Norlake GSF-VT Installation Manual

McDONALD'S GRILL SIDE FREEZER

Installation, Operation and

Maintenance Instructions

INSPECTION

When the equipment is received, all items should be carefully checked against the bill of lading to

insure all crates and cartons have been received. All units should be inspected for concealed

damage by uncrating the units immediately. If any damage is found, it should be reported to the

carrier at once, and a claim should be filed with the carrier. This equipment has been inspected and

tested in the Nor-Lake Manufacturing Facility and has been crated in accordance with

transportation rules and guidelines. Manufacturer is not responsible for freight loss or damage.

Note: The freezer has been shipped with casters attached. The top of the crate should be used as

a ramp to roll the cabinet from the shipping pallet. CAUTION! Use two or more people when rolling

the cabinet down the ramp, as the unit is top heavy.

INSTALLATION

GENERAL

IMPORTANT! To avoid breakage of copper tubing during shipment, the suspension springs on the

condensing unit compressor have been tightened. Before operation, the four top mounting nuts

securing the compressor need to be loosened to allow the

compressor to float freely. This can be accomplished by using

a box end wrench, crescent wrench, vise grips, etc. A label

has been placed on the facade of the cabinet as a reminder

and should be removed after this operation is complete.

LOCATION

The refrigeration system located at the top of the cabinet

requires free air access for proper operation. Allow a

minimum four-inch clearance on the top, rear, and sides of

the cabinet facade. Metal bumpers have been installed on the

sides of the cabinet to help guide it into a confined space and

protect the hinge covers and thumb screws from being

damaged. See the picture showing the bumpers. The cabinet

should also be leveled when it is placed in its permanent

location. Refer to the table below for the physical

specifications of the unit.

Unit Exterior Dimensions Refrigerant

GSF-VT 31-5/8" x 33-7/8" x 80-1/2" See Serial Tag

Model W x D x H (w/casters) Type/Amount

© 2006 Nor-Lake 11/06 115624

ELECTRICAL

Check the proposed outlet to be used to insure that the voltage, phase, and current carrying

capacity of the circuit from the electrical panel correspond to the requirements of the cabinet.

NEVER use an extension cord to wire any unit. All inter-wiring between the electrical panel and the

unit must be done in accordance with the National Electric Code and all state and local codes.

Refer to the Serial Tag for all pertinent electrical information.

Observe all Warning Labels. Disconnect power supply to eliminate injury from electrical

shock or moving parts when servicing equipment.

Unit Type of

GSF-VT Cord with NEMA 5-20P plug See Serial Tag

Model Connection Voltage/Hz/Ph

OPERATION

GENERAL

The Grill Side Freezer employs a cold wall evaporator located inside the cabinet as the heatremoving source. During the refrigeration process, heat is removed through the evaporator tubing

and transferred to the condensing unit on top of the cabinet, where it is expelled to the surrounding

outside air. It is extremely important to allow a four (4) inch clearance on the top, rear, and sides of

the unit for the refrigeration process to function properly.

The temperature controls for the three compartments are located in the back of the cabinet. A

cover, which is labeled, must be removed to access the temperature controls. There are three

controls. When looking in through the access opening, the control on the left is for the top

compartment, the center control for the center compartment, and the right control for the bottom

compartment. The controls monitor the temperatures of each compartment. If one of the

compartments becomes too warm, the control will activate the refrigeration cycle, which will cool all

three compartments. Any one of the controls can start the refrigeration cycle, however, the

compartments are not individually refrigerated.

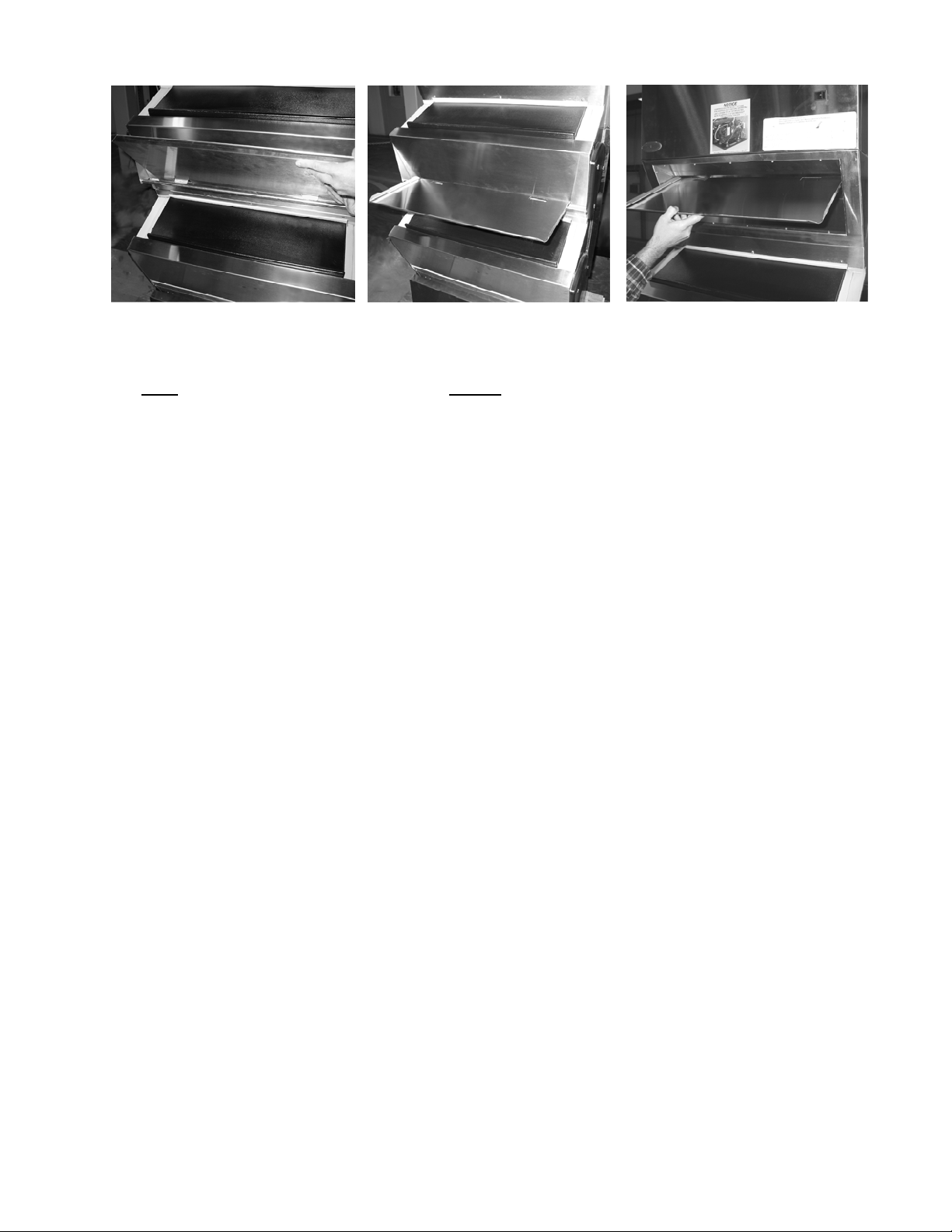

The top two refrigerated compartments can be accessed from the top by sliding up the black

covers. The front doors of the compartments can also be opened by grasping the top edge, lifting

up, and allowing the door to set down by pivoting along its bottom edge. Opening the door in this

fashion will allow for easy loading. See the pictures above.

2

The Grill Side Freezer is furnished with a removable utility shelf. The utility shelf consists of a 1/2"

diameter stainless steel bar running along the front of the top refrigerated compartment and a

stainless steel shelf that has two rectangular openings in it. The openings in the shelf are close to

back edge and have shelf stops on the bottom side. To install the shelf, hold the shelf topside

the

up by the front of the shelf. Tilt the shelf up and insert the back edge of the shelf over the top of the

bar so the lip of the shelf is under the door of the compartment, and the shelf stops are behind the

bar. Let the front of the shelf down to rest in its horizontal position. To remove, lift up the front of the

shelf and pull out from behind the bar. The utility shelf can be stored in the top non-refrigerated

compartment, using the provided brackets, when not in use. See pictures above.

The rocker switch located on the facade of the GFS-VT-601 model is the cabinet on/off switch. The

GSF-VT-603 model has three additional on/off rocker switches located on the facade. Each switch

is dedicated to one of the freezer compartments to allow for individual compartment defrost.

In

order to prevent frost build up, the product should be removed nightly,

allowing the unit, or individual compartment to be turned off and wiped down.

SOLAR THERMOMETER

Three digital temperature displays are located on the front of the cabinet to indicate the temperature

of the product inside the refrigerated compartments. The order of the displays corresponds to the

order of the compartments respectively.

The thermometer is light powered and requires just eight LUX to operate. There are no batteries to

run down or change. When first exposed to 8+ LUX the display will read -188°E for 5 seconds. This

is a self-test to be sure all LCD segments are operational. The unit may come with a protective

plastic film over the display. Remove the film to allow maximum light and readability.

The unit can be field calibrated as follows:

1. Make a mixture of crushed ice and water (slush), which will be 32°F (0°C) and place the 1/4" x

2" sensor in the slush for at least one minute.

2. Remove the thermometer from the panel and find the calibration adjustment screw on the

back of the case just to the right of where the sensor wire attaches. The screw will have some

"glyptol" sealant to prevent unwanted shifting of calibration during shipping, just turn the screw

and it will break the seal.

3. Turn the calibration screw clockwise to lower the reading and counter clockwise to increase

the reading. Note: There is a 10 second delay between readings so be sure that the unit has

settled on the 32°F reading. It may take a couple of tries turning up and down to get it right.

NSF requires a+/- 2°F accuracy.

4. Replace the unit to its original location, using the gasket (if supplied).

5. Calibration adjustment is +8°F and -8°F

Other display codes: Over range (above 160°F) = HH

3

Under range (below -40°F) = LL

Sensor short or break = Er°F

Replacement of digital display thermometer and its probe:

1. Disconnect the Grill Side Freezer from its power source.

2. If needed, move the unit to a location so that the back can be removed and the wire mesh

cover on top can be flipped open.

3. Looking down from the top of the freezer, cut the white probe wire close to the facade for the

corresponding digital thermometer that is going to be replaced. Leave the wire hang.

4. Take out the two screws holding the thermometer to the front of the facade and remove the

thermometer.

5. Retrieve the new digital display thermometer. Push the probe and wire through the hole in

the facade and attach the display to the facade with the two screws.

6. From the top of the unit, firmly attach the wire from the old probe that was cut in step 2, to the

new probe. Tying and/or taping the old wire to the new probe can accomplish this.

7. Move to the corresponding refrigerated compartment for the thermometer that is being

replaced. Find the probe hanging behind a protection plate in the back right corner of the

compartment. The silicone filling the hole around the probe wire in the back wall will have to

be removed. Removing the silicone will have to be done from inside the compartment and

from the back of the unit. The wire ties in the back of the unit will also have to be removed.

8. After the silicone is removed so the probe wire moves freely, carefully pull on the old probe

wire until the new probe comes through the hole in the cabinet.

9. Untie and/or remove the tape attaching the old probe wire to the new probe. Hang the new

probe behind the protection plate. Discard the old probe.

10. Silicone the hole shut using a NSF approved silicone such as DOW 732. Install new cable

ties.

11. Flip the wire mesh cover to its original position and reattach the back to the freezer.

Reconnect the power.

GENERAL MAINTENANCE

PERIODIC CLEANING

Beginning with the initial installation, the interior surfaces of the cabinet should be periodically

wiped down with a solution of warm water and baking soda. This solution will remove any odors

from spillage that has occurred. The exterior of the cabinet should also be cleaned frequently.

Cleaning of the hinge safety cover area and the condenser is required on a monthly basis. Cleaning

the condenser will aid the heat transfer characteristics of the refrigeration system and increase its

efficiency. Failure to keep the condenser coil clean and clear of obstructions could result in

temperature loss and damage to the compressor. Detailed steps of the cleaning procedures are

listed below.

All moving parts have been permanently lubricated and will generally require no maintenance.

PRECAUTION

Hazard Communication Standard (HCS) - The procedure(s) in this manual include the use of

chemical products. These chemical products will be followed by the abbreviation (HCS). See

Hazard Communication Standard (HCS) manual for the appropriate Material Safety Data Sheet(s).

Defrosting/Cleaning the Grill Side Freezer

(This unit should be defrosted nightly or every twenty-four hours.)

4

Loading...

Loading...