Norlake KF033SMS Installation Manual

KE2 Evaporator

1

01/13 Rev. A 151627

Enviro-Control™

thermsolutions

KE2 EvaporatorEfficiency

TM

ENTER

BACK

Installation Instructions

KE2 EvaporatorEfciency

2

01/13 Rev. A 151627

Factory Default Settings

. . . . . . . . . . . . . . Page 13-14

Enviro-Control™

Installation Instructions

Introduction

The KE2 Evaporator Eciency (KE2 Evap) is an electronically operated evaporator controller engineered to save energy in refrigeration systems through precise control of superheat, space

temperature, fan cycling, reducing compressor runtime, and

KE2 Evaporator Eciency - Controls and Communicates

implementing demand defrosts. The KE2 Evap oers quick payback, and a life expectancy that matches that of the system. The

controller pays for itself, and then continues to pay dividends for

the life of the system.

TEV/EEV

Room Temperature

Evaporator Fans

Compressor/

Liquid Line Solenoid

Defrost Heaters

Multiple Alarms

Table of Contents

KE2 Evaporator Eciency

TM

thermsolutions

KE2 EvaporatorEfficiency

ENTER

BACK

KE2 Master View on:

Tablet

KE2 Therm Evaporator Eciency

IP Address: 10.10.50.51 Location: Walk-in Freezer

ABC Contracting

STATUS

MODIFY

(888)555-3358

Mac Address: 00.04.A3.12.07.87

Evaporator FanORoom Temp

Coil Temp

Compressor

System Mode

Cool

DefrostOAux Temp

Superheat

0.0 F

Home SetpointsNetworkSettings

PWR SYS WLAN 4 3 2 1 WAN USB QSS

All Clear

-8.5 F

15.4 F

On

Dig Input 3

Dig Input 1

Dig Input 2

Dis

Dis

Closed

Dis

Sat Temp

Valve Position

Suct Pressure

Suct Temp

TM

thermsolutions

46.0 F

Manual

96.2 F

87.7 F

(

(

(

(

(

(

KE2 Router

Location . . . . . . . . . . . . . . . . . . . . . Page 3

Installation & Wiring . . . . . . . . . . . . Page 3 - 9

Figure1: Installation Locations . . . . . . . . . . . . . .

Figure 2: Return Air Sensor Placement . . . . . . . . .

Figure 3: Proper Sensor Location . . . . . . . . . . . . .

Figure 4: Coil Sensor Placement . . . . . . . . . . . . .

Figure 5: Evaporator Eciency Diagram . . . . . . . .

Figure 7: Wiring Schematic - New Install

Figure 8: Wiring Schematic - with Contactor Box

Dimensions . . . . . . . . . . . . . . . . . .Page 9

Figure 9: Dimensions . . . . . . . . . . . . . . . . . . .

Mounting the Controller

Controller Setup

Table 1: Quick Start . . . . . . . . . . . . . . . . . . . .

Adjusting Controller Parameters

. . . . . . . . . . . . . . .Page 10

Table 2: Navigation Through Controller Parameters Page 12

Table 3: Controller Menus and Menu Parameters Pgs. 12-16

Variables Menu . . . . . . . . . . . . . . . . . . . Page 12

Alarm Status Menu

Manual Menu . . . . . . . . . . . . . . . . . . . . Page 14

Setpoint Menu . . . . . . . . . . . . . . . . . . . . .Page 15

Table 4: Defrost Defaults . . . . . . . . . . . . . . . . . Page 16

. . . . . . Page 7

. . . . . . . . . .Page 10

. . .

Page 10-16

. . . . . . . . . . . . . . . . .

Page 3

Page 3

Page 4

Page 5

Page 6

Page 8

Page 9

Page 10

Page 12

Communication . . . . . . . . . . . . . . . . Page 16

Table 5: Ethernet Specications Summary . . . . . . Page 16

Specications . . . . . . . . . . . . . . . . . Page 16

Smart Phone

KE2 Therm Evaporator Eciency

IP Address: 10.10.50.51 Location: Walk-in Freezer

ABC Contracting

STATUS

MODIFY

(888)555-3358

Mac Address: 00.04.A3.12.07.87

CompressorOnSystem Mode

Evaporator FanORoom Temp

Coil Temp

All Clear

Cool

-8.5 F

15.4 F

Dig Input 3

DefrostOAux Temp

Dig Input 1

Dig Input 2

Dis

Dis

Closed

Dis

Sat Temp

Superheat

Valve Position

Suct Pressure

Suct Temp

46.0 F

0.0 F

Manual

96.2 F

87.7 F

Home SetpointsNetworkSettings

PC

KE2 Therm Evaporator Eciency

IP Address: 10.10.50.51 Location: Walk-in Freezer

ABC Contracting

STATUS

MODIFY

(888)555-3358

Mac Address: 00.04.A3.12.07.87

CompressorOnSystem Mode

Evaporator FanORoom Temp

Coil Temp

Cool

-8.5 F

15.4 F

Dig Input 3

DefrostOAux Temp

Dig Input 1

Dig Input 2

Dis

Dis

Closed

Dis

Sat Temp

Superheat

Valve Position

Suct Pressure

Suct Temp

46.0 F

0.0 F

Manual

96.2 F

87.7 F

Home SetpointsNetworkSettings

TM

thermsolutions

All Clear

TM

thermsolutions

KE2 Evaporator

3

01/13 Rev. A 151627

Enviro-Control™

Installation Instructions

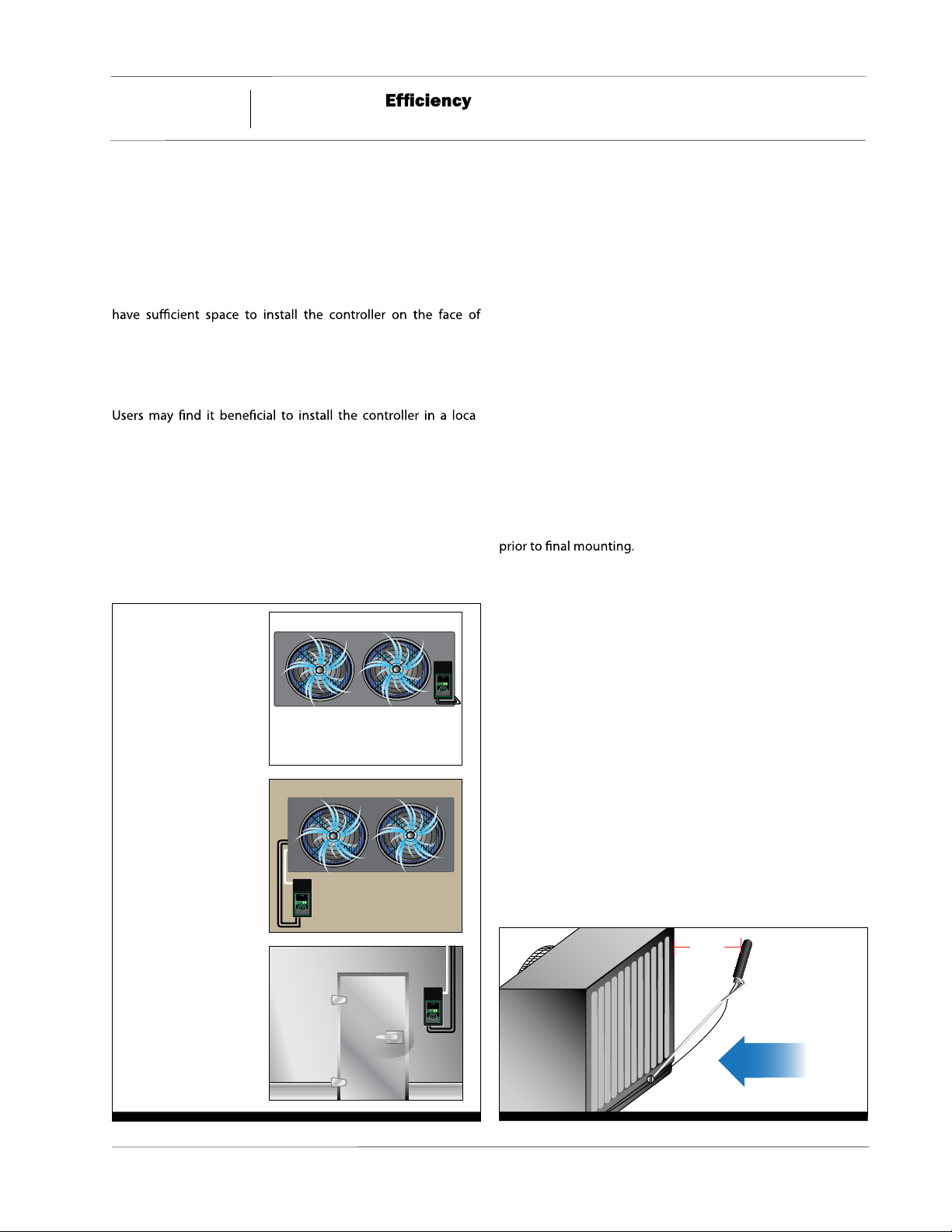

Location

The KE2 Evap was developed with ease of installation in mind.

The controller is supplied in an enclosure, and encapsulated to

protect the circuitry from moisture damage. This extra level of

protection allows the controller to be installed in the refrigerated space.

When installing the controller, it may either be installed on an

interior/exterior wall or on the evaporator. Many evaporators

evaporator or on its housing. Locating the controller as close to

the evaporator as possible reduces the amount of wiring when

converting existing systems, as well as when it is applied on new

applications.

tion providing easy access -- on the wall or near the entrance.

This enables the user to easily view the display, and eliminates

the need to use a ladder or lift to modify the setpoints or check

alarms.

If viewing the temperature outside the walk-in or refrigerated

room is desirable, the KE2 Evap may be used as a digital thermostat. The controller is then installed near the door of the space

Figure 1 - KE2 Evap Installation Locations

On the evaporator

TM

thermsolutions

KE2 EvaporatorEciency

2

2

ENTER

BACK

On the wall

TM

thermsolutions

KE2 EvaporatorEciency

2

2

ENTER

BACK

See Figure 1 for locations.

If installing the controller on the face of the evaporator, preexisting knockouts on the evaporator should be used for installing

the high voltage wiring. If knockouts do not preexist, hole(s)

may be carefully cut into an unobstructed area of the evaporator case. If modifying the face of the evaporator is not feasible

or desired, the controller’s conduit knockouts may be used with

½ inch conduit.

The bottom side of the controller includes a cutout with cable

tie slots providing a strain relief for the low voltage and sensor

wires. Additional knockouts are available on either side if conduit is preferred.

-

Installation & Wiring

The KE2 Evap is supplied with pluggable connectors for all

connections. Pluggable connectors permit the controller to

be placed in a safe location while the wiring is installed. They

also simplify the wiring, allowing the wires to be fastened to the

screw terminals in the open air. Once all wiring is completed

using accepted wiring practices, it is plugged into the controller

Although there is one pressure transducer and four temperature

sensor inputs, when used with mechanical valves (TEVs), KE2

Evap only requires the (2) sensors supplied with the kit. One

sensor reads the return air temperature and the other measures

the coil temperature. NOTE! Sensor location is critical to the

proper operation of the controller.

Return Air Temperature Sensor - The air temperature sensor is

installed in the return air of the evaporator using the included

sensor mount. Most applications allow the sensor mount to

be installed using an existing screw. On evaporators where using an existing screw is not possible, the included self-tapping

screw may be used to secure the sensor mount to the evaporator. Note: Be careful to avoid damage to an evaporator tube

or causing a leak in the

drip pan. When installing, it is impor-

tant to prevent the air sensor from coming into contact with the

mounting bracket, cable ties, or any other solid material. Figure

2 shows an example of how to mount the sensor. The sensor

must be a minimum of 6 inches from the coil surface.

Figure 2 - Return Air Sensor Placement

.sutats metsys ro/dna erutarepmet moor eht fo gniweiv ysae rof

At the entrance

>6”

Air

Sensor

TM

thermsolutions

KE2 EvaporatorEciency

2

2

ENTER

BACK

Return Air

KE2 EvaporatorEfciency

4

01/13 Rev. A 151627

Enviro-Control™

Installation Instructions

After the sensor is installed, route the wire back to the controller location. When routing sensor wire, it is important to avoid

interference from high voltage lines. If sensor wire is run parallel

to the high voltage, there is a potential for inductance to aect

the sensor reading. This is of particular concern with long wire

runs. When extending sensors, use the 18 gage, shielded twisted pair. Sensor wires can be run beyond 100 feet when using

special considerations. Contact KE2 Therm. After the wire has

been successfully routed, it may be connected to the pluggable

terminal on the controller.

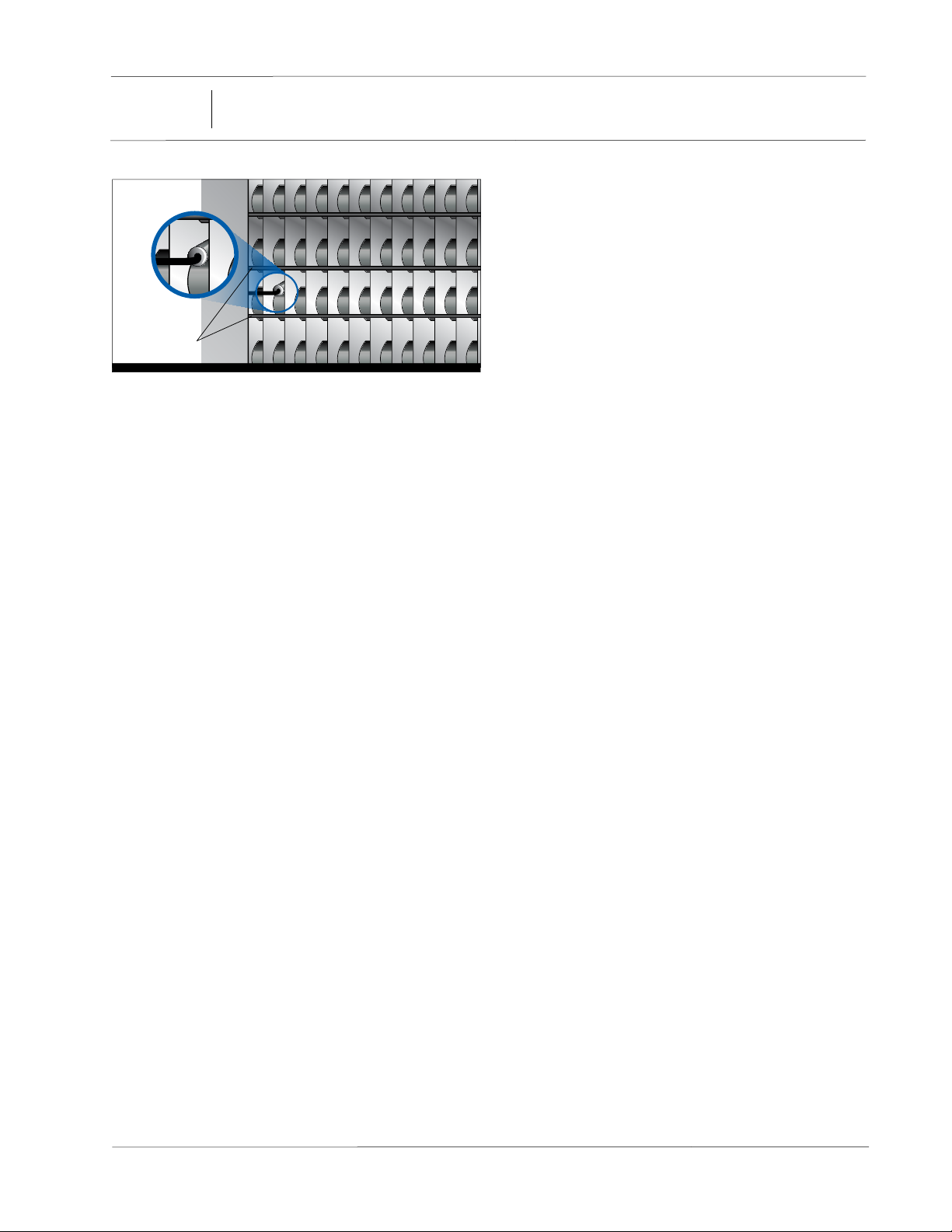

Coil Temperature Sensor - As a critical input to the controller, it is essential the sensor is located at the coldest point on

the evaporator coil for optimal operation. The coil sensor is an

integral part of the control algorithm used to determine coil efciency, to initialize defrosts, and to terminate defrosts.

KE2 Therm oers general guidance for sensor locations based

on the coil construction. Figure 3 shows the recommended locations for the coil sensor for each evaporator type.

When installing on draw through models, the sensor should be

located behind the coil in the lower corner nearest the suction

header. Blow through models should be installed on the front of

the coil, in the upper corner also nearest to the suction header.

When installing the sensor into the coil, the sensor should be positioned half way between the circuit tubes and, perpendicular

to the face of the coil. When choosing the location, the sensor

should not be located adjacent to the electric heating elements.

Locating the sensor too close to the elements will cause false

defrost termination temperatures. The sensor should be approximately half the distance between the heaters if possible.

Figure 4 shows the proper sensor placement.

Figure 3 - Proper Sensor Location

Electric Defrost - Surface Heater

Higher Frost Zone

coldest part of

evaporator

Heater Coil

3”

Electric Defrost - Dropped Tube

Higher Frost Zone

coldest part of

evaporator

Heater Coil

3”

Ideal Sensor Location

- 1/2 way between heater coils

1/2 way

- insert perpendicular to face of coil

- pinch ns together to hold

Ideal Sensor Location

- 1/2 way between heater coils

3”

- approx. 3” from top and 3”

from side

- insert parallel to face of coil

- pinch ns together to hold

Due to the many factors inuencing the evaporator performance, it is impossible for KE2 Therm to provide the proper location of every installation. However, the coil sensor is an integral

part of the control algorithm used to determine coil eciency

to initiate, as well as, terminate defrosts. The coldest point in

the coil can be identied from existing system knowledge or by

monitoring the normal operation.

Controller Power - The high voltage wiring is protected by

a metal shield screwed to the back side of the controller. The

shield should be removed to gain access to the wiring connections, making note of the location of the screws. The screws in

the upper corners are coarse thread screws, while the screw in

the middle is a 4-40 machine screw.

The controller accepts either 115V or 208/240V incoming power.

The controller includes metal oxide varistors (MOVs), providing

protection from voltage spikes. MOVs use the same technology

commonly applied to protect consumer electronics. They function by ltering out voltages high enough to damage the board.

When the voltage exceeds the allowed amount, the MOVs short

to ground, protecting the circuitry. For additional protection,

the board has a replaceable BK/MDL-1/4 fuse in line. The grey

plug is accessible without removing the metal shield in the fuse

Air Defrost

Ideal Sensor Location

- lower corner nearest expansion

valve, approx. 3” from bottom,

and 3” from side

- insert parallel to face of coil

- pinch ns together to hold

3”

3”

KE2 EvaporatorEfciency

Coil

Sensor

Defrost

Heaters

5

01/13 Rev. A 151627

Enviro-Control™

Installation Instructions

Figure 4 - Coil Sensor Placement

holder. Depress slightly and turn 1/4 turn counterclockwise to

remove. Replace by depressing slightly and turning 1/4 turn

clockwise. Do not overtighten.

The board uses a pluggable screw terminal connector to connect incoming power. The terminal is located in the top right

corner of the controller when the terminals are facing the user.

See Figure 5.

Fan and Defrost Relays - There are 2 larger relays on the controller with spade connectors. These are used for the evaporator

fans and defrost heaters. Due to the spacing of the enclosure

the spades require a 90 degree terminal. KE2 Therm has included (4) spade connectors to assist in wiring the relays.

Evaporator Fan Relay - The fan relay is rated 10A inductive at

240V. One leg of the incoming power for the fans should be

connected to the COM terminal of the fan relay, the upper of the

two larger relays. The remaining leg, (L2) should be connected

to one lead of the fan. The remaining fan lead should be connected to the NO (Normally Open) terminal on the fan relay. See

Figure 7.

Defrost Heater Relay - The heater relay is rated 20A resistive at

240V. One leg of the incoming power for the heaters should be

connected to the COM terminal of the heater relay, the lower

of the two larger relays. The remaining leg, (L2) should be connected to one lead of the heater. The remaining heater lead

should be connected to the NO (Normally Open) terminal on

the heater relay.

Alarm Relay - The alarm relay is rated at 3A inductive at 240V.

This relay uses the 3-position pluggable screw terminal to make

the connection to the board. The relay may be used to connect

an audible alarm, light, or to alert a 3rd party alarm system. One

leg of the incoming power supply (L1) should be connected to

COM terminal of the alarm relay, the lower of the two smaller

relays. The remaining leg, (L2), should be connected to one lead

on the alarm. The remaining alarm lead, should be connected to

the normally open (NO) position on the terminal.

After all high voltage wiring is completed the metal shield

must be replaced and screws tightened.

Additional Inputs

Suction Temperature Sensor - The suction temperature sen-

sor is required when applying the controller with an electronic

expansion valve. The sensor’s proximity to the evaporator outlet diers slightly for electronically controlled valves from the

placement of a TEV bulb. Due to the more rened control from

an electronically controlled valve, the sensor must be placed

as close to the outlet of the coil as feasible. Although the distance from the outlet is dierent, the nature of the refrigerant’s

ow through the tube remains unchanged, thus the orientation

of the sensor remains at the 4 or 8 o’clock position. The sensor

should be secured to the suction line using the included wire

ties designed for low ambient operation.

Pressure Transducer - In addition to the suction temperature

sensor, a pressure transducer is also required for superheat

measurement when applying an electronic expansion valve.

The pressure tap should be mounted on the top of a horizontal

section of tube. It should be located near the suction sensor, approximately 3 inches downstream from the position of the temperature sensor.

Auxiliary Temperature Sensor -The auxiliary temperature sensor provides exibility and may be used for any purpose desired

by the user. The placement of the sensor is dependent on the

requirements of the user’s intended application. The Auxiliary

Temperature sensor must be supplied by KE2 Therm.

Digital Inputs - The controller includes (3) digital inputs. See

Table 3 for conguration options.

Compressor/Liquid Line Solenoid Relay - The compressor re-

lay is rated at 3A induction at 240V. This relay uses the 3-position

pluggable screw terminal to make the connection to the board.

The relay is not intended to control the compressor directly. It is

designed to be used to control the liquid line solenoid or as a pilot to the compressor contactor. One leg of the incoming power

supply (L1) should be connected to COM terminal of the compressor relay, the upper of the two smaller relays. The remaining

leg, (L2), should be connected to one lead on the solenoid/compressor contactor. The remaining lead, should be connected to

the normally open (NO) position on the terminal.

Loading...

Loading...