Page 1

Features

Norgren GT Development Combination Valves

have an electrical switch integrated into the valve

body, which is used in conjunction with a 12-volt

air compressor. Actuation of the valve either

engages the compressor, or vents the air springs.

Combination Valve Performance

Function

Actuation

Pressure Rating

Knob

Part Number

Designed to operate air seat systems using an elec tric air compressor

Push: Closes elec trical switch Approved for use with RDH Enterprises # 64-0 0450 12 VDC compressor

or equivalent.

Pull: “OUT” port is vented to atmosphere.

200 psig

Black with GT logo

3000

Combination Valve

3000

3013-5

Combination Paddle Seat Valve Performance

Function

Actuation

Pressure Rating

Connection

Compliance

Power Rating

Part Number

Rev. 9/14 01

Provides pneumatic and electric control of air seats employing an electrically-driven air compressor

3-way, dead center, paddle style actuation

125 psig max.

1/4" Barb connection

All plastic components meet FMVSS 302 flammability requirements

Rated for steady state direct current of 7.5 amps maximum. Zero-current voltage of 16 VDC maximum.

Duty cycle of 25% maximum, and “ON” time of 60 seconds maximum.

3013-5

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Page 2

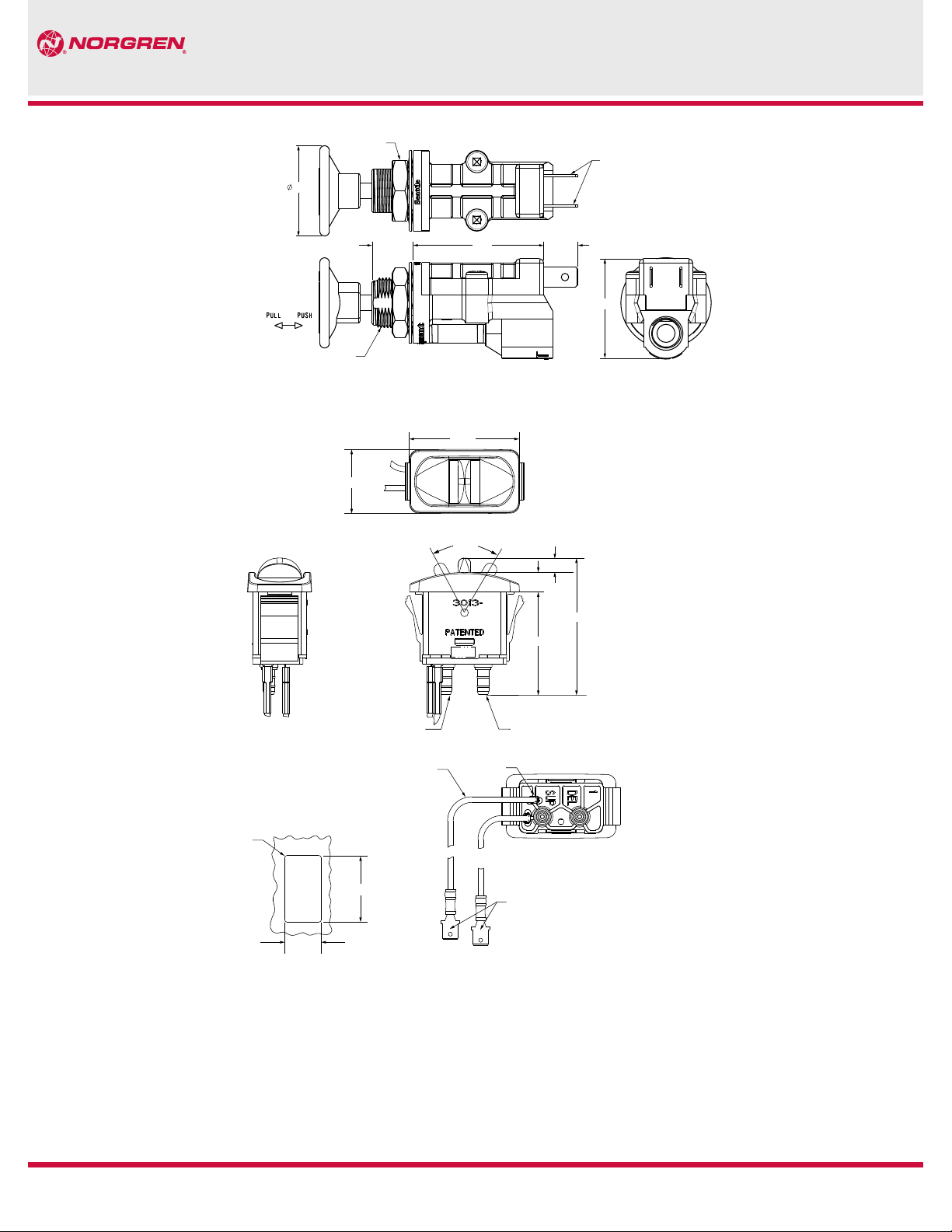

Combination Valve

Dimensions (Inches)

3000

3013-5

1-1/8

5/8-18 UNF THD

NUT & WASHER

1. 0 ± 0.3

1/4" BLADE TERMINALS

(REF SAE J858a)

1-25/32

55° OFF

1.62

INFLATEDEFLATE

1/2

7/16

1-1/4

1/4

5/16

SUPPLY PORT BARBED FITTING,

ACCEPTS 3/16 I.D. TUBE (COMPRESSOR)

WIRE ASSEMBLY

25 ± 1, 2 PL (-5 ONLY)

PANEL OPENING

R .063 max 4PL

1.610 ± 0.010

0.890

± 0.010

Warning

Improper selection, misuse, age or malfunction of components used in

commercial vehicle systems can cause failure in various modes. The system

designer is warned to consider the failure modes of all component parts

used in commercial vehicle systems and to provide adequate safeguards to

prevent personal injury or damage to equipment or property in the event of

such failure modes. System designers and end users are cautioned to consult

instruction sheets and specifications available from the factor y. The system

designer/end user is responsible for verif ying that all requirements for the

application are met.

2-3/16±1/16

1-5/8

DELIVERY PORT BARBED FITTING,

ACCEPTS 3/16 I.D. TUBE (SEAT)

RECEPTACLE

TERMINAL

1/4 BLADE

(-5 ONLY)

Warranty

The products described herein are warranted subject to seller’s Standard

Terms and Condition of Sale, available at seller’s website.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Rev. 9/1402

Loading...

Loading...