Page 1

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-1

Section 11

Contents

Features .........................................................................VAL-11-2

Specifications................................................................VAL-11-4

Assembled Valve and Manifolding Assemblies .......VAL-11-17

Assembled Valve and Fixed Length Assemblies.....VAL-11-18

Accessories.................................................................VAL-11-19

Product Numbering System .......................................VAL-11-22

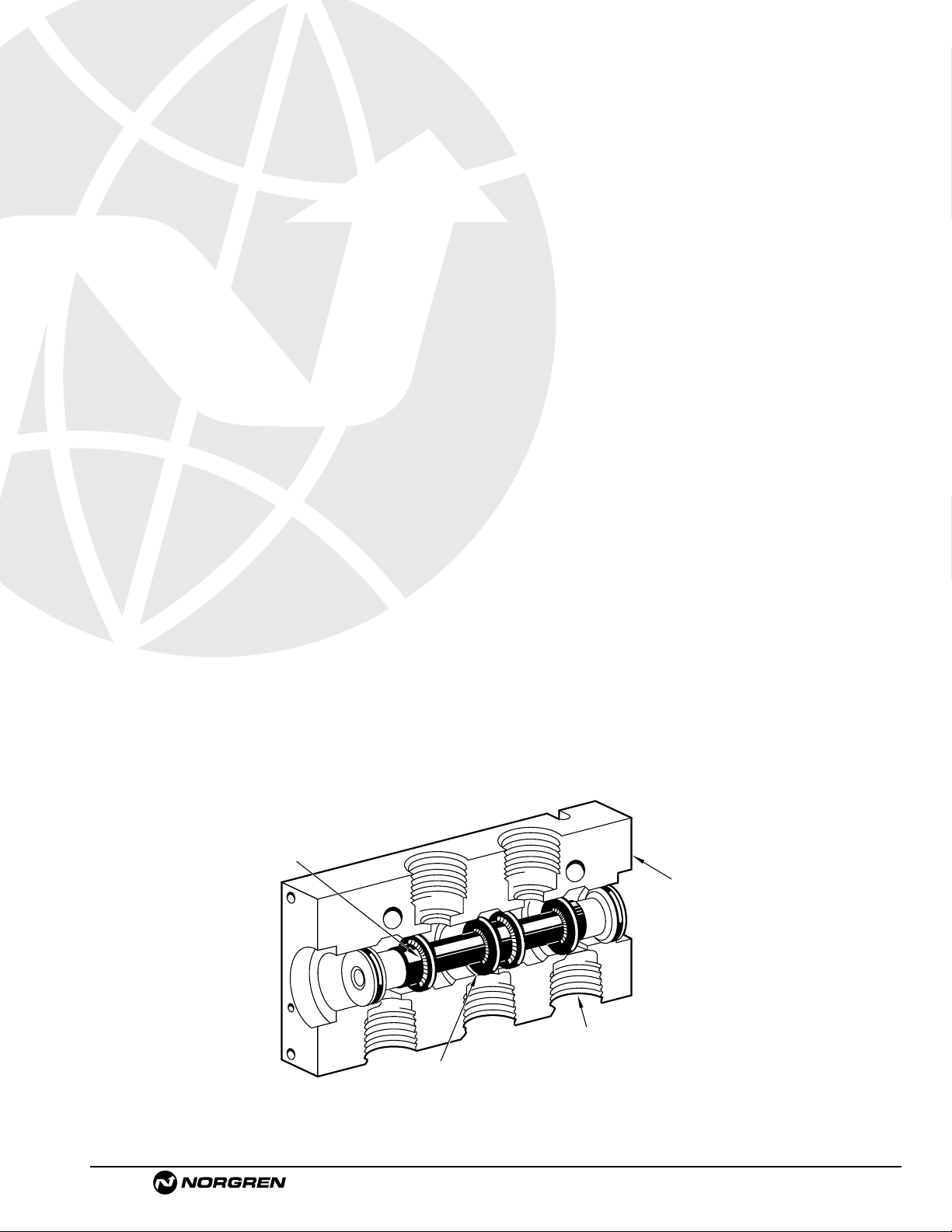

Nugget 500

Compressed air, directional

control spool valves with integral

bonded seals

Balanced

bonded seal

spool

One-piece

Die Cast

Zinc Body

NPT or ISO

Porting

Closed Crossover

Page 2

VAL-11-2

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Design Features Provide High Reliability.

Norgren Nugget 500 Valves feature a precision spool with integral

bonded seals.This design provides superior performance, fast and

easy maintenance, dependable operation, and long life. Other key

features and benefits include:

Two-Year Unconditional Warranty

All Nugget valves are warranted to be free from defects for a full two

years from the date of purchase.This extended warranty period

provides users with a valuable guarantee of quality and

serviceability .

Tw o V alve Configurations

Nugget 500 are available in a 5-Port/2-Position or 5-Port/3-Position

configuration.

A Wide Range of Valve Accessories

Norgren offers a number of accessories for use with the Nugget 500

Valve, including valve body cover plates, speed control kits, mufflers,

intermediate supply/exhaust block, solenoid exhaust filters, manifold

blanking plates, and isolating plugs.These accessories allow costeffective customizing for your specific application.

Small Subbase Footprint

All subbase valves mount on approximately 1.50" ( 38 mm) centers,

reducing installation space requirements.

High Flow

A Cv of 5.0 provides exceptionally high flow for the compact size of

the valve, making the Nugget 500 appropriate for machine control

and general purpose industrial applications.

Nitrile Rubber-Based Seals

All Norgren Nugget 500 Valves utilize nitrile O-rings and seals for

superior compatibility, wear, and operation over a wide temperature

range.

Port and Operator Identification

Each of the ports is identified by a permanent number adjacent to

the port on the body or subbase. In addition, a two-digit number at

each end of the valve body indicates the ports connected when the

operator at that end is actuated. Port and operator identification on

Nugget 500 Valves comply with ANSI and NFPA T3.21.15-1989.See

Operating Variations on page VAL-9-5 for examples.

Durable Finish

External valve body, operator and subbase

surfaces are protected with an oven cured,

epoxy resin paint that provides excellent

corrosion and chip-resistant protection.

Quality Appearance

Norgren's high luster black gives any control

circuit installation a quality appearance reflecting

the superior operating capability built into every

Nugget 500 Valve.

Four Mounting Styles

Inline Valves have two sets of mounting holes

running through the valve body. Inline valves may

be bolted to a surface or may be supported by

connecting piping.

Fixed Length Manifolds allow the installation of

inline valves on a competitively priced common

manifold.For quick installation, valves are

attached to the manifold with two socket head

cap screws.Valves share common supply and

exhaust galleries in the manifold.

A single Subbase Valve is attached to a Single

Subbase with four socket head cap screws,

providing easy installation. Inlet, exhaust,

external pilot supply and cylinder ports are

located on the sides of the subbase.

Subbase Valves are attached to Manifolding

Subbases with four socket head cap screws.

Subbases are held together with a clamping pin

and set screw combination, which reduces

potential leaks and allows quick assembly of

valve stations.Common inlet and exhaust ports

and common external pilot supply ports are

located in the end plates. Cylinder ports are

located in the ends of the subbases.

Closed Crossover

The design of the Nugget spool ensures that no

air flow occurs between supply port 1 and

exhaust ports 3 & 5, preventing the waste of

compressed air.

Fixed Length Manifold

Page 3

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-3

Nugget 500 Series Valves

Operator Choices

Solenoid pilot and air pilot operators are available for primary

actuation and return operation. For secondary operation air-assisted

spring return, spring return and integral air return operators are

offered.

Low Wattage Solenoid Operators

AC and DC operators requiring only 3.5 and 2.0 watts of power,

respectively, are ideal for computer based control systems as well as

industrial applications where minimum energy consumption is

desired. Faster response times are realized using the 7.5 watt AC

and DC operators.

Solenoid Exhaust Filter

Optional solenoid exhaust filters, for use in dusty environments, are

available .

Solenoid Diffuser Plug

A diffuser plug installed in the pilot exhaust helps prevent entry of

contaminants during shipping and normal operation. It may be

removed when minimum response times are desired.

Rotatable Connector and Coil

The standard cable grip connector can be rotated 180°, and the

solenoid coil can be turned 360° in 90° increments, making the

operators adaptable for easy installation.

Electrical Connector Options

A cable grip electrical connector with indicator light; a 1/2" NPT

conduit connector and a 5-foot, three-conductor, molded cable

connector with or without indicator light and surge suppression are

available .

Solenoid Manual Overrides

Standard solenoid operators are furnished with manual non-locking

overrides to provide a means of shifting the valve without electrical

power. Optional solenoids without overrides or with locking overrides

are also available.

Internal or External Solenoid Pilot Supply

All inline solenoid operated valves may be

quickly converted from an internal to an external

pilot supply by reversing a one-piece seal

between the operator and the body and

removing the external supply port pipe plug. All

subbase solenoid operated valves may be

quickly converted from an internal pilot to a

common external pilot supply by rotating a onepiece seal between the valve body and the

subbase to provide pilot pressure from the

external pilot supply port in the single subbase or

endplate.

Sintered Bronze Vent Filters

Internal parts are protected by built-in sintered

bronze vent filters on operators.

High Flow Pilot Exhaust Orifice

An oversized pilot exhaust orifice provides rapid

return time when the valve is deactuated.

Single Subbase Valve

Inline Double Solenoid Valve

Manifolding Subbase Valve

Page 4

VAL-11-4

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Specifications

Operating Specifications

Fluids: Filtered, lubricated or nonlubricated, compressed air or vacuum service.

Inlet Pressure Range:

Solenoid Operated Valves:*

With Internal Pilot Supply:

20 to 150 psig (1.4 to 10.3 bar)

With External Pilot Supply:

26" Hg** to 150 psig

(26" Hg** to 10.3 bar)

Air Operated Valves: 26" Hg** to 150 psig (26" Hg** to 10.3 bar).

Temperature Range (Ambient & Inlet):

Solenoid Operated Valves: -20°F to 120°F

† (-29°C to 50°C).

Air Operated Valves: -20°F to 160°F

†

(-29°C to 71°C).

Operator Pilot Pressures:

Maximum Pressure: 150 psig (10.3 bar)

Minimum Pressure requirements are given in the table below:

* Solenoid operators must be externally piloted if the supply pressure to the main

valve is below the minimum pilot pressure listed in the table below.

** With vacuum supply plumbed to an exhaust port.

†With dewpoint of supply air less than air temperature below 35°F (2°C).

Port Size (PTF Standard, ISO Optional)

Inline Valves: 3/8" & 1/2" PTF standard, (ISO G optional); 3/4" PTF only

Inline Valve Fixed Length Manifold: 3/4" PTF inlet and exhaust ports standard

(ISO G optional).

Single Subbase: 3/8" or 1/2" PTF standard (ISO G optional); 1/8" PTF or ISO G

external pilot supply.

Manifolding Subbase: 3/8" or 1/2" PTF standard (ISO G optional) cylinder

ports.

End Plates for Manifolding Subbases:3/4" PTF standard (ISO G optional) inlet

and exhaust ports;

1/8" PTF or ISO G external pilot supply.

Operator: 1/8" PTF or ISO G external pilot supply port.

Special Order Threads:ISO Rc – Consult Factory.

Valve Materials

Body: Aluminum

Spool: Aluminum

Elastomers: Nitrile

Solenoid Operator Base: PPS Plastic

Operator Housing: Zinc

Speed Control Materials

Body: Zinc

Adjusting Screw: Brass

Elastomers: Nitrile

Subbase Materials

Fixed Length Manifold: Aluminum

Single & Manifolding Subbases: Aluminum

End Plate: Zinc

Elastomers: Nitrile

Solenoid Operator Specifications

Voltages and Power Requirements:

Standard:

120V/60Hz-110V/50Hz: 3.5W .

Optional:

24V/60Hz-24V/50Hz: 3.5W;

6 VDC: 2.0W;

12 VDC: 2.0W;

24 VDC: 2.0W;

110 VDC: 3.4W .

120V/60Hz-110V/50Hz: 7.5W;

240V/60Hz-220V/50Hz: 7.5W;

24V/60Hz-24V/50Hz: 7.5W;

12 VDC: 7.5W;

24 VDC: 6.0W .

Duty: Continuous at 90 to 105 % of rated voltage.

Coil Type: Class H. Molded with three-pin electrical plug-

in connector.

Enclosure Classification: NEMA 4, and DIN 40050-IP65.

Electrical spade connections on the operator receptacle

conform to industry standard form B for 3-pin

connectors with 11 mm spacing.

Electrical Plug-in Connector: Cable grip for cables 1/4"

to 5/16" (6 to 8 mm) in diameter.

Override: Non-locking, locking or no override

External Pilot Supply Port: 1/8" PTF or ISO G

Average Flow Factor (Cv)

†

3/8", 1/2", & 3/4" Ported Valves: 4.0, 5.0, & 5.6,

respectively.

†

Flow rating determined in accordance with ANSI

(NFPA).T3.21.3, Pneumatic fluid power – Flow test

procedure and reporting method – for fixed orifice

components.

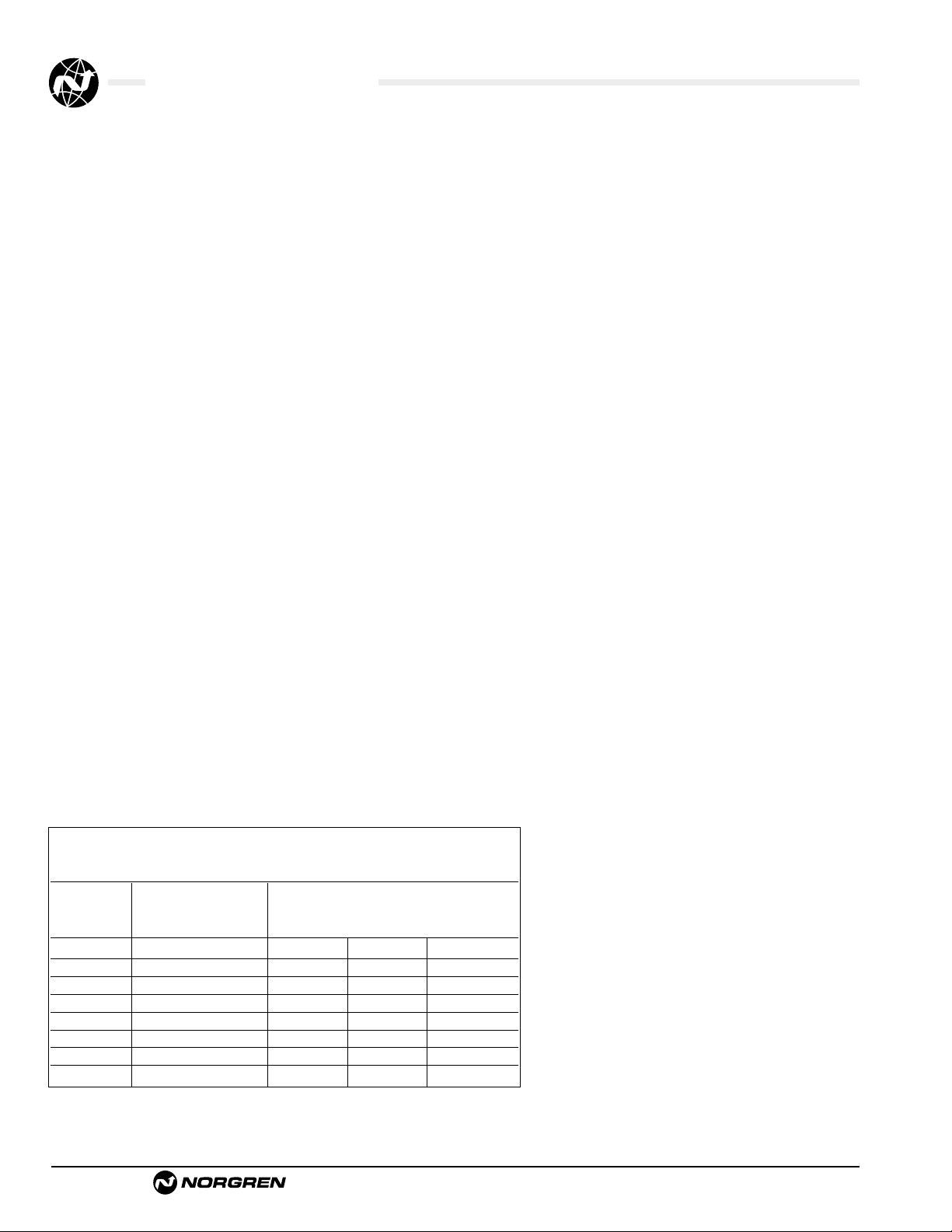

Operator Pilot Pressures

Maximum Pressure: 150 psig (10.3 bar)

Minimum Pilot Pressures are given in the following table

Minimum Operating Pressure

Primary Secondary Nondetent Detent Spring Centered

Operator Return Oper psig (bar) psig (bar) psig (bar)

Air Air 20 (1.4) 30 (2.1) 40 (2.8)

Solenoid Solenoid 20 (1.4) 30 (2.1) 40 (2.8)

Solenoid Spring 40 (2.8) — —

Solenoid Air-Assisted Spring 40 (2.8) — —

Solenoid Integral Air 40 (2.8) — —

Air Spring 40 (2.8) — —

Air Air-Assisted Spring 40 (2.8) — —

Air Integral Air 40 (2.8) — —

Page 5

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-5

Nugget 500 Series Valves

Dual Sandwich Speed Control

Seal Compatibility

Nugget 500 seals are compatible with most good

quality O-ring lubricants, including:

DC BR-2+ grease (Dow Corning)

DC 44 grease (Dow Corning)

Parker Super O-Lube (Parker Seal)

Magnalube G (Saunders Industries)

Nondetergent mineral based oil such as Mobil

DTE light oil

Nugget 500 seals are not compatible with WD-40 or

commonly used de-icer fluids. Consult factory to verify

compatibility of lubricants or fluids not listed above.

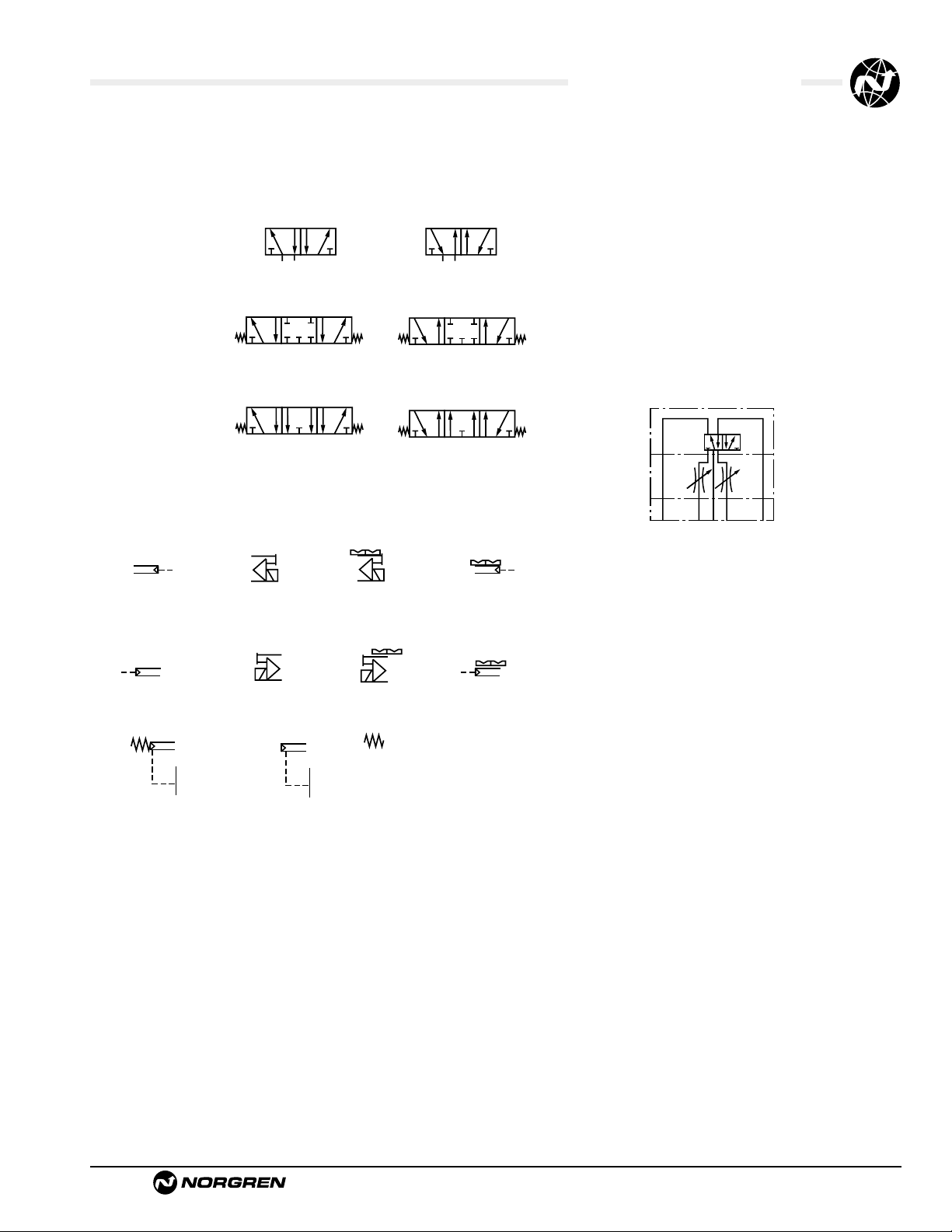

Operating Variations

Single Pressure

2

5-Port / 2-Position

1 2

5-port / 3-positon

spring centered, all

ports blocked in

the center positon*

5-port / 3-position

spring centered

cylinder open to exhaust

in the center position*

* 5-post / 3-position valves available with double

solenoid pilot or double air pilot operators only

† Dual presssure valves require externally piloted operators

Primary Operators

Air Pilot Solenoid Pilot

1 2

1 2

4

5

31

Spool Option 01

4

2

1

3

Spool Option 03

Spool Option 05 Spool Option 06

5

4

2

3

1

5

Secondary Operators

1 4

Solenoid Pilot Detent

1 4

1 4

1 2

1 2

1 2

Single Pressure†

2

4

5

31

Spool Option 02

4

2

3

1

5

Spool Option 04

4

2

1

3

5

Air Pilot

Detent

1 4

1 4

1 4

5

1

3

2

4

Air Pilot

Air Assisted Spring Integral Air

Solenoid Pilot

Solenoid Pilot Detent

Spring

Air Pilot

Detent

Page 6

5/2 and 5/2 directional control

spool valves

VAL-11-6

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

● Long lasting spool design

● High flow compact valves

● Four mounting styles: inline, fixed length

manifolds, single subbase, or subbase valves

attached to manifolding subbases

● Wide range of operators available

● Two functional types: available in 5/2, and 5/3

configurations

Technical Data

Medium:

Filtered, lubricated or non-lubricated, compressed air or vacuum

Operation:

Spool valve air pilot actuated

Mounting:

Inline, fixed length manifold, single subbase, and manifolding subbase

Port Sizes:

3/8", 1/2", or 3/4", ISO G or PTF

Operating Pressure:

Maximum 150 psig (10.3 bar).

Flow Characteristics:

Port Cv l/min scfm

3/8" Inline 4.0 4250 150

1/2" Inline 5.0 5150 180

3/4" Inline 5.6 6000 210

1/2" Subbase 4.7 5300 190

Operating Temperature

Solenoid Operated Valves:-20° to 120°F (-29° to 50°C)

Air Operated Valves: -20° to 160°F (-29° to 71°C)

*Consult our Technical Service for use below 36°F (2°C)

Materials:

Valve Body: Aluminum

Spool: Aluminum

Elastomers: Nitrile

Solenoid Operator Base: PPS plastic

Operator Housing: Zinc

Speed Control Materials

Body: Zinc

Adjusting Screw: Brass

Elastomers: Nitrile

Subbase Materials

Fixed Length Manifolds: Aluminum

Single and Manifolding Subbase: Aluminum

End Plate: Zinc

Elastomers: Nitrile

Order Information

To order standard Nugget 500 air pilot solenoid

operated valves, quote model number from table,

e.g. order

MN01CGA-35-AJJA for a 5-port/2-position, single

solenoid, spring return model.

Page 7

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-7

Nugget 500 Series Valves

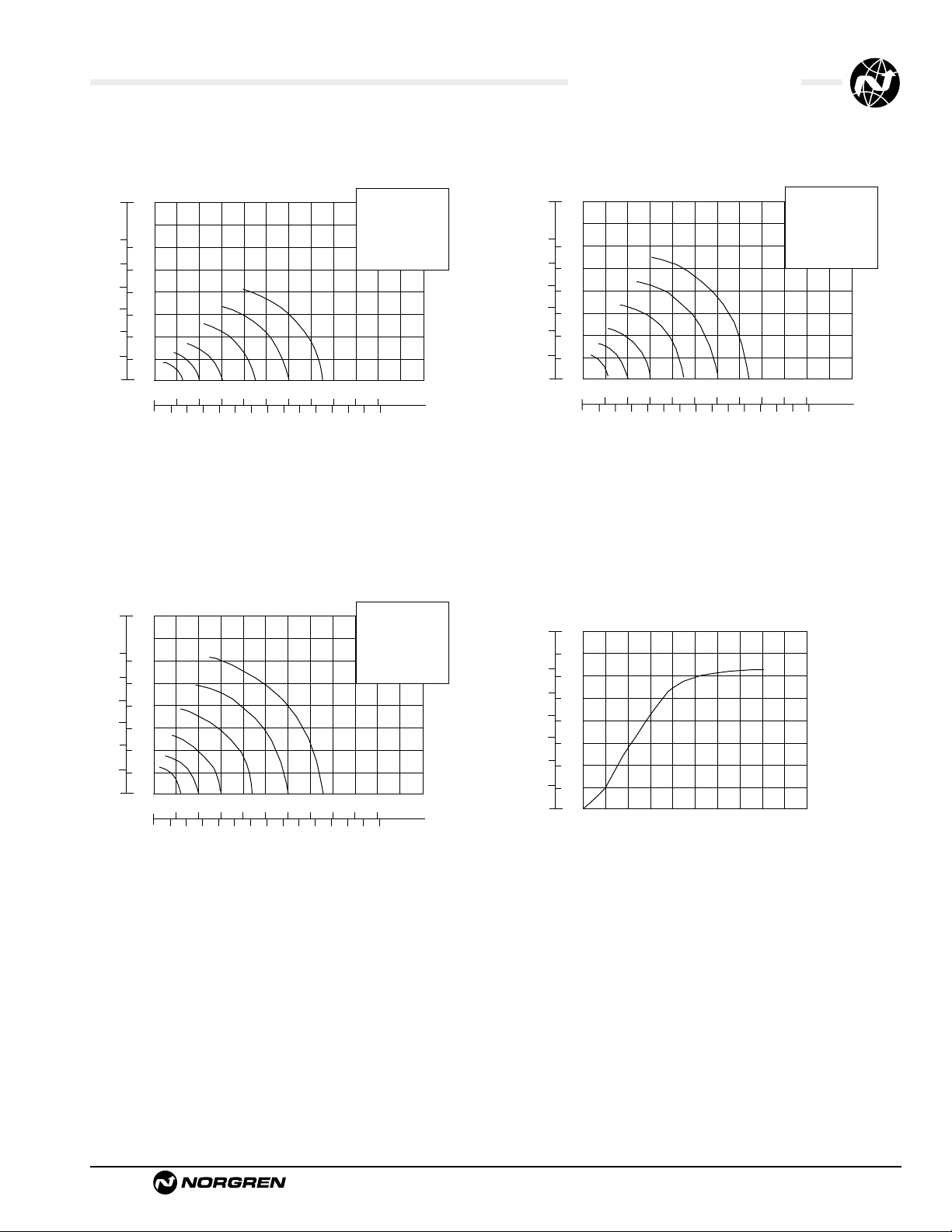

FLOW CHARACTERISTICS

3/8" Ported Inline Valves

/s

3

scfm

dm

300

600

250

500

200

400

150

300

100

200

50

100

0

20 60 100 140 180 psig

0 2 4 6 8 10 12 14 bar

FLOW CHARACTERISTICS

3/4" Ported Inline Valves

/s

3

scfm

dm

300

600

250

500

200

400

150

300

100

200

50

100

0

20 60 100 140 180 psig

02468101214

FLOW CHARACTERISTICS

1/2" Ported Inline Valves

A

Inlet Pressure

A = 150 psig (10.3)

B = 120 psig (8.3)

C = 90 psig (6.2)

D = 60 psig (4.1)

E = 40 psig (2.8)

F = 20 psig (1.4)

Inlet Pressure

A = 150 psig (10.3)

B = 120 psig (8.3)

C = 90 psig (6.2)

D = 60 psig (4.1)

E = 40 psig (2.8)

F = 20 psig (1.4)

A

BCDEF

300

250

200

150

100

50

/s

3

scfm

dm

600

500

400

300

200

100

0

20 60 100 140 180 psig

BCDEF

0 2 4 6 8 10 12 14 bar

SPEED CONTROL

Inlet Pressure: 90 PSIG (6.2 bar)

Inlet Pressure

A = 150 psig (10.3)

B = 120 psig (8.3)

C = 90 psig (6.2)

D = 60 psig (4.1)

E = 40 psig (2.8)

F = 20 psig (1.4)

A

BCDEF

Flow Path: 2 to 3 and 4 to 5 (cyl to exhaust)

/s

scfm

3

140

dm

60

120

50

100

40

80

30

60

20

40

10

20

012345678910

Needle Valve Turns Open

Page 8

VAL-11-8

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Inline Valves

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position

1/2" PTF MN01CGA 35-AJJA

40 - 150 1.42 54677-50

Single Solenoid single pressure (2.8 - 10.3) (.65)

Spring Return* 5-port/2-position

1/2" PTF MN02CGA 35-AKJA

40 - 150 1.42 54677-51

dual pressure (2.8 - 10.3) (.65)

5-port/2-position

1/2" PTF MN01CGA 25-AJJA

20 - 150 1.71 54677-50

Double single pressure (1.4 - 10.3) (.78)

Solenoid 5-port/2-position

1/2" PTF MN02CGA 25-AJJA

20 - 150 1.71 54677-51

dual pressure (1.4 - 10.3) (.78)

5-port/2 position

1/2" PTF MN01CGA 25-BJJA

30 - 150 1.99 54677-50

Double Solenoid single pressure (2.1 - 10.3) (.90)

Detent 5-port/2 position

1/2" PTF MN02CGA 25-BJJA

30 - 150 1.99 54677-51

dual pressure (2.1 - 10.3) (.90) 54677-51

5-port/3-position

single pressure,

1/2" PTF MN03CGA 25-FJJA

40 - 150 1.99 54677-52

all ports blocked in (2.8 - 10.3) (.90)

Double center position

Solenoid 5-port/3-position

1/2" PTF MN04CGA 25-FJJA

40 - 150 1.99 54677-53

dual pressure, (2.8 - 10.3) (.90)

all ports blocked in

center position

5-port/3-position

1/2" PTF MN05CGA 25-FJJA

20 - 150 1.99 54677-54

Double Solenoid single pressure, (1.4 - 10.3) (.90)

Spring Centered cylinder open to

Cylinder Open exhaust

to Exhaust

5-port/3-position dual

1/2" PTF MN06CGA 25-FJJA

20 - 150 1.99 54677-55

pressure cylinder (1.4 - 10.3) (.90)

open to exhaust

4

2

31

5

2

4

31

5

242

4

31

5

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads, solenoid operators with non-locking overrides, internal pilot, 120V/60 Hz-110V/50 Hz coils and cable

grip connectors.Optional solenoid operators, coil voltages and electrical connectors can be ordered using the information on p.VAL-11-22.

Note: For ISO-G threads, insert “G” in the 7th position.

2

4

31

5

4

2

31

5

Page 9

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-9

Nugget 500 Series Valves

Inline Valves

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position

1/2" PTF MN01CGA 33-A000

40 - 150 1.16

54677-50

Single Air single pressure (2.8 - 10.3) (.53)

Spring Return* 5-port/2-position

1/2" PTF MN02CGA 33-A000

40 - 150 1.16

54677-51

dual pressure (2.8 - 10.3) (.53)

5-port/2-position

1/2" PTF MN01CGA 23-A000

20 - 150 1.16

54677-50

Double single pressure (1.4 - 10.3) (.53)

Air 5-port/2-position

1/2" PTF MN02CGA 23-A000

20 - 150 1.16

54677-51

dual pressure (1.4 - 10.3) (.53)

5-port/2 position

1/2" PTF MN01CGA 23-B000

30 - 150 1.42

54677-50

Double Air single pressure (2.1 - 10.3) (.65)

Detent 5-port/2 position

1/2" PTF MN02CGA 23-B000

30 - 150 1.42

54677-51

dual pressure (2.1 - 10.3) (.65)

5-port/3-position

single pressure,

1/2" PTF MN03CGA 23-F000

40 - 150 1.42

54677-52

all ports blocked in (2.8 - 10.3) (.65)

Double Air,

center position

Spring Centered,

5-port/3-position

1/2" PTF MN04CGA 23-F000

40 - 150 1.42 54677-53

all ports blocked

dual pressure,

(2.8 - 10.3) (.65)

all ports blocked in

center position

5-port/3-position

1/2" PTF MN05CGA 23-F000 20 - 150 1.42 54677-54

Double Air

single pressure,

(1.4 - 10.3) (.65)

Spring Centered

cylinder open to

Cylinder Open

exhaust

to Exhaust 5-port/3-position dual

1/2" PTF MN06CGA 23-F000

20 - 150 1.42

54677-55

pressure, cylinder (1.4 - 10.3) (.65)

open to exhaust

4

2

31

5

2

4

31

5

2

4

2

4

31

5

2

4

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads..

Note: For ISO-G threads, insert “G” in the 7th position.

4

2

31

5

4

2

31

5

4

2

1

3

5

Page 10

VAL-11-10

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Valves with Manifolding Subbases

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position

1/2" PTF MN01GGA 35-AJJA

40 - 150 2.37

54677-50

Single Solenoid single pressure (2.8 - 10.3) (1.08)

Spring Return* 5-port/2-position

1/2" PTF MN02GGA 35-AKJA

40 - 150 2.37

54677-51

dual pressure (2.8 - 10.3) (1.08)

5-port/2-position

1/2" PTF MN01GGA 25-AJJA

20 - 150 2.64

54677-50

Double single pressure (1.4 - 10.3) (1.20)

Solenoid 5-port/2-position

1/2" PTF MN02GGA 25-AJJA

20 - 150 2.64

54677-51

dual pressure (1.4 - 10.3) (1.20)

5-port/2 position

1/2" PTF MN01GGA 25-BJJA

30 - 150 2.94 54677-50

Double Solenoid single pressure (2.1 - 10.3) (1.34)

Detent 5-port/2 position

1/2" PTF MN02GGA 25-BJJA

30 - 150 2.94 54677-51

dual pressure (2.1 - 10.3) (1.34) 54677-51

5-port/3-position

single pressure,

1/2" PTF MN03GGA 25-FJJA

40 - 150 2.94

54677-52

all ports blocked in (2.8 - 10.3) (1.34)

Double center position

Solenoid 5-port/3-position

1/2" PTF MN04GGA 25-FJJA

40 - 150 2.94

54677-53

dual pressure, (2.8 - 10.3) (1.34)

all ports blocked in

center position

5-port/3-position

1/2" PTF MN05GGA 25-FJJA

20 - 150 2.94

54677-54

Double Solenoid single pressure, (1.4 - 10.3) (1.34)

Spring Centered cylinder open to

Cylinder Open exhaust

to Exhaust

5-port/3-position dual

1/2" PTF MN06GGA 25-FJJA

20 - 150 2.94

54677-55

pressure cylinder (1.4 - 10.3) (1.34)

open to exhaust

2

4

2

4

31

5

242

4

31

5

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads, solenoid operators with non-locking overrides, internal pilot, 120V/60 Hz-110V/50 Hz coils and cable grip connectors.

Optional solenoid operators, coil voltages and electrical connectors can be ordered using the information on p.VAL-11-22.

Note: For ISO-G threads, insert “G” in the 7th position.

2

4

31

5

4

2

31

5

Page 11

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-11

Nugget 500 Series Valves

Valves with Manifolding Subbases

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position 1/2" PTF MN01GGA 33-A000 40 - 150 2.09 54677-50

Single Air single pressure (2.8 - 10.3) (.95)

Spring Return* 5-port/2-position 1/2" PTF MN02GGA 33-A000 40 - 150 2.09 54677-51

dual pressure (2.8 - 10.3) (.95)

5-port/2-position 1/2" PTF MN01GGA 23-A000 20 - 150 2.09 54677-50

Double single pressure (1.4 - 10.3) (.95)

Air 5-port/2-position 1/2" PTF MN02GGA 23-A000 20 - 150 2.09 54677-51

dual pressure (1.4 - 10.3) (.95)

5-port/2 position 1/2" PTF MN01GGA 23-B000 30 - 150 2.37 54677-50

Double Air single pressure (2.1 - 10.3) (1.08)

Detent 5-port/2 position 1/2" PTF MN02GGA 25-B000 30 - 150 2.37 54677-51

dual pressure (2.1 - 10.3) (1.08)

5-port/3-position

single pressure, 1/2" PTF MN03GGA 23-F000 40 - 150 2.37 54677-52

all ports blocked in (2.8 - 10.3) (1.08)

Double Air, center position

Spring Centered, 5-port/3-position 1/2" PTF MN04GGA 23-F000 40 - 150 2.37 54677-53

all ports blocked dual pressure, (2.8 - 10.3) (1.08)

all ports blocked in

center position

5-port/3-position 1/2" PTF MN05GGA 23-F000 20 - 150 2.37 54677-54

Double Air single pressure, (1.4 - 10.3) (1.08)

Spring Centered cylinder open to

Cylinder Open exhaust

to Exhaust

5-port/3-position dual 1/2" PTF MN06GGA 23-F000 20 - 150 2.37 54677-55

pressure, cylinder (1.4 - 10.3) (1.08)

open to exhaust

4

2

31

5

2

4

31

5

242

4

31

5

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads.

Note: For ISO-G threads, insert “G” in the 7th position.

4

2

31

5

4

2

31

5

4

2

1

3

5

Page 12

VAL-11-12

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Valves on a Single Subbase

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position 1/2" PTF MN01EGA 35-AJJA 40 - 150 2.08 54677-50

Single Solenoid single pressure (2.8 - 10.3) (.95)

Spring Return* 5-port/2-position 1/2" PTF MN02EGA 35-AKJA 40 - 150 2.08 54677-51

dual pressure (2.8 - 10.3) (.95)

5-port/2-position 1/2" PTF MN01EGA 25-AJJA 20 - 150 2.33 54677-50

Double single pressure (1.4 - 10.3) (1.06)

Solenoid 5-port/2-position 1/2" PTF MN02EGA 25-AJJA 20 - 150 2.33 54677-51

dual pressure (1.4 - 10.3) (1.06)

5-port/2 position 1/2" PTF MN01EGA 25-BJJA 30 - 150 2.62 54677-50

Double Solenoid single pressure (2.1 - 10.3) (1.19)

Detent 5-port/2 position 1/2" PTF MN02EGA 25-BJJA 30 - 150 2.62 54677-51

dual pressure (2.1 - 10.3) (1.19) 54677-51

5-port/3-position

single pressure, 1/2" PTF MN03EGA 25-FJJA 40 - 150 2.62 54677-52

all ports blocked in (2.8 - 10.3) (1.19)

Double center position

Solenoid 5-port/3-position 1/2" PTF MN04EGA 25-FJJA 40 - 150 2.62 54677-53

dual pressure, (2.8 - 10.3) (1.19)

all ports blocked in

center position

5-port/3-position 1/2" PTF MN05EGA 25-FJJA 20 - 150 2.62 54677-54

Double Solenoid single pressure, (1.4 - 10.3) (1.19)

Spring Centered cylinder open to

Cylinder Open exhaust

to Exhaust

5-port/3-position dual 1/2" PTF MN06EGA 25-FJJA 20 - 150 2.62 54677-55

pressure cylinder (1.4 - 10.3) (1.19)

open to exhaust

2

4

2

4

31

5

242

4

31

5

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads, solenoid operators with non-locking overrides, internal pilot, 120V/60 Hz-110V/50 Hz coils and cable grip connectors.

Optional solenoid operators, coil voltages and electrical connectors can be ordered using the information on p.VAL-11-22.

Note: For ISO-G threads, insert “G” in the 7th position.

2

4

31

5

4

2

31

5

Page 13

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-13

Nugget 500 Series Valves

Valves on a Single Subbase

Pilot

Port Pressure Weight Repair

Description Symbol Type Size Body Operator psig (bar) lbs. (kg) Kit

5-port/2-position 1/2" PTF MN01EGA 33-A000 40 - 150 1.81 54677-50

Single Air single pressure (2.8 - 10.3) (.82)

Spring Return* 5-port/2-position 1/2" PTF MN02EGA 33-A000 40 - 150 1.81 54677-51

dual pressure (2.8 - 10.3) (.82)

5-port/2-position 1/2" PTF MN01EGA 23-A000 20 - 150 1.81 54677-50

Double single pressure (1.4 - 10.3) (.82)

Air 5-port/2-position 1/2" PTF MN02EGA 23-A000 20 - 150 1.81 54677-51

dual pressure (1.4 - 10.3) (.82)

5-port/2 position 1/2" PTF MN01EGA 23-B000 30 - 150 2.09 54677-50

Double Air single pressure (2.1 - 10.3) (.95)

Detent 5-port/2 position 1/2" PTF MN02EGA 23-B000 30 - 150 2.09 54677-51

dual pressure (2.1 - 10.3) (.95)

5-port/3-position

single pressure, 1/2" PTF MN03EGA 23-F000 40 - 150 2.09 54677-52

all ports blocked in (2.8 - 10.3) (.95)

Double Air, center position

Spring Centered, 5-port/3-position 1/2" PTF MN04EGA 23-F000 40 - 150 2.09 54677-53

all ports blocked dual pressure, (2.8 - 10.3) (.95)

all ports blocked in

center position

5-port/3-position 1/2" PTF MN05EGA 23-F000 20 - 150 2.09 54677-54

Double Air single pressure, (1.4 - 10.3) (.95)

Spring Centered cylinder open to

Cylinder Open exhaust

to Exhaust 5-port/3-position dual 1/2" PTF MN06EGA 23-F000 20 - 150 2.09 54677-55

pressure, cylinder (1.4 - 10.3) (.95)

open to exhaust

2

4

31

5

4

2

31

5

2

4

31

5

242

4

31

5

2

4

1

5

3

2

4

1

5

3

2

4

1

5

3

* Standard valves are equipped with PTF threads.

Note: For ISO-G threads, insert “G” in the 7th position.

4

2

31

5

4

2

1

3

5

Page 14

VAL-11-14

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Valve ABCDEFGHJKLMN

Solenoid Pilot Operator — 5-Port/2-Position Nondetent

Single Solenoid* 9.46 3.53 1.91 1.48 0.63 1.44 2.71 2.44 1.94 3.00 0.27 1.17 1.48

(240) (90) (49) (38) (16) (37) (69) (62) (49) (76) (7) (30) (38)

Double Solenoid 12.36 3.53 1.91 1.48 — 1.44 2.71 2.44 1.94 3.00 0.27 1.17 1.48

(314) (90) (49) (38) — (37) (69) (62) (49) (76) (7) (30) (38)

Solenoid Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Solenoid 13.30 4.00 1.91 1.48 — 1.44 2.71 2.44 1.94 3.00 0.27 1.17 1.48

(338) (102) (49) (38) — (37) (69) (62) (49) (76) (7) (30) (38)

Air Pilot Operator — 5-Port/2-Position Nondetent

Single Air* 6.56 0.63 1.91 1.48 0.63 1.44 — 2.44 1.94 3.00 0.27 1.17 1.48

(167) (16) (49) (38) (16) (37) — (62) (49) (76) (7) (30) (38)

Double Air 6.56 0.63 1.91 1.48 — 1.44 — 2.44 1.94 3.00 0.27 1.17 1.48

(7) (16) (49) (38) — (37) — (62) (49) (76) (7) (30) (38)

Air Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Air 7.50 1.10 1.91 1.48 — 1.44 — 2.44 1.94 3.00 0.27 1.17 1.48

(191) (28) (49) (38) — (37) — (62) (49) (76) (7) (30) (38)

*With air-assisted spring return, spring return or integral air retur n

Manifold Kits* Fixed Length Manifold Kits and Dimensions

Ports No. of

3/4 NPT 3/4 ISO G Stations S T U V W X Y Z TA UA

13342-60 13342-70 2 4.00 (102) 4.28 (109) 3.50 (89) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-61 13342-71 3 5.50 (140) 4.28 (109) 5.00 (127) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-62 13342-72 4 7.00 (178) 4.28 (109) 6.50 (165) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-63 13342-73 5 8.50 (216) 4.28 (109) 8.00 (203) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-64 13342-74 6 10.00 (254) 4.28 (109) 9.50 (241) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-65 13342-75 8 13.00 (330) 4.28 (109) 12.50 (318) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

13342-66 13342-76 10 16.00 (406) 4.28 (109) 15.50 (394) 1.50 (38) 1.78 (45) 1.48 (38) 1.13 (29) 0.65 (17) 3.75 (95) 1.12 (28)

Note: 4 mm hex key drive required for mounting screw removal/replacement

Inline Valve Dimensions

*Kits include manifolds, seals, and valve attaching hardware.See VAL-11-19 for blanking plate kits.

All Dimensions in Inches (mm)

C

A

C BE D

A

C

C BB D

A

C

C BB D

F

Dia. L

H

K

J

N N MM

G

Dia. L

G

Valve Body

Locating Pin

3/4'' Inlet Port

Z

Y

Y

W

W

F

K

N N MM

Port

Numbers

513

T

TA

Dia. L

H

S

K

J

N N MM

Mounting

Holes

0.28

51

(7 mm)

V

X X

3/4" Exhaust Ports

UA

U

3

Page 15

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-15

Nugget 500 Series Valves

Valve ABCDEFGHJKLNOPRST

Solenoid Pilot Operator — 5-Port/2-Position Nondetent

Single Solenoid* 0.63 1.94 1.48 1.46 0.48 9.46 1.80 4.15 3.53 1.38 0.63 6.50 6.05 1.48 0.25 2.71 0.63

(16) (49) (38) (37) (12) (240) (46) (105) (90) (35) (16) (1.65) (154) (38) (6) (69) (16)

Double Solenoid 0.63 1.94 1.48 1.46 0.48 10.40 1.80 4.15 4.00 1.38 0.63 6.50 6.05 1.48 0.25 2.71 0.63

(16) (49) (38) (37) (12) (264) (46) (105) (102) (35) (16) (1.65) (154) (38) (6) (69) (16)

Solenoid Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Solenoid 0.63 1.94 1.48 1.46 0.48 12.36 1.80 4.15 3.53 1.38 0.63 6.50 6.05 1.48 0.25 2.71 0.63

(16) (49) (38) (37) (12) (314) (46) (105) (90) (35) (16) (1.65) (154) (38) (6) (69) (16)

Air Pilot Operator — 5-Port/2-Position Nondetent

Single Air* 0.63 1.94 1.48 1.46 0.48 6.56 1.80 3.89 — 1.38 0.63 6.50 6.05 1.48 0.25 — 0.63

(16) (49) (38) (37) (12) (167) (46) (99) — (35) (16) (1.65) (154) (38) (6) — (16)

Double Air 0.63 1.94 1.48 1.46 0.48 6.56 1.80 3.89 — 1.38 0.63 6.50 6.05 1.48 0.25 — 0.63

(16) (49) (38) (37) (12) (167) (46) (99) — (35) (16) (1.65) (154) (38) (6) — (16)

Air Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Air 0.63 1.94 1.48 1.46 0.48 7.50 1.80 3.89 — 1.38 0.63 6.50 6.05 1.48 0.25 — 0.63

(16) (49) (38) (37) (12) (191) (46) (99) — (35) (16) (1.65) (154) (38) (6) — (16)

*With air-assisted spring return, spring return or integral air retur n.

Single Subbase Ports

Note: 4 mm hex key drive required for mounting screws

Subbase Valve on Single Subbase Dimensions

All Dimensions in Inches (mm)

A

D

G

H

L

K

BEC

F

P P

O

N

T

G

J

H

R

A

D

L

K

BEC

F

P P

O

N

T

J

S

R

A

D

G

H

L

K

BEC

F

P P

O

N

T

R

Valve Body

Locating Pin

Exhaust Ports

3/8" External

3/8" or 1/2"

Pilot Port

1/8" External

Pilot Port

Numbers

3/8" or 1/2"

Cylinder Ports

Port

.280

4.250 (108)

(7)

(28)

1.120

Page 16

All Dimensions in Inches (mm)

VAL-11-16

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Valve ABCDFGHJKL**M**NOPRS

Solenoid Pilot Operator — 5-Port/2-Position Nondetent

Single Solenoid* 9.46 3.53 5.62 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(240) (90) (143) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Double Solenoid 12.36 3.53 5.62 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(314) (90) (143) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Solenoid Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Solenoid 13.30 4.00 5.62 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(338) (102) (143) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Air Pilot Operator — 5-Port/2-Position Nondetent

Single Air* 6.56 — 5.36 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(167) — (136) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Double Air 6.56 — 5.36 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(167) — (136) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Air Pilot Operator — 5-Port/2-Position Detent or 5-Port/3-Position Spring Centered

Double Air 7.50 — 5.36 2.85 1.48 5.76 0.97 2.48 5.13 4.58 5.14 0.53 1.44 1.35 0.97 1.82

(191) — (136) (72) (38) (146) (25) (63) (130) (116) (131) (14) (37) (34) (25) (46)

Manifold Subbase Assembly

*With air-assisted spring return, spring return or integral air retur n.

**Dimensions shown are for two end plates and two manifolding subbases. Add 1.50" (38 mm) for each additional manifolding subbase.

Note: 4 mm hex key drive required for mounting screws

Subbase Valves on Modular Manifold Dimensions

A

D

F F

G

B

C

D

P

A

F F

G

B

C

P

C

D

A

P

F F

G

Valve Body

Locating Pin

D

1/8" External Pilot

Supply Port

H

K

G

J

L

M

O

N

S

R

Page 17

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-17

Nugget 500 Series Valves

For ordering information, the valve and

manifolding subbase assembly are oriented

with the 1 2 operator end on the left side,

and the 1 4 operator end on the right side.

The valves are listed from FRONT to BACK.

This example illustrates how to order a valve

and manifolding subbase assembly, with

isolating plugs for two different working

pressures installed between valve manifold

subbases 2 and 3.

Four pipe plugs are included with the end

plate kit to allow blocking of unused common

inlet, exhaust, and pilot end plate ports to

prevent air loss and entry of contaminants.

Valve

Pos. Product Special

No. Qty. Number Instructions

1 1 MN01GCA-75-ALJA

2 1 MN01GGA-75-ALJA

1 54676-50 Install

isolating

plugs

3 1 MN01GGA-75-ALJA

4 1 MN01GGA-75-ALJA

1 13338-50 End Plate kit

4 99-059-530 Ass’y charge

Factory Assembled Valve and Manifolding Subbase Assemblies

Isolating Plug Kits

An isolating plug kit is available to allow the

use of different inlet pressures.A valve and

manifolding subbase assembly can be

divided into two sections by inserting

isolating plugs between any two manifolding

subbases.

The drawing at right illustrates a valve and

manifolding subbase assembly separated

for a two pressure applications by isolating

plugs.

Ordering Information

Isolating Plug Kit* 54676-50

*Kit contains 3-Isolating Plugs

Port 2

3/8" or 1/2"

Cylinder Ports

3/8" or 1/2"

Cylinder Ports

Port 4

Port 3

3/4" Common

Exhaust Port

3/4" Common

FRONT

1 2 END

Valve 1

Port 1

Inlet Port

Valve 2

3/4" Common

Exhaust Port

Valve 4

Valve 3

Port 5

BACK

1/8 External

Pilot Supply Port

1 4 END

Separator

Isolating Plugs

Seal

End Plate

Clamping Pin

Set Screw

Page 18

VAL-11-18

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Nugget 500 Series Valves

Factory Assembled Valve and Fixed Length Assemblies

For ordering information, the valve and manifold assembly

is oriented with the 1 2 operator end on the left side and

the 1 4 operator end on the right side.The valves are listed

from FRONT to BACK.

e.g. to order a five station, fixed length manifold assembly:

Valve

Pos. Product

No. Qty. Number

1-3 3 MN01CGA-75-AJJA

4 1 MN01CGA-25-AJJA

5 1 MN03CGA-25-FJJA

1 13342-63

4 33-059-530 (Ass’y Chg)

Special Instructions: One assembly consisting of the

Nugget stack above.

1 2 END

Valve 1

Port 3

3/4" Common

Exhaust Port

3/4" Common

FRONT

Valve 2

Port 1

Inlet Port

Valve 3

Valve 4

Port 5

3/4" Common

Exhaust Port

Valve 5

1/2" Cylinder

Ports

BACK

1 4 END

Page 19

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-19

Nugget 500 Series Valves

Blanking Plate Kit

The blanking plate kit consists of a blanking plate, seal, and attaching hardware.

The plate is installed on a subbase in place of a valve, allowing an additional valve

to be added at a later date.

For Fixed Length

Manifolds: 54689-50

For Single and

Manifolding Subbases: 54689-51

Quietaire® Mufflers and Speed Control Mufflers

Mufflers should be installed in the exhaust ports of Nugget 500 Valves to reduce

work area noise and help prevent contaminants from entering the valve. Speed

control mufflers also allow metering of the exhaust air flow to restrict the speed of

air cylinders and air motors. Do not use speed control mufflers in manifold exhaust

ports.

Port Sintered Speed

Size Type Control Shell

NPT Muffler Muffler Type

3/8 MS003A MM003A MB003A

1/2 MS004A MM004A MB004A

3/4 MS006A MM006A MB006A

See Norgren publication APC-101 for complete muffler information.

Intermediate Supply/Exhaust Block

The intermediate supply/exhaust block consists of a

supply/exhaust block, a manifolding subbase valve body

without spool, interface seals and hardware needed to

connect the subbase to the adjacent subbase and six

isolating plugs.The supply/exhaust block provides a

method of connecting an additional air supply to the valve

manifold.This helps prevent starvation of supply air to the

valves when a number of valves are operated

simultaneously.The block also allows use of three or more

supply pressures in the same manifold, and may also be

used to exhaust individual valves.

Supply/Exhaust Block

1/2" PTF .......................................................54693-50

1/2" ISO G....................................................54693-51

Dual Sandwich Speed Control Kit

The speed control kit, consisting of a speed control block, mounting

screws, and gasket, is installed between a subbase valve and a subbase.

Needle valves, located at both ends of the speed control, restrict exhaust

flow from the valve to control the speed of an air cylinder or motor. Order

the speed control kit below.

Speed Control Kit..............................13336-60

Page 20

VAL-11-20

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Single Solenoid, Spring Return

5-Port/2-Position:

Nondetent........MN01D0A-35-ALJA

Nugget 500 Series Valves

Double Solenoid

5-Port/2-Position:

Nondetent.............MN01D0A-25-ALJA

Detent...................MN01D0A-25-BLJA

5-Port/3-Position:

All Ports Blocked...MN03D0A-25-FLJA

Cylinder Open to

Exhaust.................MN05D0A-25-FLJA

Manifolding Subbase for Subbase

Valve

3/8 PTF ..........................................13335-50

3/8 ISO G.......................................13335-51

1/2 PTF ..........................................13335-52

1/2 ISO G.......................................13335-53

Single Subbase for Subbase Valve

3/8 PTF...........................................13340-70

3/8 ISO G........................................13340-71

1/2 PTF...........................................13340-72

1/2 ISO G........................................13340-73

Double Air

5-Port/2-Position:

Nondetent ................MN01D0A-23-A000

Detent ......................MN01D0A-23-B000

5-Port/3-Position:

All Ports Blocked......MN03D0A-23-F000

Cylinder Open to

Exhaust....................MN05D0A-23-F000

Single Air, Spring Return

5-Port/2-Position:

Nondetent........MN01D0A-33-A000

Subbase Valves with Operators without Subbase

Note: Mounting screws and gaskets are included.

Page 21

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

VAL-11-21

Nugget 500 Series Valves

Factory Installed Back Cover Plates for Valve Bodies

The Back Cover Plate ordered with the valve allows the valve to be used in washdown environments such as food or medical processing.If a subbase valve is

desired for wash-down environments, use only the single subbase.

● For cover plate installed on an Inline Valve body specify with 54690-11 after the

valve body number.

● For cover plate installed on a Subbase Valve body specify with 54690-12 after

the valve body number.

Pneu-Fit Push-in Tube Fittings

Push-in tube fittings are an excellent way to save valve connection time and

simplify component replacement. See Norgren Fittings catalog APC-101 for a

complete selection of push-in tube fittings, flexible tubing, tubing markers, and tube

mounts.

Part Numbers for Replacement Solenoid Coils & Armature

Bases

Solenoid Coils:

24V/60Hz-24V/50Hz, 3.5W...........54469-04

120V/60Hz-110V/50Hz, 3.5W.......54469-03

6VDC, 2W .....................................54469-05

12VDC, 2W ...................................54469-01

24VDC, 2W ...................................54469-02

110VDC, 3.4W ..............................54469-06

240V/60Hz-220V/50Hz, 7.5W.......54452-07

120V/60Hz-110V/50Hz, 7.5W.......54452-01

24V/60Hz-24V/50Hz, 7.5W...........54452-05

12VDC, 7.5W ...............................54452-02

24VDC, 6W ..................................54452-03

Solenoid Base and Armature:

Without Override

6 to 7.5 Watt................................54462-01

2 to 3.5 Watt................................54462-03

With Locking Override

6 to 7.5 Watt................................54462-02

2 to 3.5 Watt................................54462-04

With Non-Locking Override

6 to 7.5 Watt................................54462-09

2 to 3.5 Watt................................54462-10

Part Numbers for Replacement Connectors

Cable Grip Connector.......................54934-01

Cable Grip Connector with

Indicator Light

110/120 VAC/DC ..........................54934-02

24 VAC/DC ...................................54934-08

1/2" NPT Conduit .............................54934-05

Molded 5-ft Cable Connector

0-220 VAC/DC..............................54934-21

Molded 5-ft Cable Connector with

Indicator Light and surge

suppression

24 VAC/DC ...................................54934-30

110 VAC/DC .................................54934-35

240 VAC/DC .................................54934-37

Part Numbers for Repair Parts & Kits

Metal Coil Retaining Ring..................54453-01

Solenoid Connector Seal Kit.............54935-01

Solenoid Exhaust Port Diffuser.........54463-01

Solenoid Exhaust Port Filter

Ordered With Valve .......................54463-50

Ordered Separately .......................54463-51

Spool Replacement Kits: ...................

Single Pressure, 2-Position...........54677-50

Dual Pressure, 2-Position..............54677-51

Single Pressure, 3-Position,

All Ports Blocked*.........................54677-52

Dual Pressure, 3-Position,

All Ports Blocked*.........................54677-53

Single Pressure, 3-Position,Cylinder

Open to Exhaust*..........................54677-54

Dual Pressure, 3-Position, Cylinder

Open to Exhaust*..........................54677-55

*In the center position

Seal Kits

Inline Valv es..................................54692-50

Subbase Valv es.............................54692-51

Inline Valve to Fixed

Length Manifold.............................54674-89

Subbase Valv e

to Subbase....................................54672-89

Manifolding Subbase to

End Plates .....................................54673-89

Manifold clamping

pin (1) & set screws (2).................54574-50

Mounting Screws Valve to Fixed

Length Manifold or Subbase.........54580-60

Mounting Screws Valve and

Speed Control to Subbase ............54580-61

Page 22

Nugget 500 Series Valves

VAL-11-22

Littleton, CO USA Phone: 303-794-2611 www.norgren.com

Type & Family

Basic Size

Internal Variations

Mounting

Por t S i ze

Thread Type

Secondary Operator 1 2 End

Primary Operator 1 4 End

Operator Description

Solenoid Override/

Pilot Supply

Coil V oltage/W attage

Electrical Connector

M = Bonded Spool Valve

N = Nugget 500, Cv = 5.0

01 = 5-Port/2-Position, Single Pressure Valve

02 = 5-por t/2-Position, Dual Pressure Valve

03 = 5 Port/3-Position, Single Pressure Valve, Spring Centered, All Ports Blocked

04 = 5 Port/3-Position, Dual Pressure Valve, Spring Centered, All Ports Blocked

05 = 5-Port/3-Position, Single Pressure Valve, Spring Centered, Cylinder Open to Exhaust

06 = 5-Port/3-Position, Dual Pressure Valve, Spring Centered, Cylinder Open to Exhaust

C = 5-Port,

Inline Valv e

D = 5-Port, Subbase Valve

Without Subbase

E = 5-Port Subbase Valve

Assembled to a Single

Subbase

G = 5-Port, Subbase

Valve Assembled to a

Manifolding Subbase

A = PTF

G = ISO

3 = Air Pilot

5 = Solenoid Pilot

Position

1 2 3 4 5 6 7 8 9

10 11 12 13

1

2

3 4

5

6

7

8

9

10

11

12

13

Valve Body

Operator Description

0 = Use for Air Operator

Operators

= Product Number

3.5 Watt, Nominal

J = 120V/60Hz-110V/50 Hz, 3.5 Watt

L = 24V/60Hz/50z, 3.5 Watt

M = 6VDC, 2 Watt

N = 12 VDC, 2 Watt

P = 24 VDC, 2 Watt

S = 110 VDC, 3.4 Watt

A = Cable Grip

B = Cable Grip with Indicator Light 110/120 VAC/DC

C = 1/2" NPT Conduit

D = 5-ft Molded Cable 0-220 VAC/DC

E = 5-ft Molded Cable with Indicator Light and Surge Suppression, 24 VAC/DC

G = 5-ft Molded Cable with Indicator Light and Surge Suppression, 110 VAC/DC

H = 5-ft Molded Cable with Indicator Light and Surge Suppression, 240 VAC/DC

J = Cable Grip with Indicator Light, 24 VAC/DC

X = Solenoid Without Connector

F = 3/8"

G = 1/2"

F = 3/8"

G = 1/2"

H = 3/4" (PTF only)

1 = Integral Air Return

2 = Same as Primar y Operator

3 = Spring Retur n

7 = Air-Assisted Spring Retur n

A = Nondetent

B = Detent

F = Spring Centered

0 = Use for Air Operator

7.5 Watt, Nominal

N = No Override, Internal Pilot

P = No Override, External Pilot

R = Non-Locking Override, Internal Pilot

S = Non-Locking Override, External Pilot

T = Locking Override, Internal Pilot

V = Locking Override, External Pilot

7.5 Watt, Nominal

T = 120V/60Hz-110V/50Hz, 7.5 Watt

V = 240V/60Hz-220V/50Hz, 7.5 Watt

W = 24V/60Hz/50Hz, 7.5 Watt

Z = 12 VDC, 7.5 Watt

1 = 24 VDC, 6.0 Watt

3.5 Watt, Nominal

G = No Override, Internal Pilot

H = No Override, External Pilot

J = Non-Locking Override, Internal Pilot

K = Non-Locking Override, External Pilot

L = Locking Override, Internal Pilot

M = Locking Override, External Pilot

— —

0 = Subbase Valve

Without Subbase

0 = Use for Air Operator

Loading...

Loading...