Page 1

OPERATING INSTRUCTIONS

18G FlOORING STAPLER

MODEL: 10023321

6

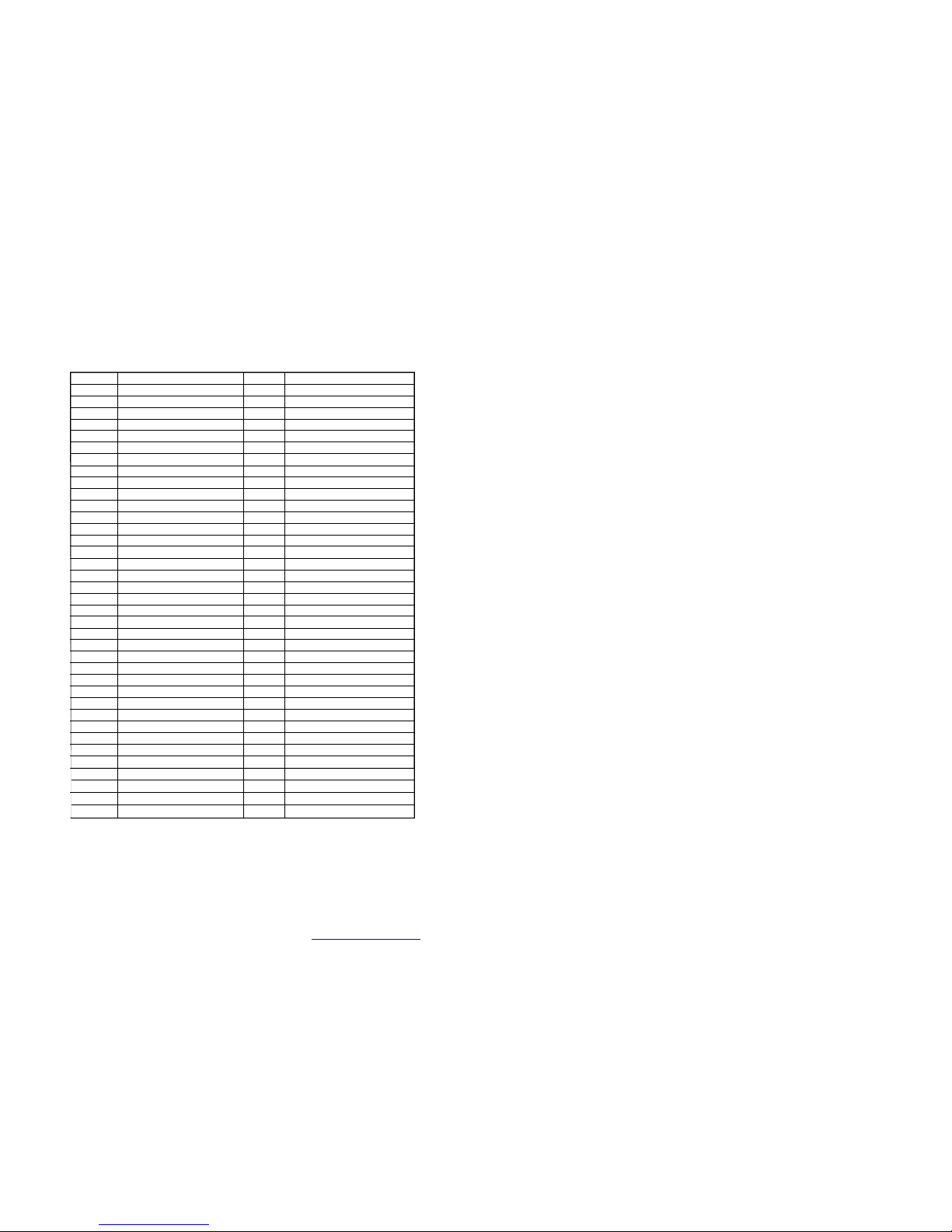

PARTS LIST

Refer to the Exploded View Drawing for the location of parts listed below

DESCRIPTION

WASHER

TRIGGERASSEMBLY

TRIGGERPIN

SCREWM4*16

WASHER

OBLIQUEBLOCK

SCREWM4*25

DRIVEGUIDE

LIMITEDBLICK

SLIDEPLATE

BUSHING

SCREW

DRIVEGUIDE

SPRINGP IN2.5*12

MOVABLEMAGAZINE

FEEDERSHOE

SPRING

FIXEDMAGAZING

NUTM4

MAGAZINGPLATE

SCREWM4*6

SCREWM4*14

SPRINGPIN

SPRING

LOCK

JIONTGUIDE

WASHER

STOPPEDSCREW

SUPPORT

NUT

SCREW

SOFTGRIPSLEEVE

GASKET

ENDCAP

WASHER 4

AIRPLUG

1

2

3

4

5

6

7

8

8a

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

ITEM

37

38

3

9

4

0

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

DESCRIPTION

SCREWM4*10

BUSHING

EXHAUSTCOVER

WASHER

SCREWM5*20

SPRINGWASHER 5

CYLINDERCAP

GASKET

SPRING

VALVESEAT

O-RING15.7*2

O-RING38.8*3

VALVE

O-RING33.5*3.5

STOPPEDWASHER

COLLAR

O-RING50.5*2.5

O-RING28.3*3

PISTONASSEMBLY

CYLINDER

O-RING36.3*2.5

O-RING35.3*2.5

BUMPER

BODY

JOINTGUIDE

SAFEGUIDE

SPRING

SAFEBRACKET

SPRINGPIN3*26

SEAL

TRIGGERVALVEHEAD

O-RING15*1.9

TRIGGERVALVEGUIDE

O-RIN

G 5.5*

1.5

SPRING

TRIGGERVALVESTEM

SPRING

ITEM

PDF !"# "pdfFactory Pro" $#%&'( www.fineprint.cn

Page 2

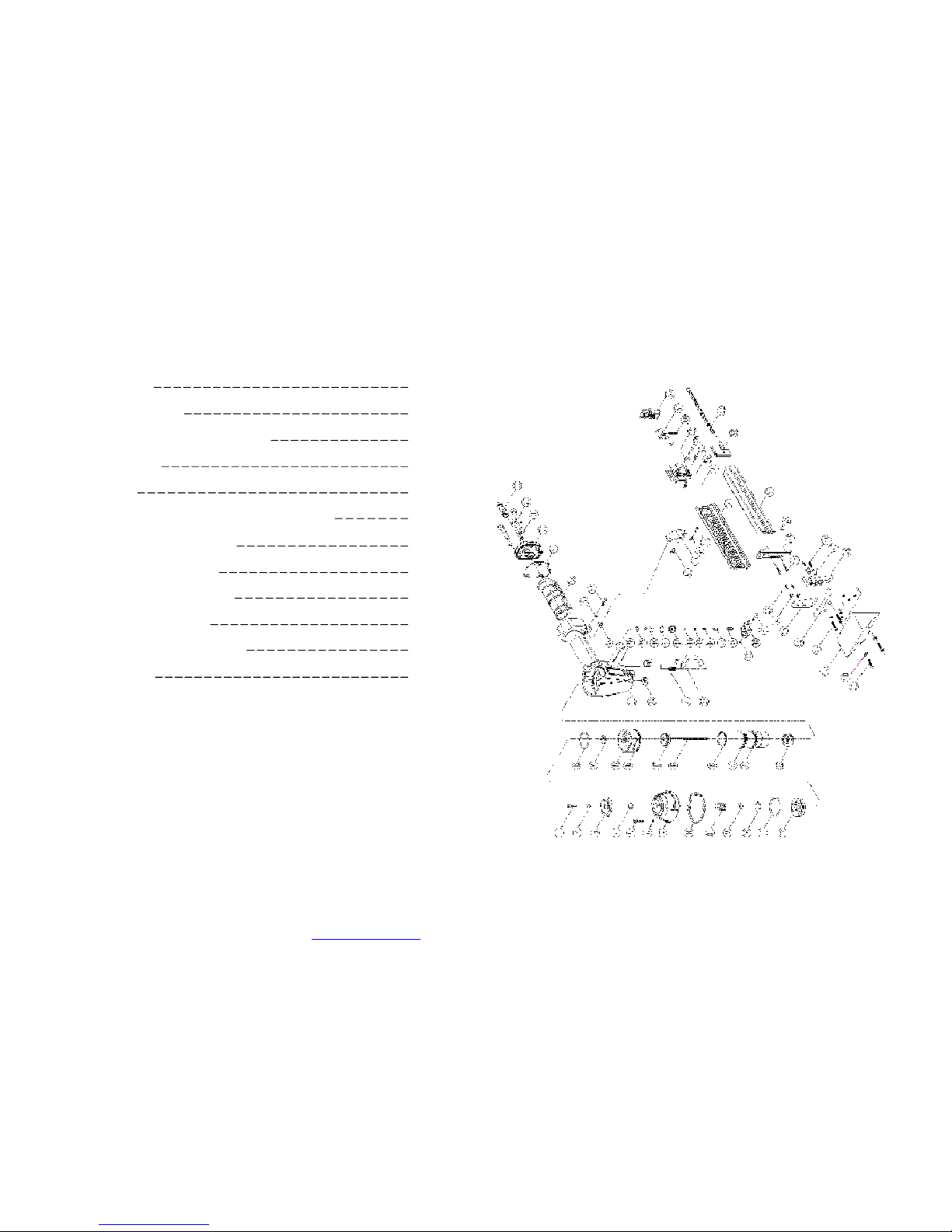

5

EXPLODED VIEW DRAWING

CONTENTS

SUMMARY

SPECIFICATIONS

SAFETY WARNINGS & CAUTIONS

UNPACKING

SETTING

CONNECTING THE TOOL TO AN AIR SUPPLY

LOADING THE FASTENERS

OPERATING THE TOOL

REGULAR MAINTENANCE

TROUBLE SHOOTING

EXPLODED VIEW DRAWING

PARTS LIST

1

1

1

2

2

3

3

3

3

4

5

6

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Page 3

Characteristic

Minimum Operating Air Pressure

Maximum Operating Air Pressure

Stapler Length Range

Stapler Size

Stapler Capacity

Air Inlet

Air Consumption

Tool Weight

Value

60 PSI

100 PSI

3/8" -- 1/4"

18 Gauge

100

1/4" NPT

3.8 CFM

3.59 lbs

1

SPECIFICATIONS

SUMMARY

You will need the instructions for the safety warning and cautions, assembly instructions, operating and maintain-

ing procedures, exploded view drawing and parts list. Keep your invoice with these instructions. Keep the instructions and invoice in a safe and dry place for future reference.

READ ALL INSTRUCTIONS BEFORE OPERATING THE TOOL

1. Lubricate as instructed.

2. Check air supply.

3. Replace spring.

4. Replace damaged internal

parts.

1. Replace joint guider.

2. Use the recommended and

undamaged fastenerls.

3. Tighten screws.

4. Replace piston assembly.

1. Replace piston assembly.

2. Adjust to adequate air

pressure.

3. Check cylinder cap spring for

broken coils or reduced length.

Check if exhaust port of cylinder cap is restricted.

1. Replace bumper or pusher

spring.

2. Clean drive channel of front

plate.

3. Check hose and compressor

fittings.

4. Replace O-ring or lubricate.

5. Replace seal.

4

TROUBLE SHOOTING

PROBLEM

Air leaking at

Trigger area

PROBLEM CAUSE SOLUTION

1. O-ring in trigger valve is damaged.

2. Trigger valve head is damaged.

3. Trigger valve stem, seal or O-ring is damaged.

1. Check and replace O-ring.

2. Check and replace trigger

valve head.

3. Check and replace trigger

valve stem, seal or O-ring.

Air leaking between

body and drive guider

Damaged bumper.

Air leaking between

body and cylinder cap

1. Screw loose.

2. Damaged gasket.

1. Tighten screws.

2. Check and replace gasket.

Blade driving fastener

too deeply

1. Worn bumper .

2. Air pressure is too high.

1. Replace bumper.

2. Adjust the air pressure.

Check and replace bumper.

Runs slowly or has

power loss

Tool skips a fastener

Fasteners are jammed

Tool will not drive

down tight

1. Insufficient oil.

2. Insufficient air supply.

3. Broken spring in cylinder cap.

4. Exhaust port in cylinder cap is blocked.

1. Worn bumper or damaged spring (53).

2. Dirt in drive guider.

3. Inadequate airflow to tool.

4. Worn or dry O-ring on piston.

5. Cylinder cap seal leaking.

1. Joint guider is worn.

2. Fasteners are wrong size or damaged.

3. Magazine or front plate screws are loose.

4. Blade in piston assembly is damaged.

1. Worn blade in piston assembly.

2. Lack of power.

3. Slow cycling and loss of power.

STOP USING THE TOOL IMMEDIATELY IF ANY OF THE FOLLOWING PROBLEMS

OCCUR. SERIOUS PERSONAL INJURY COULD OCCUR. ANY REPAIRS OR REPLACEMENTS MUST BE DONE BY A QUALIFIED PERSON OR AN AUTHORIZED SERVICE CENTER

ONLY.

SAFETY WARNINGS& CAUTIONS

1. KEEP WORKING AREA CLEAN. Cluttered areas invite injuries.

2. DON’T ALLOW CHILDREN AT THE WORKING AREA. Don’t let them handle the tool.

3. DO NOT OPERATE THIS TOOL IF UNDER THE INFLUENCE OF ALCOHOL OR DRUGS. Read

warning label on prescriptions to determine if your judgment or reflexes are impaired while taking drugs. If there

is any doubt, do not attempt to operate.

4. USE SAFETY GLASSES. Safety glasses should conform to ANSI Z87.1 specifications. Before operating,

wear safety glasses against flying debris from the front and side. Safety glasses should be worn when loading,

operating, unloading or servicing this tool.

5. USE EAR PROTECTION. The working area may be exposed to high noise levels that can lead to hearing

damage.

6. NEVER USE OXYGEN COMBUSTIBLE GASES, BOTTLED GASES OR HIGH PRESSURE

COMPRESSED GAS AS A POWER SOURCE FOR THIS TOOL. The tool may explode and cause

serious injury.

7. DRESS SAFELY. Protective gloves and nonskid footwear or safety shoes are recommended when working

with and operating this tool. Don’t wear loose clothing or jewelry. They can get caught in moving parts. Also,

wear a protective hair covering to prevent long hair from getting caught in the tool.

8. DO NOT FIRE INTO HARD MATERIALS. Do not attempt to shoot toward hard or brittle material such

as concrete, steel or tile.

9. WHEN OPERATING TOOL. keep the proper footing and balance to avoid damage resulting from losing

balance.

10.CHECK DAMAGED PARTS. Before using tool, carefully check if there is any part damaged.

11.REPLACE PARTS AND ACCESSORIES. Only allow the use of the same replacement parts while servicing.

Approved accessories and replacement parts are available.

12.KEEP ALERT. Watch what you are doing. Use common sense. Do not operate any tool when you are tired.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Page 4

CONNECTING THE TOOL TO AN AIR SUP PLY

1. Determine if the toolneed soil and, if necessary, place twod rops of oil in

the AIR PLUG(72) as shownin Figure 2. If you are using an automatic in-line

oiler, check and add oil if necessary.

2. Turnt he compressor on and set the regulator to the proper pressure for the

size and type of fastener being used.

3. Conne ct the tool to the air supply (see Setup for air supply connection

recommendations).

Figure 2

Figure 3

LOADING THE FASTENERS

1. Depre ss the LOC K(60 ) to rel ease the MOVABL E

MAGAZINE (51) and pull themagazine out fully asshown

in Figure 3.

2. Place a full clip of the specified type and size fasteners on

the FIXED MAGAZINE (54), up to 100 fasteners may be

loaded inthe magazine.

3. Pusht he MOVABLE MAGAZINE ASSEMBLYforward

untilit is locked.

OPERATING THE TOOL

Test the driving depth in a sample piece of wood before using. If the fasteners are being driven too far or not far

enough, adjust the regulator to provide l

ess air pressure or more air pressure.

1. Connect the tool t o the air supply. Make sure the air pressure is i n corre ct ra nge denote d in section of

SPECIFICATIONS.

2. Load fastener as above the direction given in the section called LOAD THE FASTENER.

3. Hold the Body (23) and press the Drive guide (44) t o work surface , be sure the t ool is straight and then gently

depress the Trigger (38) to drive the fastener.

4. Lift the tool off the work surface.

3

REGULAR MAINTENANCE

1. Frequent, but not excessive, lubrication is required for best performance. Oil added through the airline connection

will lubricate internal parts. An automatic airline oilier is recommended but oil may be added manually before every

operation or after about 1 hour of continuous use. Only a few drops of oil at a time are necessary. Too much oil will

collect inside the tool and be blown out duringt he exhaust cycle. ONLY USE PNEUMATIC TOOL OIL. Do not

use detergent oil or additi ves, as these lubr

icants will cause accelerated wear to the seal in the tool.

2. Use a small amount ofoil on all moving surface and pivots.

3. Dirt and water in t he air supply are major cau ses of pneumatic tool wear. Use a filter/oiler for bette r perfor-

mance and longe r life. The fi lter must have ade quate flo w capacit y for the specifi c appl ication. Consult the

manufacturer's instructions for proper maintenance of your filter.

4. Ke ep tools cl ean for better a nd safer performance. U se nonflammab

le c leaning solutions ( CAUTION: Such

solutions may damage O-ring and other tool parts) only if necessary- DO NOT SOAK.

Description

Stapler

S3 Hex Key

S4 Hex Key

AirToolOil

Teflon Tape

Operatinginstruction

Qty

1

1

1

1

1

1

2

Figure 1

SETTING

Your air tool is fully assembled when you receive it. Be fore using it, attach the air line and desired air system

accessories. See Figure 1 for the recommended accessories and connection order. Be sure the air hose is depressur-

ized wheninstalling or removing adapters to the air line.

WARNING: The warning,c aution, and instructions explained in this instruction manualcannot cover

all possibleco nditions and situationsthat may occur.I t must be understood byth

e operator that COM-

MO N SENS E AND CAU TION ARE FACTO RS WH ICH CAN NOT BE B UILT I NTO THIS

PRODUCT, BUTMUST BE SUPPLIED BY THE OPERATOR.

UNPACKING

When unpacking, check and make sure that all the accessoriesare included.If anyone ismissed or broken,

pleasecall seller forhelp. Refer tothe follow lists.

13. STORE THE TOOL. When not in use, tool should be cleaned, fully assembled and then, stored in a dry

locationto reduce rust. For safety, keep out of reach of children.

14. OUTD

OOR EXTENSION CORDS. When air compressor is used outdoors, use only roundedjacket ex-

tension cords intendedfor outside use.See manufacturer’s manual for theAWG required for thecompressor’s

amperagedraw.

15. PAYATTENTIONTO AIRHOSE ANDTHEIR CONNECTIONS.Don’t trip over hoses.Make sure all

connectionsare tight.

16. AFTER LOADING THE FASTENERS. never point the tool atyourself or bystanders.

17. USE THE CORRECTAIR CONNECTOR.The connector on the tool must not h

old pressurewhen the air

supplyis disconnected.If thewrongfittingis used, thetool can bechargedwith air afterbeingdisconnectedand

still be able to drive afastener.

18. WHEN CONNECTINGTHE AIR.T he toolmay possibly firethe fasteners assoon as you plug itin to air

hose.Therefore, remove all thefastenersbefore connecting to the air.

19. DO NOT DEPRESS THE TRIGGER WHEN LOADING.

20. IF THE FASTENERSARE JAMMED. Disconnect thetool from the airand remove thejammed f

asteners.

STAPLER

QUICK

CONNEC TOR

OILER

REGUL ATOR

AIR HOS E

AIR SUPP LY

PDF !"# "pdfFactory Pro" $#%&'( www.fineprint.cn

Loading...

Loading...