Norlake BC734870-X-EC Installation Manual

BLAST CHILLER

Installation Instructions

BC734870-X-EC

Nor-Lake, Incorporated

727 Second Street

Hudson, WI 54016

800-955-5253

4/11 Rev. A 143463

2

TABLE OF CONTENTS

INTRODUCTION………………...………………………………………………………………….4

ABOUT THIS MANUAL…………………………………………………………………………….5

WARNING LABELS AND SAFETY INSTRUCTIONS…………………...……………………….6

UNDERSTAND SIGNAL WORDS……………………………………….…………………..….6

AVOID HIGH VOLTAGE ELECTRICAL SHOCK……………………………...………..………………….7

PREPARE FOR EMERGENCIES……………….……………………………………………….7

FOLLOW SAFETY INSTRUCTIONS.………….………………………………………………. 8

OBSERVE SAFETY SIGNS…………………………………………………..……………………………... 8

ELECTRICAL CONNECTIONS.

……………….…………………………………………….….8

INSTALLATION............................................................................................................................…. 9

PACKING LIST..............................................................................................................................…10

VAN SHIPMENT.........................................................................................................................…...11

FREIGHT CLAIMS................................................................................................................…..…..12

PRE-ASSEMBLY PROCEDURES……………………………..…………………………………..13

HANDLING AND SET-UP PRECAUTIONS……………….…………….…………………….13

STORAGE…………………………………………….………...………………………… 13

SITE CHECKLIST .......................................................................................................................… 14

BLAST CHILLER BOX INSTALLATION..............................................................................…… 15

WALK-INS WITHOUT FLOORS…………………………….…………………………..…...15

SEAL JUNCTURE OF WALLS…………………………….……………………………..…..16

INSTALL INSULATED WALL PANELS…..…………………….………………………...16-17

INSTALL EVAPORATOR AND FAN ASSEMBLYS……...…………..……………………...17-19

INSTALL CEILING PANELS.......................................................................................................... 20

INSTALLATION OF DOOR PANEL………….................…………………………………….21-22

INSTALL INTERIOR TRIM……….……………..………………………………………………...22

INSTALL EXTERIOR TRIMS..….…………………….……………………………………….25-26

MOUNT CONTROL PANEL….……………………………..……………………………………..23

ROUTE TEMPERATURE SENSOR & MOUNT CONTROL PANEL...…………………...……..23

CONTROL WIRING………………………………………………………..…………………...24-25

CHECK DRAIN FOR LEAKS….………………………..………………………………………….26

CHECK DOOR SWING…….……………………..………………………………………………...26

DELIVERY INSPECTION…………………………...…………. ............................................……27

INSTALLATION DATA........................................................................................................………27

BLAST CHILLER CONTROL OPERATION & PROGRAMING................................………..28-39

FOOD AND PANS INTRUCTIONS……………………………………..……………………...40-41

BLAST CHILLER CHILLING RATES…………………….…………..…………………………..41

START UP & OPERATION CHECK…………………………………………...………………….42

PERFORM THE FINAL CHECKLIST………………...…………………………………………..42

CLEANING ..................................................................................................................................…. 43

FINAL INSTALLATION DATA SHEETS……………………………………………………...44-46

WIRING DIAGRAM…………………………………………………………………………..…….47

3

INTRODUCTION

THANK YOU for purchasing a Nor-Lake Blast Chiller. The Nor-Lake Blast Chiller is designed

for accurate and rapid field assembly.

NOTICE

Read this manual carefully before you begin

Blast Chiller installation or operation. Failure to

do so could result in personal injury or damage

to your Blast Chiller.

NOTICE

This manual is a necessary and permanent part

of your Blast Chiller. Always keep this manual

accessible for installation and operation

procedures.

This manual cannot cover every installation, use or operation situation. If you need additional

information, call or write our customer service department for assistance.

Nor-Lake, Incorporated

727 Second Street

Hudson, WI 54016

Phone: 1-800-955-5253

If this manual or any of the warning labels on your Nor-Lake Blast Chiller are marred or destroyed,

contact Nor-Lake to replace them.

Locate the serial number plate on the Blast Chiller. Write the 10-digit serial number below. Your

Nor-Lake dealer needs this number when you order parts.

Serial Number ________________________

"COPYRIGHT © 1994 BY: STANDEX INTERNATIONAL CORPORATION"

4

ABOUT THIS MANUAL

Please read this entire installation manual before you install your Nor-Lake Blast Chiller. It

provides information on installation and operation of the Blast Chiller. It is very important

that you complete each step of installation in the order that the steps appear in the installation

sections of this manual. Otherwise, you may find yourself unnecessarily disassembling and

re-assembling parts.

The information and graphics in this manual are common to installation of all Nor-Lake

Blast Chillers. A customized print is provided specific to your order. Your print provides

information specific to your design and installation. This manual indicates when you should

refer to your site-specific drawings.

BLAST CHILLER MODELS

-All Blast Chiller electrical connections should be made per the wiring diagrams found in this

manual for the electrical box and control panel.

-All Blast Chiller refrigeration connections should be made per the attached refrigeration

diagrams and charts found in this manual according to the correct model. Refer to the correct

air or water-cooled schematic per the condensing unit markings and labels.

-All Blast Chillers accept the same size rack.

4/11 Rev. A 143463

WARNING LABELS AND SAFETY INSTRUCTIONS

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on your

equipment or in this manual, be alert to the potential for personal

injury or damage to your Nor-Lake Blast Chiller.

Be sure you understand all safety messages and always follow

recommended precautions and safe operating practices.

UNDERSTAND SIGNAL WORDS

Important safety information is presented in this section and throughout the manual.

These signal words are used in the warnings and safety messages.

DANGER

Severe injury or death will occur if you ignore

the message.

WARNING

Severe injury or death can occur if you ignore

the message.

CAUTION

Minor injury or damage to your Nor-Lake Blast

Chiller can occur if you ignore the message.

CAUTION also calls attention to safety

messages in this manual.

NOTICE

This is important installation, operation, or

maintenance information that you should pay

special attention to. If you ignore this

information, you may damage your Nor-Lake

Blast Chiller.

6

AVOID INJURY FROM HIGH VOLTAGE ELECTRICAL SHOCK

Disconnect power before cleaning or servicing the

Blast Chiller. Do not spray with water or steam.

Use a damp cloth to remove dirt.

Be sure Blast Chiller is grounded. Check ground

connection. Do not use if unit is not grounded.

PREPARE FOR EMERGENCIES

Be prepared if a fire starts. Keep a first aid kit

and fire extinguisher handy.

Keep emergency numbers for doctors,

ambulance service, hospital and fire

department near your telephone.

WARNING TO EMPLOYERS

Never allow small children inside or around your

Blast Chiller. They can become trapped inside

and be injured or killed.

7

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and safety signs on your equipment. Keep

safety signs in good condition. Replace any missing or damaged safety signs.

Learn how to operate the equipment and how to use controls properly. Do not let anyone operate

without instruction and proper training.

NOTICE TO EMPLOYERS

It is the employers’ responsibility to make sure all persons around this equipment know

where the inside latch is and how it works.

Keep your equipment in proper working condition. Unauthorized modifications to the

equipment may impair the functions and/or safety and reduce equipment life.

OBSERVE SAFETY SIGNS

Your Nor-Lake Blast Chiller requires two electrical supplies: an electrical supply for the blast

chiller box, fan, controls, etc., and an electrical supply for the condensing unit.

ELECTRICAL CONNECTIONS

The wiring will be performed by a qualified and certified electrician.

Improper or faulty hook-up of electrical components of the walk-in can result in severe injury or

death.

Installation of the refrigeration and electrical components of the walk-in must be performed only

by a refrigeration mechanic or licensed electrician.

NOTICE

Electrical connections must be done in accordance with

all applicable local, regional, or national standards as

well as the National Electrical Code.

NOTICE

Installation and service of blast chiller must be

preformed by licensed refrigeration mechanic

and/or licensed electrician.

8

INSTALLATION

PRE-INSTALLATION

Read and comply with the following information:

-Packing List Page 10

-Van Shipment (if applicable) Page 11

-Freight Claims Page 12

-Site Checklist Page 14

INSTALLATION

Special equipment needed for installation includes:

-Fork lift or hoist

Your envelope contains:

-Your Nor-Lake Blast Chiller Installation and Operations Manual

-Customized drawings and diagrams for your specific order:

Installation diagram

Panel numbering diagram

Wiring diagram*

*2 identical wiring diagrams are provided:

One is included in the envelope for use at the installation site.

One is a permanent part of your manual.

NOTICE

Nor-Lake recommends you practice safe lifting

and safe moving techniques.

AFTER INSTALLATION

Complete the Installation Data on pages 44 to 46.

Retain one copy.

Return one copy to Nor-Lake.

Leave one copy at the installation site.

9

PACKING LIST

Assure that all components on this packing list are included when unit arrives:

Quantity Description

______ Insulated Wall Panels

______ Insulated Ceiling Panels Assembly

______ Control Box

______ Top Trim Panels

______ Top Trim Panel Mounting Strips

______ Evaporator Coil Assembly

______ Evaporator Fan Assembly

______ Interior Top Trim Panels

______ Interior Side Trim Panels

______ Optional Stainless Steel Floor Pan

Box of Hardware: Screws, Bolts, Light Globe, Wall Panel, Plug Buttons, Locking

Wrench, Installation Manual

______ Blast Chiller Rack

______ Compressor/Condenser Unit

10

VAN SHIPMENT

If your Blast Chiller is shipped by van, it is not crated. Components are blanket wrapped

and secured carefully in the van. Be sure to check your packing list (page 10) to be sure

all parts are received.

If parts are missing or damaged:

-Make a notation to that effect on the driver's Bill of Lading

-Notify the van company at once

Since van shipped parts are not crated, handle and store them carefully before you begin

installation.

11

FREIGHT CLAIMS

IMPORTANT

FREIGHT CLAIMS INSPECTION:

You are responsible for all claims. It is vitally important that upon arrival, all

cartons and crates are inspected for visible damage. If at all possible, cartons and

crates should be opened immediately to check for concealed damage within. All

cartons and crates must be saved until the unit is completely removed from the carton

so concealed damaged claims can be filed.

You, as the consignee, must file freight claims with the delivering truck line. If there

is any question whatsoever regarding the condition of the equipment, this question

should be noted on the bill of lading, which you sign as a delivery receipt.

All shortages must be noted on the bill of lading as the shipment is received. If a bill

of lading is signed as complete for the delivering truck driver, there is virtually no

way to secure a claim for shortages which are found later.

Nor-Lake, Incorporated

727 Second Street

Hudson, WI 54016

Phone: 1-800-955-5253

12

PRE-ASSEMBLY PROCEDURES

HANDLING AND SET-UP PRECAUTIONS

It is the responsibility of the installer to use safe unloading, handling, and construction

practices. If you have any questions about proper installation of the unit or accessories,

contact Nor-Lake.

NOTICE

Use material handling procedures appropriate to the job you are doing. Failure to use proper

loading or handling procedures or to follow manual instructions can cause bodily injury or

damage to your Blast Chiller.

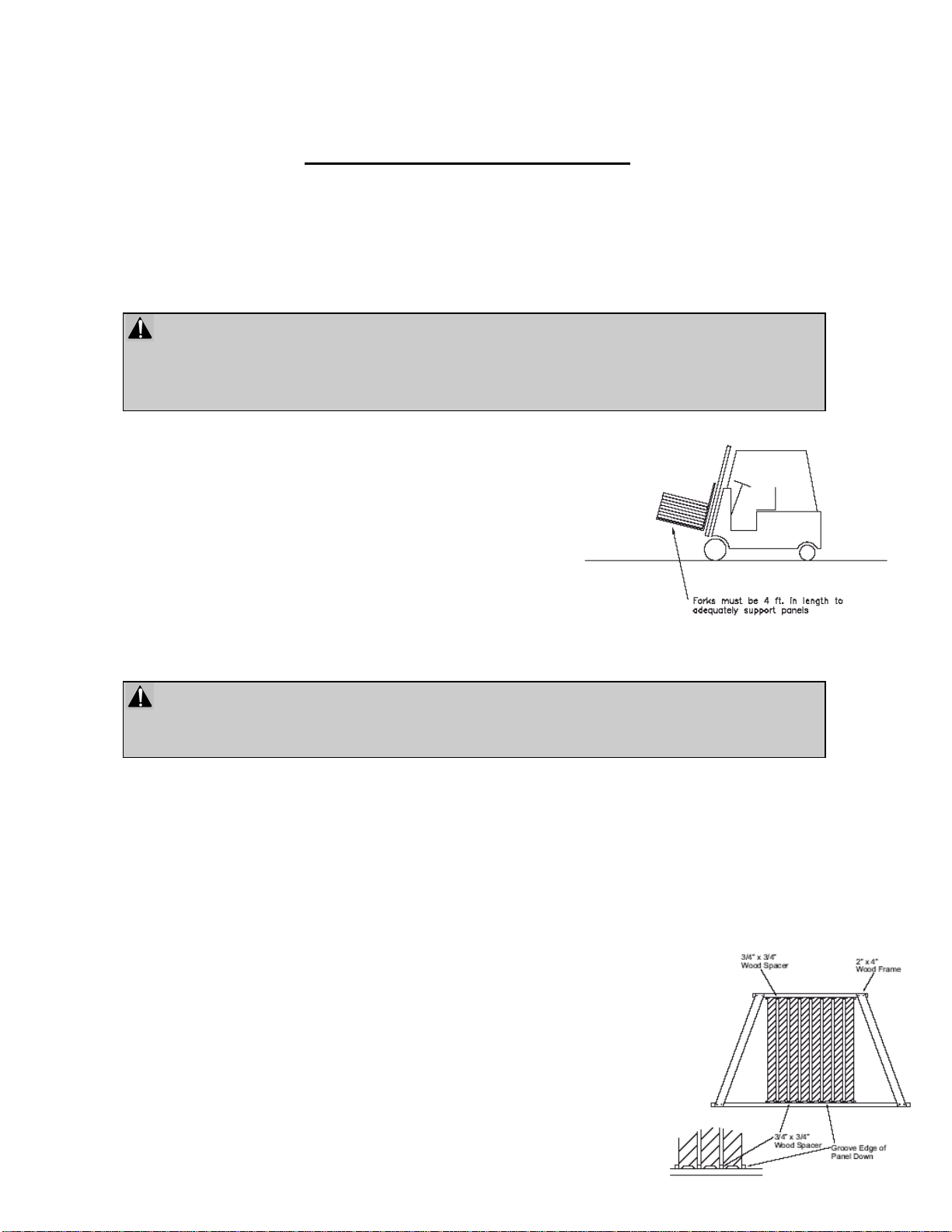

Forklifts used to handle skids or panels must have forks

at least four feet long and set far enough apart to

adequately support panels or skids (see Figure Below).

Forklifts must have the capacity to support panels

weighing two pounds per square foot each.

STORAGE

When the unit must be stored at the job site prior to set-up, it is very important that it be

stored properly.

NOTICE

The panels should be stored on a level area eliminating the risk of the panels falling and

injuring someone. The panels being stored should not be stacked over 2 skids high.

Whenever possible store the unit indoors. Panels stored indoors may be stored in their

original factory packaging. If it is necessary to store panels outdoors, stack them vertically

on skids, with spacers between the panels. This protects the panel edges and provides

proper ventilation. This method of stacking permits drain-off of moisture and guards

against rust stains.

Panels should be covered with a waterproof covering to protect them from the weather.

Nor-Lake recommends black polyethylene sheeting, which keeps

sunlight out and eliminates the "greenhouse" condition, which

occurs when clear plastic is used. In heavy traffic areas, it is

advisable to place protective rails around stacks of panels to guard

them from any possible damage

13

SITE CHECKLIST

Inspect the area where your Nor-Lake Blast Chiller will be installed.

1. Check to make sure the floor is level.

a. The entire floor under the Blast Chiller must be level, clean, and smooth.

NOTICE

The existing surface must be level before the Blast Chiller is installed. If it is not, leveling must

be performed to insure proper installation.If the floor area under the Blast Chiller is not level and

smooth, have the area grouted.

2. Check the ceiling height above the Blast Chiller area:

a. Refer to the enclosed print specific to this project.

b. The top area of the Blast Chiller must be accessible for servicing.

c. Make sure proper clearance is allowed.

3. Assure a drain is located near the Blast Chiller.

a. Make sure the drain is located relative to the enclosed Blast Chiller print.

b. Measure and locate where the drain will exit the Blast Chiller box.

4. Assure electrical supply is near the Blast Chiller.

a. Review the enclosed Blast Chiller print to determine the best location for

the (customer supplied) electrical disconnects for the two electrical

supplies required.

i. On an adjacent wall for blast chiller.

ii. At condensing unit.

b. Measure and locate where the electrical supply will be located.

c. Review the enclosed Blast Chiller prints for voltage, amperage, and phase

and location.

5. Assure adequate clearance is allowed for the door to the Blast Chiller to swing

open.

14

BLAST CHILLER BOX INSTALLATION

STEP 1

In this step, you will prepare the floor and install either the wall angles, or optional floor pan or

optional floor.

WALK-INS WITHOUT FLOORS

-Locate the Blast Chiller print sent with the unit.

-Mark the floor with the inside dimensions.

-Check the marked area for:

1. Level surface

a. Floor must be completely level around wall parameter.

b. Add grout as needed

2. Surface condition

a. Surface must be smooth.

b. Add grout as needed

3. Cleanliness

a. Sweep and clean area to assure surface is free of dirt, debris, water, oil, and

grease.

4. Adequate space.

a. Allow for insulated panel thickness if the Blast Chiller location is against a

wall or partition.

b. Measure between the inside flange and the wall to assure adequate space is

allowed.

c. Refer to the Blast Chiller print (the standard Nor-Lake panel is 4" thick)

-Correct any of the above problems with the floor BEFORE proceeding with Blast Chiller

installation.

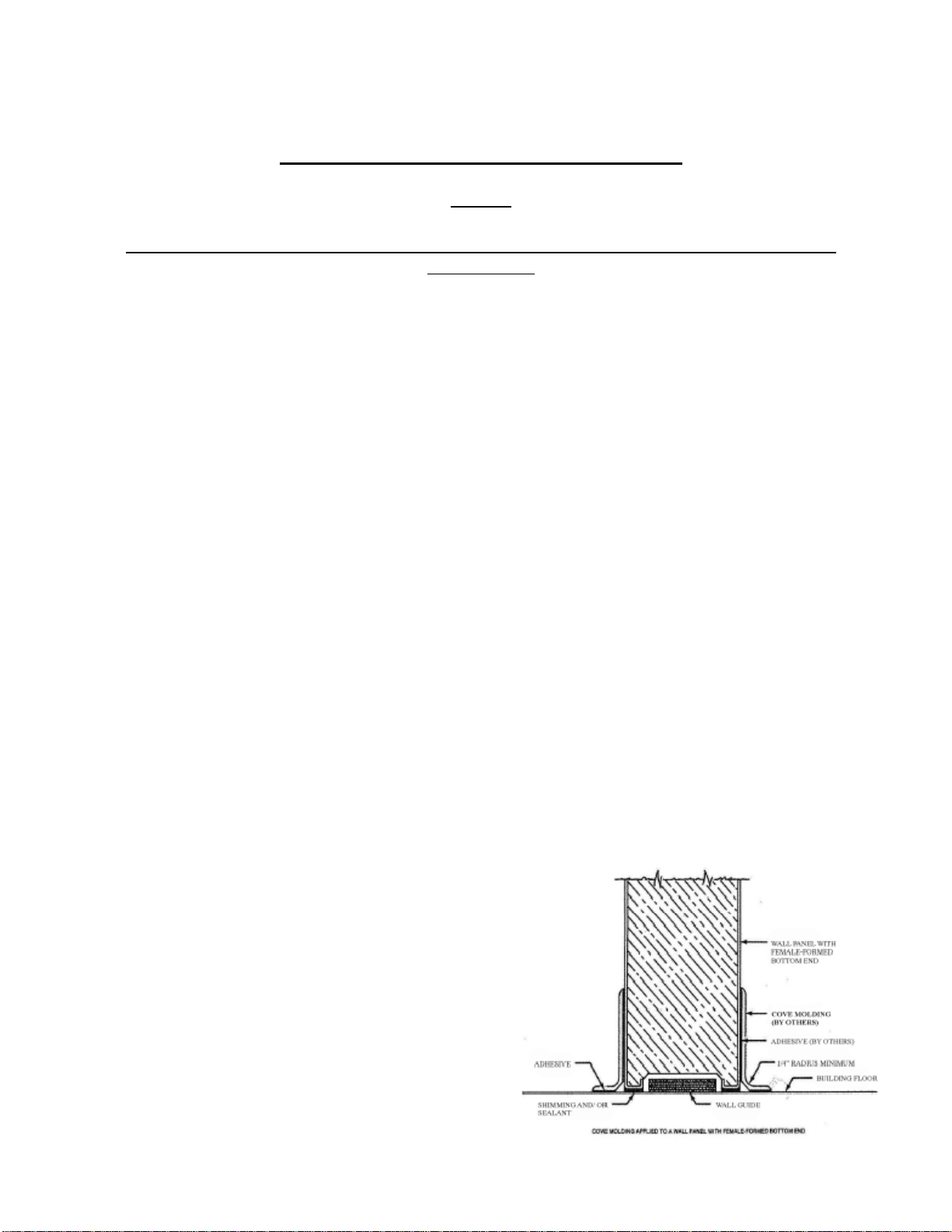

SEAL THE JUNCTURE OF WALLS TO BUILDING FLOOR

Apply a generous amount of NSF approved

sealant to achieve a vapor seal between the

bottom edge of all wall, corner, door and

partition panels and the building floor. The

sealant must be applied to both inner and outer

edges of all perimeter walls and to both edges

of partition walls where they meet the building

floor. Make certain that the sealant produces a

continuous, air-tight seal, without gaps, and

that special care is taken to seal around the

shimming material.

15

Loading...

Loading...