NORSE 9683124 Operating Manual

Operating Instructions & Parts Manual

9643312.01 0318

Model 9683124

10˝

Bench Top

Band Saw

9683124_oipm_En011_9643312.01 03/21/18 Page 1

2

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

NORSE Operating Manual & Parts List 9683124

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! retain instructions for future reference.

Model #: ________________________

Serial #: _________________________

Purchase Date: ___________________

9683124_oipm_En011_9643312.01 03/21/18 Page 2

GETTING STARTED

Structural Requirements

Make sure all supporting structures and load attaching devices are

strong enough to hold your intended loads. If in doubt, consult a

qualified structural engineer.

Electrical Requirements

The power supply to the Band Saw needs to be 120 volt/ 3.4 amp,

single phase, 60 Hz. The standard allowable voltage variation is

plus or minus 10%.

Tools Needed:

Standard mechanic’s hand tool set.

UNPACKING

Be careful not to touch overhead power

lines, piping, lighting, etc. if lifting

equipment is used. Band Saw weighs approximately 77 lbs,

proper tools, equipment and qualified personnel should be

employed in all phases of unpacking and installation.

Carton should be handled with care to avoid damage from

dropping, bumping, etc. Store and unpack carton with correct side

up. After unpacking Band Saw, inspect carefully for any damage

that may have occurred during transit. Check for loose, missing or

damaged parts. If any damage or loss has occurred, claim must be

filed with carrier immediately. Check for completeness. Immediately

report missing parts to dealer.

Band Saw is shipped partially assembled. End user will need to

assemble loose parts to machine.

IMPORTANT: The tool has been coated with a protective coating.

In order to ensure proper fit and operation, the coating must be

removed. Remove coating with mild solvents such as mineral

spirits and a soft cloth. Nonflammable solvents are recommended.

After cleaning, cover all exposed metal surfaces with a light coating

of oil.Paste wax is recommended for table top.

Never use highly volatile solvents. Avoid

getting cleaning solution on paint as it

may tend to deteriorate these finishes. Use soap and water

on painted components.

Contents:

• Band Saw (1)

• Table (1)

• Guide rail (1)

• Rip fence with knob (1)

• Miter gauge assembly (1)

• Pushstick (1)

• Hardware bag (1) - Includes: M6 x 30 hex head bolt and nut;

four each hex bolts and M6 serrated washers; four each wing

nut bolts and washers.

• Operating Instructions and Parts Manual (1)

Unpack:

Do not discard packing materials until after machine has been

inspected for damage and completeness. Locate loose parts and

set aside.

Inspect:

After unpacking the unit, carefully inspect for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with the carrier.

All tools should be visually inspected before use, in addition to

regular periodic maintenance inspections.

Be sure that the voltage labeled on the unit matches your power

supply.

SAFETY RULES

For your own safety, read all of the

instructions and precautions before

operating tool.

PROPOSITION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

Always follow proper operating

procedures as defined in this manual even

if you are familiar with the use of this or similar tools.

Remember that being careless for even a fraction of a

second can result in severe personal injury.

Be Prepared for Job

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NOT safety glasses.

3

NORSE Operating Manual & Parts List 9683124

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

9683124_oipm_En011_9643312.01 03/21/18 Page 3

SAFETY RULES (CONTINUED

)

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

Prepare Work Area for Job

• Keep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool. Threeprong plug should be plugged directly into properly grounded,

three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

Tool Should Be Maintained

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool’s operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs. (Use

parts list provided to order repair parts.)

Know How to Use Tool

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool when changing the blade.

• Avoid accidental start-up. Make sure that the tool is in the OFF

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from moving parts and cutting surfaces.

• Never leave tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

or if blade is unintentionally contacted.

• Know your tool. Learn the tool’s operation, application and

specific limitations.

• Use recommended accessories. Use of improper accessories

may cause risk of injury to persons.

• Handle workpiece correctly. Protect hands from possible injury.

• Turn machine off if it jams. Blade jams when it digs too deeply

into workpiece. (Motor force keeps it stuck in the work.) Do not

remove jammed or cut off pieces until the saw is turned off,

unplugged and the blade has stopped.

• Maintain proper adjustment of blade tension, blade guides and

thrust bearings.

• Adjust upper guide to just clear workpiece.

• Hold workpiece firmly against table.

• DIRECTION OF FEED: Feed work into a blade or cutter

against the direction of rotation of the blade or cutter only.

The operation of any power tool can

result in foreign objects being thrown into

the eyes, which can result in severe eye damage. Always

wear safety goggles complying with United States ANSI

Z87.1 before commencing power tool operation.

Think safety! Safety is a combination of

operator common sense and alertness at

all times when tool is being used.

SPECIFICATIONS

The NORSE 10" Bench Top Band Saw features welded steel frame

construction and a solid cast iron table surface to insure durability. It

is designed for cutting hard and soft woods. The saw is equipped

with a miter gauge for performing many different operations. A

convenient quick tensioning and comprehensive tracking

mechanism makes blade changing quick and easy. Saw also

features a rip fence and dust collection port.

Depth of throat at 90° 9

1

⁄2˝

Maximum depth of cut at 90° 4˝

Maximum depth of cut at 45° 2˝

Table size 131⁄4x 131⁄4˝

Table tilt 0° to 45°

Wheel diameter 10˝

Blade length 67

3

⁄8˝

Blade width 1/4 - 1/2˝

Blade speed 2900 FPM

Motor 1/3 HP, 120V, 3.4A, 60 Hz, 1720 RPM

Overall dimensions 21 x 16

1

⁄2x 34˝

Weight 70 lbs

Shipping weight 77 lbs

Dust collection port 2, 21⁄2and 4˝

4

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

NORSE Operating Manual & Parts List 9683124

9683124_oipm_En011_9643312.01 03/21/18 Page 4

ASSEMBLY

Refer to Figures 4, 5, 6 and 8.

Do not attempt assembly if parts are

missing. Use this manual to order repair

parts.

The machine is supplied partly assembled. Prior to use, the

following items have to be installed: Table, Guide Rail, Rip Fence,

Dust Collector (not included) and Rip Fence.

To avoid injury, do not attempt to run or

use this machine until all parts are

assembled and working properly.

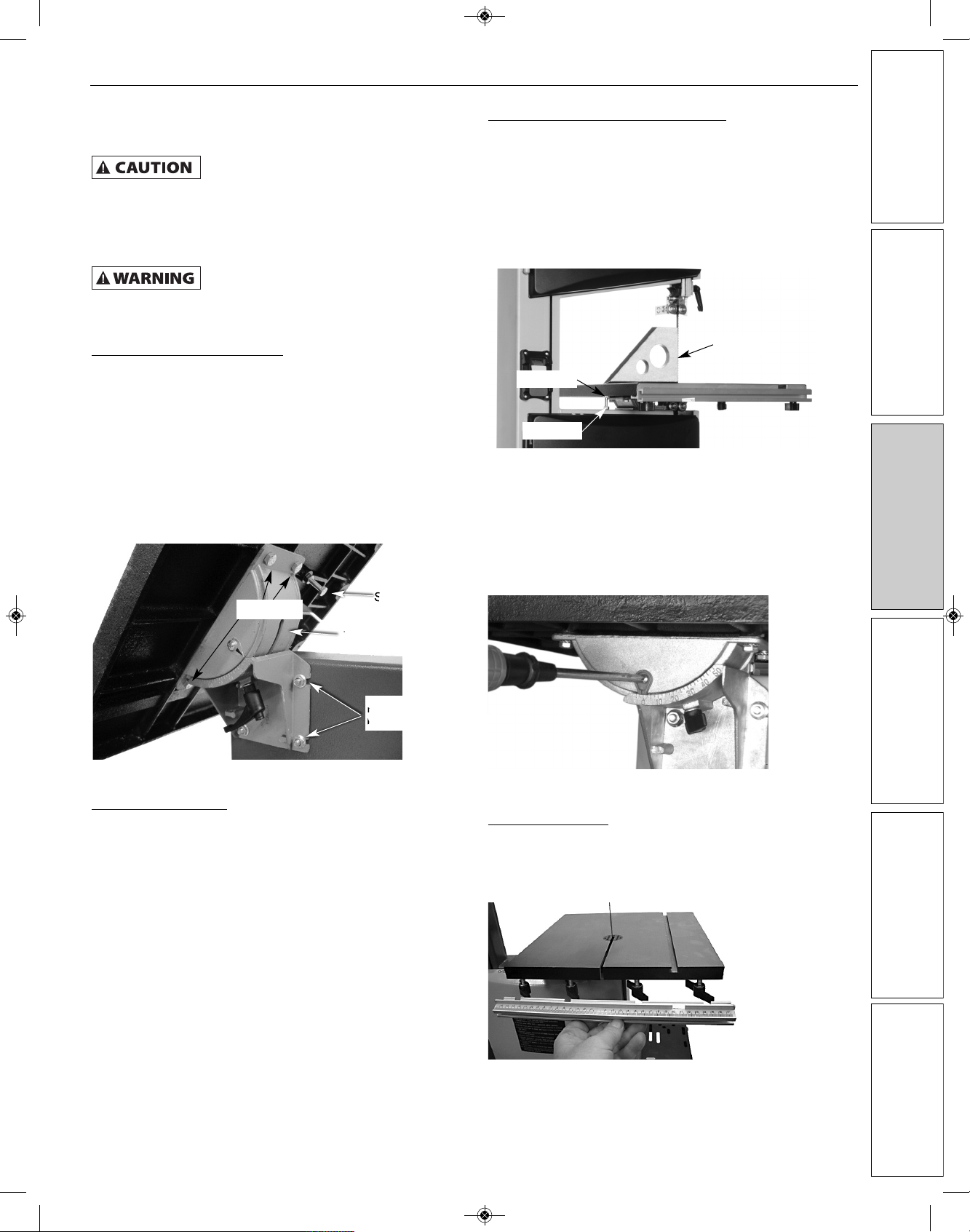

Assemble Table to Trunnion

Refer to Figure 1

Assemble the table on to the upper table trunnion, taking care

when passing the saw blade through the slot of the table.

1. Attach M6 x 30 hex head bolt and nut (Stop Bolt) into hole next

to the insert on table bottom.

2. Locate four hex bolts and four M6 serrated washers from the

bag of loose parts. Mount the table to the upper table trunnion

and install a bolt with washer in each hole, and then tighten

with adjustable wrench.

Centering the Table

Refer to Figure 1

1. Loosen the four hex bolts mounting the table to the upper table

trunnion.

2. Move the table sideways as required, until the saw blade runs

through the center of the table insert.

3. If moving the upper table trunnion is not enough to center the

table, loosen the four flange nuts holding the lower table

trunnion and move the table sideways to place the table in the

center.

4. Re-tighten hex bolts for trunnion and flange nuts, recheck the

saw blade position.

Setting Table Square to Saw Blade

Refer to Figures 2 and 3.

Loosen the knob on the lower table trunnion and place a suitably

sized square against the saw blade. If the table requires

adjustment, proceed as follows:

1. Using a wrench, release the hex nut on the bolt (see Figure 2).

Place the wrench on the hex bolt and adjust until the table is

square to the saw blade.

2. Tighten the hex nut and recheck the saw blade and the table

for squareness.

3. Lock the table into position and check that the indicator reads

zero degree on the side of lower table trunnion. Loosen the

screw securing the indicator and reset if necessary to give zero

degree reading (see Figure 3).

Fasten Guide Rail

Refer to Figure 4.

• Fasten the guide rail with four each wing nut bolts and washers

to the table.

5

NORSE Operating Manual & Parts List 9683124

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

Figure 1 - Assemble table to trunnion.

Hex Bolts

Trunnion

Stop Bolt

Flange

Bolts

Figure 2 - Square table to saw blade.

Square

Hex Bolt

Hex Nut

Figure 3 - Set indicator to zero.

Figure 4 - Fasten guide rail.

9683124_oipm_En011_9643312.01 03/21/18 Page 5

ASSEMBLY (CONTINUED

)

Install Rip Fence

Refer to Figure 5.

• Lay the rip fence onto the guide rail. Adjust the rip fence

parallel to the saw blade. Tighten rip fence handle by pressing

downward.

Stabilize Machine

Refer to Figure 6.

• To ensure sufficient upright stability of the machine it should be

bolted to floor, bench or worktable. For this purpose 8mm holes

are provided in the machine’s base. Mounting hardware not

provided.

Use Suitable Dust Collector

Refer to Figure 6 and 8.

• The band saw has a dust port included that will accommodate

2", 2

1

⁄2" and 4" dust collection hoses.

It is recommended that when in use, the band saw is connected to

a suitable dust collector.

INSTALLATION

Electrical Connections

All electrical connections must be

performed by a qualified electrician.

Make sure unit is off and disconnected

from power source any time wiring is

inspected.

Power Source

Band Saw is prewired for 120 volt, 60 HZ power source.

The motor is designed for operation on the voltage and frequency

specified. Normal loads will be handled safely on voltages not more

than 10% above or below the specified voltage.

Running the unit on voltages which are not within the range may

cause overheating and motor burn-out. Heavy loads require that

the voltage at motor terminals be no less than the voltage specified.

Power supply to the motor is controlled by a single pole toggle

switch.

Grounding Instructions

Improper connection of equipment

grounding conductor can result in the risk

of electrical shock. Equipment should be grounded while in

use to protect operator from electrical shock.

• Check with a qualified electrician if grounding instructions are

not understood or if in doubt as to whether the tool is properly

grounded.

This tool is equipped with an approved 3-conductor cord rated at

150V and a three prong grounding type plug or your protection

against shock hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3- prong grounding-type receptacle, as

shown (Figure 9).

6

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

NORSE Operating Manual & Parts List 9683124

Figure 5 - Install rip fence.

Figure 6- Mounting holes and dust port.

Mounting

Holes

Dust Port

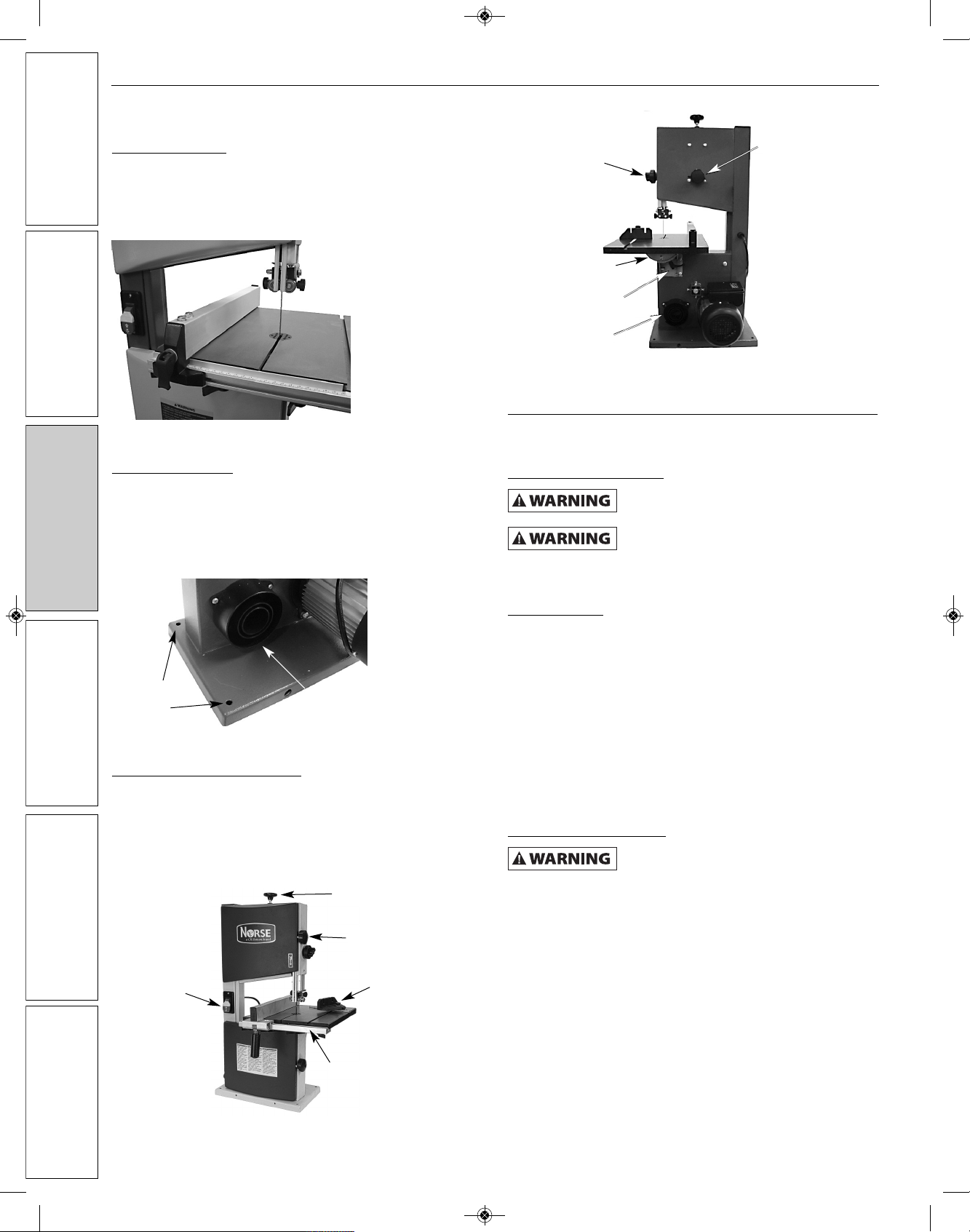

Figure 7 - Know your band saw.

Blade Tension Knob

Door Locking

Knob

Miter Gauge

Switch

Guide Rail

Figure 8 - Know your band saw.

Blade Tracking

Knob

Dust Port

Upper Trunnion

Lower Trunnion

Guide Post

Adjusting and

Lock Knob

9683124_oipm_En011_9643312.01 03/21/18 Page 6

Loading...

Loading...