Norlake Fineline Specifications

NOR-LAKE, INCORPORATED 800-955-5253

Nor-Lake, Inc.

Registered to ISO 9001:2008

File No. 10001816

727 Second Street 715-386-2323

P.O. Box 248 800-388-5253 Service

Hudson, Wisconsin 54016 866-961-5253 Parts

715-386-6149 FAX

www.norlake.com

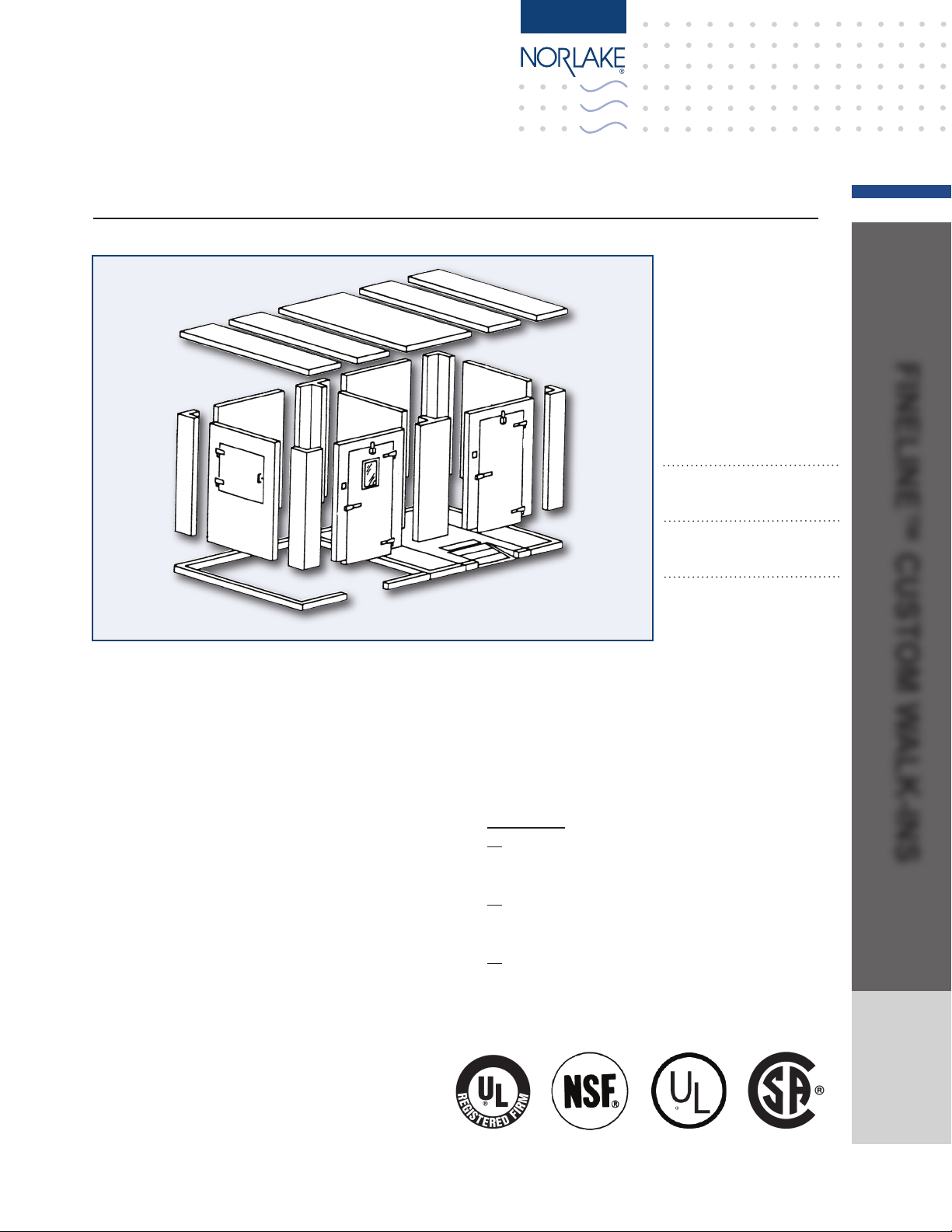

FINELINE™ CUSTOM WALK-INS

Condensed speCifiCations for arChiteCts and Consultants

DesigneD

to Your

s

pecifications!

PROJECT:

ITEM NUMBER:

FINELINE™ CUSTOM WALK-INS

STANDARD FEATURES

Coolers, freezers and combination cooler/freezers

■

■

Modular panel construction for easy installation, expansion and

relocation

26 gauge corrosion resistant stucco embossed coated steel

■

.100 smooth aluminum interior floor (on models with floor)

■

■

Floorless models provided with NSF approved vinyl sealers, foamed-in-

place screeds or female bottom rails

Full 4” or 5” thick panels foamed-in-place with HFC-134a

■

polyurethane insulation which is CFC & HCFC Free.

Zero Ozone Depletion

Doors equipped with heavy duty polished chrome hardware

■

Heavy duty, extruded, anodized aluminum load bearing door frame jamb

■

■

Deadbolt locking handle with independent key/padlock feature and

inside safety release

Vapor proof light fixture

■

Magnetic door gaskets and spring actuated door closer

■

Heated pressure relief port on all freezers

■

Indoor and outdoor roof and ceiling support systems

■

Fifteen year panel warranty

■

NSF approved

■

UL & FM flame spread 25 approved panels

■

UL and CSA electrical approved door section

■

City of New York (MEA) approved

■

City of Los Angeles approved

■

City of Houston approved

■

Oregon State approved

■

State of Wisconsin Building Product approved

■

USDA accepted

■

Factory Mutual

■

Registered by UL to ISO 9001:2008

■

MODEL NUMBER:

ACCESSORIES

Interior and exterior door kickplates

■

Cooler and freezer door viewports

■

Interior and exterior ramps

■

Bumper rails, trim strips and closure panels

■

Various security alarm systems

■

Extra lights and special switches

■

Shelving (free-standing)

■

Special floor underlayments and topside plating

■

SPECIFICATIONS

1.0 GENERAL:

1.1 Walk-in coolers and freezers to consist of precision constructed

modular 4” or 5” thick rigid polyurethane foamed-in-place

interchangeable panels. Panels are designed for easy installation,

expansion and relocation.

1.2 Panels shall be prefabricated modular construction consisting

of 100% foamed-in-place polyurethane insulation, bonded by an

adhesive to the interior and the exterior metal pan skins and heat

cured for life long stability.

1.3 Each wall panel skin is to be formed using a double 90° bend

on each edge to add strength and rigidity. Panels are to be in 6 inch

increments, with a minimum width of 12 inches.

OPTIONS

Selection of interior and exterior surfaces and finishes

■

Various door styles and sizes

■

■

Wide range of computer sized and balanced refrigeration

systems

Indoor and outdoor roof and ceiling support systems

■

SPECIFICATION

GUIDE

1.4 All panels are to bear the UL, FM and NSF label. The panels

shall incorporate cam lock type fasteners with reverse wing structural

support as joining devices for the adjacent tongue and groove panels.

Each device is to consist of a cam action locking arm and a steel rod in

adjoining panel so that by rotating the locking arm, the hook engages

over the rod and the cam action draws the panel together. The resulting

panel joints shall be sealed by a foamed-in-place, continuous one

piece gasket.

1.5 Panel joints are to be precisely formed male and female tongue and

groove shapes fabricated to force the male edge to contact the female

edge, providing additional seal. The panel joint shall have a gasket

which provides a positive seal that meets NSF standards. Gasket shall

be “locked” to the skins and run in a continuous piece, completely around

the panel with only one break to provide the optimal seal.

2.0 INSULATION

2.1 Insulation shall be a full 4 inches or 5 inches thick, UL and FM

Class 1 rigid foamed-in-place HFC-134a polyurethane with a minimum

2.0 lbs/cubic foot density. Foam polyurethane shall be injected into

the panels by means of a high output, high impingement, froth mixer.

Poured-in-place foam injection is not acceptable.

2.2 Environmentally friendly HFC-134A polyurethane foam insulation

provides a minimum “R” value of 9 per inch of thickness at a very low

mean core temperature.

2.3 Insulation shall be 95% closed cell structure. Flame spread rating

according to ASTM E-84/UL 723 shall be 25 or less.

2.4 The use of R-12 and/or R-22 as a blowing agent is specifically

prohibited.

3.0 FLOOR STYLES:

3.1 Less floor 4” wall walk-ins shall be supplied with PVC extruded floor

sealers with semi-flexible edges, which seal to floor without the use of

exposed fasteners. Sealer shall encase the wall panel on both interior

and exterior surfaces with a flexible rubber collar a minimum of 3” high

from finished building floor. Sealer shall meet NSF requirements for floor

cove molding. Additional less floor options include female bottom rail

walls for 4” and 5” thick walk-ins and various height foam sealers for 4”

thick walk-ins. Consult factory for detailed specifications.

3.2 With floor walk-ins shall be a full 4 inches thick with one piece

foamed-in-place edge caps. Edge caps include metal formed adhesion

edges which result in the edge caps being a foamed integrated member

of the floor panels. Glued-in-place edge caps are not acceptable. Floor

panels shall be designed to withstand uniformly distributed loads of 800

pounds per square foot. The joint between the floor and wall shall form

a NSF approved 45° angle to allow for easy cleaning.

4.0 CEILING PANELS:

4.1 Ceiling panels shall be a full 4 inches or 5 inches thick with one piece

foamed-in-place edge caps. Edge caps include metal formed adhesion

edges which result in the edge caps being a foamed integrated member

of the ceiling panels. Glued-in-place edge caps are not acceptable.

4.2 Metal face skins are to incorporate seams using a double 90° bend

at a maximum width of two feet for additional strength. The joint between

the ceiling and wall shall form a 45° angle to allow for easy cleaning.

5.0 FINISHES:

5.1 The interior and exterior walls and interior ceiling shall be supplied

with 26 gauge corrosion resistant stucco embossed coated steel. The

interior floor surface (when applicable) shall be .100 smooth aluminum.

Other finisheds are available.

6.0 DOOR CONSTRUCTION:

6.1 Entrance door shall be in fitting, flush design. The door section shall

provide a full 4 inches or 5 inches of polyurethane HFC-134a insulation,

construction and finish shall be the same as the adjoining wall panels.

6.2 The door shall be 4 inches thick, constructed to incorporate heavy

duty, molded ABS breaker strip, which is permanently foamed-in-place.

Bottom of door shall seal with an adjustable double sweep gasket,

uniquely designed to provide complete seal between door, threshold,

and door jamb.

6.3 Door jamb to be a fully coved, extruded, welded, structural anodized

aluminum, rigid frame design for easy cleaning and maintenance.

6.4 Threshold plate provided shall be constructed of extruded aluminum

for bearing strength. Cooler/freezer shall have an anti-sweat heater wire

around the entire perimeter of the door opening and under threshold.

6.5 The heater wire (standard in both coolers and freezers) shall provide

enough heat to prevent condensation. All conduit for the inner-wiring

of the door panel shall be totally concealed in the polyurethane foam

panel, exposed conduit is not acceptable.

6.6 Door section to be field wired to surface mounted junction box on the

interior door panel. The door size, location and swing to be as indicated

in Specifications Drawings.

6.7 Door hardware shall be highly polished chromium plated steel.

Hardware shall include a spring actuated door closer, field adjustable

cam lift hinges, & deadbolt locking handle with independent key/padlock

feature and inside safety release. All hardware shall be attached to extra

large 1/2 inch thick, nonconducting synthetic tapping plates.

6.8 Digital thermometer calibrated to indicate interior walk-in temperature

shall be provided with each entrance door.

6.9 Remote incandescent vapor proof gasketed UL listed light fixture,

made of cast aluminum with plastic coated glass globe. Mounted. at the

interior handle side of the door section. Locate light switch with pilot light

adjacent to door, on exterior handle side of door section, with all inner

wiring in rigid conduit concealed inside the door section and terminated

at a surface mounted junction box on the interior door frame. Fixture

shall operate on 115 VAC.

7.0 INSTALLATION AND MAINTENANCE:

7.1 Included with each walk-in shipment is a complete set of installation

instructions covering all phases of panel erection, accessories, and

maintenance procedures.

8.0 APPROVALS:

8.1 Walk-in construction is approved by NSF International and shall

have the NSF seal on the door section.

8.2 Walk-in panels shall have a UL & FM flame spread rating of 25.

8.3 The door section shall be UL and CSA approved as an electrically

approved assembly.

8.4 City of Los Angeles approved, City of Houston approved, Oregon State

approved, State of Wisconsin Building Product approved, USDA accepted,

Factory Mutual Specification tested.

9.0 WARRANTIES:

9.1 Manufacturer shall provide a written warranty to the owner stating

the product is free from defects or workmanship under normal use and

service. Warranty shall become effective following the acceptance date

and cover the insulated panels for a period of fifteen years and parts for

a period of 18 months.

10.0 QUALITY ASSURANCE:

10.1 To insure the finest quality in material and workmanship the above

specifications shall be held in full compliance. Please specify the walk-in

cooler or freezer is to be as manufactured by Nor-Lake, Incorporated,

Hudson, Wisconsin.

10.2 Contact Nor-Lake, Incorporated for a copy of the most detailed

Specification Manual available in the Foodservice Industry.

Revision Date: 1/10

© 2010 NOR-LAKE, INC.

Printed in the U.S.A.

Part Number: 090773

11.0 SITE CONDITIONS:

11.1: To assure proper operation, site conditions should be controlled.

The walk-in product should be in a well ventilated location. Indoor

ambient conditions should be controlled, relative humidity between

30%-60% and maintaining a dew point of 50ºF (or less).

Loading...

Loading...