Nordyne 14 SEER, S4BE-018K, S4BE-024K, S4BE-030K, S4BE-036K Owner's Manual

...

Outdoor Air Conditioner

14 SEER R-410A High Efficiency Split System

These units have been designed and tested for

capacity and efficiency in accordance with A.R.I.

Standards. Split System Air Conditioning units

are designed for use with a wide variety of fossil

fuel furnaces, electric furnaces, air handlers, and

evaporator coil combinations.

These instructions are primarily intended to assist

qualified individuals experienced in the proper

installation of heating and/or air conditioning

appliances. Some local codes require licensed

installation/service personnel for this type of

equipment. Read all instructions carefully before

starting the installation.

USER'S INFORMATION

Read this owner information to become familiar

with the capabilities and use of your appliance.

Keep this with literature on other appliances

where you have easy access to it in the future.

If a problem occurs, check the instructions

and follow recommendations given. If these

suggestions don't eliminate your problem, call

your servicing contractor.

OPERATING INSTRUCTIONS

To Operate Your Furnace for

Heating m

1. Set the thermostat system switch to HEAT

or AUTO and the thermostat fan switch to

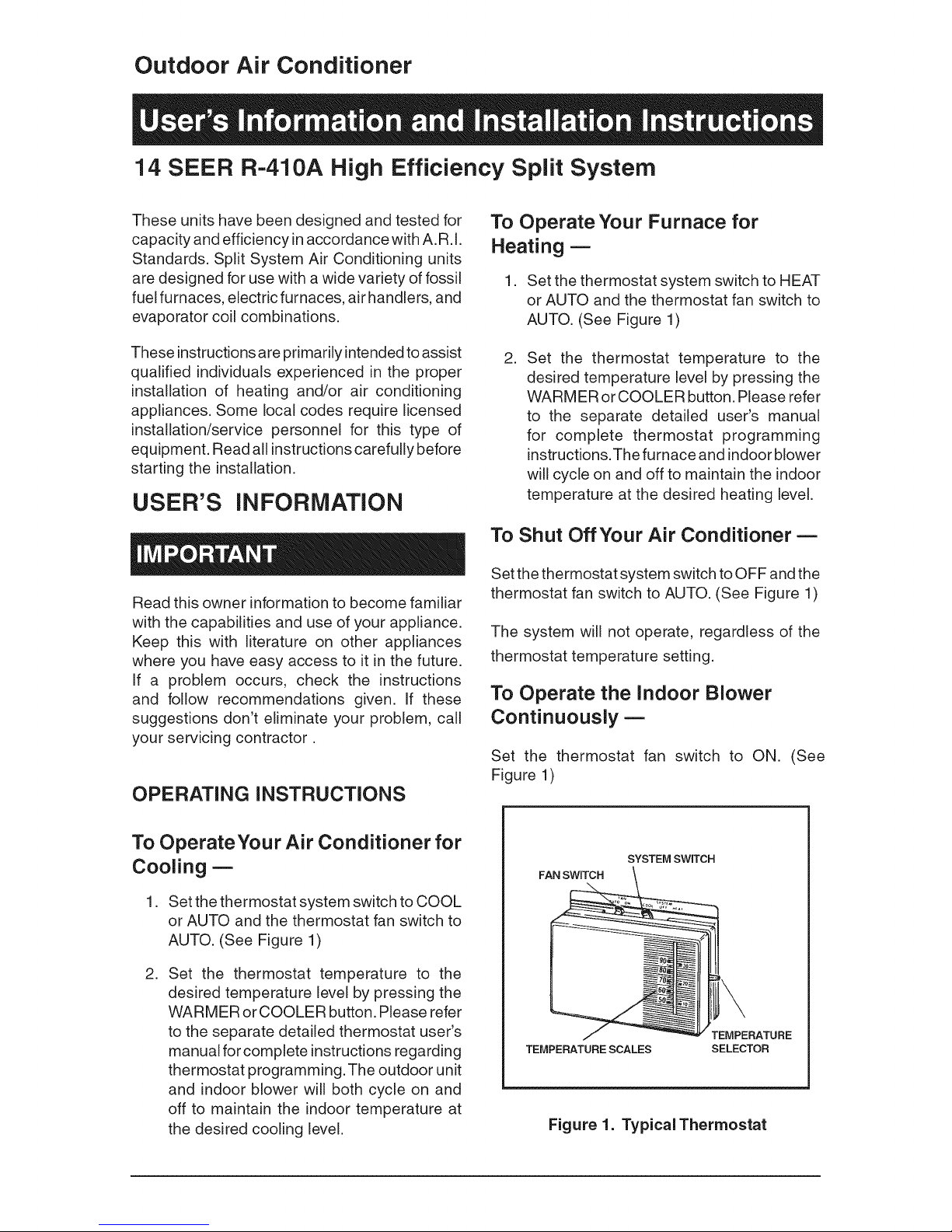

AUTO. (See Figure 1)

.

Set the thermostat temperature to the

desired temperature level by pressing the

WARMER or COOLER button. Please refer

to the separate detailed user's manual

for complete thermostat programming

instructions.The furnace and indoor blower

will cycle on and off to maintain the indoor

temperature at the desired heating level.

To Shut Off Your Air Conditioner

Set the thermostat system switch to OFF and the

thermostat fan switch to AUTO. (See Figure 1)

The system will not operate, regardless of the

thermostat temperature setting.

To Operate the Indoor Blower

Continuously

Set the thermostat fan switch to ON. (See

Figure 1)

To OperateYour Air Conditioner for

Cooling

1. Set the thermostat system switch to COOL

or AUTO and the thermostat fan switch to

AUTO. (See Figure 1)

.

Set the thermostat temperature to the

desired temperature level by pressing the

WARMER or COOLER button. Please refer

to the separate detailed thermostat user's

manual for complete instructions regarding

thermostat programming. The outdoor unit

and indoor blower will both cycle on and

off to maintain the indoor temperature at

the desired cooling level.

SYSTEM SWITCH

FAN SWITCH

TEMPERATURE SCALES

Figure 1. Typical Thermostat

TEMPERATURE

SELECTOR

The indoor blower will start immediately, and

will run continually until the fan switch is reset

to AUTO.

The continuous indoor blower operation can be

obtained with the thermostat system switch set

in any position, including OFR

The continuous indoor blower operation is

typically used to circulate the indoor air to

equalize a temperature unbalance due to a sun

load, cooking, or fireplace operation.

To Maintain Your Air Conditioner --

a,

The unit thermostat is properly set

-- see "To Operate Your Air Conditioner for

Cooling" and "To Operate Your Furnace for

Heating."

b. The unit disconnect fuses are in good

condition, and the electrical power to the

unit is turned on.

1. GENERAL INFORMATION

Read the following instructions completely before

performing the installation.

CAUTION:

Be certain the electrical power to

the outdoor unit and the furnace/

air handier is disconnected before

doing the following recommended

maintenance.

1. Regularly:

a,

Clean or replace the indoor air filter at the

start of each heating and cooling season,

and when an accumulation of dust and dirt

is visible on the air filter.

b. Remove any leaves and grass clippings

from the coil in the outdoor unit, being

careful not to damage the aluminum fins.

c. Check for any obstruction, such as twigs,

sticks, etc.

2. Before Each Cooling Season:

If the furnace/air handler blower motor and

the outdoor unit fan motor(s) have oil tubes

at the motor bearings, apply 10 drops of

SAE No. 20 motor oil to each oil tube.

CAUTION:

This unit uses refrigerant R=410A. DO

NOT under any circumstances use

any other refrigerant besides R=410A

in this unit. Use of another refrigerant

will damage this unit.

Condensing Unit Section -- Each condens-

ing unit is shipped with a refrigerant charge

adequate to operate the outdoor section with

an indoor matching coil or air handler, and 15

feet of refrigeration line.

NOTE: DO NOT USE ANY PORTION OF THE

CHARGE FOR PURGING OR LEAK TEST-

ING.

Matching coils and air handlers are shipped with

a small pressurized holding charge to pressurize

them to keep out contaminants. To release the

pressure, read the indoor section installation

instructions carefully.

Liquid and Suction Lines-- Refrigerant grade

copper tubing should be used when installing the

system. Refrigerant suction line tubing should

be fully insulated.

CAUTION:

Do not over=oil, or oil motors not

factory=equipped with oil tubes. The

compressor is hermetically "sealed"

and does not require lubrication.

=

Before Calling a ServiceTechnician, Be

Certain:

Field Connections for Electrical Power

Supply -- All wiring must comply with current

provisions of the "National Electrical Code" (ANSi

C1.) and with applicable local codes having

jurisdiction. The minimum size of electrical

conductors and circuit protection must be in

compliance with information listed on the outdoor

unit data label.

NOTICE:

Certain models have external panels fabricated

from a premium grade of stainlesssteeldesigned

to inhibit corrosion. For such units, if the unit is

located in acoastal region or other area subjected

to high concentrations of salt, then the unit should

be hosed off after storms and monthly otherwise

to maintain its new appearance.

2. SAFETY CONSiDERATiONS

Pressures within the System -- Split system

air conditioning equipment contains liquid and

gaseous refrigerant under pressure. Installation

and servicing of this equipment should be accom-

plished by qualified, trained personnel thoroughly

familiar with this type of equipment. Under no

circumstances should the Homeowner attempt

to install and/or service the equipment.

Labels, Tags, Precautions -- When working

with this equipment, follow all precautions in the

literature, on tags, and on labels provided with

the equipment. Read and thoroughly understand

the instructions provided with the equipment prior

to performing the installation and operational

checkout of the equipment.

Brazing Operations--Installation of equipment

may require brazing operations. Safety codes

must be complied with. Safety equipment (e.g.;

safety glasses, work gloves, fire extinguisher,

etc.) must be used when performing brazing

operations.

WARNING:

Ensure all electrical power to the unit

is off prior to installing or servicing

the equipment. Failure to do so may

cause personal injury or death.

3. SITE PREPARATION

the job site. Ensure coil fins are straight and, if

necessary, comb fins to remove flattened and

bent fins.

Preferred Location of the Outdoor Unit at the

Job Site -- Conduct a survey of the job site to

determine the optimum location for mounting

the outdoor unit. Overhead obstructions, poorly

ventilated areas, and areas subject to accumula-

tion of debris should be avoided. The outdoor

unit should be installed no closer than 18 inches

from the outside walls of the facility and in an

area free from overhead obstructions to ensure

unrestricted airflow through the outdoor unit.

Facility Prerequisites -- Electrical power

must be supplied to the equipment. Electrical

power supplied must be adequate for proper

operation of the equipment. The system must

be wired and provided with circuit protection in

accordance with local building codes and the

National Electrical Code.

4. INSTALLING THE OUTDOOR UNIT

Slab Mount--The site selected for aslab mount

installation requires astable foundation and one

not subject to erosion. The slab should be level

and anchored (if necessary) prior to placing the

equipment on the slab.

Cantilever Mount- The cantilever mount

should be designed with adequate safety factor

to support the weight of the equipment, and for

loads subjected to the mount during operation.

Installed equipment should be adequately se-

cured to the cantilever mount and levelled prior

to operation of the equipment.

Roof Mount--The method of mounting should

be designed so as not to overload roof structures

nor transmit noise to the interior of the structure.

Refrigerant and electrical line should be routed

through suitably waterproofed openings to pre-

vent water leaking into the structure.

Unpacking Equipment -- Remove the card-

board carton and User's Manual from the

equipment. Take care not to damage the tubing

connections when removing the carton.

Inspect for Damage -- Inspect the equipment

for damage prior to installing the equipment at

5. INSTALLING THE INDOOR UNIT

The indoor section should be installed before

proceeding with routing of refrigerant piping.

Consult the installation instructions of the indoor

unit (i.e.: air handler, furnace, etc.) for details

regarding installation.

6. CONNECTING REFRIGERANT

TUBING BETWEEN THE

iNDOOR AND OUTDOOR UNiT

CAUTION:

This system utilizes R-410A refrigerant

with POE oil. When servicing, cover

or seal openings to minimize the

exposure of the refrigerant system

to air to prevent accumulation of

moisture and other contaminants.

General -- Once outdoor and indoor unit place-

ment has been determined, route refrigerant

tubing between the equipment in accordance

with sound installation practices. Refrigerant

tubing should be routed in a manner that mini-

mizes the length of tubing and the number of

bends in the tubing. Refrigerant tubing should

be supported in a manner that the tubing will

not vibrate or abrade during system operation.

Tubing should be kept clean of foreign debris

during installation and installation of a liquid

line filter drier is recommended if cleanliness

or adequacy of system evacuation is unknown

or compromised. Every effort should be made

by the installer to ensure that the field installed

refrigerant containing components of the system

have been installed in accordance with these

instructions and sound installation practices

so as to insure reliable system operation and

longevity.The maximum recommended intercon-

necting refrigerant line length is 75 feet, and the

vertical elevation difference between the indoor

and outdoor sections should not exceed 20 feet.

Consult long line application guide for installa-

tions in excess of these limits.

Filter Dryer Installation--A filter dryer is

provided with the unit and must be installed in

the liquid line of the system. If the installation

replaces a system with a filter dryer already

present in the liquid line, the filter dryer must be

replaced with the one supplied. The filter dryer

must be installed in strict accordance with the

manufacturer's installation instructions.

7. MAKING ELECTRICAL

CONNECTIONS

WARNING:

Turn off all electrical power at the main

circuit box before wiring electrical

power to the outdoor unit. Failure to

comply may cause severe personnel

injury or death.

Wiring Diagram/Schematic -- A wiring dia-

gram/schematic is located on the inside cover

of the electrical box of the outdoor unit. The

installer should become familiar with the wiring

diagram/schematic before making any electrical

connections to the outdoor unit.

Outdoor Unit Connections -- The outdoor

unit requires both power and control circuit

electrical connections. Refer to the unit wiring

diagram/schematic for identification and location

of outdoor unit field wiring interfaces.

Control Circuit Wiring --The outdoor unit is

designed to operate from a 24 VAC Class IIcontrol

circuit. Control circuit wiring must comply with

the current provisions of the "National Electrical

Code" (ANSI C1.) and with applicable local codes

having jurisdiction.

Thermostat Connections -- Thermostat con-

nections should be made in accordance with the

instructions supplied with the thermostat, and

with the instructions supplied with the indoor

equipment.

Electrical PowerWiring-- Electrical power wir-

ing shall comply with the current provisions of the

"National Electrical Code" (ANSI C1 .) and with

applicable local codes having jurisdiction. Use

of rain tight conduit is recommended. Electrical

conductors shall have minimum circuit ampac-

ity in compliance with the outdoor unit rating

label. The facility shall employ electrical circuit

protection at a current rating no greater than that

indicated on the outdoor unit rating label.

Optional Equipment- Optional equipment

(e.g. :filter/driers, liquid line solenoid valves, etc.)

should be installed in strict accordance with the

manufacturer's installation instructions.

Minimum Circuit Ampacity-- Electrical wiring

to the equipment must be compatible and in

compliance with the minimum circuit ampacity

listed on the outdoor unit data label.

Loading...

Loading...