Page 1

Gas Furnaces

Installation Instructions

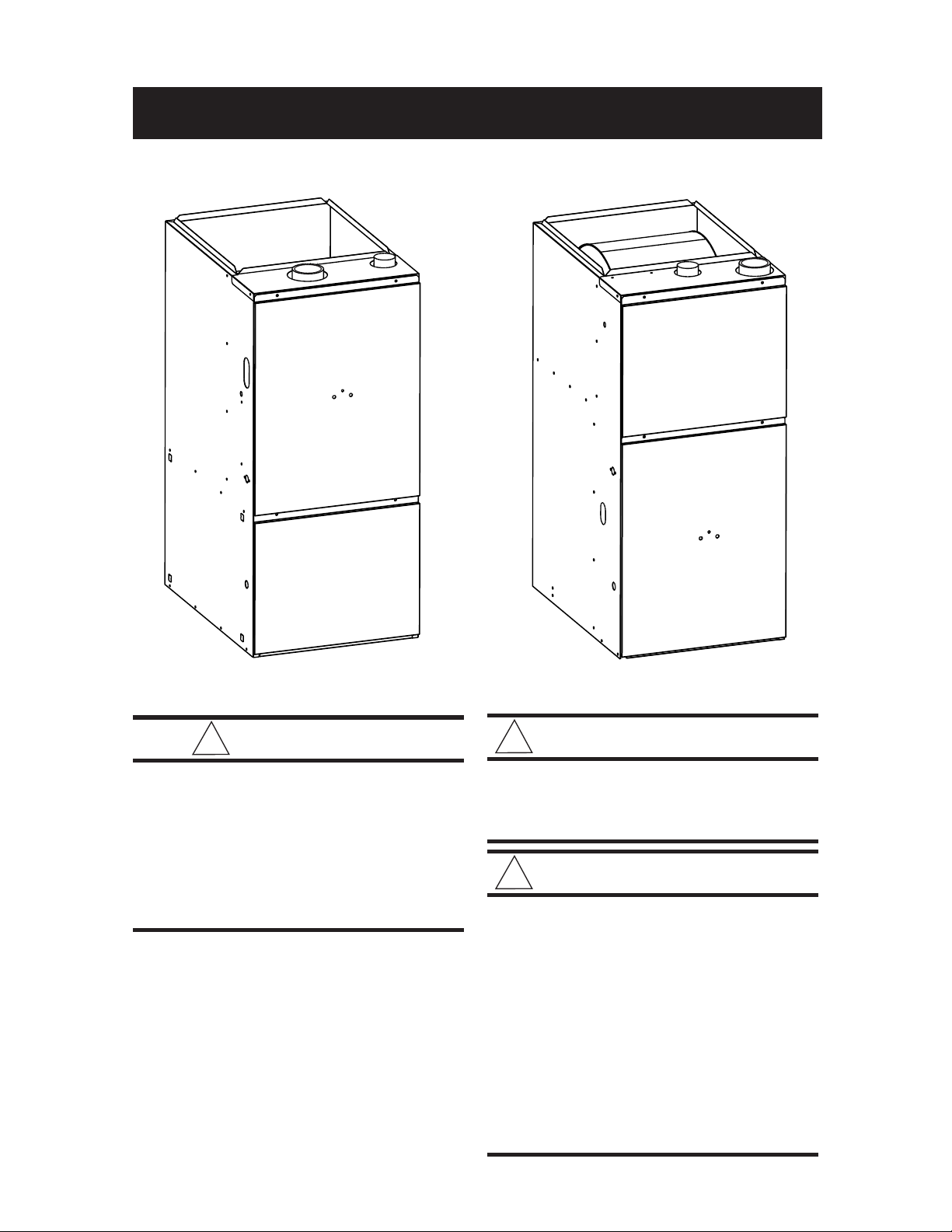

*RC 92+ Full Size Upfl ow Condensing Furnace

*RL 90+ Full Size Downfl ow Condensing Furnace

*RC 92+ Upfl ow *RL 90+ Downfl ow

!

WARNING:

Improper installation, adjustment,

alteration, service, or maintenance

can cause injury or property damage.

Refer to this manual for assistance.

For additional information consult a

qualifi ed installer, service agency, or

the gas supplier.

These instructions are primarily intended

to assist qualifi ed individuals experienced

in the proper installation of this appliance.

Some local codes require licensed installation/service personnel for this type of equipment. Read all instructions carefully before

starting the installation.

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR

FUTURE REFERENCE.

!

FOR YOUR SAFETY:

Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of this or any other appliance.

!

FOR YOUR SAFETY:

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

• Extinguish any open fl ame.

Page 2

2

Page 3

Table of Contents

Furnace Specifi cations ............................................................................................................ 4-5

Furnace Airfl ow Data .......................................................................................................... 6-7

Safety Information ....................................................................................................................... 8

Installation Requirements ........................................................................................................... 8

Requirements and Codes ...................................................................................................... 8

Location ................................................................................................................................. 8

Downfl ow Warning ................................................................................................................. 9

Horizontal Installations ........................................................................................................ 10

Supply Air Plenum Installation .................................................................................................11

Installation on a Concrete Slab ........................................................................................... 11

Installation on a Combustible Floor ..................................................................................... 11

Circulating Air Supply ............................................................................................................... 11

Return Air ............................................................................................................................ 13

Venting and Combustion Air Requirements ........................................................................... 13

Combustion Air Quality ........................................................................................................ 15

Air Requirements for One-Pipe Installation ......................................................................... 15

Installation in An Unconfi ned Space .................................................................................... 15

Installation in A Confi ned Space ......................................................................................... 15

• Air From Inside .................................................................................................................. 16

• Air Directly Through An Exterior Wall ................................................................................ 16

• Outdoor Air Through Vertical Openings or Ducts .............................................................. 17

• Outdoor Air Through Horizontal Openings or Ducts .......................................................... 17

Venting Requirements ............................................................................................................... 17

Vent Pipe Material ............................................................................................................... 18

Vent Pipe Length and Diameter ........................................................................................... 18

Vent Pipe Installation ........................................................................................................... 19

Pipe Routing & Support ....................................................................................................... 19

Location of Outdoor Terminations ........................................................................................ 20

• Horizontal Venting ............................................................................................................ 20

• Vertical Venting .................................................................................................................. 25

• Vent Freezing Protection ................................................................................................... 26

• Concentric and Side Wall Vent Termination ....................................................................... 27

Drainage of Condensate From Furnace ................................................................................. 27

Gas Supply and Piping ........................................................................................................ 27

Leak Check ......................................................................................................................... 27

Conversion .......................................................................................................................... 27

High Altitude Application ..................................................................................................... 29

Natural Gas High Altitude Conversion ................................................................................. 29

LP/Propane Gas Sea Level and High Altitude Conversion .................................................. 29

Electrical Wiring ......................................................................................................................... 31

Line Voltage Wiring .............................................................................................................. 31

Low Voltage Wiring .............................................................................................................. 31

Start-up and Adjustments.................................................................................................... 32-34

Start-Up Procedure .............................................................................................................32

Verifying and Adjusting Firing Rate ..................................................................................... 33

Verifying and Adjusting Temperature Rise ........................................................................... 34

Verifying Burner Operation .................................................................................................. 34

Verifying Operation of the Supply Air Limit Switch .............................................................. 34

Description of Components ..................................................................................................... 35

Maintenance ............................................................................................................................... 35

Combustion Air and Vent System ........................................................................................ 35

Air Filter(s) ........................................................................................................................... 35

Lubrication ........................................................................................................................... 35

Condensate Drain Assembly ............................................................................................... 35

Blower Compartment ........................................................................................................... 35

Heat Exchanger and Burner Maintenance .......................................................................... 34

Location of Major Components ........................................................................................... 37

System Operation Information ................................................................................................. 38

Sequence of Operation ....................................................................................................... 38

Furnace Fails to Operate ..................................................................................................... 39

Twinning of Two Furnaces ................................................................................................... 39

Installation/Performance Checklist .......................................................................................... 40

3

Page 4

FURNACE SPECIFICATIONS

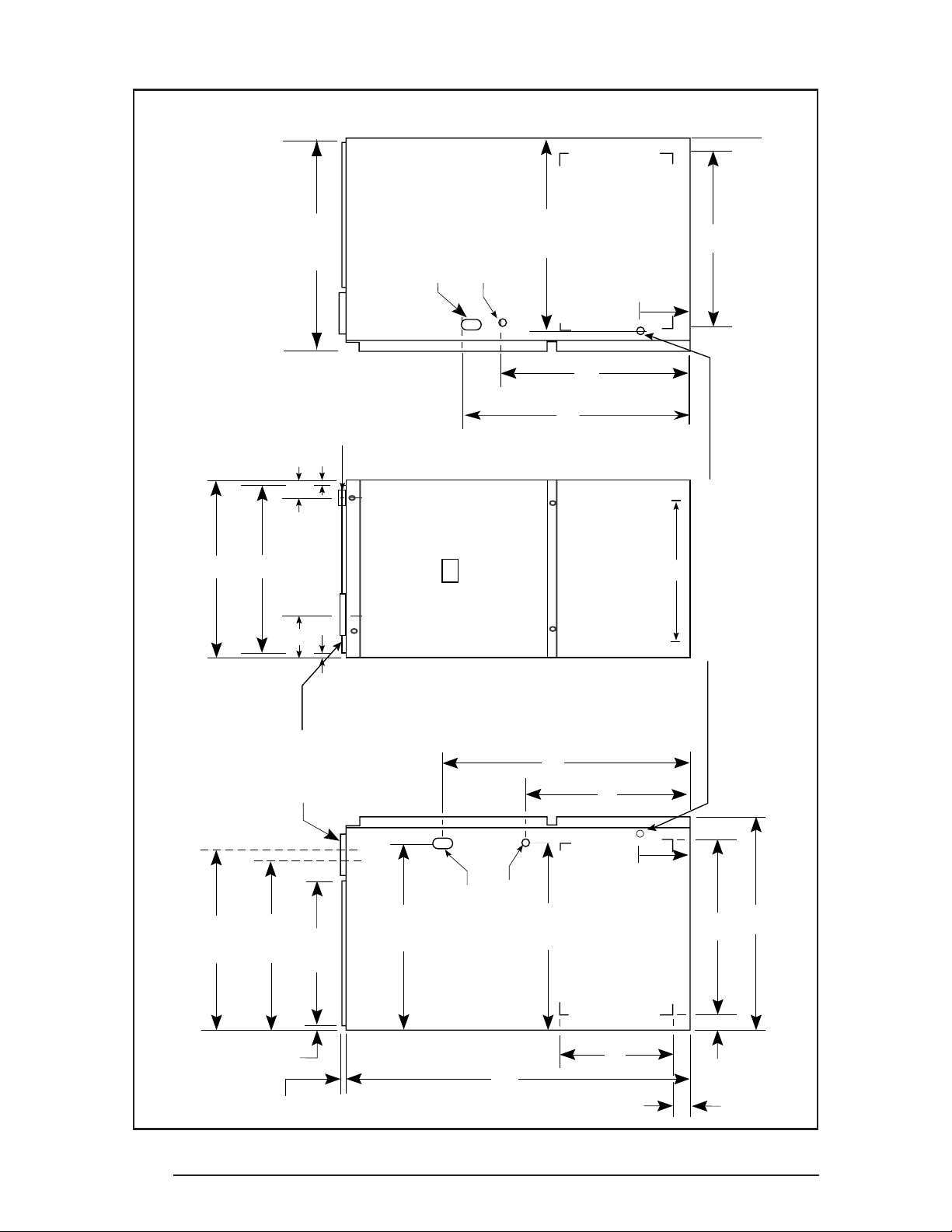

27 5/8"

2" PVC

Exhaust

Vent

3/4"

2 1/4"

‡

‡

A

B

‡

C

3/4"

1 1/2" x 3 1/2" Dia.

Opening for

(See Fig. 15

for sizes)

Gas Connection

7/8" Dia. Electric

25 5/8"

Connection

8"

+

25 1/4"

30 1/4"

(Bottom)

Return Air Opening

23"

Bottom Return Opening

‡

D

Condensate Drain Outlets

See Table 3

‡

Inlet

23 1/4"

Combustion Air

Exhaust Vent

Upfl ow *RC Furnaces

4

Combustion Air

Vent 3"

(See Fig. 15

for sizes)

22 1/2"

19 3/4"

3/4"

3/4"

Figure 1. Upfl ow Unit Dimensions

25 1/8"

Opening for

Gas Connection

1 1/2" x 3 1/2" Dia.

33"

+

25 1/4"

Connection

7/8" Dia. Electric

43"

20 1/2"

8"

15"

1"

28"

23"

Side Return

1 1/4"

Page 5

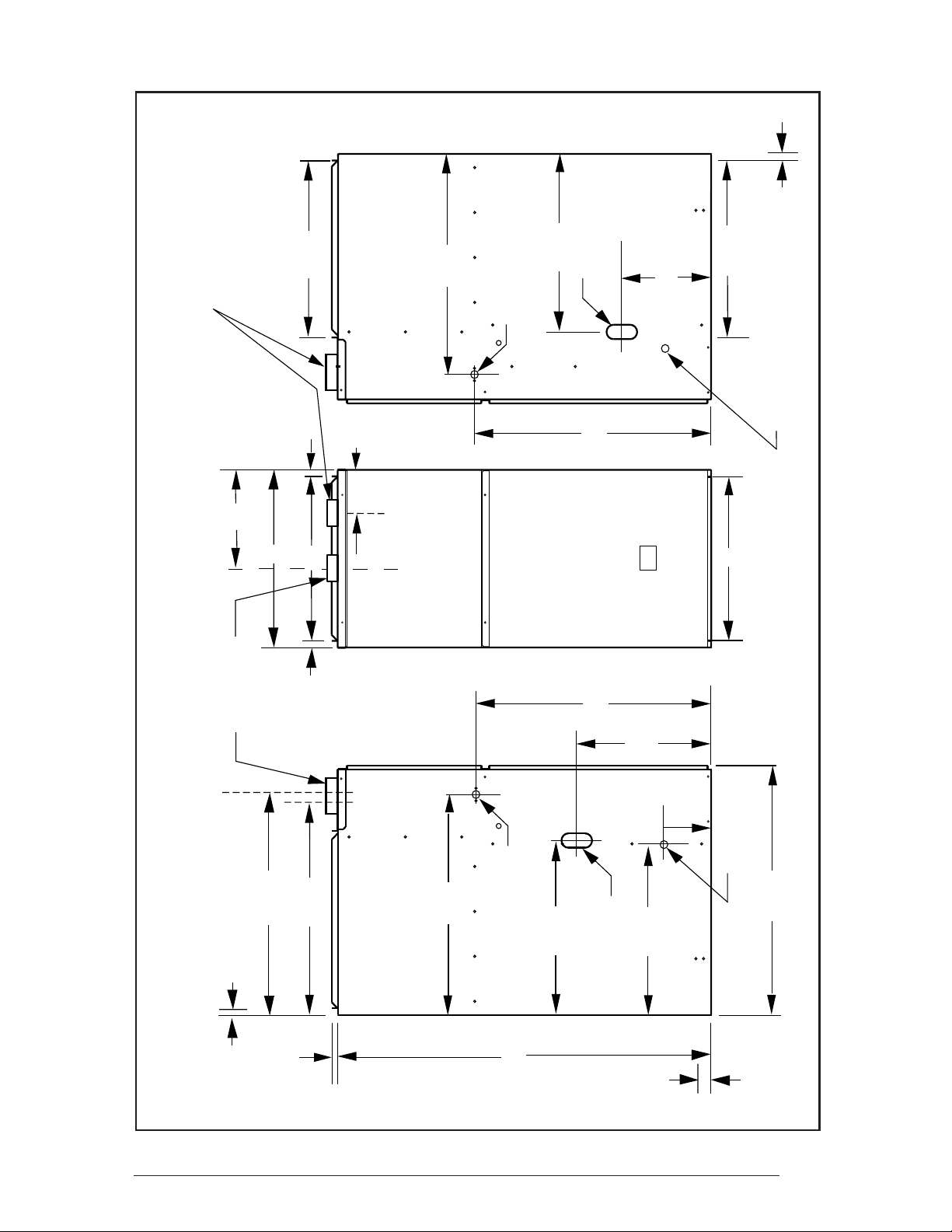

3/4"

Vent

Combustion

2" for 40/60)

(3" for 80/100

‡

C

‡

A

2" Dia.

Exhaust Vent

19 3/4"

3/4"

‡

B

3/4"

2 1/2"

24 7/8"

21 7/8"

Connection

7/8" Dia. Electric

Knockout For

1 1/2" x 2 1/2"

Gas Connection

10 1/4"

19 3/4"

Bottom Opening

Condensate

Drain Outlet

21 1/2"

L

C

D

Air Opening

Bottom Supply

‡

See Table 3

21 1/2"

24 1/2"

Combustion Air Inlet

3/4"

Downfl ow *RL Furnace

Connection

22 1/2"

Exhaust Vent

24 7/8"

7/8" Dia. Electric

3/4"

Figure 2. Downfl ow Unit Dimensions

43"

21 7/8"

15 1/2"

21 1/4"

Opening for

Gas Connection

1 1/2" x 3 1/2" Dia.

8"

Condensate

Drain Outlet

1"

27 7/8"

5

Page 6

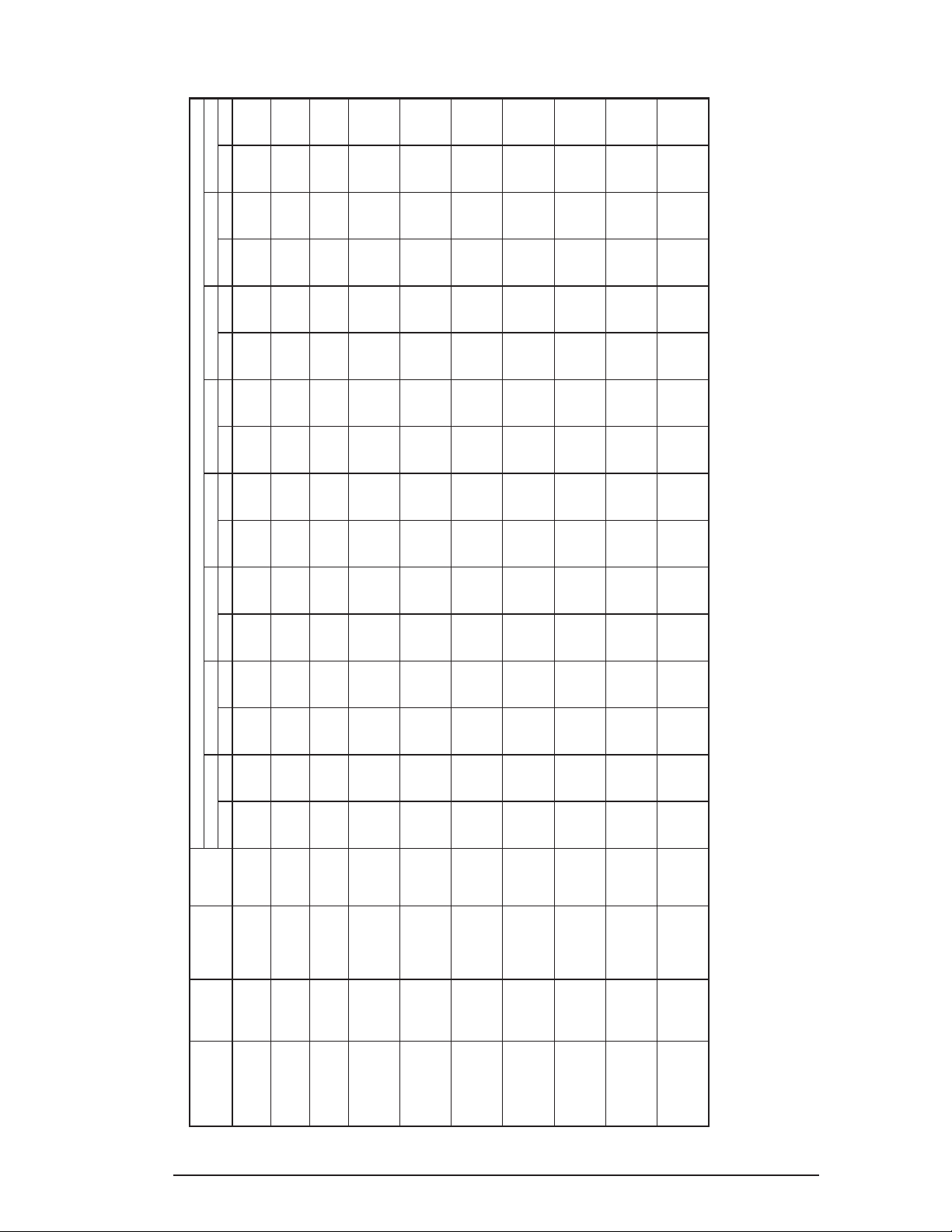

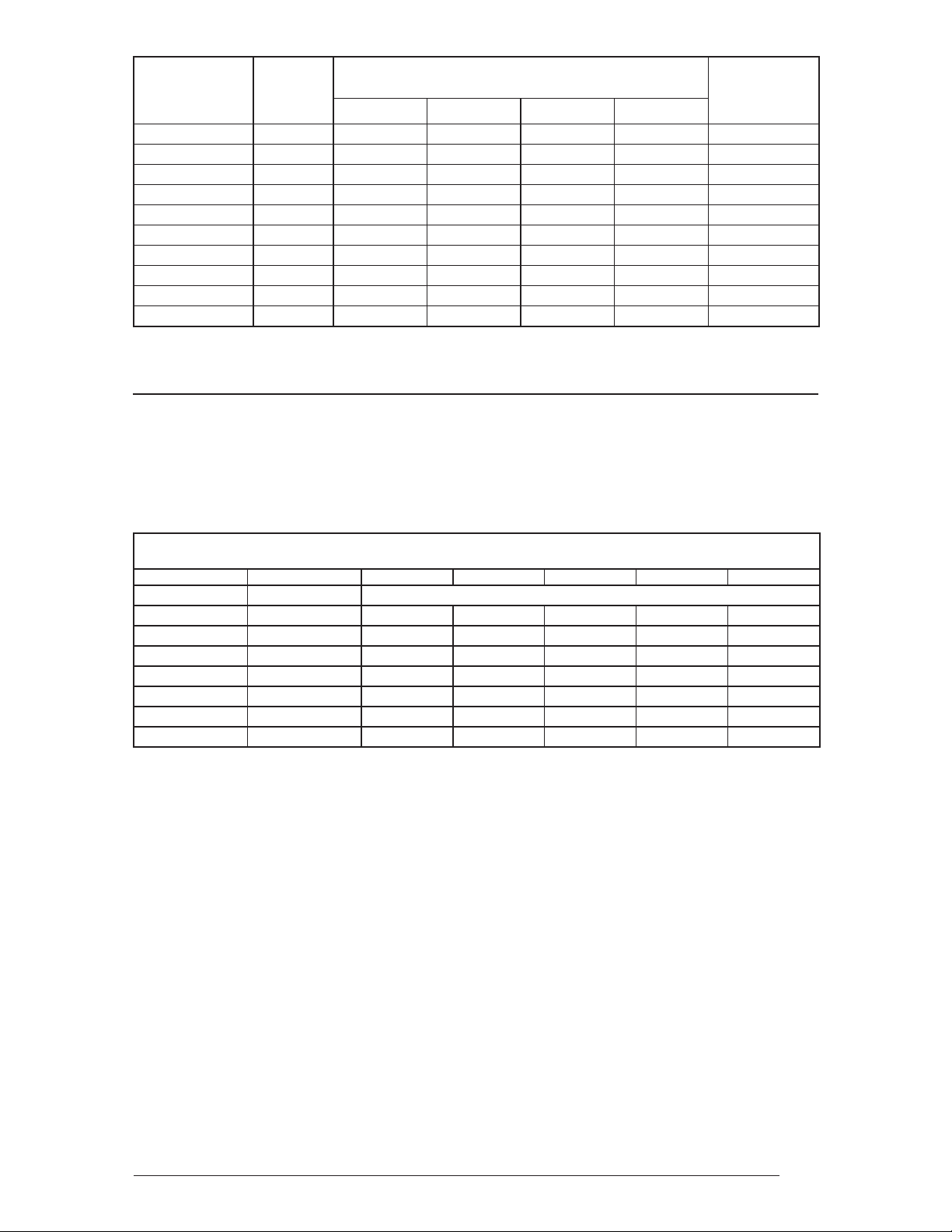

CAPACITIES —Furnace Airfl ow Data

External Static Pressure (Inches Water Column)

CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

High* 950 36 920 38 890 39 850 41 800 43 750 46 690 50 630 55

NOTES: 1. Airfl ow rates of 1800 CFM or more require two return air connections. Data is for operation with fi lter(s).

2. Temperature rises in the table are approximate. Actual temperature rises may vary.

3. Temperature rises and airfl ows for external static pressures greater than 0.5 are for reference only.

These conditions are not recommended.

Low 620 56 590 59 560 62 520 - 470 - 410 - 350 - 290 -

High* 1330 - 1280 - 1230 - 1170 - 1120 - 1030 - 940 37 850 41

High* 1310 - 1260 - 1210 - 1160 45 1100 47 1040 50 980 53 920 56

Low 800 65 780 67 760 68 740 70 710 73 680 - 650 - 620 -

Low 830 42 810 43 780 44 760 46 720 48 670 52 610 57 550 63

High* 1775 38 1724 39 1652 40 1583 42 1505 44 1430 46 1343 49 1226 54

Low 808 - 751 - 717 - 679 - 641 - 595 - 538 - 430 -

Med-Low 1031 65 987 67 967 69 914 73 882 75 839 - 783 - 692 -

High* 1840 - 1780 - 1700 41 1630 42 1550 45 1470 47 1380 50 1290 54

Low 1100 63 1050 66 1000 69 950 - 900 - 850 - 800 - 750 -

High* 2215 30 2155 31 2090 32 2030 33 1975 34 1885 35 1810 37 1730 39

Med-Low 1380 50 1350 51 1300 53 1250 55 1190 58 1120 62 1040 67 960 -

Med-Low 1670 39 1665 40 1660 41 1630 41 1590 42 1535 43 1470 45 1410 47

Low** 1365 48 1360 49 1350 49 1340 50 1305 51 1300 51 1255 53 1225 54

High* 1910 45 1860 47 1780 49 1700 51 1620 53 1520 57 1420 61 1310 66

Low 1230 70 1210 72 1180 73 1140 - 1090 - 1030 - 960 - 880 -

Med-Low 1440 60 1410 61 1370 63 1320 66 1270 68 1210 72 1140 - 1060 -

High* 2195 39 2140 40 2065 41 2000 42 1960 44 1860 46 1780 48 1695 50

Med-Low 1650 51 1615 52 1605 53 1570 54 1540 55 1485 57 1435 59 1370 62

Low 1320 64 1300 65 1280 66 1275 67 1265 67 1250 68 1210 70 1160 73

High* 1860 56 1800 58 1730 60 1650 63 1570 66 1480 70 1380 75 1270 82

Low 1230 84 1210 - 1180 - 1140 - 1090 - 1030 - 960 - 880 -

Med-Low 1440 72 1410 74 1380 75 1320 79 1280 81 1220 85 1150 - 1080 -

High* 2260 - 2200 - 2140 - 2070 - 1990 - 1910 - 1810 57 1710 61

Low 1360 76 1330 78 1310 79 1280 81 1250 83 1220 85 1190 - 1150 -

Med-Low 1540 67 1530 68 1510 69 1470 71 1430 73 1370 76 1300 80 1220 85

*RC- (Btuh) Speed HP

Model Heating

G6RC UPFLOW FURNACE

Number Input Motor Motor 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

040( )-12A 40,000 Medium** 1/3 1190 - 1160 - 1110 - 1060 - 1010 - 910 38 820 42 720 48

040( )-08A 40,000 Medium** 1/5 740 47 710 49 680 51 650 53 600 58 550 63 490 - 430 -

060( )-12A 60,000 Medium** 1/3 1160 45 1120 46 1080 48 1050 49 990 52 940 55 890 58 830 63

080( )-12B 80,000 Med-High** 1/2 1417 47 1385 48 1339 50 1280 52 1224 54 1163 57 1097 61 1013 66

080( )-16B 80,000 Med-High** 1/2 1600 43 1560 44 1470 47 1400 49 1350 51 1280 54 1210 57 1150 60

080( )-20B 80,000 Med-High 3/4 2000 33 1970 34 1930 35 1870 36 1820 37 1755 38 1695 39 1625 41

100( )-16B 100,000 Med-High** 1/2 1640 53 1620 53 1540 56 1480 58 1420 61 1340 65 1250 69 1150 75

100( )-20B 100,000 Med-High** 3/4 1975 43 1910 44 1875 45 1845 46 1805 47 1735 50 1670 51 1590 53

120( )-16C 120,000 Med-High** 1/2 1650 63 1610 65 1550 67 1480 70 1410 74 1320 79 1230 84 1120 -

120( )-20C 120,000 Med-High** 3/4 1870 56 1840 56 1790 58 1760 59 1710 61 1660 63 1610 65 1560 67

( ) Can be C or N

** Factory Set Cooling Speed

** Factory Set Heating Speed

- Not Recommended

Table 1. Furnace Airfl ow Data

6

Page 7

CAPACITIES —Furnace Airfl ow Data continued

*RL- (Btuh) Speed HP CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

Model Heating External Static Pressure (Inches Water Column)

Number Input Motor Motor 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

1. Airfl ow rates of 1800 CFM or more require two return air connections.

Data is for operation with fi lter(s).

2. Temperature rises in the table are approximate. Actual temperature rises may vary.

3. Temperature rises and airfl ows for external static pressures greater than 0.5 are for reference only.

These conditions are not recommended.

High* 1280 - 1210 - 1180 - 1140 - 1090 - 1070 - 1030 - 990 -

Low** 875 39 835 41 820 41 805 42 780 43 770 44 760 45 750 45

040()-12 40,000 Medium 1/3 1140 - 1090 - 1060 - 1030 - 980 35 950 36 910 37 870 39

High* 1260 40 1190 43 1155 44 1120 45 1075 47 1030 49 980 52 940 54

060()-12 60,000 Medium** 1/3 1120 45 1070 48 1040 49 1010 50 960 53 930 55 890 57 850 60

Low 855 59 815 62 800 64 780 65 760 67 730 70 710 - 690 -

High* 1635 - 1585 - 1525 - 1460 46 1400 48 1330 51 1260 54 1180 57

080()-16 80,000 Med-High** 1/2 1435 47 1395 49 1350 50 1300 52 1255 54 1200 56 1150 59 1090 62

Med-Low 1230 55 1200 56 1165 58 1130 60 1090 62 1050 65 1000 68 960 71

Low 1050 - 1035 - 1010 - 980 - 950 - 910 - 870 - 820 -

High* 1600 53 1555 54 1500 56 1445 59 1380 61 1310 65 1240 68 1160 73

100()-16 100,000 Med-High** 1/2 1475 57 1435 59 1385 61 1335 63 1290 66 1240 68 1190 71 1130 75

Low 1150 - 1130 - 1110 - 1075 - 1040 - 1000 - 950 - 890 -

Med-Low 1320 - 1290 - 1250 - 1215 - 1170 - 1120 - 1070 - 1020 -

High* 2085 48 2035 49 1965 51 1910 52 1840 54 1780 56 1715 58 1630 61

120()-20 100,000 Med-High** 3/4 1925 52 1885 53 1835 55 1780 56 1730 58 1675 60 1615 62 1540 65

Med-Low 1720 58 1670 60 1630 61 1610 63 1570 64 1510 66 1465 68 1415 72

Low 1500 66 1495 69 1460 66 1430 70 1400 72 1365 73 1315 - 1265 -

( ) Can be C or N

* Factory Set Cooling Speed

** Factory Set Heating Speed

- Not Recommended

Table 2. Furnace Airfl ow Data

7

Page 8

SAFETY INFORMATION

1. Use only with type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in a location and

position as specifi ed on Table 4 of these

instructions.

3. Provide adequate combustion and ventilation air to the furnace space as specifi ed

on Pages 13 through 16.

4. Provide adequate clearances around the

vent air intake terminal(s) as specifi ed on

Figures 18 through 23 of these instructions.

5. Combustion products must be discharged

outdoors. Connect this furnace to an approved vent system only, as specifi ed on

Pages 16 through 26.

6. Never test for gas leaks with an open fl ame.

Use a commercially available soap solution

made specifi cally for the detection of leaks

to check all connections, as specifi ed on

Page 28 of these instructions.

7. Always install furnace to operate within the

furnace’s intended temperature-rise range

with a duct system which has an external

static pressure within the allowable range,

as specifi ed on Table 2 of these instructions.

See furnace rating plate.

8. When a furnace is installed so that supply

ducts carry air circulated by the furnace

to areas outside the space containing the

furnace, the return air shall also be handled

by duct(s) sealed to the furnace casing and

terminating outside the space containing

the furnace.

9. A gas-fi red furnace for installation in a residential garage must be installed as specifi ed

on Page 10 of these instructions.

10. The furnace is not to be used for temporary

heating of buildings or structures under

construction.

INSTALLATION REQUIREMENTS

American National Standards Institute, Inc.

1430 Broadway

New York, New York 10018

Canada installations shall comply with CAN/CGAB149 installation codes, local plumbing or waste

water codes and other applicable codes.

Additional helpful publications are:

• NFPA-90A - Installation of Air Conditioning

and Ventilating Systems.

• NFPA-90B - Warm Air Heating and Air

Conditioning Systems.

These publications are available from:

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, Massachusetts 02269

!

WARNING:

This furnace is not approved for installation in mobile homes. Installation in a

mobile home could cause fi re, property

damage, and/or personal injury.

IMPORTANT NOTE

The Commonwealth of Massachusetts requires

compliance with regulation 248 CMR 4.00 and

5.00 for installation of through – the – wall vented gas appliances as follows:

(a) For direct-vent appliances, mechanical-

vent heating appliances or domestic hot

water equipment, where the bottom of the

vent terminal and the air intake is installed

below four feet above grade the following

requirements must be satisfi ed:

1. If there is not one already present,

on each fl oor level where there are

bedroom(s), a carbon monoxide detector and alarm shall be placed in the living area outside the bedroom(s). The

carbon monoxide detector shall comply

with NFPA 720 (2005 Edition).

Requirements and Codes

This furnace must be installed in accordance with

these instructions, all applicable local building

codes, and the current revision of the National

Fuel Gas Code (ANSI-Z223.1, NFPA-54). The

current revision of the National Fuel Gas Code

is available from:

8

2. A carbon monoxide detector shall be

located in the room that houses the appliance or equipment and shall:

a. Be powered by the same electrical

circuit as the appliance or equipment

such that only one service switch

Page 9

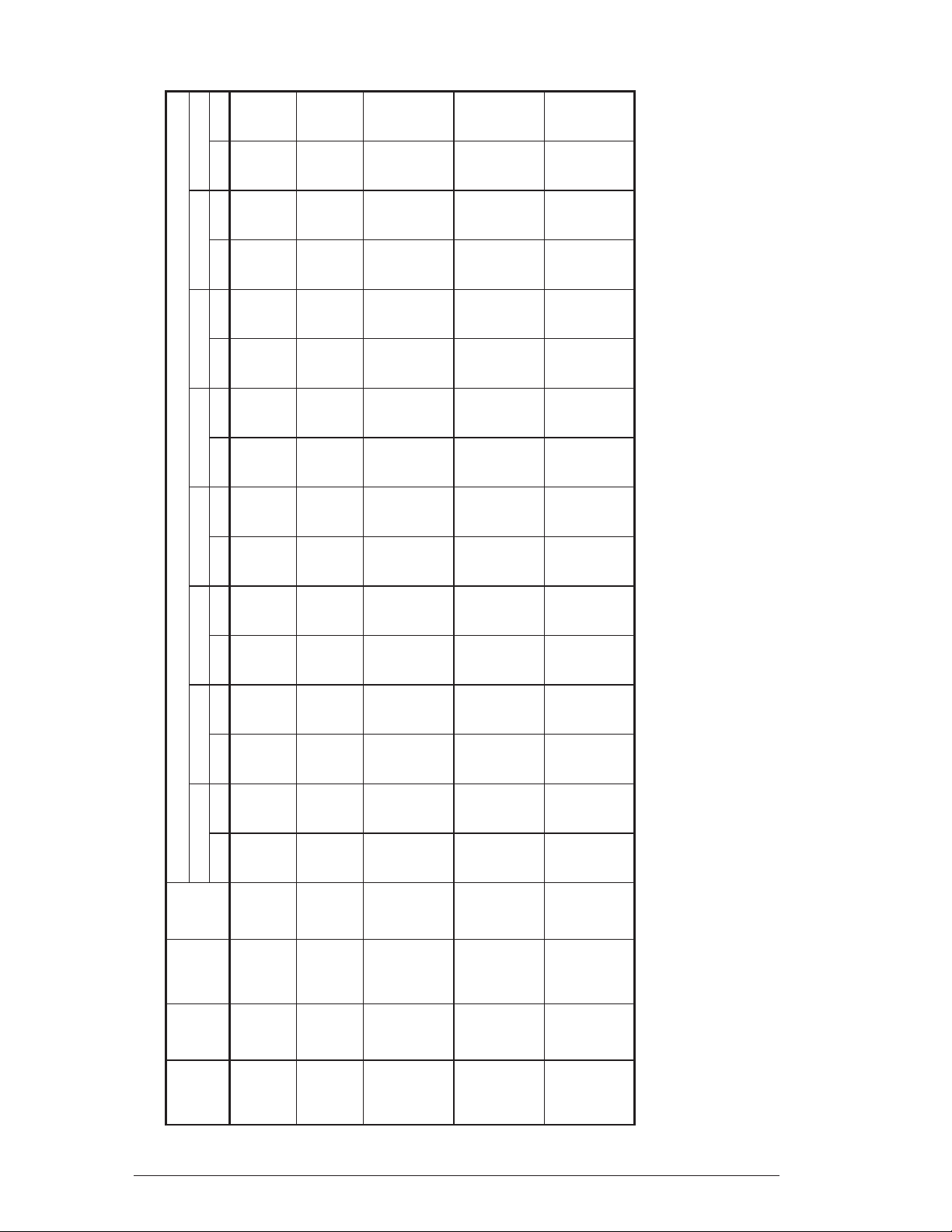

Model

Number

*RC040 40,000 14 1/4 12 3/4 5 1/8 11 3/4 133

*RC060 60,000 14 1/4 12 3/4 5 1/8 11 3/4 140

*RC080 80,000 19 3/4 18 1/4 7 7/8 17 1/4 172

*RC100 100,000 19 3/4 18 1/4 7 7/8 17 1/4 180

*RC120 120,000 22 1/2 21 9 1/4 20 204

*RL040 40,000 14 1/4 12 3/4 4 5/8 12 3/4 135

*RL060 60,000 14 1/4 12 3/4 4 5/8 12 3/4 135

*RL080 80,000 19 3/4 18 1/4 10 18 1/4 174

*RL100 100,000 19 3/4 18 1/4 10 18 1/4 185

*RL120 120,000 22 1/2 21 12 1/2 21 1/8 209

Furnace

Btuh

Table 3. Furnace Dimensions and Shipping Weights

ABCD

Dimensions (inches)

Shipping

Weight

(lbs

)

CLEARANCES TO COMBUSTIBLE MATERIALS

This furnace is Designed Certifi ed by CSA International for the minimum clearances to combustible material listed in Table 4. See the furnace name plate, located inside the furnace cabinet, for

specifi c model number and clearance information.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIAL

Furnace Cabinet Minimum Clearances (Inches)

Input Width

(Btuh) (Inches) Side Vent Back Top Front

40,000 14 1/4 00011*

60,000 14 1/4 00011*

80,000 14 1/4 00011*

100,000 19 3/4 00011*

120,000 22 1/2 00011*

* When installed horizontally, 24 inches is required for servicing.

Table 4. Minimum Clearances to Combustible Materials

services both the appliance and the

carbon monoxide detector;

b. Have battery back-up power;

c. Meet ANSI/UL 2034 Standards

and comply with NFPA 720 (2005

Edition);and

d. Have been approved and listed by

a Nationally Recognized Testing

Laboratory as recognized under 527

CMR.

3. A Product-approved vent terminal must

be used, and if applicable, a Productapproved air intake must be used. In-

stallation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

4. A metal or plastic identifi cation plate

shall be mounted at the exterior of the

building, four feet directly above the location of vent terminal. The plate shall

be of suffi cient size to be easily read

from a distance of eight feet away, and

read “Gas Vent Directly Below”.

9

Page 10

(b) For direct-vent appliances, mechanical-

vent heating appliances or domestic hot

water equipment where the bottom of the

vent terminal and the air intake is installed

above four feet above grade the following

requirements must be satisfi ed:

This furnace is certifi ed for use on wood fl ooring.

The furnace must be installed on a solid surface

and must be level front to back and side to side.

This furnace must not be installed directly on

carpeting, tile, or any combustible material other

than wood fl ooring.

1. If there is not one already present,

on each fl oor level where there are

bedroom(s), a carbon monoxide detector and alarm shall be placed in the living area outside the bedroom(s). The

carbon monoxide detector shall comply

with NFPA 720 (2005 Edition).

2. A carbon monoxide detector shall:

a. Be located in the room that houses

the appliance or equipment;

b. Be either hard-wired or battery pow-

ered or both; and

c. Shall comply with NFPA 720 (2005

Edition).

3. A Product-approved vent terminal must

be used, and if applicable, a Productapproved air intake must be used. Installation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

DOWNFLOW WARNING

(*RL Models):

The design of the downfl ow furnace is certifi ed

for natural or propane gas and for installation on

non-combustible fl ooring. A special combustible

fl oor sub-base is required when installing on a

combustible fl oor. Failure to install the sub-base

may result in fi re, property damage and personal

injury. The special downfl ow sub-bases are factory supplied accessories, part number 902974,

902677, 904108 and 904165. Part #904108 is

an adjustable sub-base kit and it can be used on

all cabinet sizes. When the furnace is installed

on a factory or site-built cased air conditioning

coil, the sub-base is not necessary. However,

the plenum attached to the coil casing must be

installed such that its surfaces are at least 1”

from combustible construction.

A gas-fi red furnace installed in a residential garage must be installed so that the burners and the

ignition source are located a minimum of 18” from

the fl oor. The furnace must be located or protected

to avoid physical damage by vehicles.

Location

The furnace must be installed on a level surface,

and as close to the center of the air distribution

system as possible. See Table 3 for overall dimensions to determine the required clearances

in hallways, doorways, stairs, etc. to allow the

furnace to be moved to the installation point. The

furnace must be installed so that all electrical

components are protected from water.

Minimum clearances to combustible materials

are listed in Table 4. Access for positioning and

servicing must be considered when locating the

unit. Twenty four inches is the minimum required

clearance for servicing the unit. Thirty inches is

the minimum required clearance for positioning

the unit. Thirty six inches is the recommended

clearance from the front of the unit. Please note

that a panel or door can be located such that the

minimum clearance on the rating plate is satisfi ed, but that panel or door must be removable

and allow the appropriate clearance for your

installation.

HORIZONTAL INSTALLATIONS

The upfl ow model furnaces are approved for

horizontal installation. Installation Kit #903568

is available for horizontal applications. The

parts may also be fi eld supplied. NOTE: Downfl ow models are NOT approved for horizontal

installation.

!

CAUTION:

Damage to the product resulting

from failure to follow instructions or

use of unauthorized parts may void

the manufacturer’s product warranty

coverage.

The 90+ upfl ow furnace can be installed horizontally in an attic, basement, crawl space or

alcove. This furnace can be installed horizontally

to the clearances listed in Table 4 on a platform

10

Page 11

5/8" Vinyl Cap

Pressure Switch

1/4" Vinyl Cap

Drain Trap

1/2" Vinyl

Cap

Soft

Tubing

Grey

Tubing

3" to 2"

Reducer

(Optional)

PVC Tee

PVC Reducer

Bushing

Soft Tubing

Looped to Provide

a Drain Trap

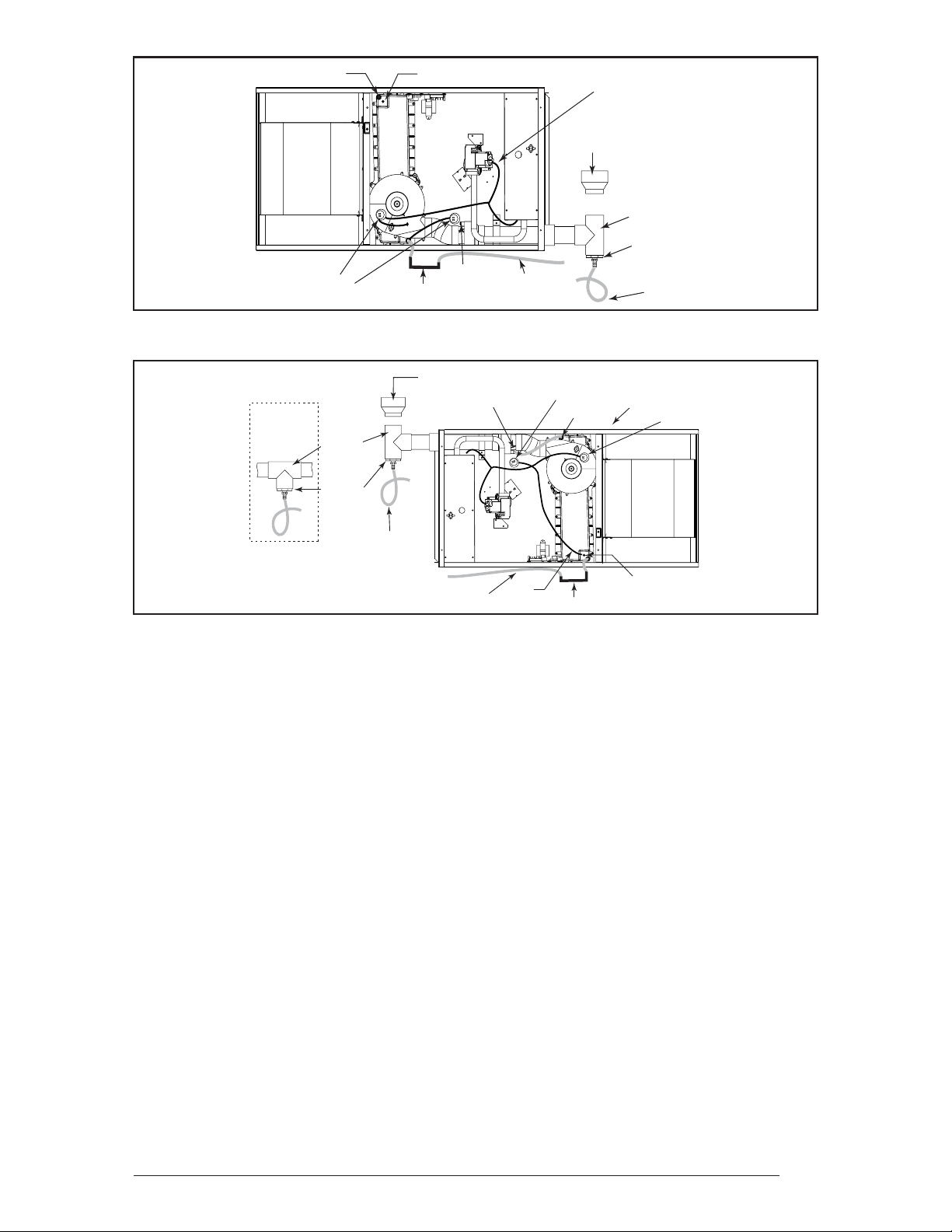

Figure 3. 90+ Upfl ow Converted for Horizontal Installation (Horizontal Right)

3" to 2"

Alternative

for

Horizontal

Vent

PVC Tee

Reducer

Bushing

Reducer

(Optional)

Drainage Port

is Downard

Pressure Switch

(Condensate)

Soft Tubing

Vinyl Cap

Pressure

Switch

Soft Tubing

Looped to Provide

a Drain Trap

Tubing

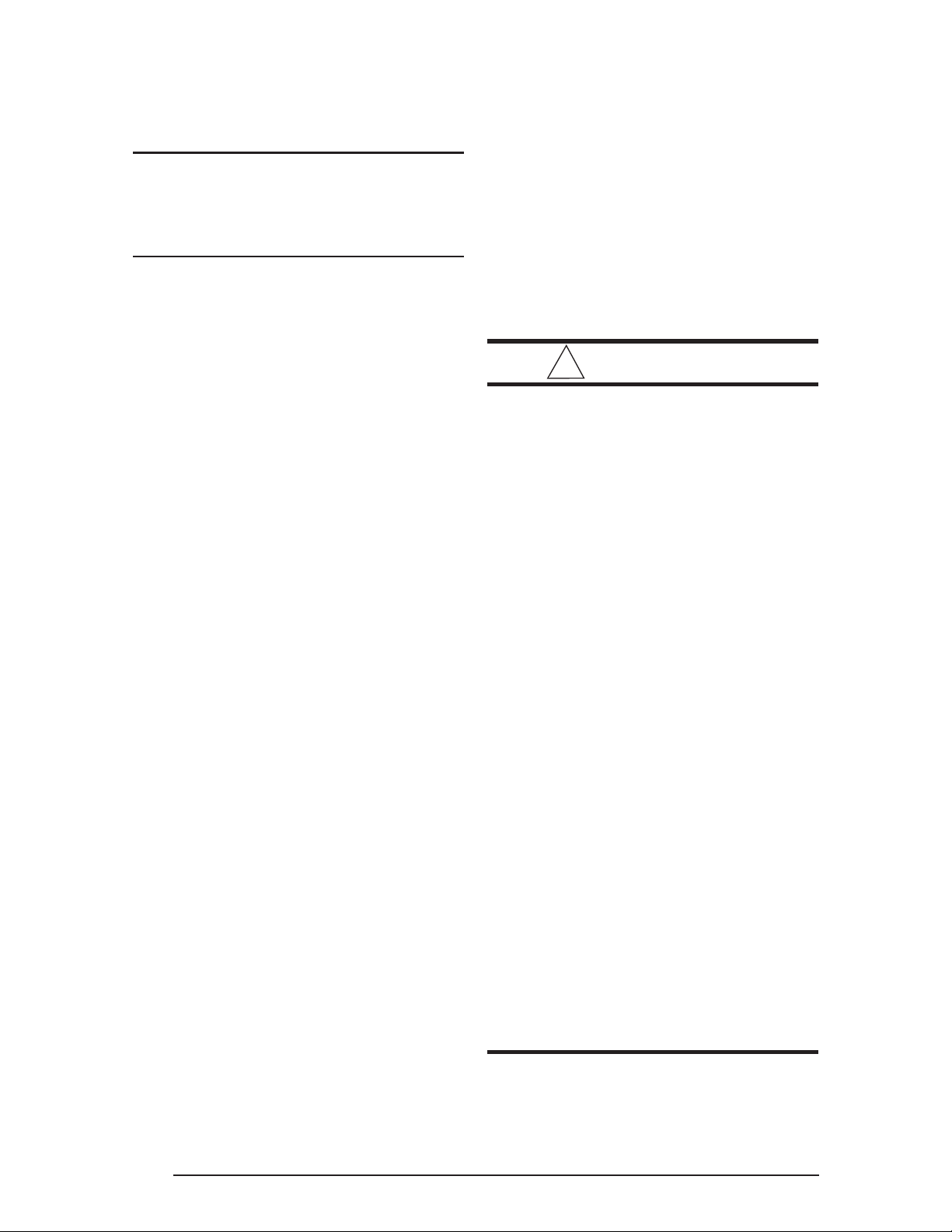

Figure 4. 90+ Upfl ow Converted for Horizontal Installation (Horizontal Left)

or on the ceiling rafters. Note that the platform

and the ceiling rafters must be able to support

the weight of the furnace being installed. It can

also be suspended from a ceiling in a basement

or utility room in either a right to left airfl ow or

left to right airfl ow.

When installed horizontally, the furnace must

be raised above the surface to allow a drain

trap to hang vertically below the furnace. This

will allow for proper drainage of the condensate

from the furnace.

Conversion of the 90+ Upfl ow Furnace for a

Horizontal Right Installation.

1. Remove the hard “J” tube drain trap assembly.

2. Place the 5/8” cap plug over the drain

tap in the header box from which the “J”

drain trap assembly was removed.

3. Remove the piece of soft tubing running

from the in-line drain assembly to the

header box and place a 1/2” vinyl cap

over the drain tap in the in-line drain

assembly.

Soft

Grey

Tubing

Drain Trap

1/4" Vinyl Cap

4. Remove the grey tubing from the pressure switch to the header box. Remove

the 1/4” cap from the pressure tap on the

right side of the header box and place it

on the corresponding pressure tap on the

opposite side of the header box.

Conversion of the 90+ Upfl ow Furnace for a

Horizontal Left Installation.

Refer to Figure 4 for details and description

of parts required for the horizontal left conversion.

1. Remove the hard “J” tube drain trap assembly.

2. Ensure that the piece of soft tubing running from the in-line drain assembly to

the header box is in place with the drain

oriented downwards (See Figure 4).

3. Connect a draw trap to the right side of

the header on the furnace. The drain

trap must be installed according to local

code. NOTE: A downward slope must

be maintained on the tube as it is routed

through the furnace (when the furnace

is in the horizontal position).

11

Page 12

NOTE: To avoid condensate freezing in the drain

trap assembly and tubing, insulate around

the drain trap assembly and all tubing located

in unconditioned space.

When a cooling system is installed which uses the

furnace blower to provide airfl ow over the indoor

coil, the coil must be installed downstream (on the

outlet side) or in parallel with the furnace.

NOTE: When converting the furnace, to horizontal

left, ensure that the drainage port on the in-line

drain assembly is downward as shown in Figure

4. If the in-line drain assembly is not rotated, then

the furnace may not drain properly.

SUPPLY AIR PLENUM INSTALLATION

A. Installation on a concrete slab - *RL

1. Construct a hole in the fl oor per the

dimensions in Figure 5.

2. Place the plenum and the furnace as

shown in Figure 6.

B. Installation on a combustible fl oor - *RL

1. Cut hole and frame the hole per the

dimensions in Figure 7.

2. Place sub-base for combustible fl oors

over the hole with its duct collar extended

downward. Attach the supply air plenum

to the base in a manner which will assure 1” clearance to the fl ooring or other

combustible material. Place furnace

on the combutsible base as shown in

Figure 8.

3. When the furnace is installed on a factory or site-built cased air conditioning

coil, the sub-base is not necessary.

However, the plenum attached to the

coil casing must be installed such that its

surfaces are at least 1” from combustible

material in Figure 9.

CIRCULATING AIR SUPPLY

Plenums and air ducts must be installed in accordance with the Standard for the Installation of

Air Conditioning and Ventilating Systems (NFPA

No. 90A) or the Standard for the Installation of

Warm Air Heating and Air Conditioning Systems

(NFPA No. 90B).

If a cooling system is installed in parallel with the

furnace, a damper must be installed to prevent

chilled air from entering the furnace and condensing on the heat exchanger. If a manually operated

damper is installed, it must be designed so that

operation of the furnace is prevented when the

damper is in the cooling position and operation

of the cooling system is prevented when the

damper is in the heating position.

!

WARNING:

Products of combustion must not be

allowed to enter the return air ductwork

or the circulating air supply. Failure

to prevent products of combustion

from being circulated into the living

space can create potentially hazardous

conditions including carbon monoxide

poisoning that could result in personal

injury or death.

All return ductwork must be secured

to the furnace with sheet metal screws.

For installations in confi ned spaces,

all return ductwork must be adequately

sealed and joints must be taped. When

return air is provided through the bottom of the furnace, the joint between

the furnace and the return air plenum

must be sealed.

The fl oor or platform on which the furnace is mounted must provide sound

physical support of the furnace with no

gaps, cracks, or sagging between the

furnace and the fl oor or platform.

If outside air is utilized as return air to the furnace

for ventilation or to improve indoor air quality, the

system must be designed so that the return air to

the furnace is not less than 50°F (10°C) during

heating operation. If a combination of indoor and

outdoor air is used, the ducts and damper system

must be designed so that the return air supply to

the furnace is equal to the return air supply under

normal, indoor return air applications.

12

Return air and circulating air ductwork

must not be connected to any other

heat producing device such as a fi replace insert, stove, etc.

Page 13

Return Air

The return air ductwork may be connected to any

or all of the following: left side return, right side

return, or bottom return. Tables 1 and 2 show

the airfl ow data for each furnace model. Where

maximum airfl ow is 1800 CFM or more two

openings must be used.

VENTING AND COMBUSTION AIR

REQUIREMENTS

NORDYNE condensing furnaces may be installed

with outdoor combustion air piped directly to the

furnace, or without such special piping. Codes

refer to the former as “direct vent” or “two pipe”

installation. Installation with air taken from around

the furnace is sometimes referred to as “one

pipe” installation where only the vent (exhaust)

pipe is provided.

Provisions must be made for adequate supply of air for combustion and ventilation. For

United States installations, the adequacy of air

provisions can be determined by consulting the

current version of the National Fuel Gas Code

(ANSI Z223.1/NPFA-54). For Canadian installations, requirements are specifi ed in the National

Standard of Canada (CAN/CGA B149.1 & .2).

Consult local codes for special requirements.

An important consideration in selecting one or

two pipe installation is the quality of the combustion air. Indoor air is sometimes contaminated

with various household chemicals which can

cause severe corrosion in the furnace combustion system.

NOTE: If the furnace is operated without adequate air for combustion and ventilation, it may not

perform properly. Furnace components may be

strained by high temperature and could fail .

!

WARNING:

Furnace installation using methods

other than those described in the following sections must comply with the

National Fuel Gas Code and all applicable local codes to provide suffi cient

combustion air for the furnace.

Concrete

Furnace

Floor

Sheet

Metal

Plenum

Figure 6. Furnace on a Concrete Slab

A

B

MODEL A B

*RL 040/060 13.25” 19.25”

*RL 080/100 18.75” 19.25”

*RL 120 21.50” 19.25”

Figure 5. Opening for Concrete Slab

A

B

MODEL A B

*RL 040/060 13.25” 19.63”

*RL 080/100 18.75” 19.63”

*RL 120 21.50” 19.63”

Figure 7. Opening in Wood Floor

13

Page 14

Downflow

Sub-base

Furnace

Wood

Floor

Sheet

Metal

Plenum

Figure 8. Furnace on a Wood Floor

* RL 040/060

18.75"

or 13.25" or 21.50"*

** RL 120

9.25"

2.0"

Upfl ow Models

Screen

Downfl ow Models

Figure 10. Protective Screen for

One Pipe Installations

Each opening must

be at least 100 sq. in.

or 1 sq. in. per 1000

Protective

Vent or

Chimney

Btuh of total input

rating, whichever is

greater. See minimum

area per table.

16.75"

or 11.25"

1.50"

19.75"

or 14.25"*

or 22.50"**

28.38"

1.58"

1 inch thick fiberglass 3 lb density

3"

Figure 9. Downfl ow Sub-Base

Dimensions

19.63"

12" Max.

Furnace

12" Max.

Water Heater

Total Input

Rating (Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

Minimum

Free Area

(Each Opening)

100 sq. in.

100 sq. in.

100 sq. in.

100 sq. in.

120 sq. in.

140 sq. in.

160 sq. in.

Round Duct

Diameter

12"

12"

12"

12"

13"

14"

15"

Figure 11. Equipment in a Confi ned Space

with all Combustion Air drawn from Inside

14

Page 15

Each opening

to outside must

be at least

1 sq. in. per

4000 Btuh of

total input

rating.

-

-

-

-

-

-

12"

-

-

-

Max

-

-

-

-

-

-

-

-

-

12" Max

Vent or

Chimney

Water Heater

Furnace

Furnace

Alternate

Air Inlet

---------

Vent or

Chimney

Water

Heater

Inlet Air

---------

Ventilation Louvers

(each end of attic)

---------

Outlet

NOTE: Air openings shall each

Air

have a free area

of not less than

one square inch

per 4,000 Btuh of

the total input rating of all equipment

in the enclosure.

---------

Total Input

Rating (Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

Free Area

(Each Opening)

10 sq. in.

15 sq. in.

20 sq. in.

25 sq. in.

30 sq. in.

35 sq. in.

40 sq. in.

Round Duct

Diameter

4"

5"

5"

6"

6"

7"

8"

Figure 12. Equipment in a Confi ned Space

with all Combustion Air drawn from Out-

doors through Exterior Wall

Ventilation Louvers at each end of attic

Minimum

Vent or

Chimney

Attic

Insulation

Water Heater

Total Input

Rating (Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

Furnace

Minimum

Free Area

(Each Opening)

10 sq. in.

15 sq. in.

20 sq. in.

25 sq. in.

30 sq. in.

35 sq. in.

40 sq. in.

Air Duct must be

at least 1 sq. in.

per 4,000 Btuh of

total input rating.

Ducts must

extend above

attic insulation.

Air Duct must be

at least 1 sq. in.

per 4,000 Btuh of

total input rating.

12" Max

Round Duct

Diameter

4"

5"

5"

6"

6"

7"

8"

Ventilation Louvers For

Unheated Crawl Space

Figure 14. Equipment in a Confi ned Space

with all Combustion Air drawn from Out-

doors through Ventilated Crawl Space and

Ventilated Attic

Vent or

Chimney

Air Duct

must be

at least

1 sq. in.

per 2000

Btuh of

total input

rating.

Round Duct

Diameter

5"

6"

7"

8"

9"

10"

10"

Total Input

Rating (Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

Air Duct

Furnace

Air Duct

Water Heater

Minimum

Free Area

(Each Opening)

20 sq. in.

30 sq. in.

40 sq. in.

50 sq. in.

60 sq. in.

70 sq. in.

80 sq. in.

Figure 13. Equipment in a Confi ned

Space with all Combustion Air drawn from

Outdoors through Vertical Ducts – from

Ventilated Attic

Figure 15. Equipment in a Confi ned Space

with all Combustion Air Drawn from the

Outside through Horizontal Ducts

15

Page 16

Combustion Air Quality

The recommended source of combustion air is

to use the outdoor air supply. However, the use

of indoor air in most applications is acceptable

except as follows:

1. If the furnace is installed in a confi ned

space it is recommended that the necessary

combustion air come from the outdoors by

way of attic, crawl space, air duct, or direct

opening.

2. If outdoor combustion air is used, there

must be no exposure to the installations or

substances listed in Item 3 below.

3. The following types of installation may require Outdoor Air for combustion, due to

chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft

rooms

• Furnaces installed near chemical storage

areas

Exposure to the following substances in

the combustion air supply may also require

Outdoor Air for combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemi-

cals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes,

etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

Air Requirements For One-Pipe

Installation

When air for combustion is to be taken from

around the furnace, a protective screen must be

installed over the combustion air intake opening.

This screen is provided with the furnace installation instructions and functions to prevent debris

from entering the combustion system. It should

be installed on the combustion air intake collar

or inlet PVC. If furnace location is such that this

opening might be unintentionally obstructed, a 3”

PVC elbow must be installed on the collar, and

the screen placed inside the inlet of the elbow.

See Figure 10.

Installation In An Unconfi ned

Space

!

CAUTION:

“Tight” buildings (with weather stripping and caulk to reduce infi ltration),

may require special provisions for

introduction of outside air to ensure

satisfactory combustion and venting,

even though the furnace is located in

an unconfi ned space.

An unconfi ned space is an area including all

rooms not separated by doors with a volume

greater than 50 cubic feet per 1,000 Btuh of the

combined input rates of all appliances which

draw combustion air from that space. For example, a space including a water heater rated

at 45,000 Btuh and a furnace rated at 75,000

Btuh requires a volume of 6,000 cubic feet [50 x

(45 + 75) = 6,000] to be considered unconfi ned.

If the space has an 8 foot ceiling, the fl oor area

of the space must be 750 square feet (6,000

/ 8 = 750). In general, a furnace installed in an

unconfi ned space will not require outside air for

combustion.

!

WARNING:

Furnaces installed with combustion

air drawn from a heated space which

includes exhaust fans, fi replaces, or

other devices that may produce a negative pressure should be considered

confi ned space installations.

Installation In A Confi ned Space

A confi ned space is one which does not meet

the unconfi ned space volume requirements, and

typically involves installation in a small room. All

such installations must have specifi c provisions

for introduction of combustion and ventilation air.

Codes require that two openings be provided for

this - one with bottom edge within 12” of the fl oor

and one with top edge within 12” of the ceiling.

16

Page 17

The size and other criteria for these openings

must be per the following sections.

!

CAUTION:

Combustion air openings must not be restricted

in any manner.

Furnaces installed in a confi ned space which

supply circulating air to areas outside of the

space must draw return air from outside the

space and must have return air ducts tightly

sealed to the furnace.

Air From Inside

Air for combustion and ventilation may be taken

from inside the building through an interior wall if

the building is not “tight” and if the total volume

of the furnace space and the space from which

air is drawn meets the volume requirements for

an unconfi ned space. In such cases, the two

openings in the wall must each have free area of

at least one square inch per 1000 Btuh of total

appliance input, but not less than 100 square

inches of free area. See Figure 11. For example,

if the combined input rate of all appliances is less

than or equal to 100,000 Btuh, each opening must

have a free area of at least 100 square inches.

If the combined input rate of all appliances is

120,000 Btuh, each opening must have a free

area of at least 120 square inches.

Air Directly Through An Exterior Wall

If combustion air is provided directly through an

exterior wall, the two openings must each have

free area of at least one square inch per 4000

Btuh of total appliance input. (See Figure 12.)

Outdoor Air Through Vertical Openings or

Ducts

If combustion air is provided through vertical ducts

or openings to attics or crawl spaces, the two

openings must each have free area of at least

one square inch per 4000 Btuh of total appliance

input. Ducts must have cross-sectional areas at

least as large as the free area of their respective

openings to the furnace space. Attics or crawl

spaces must communicate freely with the outdoors if they are the source of air for combustion

and ventilation. (See Figures 13 and 14.)

Do not supply combustion air from an

attic space that is equipped with power

ventilation or any other device that may

produce a negative pressure.

VENTING REQUIREMENTS

This section specifi es installation requirements

for vent and “2-pipe” combustion air piping. For

“one pipe” installations, install vent piping per

this section and provide air for combustion and

ventilation per the previous section. The capacity

table provided in this section applies to the total

of vent and combustion air piping for either type

of installation.

NORDYNE condensing furnaces are classifi ed as

“Category IV” appliances, which require special

venting materials and installation procedures.

Category IV appliances operate with positive

vent pressure and therefore require vent systems

which are thoroughly sealed. They also produce

combustion condensate, which is slightly acidic

and can cause severe corrosion of ordinary venting materials. Furnace operation can be adversely

affected by restrictive vent and combustion air

piping. Therefore, vent and combustion air piping

lengths must conform completely to the requirements of Table 5.

The furnace must be vented to the outdoors. It

must not be vented in common with any other

appliance, even if that appliance is of the condensing type. Common venting can result in severe

corrosion of other appliances or their venting and

can allow combustion gases to escape through

such appliances or vents. Do not vent the furnace

to a fi replace chimney or building chase.

!

WARNING:

FURNACE MUST NOT BE COMMON

VENTED WITH OTHER APPLIANCES.

Outdoor Air Through Horizontal

Openings or Ducts

If combustion air is taken from outdoors through

horizontal ducts, the openings must each have

free area of at least one square inch per 2000

Btuh of total appliance input. Ducts must have

cross-sectional area at least as large as the free

area of their respective openings to the furnace

space. (See Figure 15.)

Horizontal Installations

In order to ensure complete drainage of all

condensate, an additional “T” drain assembly

may be installed in line with the vent piping (see

Figures 3 & 4). The “T” assembly may consist

of a 2” PVC tee with a 2’ to 1/2” PVC reducer

bushing , and a barb fi tting. These parts are

available in Horizontal Vent Kit 903568, or they

can be fi eld supplied.

17

Page 18

!

WARNING:

CARBON MONOXIDE

POISONING HAZARD

1. Seal any unused openings in the venting system

2. Inspect the venting system for proper

size and horizontal pitch, as required

in the National Fuel Gas Code, ANSI

Z223.1 or the CAN/CGA B149 Installation Codes and these instructions.

Determine that there is no blockage

or restriction, leakage, corrosion and

other defi ciencies which could cause

an unsafe condition.

3. So far as is practical, close all building doors and windows and all doors

between the space in which the

appliance(s) connected to the venting

system are located and other spaces

of the building.

4. Follow the lighting instructions. Place

the appliance being inspected in operation. Adjust thermostat so appliance

shall operate continuously.

5. Turn on clothes dryers and any other

appliance not connected to the venting system. Turn on any exhaust fans,

such as range hoods and bathroom

exhausts, so they shall operate at maximum speed. Do not operate a summer

exhaust fan.

6. Close fi replace dampers.

7. Test for spillage from draft hood

equipped appliance at the draft hood

relief opening after 5 minutes of main

burner operation. Use the fl ame of a

match or candle.

8. If improper venting is observed during

any of the above tests, the venting system must be corrected in accordance

with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149.1,

Natural Gas and Propane Installation

Codes.

9. After it has been determined that each

appliance connected to the venting

system properly vents when tested as

outlined above, return doors, windows,

exhaust fans, fi replace dampers and

any other gas burning appliance to

their previous conditions of use.

Vent Pipe Material

Vent and combustion air pipe and fi ttings must be

one of the following materials and must conform

to the indicated ANSI/ASTM standards:

Material Standard

Schedule 40 PVC D1785

PVC-DWV D2665

SDR-21* D2241

& SDR-26*

ABS-DWV D2661

Schedule 40 ABS F628

Foam/Cellular Core PVC F891

*In Canada, check the local codes to ensure that

SDR is approved for use. SDR is not approved

for all Canadian installations.

Cement and primer must conform to ATSM

Standard D2564 for PVC and Standard D2235

for ABS. When joining PVC piping to ABS, use

PVC solvent cement. (See procedure specifi ed

in ASTM Standard D3138.)

Vent Pipe Length and Diameter

In order for the furnace to operate properly,

the combustion air and vent piping must not be

excessively restrictive. To ensure this use Table

5, which indicates the maximum allowable piping length for a furnace of specifi ed input rate,

when installed with piping of selected diameter

and number of elbows. This table applies to the

length and number of elbows for each pipe. To

use the table, the furnace input rate, the centerline length and the number of elbows on each

pipe must be known. Choose the diameter for

which the tabulated length is equal to or greater

than required.

Proper use of the table is illustrated by the following example:

Example:

An 80,000 Btu/h furnace is to be installed in a

“one-pipe” system with 40 feet of vent piping.

There are a total of four long radius 90-degree

elbows used in the vent, including the one exterior

to the building.

Solution:

For this particular installation, the equivalent vent

length must be calculated. This equivalent vent

length will then be compared to the maximum

allowable vent length given in Table 5. Then, the

diameter of the piping can be chosen for which the

18

Page 19

e

APPLICATION

SINGLE PIPE LENGTH (ft.)

with 1 long radius elbow*

DIRECT VENT, DUAL PIPE LENGTH (ft.)

with 1 long radius elbow on each pipe*

PVC,CPVC or ABS Outlet Outlet Inlet/Outlet Inlet/Outlet Inlet/Outlet

SCH. 40 Pipe Size 2” 3” 2” 2” 3” 2” 3” 3”

Models 040

80 150 40 40 50 50 90 90

Models 060 & 080 60 150 30 30 35 35 90 90

Models 100 & 120 30 150 15 15 25 25 90 90

**NOTES

1. Subtract 2.5 ft. for each additional 2” long radius elbow, 5 ft. for each additional 2” short radius elbow, 3.5’

for each additional 3” long radius elbow, and 7’ for each additional 3” short radius elbow.

2. Two 45 degree elbows are equivalent to one 90 degree elbow.

3. Do not include termination elbows in calculation of vent length

4. This table is applicable for elevations from sea level to 2000 ft. For higher elevations decrease vent pipe

lengths by 8% per 1000 ft. of altitude.

5. Only the above pipe materials are approved for use with these condensing furnaces.

Table 5. Vent Table

Upfl ow Furnaces

5/8"

Combustion

Offset with

Exhaust Pipe

for Adequate

Dimensional

Clearance

PVC or

ABS Pipe

Straight Neoprene Coupling

with 2 Hose Clamps*

(Optional - Not Shown)

Inlet

Exhaust

See Vent Table 5

Straps or Other Suitable

Supports at Minimum of 5 ft. Intervals

Upward Pitch - 1/4" per Foot

Outlet Exhaust Vent

First Support Placed

as Close to Furnace

Connection as Possible

Exhaust Vent

Wall

Seal/Caulk

around Pip

at Building

90˚ Elbow

12" Min.

7"

Normal Snow Level

Downfl ow Furnaces

Exhaust

Seal/Caulk

around Pipe

at Building

90˚ Elbow

12" Min.

Normal Snow Level

See Vent Table 5

Straps or Other Suitable

Supports at Minimum of 5 ft. Intervals

Upward Pitch - 1/4" per Foot

Outlet Exhaust Vent

First Support Placed

Wall

as Close to Furnace

Connection as Possible

Exhaust Vent

* These neoprene couplings are fi eld-supplied and can be used if the installation requires breakable connections in the piping.

Note that a maximum of two couplings per pipe are allowed.

Figure 16. Horizontal Venting

Inlet

5/8"

Combustion Air

Inlet

Offset with Exhaust

Pipe for Adequate

Dimensional

Clearance

PVC or

ABS Pipe

Straight Neoprene

Coupling with

2 Hose Clamps*

19

Page 20

equivalent vent length is less than the maximum

allowable vent length. Returning to our example,

we consult Table 5 and determine that for an

80,000 Btu/h furnace the maximum vent length

for 2” diameter piping is 60 feet or for 3” diameter

piping is 150 feet. Note that the maximum vent

length given in Table 5 includes one long radius

elbow. Therefore, for our example, we have three

additional long radius elbows for which we must

add to our piping. Each long radius elbow is

equivalent to 2.5 feet, so we must add 7.5 feet

to our vent length. Therefore, the equivalent vent

length for our installation is 47.5 feet. We compare

this with the maximum vent length for 2” and 3”

diameter piping. For both cases, our equivalent

vent length is less than the maximum allowable

vent length, so for our “one-pipe” installation we

can use either 2” or 3” diameter piping.

Condensing furnace combustion products have

very little buoyancy, so Table 5 is to be used

without consideration of any vertical rise in the

piping.

NOTE: Always use the same or larger size

piping for combustion air as is used for the

exhaust vent.

Vent Pipe Installation

Pipe Routing and Support

Route piping as directly as possible between

the furnace and the outdoors and remember

that routing affects pipe size requirements per

the preceding section. If a two pipe system is

used, locate the combustion air intake and the

vent exhaust in the same atmospheric pressure

zone - i.e. both must exit the building though the

same portion of exterior wall or roof (See Figure

22). Vent piping must be sloped upwards not

less than 1/4” per foot in the direction from the

furnace to the terminal. This is to ensure that

any condensate fl ows back to the furnace (where

it can be disposed of through the condensate

disposal system).

The quality of outdoor air must also be considered. Be sure that the combustion air intake is

not located near a source of solvent fumes or

other chemicals which can cause corrosion of

the furnace combustion system.

!

CAUTION:

Piping must be mechanically supported so that

its weight does not bear on the furnace. Supports must be at intervals no greater than fi ve

feet, and at smaller intervals if necessary to

ensure that there are no sagging sections to

trap water. (See Figure 16.) It is recommended

to install couplings along the vent pipe, on either

side of the exterior wall. These couplings may

be required by local code.

Figure 18 illustrates vent and combustion air pipe

sizes exiting the furnace. Transition to the correct

pipe size must be done close to the furnace so

that the full length of pipe is of proper size.

Straight neoprene couplings are supplied with

the downfl ow furnaces only. These couplings

are to be installed in the combustion air inlet (if

present) and exhaust vent piping at the furnace

as shown in Figures 16. For an upfl ow furnace

installation, if breakable connections are required

in the combustion air inlet (if present) and exhaust

vent piping, then straight neoprene couplings for

2” or 3” piping with hose clamps can be used.

These couplings can be ordered through your

local furnace distributor.

To install a coupling, slide the rubber coupling

over the end of the pipe that is attached to the

furnace and secure it with one of the hose clamps.

Then slide the other end of the rubber coupling

onto the other pipe from the vent and secure the

coupling with the second hose clamp. Ensure that

the connection is tight and leak free.

NORDYNE condensing furnaces have been certifi ed for installation with zero clearance between

vent piping and combustible surfaces. However,

it is good practice to allow space for convenience

in installation and service.

Location of Outdoor Terminations

Horizontal Venting

Vent and combustion air intake terminations

must be as shown in Figure 19 and 20. Vent

termination clearances shall be consistent with

the National Fuel Gas Code, ANSI 2223.1/NFPA

54 and/or the CSA B149.1, Natural Gas and

Propane Installation Code.

All minimum clearances specifi ed must be

maintained to protect building materials from

degradation by fl ue gases.

Combustion air must not be drawn

from a corrosive atmosphere.

20

Page 21

Upfl ow Furnaces

Support System on

Vertical Rise Below Joints

Support System with

first support as close

to furnace as Possible

5'

Combustion

Air Pipe

Furnace Front

Downfl ow Furnaces

Exhaust

Vent

Exhaust

Vent

Straight Neoprene

Couplings with

2 Hose Clamps*

(Optional - Not

Shown)

Cabinet

Vertical Rise Below Joints

Support System with

first support as close

to furnace as Possible

Combustion

Air Pipe

Upward Pitch

1/4" per Foot

Support System on

5'

Straight Neoprene

Rubber Couplings

with 2 Hose Clamps*

Cabinet

Furnace Front

Upward Pitch

1/4" per Foot

Figure 17. Vertical Venting

* These couplings are fi eld-supplied and can be used if the installation requires breakable connec-

tions in the piping. Note that a maximum of two couplings per pipe are allowed.

Upfl ow Furnaces

Combustion Air Inlet Pipe Collar

Diameter 3" for coupling or reducer

Furnace Top

2" PVC Exhaust Vent All Models

Downfl ow Furnaces

Combustion Air Inlet

2" PVC on 040/060 models,

3" PVC on 080/100 models

Furnace Top

2" PVC

Exhaust Vent

All Models

Figure 18. Furnace Pipe Adaptions

21

Page 22

!

WARNING:

Ensure that the combustion air vent

and the exhaust vent are confi gured as

shown in Figure 19 and 20. Improper

vent termination can cause recirculation of the fl ue gases. This may

result in furnace vibration. In severe

cases, the furnace will cycle due to

the intermittent contact between the

fl ame and the fl ame sensor. If you

note oscillations occurring, check the

vent confi guration. Make sure that

the exhaust vent does not have a 90

degree termination.

Vent and combustion air intake terminations must

be located to ensure proper furnace operation

and to conform to applicable codes. Figure 19

and 20 illustrates necessary distances from the

vent termination to windows and building air intakes. In Canada, the Canadian Fuel Gas Code

takes precedence over these instructions.

Specifi cally, all minimum distance requirements with respect to termination of the vent

piping listed below (items 1 through 8).

These distances apply ONLY to U.S. installations. In Canada, the Canadian Fuel Gas

Code takes precedence.

7. Avoid areas where condensate drainage

may cause problems by dropping on planters or patios, etc. Also ensure that exhaust

gases will not impinge on windows or building surfaces, which may be compromised or

damaged by condensation. Do not install the

vent terminal such that exhaust is directed

into window wells, stairwells, under decks

or into alcoves or similar recessed areas,

and do not terminate above any public

walkways.

8. Select the point of wall penetration where

the minimum 1/4 inch per foot of slope up

can be maintained.

!

CAUTION:

For optimum performance, vent furnace through wall which experiences

the least exposure to winter winds.

For Canadian installations please refer to the

Canadian Installation Code (CAN/CGA-B149.1

or 2) and/or local codes.

The following list is a summary of vent terminal

location requirements:

1. The termination must be 12 inches above

snow level or grade level whichever is

higher. See Figure 18 for alternate method

to achieve 12” above snow level.

2. The minimum distance for a (1-pipe installation) from any door, (openable) window, or

gravity air inlet is 4 ft. below, 4 ft. horizontally,

or 1 ft. above.

3. The minimum distance for a direct vent (2pipe) installation from any door, (openable)

window, or air gravity inlet is 1 ft. below, 1

ft. horizontally, or 1 ft. above.

4. For one-pipe installations the recommended

minimum distance from an inside corner

formed by two exterior walls is 6 feet, but

is not required.

5. The vent termination for a 1-pipe installation

shall be a minimum of 3 ft. above any forced

air inlet within 10 ft.

6. The vent termination shall be located at least

3 ft. horizontally from any electric meter, gas

meter, regulator and any relief equipment

in accordance to ANSI 2223.1/NFPA S4.

The horizontal venting kits consist of two face

plates and an insulating gasket to seal the exterior

surface. A hole sized closely to the pipe diameter

must fi rst be cut through the wall. A short length

of pipe is then cut such that it can penetrate

the wall and be held in place by closely fi tting

standard couplings. The face plates are retained

on both sides of the wall by the couplings, and

the gasket is retained against the wall by the

outer face plate. Face plates must be fastened

to the wall and the outside one must be fl ashed

as appropriate to prevent entry of water.

When the horizontal kits are not used, the following steps are required:

1. Check the hole size cut through the exterior

wall. Insure that the hole diameter is less

than the diameter of the couplings to be

used.

2. Extend the vent pipe through the wall approximately 1” and seal the area between

the wall and pipe.

3. If required by local code, apply couplings

to the vent pipe on the interior and exterior

sides of the wall to insure the pipe can not

be pushed or pulled through the wall.

22

Page 23

VENT TERMINAL

AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

A =

Clearance above grade, veranda, porch,

Canadian Installations

1

US Installations

12 inches (30 cm) 12 inches (30 cm)

2

deck, or balcony

B =

Clearance to window or door that may be

opened

C =

Clearance to permanently closed window

D =

Vertical clearance to ventilated soffi t

located above the terminal within a

horizontal distance of 2 feet (61 cm) from

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 12 inches (30 cm) for

appliances > 10,000 Btuh (3 kW) and

100,00 Btuh (30 kW), 36 inches (91 cm)

for appliances >100,00 Btuh (30 kW)

**

**

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 9 inches (23 cm) for

appliances > 10,000 Btuh (3 kW) and

50,000 Btuh (15 kW), 12 inches (30 cm)

for appliances > 50,000 Btuh (15 kW)

the center line of the terminal

E =

Clearance to unventilated soffi t

F =

Clearance to outside corner

G =

Clearance to inside corner

H =

Clearance to each side of center line

extended above meter/regulator assembly

I =

Clearance to service regulator vent outlet 3 feet (1.83 m)

J =

Clearance to nonmechanical air supply inlet

to building or the combustion air inlet to any

other appliance

3 feet (91 cm) within a height 15 feet

above the meter/regulator assembly

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 12 inches (30 cm) for

appliances > 10,000 Btuh (3 kW) and

100,00 Btuh (30 kW), 36 inches (91 cm)

for appliances >100,00 Btuh (30 kW)

K =

Clearance to a mechanical air supply inlet 6 feet (1.83 m) 3 feet (91 cm) above if within 10 feet

**

**

**

*

*

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 9 inches (23 cm) for

appliances > 10,000 Btuh (3 kW) and

50,000 Btuh (15 kW), 12 inches (30 cm)

for appliances > 50,000 Btuh (15 kW)

(3 m) horizontally

L =

Clearance above paved sidewalk or paved

driveway located on public property

M =

Clearance under veranda, porch deck, or

balcony

7 feet (2.13 m) †

12 inches (30 cm) ‡

*

*

1

In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2

In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves

both dwellings.

‡ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the fl oor.

* For clearances not specifi ed in ANSI Z223.1 / NFPA 54 or CSA B149.1, the following statement shall be included:

“Clearance in accordance with local installation codes, and the requirements of the gas supplier and the manufacturer’s

installation instructions.”

Figure 19. Vent Termination Clearances for Direct Vent Furnaces

23

Page 24

VENT TERMINAL

AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

A =

Clearance above grade, veranda, porch,

Canadian Installations

1

US Installations

12 inches (30 cm) 12 inches (30 cm)

2

deck, or balcony

B =

Clearance to window or door that may be

opened

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 12 inches (30 cm) for

4 feet (1.2 m) below or to side of opening;

1 foot (300 mm) above opening

appliances > 10,000 Btuh (3 kW) and

100,00 Btuh (30 kW), 36 inches (91 cm)

for appliances >100,00 Btuh (30 kW)

C =

Clearance to permanently closed window

D =

Vertical clearance to ventilated soffi t

located above the terminal within a

horizontal distance of 2 feet (61 cm) from

**

**

the center line of the terminal

E =

Clearance to unventilated soffi t

F =

Clearance to outside corner

G =

Clearance to inside corner

H =

Clearance to each side of center line

extended above meter/regulator assembly

I =

Clearance to service regulator vent outlet 3 feet (1.83 m)

J =

Clearance to nonmechanical air supply inlet

to building or the combustion air inlet to any

other appliance

3 feet (91 cm) within a height 15 feet

above the meter/regulator assembly

6 inches (15 cm) for appliances 10,000

Btuh (3 kW), 12 inches (30 cm) for

appliances > 10,000 Btuh (3 kW) and

**

**

**

*

*

4 feet (1.2 m) below or to side of opening;

1 foot (300 mm) above opening

100,00 Btuh (30 kW), 36 inches (91 cm)

for appliances >100,00 Btuh (30 kW)

K =

Clearance to a mechanical air supply inlet 6 feet (1.83 m) 3 feet (91 cm) above if within 10 feet

(3 m) horizontally

L =

Clearance above paved sidewalk or paved

7 feet (2.13 m) † 7 feet (2.13 m)

driveway located on public property

M =

Clearance under veranda, porch deck, or

balcony

12 inches (30 cm) ‡

*

1

In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2

In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both

dwellings.

‡ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the fl oor.

* For clearances not specifi ed in ANSI Z223.1 / NFPA 54 or CSA B149.1, one of the following statement shall be included:

“Clearance in accordance with local installation codes, and the requirements of the gas supplier and the

manufacturer’s installation instructions.”

Figure 20. Vent Termination Clearances for Other Than Direct Vent Furnaces

24

Page 25

4. Insure the combustion air inlet pipe (for a 2

pipe installation) has a 90 degree termination

elbow as shown in Figures 21 and 22.

Vent Configuration to

Provide 12" Minimum

height above

Snow Level.

Outside

Wall

12" Min.

19" Max.

Support

1/2"

Armaflex

Insulation or

Equivalent

(If Required)

12" Above

Normally

Expected

Snow

Level

Figure 21. Alternate Horizontal

Vent Installation

Note: A combustion air intake must be provided

with an elbow opening downward. The screen

provided with the furnace must be installed in the

elbow to prevent entry of debris or creatures.

When the vent pipe must exit an exterior wall

close to the grade or expected snow level, a riser

should be provided as shown in Figure 20.

Table 6 describes the maximum length of fl ue pipe

that can travel through an unconditioned space

or an exterior space. The total vent length must

not exceed the lengths noted on Table 5.

Vertical Venting

Figure 23 shows the proper installation and

clearances for vertical vent termination. The

roof penetration must be properly fl ashed and

waterproofed with a plumbing roof boot or equivalent fl ashing. Termination spacing requirements

from the roof and from each other must be per

Figure 23.

Maximum Flue Pipe Length in

Unconditioned and Exterior Spaces

Winter Design

Termperature (°F)

20 45 70

020 70

-20 10 60

Without Insulation

(feet)

With Insulation

(feet) ‡

‡ = Insulation thickness greater than 3/8 inch, based on an

R value of 3.5 (ft*°F*hr)/(BTU*in)

Table 6. Vent Protection

Exhaust Vent

Option B

Mounting Kit

Faceplate Secured

to Wall with Screws

Combustion

Air Inlet

Exhaust Vent

Option C

18" Min.

36" Max.

7" Min.

18" min.

36" max.

18" Min.

36" Max.

12" Min. to

Normal Snow Level

Inlet

8" Min.

Exhaust Vent

Option A

Grade

Level

or Normal

Snow

Exhaust

Figure 22. Exhaust and Combustion Air Pipe Clearances

25

Page 26

Exhaust

Elbow

Vent

1"

Combustion

Air

Intake

18" Min.

36" Max.

A

A

Exhaust

Plumbing Vent Roof Boot

(Typ. Both Pipes)

A= 12” Above Roof or Snow Accumulation Level

Figure 23. Vertical Vent Termination

Vent and combustion air piping may be installed

in an existing chimney which is not in use provided that:

a. Both the exhaust vent and air intake run

the length of the chimney.

b. The top of the chimney is sealed and

weatherproofed.

c. The termination clearances shown in

Figure 23 are maintained.

d. No other gas fi red or fuel-burning equip-

ment is vented through the chimney.

Vent Freezing Protection

When the vent pipe is exposed to temperatures

Upfl ow Models

A

Collector Box

below freezing, i.e., when it passes through

unheated spaces, chimneys, etc., the pipe

must be insulated with 1/2 inch thick sponge

rubber insulation, Armafl ex-type insulation or

equivalent. Insulating pipe is important to avoid