Page 1

Features

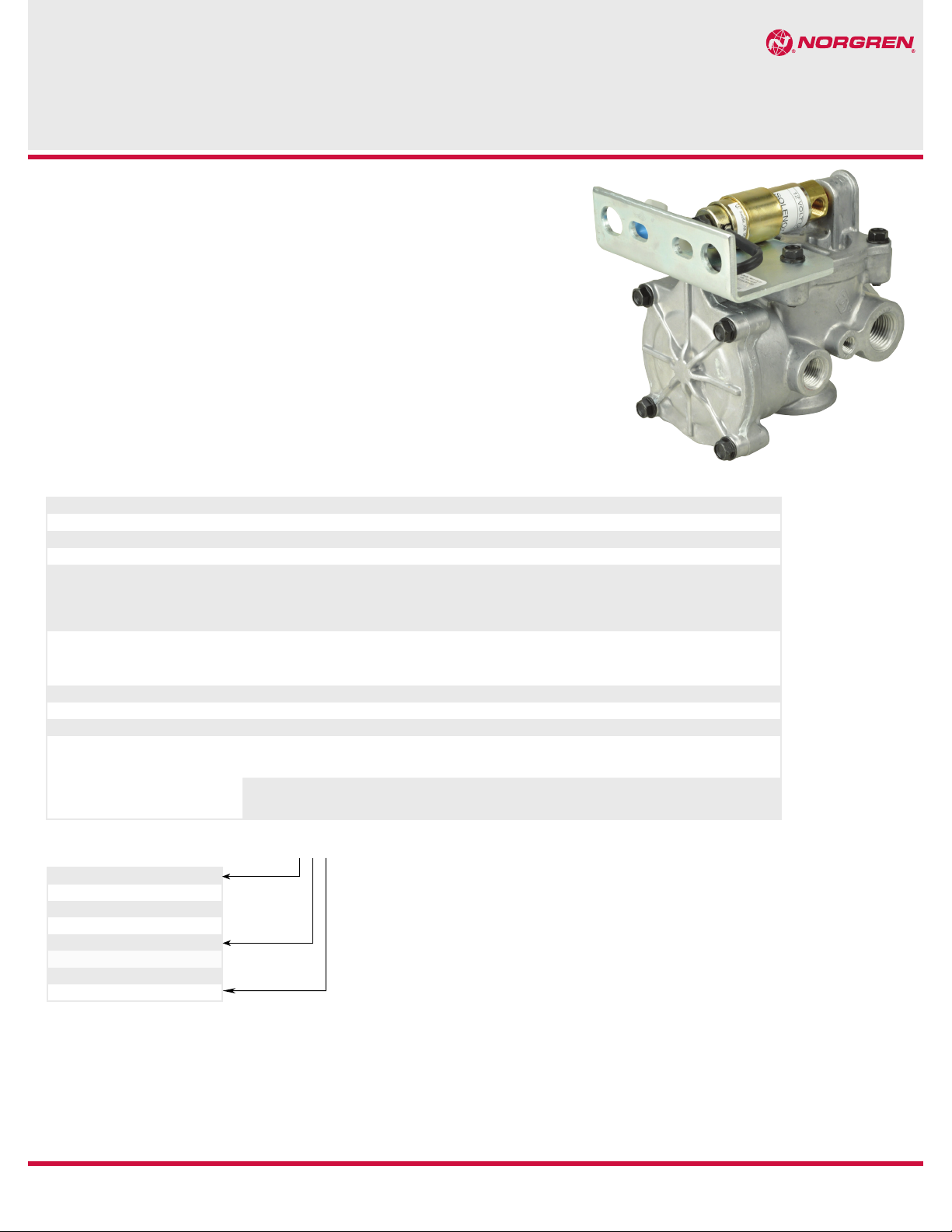

This chassis-mounted lift axle control module,

specifically designed for the heav y duty truck and

trailer industry, provides full pneumatic control.

The module includes two industry-proven brakestyle relay valves integrated into a single unit for

compactness and ease of installation. The module

provides excellent flow capabilit y for rapid axle

actuation and is available with an optional control

solenoid for electric control. More robust than

commonly used spool valves that can suffer from

contamination and temperature extremes.

Performance

Application

Material

Working Pressures

Operating Temperature

Ports

Minimum Flow Orifices

Mounting

Overall Dimensions

Weight

Electrical

Provides rapid air control of lif t axles.

Cast aluminum body with thermoplastic pistons and low temperature nitrile seal s

Regulated pilot supply: 30 to 120 PSI System supply: 150 PSI M AX

-40° (-40°C) to 190° F (87.7°C)

1) System supply

2) Two deliver y to load bag

3) Two delivery to lift bag

4) Regulated supply

5) Gauge port

1) Supply to lift delivery

2) Lift delivery to exhaust

3) Supply to load delivery

4) Load delivery to exhaust

Two M12 or 1/2" bolts on 3" spacing or M8 or 5/16" bolts on 1.5" spacing

5 1/4" H x 6" L x 4 1/8" W

3.3 to 3.4 lbs (approximate)

O p ti on al : Internal 12 volt solenoid valve with

Specifications: Operating voltage 12 volt coil

Metri-pack 150 series 2 way

connector.

resistance Current rating

Lift Axle Control Module

5040 Series

1/2-14 NPTF

1/2-14 NPTF

3/8-27 NPTF

1/8-27 NP TF

1/8-27 NP TF

.38"

.40"

.38"

.40"

— 9 to 16 volts DC

— 25.5 ohms at 68°F (20°C)

— 0.47 amps at 12 volts and 68°F (20°C)

Part Number 5040-H1 1-01C

Valve Type Substitute

Air actuation 1

N/O solenoid 2

N/C solenoid 3

Check Valve Substitute

Check valve 1

Gage Port Substitute

“A” side gage port 1

REV: 8/14 01

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Page 2

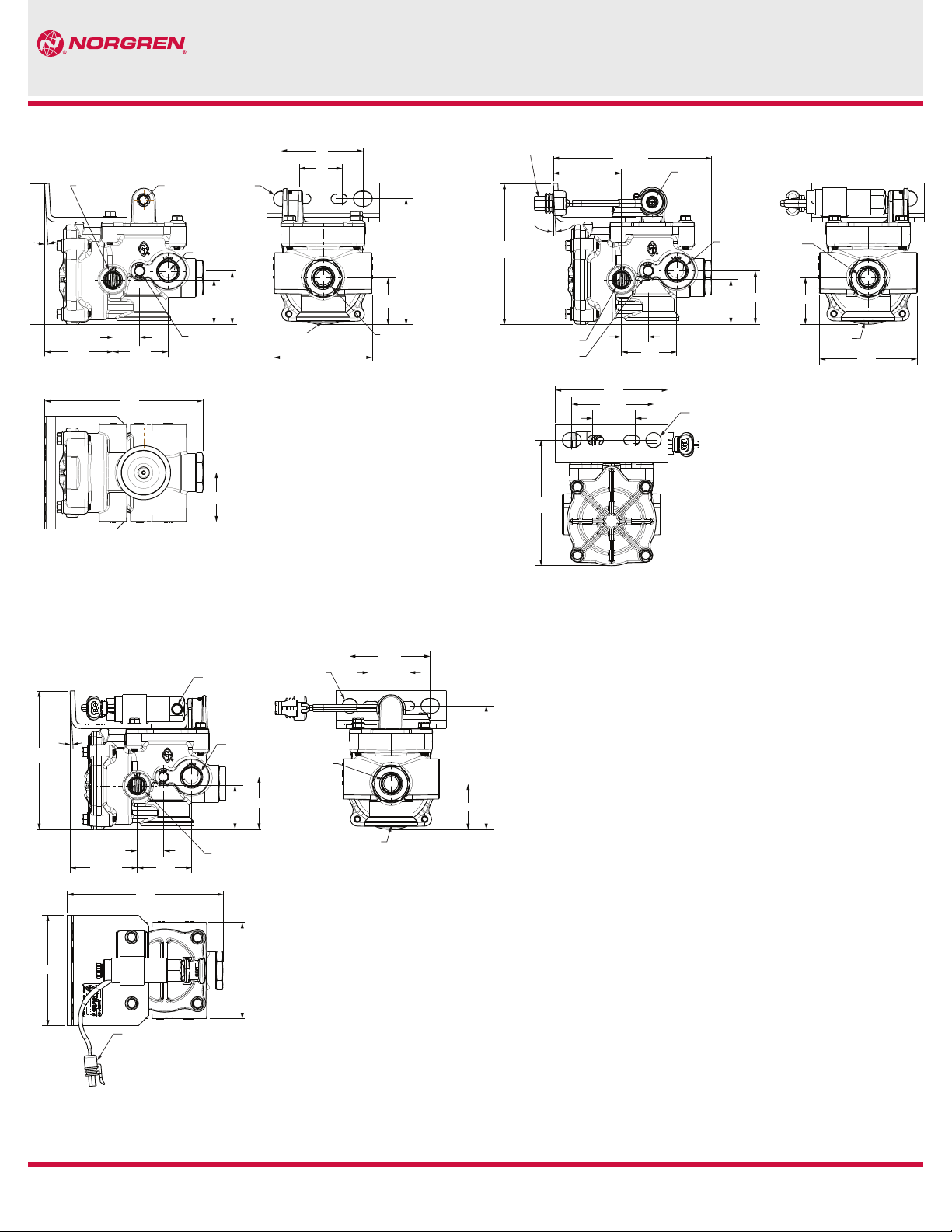

Lift Axle Control Module 5040 Series

Dimensions (Inches)

3.0

2 x 3/8-18 NPTF8 1/8-27 NPTF

2 x 1/2-14 NPTF

ø .56

1.5

4.614

MACHINE CRIMPED

METRI-PACK

150 SERIES CONNECTOR

PACKARD P/N 12052644

5.167

REF

3° REF

2.507 REF

5.807 REF

1/8-27

NPTF

2X 1/2-14

NPTF

1/2-14

NPTF

5.167

REF

2.507

0.975

5.807

2.023

1.962

1.638

“A” SIDE GAGE

PORT LOCATION

1/8-27 NPTF

1.820

VENT

3.600

1.712

1/2-14 NPT

2X 3/8-18 NPTF

1/8-27 NPTF

4.600

REF

4.125

3.0 REF

1.5 REF

0.975

2.023

Ø 0.56

1.638

1.963

1.712

VENT

3.600

5040-211-01C5040-111-01C

3.0 REF

1/8-27 NPTF

3°

REF

2X 1/2-14 NPTF

Ø 0.56

1/2-14 NPTF

1.5 REF

4.614

REF

4.125

5040-311-01C

02

0.975

2.0232.507 REF

5.807

MACHINE CRIMPED

METRI-PACK

150 SERIES CONNECTOR

PACKARD P/N 12052644

1.638

1.963

1.712

Warning

Improper selection, misuse, age

or malfunction of components

1/8-27 NPTF

2X 3/8-18 NPTF

VENT

used in commercial vehicle

systems can cause failure in

various modes. The system

designer is warned to consider

the failure modes of all

component par ts used in

commercial vehicle systems and

to provide adequate safeguards

to prevent personal injury

3.600

or damage to equipment or

property in the event of such

failure modes. System designers

and end users are cautioned to

consult instruction sheets and

specifications available from the

factory. The system designer/end

user is responsible for verifying

that all requirements for the

application are met.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Warranty

The products described herein

are warranted subject to seller’s

Standard Terms and Condition of

Sale, available at seller’s website.

REV: 8/14

Loading...

Loading...