Page 1

Features

Norgren GT Development Inline Pressure

Protection Valve with DOT push- to-connect

fittings designed to isolate vehicle air systems in

case of leakage, protects the integrity of the air

supply.

Performance

Application

Material

Part Number

Rated P SI

Operating Temperature

Equivalent Orifice

Flow Rate

Connectors

Opening Pressure

(On Rising Pressure)

Closing Pressure

(On Closing Pressure)

Supply Port

Delivery Port

Spray Cap

Designed to isolate vehicle air s ystems in case of leakage. Protects the integrity of the air supply.

Thermoplastic Body with Fluorosilicone Seals.

5200-75

150 PSIG maximum

-40°F to 230°F

Cd = .65 equivalent orifice = .07 " minimum. The valve shall flow 10 SCFM minimum with 120 PSIG applied

at the inlet and the outlet at ambient air pres sure.

3.3 SCFM minimum with 120 PSIG at the inlet and 110 PSIG at the outlet.

1/4" push-to-connect fittings meeting FMVSS 571.106 standards when used with SAE J8 44 tubing.

75 PSIG ± 10 PSIG

60 PSIG ± 5 PSIG

1/4"

1/4"

Black

Inline Pressure Protection Valve

5200-75

REV: 8/14 01

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Page 2

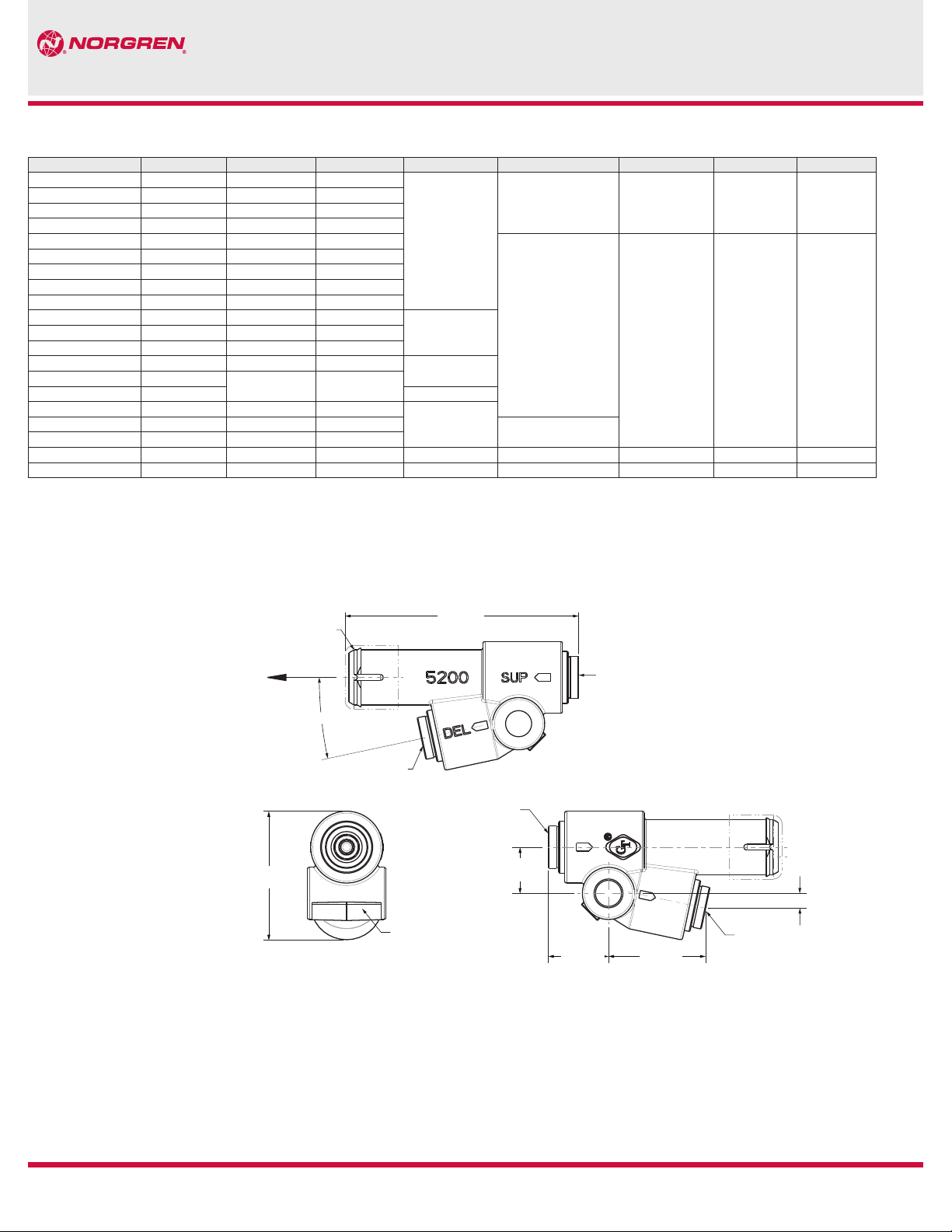

0.15 REF

Inline Pressure Protection Valve 5200-75

Pressure Protection Valve Cross Reference

Part Number 223-XX X

355, 355V

365

375

385, 3 85V

455, 4 55V

465, 4 65V

475

485

485 V, 485V2

565, 5 65-1

565 -2

585-V

1

585

1

585-1

3

585-2

585-2B, 285-2BV

585N , 585NP

585T

685V

785

1 One of th e outlet por ts to be plugged (223-585 , 585-1, and 585NP only) pip e seal ant PST 567 applied to male thread plug

2 Thre ad height

3 No plug f or 22 3-585-2

4 Open and clos ed piston tr avel height

5 Vibr a-Seal app lied to male threads for 223-585 N, 58 5NP, and 58 5-2BV

6 Inter nal 1/4-18 NPT thread only, no nipple

1 6

5

Cap Color Open (P SIG) Close (PSIG) Outlets (Female) Inlet (Male)

Black 55 ± 10 45 ± 10

Black 65 ± 10 55 ± 5

Black 75 ± 10 60 ± 5

Red 85 ± 10 67 ± 5

Black 55 ± 10 45 ± 10

Black 65 ± 10 55 ± 5

Black 75 ± 10 60 ± 5

Red 85 ± 10 67 ± 5

Red 85 ± 10 67 ± 5

Black 65 ± 10 55 ± 5

Black 65 ± 10 55 ± 5

Red 85 ± 10 67 ± 5

Red ≤ 100 ≥ 70

Red

Red 1/4 - 18 NPT

5

Black 85 ± 10 67 ± 5

Red 85 ± 10 67 ± 5

Red 85 ± 10 67 ± 5

Red 85 ± 10 67 ± 5 1/4 - 18 NPT 3/8 - 18 NPT 0.62 2.48 ± .05 2.68 MA X

Red ≤ 100 ≥ 70 3/8-1/8 NPT 1/2-14 PTF SAE SHORT 0.69 2.56 ± .05 2.76 MAX

≤ 100 ≥ 70

3/8 - 18 NPT

1/4 - 18 NPT

1/4 - 18 NPT

1/4 - 18 NPT

3/8 - 18 NPT 0.62 2.4 8 ± .05 2.68 MAX

1/2 - 14 PTF S AE SHORT

1/4 - 18 NPT

2

0.69 2 .56 ± .05 2 .76 MAX

Close

4

Open

4

Dimensions (Inches)

SPRAY CAP

DOWN

0.31

REF

12° REF

DELIVERY PORT

DATE CODE/PART ID

2.38 REF

SUPPLY PORT

Warning

Improper selection, misuse, age or malfunction of components used in

commercial vehicle systems can cause failure in various modes. The system

designer is warned to consider the failure modes of all component parts

used in commercial vehicle systems and to provide adequate safeguards to

prevent personal injury or damage to equipment or property in the event of

such failure modes. System designers and end users are cautioned to consult

instruction sheets and specifications available from the factor y. The system

designer/end user is responsible for verif ying that all requirements for the

application are met.

SUPPLY PORT

0.47

REF

DELIVERY PORT

0.99 REF0.61 REF

Warranty

The products described herein are warranted subject to seller’s Standard

Terms and Condition of Sale, available at seller’s website.

02

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

REV: 8/14

Loading...

Loading...