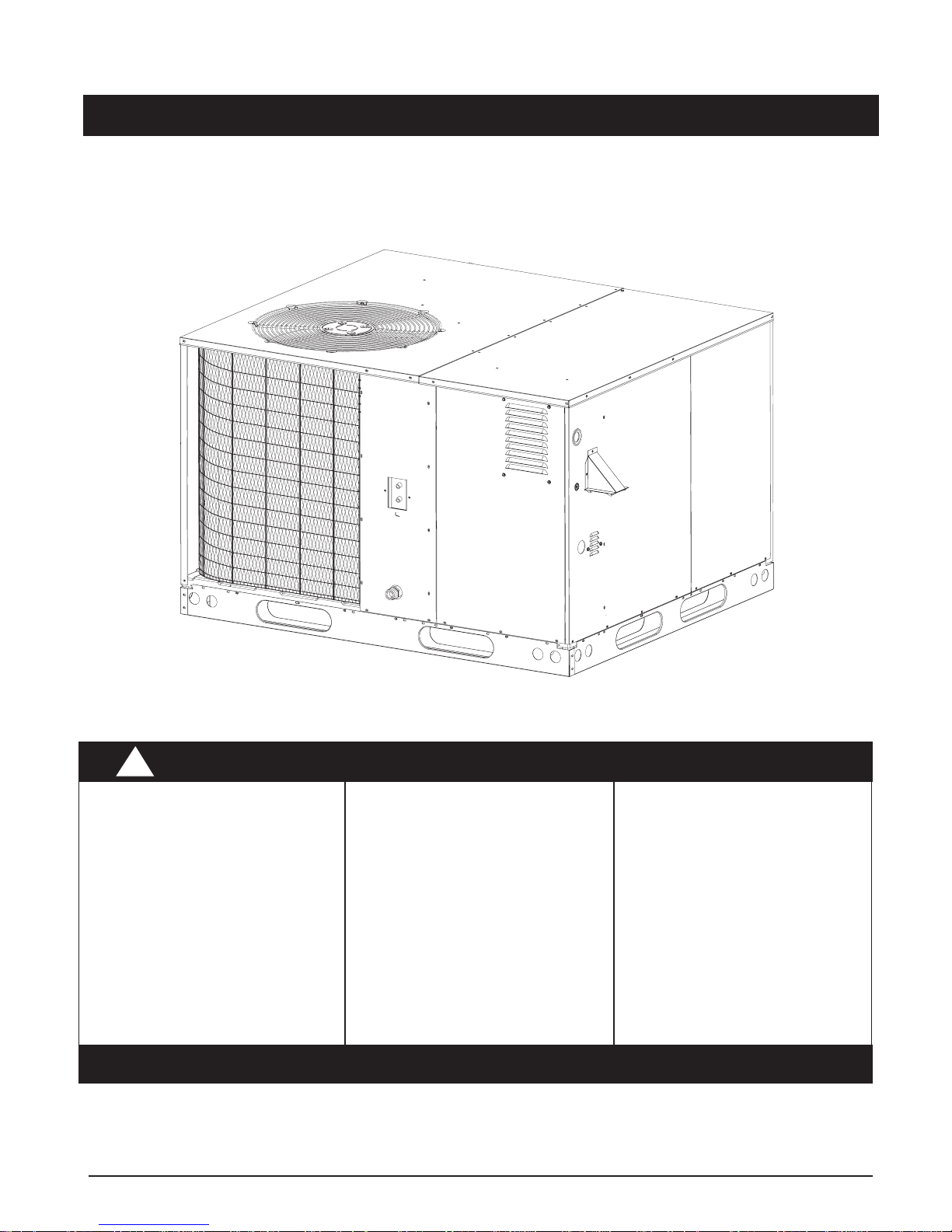

Nordyne R4GD 024K045, R4GD 030K072, R4GD 024K072, R4GD 030K045, R4GD 036K072 Installation Instructions Manual

...Page 1

High Efficiency

Installation Instructions

Single Package Gas Heating/Electric Cooling

WARNING:

!

Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property

damage. Refer to this manual. For assistance or additional information consult a

qualified installer, service

agency, or the gas supplier.

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

These instructions are primarily intended to assist qualified individuals experienced in the proper installation of this

appliance. Some local codes require licensed installation/service personnel for this type of equipment. Read all

instructions carefully before starting the installation.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any

• Do not touch any electrical

• Immediately call your gas

• If you cannot reach your gas

• Extinguish any open flame.

FOR YOUR SAFETY

appliance.

switch; do not use any phone

in your building.

supplier from a neighbor's

phone. Follow the gas

supplier's instructions.

supplier, call the fire

department.

Page 2

2

Page 3

TABLE OF CONTENTS

GENERAL SPECIFICATIONS ..................................... 4

SAFETY CONSIDERATIONS...................................... 4

• Literature, Labels, and Tags..................................4

• Pressures Within The System .............................. 4

INSTALLATION REQUIREMENTS .............................. 4

• Equipment Application .......................................... 4

• Equipment Check ................................................. 4

• Requirements and Codes...................................... 4

• Unit Location......................................................... 4

• Venting Requirements........................................... 4

• Unit Dimensions ................................................ 5-6

• Clearances to Combustible Materials.................... 7

• Thermostat ........................................................... 7

• Air Filter Requirements ......................................... 7

• Condensate Drain ................................................. 9

UNIT INSTALLATION .................................................. 9

• Ground Level ........................................................ 9

• Rigging and Hoisting ............................................. 9

• Rooftop ................................................................. 9

AIR SUPPLY FOR COMBUSTION

AND VENTILATION .............................................. 10

CIRCULATING AIR SUPPLY ..................................... 10

• Airflow Data ........................................................ 11

• Unconditioned Spaces ........................................ 12

• Acoustical Ductwork ........................................... 12

• Horizontal to Down Flow Conversion ................... 12

GAS SUPPLY AND PIPING ...................................... 12

• Leak Check ........................................................ 13

GAS AND HIGH ALTITUDE CONVERSIONS ............ 13

• High Altitude Application ..................................... 13

• Natural Gas High Altitude Conversion ................. 13

• LP/Propane Gas Conversion............................... 13

ELECTRICAL WIRING............................................... 14

• General ............................................................... 14

• Line Voltage........................................................ 14

• Electrical Data Table .......................................... 15

• Blower Speed ..................................................... 15

• Room Thermostat ............................................... 16

SYSTEM CHECK ..................................................... 16

• Pre-Start Check List .......................................... 16

WIRING DIAGRAMS ................................................ 18

START-UP PROCEDURE......................................... 16

• Air Circulation .................................................... 16

• Short Cycle Protection ....................................... 19

• System Cooling ................................................. 19

• System Heating ................................................. 19

• Verifying and Adjusting Firing Rate .................... 19

• Verifying and Adjusting Temperature Rise ......... 19

• Lighting/Operating Instructions .......................... 20

• Verifying Burner Operation ................................. 21

• Verifying Operation of Over-Temperature

Limit Control ................................................... 21

COMPONENT FUNCTIONS ..................................... 21

• Flame Sensor .................................................... 21

• Flame Roll-Out Control....................................... 21

• Gas Valve.......................................................... 21

• Pressure Switch ................................................ 21

• Over-Temperature Limit Control ......................... 21

UNIT MAINTENANCE............................................... 21

• Refrigerant Charging .......................................... 22

• Routine Maintenance ......................................... 22

• Air Filter............................................................. 22

• Vent Cover Assembly ........................................ 22

• Condensate Drain and Outdoor Coil ................... 22

• Electrical ........................................................... 23

• Motor Lubrication ............................................... 23

• Blower Compartment ......................................... 23

• Heat Exchanger and Burner Maintenance .......... 23

• Cleaning of Heat Exchanger............................... 23

• Cleaning of Burners ........................................... 24

OPERATING SEQUENCE ........................................ 24

• Cooling Mode..................................................... 24

• Blower Mode ...................................................... 24

• Heating Mode .................................................... 24

• Unit Fails to Operate.......................................... 2 5

INSTALLATION CHECKLIST................................... 26

3

Page 4

GENERAL SPECIFICATIONS

!

!

Single Package Gas Heating/Electric Cooling units are

designed for outdoor rooftop or ground level slab installations.

The units are shipped ready for horizontal duct connections

and are easily converted for down flow connections.

All models are shipped from the factory with the following:

1. Multispeed fixed torque variable speed blower.

2. Horizontal or down flow duct connections.

3. 24V fuse protection.

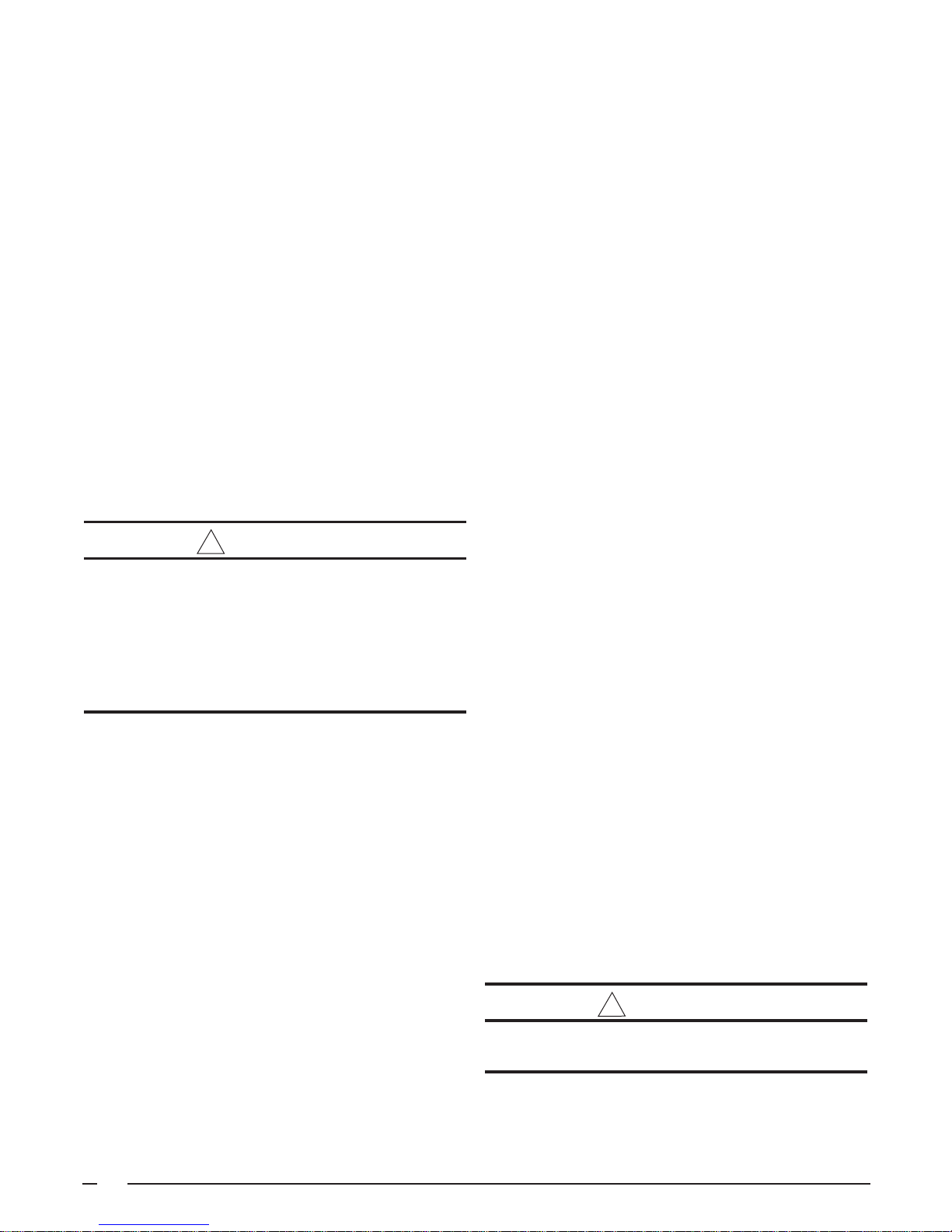

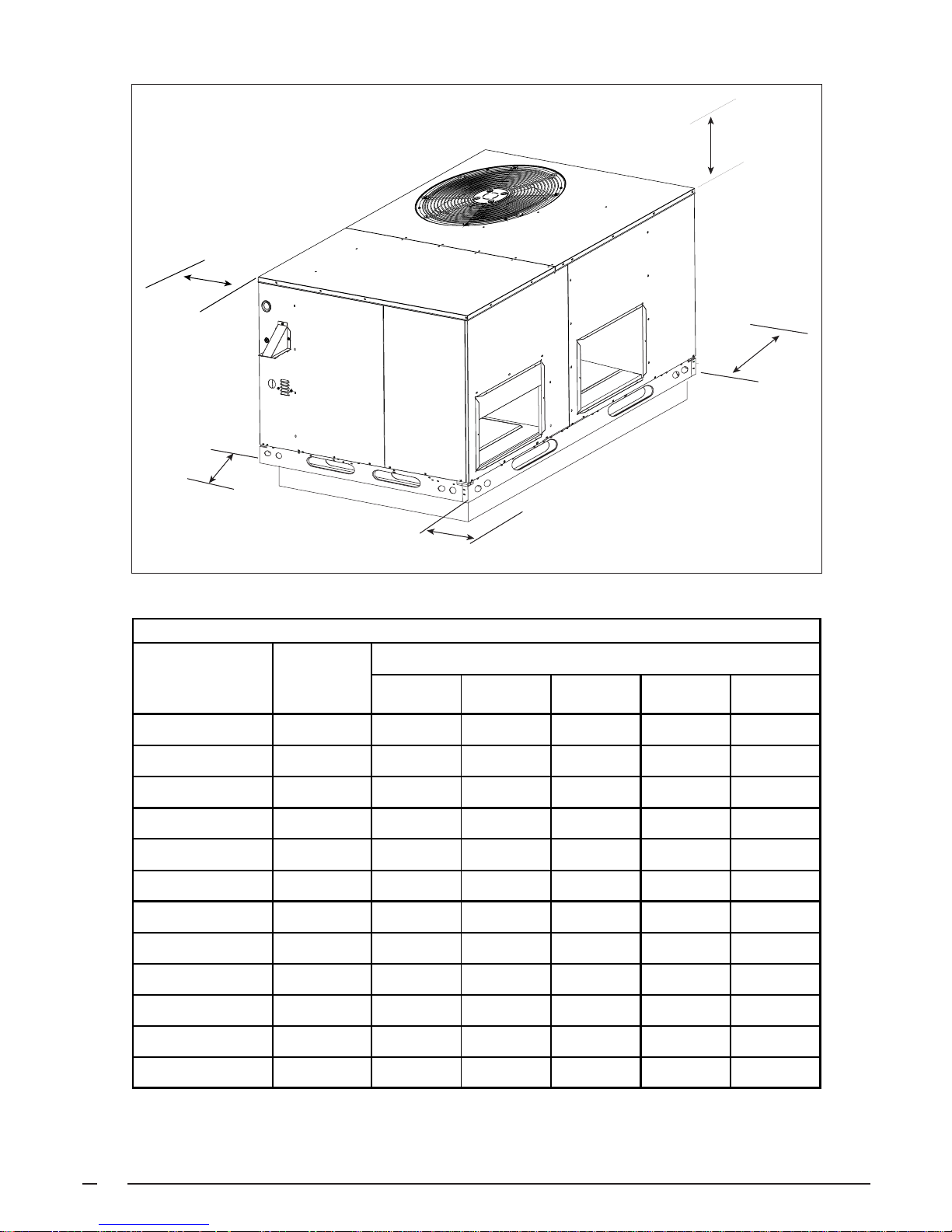

The unit dimensions are shown in Figure 1.

SAFETY CONSIDERATIONS

It is the responsibility of the installer to ensure that the

installation is made in accordance with all applicable local

and national codes.

WARNING:

Improper installation, service, adjustment, or

maintenance may cause explosion, fire, electrical

shock or other hazardous conditions which may

result in personal injury or property damage.

Unless otherwise noted in these instructions,

only factory authorized kits or accessories may

be used with this product.

Equipment Check — All units have been securely packaged

at the point of shipment. After unpacking the unit, carefully

inspect it for apparent and concealed damage. Claims for

damage should be filed with the carrier by the consignee.

Requirements and Codes — The installer must comply

with all local codes and regulations which govern this type

equipment. Local codes and regulations take precedence

over any recommendations contained in these instructions.

In the absence of local codes, the installation must

conform with the National Fuel Gas Code (ANSI 2223.1,

NFPA-54), or Canadian installations must conform with

CAN/CGA-B149 installation codes. All electrical wiring

must be made in accordance with codes and regulations

and with the National Electric Code (ANSI/NFPA 70) or in

Canada the Canadian Electric Code Part 1 CSA C.22.1. Air

Ducts must be installed in accordance with the standards

of the National Fire Protection Association “Standards for

Installation of Air Conditioning and Ventilation Systems”

(NFPA 90A), “Standard for Installation of Residence Type

Warm Air Heating and Air Conditioning Systems” (NFPA

90B), these instructions, and all applicable local codes.

The National Fuel Gas Code is available by writing:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, ME 02269

Literature, Labels, and Tags — When working with this

equipment, follow all precautions in the literature, on tags,

and on labels provided with the unit and/or approved field

installed kits. The type of hazard and severity are described

on each label or tag.

Pressures Within The System — This equipment contains

liquid and gaseous refrigerant under high pressure.

Installation or servicing should only be performed by

qualified trained personnel thoroughly familiar with this type

equipment.

INSTALLATION REQUIREMENTS

Equipment Application — Before beginning the installation,

verify that the unit model is correct for the job. The unit

model number is printed on the data label. This furnace is

NOT to be used for temporary heating of buildings or

structures under construction.

4

Unit Location — The gas/electric unit is designed only for

outdoor installations. Choosing the location of the unit

should be based on minimizing the length of the supply and

return ducts. Consideration should also be given to

availability of fuel, electric power, service access, noise,

and shade.

Venting Requirements — This unit has been equipped

with an integral venting system and designed to operate

only with this venting system. No additional venting shall

be used. This unit must be vented to the outdoors.

WARNING:

Do not vent furnace through a conventional

venting system.

Page 5

3

.0

.0

DIMENSIONS

1.0

24.6

1.8

16.6

2.9

Electric

Supply Entry

Low V oltage Entry

Gas Supply

Entry

47.5

4

Side View

1.75

Horizontal

Supply Duct

Opening

C

16.0

16.0

8.75

13.5

12.45

9.75 24.75

12.45

Horizontal

Return Duct

Opening

16.0

13.5

55.8

4.0

Condensing

Coil

4

Back View

5

Page 6

4

5

DIMENSIONS-Continued

Center of Gravity

Height (in inches)

C

R4GD

Shipping

To Electrical

Opening

5.7

B

13.3

Downflow

Supply Duct

Opening

12.0

13.5

24.9

A

16.0

23.5

CG

13.5

16.0

Downflow

Return Duct

Opening

Inside

Perimeter

of Base Rail

2.63"

12.0

47.

Top View

Model

Number

Unit

Weight

Weight A B

with base rails without base rails

024K045† 425 435 26.5 26.5 39.0 35.3

024K072† 435 445 26.0 26.5 39.0 35.3

030K045† 430 440 26.5 26.5 39.0 35.3

030K072† 440 450 26.0 26.5 39.0 35.3

036K072† 470 480 26.5 26.5 39.0 35.3

036K096† 485 495 26.0 26.5 39.0 35.3

042K072† 500 510 27.0 26.5 39.0 35.3

042K096† 515 525 27.0 26.5 39.0 35.3

048K096† 540 550 27.5 26.5 43.0 39.3

048K120† 555 565 27.5 26.5 43.0 39.3

060K096† 560 570 27.5 26.5 43.0 39.3

060K120† 575 585 27.5 26.5 43.0 39.3

† Denotes either "C" or "X"

6

Page 7

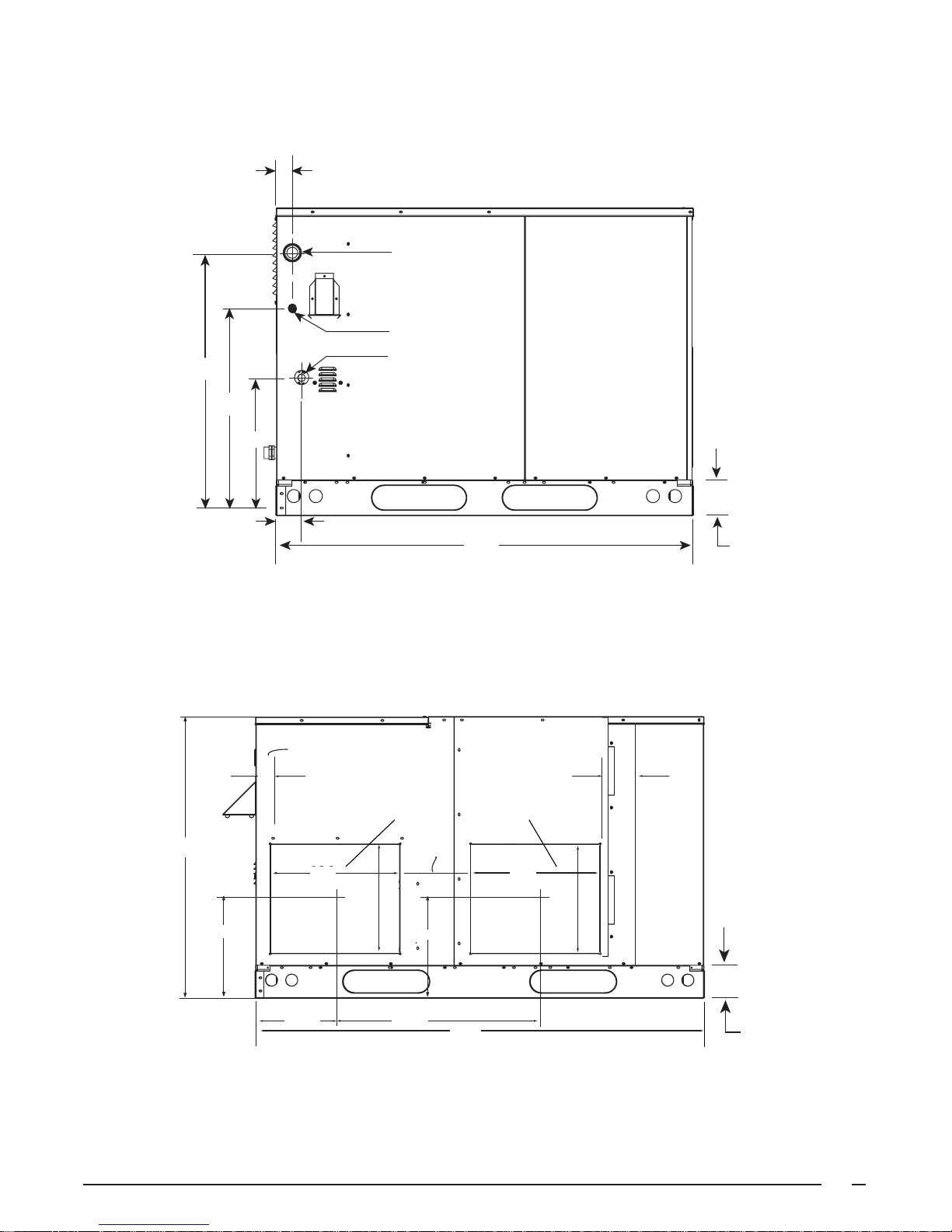

A vent cover assembly has been supplied with the unit. It

!

!

can be found secured to the gas controls within the control

area of this unit. Figure 2 shows the proper installation of

the vent cover assembly over the vent outlet on the exterior

of the corner panel. The fasteners used to secure the vent

cover assembly have been included in the homeowner's

package.

WARNING:

The vent cover assembly must be installed to

assure proper operation of the unit.

Corner Panel

of Unit

Exhaust Duct

Opening

Vent Cover

Assembly

Fastener

Figure 2. Vent Assembly

The following list is a summary of the requirements for the

location of the termination of the venting system:

1. The location of the vent termination must be consistent

with the National Fuel Gas Code (ANSI Z223.1) or CAN/

CGA-B149 Installation Codes.

2. The vent termination must be located at least four (4)

feet horizontally from any electric meters, gas meters,

regulators, and relief equipment.

3. The vent termination must be located at least three (3) feet

above any forced air inlet located within ten (10) feet.

4. The vent termination must be located at least four (4) feet

below, four (4) feet horizontally from, or one (1) foot above any

door, window, or gravity air inlet into any building.

5. The vent termination must be located at least one (1)

foot above grade.

6. The unit should be installed in such a manner as to

prevent snow accumulation from obstructing the vent

termination.

7. The unit installation shall avoid areas where condensate

drainage may cause problems by dropping on planters

or patios, etc. Furthermore, ensure that the exhaust

gases will not impinge on windows or building surfaces,

which may be compromised or damaged by

condensation. Do not install the unit such that exhaust

from the vent termination is directed into window wells,

stairwells, under decks, or in alcoves or similarly

recessed areas. The vent termination must not be

located above any public walkways.

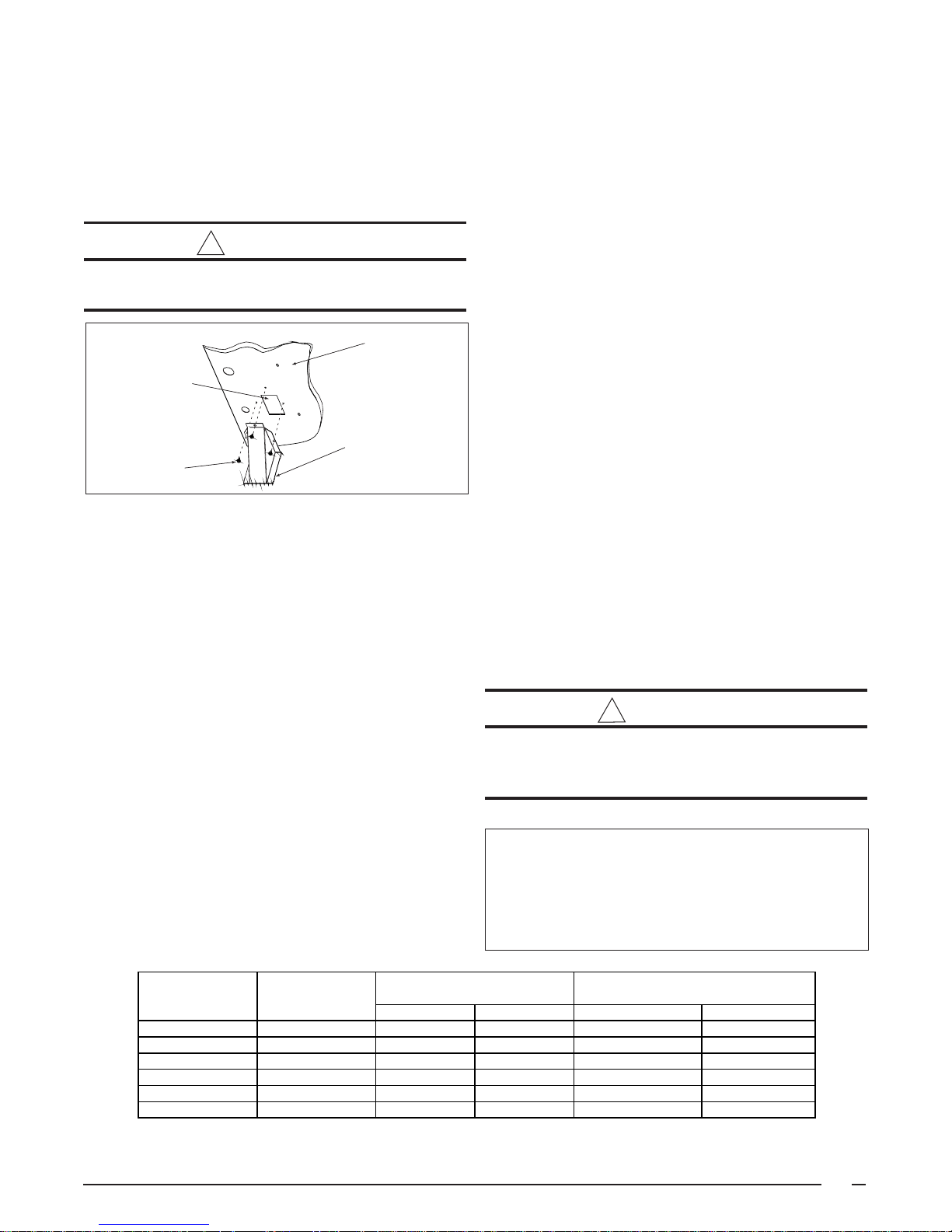

Clearances to Combustible Materials — See Table 2 for

required clearances to combustible materials. Refer to the

unit data label for the model number. The gas/electric unit

is suitable for installation on combustible flooring or class

A, B, or C roofing materials. A clearance of at least 36

inches from the blower access panel and from the louvered

control access panel is recommended to allow for servicing

and maintenance. Where accessibility to combustibles

clearances are greater than minimum clearances,

accessibility clearances must take preference. Sufficient

clearance for unobstructed airflow through the louvered

control access panel and through the outdoor coil must be

maintained in order to achieve rated performance. See

Figure 3 for minimum clearances to obstructions.

Thermostat — A single stage cooling/single stage heating

24VAC thermostat should be used with these units. A twostage cooling/single-stage heating thermostat is

recommended for economizer operation.

Air Filter Requirements — A suitable air filter system

must be installed in the unit or in the return air system

upstream of the evaporator coil. Refer to Table 1 for

recommended filter sizes. Air filter pressure drop must not

exceed 0.08 inches WC. This unit is not supplied with air

WARNING:

Never operate unit without a filter. A failure to

follow this warning could result in a fire, personal

injury, or death.

IMPORTANT NOTICE TO INSTALLER: After installing

or replacing the filtration system for this unit, add the

following marking on the filter service panel or reasonably

adjacent thereto: “Replace filter(s) installed in your

system only with the same dimensional size filters

that are being replaced.”

Nominal Approximate Approximate Recommended

Cooling Air Flow Range Filter Area (Sq. In.)* Filter Size (In. x In.)

Tonnage (Ton) (CFM) Disposable High Velocity Disposable High Velocity

2.0 600-1200 450 275 20 x 25 15 x 20

2.5 600-1200 550 325 20 x 30 16 x 20

3.0 800-1250 625 375 25 x 25 20 x 20

3.5 850-1500 725 450 24 x 30 20 x 25

4.0 1050-1650 825 500 18 x 24 (2 required) 20 x 25

5.0 1050-1650 1000 600 20 x 25 (2 required) 25 x 25

*Based on velocity of 300 ft/min for disposable filters and 500 ft/min for high velocity (cleanable) filters.

Table 1. Air Filter Requirements

7

Page 8

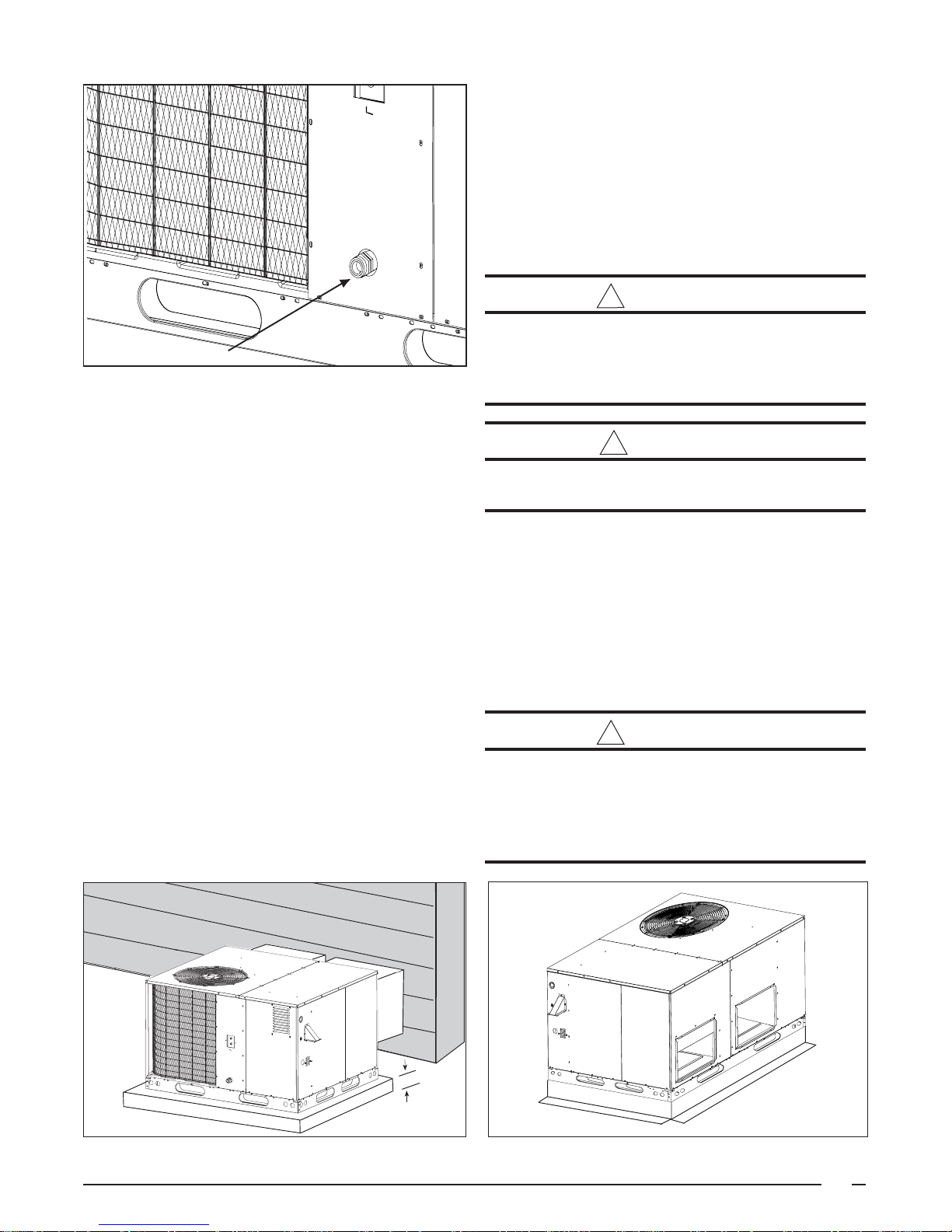

A

C

Blower

Control

Duct

Coil

Minimum Clearances to Combustible Material**

E

B

D

Figure 3. Minimum Clearances.

Heating

Model

Number

024(-)045(†) 45 ,000 36 36 1* 36 36

024(-)072(†) 72 ,000 36 36 1* 36 36

030(-)045(†) 45 ,000 36 36 1* 36 36

030(-)072(†) 72 ,000 36 36 1* 36 36

036(-)072(†) 72 ,000 36 36 1* 36 36

036(-)096(†) 96 ,000 36 36 1* 36 36

042(-)072(†) 72 ,000 36 36 1* 36 36

042(-)096(†) 96 ,000 36 36 1* 36 36

048(-)096(†) 96 ,000 36 36 1* 36 36

048(-)120(†) 120,000 36 36 1* 36 36

060(-)96(†) 96,000 36 36 1* 36 36

060(-)120(†) 120,000 36 36 1* 36 36

* If accessories (filters, economizers, fresh air dampers . . .) are installed, see accessory installation instructions for proper clearances.

**Suitable for installation on combustible flooring or class A, B, or C roofing material.

† Can be C or X.

Input

(Btuh)

Panel (A) Panel (B) Panel (C) End (D) T o p (E)

Minimum Clearances (Inches)

Table 2. Minimum Clearances to Combustible Materials.

8

Page 9

!

!

!

Condensate Drain

Figure 4. Condensate Drain.

filter(s) and has no factory equipped means for

accommodating internal air filter(s). For downflow

installations only, an internal filter accessory kit can be

ordered. For horizontal installations, the air filter system

must be installed in the return air ductwork. All return air

to this unit must pass through the filter(s) before entering

the evaporator coil.

Rigging and Hoisting — The unit should be lifted using

slings and spreader bars. The spreader bars are necessary

to prevent damaging the top of the unit’s cabinet. Make

sure

that the lifting equipment is adequate for the load.

Refer to Figure 1 for unit weights. Keep the unit in an

upright position at all times. The rigging must be located

outside the unit’s center of gravity. Refer to Figure 1 for

center of gravity location. For rooftop installations,

remove and discard the two supports attached beneath

the unit.

WARNING:

To avoid the risk of property damage or personal

injury, it is the rigger’s responsibility to ensure

that whatever means are used to hoist the unit

are safe and adequate.

CAUTION:

All panels must be securely in place when rigging

and hoisting.

Condensate Drain — Condensate is removed from the

unit through the 3/4" female pipe fitting located on the front

side of the unit. (See Figure 4.) Install a 2 inch deep

condensate trap in the drain line of the same size and prime

with water.

When connecting rigid drain line, hold the female fitting with

a wrench to prevent twisting. Do not over tighten! Refer

to local codes and restrictions for proper condensate

disposal requirements.

UNIT INSTALLATION

Ground Level — When installing the unit at ground level

(See Figure 5), provide a concrete mounting pad separate

from the building foundation. The pad must be level to insure

proper condensate disposal and strong enough to support the

unit’s weight (Refer to Figure 1). Make sure the slab is a

minimum of 2" above the grade and in an area that drains well.

Rooftop — For rooftop installations (See Figure 6) use the

appropriate accessory roof curb and follow all instructions

included with it. Make sure the supports beneath the unit

have been removed. Locate the unit according to local

building codes and ordinances. The curb must be level to

insure proper condensate drainage.

The roof must be capable of handling the weight of the unit.

See Figure 1 for unit weights. Reinforce the roof if

required.

WARNING:

Do not place combustible material on or against

the unit cabinet. Do not place combustible

materials, including gasoline and any other

flammable vapors and liquids, in the vicinity of

the unit.

Figure 5. Ground Level Installation.

2"

2”

Figure 6. Roof Curb Installation.

9

Page 10

AIR SUPPLY FOR COMBUSTION AND

!

!

!

VENTILATION

CIRCULATING AIR SUPPLY

Provisions must be made in the installation of this unit to

provide an adequate supply of air for combustion. Detailed

instructions for determining the adequacy of an installation

can be found in the current revision of the National Fuel Gas

Code (ANSI Z223.1) and NFPA 54, or in Canadian installation

codes (CAN/CGA-B149), or in applicable local building

codes. Consult local codes for special requirements.

WARNING:

Installation using methods other than those

described in the following sections must comply

with the National Fuel Gas Code and all applicable

local codes to provide sufficient combustion air

for the furnace.

If the unit is operated with inadequate combustion air

supply the flame roll-out control located above the burners

will open, turning off the gas supply to the burners. The

flame roll-out control is a manually re-setable device. DO

NOT install a jumper wire across this control to defeat its

function. DO NOT reset the control without identifying and

correcting the fault condition which caused the control to

trip. If this control must be replaced, use only the replacement

part specified in the Replacement Parts List.

Air Openings in the door of the unit, warm air registers, and

return air grilles must not be restricted.

To maximize heat exchanger life, the combustion air

must be free of chemical contaminants which form

corrosive acidic compounds when combusted. Some

examples of these chemical contaminants are chlorine,

fluorine, and sulphur. Some common sources of these

chemical contaminants are detergents, bleaches,

aerosol sprays, cleaning solvents, and a wide variety of

commercial and household products.

WARNING:

Combustible air must not be drawn from a

contaminated atmosphere. Excessive exposure

to contaminated combustion air will result in

safety and performance related problems.

WARNING:

Products of combustion must not be allowed to

enter the return air ductwork or the circulating

air supply. Failure to prevent products of

combustion from being circulated into the living

space can create potentially hazardous conditions

including carbon monoxide poisoning that could

result in personal injury or death.

All return ductwork must be adequately sealed,

all joints must be taped, and the ductwork must

be secured to the unit with sheet metal screws.

When return air is provided through the bottom

of the unit, the joint between the unit and the

return air plenum must be air tight.

The roof curb or cement pad on which the unit is

mounted must provide sound physical support

of the unit with no gaps, cracks, or sagging

between the unit and the curb or pad.

Return air and circulating air ductwork must not

be connected to any other heat producing device

such as a fireplace insert, stove, etc. Doing so

may result in fire, explosion, carbon monoxide

poisoning, personal injury, or property damage.

This unit is designed only for use with a supply and return

duct. Air ducts should be installed in accordance with all

applicable local codes and the standards of the National

Fire Protection Association “Standard for Installation of Air

Conditioning Systems” (NFPA 90A), and “Standard for

Installation of Residence Type Warm Air Heating and Air

Conditioning Systems” (NFPA 90B).

Design the ductwork according to methods described by

the Air Conditioning Contractors of America (ACCA) Manual

D. The ducts must be properly sized not to exceed 0.2

inches WC pressure drop at 400 scfm per nominal ton of

cooling capacity.

Ductwork should be attached directly to the unit flanges for

horizontal applications. On roof curb installations the ducts

must be attached to the curb duct supports, not the unit.

10

Page 11

T1

845

735

625

60

72

--

217

207

* T2

905

830

750

47

51

56

515

495

** T3

950

880

810

43

46

49

600

570

T4

1110

1065

1020

34

36

37

825

790

T5

1260

1215

1175

--

30

31

990

960

T1

845

735

625

--

--

--

217

207

* T2

905

830

750

--

--

--

515

495

** T3

950

880

810

69

--

--

600

570

T4

1110

1065

1,020

54

57

60

825

790

T5

1260

1215

1,175

46

48

50

990

960

T1

845

735

625

60

72

--

217

207

T2

905

830

750

47

51

56

515

495

** T3

950

880

810

43

46

49

600

570

* T4

1110

1065

1,020

34

36

37

825

790

T5

1260

1215

1,175

--

30

31

990

960

T1

845

735

625

--

--

--

217

207

T2

905

830

750

--

--

--

515

495

** T3

950

880

810

69

--

--

600

570

* T4

1110

1065

1,020

54

57

60

825

790

T5

1260

1215

1,175

46

48

50

990

960

T1

950

880

810

69

--

--

600

570

T2

1110

1065

1020

54

57

60

825

790

T3

1220

1180

1135

48

50

52

945

915

** T4

1260

1215

1175

46

48

50

990

960

* T5

1345

1300

1250

43

44

46

1070

1030

T1

950

880

810

--

--

--

600

570

T2

1110

1065

1020

72

--

--

825

790

T3

1220

1180

1135

64

67

70

945

915

** T4

1260

1215

1175

62

65

67

990

960

* T5

1345

1300

1250

57

59

62

1070

1030

T1

1020

940

860

65

70

--

615

570

T2

1185

1110

1035

53

56

59

820

785

* T3

1410

1330

1250

43

45

48

1030

975

** T4

1525

1450

1370

--

41

43

1150

1100

T5

1650

1585

1520

--

--

--

1280

1235

T1

1020

940

860

--

--

--

615

570

T2

1185

1110

1035

--

--

--

820

785

* T3

1410

1330

1250

58

61

64

1030

975

** T4

1525

1450

1370

53

55

57

1150

1100

T5

1650

1585

1520

47

49

52

1280

1235

T1

1185

1110

1035

71

75

--

820

785

T2

1410

1330

1250

58

61

64

1030

975

T3

1525

1450

1370

53

55

57

1150

1100

* T4

1650

1585

1520

47

49

52

1280

1235

** T5

1775

1715

1650

--

45

48

1375

1330

T1

1185

1110

1035

--

--

--

820

785

T2

1410

1330

1250

73

--

--

1030

975

T3

1525

1450

1370

66

69

72

1150

1100

* T4

1650

1585

1520

59

62

65

1280

1235

** T5

1775

1715

1650

54

57

60

1375

1330

T1

1185

1110

1035

71

75

--

820

785

T2

1525

1450

1370

53

55

57

1150

1100

T3

1625

1560

1490

48

50

53

1255

1210

* T4

1725

1660

1600

45

47

49

1340

1300

** T5

1775

1715

1650

--

45

48

1375

1330

T1

1185

1110

1035

--

--

--

820

785

T2

1525

1450

1370

66

69

72

1150

1100

T3

1625

1560

1490

61

63

66

1255

1210

* T4

1725

1660

1600

56

59

62

1340

1300

** T5

1775

1715

1650

54

57

60

1375

1330

0.5 0.6 0.7 0.8

Range(F)

(BTU h)

External Static Pressure (Inch es Water Column)

Table 3. Airflow Data.

0.1 0.2 0.3 0.4

CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

HP

Motor

Size

Blower

Tap

Motor

23,000 10 X 10 1/2

Output

Cooling

Rise

Heating

Output

Heating

Input

Heating

Model

Number

24K045(†) 45,000 35,000 30-60

23,000 10 X 10 1/2

24K072(†) 72,000 56,000 40-70

1/235,000 30-60 28,000 10 X 10

28,000 10 X 10 1/2

30K045(†) 45,000

30K072(†) 72,000 56,000 40-70

35,000 10 X 10 1/2

75,000 45-75

36K072 (†) 72,000 56, 000 40-70 35,000 10 X 10 1/2

36K096(†) 96,000

42K072 (†) 72,000 56, 000 40-70 40,000 10 X 10 3/4

40,000 10 X 10 3/4

42K096(†) 96,000 75,000 45-75

48K096 (†) 96,000 75, 000 45-75 46,000 10 X 10 3/4

46,000 10 X 10 3/4

48K120(†) 120,000 94,000 45-75

60K096 (†) 96,000 75, 000 45-75 55,000 10 X 10 3/4

55,000 10 X 10 3/460K120(†) 120,000 94,000 45-75

* Denotes Factory Set Cooling Speed

** Denotes Factory Set Heating Speed

† Can be C or X

11

Page 12

ff

It is recommended that the outlet duct be provided with a

!

removable access panel. This opening should be accessible

when the unit is installed in service and shall be of a size

such that the smoke or reflected light may be observed

inside the casing to indicate the presence of leaks in the

heat exchanger. The cover for the opening shall be

attached in such a manner as to prevent leaks.

GAS SUPPLY AND PIPING

This unit has right side gas entry. A typical gas service

hookup is shown in Figure 7. When making the gas

connection, provide clearance between the gas supply

line and the entry hole in the unit’s casing to avoid

unwanted noise and/or damage to the unit.

If outside air is utilized as return air to the unit for ventilation

or to improve indoor air quality, the system must be

designed so that the return air to the unit is not less than

50°F (10°C) during heating operation. If a combination of

indoor and outdoor air is used, the ducts and damper

system must be designed so that the return air supply to

the furnace is equal to the return air supply under normal,

indoor return air applications.

Unconditioned Spaces — All ductwork passing through

unconditioned space must be properly insulated to minimize

duct losses and prevent condensation. Use insulation

with an outer vapor barrier. Refer to local codes for

insulation material requirements.

Acoustical Ductwork — Certain installations may require

the use of acoustical lining inside the supply ductwork.

Acoustical insulation must be in accordance with the

current revision of the Sheet Metal and Air Conditioning

Contractors National Association (SMACNA) application

standard for duct liners. Duct lining must be UL classified

batts or blankets with a fire hazard classification of FHC25/50 or less. Fiber ductwork may be used in place of

internal duct liners if the fiber ductwork is in accordance

with the current revision of the SMACNA construction

standard on fibrous glass ducts. Fibrous ductwork and

internal acoustical lining must be NFPA Class 1 air ducts

when tested per UL Standard 181 for Class 1 ducts.

Horizontal to Down flow Conversion — The unit is

shipped ready for horizontal duct connections. If down

flow ducts are required, the unit must be converted following

the steps below for both the supply and return ducts.

All gas piping must be installed in compliance with local

codes and utility regulations. Some local regulations require

the installation of a manual main shut-off valve and ground

joint union external to the unit. The shut-off valve should

be readily accessible for service and/or emergency use.

Consult the local utility or gas supplier for additional

requirements regarding placement of the manual main gas

shut-off. In the absence of local codes the gas line

installation must comply with the latest edition of the

National Fuel Gas Code ANSI Z223.1 or CAN/CGA B149

Installation Codes.

CA UTION:

Do not use matches, lighters, candles or other

sources of open flame to check for gas leaks.

A 1/8 inch NPT plugged tap must be installed in the gas line

immediately upstream of the gas supply connection to the

furnace for use when measuring the gas supply pressure.

The plug should be readily accessible for service use. A

drip leg should be installed in the pipe run to the unit. Table

4 lists gas flow capacities for standard pipe sizes as a

function of length in typical applications based on nominal

pressure drop in the line.

Shut-Off Valve

with 1/8 NPT

plugged tap

Automatic Gas

Valve (with manual

shut-off)

Some utilities

require Shut-O

Valve to be

4 to 5 feet

above floor

1. Locate the duct cap inside the duct openings and

remove the screw holding it in place.

2. Lift the cap out of the unit. The cap can be pushed

up from the bottom by reaching through the fork slot.

3. Cover the horizontal duct opening with the cap. The

insulation will be on the indoor side.

4. Fasten the cover with screws and seal to prevent air

leakage.

12

Ground Joint

Union

Burner

Assembly

Manifold

Figure 7. Typical Right Side Entry

Gas Service Connection.

Dripleg

Page 13

1/2

130907565555045403/4

280

190

150

130

115

10595901520

350

285

245

215

195

180

170

1 1/4

1050

730

590

500

440

400

370

350

1 1/2

1600

1100

890

760

670

610

560

530

C

=

IMPORTANT NOTES:

!

1. Gas piping must not be run in or through air ducts,

chimneys, gas vents, elevator shafts, etc.

2. Compounds used on threaded joints of gas piping must be

resistant to the actions of liquefied petroleum gases.

3. The main manual gas valve and main power

disconnect to the furnace must be properly labeled

by the installer in case emergency shutdown is

required.

Leak Check — After the gas piping to the unit is complete,

all connections must be tested for gas leaks. To check for

leaks in gas piping systems, use only a soap and water

solution or other approved method.

IMPORTANT NOTE: When pressure testing the gas

supply lines at pressures greater than 1/2 psig (14

inches WC), the unit must be disconnected from the

gas supply piping system to prevent damage to the gas

control valve.

If the test pressure is less than or equal to 1/2 psig (14

inches WC), the unit must be isolated from the gas

supply line by closing the manual shut-off valve.

WARNING:

This unit was equipped at the factory for use with

natural gas only. A special kit, supplied by the

manufacturer, is required to convert the unit to

operate on LP/propane gas. Failure to use the

proper conversion kit can cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

GAS AND HIGH ALTITUDE CONVERSIONS

can be achieved simply by adjusting the furnace manifold

pressure as shown in Table 5.

LP/Propane Gas Conversion

IMPORTANT NOTE: When converting a low NOx Furnace

from Natural gas to LP/Propane gas, it is necessary to

remove the NOx Baffles.

Conversion of this furnace to utilize LP/Propane gas must

be made by qualified service personnel, using approved

parts. Conversion for the LP/Propane gas can be

accomplished by adjusting the manifold pressure, after

replacing the natural gas orifices with the appropriate LP/

Propane orifices shown in Table 6. Note: that for

installations between zero and 5000 ft. above sea level, a

#54 drill size orifice should be used. However for installations

above 5000 ft. over sea level, a # 55 drill size orifice should

be used. Then use Table 6 to determine the appropriate

manifold pressure for your altitude installation. Conversion

to LP/Propane (sea level and high altitude ) is detailed in the

installation instructions provided with the conversion kit.

Approved conversion kits are:

United States LP/Propane Gas Sea Level and High Altitude

Conversion Kit - P/N 903616

This kit is for LP/propane conversion in the United States

at altitudes between zero and 10,000 ft. above sea level.

Follow the installation instructions supplied with the kit for

proper installation.

CAPA CITY OF BLACK IR ON GAS PIPE (CU. FT. P E R HOUR)

FO R NATURAL GAS (SPECIFIC GRAVIT Y - 0.60)

NOMINAL LENGTH OF PIPE RUN

BLACK IRON (feet)

PIPE DIAMETER

(in.) 1020304050607080

Conversion: conversion of this unit must be performed by

qualified service personnel, using only approved parts.

High Altitude Application

High altitude application with this furnace can be field

performed by a simple adjustment of manifold pressure and

if necessary, a change of the orifices. The changes

required depend on the installation altitude and the heating

value of the gas. The gas heating value based on sea level

can be obtained from your local gas utility. The heating

value of gas at high altitude is always lower than the sea

level heating value. The heating values used in the Tables

5 & 6 are based on sea level values.

Natural Gas High Altitude Conversion

All factory shipped furnaces are ready to operate between

zero and 4999 ft. above sea level. For higher altitudes

(between 5000 and 10,000 ft. above sea level), conversion

The cubic feet per hour listed in the table above must be greater than the

cubic feet per hour of gas flow required by the unit.

To determine the cubic feet per hour of gas flow required by the unit, divide

the input rate of the unit by the heating value of the gas:

ubic Feet Per Hour Required

Table 4. Capacity of Black Iron Gas Pipe (cubic feet per

hour) for Natural Gas (specific gravity = .60).

Input To Unit (Btu/hr)

Heating Value of Gas (Btu/Cu. Ft.)

13

Page 14

o

Heating Value of 2,500 Btu/ft.

For a Natural G as Sea L evel Heatin g V al u e of 800 to 899 Btu/cu .ft.

!

!

Elev ation (f eet above sea lev el )

zero to

1999

Manif ol d P res sure Set ting (in WC)

For a Natural G as Sea L evel Heatin g V al u e of 900 to 999 Btu/cu .ft.

Manif ol d P res sure Set ting (in WC)

For a Natural Gas Sea Level Heating V alue of 1, 000 to 1, 100 Btu/ cu . ft.

Manif ol d P res sure Set ting (in WC)

Table 5. Manifold Pressure (in WC) for Natural Gas at Various Altitudes and Heating Values

Manifold Pressure in (WC)

Based on Sea Level LP

3.5 3.5 3 .5

zero to

1999

3.5 3.5 3 .5

zero to

1999

3.5 3.5

1,999 4,999 5,999 7,999 10,000

3

2000 to

4999

Elev ation (f eet above sea lev el )

2000 to

4999

Elev ation (f eet above sea lev el )

2000 to

4999

Elevation, (feet abo ve sea level)

0 to 2, 0 00 t o 5, 000 t o 6,00 0 to 8,0 00 t

10.0 8.5 10.0 9.0 8.5

5000 to

5999

5000 to

5999

5000 to

5999

3.0 2.8 2.5

6000 to

7999

3.5 3.0

6000 to

7999

3.2 2.8

6000 to

7999

8000 to

10000

8000 to

10000

8000 to

10000

Or i f ice Size

Table 6. Manifold Pressure (in WC) for LP/Propane Gas at Various Altitudes

Canadian LP/Propane Gas Sea Level and High Altitude

Conversion Kit - P/N 903617

This kit is for LP/propane conversions in Canada at

altitudes between zero and 4500 ft. above sea level.

Follow the installation instructions supplied with the kit for

proper installation.

WARNING:

To avoid the risk of electrical shock, personal

injury, or death, disconnect all electrical power

to the unit before performing any maintenance

or service. The unit may have more than one

electrical power supply.

WARNING:

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. This

ground may consist of electrical wire or approved

conduit when installed in accordance with

existing national or local codes.

54 54 55 55 55

ELECTRICAL WIRING

General — Electrical power wiring must be made in

accordance with all applicable local codes and ordinances,

and with the current revision of the National Electric Code

NFPA 70 or in Canada CSA C.22.1 Canadian Electrical

Code Part 1. If any of the original wire as supplied with the

unit must be replaced, it must be replaced with material of

the same gauge and temperature rating.

Line Voltage — Before proceeding with the electrical

connections, make certain that the voltage, frequency and

phase of the supply source are the same as those

specified on the unit rating plate. Also verify that the

service provided by the utility is sufficient to handle the

additional load imposed by this equipment.

This unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code (ANSI/NFPA 70) or the CSA

C22.1 Electrical Code.

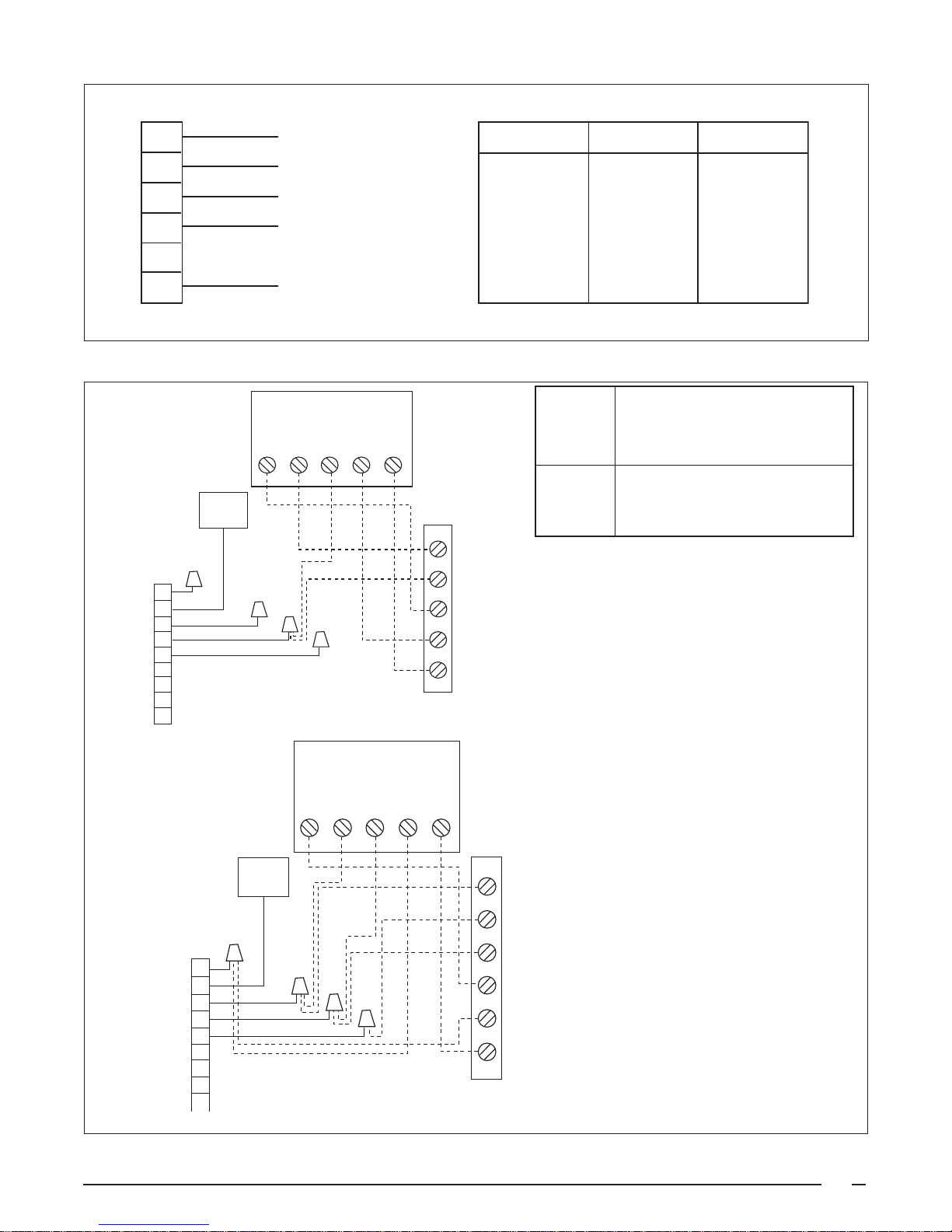

See Figure 10 or the unit wiring label for proper high and low

voltage wiring. Make all electrical connections in accordance

with all applicable codes and ordinances.

14

Page 15

!

Use a separate branch electrical circuit for this unit. A

(

)

pply

g

p

p

p

y

means of electrical disconnect must be located within sight

of and readily accessibility to the unit.

The unit is shipped from the factory wired for 240 volt

transformer operation. For 208 volt operation, remove the

lead from the transformer terminal marked 240V and

connect it to the terminal marked 208V. For maximum

circuit ampacity and maximum over current protection, see

the unit rating plate or Table 7.

Overcurrent protection must be provided at the branch

circuit distribution panel and sized as shown in Table 7 or

on the unit rating label and according to the National

Electric Code and applicable local codes.

Provide power supply (or supplies) for the unit in

accordance with the unit wiring diagram, and the unit

rating plate. Connect the line-voltage leads to the

corresponding terminals on the contactor inside the

control compartment. Use only copper wire for the line

voltage power supply to this unit. Use proper code

agency listed conduit and a conduit connector for

connecting the supply wires to the unit and for obtaining

proper grounding. Grounding may also be accomplished

by using the grounding lug provided in the control box.

Do not use gas piping as an electrical ground.

CAUTION:

To avoid personal injury or property damage,

make certain that the motor leads cannot come

into contact with any uninsulated metal

components of the unit.

Blower Speed — The blower speeds are preset at the

factory. See Table 3 for factory settings. For optimum

system performance and comfort, it may be necessary to

change the factory set speed. To change the blower speed:

1. Disconnect all electrical power to the unit and remove

the blower panel.

2. Locate the orange and red wires terminated to the

blower motor. The orange wire controls cooling

operation while the red wire controls heating operation.

3. Verify the required speed from the airflow data found in

table 3. Place appropriate wire on the appropriate motor

speed tap for the required airflow point.

Voltage

Ran

e Compressor

Min. Max.

RLA LRA

11.6 54.0 1.2 4.1 19.8 30

11.6 54.0 1.2 4.1 19.8 30

15.7 68.0 1.2 4.1 24.9 40

15.7 68.0 1.2 4.1 24.9 40

16 77.0 1.2 4.1 25.3 40

16 77.0 1.2 4.1 25.3 40

21.5 104.0 1.2 6 34.1 50

21.5 104.0 1.2 6 34.1 50

22.5 137.0 1.2 6 35.3 50

22.5 137.0 1.2 6 35.3 50

28.2 118.0 1.2 6 42.5 70

28.2 118.0 1.2 6 42.5 70

Nominal

Model

Number

R4GD-024K

R4GD-030K

R4GD-036K

R4GD-042K

R4GD-048K

R4GD-060K

Notes: FLA = Full Load Amps; LRA = Lock Rotor amps; RLA = Rated Load Amps.

Heating Input

BTUh

45,000 208/-230/60/1 187 253

72,000 208/-230/60/1 187 253

45,000 208/-230/60/1 187 253

72,000 208/-230/60/1 187 253

72,000 208/-230/60/1 187 253

96,000 208/-230/60/1 187 253

72,000 208/-230/60/1 187 253

96,000 208/-230/60/1 187 253

96,000 208/-230/60/1 187 253

120,000 208/-230/60/1 187 253

96,000 208/-230/60/1 187 253

120,000 208/-230/60/1 187 253

Electrical

Su

Table 7. Electrical Data.

Fan

Am

s

Minimum

Circuit

Am

acit

Blower

Motor

Am

s

Maximum

Over-current

Protection

15

Page 16

!

Note: If the same speed is required for both heating and

cooling, remove either the red or orange wire from the

blower motor. Next, obtain the jumper wire from the

homeowners packet and connect it to the blower relays

at the coils on the blue wire and red wire side.

Check all factory wiring per the unit wiring diagram and

inspect the factory wiring connections to be sure none

loosened during shipping or installation.

Room Thermostat — Several options are available for a

room thermostat depending on the accessories installed with

the unit. The available thermostats recommended for use

with the gas/electric units are listed with the accessories in

Table 10. Select a thermostat which operates in conjunction

with the installed accessories. The thermostat should be

mounted about five feet above the floor on an inside wall. The

thermostat should be kept away from drafts, slamming

doors, lamps, direct sunlight and the supply air flow.

To install the thermostat:

1. Position the subbase on an inside wall and mark the

mounting holes and thermostat cable openings.

2. Cut out the cable opening and route the thermostat

cable from the unit’s low voltage compartment to the

thermostat location. The thermostat cable is supplied

by the installer.

3. Connect the cable leads to the subbase or thermostat

terminals and to the unit’s low voltage connector on

the furnace board as shown in Figure 9. A system

wiring diagram is also provided on the inside of the

louvered control access panel and in Figure 10 of

these installation instructions.

4. Secure the subbase or thermostat to the wall using

screws provided with the thermostat.

5. If subbase is used, install the correct thermostat

housing to subbase.

6. Refer to thermostat instruction sheet for complete

detailed mounting information.

To determine the heat anticipator setting, either:

1. Add the current draw of the system components or,

2. Measure the current flow on the thermostat R-W

circuit after the circulating blower motor has started.

• Verify that the ductwork is sealed to prevent air

leakage.

• Verify that the line voltage power leads are securely

connected and the unit is properly grounded.

• Verify that the low voltage wires are securely connected

to the correct leads in the low voltage area of the

control box.

• Verify that the gas line service pressure does not

exceed 10.0 inches WC (0.36 psig), and is not less than

4.5 inches WC (0.16 psig) for natural gas. For LP gas

the line service pressure must not exceed 14 inches

WC (0.51 psig) and must not be less than 11.0 inches

WC (0.40 psig).

• Verify that the flame roll-out control is closed. If

necessary, press the red button to reset the control. DO

NOT install a jumper wire across the control to defeat

its function. If the control reopens upon start-up, DO

NOT reset the control without identifying and correcting

the fault condition which caused the control to trip.

• Verify that the gas line has been purged and all

connections are leak tight.

• Verify that all exterior panels are replaced and securely

fastened.

• Verify that the outdoor fan turns freely.

• Verify that the power supply branch circuit overcurrent

protection is sized properly.

• Verify that the thermostat is wired correctly. The

thermostat function switch should be set to “Off” and

the thermostat fan switch should be set to “Auto.”

WARNING:

If the unit is equipped with a crankcase heater,

allow 24 hours prior to continuing the start up

procedures to allow for heating of the refrigerant

compressor crankcase. Failure to comply may

result in damage and could cause premature failure

of the system. This warning should be followed at

initial start up and any time the power has been

removed for 12 hours or longer.

SYSTEM CHECK

Pre-Start Check List

• Verify that the unit is level to allow proper condensate

drainage.

• Verify that there is free airflow to and from the outdoor

coil and that all clearance requirements are met.

16

START-UP PROCEDURE

Close all electrical disconnects to energize the system.

Air Circulation — Leave the thermostat system switch set

to “Off” and set the thermostat fan switch to “On.” The

blower motor should run continuously. Check for air delivery

at the register(s). Ensure that there are no obstructions at

Page 17

1

Y

1

1

RED

PIN NUMBER

WIRE COLOR

MOTOR SPEED

2

3

4

5

6

ECONOMIZER

PLUG

Green

1

Gray

2

Black

3

ellow

4

Blue

5

6

7

8

Typical Wiring (Field Supplied) for 1-Stage Cool, 1-Stage Heat

9

Gas

Valve

ORANGE

BLUE

BLACK

WHITE

(Not Used on

3 Speed Motors)

Figure 8. Indoor Blower Motor Leads.

FURNACE BOARD

R C Y G W

1

2

3

4

5

6

RED

ORANGE

BLUE

BLACK

N/A

WHITE

Recommended T’stat

T’stat Wire Length Ft. (Unit to T'stat)

Wire 2-wire 4/5-wire

Gauge (Heating) (Cooling/HP)

24 55 25

22 90 45

20 140 70

18 225 110

(Optional, Check thermostat Instructions)

X

Y

R

G

W

INDOOR

THERMOSTAT

SUB-BASE

LOW

MED LOW

MED HIGH

or MEDIUM

HIGH

N/A

COMMON

FURNACE BOARD

R C Y G W

Gas

Valve

ECONOMIZER

PLUG

Green

1

Gray

2

Black

3

Yel lo w

4

Blue

5

6

7

8

Typical Wiring (Field Supplied) for 2-Stage Cool, 1-Stage Heat

9

Figure 9. Typical Thermostat Connections.

(Optional, Check thermostat Instructions)

X

Y2

INDOOR

THERMOSTAT

Y1

SUB-BASE

R

G

W1

17

Page 18

FAULT CONDITION STATUS LIGHT (RED

Power On On

Limit Circuit Open 1 Flash

Pressure Switch Stuck Open

with Inducer On

2 Flash

Pressure Switch Stuck Closed

with Inducer Off

3 Flash

Ignition Failure (Check Ground) 4 Flash

230 VAC & Neutral Reversed

or No Ground

5 Flash

False Flame or Gas Relay Shorted

Continuous Flash

Power Off Off

FAULT CONDITION STATUS LIGHT (YELLOW)

Low Flame Sensor Signal Continuous Flash

Flame Present On

BLOWER

MOTOR

RED

ORANGE

T2

T1

G

GREEN-YELLOW

WHITE

7105850

RELAY

RED

BLUE

T3

T4

T5

C

L

N

RED

XFMRL1EAC

INDUCER

RELAY

RED

COOL

M3M2M1

HEAT

HUM

R

C

2

1

2

1

BLACK

BLACK

BROWN

BROWN

4

215

3

6

HUM

EAC

S

NEUTRAL

7

1

4

2

8

5

9

3

6

24V

COM

RCYGW

WHITE

1

1

WHITE

BROWN

YELLOW

IGNITOR

2

2

RED

ORANGE

PRESSURE

SWITCH

ORANGE

GAS

FLAME

GREEN

VALVE

SENSOR

TO THERMOSAT

Y

C

R

G

Y2

W1

GROUND

BLUE

FLAME

SWICH

ROLL-OUT

BLUE

LIMIT

SWITCH

BLUE

RED

BLACK

RED

WHITE

BLUE

TO 208/230 VAC

POWER SUPPLY

BLACK

HEATER

CRANKCASE

(IF EQUIPPED)

BLACK

CONTACTOR

COMPRESSOR

L1

L2

BLACK

RED

BLACK

T2 T1

COM

24V

240V

LOCATION

PROVIDED

GROUND ON

PRESSURE

208V

ORANGE

WHITE

INSIDE

COMPRESSOR

TERMINAL BOX

YELLOW

YELLOW

BLACK

SWITCH (44)

IF EQUIPPED

BLUE

GREY

BLACK

GREEN

YELLOW

ORANGE

BLUE

ORANGE

YELLOW

34567

34567

BLACK

YELLOW

34567

34567

8

R

C

R

C

BLACK

BLUE

S

FAN M OTOR

CHF

DUAL CAPACITOR

S

RED

COMPRESSOR OUTDOOR

RED

RED

AIR SENSOR

TO DISCHARGE

9

8

9

RED

RED

8

9

8

9

2

2

GREY

2

2

1

1

GREEN

1

1

PLUG

ECONOMIZER

8-WIRE

HARNESS ASSY

ECONOMIZER JUMPER

PLUG

ECONOMIZER

Factory Wiring

Low Voltage

Field Wiring

High Voltage

18

servicing.

copper conductors only.

exceed 150 V to ground.

supplied with the furnace must be

replaced, it must be replaced with

wiring material having a temperature

rating of at least 105°C.

overcurrent protection, see unit

rating plate.

1. Disconnect all power before

2. For supply connections use

3. Not suitable on systems that

N NOTES:

4. If any of the original wire as

5. For supply wire ampacities and

1. Couper le courant avant de faire

Figure 10. Single-Phase Wiring Diagram.

letretien.

conducteurs en cuivre.

de plus de 150 V a la terre.

2. Employez uniquement des

3. Ne convient pas aux installations

WD# 7105850

Page 19

the registers or in the ductwork. Set thermostat fan switch

!

to “Auto,” the blower will shut down in 60 seconds.

Short Cycle Protection — For single phase units only,

with the system operating in cooling mode, note the

temperature setting of the thermostat and gradually raise

the set-point temperature until the unit de-energizes.

Immediately lower the set point temperature of the

thermostat to its original setting and verify that the indoor

blower is energized. Verify that after approximately 5

minutes the compressor and fan energize and that the

temperature of the discharged air is cooler than the room

temperature.

System Cooling

1. Set the thermostat system switch to “Cool” and the

thermostat fan switch to “Auto.” Gradually lower the

thermostat temperature switch below room

temperature and observe that the blower, compressor

and fan energize. Check that air cooler than room

temperature is being discharged at the register.

Listen for any unusual noises. Locate the source

and correct as needed.

2. After allowing the unit to run for several minutes, set

the temperature selector above room temperature,

verify that:

a. The fan and compressor cycle off with the

thermostat.

b. The blower also stops after the 90 second

delay.

System Heating

1. Set the thermostat to the lowest setting.

2. Follow the procedures given on the operating

instruction label, in this installation instructions or

attached inside the louvered control access panel.

3. Set the thermostat above room temperature and

verify the sequence of operation. (See Operating

Sequence on page 25.)

4. Verify that the compressor and outdoor fan motor are

not energized.

5. After the unit has run for approximately five minutes,

set the thermostat below room temperature and

verify the shutdown sequence. (See Operating

Sequence on page 25.)

Verifying and Adjusting Firing Rate — The firing rate

must be verified for each installation to prevent over-firing

of the furnace.

IMPORTANT NOTE: The firing rate must not exceed the

rate shown on the unit data label. At altitudes above

2,000 ft. it must not exceed that on the data label less

4% for each 1,000 ft.

Follow the procedure below to determine the firing rate:

1. Shut off all other gas fired appliances.

2 Start the unit in heating mode and allow it to run for

at least three minutes.

3. Measure the time (in seconds) required for the gas

meter to complete one revolution.

4. Convert the time per revolution to cubic feet of gas

per hour using Table 8.

5. Multiply the gas flow rate in cubic feet per hour by the

heating value of the gas in Btu per cubic foot to obtain

the firing rate in Btu per hour. Example:

a. Time for one revolution of a gas meter with a

one cubic foot dial = 40 seconds.

b. From Table 8 read 90 cubic feet per hour of gas.

c. Heating value of the gas (obtained from gas

supplier) = 1040 Btu per cubic foot.

d. Firing rate = 1040 x 90 = 93,600 Btuh.

6. Adjustments to the firing rate can be made by

adjusting the gas manifold pressure. See the High

Altitude Application section for additional information

of firing rate at elevations above 2000 ft.

The manifold pressure must be set to the appropriate value

for your installation. Refer to either Table 5 for natural gas or

Table 6 for LP/propane gas to verify the manifold pressure

setting required for your particular installation. To adjust the

manifold pressure, remove the regulator cap and turn the

adjusting screw clockwise to increase pressure or counterclockwise to reduce pressure. Replace the regulator cap

after adjustments are complete.

Verifying and Adjusting Temperature Rise — Verify that

the temperature rise through the unit is within the range

specified on the unit data label. Temperature rises outside

the specified range could result in premature heat exchanger

failure.

Place thermometers in the return and supply air stream as

close to the duct connections as possible. The thermometer

on the supply air side must be shielded from direct radiation

from the heat exchanger to avoid false readings. Adjust

all registers and duct dampers to the desired position and

run the unit for ten to fifteen minutes before taking any

temperature readings. The temperature rise is the difference

between the supply and return air temperatures.

CA UTION:

Do not re-drill the burner orifices. If the orifice

size must be changed, use only new orifices.

For typical duct systems, the temperature rise will fall

within the range specified on the data label with the blower

speed at the factory recommended setting (see Table 3).

If the temperature rise measured is outside the range

19

Page 20

FOR YOUR SAFETY

I

I

Manifold

et

READ BEFORE OPERATING

POUR VOTRE SÉCURITÉ.

À LIRE A V ANT L ’EMPLOI

WARNING: If you do not follow these

instructions exactly, a fire or explosion may

result causing property damage, personal

injury, or loss of life.

A . This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner. Do

to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or move by hand,

do not try to repair it, call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

not try

ATTENTION! L’inobservation de ces

instructions peut entraîner un incendie ou une

explosion pouvant causer des dammages à

votre propriété à votre personne, ou la mort.

A . Cet appareil ménager n'a pas de veilleuse. II est doté d’un

système d’allumage automatique. Ne pas essayer d'allumer le

brûleur manuellement.

B. AVANT L’USAGE. Attention à une possible odeur de gaz

surtout au niveau du plancher où les gaz les plus lourds ont la

tendance de se concentrer.

EN CAS D’ODEUR DE GAZ.

• Ne mettre en marche aucun appareil électrique.

• Ne toucher à aucun commutateur électrique, ne pas employer le

téléphone.

• Quitter le bâtiment immédiatement et avertir la compagnie du

gaz en utili sant le téléphone d'un voisin.

• A défaut de la compagnie du gaz, avertir le service des

pompiers.

C. Enfoncer ou faire tourner le robinet à gaz à la main seulement. Ne

jamais utiliser d'outils. S’il n’est pas possible de faire tourner ou

d’enfoncer le robinet à la main, ne pas essayer de le réparer. Faire

appel à un spécialiste. Forcer ou tenter de réparer le robinet

pourrait être à l’origine d’une explosion ou d’un incendie.

D. II est déconseillé d’utiliser cet appareil en contact prolongé avec

l’eau. Faire inspecter ou remplacer toute commande par un

technicien qualifié si un des systèmes de contrôle du gaz s'est

trouvé sous l'eau.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to the lowest setting.

3. Turn off all electrical power to the appliance.

4. The appliance’s ignition device automatically lights the burner.

Do not try to light burner by hand.

5. Remove the control access door/panel (upper door if two-door

model).

6. Move the gas control knob clockwise to “OFF”.

(See Figure 11)

7. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B”

in above information. If you don’t smell gas, go to the next step.

8. Move the gas control knob counterclockwise to “ON”.

(See Figure 11)

9. Replace the control access door/panel

(upper door if two-door model).

10. Turn on all electrical power to

the appliance.

11. Turn the thermostat to a desired

setting.

12. If the appliance will not

operate, follow the instructions

“To Turn Off Gas To Appliance”

and call your service technician or gas supplier.

KNOB

(ROBINET)

nlet Pressure Tap

nlet

Figure 11

Protective

Cap

On/Off Lever

Pressure Tap

1. ATTENTION! Lire d'abord la liste des mesures de sécurité cidessus.

2. Mettre le thermostat à la position minimale.

3. Couper le courant électrique qui mène à l’appareil.

4. Cet appareil ménager étant doté d’un système d’allumage

automatique, ne pas essayer d'allumer le brûleur manuellement.

5. Retirer le panneau/volet d’accès de commande (panneau

supérieur s’il s’agit d’un modèle à deux panneaux).

6. Faire tourner le robinet à gaz dans le sens des aiguilles d’une

montre pour l’amener sur la position OFF (Arrêt) (Voir

Figure 11).

7. Attendre cinq (5) minutes pour s’assurer de la dissipation du gaz

En cas d’odeur, ARRÊTER LE PROCÉDÉ. Suivre les instructions ci-dessus (Section B). En l’absence de toute odeur de

gaz, avancer à l’étape suivante.

Faire tourner le robinet à gaz dans le sens inverse des aiguilles

8.

d’une montre pour l’amener sur la position ON (Marche)

(Voir Figure 11).

9. Remettre le panneau/volet d’accès de commande en place

(panneau supérieur s’il s’agit d’un modèle à deux panneaux).

10. Rebrancher l’appareil sur le réseau électrique.

Outl

11. Ajuster le thermostat à la position désirée.

12. Si l’appareil ne fonctionne pas, suivre les “Directives d’arrêt”

cidessous et appeler le technicien de service.

MODE D'EMPLOI

TO TURN OFF

GAS TO APPLIANCE

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the appliance if service is to

be performed.

3. Remove the control access door/panel (upper door if twodoor model).

4. Move the gas control knob clockwise to “OFF”. Do

not use force. (See Figure 11)

5. Replace the control access door/panel (upper door if twodoor model).

1. Mettre le thermostat à la position minimale.

2. Débrancher l’appareil en prévision de la réparation.

3. Retirer le panneau/volet d’accès de commande (panneau

supérieur s’il s’agit d’un modèle à deux panneaux).

4. Faire tourner le robinet à gaz dans le sens des aiguilles d’une

montre pour l’amener sur la position OFF (Arrêt) Ne

pas forcer (Voir Figure 11).

5. Remettre le panneau/volet d’accès de commande en place

(panneau supérieur s’il s’agit d’un modèle à deux panneaux).

DIRECTIVES D’ARRÊT

Page 21

!

!

specified, it may be necessary to change the blower speed.

!

Lower blower speeds will increase the temperature rise and

higher blower speeds will decrease the temperature rise.

The unit is equipped with a multi-speed motor. Heating and

cooling speed selection is made by moving the leads on the

integrated control located in the unit control box. The wiring

diagram on the unit and in Figure 10 show the speed taps

for adjusting motor speed. Refer to the Blower Speed

Section of this installation instruction for more details.

The integrated control is designed to start the circulating air

blower 30 seconds after the gas valve is opened. The

integrated control is factory wired to turn the blower motor

off 120 seconds after the gas valve is closed.

COMPONENT FUNCTIONS

Flame Sensor — The flame sensor acts to prove that

flame has carried over from the ignitor to the right-most

burner. If no flame is sensed, the unit will be shut down

automatically.

Flame Roll-Out Control — The flame roll-out control acts

to verify that the burner flame is being drawn into the heat

exchanger tubes. If the burner flame is not being drawn into

the heat exchanger tubes, the roll-out control will open

within several seconds and the integrated control diagnostic

light will flash one time. The circulating air blower and

combustion blower will continue to operate if the flame rollout control opens.

Verifying Burner Operation — To verify operation of the

burners remove the louvered control access panel to

ensure there is power to the unit. Set the thermostat to a

temperature above room temperature and observe the

ignition sequence. The burner flame should carry over

immediately between all burners. The flames should be

blue, without yellow tips. Flames should extend from each

burner without lifting off, curling, or floating. After verifying

satisfactory flame characteristics, set the thermostat to a

temperature below room temperature and verify that the

burner flame extinguishes completely.

WARNING:

Uninsulated live components are exposed when

louvered control access panel is removed.

Verify Operation of Over-Temperature Limit Control –

To verify operation of the over-temperature limit control,

make sure that the louvered control access panel is in

place and that there is power to the unit. Block the return

airflow to the unit by installing a close-off plate in place of

or upstream of the filter. Set the thermostat to a temperature

above room temperature and verify the unit operates with

the correct sequence of operation (see page 25). The overtemperature limit control should function to turn off the gas

valve within approximately four minutes (the exact time

depending on the efficiency of the close-off in blocking the

return air to the unit). The circulating air and combustion

blowers should continue to run when the over-temperature

limit control switch opens. Remove the close-off immediately

after the over-temperature limit control opens. If the unit

operates for more than four minutes with no return air, set

the thermostat to a temperature below room temperature,

shut off the power to the unit, and replace the overtemperature limit control.

Gas Valve — The gas valve acts to control the flow of gas

to the burners. When the gas valve is energized it

automatically opens and regulates the gas pressure in the

manifold.

Pressure Switch — The pressure switch acts to verify that

the inducer motor is drawing the combustion gases through

the heat exchanger tubes and venting the gases through

the vent system.

Over-Temperature Limit Control — The over-temperature

limit control acts to prevent the air temperature leaving

the unit from exceeding the maximum outlet air

temperature. If the limit opens, the integrated control

diagnostic will flash one time. The circulating air blower

and combustion blower will continue to operate if the

over-temperature limit control opens.

UNIT MAINTENANCE

WARNING:

To avoid risk of electrical shock, personal injury,

or death, disconnect all electrical power to the

unit before performing any maintenance or

service. The unit may have more than one

electrical supply.

CAUTION:

Use care when removing parts from this unit.

Personal injury can result from sharp metal edges

present in all equipment of sheet metal

construction.

21

Page 22

Refrigerant Charging — The packaged gas/electric units

!

!

are fully charged at the factory. The system refrigerant

charge can be checked and adjusted through the service

ports provided behind the service panel. Use only gauge

lines which have a “Schrader” depression device present to

actuate the valve. Refrigerant charging must be done by

qualified personnel familiar with safe and environmentally

responsible refrigerant handling procedures.

WARNING:

The gas/electric units are shipped fully charged

and ready for installation. When a system is

installed according to these instructions, no

refrigerant charging is required. If repairs make

it necessary for evacuation and charging, it

should only be done by qualified, trained

personnel thoroughly familiar with this

equipment. Some local codes require licensed

installation/service personnel to service this type

of equipment. Under no circumstances should

the owner attempt to install and/or service this

equipment. Failure to comply with this warning

could result in property damage, personal injury,

or death.

Routine Maintenance — Proper maintenance is important

to achieve optimum performance from the air conditioner.

The ability to properly perform maintenance on this equipment

requires certain mechanical skills and tools.

If you do not possess these skills, contact your dealer for

maintenance. Consult your local dealer about the availability

of maintenance contracts. At a minimum, routine

maintenance should include the following:

Air Filter — Inspect and clean or replace the air filter