Page 1

Features

Norgren GT Development’s Return Flow Splitter

is used in many of today’s Class 8 vehicles to

evenly distribute return flow of fuel to the fuel

tanks, eliminating the need for a crossover line.

This innovative product for dual draw, dual return

fuel systems was introduced in the early 1990’s,

and has been adopted as standard equipment on

a variety of vehicle makes. This patented product

features identical variable flow openings to

control return fuel flow which will, with a properly

designed and maintained draw system, provide

proper fuel balance in dual tank systems.

Performance

Application

Material

Part Number

Flow Rate & Restriction Values

Operating Temperature

Allowed Leakage

Equally distributes fuel for dual fuel tank applications

Heav y duty zinc die cast construction.

2252-1 ( Return Flow Splitter— wor ks with most engines)

A2252-2 (High-flow Return Flow Splitter— works with Cummins ISX engines.)

2252-1: Fuel flow of 60 GPH, the back pressure is approx. 20 inches H2O.

A2252-2: Fuel flow of 60 GPH, the back pressure is approx. 13 inches H2O when both ports are open, and

30 inches H2O when one port is closed.

-40°F to 180°F (-40°C to 82°C)

The Return Flow Splitter shall not leak diesel fuel in excess of one drop in 30 minutes at any internal

pressure up to 20 PSIG.

Return Flow Splitter

2252 Series

Rev. 8/14 01

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Page 2

Return Flow Splitter 2252 Series

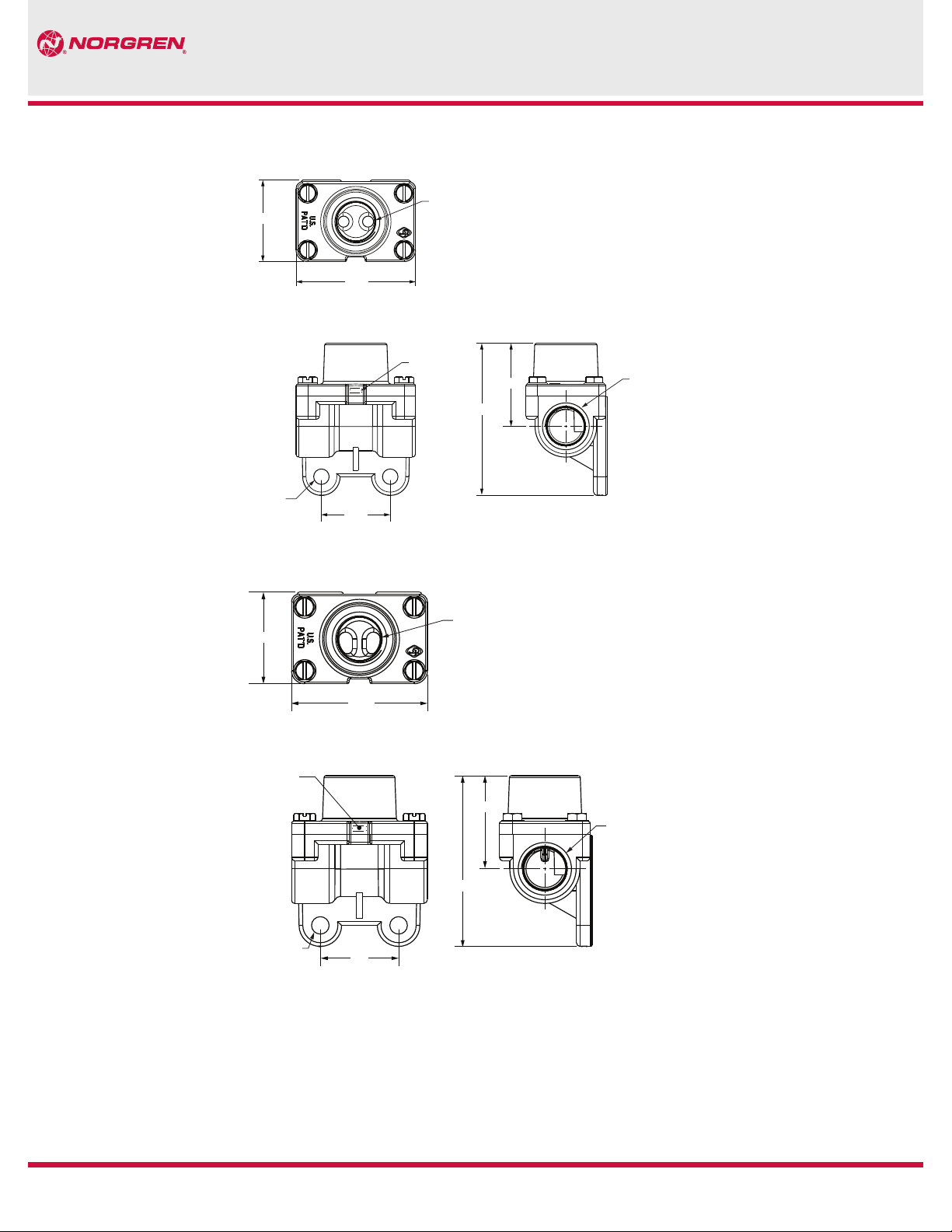

2-3/16

1-1/2

INLET

1/2-14 NPT THD.

DATE CODE

(P/N ON

OTHER SIDE)

OUTLET

1/2-14 NPT THD.

2 PL (OPPOSITE SIDE

2-3/4

1-1/2

1.25

Ø 0.28

MOUNTING

THRU HOLE

2 PL

Dimensions (Inches)

Return Flow Splitter

2252-1

1-1/2

Ø 0.28

MOUNTING

THRU HOLE

2 PL

2-3/16

1.25

INLET

1/2-14 NPT THD.

DATE CODE

(P/N ON

OTHER SIDE)

2-3/4

1-1/2

OUTLET

1/2-14 NPT THD.

2 PL (OPPOSITE SIDE)

High-flow Return Flow Splitter

A2252-2

Warning

Improper selection, misuse, age or malfunction of components used in

commercial vehicle systems can cause failure in various modes. The system

designer is warned to consider the failure modes of all component parts

used in commercial vehicle systems and to provide adequate safeguards to

prevent personal injury or damage to equipment or property in the event of

such failure modes. System designers and end users are cautioned to consult

instruction sheets and specifications available from the factor y. The system

designer/end user is responsible for verifying that all requirements for the

application are met.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren GT Development Corporaton, 2014

Warranty

The products described herein are warranted subject to seller’s Standard

Terms and Condition of Sale, available at seller’s website.

Rev. 8/1402

Loading...

Loading...