Page 1

LARGE CAPACITY CO2 INCUBATOR

Installation, Operation and

Maintenance Instructions

GENERAL

Inspection 2 Location 2

INSTALLATION

Door Alignment 2 Shelf Installation 2 Remote Contacts 2 2-10 Volt DC Output 2 RS485 Port 3 Duplex or European Outlet 4 Amp Max. 3 Access Port 3 Glycerin Well Assembly 3

OPERATION

CO

Humidity Pan Option 5

Operation 4

2

Drawer Option 5 Drawer Slide Removal/Adjustment 6

MAINTENANCE

Periodic Cleaning 6

2

2

3

6

Maintenance Service and Analysis Guide

1 11/10 Rev. B 143314

6

Page 2

GENERAL

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to

insure all crates and cartons have been received. All units should be inspected for concealed

damage by uncrating the units immediately. If any damage is found, it should be reported to the

carrier at once, and a claim should be filed with the carrier. This equipment has been inspected and

tested in the manufacturing facility and has been crated in accordance with transportation rules and

guidelines. Manufacturer is not responsible for freight loss or damage.

Location

The cabinet should also be leveled when it is placed in its permanent location. Do not stack items

on top of the unit. Vibration during shipping and handling may loosen mechanical connections.

Check all connections during installation. Check all wiring and fasteners.

CAUTION

• Do not modify cabinet construction or associated equipment assemblies.

• Do not remove labeling or information supplied with the unit.

Observe all Warning Labels. Disconnect power supply to eliminate injury from electrical

shock or moving parts when servicing equipment.

INSTALLATION

Door Alignment - If for some reason the doors are not squared up on the cabinet, the doors can be

adjusted. Opening the door(s) and loosening the screws that hold both the top and bottom hinges to

the cabinet can accomplish this. After adjusting the door so that it is aligned correctly, tighten the

screws to securely hold the hinges in place.

Shelving Installation - Locate shelves inside cabinet, install shelf supports (1 RH

support, 1 LH support per shelf.)

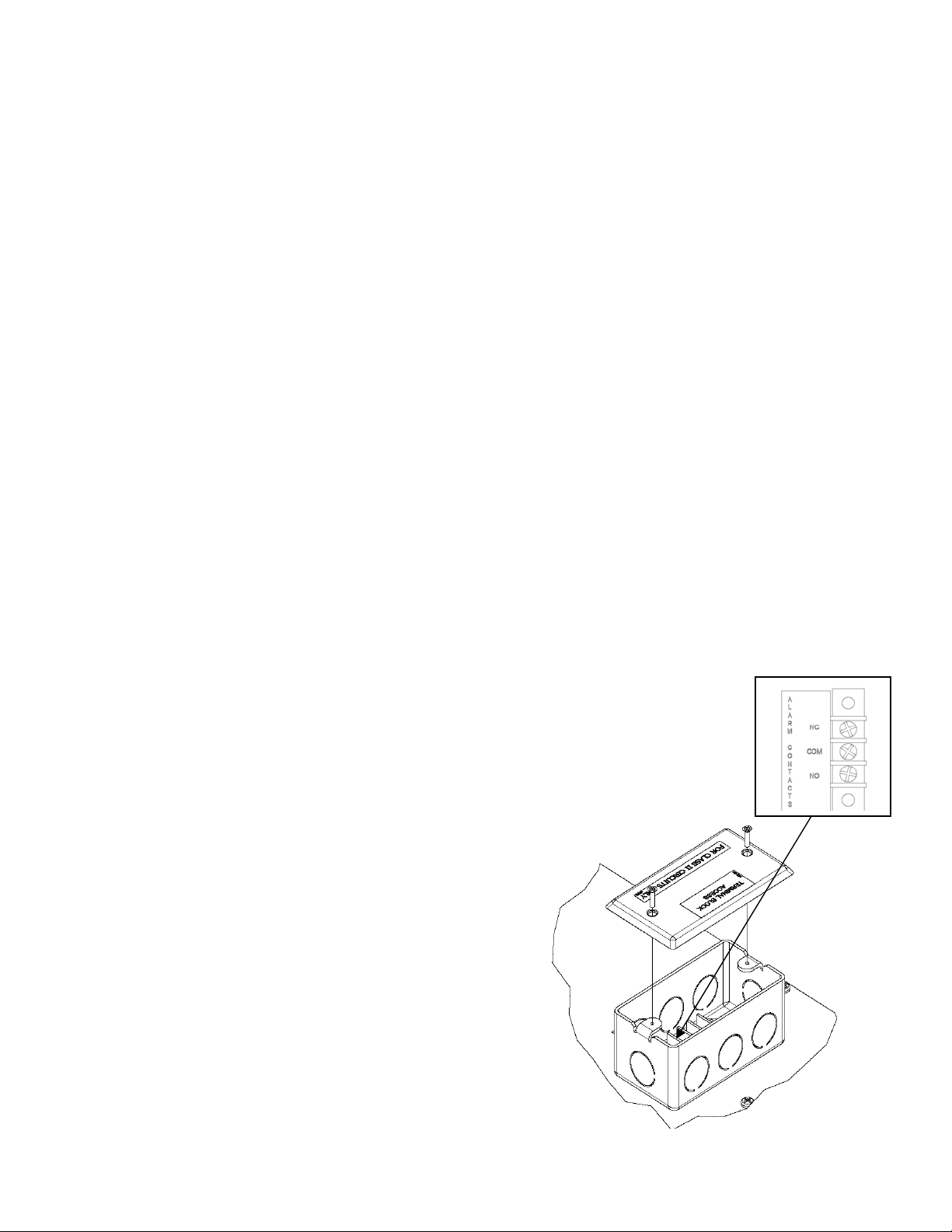

Remote Alarms Contacts Access - The factory installed Remote alarm contacts

access box is located at the top of the cabinet behind the microprocessor control

(see illustration.)

1. Remove the cover to access the terminal

connections.

2. Select and knock-out a hole to run field leads

into electrical box terminals.

3. The terminal block in the electrical box is

labeled for “normally open” and “normally

closed” activation. End user is responsible for

proper field installation.

Terminal connections are rated for class II

circuits only per NEC table 11(A). (Limited

power source less than 30vac 8 Amp. max,

see applicable notes in NEC).

2-10 volt DC Output – Terminal board for 2-10v DC

Output is located behind the cabinet façade, next to

Remote Alarm access box. Connect wires as per label.

2 11/10 Rev. B 143314

Page 3

RS485 port - (Optional) terminal board for RS485 port is located behind the cabinet façade, next to

the Remote Alarm access box, connect wires as per label.

Duplex, or European Outlet 4 Amp Max. – (Optional) is located near the back of the left hand

interior wall, 20” from the cabinet interior floor. Outlet is wired thru main cabinet power supply, and

includes a 4 amp, MANUAL RESET, circuit breaker. Breaker is located behind façade, on the side

of the control box.

Access Port - (Optional) 2” port is provided with a spring loaded, exterior cover, RH or LH side of

the cabinet.

Glycerin Well Assembly

Important: For accurate product temperature reading, the

product-sensing bulb must be immersed in glycerin solution

contained in the provided well.

One glycerin well is furnished with each model. The

purpose of the glycerin is to simulate the product stored in

the Incubator. The glycerin temperature reflects the

product's temperature during normal operation.

Figure 1

After the unit is put into operation, check to make sure that

the temperature indicating or alarm sensing bulb is

positioned inside the glycerin well as far as possible without

touching the well itself.

OPERATION

The Large Capacity Incubator is designed for an operating range of 5°C above room ambient to

70°C and is intended for indoor use only. A transverse blower optimizes airflow and ensures tight

temperature uniformity.

These units employ a programmable controller to control the temperature and CO2 option. The

controller is located on the facade of the unit. Please see the separate instructions, part number

113635, on the operation of the controller used in the Large Capacity Incubator.

The Incubator utilizes an electrically operated heater to warm the cabinet. The programmable

control is factory set with a cutout temperature of 70°C (158°F) to prevent the cabinet from

exceeding its design limitations.

Chamber CO

instrument.

sample port used for sampling chamber content using a FYRITE or similar

2

3 11/10 Rev. B 143314

Page 4

CO2 Operation

Figure A

The Large Capacity Incubator is offered with a CO2 dispensing and measurement system. The CO

system is microprocessor based and controlled by a sensor based on the NDIR Single-Beam DualWavelength principle. The sensor (included with CO

and provides a reliable and stable reference measurement over time. Water vapor, dust, debris and

most chemicals do not affect measurement accuracy; therefore, the sensor may be used in a harsh

and humid environment.

The CO

default and adjustable settings in the separate instructions, part number 136349.

Installation Requirements – The end user must supply two CO

regulators for the CO

above 4 psi as the CO

pressure drops to 4 psi.

psi.

Connecting a CO

settings are controlled by the controller located on the façade of the unit. Please see the

2

input. See Figure B for hook up points. The input gas pressure must be

2

tank switch over valve is factory set to recognize an empty tank when the

2

The maximum recommended input pressure should not exceed 25

Supply

2

option) measures from 0-20% CO2 density

2

tanks and two-two stage gas

2

High concentrations of carbon dioxide can cause

!

asphyxiation. The use of CO

is recommended for areas where CO

monitors and alarms

2

can collect.

2

2

4 11/10 Rev. B 143314

Page 5

CO2 Sample Port

The chamber atmosphere can be taken from the Sample Port located at the bottom of the front

control panel. CO

instrument such as a gas chromatograph.

concentration can then be checked using a FYRITE gas analyzer or other

2

Humidity Pan Option (CO2 Incubators only)

The Large Capacity Incubator humidity pan is manually filled with water as required. Humidity

(moisture) is introduced into the incubator interior by evaporation only.

The humidity pan is 22 Ga. stainless steel with dimensions of 20-3/4 inches long x 12-3/4 inches

wide x 2-1/2 inches deep. The pan capacity is 9 quarts (8.52 liters). A stainless steel pan cover is

also supplied.

Note: With the CO

/humidity pan feature, the cabinet is also provided with a drip pan that mounts

2

under the door. The drip pan catches any condensation that drips during door openings. The drip

pan is supplied with 4’ of 3/8” ID tubing and a 3/8” drain stopper. Tubing must be connected to

adequate drain or stopper needs to be installed and accumulated moisture removed as needed.

Figure B

Drawer Option

The Large Capacity Incubator is offered

with drawers as an option.

Drawer Removal – The Large Capacity

Incubator may accommodate up to eight

drawers. To remove the drawers for

cleaning, locate the black release tabs

found on the inside front of the drawer. See

Figure C. Push the release tabs on each

5 11/10 Rev. B 143314

Page 6

side inward and lift up the drawer. Slide the drawer towards you and remove.

Drawer Slide Removal/Adjustment

Each drawer slide is independently removable and can be adjusted to different levels. First remove

the drawer per above instructions. Release the locking tabs located on the drawer slide, move the

front tab up and release the tab in the back of the cabinet, by sliding the locking tab towards the

front. See illustration. Unhook the drawer slide assembly from both the front and back shelf

standards by lifting up on the assembly.

To install a drawer slide, reverse the process used to remove the slide. Secure the locking tabs into

position after the drawer slide assembly is in place. Reinstall the drawer.

Figure C

MAINTENANCE

Periodic Cleaning

Beginning with the initial installation, the interior surfaces of the cabinet should be periodically wiped

down with a solution of warm water and baking soda. This solution will remove any odors from

spillage that has occurred. The exterior of the cabinet should also be cleaned frequently with a

commercial grade of glass cleaner. Caution: Do not use an abrasive or alkaline solution.

All moving parts have been permanently lubricated and will generally require no maintenance.

MAINTENANCE SERVICE AND ANALYSIS GUIDE

MALFUNCTION POSSIBLE CAUSE SOLUTION

No power to optional 1. Internal circuit breaker tripped 1. Reset circuit breaker

duplex receptacle 2. Wiring incorrect 2. Check wiring against the diagram

Heater inoperative 1. High limit thermostat tripped 1. Manually reset thermostat

2. Wiring incorrect 2. Check wiring against diagram

No power to cabinet 1. Service cord unplugged 1. Plug in service cord

2. Circuit breaker supplying 2. Determine reason and correct

main electrical receptacle tripped

3. Wiring incorrect 3. Check wiring against diagram

4. Main cabinet power switch off 4. Turn on power switch

Objectionable noise 1. Vibrating fan blade 1. Replace fan blade

2. Worn fan motor bearings 2. Replace fan motor

measurement does not equal 1. Poor analyzer 1. Verify analyzer operation

CO

2

the display 2. Display not calibrated 2. Check calibration (see control manual)

measurement less than 1. CO2 regulator set too low 1. Adjust regulator (not to exceed 25 PSI)

CO

2

setpoint 2. Door recent opened or poor seal 2. Correct door seal

3. CO

4. Display not calibrated 4. Check calibration (see control manual)

and analyzer read zero 1. Loss of CO2 supply 1. Identify and correct

CO

2

(setpoint ok) 2. Defective solenoid 2. Replace solenoid

3. Supply tank(s) empty 3. Change tank(s)

tank(s) low 3. Change tank(s)

2

6 11/10 Rev. B 143314

Loading...

Loading...