Norlake CPX150DC-A Installation Manual

REFRIGERATION SYSTEMS

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

TABLE OF CONTENTS

INSTALLATION 2 - 7

Wall Mounted Systems 2 - 3

General Instructions 2 - 3

Freezer Models 100 and 150 or Cooler Model 075 3

Ceiling Mounted Systems 4 - 6

General Instructions 4 - 5

Outdoor Systems Utilizing a Membrane Roof 5 - 6

Remote Systems with Electric Vaporizer 6

Instructions for Pre-Charged Lines 7

OPERATION 8 - 10

Standard Temperature (Cooler) Systems 8

Low Temperature (Freezer) Systems 8 - 10

Defrost __________________________________________8

Drain Tube Heater _________________________________10

Extra Low Temperature (Freezer) Systems 10

Operation

Refrigeration Control __________________________________10

MAINTENANCE

General

Service and Analysis Guide 12

ELECTRICAL DATA

Electrical and Refrigerant information can be found on the

Serial Tag.

8 – 9

11 - 12

11

05/12 Rev. D 040086

INSTALLATION

WALL MOUNTED SYSTEMS

General Installation Instructions

Note: If the system to be wall mounted is a freezer model 100 or 150 or cooler model 075, please see the

next section with special instructions on mounting these units.

Carefully raise the entire refrigeration system and insert the projecting sleeve of the evaporator section into

the opening of the walk-in wall. While supporting the system, lock it into position by turning the locks exactly

as you did when locking the walk-in sections together. Make sure that the locks are positively engaged and

insert the plug buttons into the lock access holes when finished. Refer to Figure 1.

Note: Some motor compressors are openly spring mounted to absorb vibration. Be sure that these bolts are

loosened to permit the compressor to float freely on the springs. A reminder label is applied to systems where

this procedure applies.

Some systems require a permanent connection to an electrical service and a connection at the junction box

located within the condensing unit housing. Refer to the serial tag for all pertinent electrical data. These

systems must be connected to a power supply disconnect switch and wired according to local and national

electric codes.

Wall Mounted Refrigeration System

Figure 1

2 05/12 Rev. D 040086

No plumbing drain is required, under normal conditions, for indoor installations. A built-in hot gas vaporizer

dissipates the condensate moisture automatically. In outdoor installations, the condensate should be plumbed

to the nearest drain. Check local building codes. Outside drain lines must also be wrapped with a suitable

heater wire if they are ever subjected to below freezing temperatures. Outdoor installations also require the

attachment of the rain hood that will divert rainfall from the upper surface of the evaporator housing. See

Figure 1 for an illustration.

Be sure to allow for sufficient airflow around the condenser. A minimum clearance of two feet is required for

proper unit operation. If multiple units are located in the same area, be sure they do not exhaust hot air flows

into one another.

Please see the section “Instructions for Pre-Charged Lines” if the installation of this system involves the use

of pre-charged lines to connect the evaporator and condenser secti ons.

Freezer Models 100 and 150 or Cooler Model 075

1. After uncrating, before attempting to attach the refrigeration system to the walk-in, a substantial

temporary support should be built. The support should be approximately 28 inches high and placed

directly below the wall opening of the walk-in.

Note: Due to the weight of these systems it is highly recommended that proper lifting equipment, such as

a fork truck, be utilized during installation.

2. Lift the refrigeration system onto the temporary support. Determine whether the coil section sleeve is

positioned properly so that it can be inserted into the opening without being bent or damaged. Shim the

system appropriately so that this can be accomplished.

3. Carefully slide the entire system so that the coil section sleeve enters the opening without disturbing the

temporary support below the refrigeration system. Continue until the gasket around the coil section

contacts and seals around the entire perimeter of the coil section. Shim the system and adjust it

accordingly so that the gasket seal will be uniform on all four sides.

4. Using the section-latching wrench provided for the erection of the walk-in, insert the wrench into the latch

access holes of the coil section. Turn each of the locks clockwise until the latches engage the strikes in

the walk-in. Turn the lock until a full stop is encountered. DO NOT REMOVE THE TEMPORARY

SUPPORT!

5. Remove the louver assembly and drill four 9/16”

diameter holes through the two upright angles of the

condensing unit section. Drill completely through the

walk-in wall and insert the 1/2" threaded nylon rods.

Secure with the flat washers and nuts provided. Refer

to Figure 2.

6. With the leveling screws threaded completely into the

leg support, insert the leg support into the leg retainers

at the outer corners of the condensing unit section.

Unscrew the leg leveling screws until they contact the

floor or other supporting surface. Note: If the

supporting surface is extremely uneven, suitable

shimming material must be provided under one or both

of the leg supports.

7. Attach the diagonal leg support braces using the

threaded fasteners provided. Make the final

adjustments to the leg leveling screws so that they

serve as supporting devices to the outer edge of the

refrigeration system.

8. Insert plug buttons into each of the latch access holes.

Figure 2

9. Remove the temporary support assembly that was provided in Step 1.

3

05/12 Rev. D 040086

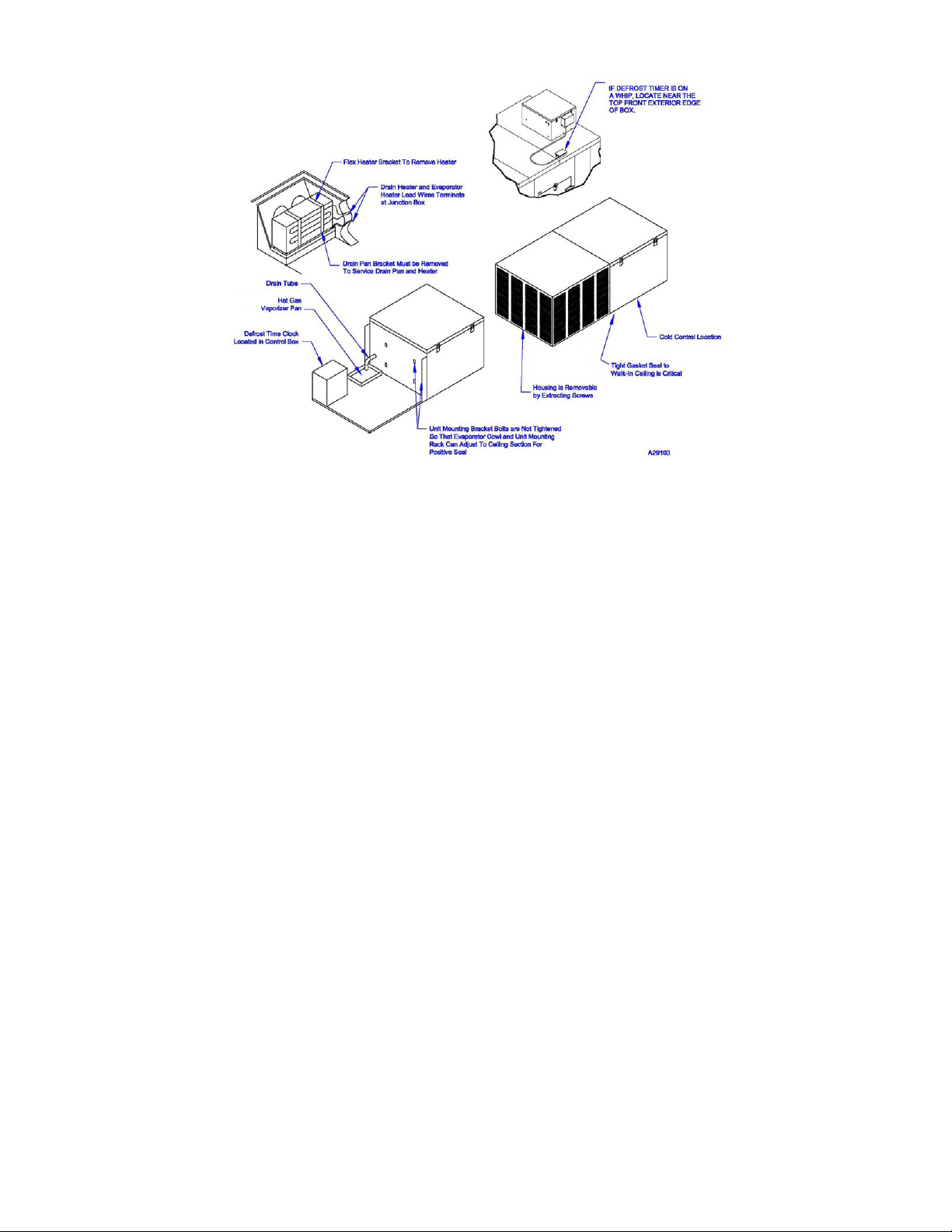

CEILING MOUNTED SYSTEMS

General Installation Instructions

This section has the general instructions for installing the ceiling mounted Refrigeration System. Before

proceeding, please also see the following sections on mounting “Outdoor Systems Utilizing a Membrane

Roofing Material”, or “Remote Systems with Curb and Electric Vaporizer”, if applicable.

Note: Due to the weight of these systems, it is highly recommended that proper lifting equipment, such as a

fork truck, be utilized during installation. Also, be sure to allow for sufficient airflow around the condenser. A

minimum clearance of two feet is required for proper unit operation. If multiple units are located in the same

area, be sure they do not exhaust hot air flows into one another.

1. Mount eyebolts to the base of the refrigeration system through the holes that were used to lag the base to

the shipping crate. Note: The holes can be drilled out to a larger diameter, if required, for eyebolts that

are available.

2. Insert chains or cables from an overhead lifting source through the eyebolts and carefully raise the entire

refrigeration system to the top of the walk-in.

3. Position the unit cooler section of the refrigeration system over the hole in the walk-in ceiling section.

4. Align the tabs on the side of the unit cooler section with the predrilled holes in the ceiling section. Before

proceeding to the next step, the cowl cover should be removed. Look inside the unit cooler section and be

sure the air divider in the ceiling section lines up with the black gasket divider in the unit cooler. Simply

bending the ceiling section divider slightly forward or backward may be required. This will prevent any

short cycling of discharge and return air.

5. Fasten the unit cooler section down to the ceiling using the provided drive screws, which can be found in

the small cloth bag. CAUTION! This must be done to prevent the entire refrigeration system from

moving during operation.

Note: On smaller refrigeration systems, you may elect to install the system on the ceiling section while the

section is still on the floor. CAUTION! Make sure to fasten down the system to the ceiling panel. The

ceiling section and the refrigeration system may then be erected together in the normal sequence of assembly

as shown in the walk-in installation instructions. This method is not practical and should not be used with

larger systems of 1 horsepower or above, such as a model CPF100 or CPF150.

4

05/12 Rev. D 040086

Loading...

Loading...