Page 1

11-042

Installation & Maintenance

Instructions

4.

Install a pressure gauge in a gauge port on the 11-042, or

to the application point downstream of the 11-042. Do not

connect the gauge to the pilot pressure line, as this

pressure is not the same as the 11-042 outlet pressure.

Locate the gauge next to the pilot regulator. Plug unused

gauge ports.

5. Install a general purpose filter upstream of the regulator.

6. Install a Norgren muffler (see Replacement Parts) in the

exhaust port of the 11-042 regulator. Installation of a

muffler will reduce work area noise and protect 11-042

internal parts from contamination.

Warning

Do not plug exhaust port. Relief feature will fail if

exhaust port is plugged.

ADJUSTMENT

1. Before applying inlet pressure to regulators, turn pilot

regulator adjustment counterclockwise to remove all

force on regulating spring.

2. Apply inlet pressure, then turn pilot regulator adjustment

clockwise to increase and counterclockwise to decrease

pressure setting.

3. Always approach the desired pressure from a lower

pressure. When reducing from a higher to a lower

setting, first reduce to some pressure less than that

desired, then bring up to the desired pressure.

DISASSEMBLY

1. Regulator can be disassembled without removal from air

line.

2. Shut off inlet pressure to pilot regulator and to the 11-

042. Reduce pressure in inlet and outlet lines to zero.

3. Turn pilot regulator adjustment counterclockwise to

remove all force on regulating spring.

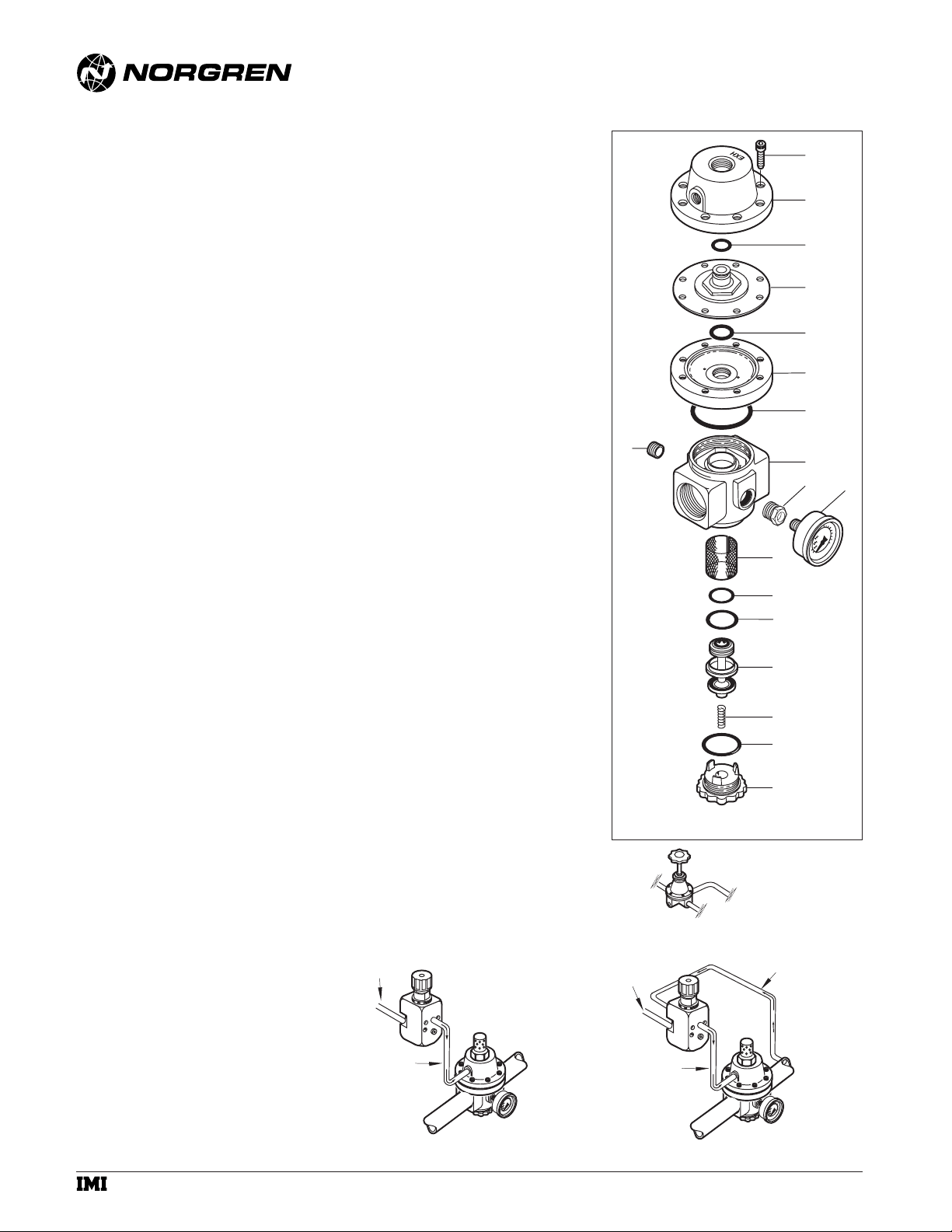

4. Disassemble the 11-042 in general accordance with the

item numbers on exploded view.

CLEANING

1. Clean parts with warm water and soap

2. Rinse and dry parts. Blow out internal passages in body

(8) with clean, dry compressed air.

3. Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate o-rings and surfaces in contact with o-rings

with a light coat of good quality o-ring grease.

2. Assemble the unit as shown on the exploded view. Apply

increasing torque to the bonnet screws (1) in a

crisscross pattern. Apply final torque of 5,6 to 7,9 Nm

(50 to 70 inch-pounds). Tighten bottom plug (9) hand

tight.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

If outlet pressure in excess of the regulator pressure

setting could cause downstream equipment to rupture or

malfunction, install a pressure relief device downstream of

the regulator. The relief pressure and flow capacity of the

relief device must satisfy system requirements.

The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be

used with these products and if inaccurate indications may

be hazardous to personnel or property, the gauge should be

calibrated before initial installation and at regular intervals

during use.

Before using these products with fluids other than air,

for non industrial applications, or for life-support systems

consult Norgren.

TECHNICAL DATA

Fluid: Compressed air

Inlet pressure range: 0,7 bar to 27,6 bar (10 to

400 psig). For best performance, inlet pressure

should be at least 0,7 bar (10 psig) greater than the

desired regulated pressure, but must not exceed the

specified maximum.

Operating temperature: -20° to +80°C (0° to +175°F)

Air supply must be dry enough to avoid ice

formation at temperatures below +2°C (+35°F).

Typical flow with a conventional pilot regulator at 6,9

bar (100 psig) inlet pressure, 6,3 bar (90 psig) set

pressure, and a droop of 0,35 bar (5 psig) from

set:

1/2" ports: 57 dm

3

/s (120 scfm)

1" ports: 142 dm

3

/s (300 scfm)

Port sizes:

Main Gauge Pilot Exhaust

1/4" 1/4" 1/4" 3/4"

3/8" 3/8" 1/4" 3/4"

1/2", 3/4", 1", 1-1/4" 1/2" 1/4" 3/4"

Thread type:

Main and gauge ports: PTF, ISO G, or ISO Rc

Pilot port: PTF with PTF main ports, ISO G with

ISO G and ISO Rc main ports

Exhaust port: PTF with PTF main ports, ISO G

with ISO G and ISO Rc main ports

Materials:

Body: Zinc

Bonnet: Aluminum

Bottom plug: Acetal

Valve: Brass

Elastomers: Nitrile

REPLACEMENT ITEMS

Repair kit - items 3, 4, 5, 7, 10, 12, 13, 14, 15

1/4", 3/8" 1/2" regulators......................................4158-01

3/4", 1", 1-1/4" regulators .....................................4158-02

Elastomer kit - items 3, 5, 7, 10, 13, 14, 15

1/4", 3/8" 1/2" regulators.......................................4158-03

3/4", 1", 1-1/4" regulators .....................................4158-04

Exhaust muffler, 3/4 PTF .........................................MB006A

INSTALLATION

1. Shut off air pressure. Install regulators in air line -

● upstream of lubricators and cycling valves.

● at any angle.

● install the 11-042 pilot operated regulator as close as

possible to the device being serviced.

● install the pilot regulator at any convenient, accessible

location.

2. Use pipe thread sealant on male threads only when

making the following pipe connections. Do not allow

sealant to enter interior of regulator.

● Connect inlet and outlet air lines to 11-042 main ports.

Inlet port is marked IN.

● Connect inlet and outlet air lines to pilot regulator main

ports. The inlet port of the R40 and R41 is marked IN,

and the outlet port is marked OUT. The direction of air

flow thru the 11-104 pilot is indicated by an arrow on

the bottom of the body.

● Connect the outlet of the pilot regulator to the pilot port

in the side of the 11-042 bonnet. This is the pilot

pressure line.

3.Special Instructions for a Feedback Pilot:

Connect one end of the feedback line to the feedback

port on the pilot regulator. The feedback port on the R41

is marked FDBK. The 11-104 has two 1/8" PTF feedback

ports. Plug the unused feedback port. Connect the other

end of the feedback line to a gauge port on the 11-042

or, if maximum precision pressure regulation is desired,

to the application point downstream of the 11-042. Keep

the feedback line as short as possible and unrestricted.

Use 1/4" or 3/8 " OD copper tube for the feedback line.

Plug unused gauge ports.

Warning - Feedback Pilot Regulators

Norgren manufacturers two feedback pilot

regulator types (the R41 and the 11-104). Use the

R41, the 11-104-002, or the 11-104-003 feedback

pilot regulator to control outlet pressures greater than

100 psig (7 bar). Use the Norgren 11-104-001

feedback pilot regulator to control outlet pressures at

or less than 100 psig (7 bar).

The feedback line must sense 11-042 outlet

pressure and must be connected before turning on air

pressure. If the feedback line is not connected, 11-042

outlet pressure will rapidly increase to inlet pressure

when the feedback pilot adjusting knob is turned

clockwise.

IM-422.245

(7/01)

Pilot Operated Regulator

© Norgren 2001

Figure 1. Conventional Pilot Installation Figure 2. Feedback Pilot Installation

a subsidiary of IMI plc

Pilot

Pressure

Line

Inlet Air

R40 CONVENTIONAL

PILOT REGULATOR

11-042 PILOT

OPERATED

REGULATOR

Outlet

Air

Inlet Air

16

11-104 FEEDBACK

Pilot

Pressure

Line

Inlet Air

PILOT REGULATOR

Pilot Pressure Line

Inlet

Air

R41 FEEDBACK

PILOT REGULATOR

Inlet Air

1

2

3

4

5

6

7

8

17

15

14

13

12

11

10

9

Feedback

Line

Feedback

Line

Outlet

Air

11-042 PILOT

OPERATED

REGULATOR

18

Loading...

Loading...