Norlake BCF44244, BCB44244, BC40-4, BCF93558, BC80-8 Installation Manual

...

INSTALLATION, OPERATION AND MAINTENANCE

MANUAL FOR

Blast Chillers/Freezers

1

09/12 Rev. B 143573

X

X

--IINNDDE

E

-

-

1 GENERAL INSTRUCTIONS ON DELIVERY ……………………………………3

GENERAL INSTRUCTIONS …………………………………………………… ………………3

TECHNICAL DATA ………………………………………………………………………………3

LIST OF REGULATION REFERENCES ……………………………………………… ……3

GENERAL INSTRUCTIONS …………………………………………………… ………………3

SETTING UP ………………………………………………………………………………………4

MACHINE LOADING …………………………………………………………………………………………………5

POSITION OF TRAYS ………………………………………………………………………………………………5

STORAGE TIME AND TEMPERATURE …………………………………………………………………………5

CORE PROBE ………………………………………………………………………………………………………6

2 CONTROL PANEL …………………………………………………………………7

DESCRIPTION OF CONTROLS ………………………………………………………………7

3 OPERATION ..……………………….………………………………………………10

PROGRAMS .…………………….………………………………………………………………10

MANUAL CYCLES .…………….………………………………………………………………15

STORING CYCLES …………...………………………………………………………………20

DEFROSTING ………………………….………………………………………………………21

PRINTING …………………………………….…………………………………………………21

IFR CHILLING CYCLE ………….………….………………………………………………………………………10

RECOMMENDED WORKING CYCLES ………………….………………………………………………………11

USER’S CYCLE …………………………………………….………………………………………………………11

User’s programs ..…………….………………………………………………………………………………11

Storing User’s programs ………..……………………………………………………………………………12

Delete a User’s programs ……………………………………………………………………………………13

Rename a User’s programs …....……………………………………………………………………………13

PRE-COOLING CYCLE ……………………………………………………………………………………………14

Negative freezing cycle with core probe …………………………………………………………………16

Negative freezing cycle with timer …………………………………………………………………………16

Soft positive chilling cycle with core probe ………..……………………………………………………17

Soft positive chilling cycle with timer ……………….……………………………………………………18

Hard positive chilling cycle with core probe ………….…………………………………………………18

Hard positive chilling cycle with timer ……………………………………………………………………19

POSITIVE STORE ………………………….………………………………………………………………………20

NEGATIVE STORE ………………………………………..………………………………………………………20

4 MAINTENANCE ……………………………………………………………………23

MAINTENANCE AND CLEANING ……………………………………………………………23

CLOCK SETTING ………………………………… ……………………………………………29

LANGUAGE …….……………………………………………………………………… ………29

ALARMS AND FAULT ANALYSIS …………………………………………………………30

SERVICE ……………..…………………………………………………………………………32

INPUTS/OUTPUTS ………………………….…………………………………………………37

PRINTER INSTALLATION ………………………..…………………………………………37

MAINTENANCE OF PANEL BOARD ………………………………………………………38

WIRING DIAGRAM PLATE …………………………………………………………………39

CONTROL AND SAFETY SYSTEMS ………………………………………………………39

DISPOSAL ………………………………………………………………………………………39

DOOR REVERSAL ……………………………………………………………………………40

REFRIGERANT MATERIAL SAFETY DATA SHEE T………………………………………4 0

DIMENSIONS …………………………………………………………………………………42

CLEANING THE

CLEANING THE AIR CONDENSER ……………………………………………………………………………24

STAINLESS-STEEL MAINTENANCE ……………………………………………………………………………24

DISCONTINUED USE ……………………………………………………………………………………………25

INSTALLATION ………………………… …………………… ……………… ……………… …26

INTRODUCTION ……………………………………………………………………………………………………26

MAX ROOM TEMPERATURE ……………………………………………………………………………………26

LOCATION ….………………………………………………………………………………………………………26

WIRING ………………………………………………………………………………………………………………28

CONNECTION TO CONDENSATE DRAIN ……………………………………………………………………28

TESTING ……………………………………………………………………………………………………………28

PARAMETERS ………………………………………………………………………………………………………32

Description of parameters ……………………………………………………………………………………32

Changing parameters ………………………………………………………………………………………34

RESET MEMORY …………………………………………………………………………………………………35

RESTORING DEFAULT PARAMETERS …………..……………………………………………………………36

CABINET

…………………………………………………………………………………………23

APPENDIX …………………………………………………………………………44

2

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

M

U

NNU

L --

L

INFORMATION FOR THE READER CHAPTER 0

This manual is subdivided into two parts.

1st part: covers all the information

necessary to the user.

2nd part: covers all the information necessary to

the qualified operators authorized to move,

transport, install, service, repair and demolish the

appliance.

While users are instructed to refer to the 1st part

only, the 2nd part is addressed to skilled

operators. They may also read the 1st part for a

more complete picture of the information provided

if necessary.

GENERAL INSTRUCTIONS ON DELIVERY CHAPTER 1

GENERAL INSTRUCTIONS

Make sure that the product has not been tampered with or damaged during transport.

After unpacking the cooling cabinet make sure all sections or components have been included and

specifications and conditions are as to your order.

If not, please inform the seller immediately.

We assure you have made the best choice in purchasing our products and hope you will be fully satisfied

with their performance. To this purpose, we recommend you strictly follow with the instructions and

regulations contained in this handbook.

Please remember that no reproductions of this handbook are allowed. Due to our constant technological

updating and research, the features described in this handbook may be altered without prior notice.

TECHNICAL

Please refer to the technical data of your own appliance. (tab.1a-1b), see page 44.

DATA

LIST OF REGULATION REFERENCES

The cooling cabinet we manufacture fully complies with the following regulations:

UL Listed for electrical safety

NSF standard 7 for sanitation

GENERAL INSTRUCTIONS

The quick cooler is a refrigerating appliance which can cool cooked foodstuffs to a temperature of +38 [°F]

(positive quick cooling) and to 0 [°F] (negative quick cooling).

Machine capacity as to the quantity to be cooled depend on the model purchased.

3

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

Before setting to operation thoroughly clean the cooling cabinet with a suitable detergent or sodium bycarb

dissolved in lukewarm water. Clean the appliance inside to remove any condensate caused by the

Manufacturer's final testing.

Cooling and freezing speed depends on the following factors:

a) container shape, type and material;

b) whether container lids are used;

c) foodstuff features (density, water contents, fat contents);

d) starting temperature;

e) thermal conduction inside the foodstuffs

Positive /Negative quick cooling time depends on type of foodstuffs to be processed.

Full-speed cycle is recommended for high-density or large-sized foodstuffs. However, the following limits

should never be exceeded : a 2” thickness for freezing and a 3” thickness for cooling (tab.2).

The low-speed cycle is suitable to process delicate foodstuffs, such as vegetables, creamy products, creamy

desserts or low-thickness products.

We recommend making sure that any positive quick cooling cycles, to +38 [°F] to the core of the product, do

not last over 180 minutes, and that negative quick cooling cycles, to 0 [°F] to the core of the product, do not

last over 4 hours.

The processing room is to be pre-cooled before starting the positive and /or negative quick cooling cycle.

Moreover, avoid covering the foodstuffs during the cycle, which would increase the cycle length.

We recommend using the core probe in order to have the exact core temperature reading. Do not stop the

cycle before reaching a temperature of +38 [°F] during positive quick cooling and 0 [°F] during negative quick

cooling.

E

RRAATTIIOONNM

SETTING

M

UP

U

NNU

L --

L

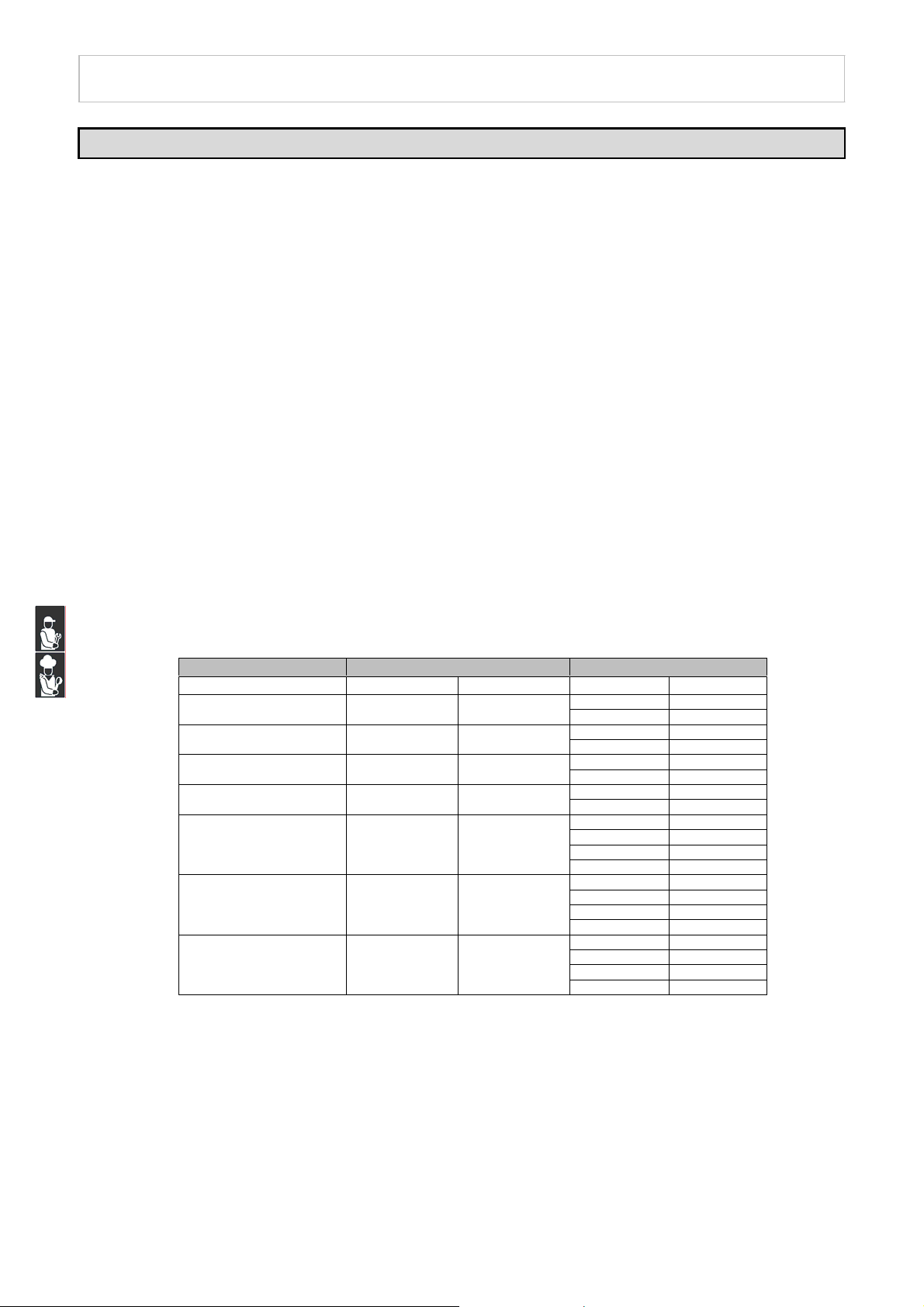

Tab.2

Model Max. output/cycle Capacity

BCF44244- BCB44244

BC40-4

BCF93558

BC80-8

BCF11514

BC113-14

BCF22020

+160[°F] to+38[°F] +160[°F] to +0[°F] max shelves pan size

5

44[lb]

40[lb]

93[lb]

80[lb]

115[lb]

113[lb]

220[lb]

24[lb]

-

55[lb]

-

55[lb]

-

110[lb]

12“x20“x1.5“

4

12“x20“x2.5“

5

12“x20“x1.5“

4

12“x20“x2.5“

14

12“x20“x1.5“

8

12“x20“x2.5“

14

12“x20“x1.5“

8

12“x20“x2.5“

26

12“x20“x1.5“

14

12“x20“x2.5“

13

18“x26“x1.5“

7

18“x26“x2.5“

26

12“x20“x1.5“

14

12“x20“x2.5“

13

18“x26“x1.5“

7

18“x26“x2.5“

32

12“x20“x1.5“

20

12“x20“x2.5“

16

18“x26“x1.5“

10

18“x26“x2.5“

4

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

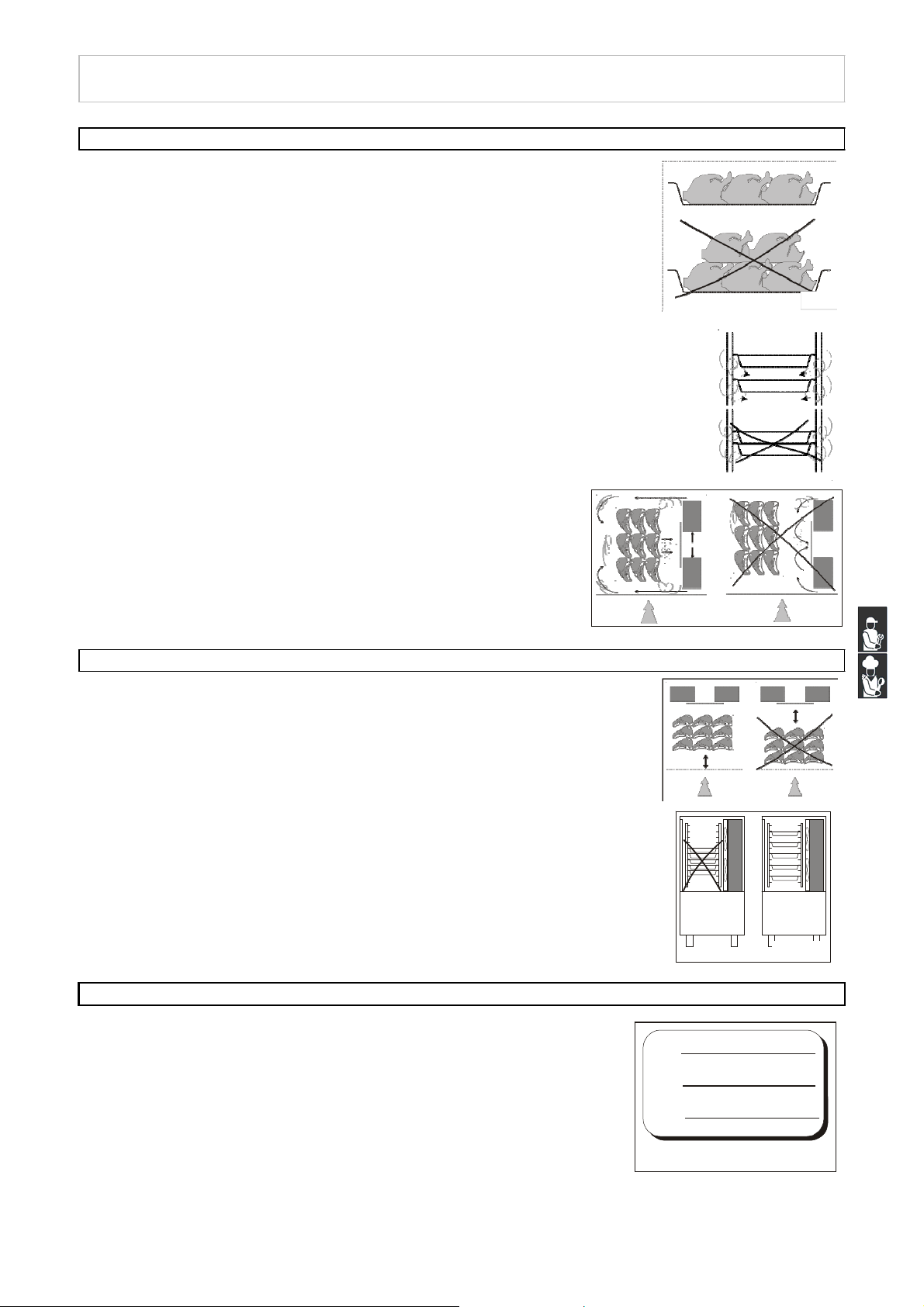

Do not stack foodstuffs to be cooled. Thickness should be lower than 2” in

negative quick cooling and lower than 3” in positive quick cooling. (pict.1)

E

RRAATTIIOONNM

MACHINE LOADING

M

NNU

U

Make sure air circulation is not hampered between food trays. (pict.2)

The grid-holding frame (included in those models which include

trolleys) is to be located at the center of the cabinet. (pict.3)

Place the trays as close to the evaporator as possible. (pict.4)

POSITION OF TRAYS

If the cabinet is not full place the trays at equal distance from one another. (pict.5)

STORAGE TEMPERATURES AND TIMES

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5

days of processing without food quality degradation.

Storing time may be increased to approx. two weeks by using vacuum

processing.

After a negative quick cooling cycle, foodstuffs may be stored safely for 3 to 18

months, according to the type of foodstuff processed.

It is strongly recommended to keep storing temperatures at 0[°F] or below.

L --

L

A

B

C

0,19”-0,79”

Pict.5

Pict.1

Pict.2

Pict.3

Pict.4

Pict.6

5

09/12 Rev. B 143573

A

A

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

M

U

NNU

L --

L

Table 3 shows the storing time rates for a few examples of frozen food.

Do not leave cooked products at room temperature before quick cooling, as

this may allow the loss of moisture, which will affect food freshness.

The cooled product should be wrapped in a specific film for foodstuffs (better

still, vacuum stored) and provided with a sticker reporting the content [A], date

of processing [B] and expiration date [C] written in permanent type ink (pict.6).

Tab.3

Foodstuff Storage

Pork

Beef

Poultry

Fat fish Lean

fish Peas

Strawberries

Spinach

Note: th e above storage times and temperatures are recommendations. Consult food and drug

administration (FDA) documentation for current agency approved storag e temperatures and times.

For proper position of the probe, refer to the following pictures.

S ON DA A SING OL O

SINGLE-DETECTOR

RI L E VA M EN T O

PROBE

temperature

[°F]

0

0

0

0

0

0

0

0

PRODUCT CORE

C

U OR E P R O D OT T O

CORE PROBE

Storage

time

months

6

9

10

2

4

12

12

6

SOND

MULTI-DETECTOR

RIL E VA M E

PROBE

MULTIPL

NTO

O

PRODUCT SURFACE

U

P E R F IC IE PR OD

S

CORE

PROBE

OTT

O

OVER SURFACE PROBE

UNDER SURFACE PROBE

6

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

M

U

NNU

L --

L

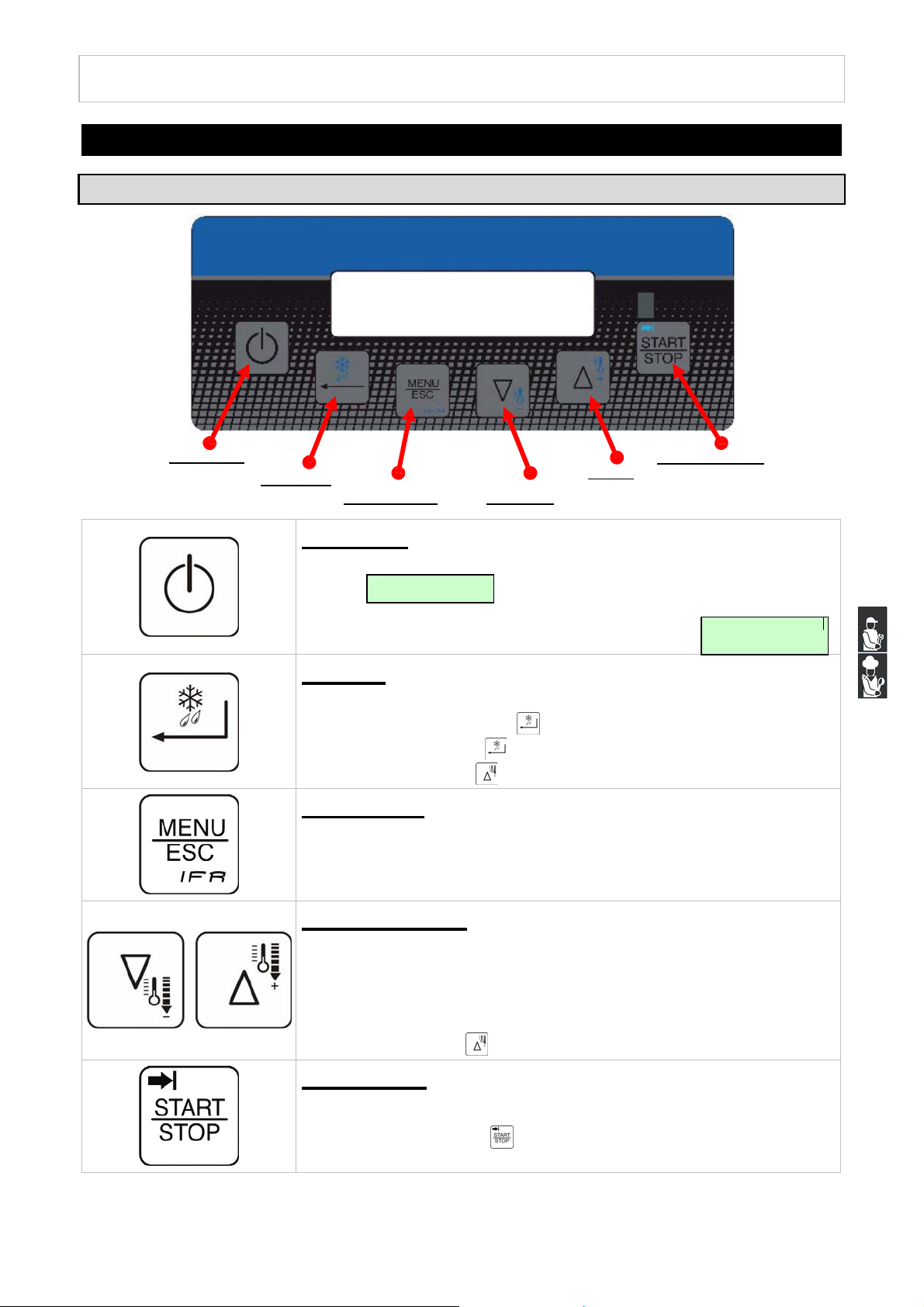

CONTROL PANEL CHAPTER 2

DESCRIPTION OF CONTROLS

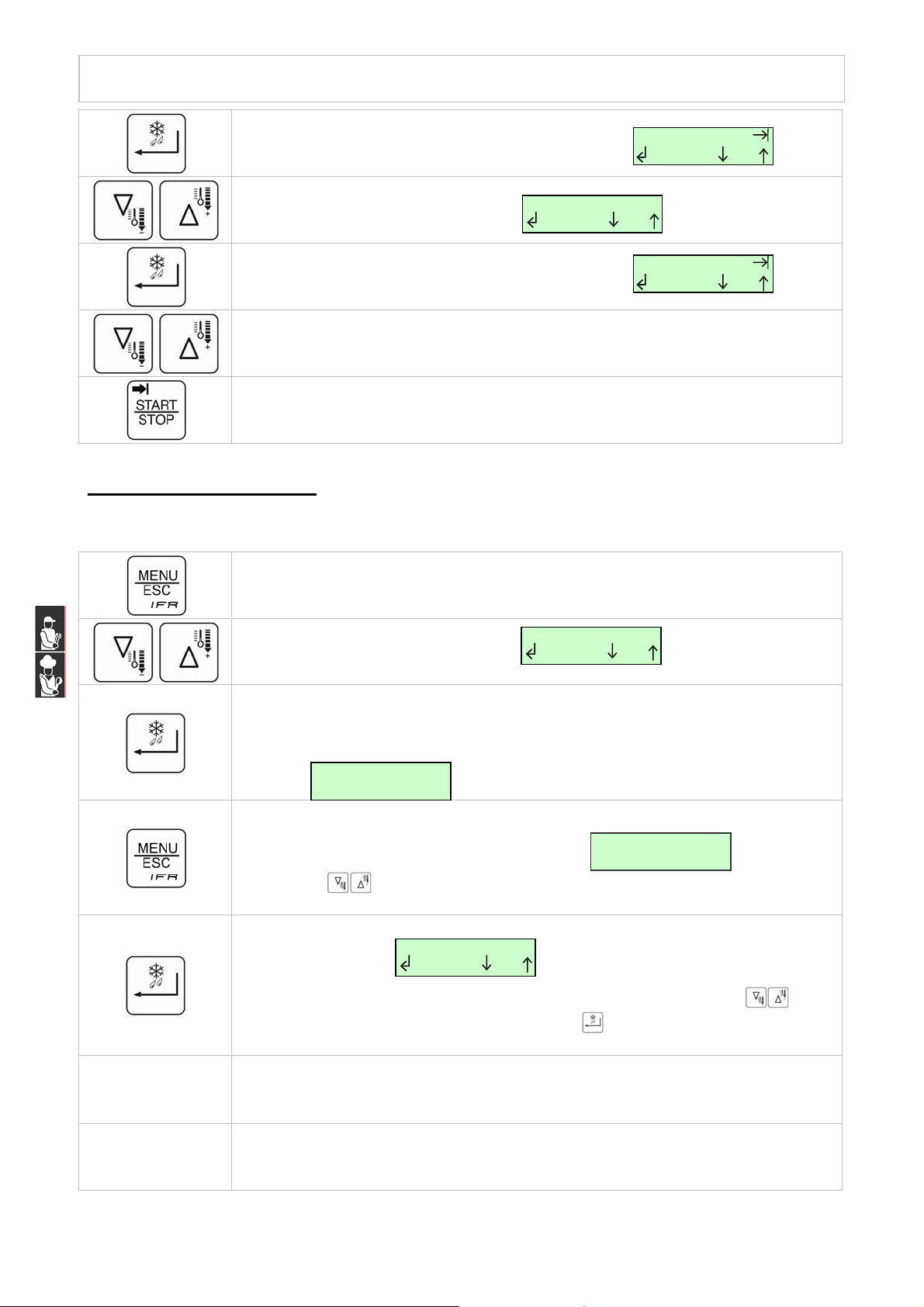

ON/OFF KEY

ENTER KEY

MENU/ESC KEY DOWN KEY

ON/OFF key

Pressing the key for 5 sec the controller turns off and the sign blinks on the

display

OFF _

UP KEY

START/STOP KEY

When this button is pressed the controller lights up

again, preparing itself to start an IFR chilling cycle.

Esc

Enter key

Allows access to a menu or parameter selection.

Manual defrost: press the key fro 5 s (default parameter values)

During a cycle: press the

the ongoing cycle. Press to scroll through this information.

button to display all the information regarding

Menu/Esc key

Allows access to the main menu or return to the previous menu.

Quick IFR chilling key: press the key for 5 s (default parameter values)

Up and Down keys

Use to scroll the different menus or change parameter values.

Quick Soft posit. chilling key: press the key for 5 s (default parameter values)

Quick negative freezing key: press the key

Keyboard lock: press the keys for 5s (default parameter values)

During a cycle: press the

button to display, for a few seconds, the elapsed time.

for 5 s (defa ult parameter values)

Start/Stop key

Use to start/stop a quick cooling cycle.

Quick cooling key: keep the key pressed for 5 s (default parameters)

7

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

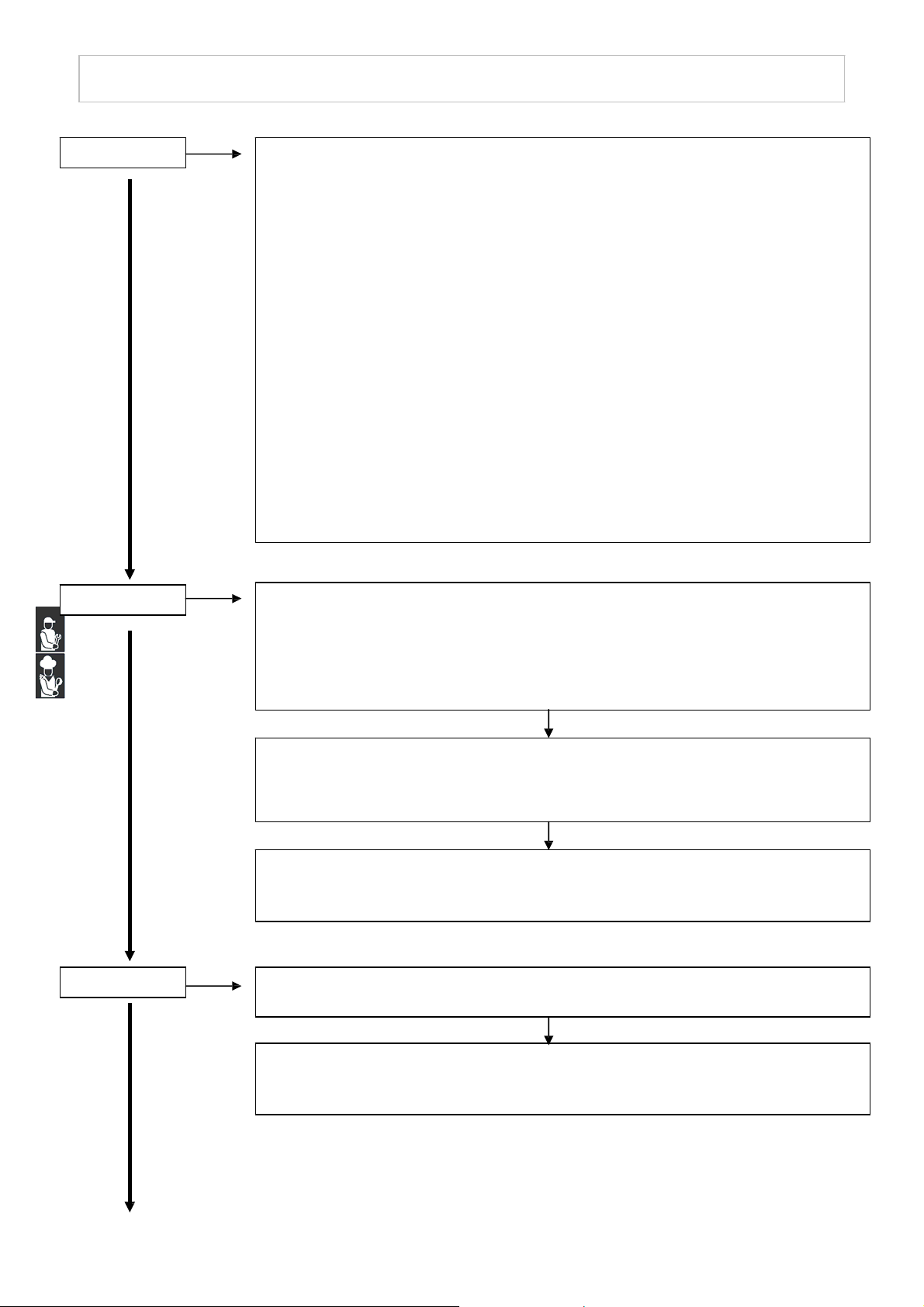

Programs Program selection

IFR: Automatic quick cooling program

Values setting not required. Can be activated with core probe only.

With the IFR program, there is no freezing on foodstuffs outer surface. (no risk

of third-degree freezing).

The IFR program must not be used in negative quick cooling cycles.

Recommended: preset programs

Meat (core probe chilling) Dairy

(time-controlled chilling) Pie

(time-controlled chilling) Stew

(time-controlled chilling) Fish

(time-controlled chilling) Poultry

(time-controlled chilling)

Vegetables (time-controlled chilling)

Freezing Temp (with core probe freezing)

Freezing Time (time-controlled freezing)

User: 01 – 20 numbers available for programming according to the customers’

needs.

Manual

Cooling: this program cools the room before any chilling cycle.

Negative = QC with max. refrigerating air temp -13°F, max. core temp 0°F

Positive Soft = QC with max. refrigerating air temp. +14°F, max. core temp. +36°F

Positive Hard = QC, 40% of time at -13°F, remaining time at +14°F, core temp. is set

to +50°F. Suitable for big cuts of meat.

Automatic temp. regulation prior to ice formation on the surface.

… Core

… Time

If the core probe stays off, time-control turns on automatically.

Manual setting

Use the menu to manually configure core temperature values or the time and/or

Store

speed of the fans.

Positive = storing-cooling at + 36°F

Negative = storing-freezing at -8°F

Manual setting

Menu allows the user to set the products storing temp. after quick cooling.

M

U

NNU

L --

L

8

09/12 Rev. B 143573

A

A

A

A

E

RRAATTIIOONNM

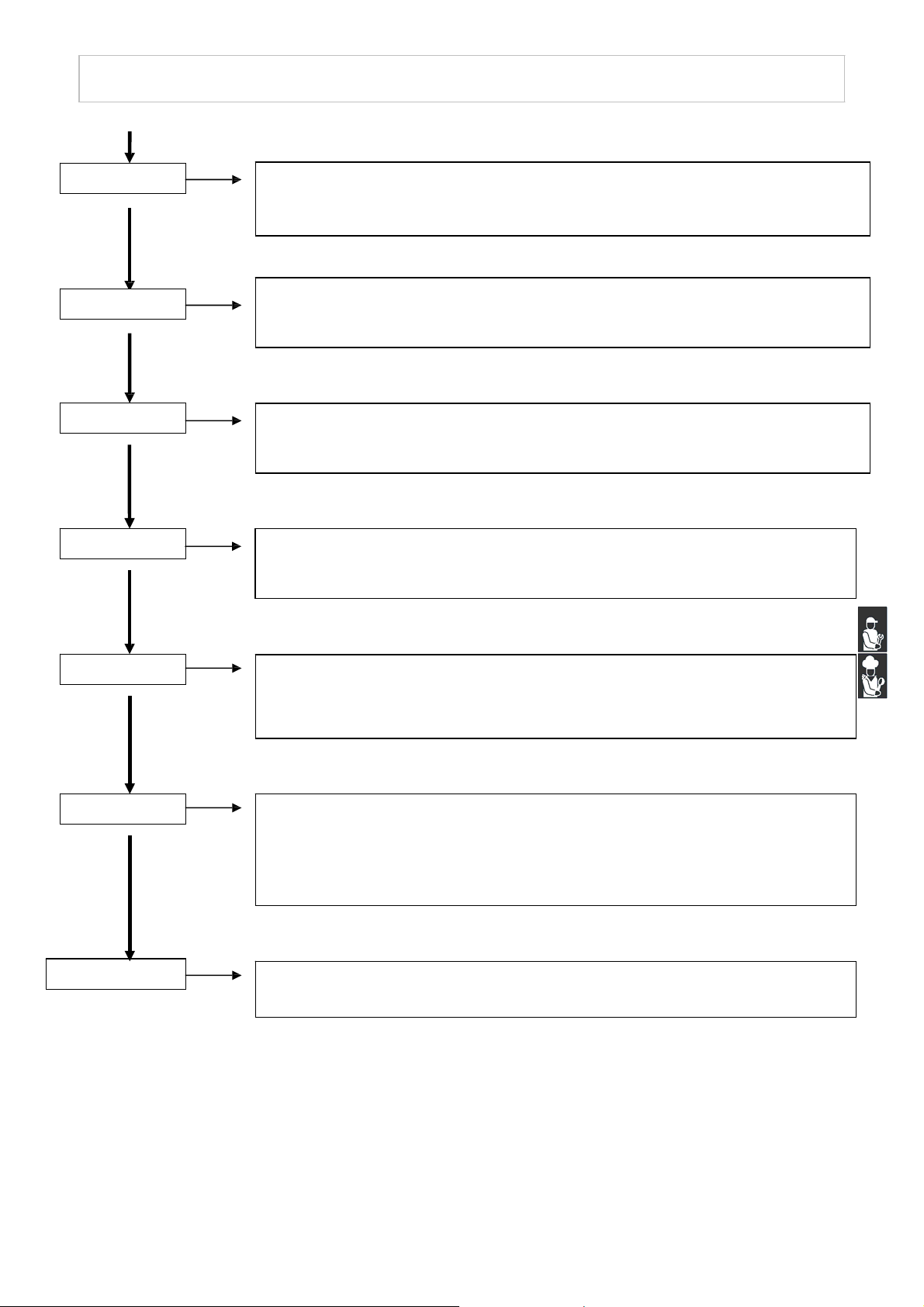

Defrost

Print

-

OOPPE

-

Defrost start

Select Ok or No

Menu for printing memorized quick cooling cycles

With printer available, select: Ok or No

Clock Setting Clock setting

Set date and time

Language Set language

Select the desired language

Alarm Menu for displaying the alarms.

(reading only)

Service Appliance basic setting. Set password “-19”.

Inputs/Outputs

S = alarm start, E = alarm stop, Service = customer service

Parameters customer service parameters

Reset Memory memory complete deletion

Restore default parameters restore

Menu for displaying inputs/outputs state.

(reading only)

M

U

NNU

L --

L

9

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

M

U

NNU

L --

L

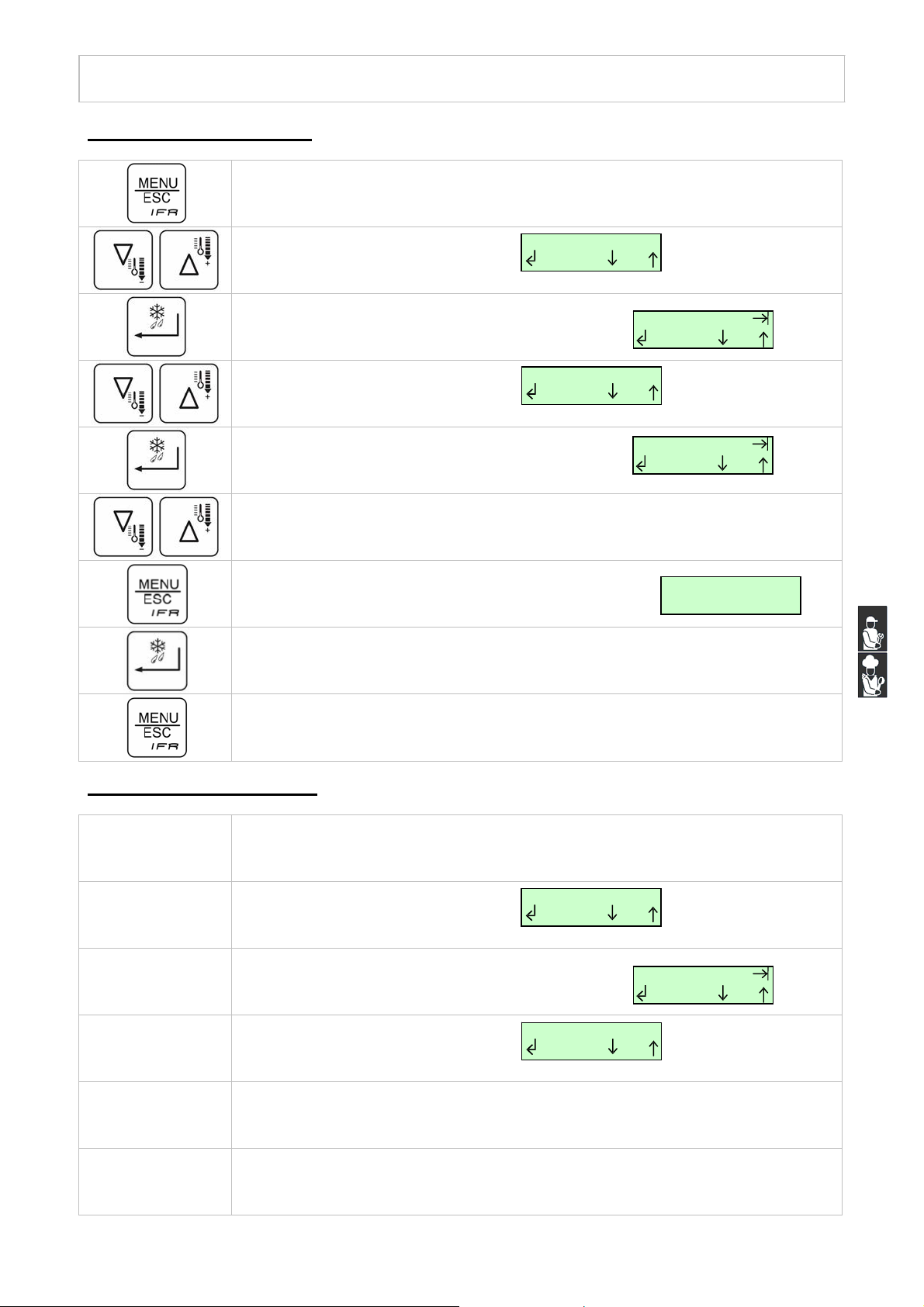

OPERATION CHAPTER 3

PROGRAMS

The IFR is an innovative patented system of positive quick cooling which allows the cycle optimization for

each type of foodstuffs by preventing superficial freezing.

IFR CHILLING CYCLE

Temperatures are detected by a three-sensor needle probe (ref. page 6,

“Core probe”).

Press menu/esc to select the desired menu

Use the keys up and down to display

Programs

Esc

Notes:

- immediately after power up

the cycle will start immediately.

- from the main menu

- during the cycle

Press enter to confirm your choice.The display shows

Esc

Press start/stop to immediately activate the selected cycle

, the controller automatically prepares itself to start an IFR chilling cycle: simply press and

it is possible to immediately start an IFR chilling cycle: keep the pressed for 5 seconds.

it is possible to view fan speed by pressing ; use the button to modify the value.

F

176

140

104

68

32

-4

-40

100

50

0

F

176 PRODUCT SURFACE

140

104

68

32

-4

-40

100

50

0

PRODUCT CORE

INTERMEDIATE

ROOM TEMPERATURE

ROOM VENTILATION SPEED

IFR

10

09/12 Rev. B 143573

A

A

A

A

-

OOPPE

-

E

RRAATTIIOONNM

M

U

NNU

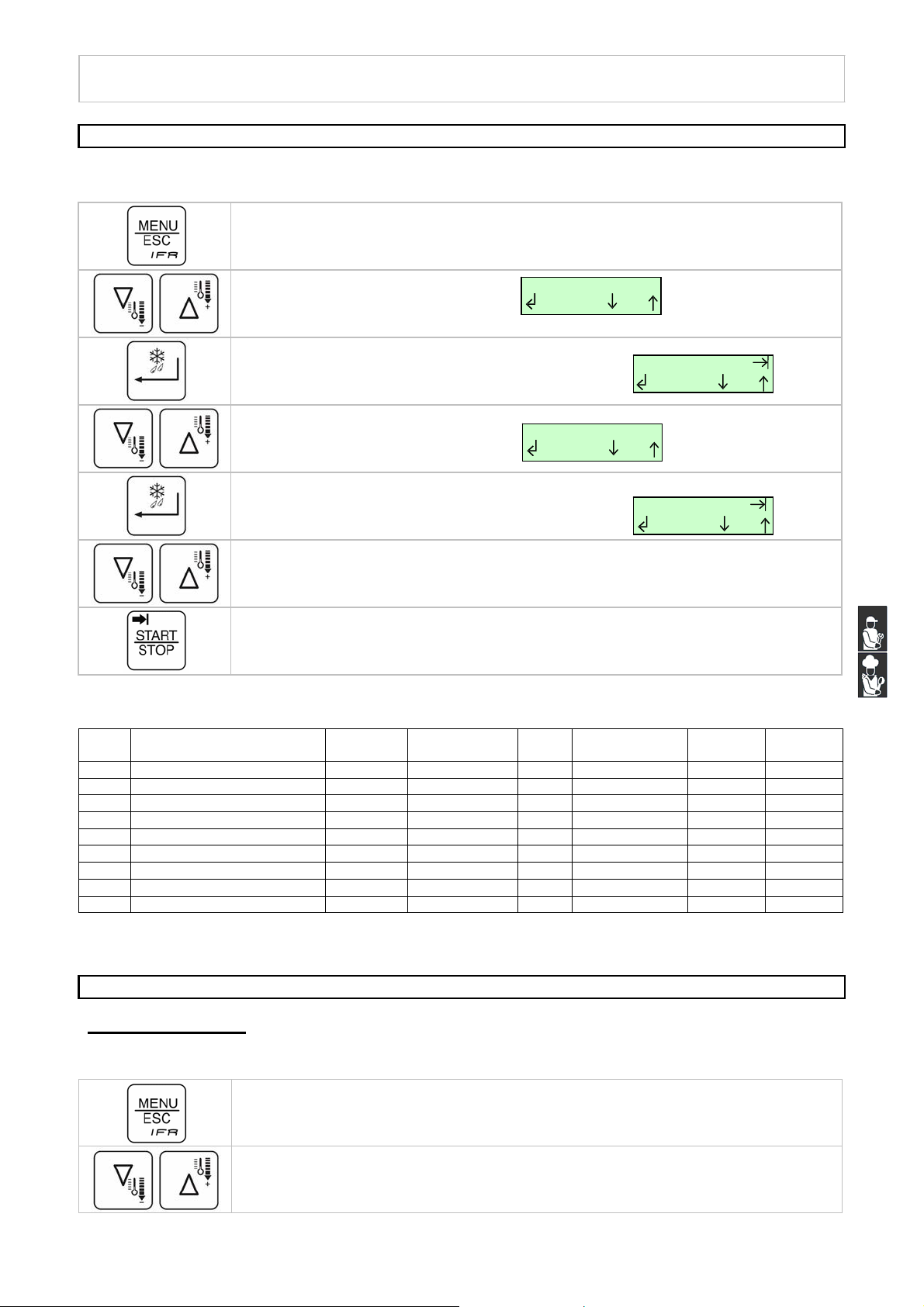

RECOMMENDED WORKING CYCLES

Recommended working cycles are pre-programmed. Parameters cannot be changed.

Press menu/esc to select the desired menu

L --

L

Use the keys up and down to display

The recommended programs are listed below:

Prog Name of the program

21

22

23

24

25

26

27

28

29

Note: It is the responsibility of the user that the storage temperature and pull down is time appropriate for

their application

Freezing Temp negative core yes -8°F 240 min 100%

Press enter to confirm your choice. The display shows

Use the keys up and down to display

Press enter to gain access to the saved programs selection (21-29)

The display shows the program number and name

Use the keys up and down to scroll all the saved programs

Press start/stop to immediately activate the selected cycle

Positive

negative

Meat positive core yes +35°F 120 min 100%

Dairy positive time no +35°F 90 min 100%

Pie positive time no +35°F 90 min 100%

Stew positive time no +35°F 90 min 100%

Fish positive time yes +35°F 90 min 100%

Poultry positive time yes +35°F 90 min 100%

Vegetables positive time no +35°F 90 min 100%

Freezing Time negative time yes -8°F 240 min 100%

Time/Core hard

Programs

Esc

Recommended

Esc

Room set

storing

IFR

Esc

Meat

Esc

time Ventilat.

USER’S CYCLE

USER’S PROGRAMS

The saved USER programs can be activated as follows:

Press menu/esc to select the desired menu

Use the keys up and down to display

11

Programs

Esc

09/12 Rev. B 143573

A

A

A

A

N

-

OOPPE

-

Press enter to confirm your choice. The display shows

E

RRAATTIIOONNM

M

U

NNU

L --

L

Esc

IFR

STORING USER’S PROGRAMS

It is possible to save up to 20 USER programs.

Use the keys up and down to display

Press enter to confirm your choice. The display shows

Use the keys up and down to scroll all the saved programs

Press start/stop to immediately activate the selected cycle

Press menu/esc to select the desired menu

Use the keys up and down to display

User

Esc

(example) Esc

Manual

Esc

01 NAME

Press enter to confirm your choice.

Select the manual cycle as described in the previous paragraphs, replacing the

standard values with the desired ones.

Once the cycle is completely configured, the display will show.

(example)

Keep menu/esc pressed for 5 seconds to save the program.

The display will show the first available position

Use buttons to scroll through the 20 programs

and select the desired position.

Press enter to confirm the selected position.

The display shows

Type in the name of the program which is to be memorised using buttons to

scroll through the letters and numbers, and pres s

next character

Press menu/esc to save the name.

The display shows

Press start/stop to immediately activate the selected cycle

eg Core

Esc

(example)

A _ _ _ _ _ _

Esc

NAME

Esc

Programs 03

to confirm and move on to the

---------

12

09/12 Rev. B 143573

A

A

A

A

-

-

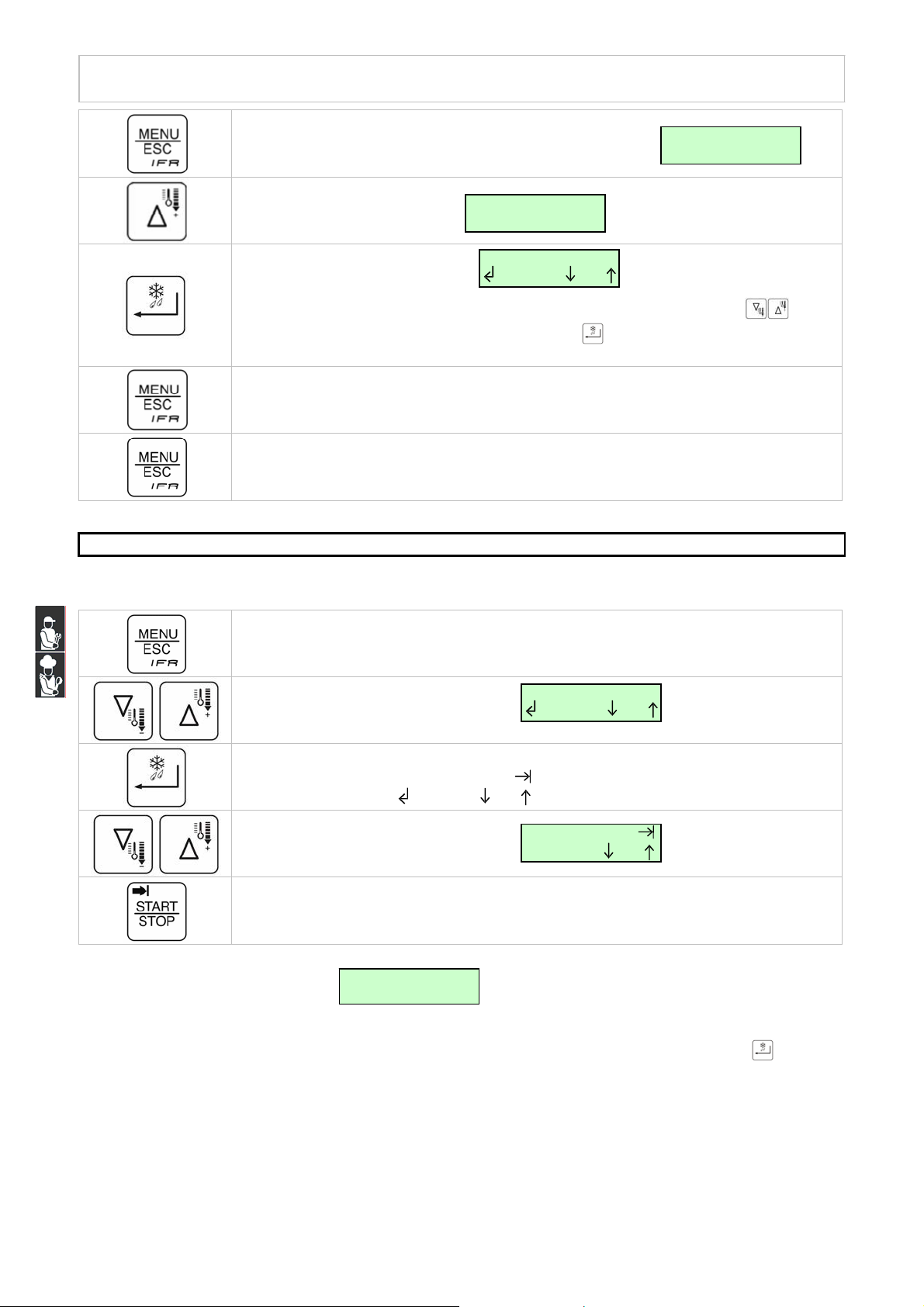

DELETE A USER’S PROGRAM

Press menu/esc to select the desired menu

OOPPE

E

RRAATTIIOONNM

M

NNU

U

L --

L

Use the keys up and down to display

Press enter to confirm your choice. The display shows

Use the keys up and down to display

Press enter to confirm your choice. The display shows

Use the keys up and down to scroll all the saved programs

Keep menu/esc pressed for 5 seconds. The display

shows

Press enter to cancel the program

Programs

Esc

User

Esc

IFR

Esc

01 NAME

Esc

Cancel progr

Ok No

RENAME A USER’S PROGRAM

Press menu/esc to exit

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice. The display shows

Use the keys up and down to display

Press enter to confirm your choice. The display shows

Programs

Esc

User

Esc

Esc

01 NAME

Esc

IFR

Use the keys up and down to scroll all the saved programs

13

09/12 Rev. B 143573

A

A

A

A

E

-

OOPPE

-

Keep menu/esc pressed for 5 seconds. The display

shows

E

RRAATTIIOONNM

M

U

NNU

L --

L

Cancel progr

Ok No

Press up. The display shows

Rename progr

Ok No

A _ _ _ _ _ _

Press enter. The display shows

Type in the name of the program which is to be memorized using buttons to

scroll through the letters and numbers, and pres s

next character.

Press menu/esc to confirm the new name

Press menu/esc to exit

Esc

to confirm and move on to the

PRE-COOLING CYCLE

It is advisable to run a cooling cycle prior to selecting any chilling cycle.

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

The display shows

sc

Use the keys up and down to display

Press the start/stop button to immediately activate the cooling cycle

IFR

Programs

Esc

Cooling

Esc

Once the temperature in the room reaches -13°F, the buzzer will sound for 10 seconds, and the “insert

Room -13°F

Insert prod

product” request will be displayed.

Closing the door terminates the cooling cycle.

Note: From the main menu it is possible to immediately activate a cooling cycle; simply keep the

pressed for 5 seconds.

button

14

09/12 Rev. B 143573

Loading...

Loading...