beveled wall-mounting base from the back of

the telephone. Grip the telephone, and with your thumbs,

push on the wide edge of the base to pop it out from the

telephone.

2.

Remove the receiver clip from the wall-mounting base. Install

the clip in the forward lip of the receiver rest.

3.

Use a screwdriver or similar tool to remove the center

knock-out panel in the wall-mounting base.

4.

Screw the base to the wall (thin end up) so that the wall jack

projects through the knock-out.

5.

Connect one end of the line cord to the telephone line jack

(indicated by the symbol below).

6.

Route the line cord through the appropriate cord guide in the

bottom of the telephone.

7.

Connect the other end of the line cord to the wall jack. Store

any spare cord neatly in the base of the telephone and

mount the telephone on the base.

Modular

Installer Guide

Page 62

telephones 57

Removing the

wail-mounting base

Removing the knock-out

panel

Installing the receiver clip

Installing the

wall-mounting base

Connecting the line cord

Mounting the telephone

Modular DR5 Installer Guide

Page 63

58 telephones

Applying the button cap labels

Before you apply button labels, activate the Button Inquiry

feature

functions, and to avoid activating features as you put the labels

onto the buttons.

There are two types of button labels: printed and blank. Keep the

extra labels and button caps with each

leave them with the System Coordinator.

Types of button caps

Unlabeled, clear button caps

with appropriate green or grey paper for typing in line

numbers, telephone numbers, and features

Pre-printed, colored button caps

in green or grey

to verify the buttons’ programmed

telephone or

Some example pre-printed button caps

Green caps

To make identification of line types easier, use preprinted

green button caps for lines that support incoming and

outgoing calls. Use clear button caps for target lines that

are incoming only.

Grey caps

Identifying the telephones

1.

Write the individual telephone numbers on the labels and

attach them to the appropriate

2.

Write the telephone number and the internal number on the

appropriate Receiver Card for each type and color of

telephone that is to be installed.

3.

Cover the Receiver Card underneath the receiver of

each telephone with the plastic lens.

telephones.

Modular DR5 Installer Guide

Page 64

telephones 59

default button assignments

During Startup, the Installer chooses one of four default

templates: Square, Hybrid, or PBX. Default features are

assigned automatically to the programmable buttons on

telephones, and vary with the template and the telephone. The

default features are listed in the tables in this chapter.

Note:

button caps‘in place for the Square template.

telephones are shipped from the factory with the

Rules of default button assignment

Line and Intercom buttons are assigned by default templates and

can be changed in Configuration programming. Handsfree/Mute

and Answer buttons are not assigned by default. If these features

are defined, however, they are automatically assigned to specific

buttons, as described on this and the following page. None of

these buttons can be assigned to

Handsfree/Mute

This feature appears on the bottom right-hand button (the bottom

button on the M7208 Telephone), moving the Intercom button(s)

up one position.

Intercom

Each telephone can have up to eight Intercom buttons. They

appear above the button at the bottom

right-hand position on your telephone (the bottom button on the

M7208 Telephone).

Telephones.

Answer

Each telephone can have up to four Answer buttons. They

appear above Intercom buttons in the right column and continue

up from the bottom in the left column, replacing the features on

those buttons. (On the M7208 Telephone, Answer buttons

appear above Intercom buttons and below external line buttons

in a single column.)

Modular Installer Guide

Page 65

60 telephones

External line

External line buttons appear in ascending line order, starting at

the top button in the left column (the top button on the M7208

Telephone). If more than five external lines are assigned to an

M7310

Telephone, or more than 12 to an M7324 Telephone,

assignment continues down the buttons on the right column,

erasing the features on those buttons. Line buttons have priority

over feature access buttons but not Handsfree/Mute, Intercom, or

Answer buttons.

Telephone button defaults

Each column-Square, Hybrid, and PBX-shows the

defaults specific to these templates.

M7100 Telephone

For Square, Hybrid, and PBX templates, the one

programmable button on the

Telephone is

M7208 Telephone

The default button assignments for the M7208 Telephone

depend on the template applied.

Square

[Line]

[Last]

(Speed]

(Intercom]

[Intercom]

Note:

Hybrid

(Line]

[Last No.

I

Dial

[Intercom]

I

[No.]

[Ii-

The default Page button activates the External Page

PBX

[Pick-Up]

[Last]

(Intercom]

option

Modular DR5 Installer Guide

Page 66

telephones 61

Telephone

The default button assignments for the Telephone

depend on the template applied. The exception is the default

numbering for the dual-memory buttons.

Dual-memory buttons

This example shows defaults for a system with three-digit internal

numbers.

These defaults do not actually exist on any telephone, as no

telephone has an

would be taken by the button for itself, is blank.

,

Template button assignments

button for itself. The position that

Modular DR5 Installer Guide

Page 67

62 telephones

M7324 Telephone

The default button assignments for the M7324 Telephone

depend on the template applied.

Square

[Call]

(Speed]

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

Hybrid

(Line]

[Speed]

(Pick-Up]

(Intercom]

[Intercom]

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

[Call]

[Speed]

[No.]

[Link]

[Pick-Up]

[Call]

(Intercom]

PBX

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

[Saved]

[Transfer]

[Intercom]

Modular DR5 Installer Guide

blank

blank

blank

blank

blank

blank

blank

blank

blank

blank

[Transfer]

[Intercom]

(Intercom]

Page 68

Optional

Optional equipment 63

Auxiliary ringer

The

external ringer. The auxiliary ringer can be activated by setting

auxiliary ring for specific external lines, and auxiliary ring for

specific telephones.

Refer to the chapters on programming for more details. Refer

specifically to the following headings in Administration and

Configuration.

Heading

Capabilities

Service Modes

1.

Follow the manufacturer’s installation instructions.

KSU provides a control contact to operate an

Data

(Customer Supplied)

Programmed in:

Configuration

Administration

Administration

2.

Connect the Auxiliary Ring Generator to the

distribution block as shown in the wiring charts in this Guide.

The pins in this chart provide a control contact. They do not

provide ring current or dc voltage. The ringer must not draw

more than 50

from a 40-V dc source.

Modular DR5 Installer Guide

Page 69

64 Optional equipment

External source

Music for callers on Hold and for Background Music must be

enabled through programming. Refer to the Programming

chapter for more details. Refer specifically to the following

programming headings in Configuration and confirm that the

following settings are implemented:

Heading

Call Handling

Miscellaneous Background Music: Yes

External music source programming

The music source can be any approved low-power device such

as a radio with a high-impedance earphone jack. The

recommended KSU input level is 1 V rms across an input

impedance of 3300

Setting

On Hold:

(Customer Supplied)

Music

Connect the music source and ground to the

distribution block, as shown in the internal wiring charts in

this Guide.

‘CAUTION

To avoid damage to audio equipment, ensure that the

polarity of the audio input is correct according to the

KSU internal wiring connector chart.

2.

Adjust the volume of the music source to a comfortable level

by activating Music on Hold or Background Music and

adjusting the volume at the music source.

Background Music volume can also be adjusted at each

telephone.

Modular Installer Guide

Page 70

Optional equipment 65

Installing an external paging system

The paging system uses the speakers on telephones and

can also be used with external loudspeakers provided by the

customer. The paging output from the KSU is

775

1.

2..

3.

rms across an input impedance of 600

Follow the manufacturer’s installation instructions.

Connect the paging system audio input to the

distribution block as shown in the internal wiring charts in this

Guide.

Connect the pagingsystem relay to the distribution

block as shown in the internal wiring charts.

Note:

system external paging does not support

talk-back paging equipment unless an external line port

is used.

In addition, the KSU provides a relay contact that can be

used for other applications (for example, switching music ON or

OFF).

External paging contacts

idle

Yellow-Slate

(make)

Slate-Yellow

(common)

Violet-Blue

(break)

l

active

Yellow-Slate

(make)

Slate-Yellow

(common)

Violet-Blue

(break)

The KSU provides both a “make” (normally open) and a

“break” (normally closed) set of contacts that operate in

conjunction with the External Page feature. These contacts can

be used to control various external devices. The external device

being connected through these contacts must not draw more

than 50

from a 40-V dc source.

Modular DR5 Installer Guide

Page 71

66 Power Bar installation

Power Bar installation

CAUTION

For 110-V systems, use only a CSA certified and UL

listed Power Bar having a third wire ground.

For 220-V systems, use only an approved

Power Bar having a third wire ground.

1.

Slide the Power Bar into the lower shelf of the cable trough.

All power cords must go only in the lower shelf.

Where any combination of four or more Trunk or Station

Modules is present, use a second Power Bar to provide

additional plugs. On a 110-V system, the power cord from

the second Power Bar must be plugged into the first Power

Bar. On a 220-V system, the Power Bars are connected with

a separate power cord.

220-V

2.

Route the power cord from the KSU, Trunk Module, and

Station Module through the cable clips located in the lower

shelf of the cable trough.

3.

Plug the KSU, Trunk Module, and Station Module power

cords into the Power Bar(s).

4.

If you have a 220-V system, plug the ac power cord into the

Power Bar.

Modular DR5 Installer Guide

Page 72

Power up the system 67

Power up the system

Double check all wiring before turning the system power ON.

1.

Connect to the outlet (a non-switchable, third-wire ground

2.

ac outlet):

For a 11 O-V system:

If a Power Bar is used, plug the Power Bar into the ac outlet.

plug the KSU power cord into the ac outlet.

For a 220-V system:

If a Power Bar is used, plug the Power Bar into the separate

ac power cord. This ac power cord plugs into the ac outlet.

Otherwise, plug the KSU power cord into the ac power cord.

This ac power cord plugs into the ac outlet.

Check that the red power are ON. (The KSU, Trunk

3.

Module, and Station Module each have one LED.)

LED

TM LED

SM LED

If none of the are ON, check the power at the ac outlet.

4.

If there is no power, check with building maintenance.

OR

If there is ac power at the outlet, replace the module(s)

that do not have a red LED ON.

Modular Installer Guide

Page 73

68 Telephone relocation and replacement

Telephone relocation and

replacement

Automatic Telephone Relocation and telephone replacement are

features associated with moving and replacing

telephones in the system. The basic difference is that relocation

allows a moved telephone to retain its programming, and

replacement re-assigns or removes programming.

Automatic Telephone Relocation

Automatic Telephone Relocation is disabled by default. For

Automatic Telephone Relocation to work, the system power must

be ON and the Automatic Telephone Relocation feature must be

activated in Configuration programming.